battery ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 343 of 421

Air Conditioning

Portable Diagnostic Unit - Signal Monitoring 3^^?

Air Conditioning Signal Monitoring

The following signals can be monitored using the PDU. The abbreviated name of the signal is shown on the PDU

display.

Display Name Full Signal Name

AMBTEMP Ambient temperature sensor

ARECIP Auto-Recirculation input

ARECOP Auto-Recirculation output

AUX+ Auxiliary battery positive

CLUREL Clutch relay drive output

CVSOL Centre vent solenoid

DEFSOL Defrost solenoid

DIFF Temperature differential

EVSEN Evaporator sensor

FANDEF Fanspeed defrost

FANHIG Fanspeed high

FAN LOW Fanspeed low

FANMED Fanspeed medium

FIVEV Five volt supply voltage

FORSERL Lower servo forward drive

FORSERU Upper servo forward drive

GND10 Ground voltage

GND2 Ground voltage

GND38 Ground voltage

GND45 Ground voltage

GND6 Ground voltage

HSREL High speed relay drive

ICSEN In-Car sensor

LBLOFB Left blower feedback voltage

LBLOWOP Left blower output voltage

LSERFB Lower servo feedback potentiometer

MPROBE Measurement probe

POWIN+ Switched power input

POWOP+ Power output

RBLOFB Right blower feedback voltage

RBLOWOP Right blower output voltage

REF Reference signal

REVSERL Lower servo reverse drive

REVSERU Upper servo reverse drive

TEMPDEM Temperature demand

USERFB Upper servo feedback potentiometer

WATSW Water switch

WATVAL Water valve

8-66 May 1996

Page 344 of 421

^=2?

Air Conditioning

Portable Diagnostic Unit - Signal Definitions

ThefollowingsignalsaresupportedontheAir-ConditioningControlModule. For each signal. The signal name, mnemonic

and background information are detailed.

Ambient Temperature Sensor

(AMBTEMP)

Auto-Recircuiation Input

(ARECIP)

Auto-Recirculation Output

(ARECOP)

Auxiliary Battery Positive

(AUX+)

Clutch Relay Drive Output

(CLUREL)

A/CCM Pin 34 ref Pin 6

This sensor is located in the right hand blower motor. This signal is used to enable

the A/C system to compensate for changes in ambient air temperature. The output

to pin 34 is 2.732 volts at 0 degrees Celsius and changes by 0.01 volts for each

degree Celsius above or below zero.

A/CCM Pin 9 ref Pin 6

This is effectively an On/Off switch for the A/C system and forms part of the fan

control switch.

Switch Off - Pin 9 should be at ground

Switch On - Pin 9 should be at 10+ volts.

When pin 9 is at ground, pin 3 will be at 10+ volts causing the recirculation flaps

to open.

A/CCM Pin 3 ref Pin 6

This signal will cause the recirculation flaps to close. Operating conditions should

be:

A/C Off - 10+ volts at pin 3, flaps open.

Temp demand minimum - 10+ volts at pin 3, flaps open.

Defrost - 0 volts at pin 3, flaps closed.

Temp demand max - 0 volts at pin 3, flaps closed.

A/CCM Pin 1 ref Vehicle Battery -ve

This signal istheauxiliary supply to the A/CCM. Pin

1

should read battery voltage

if the ignition switch is in the auxiliary or ignition on positions. Pin

1

should read

0 volts when the ignition switch is in the Off position or in position III whilst

cranking the engine. Loss of this supply will cause total failureof the A/C system.

A/CCM Pin 20 ref Pin 6

This signal responds to the input at pin 5 (evaporator sensor). When pin 5 is

between 2.715 and 2.725 volts, pin 20 should read below 1 volt, and the

compressor clutch will be switched off. When pin 5 is between 2.735 and 2.745

volts,

pin 20 will rise to 10+ volts and the compressor will re-engage.

Centre Vent Solenoid

(CVSOL) A/CCM Pin 18 ref Pin 6

The centre vent solenoid controls the operation of the centre vent flap. The centre

vent will open to increase the cooling capabilities of the vehicle when cooling is

selected.

In all other conditions, the centre vent will be closed.

Solenoid energised: pin 18 should read 10+volts and the centre vent will be open.

Solenoid de-energised; pin 18 should read below 0.5 volts and the centre vent

should be closed.

May 1996 8-67

Page 347 of 421

Air Conditioning

Portable Diagnostic Unit - Signal Definitions ^^P

Ground Voltage

(GND2)

Ground Voltage

(GND38)

Ground Voltage

(GND45)

Ground Voltage

(GND6)

High Speed Relay Drive

(HSREL)

In-Car Sensor

(ICSEN)

A/CCMPin2refPin6

A/CCM Pin 38 ref Pin 6

A/CCM Pin 45 ref Pin 6

A/CCM Pin 6 ref Battery -ve

The four ground signals above must be at battery negative voltage at all times.

A/CCM Pin 16 ref Pin 6

The high speed relay drive signal is used to energise the high speed relay and to

run the blowers at full speed, bypassing the normal fan control circuit. The high

speed relay will be energised whenever Defrost or High speed Fans is selected.

Relay energised, pin 16 should read 10+ volts

Relay de-energised, pin 16 should read below 0.5 volts.

If the signal at pin 16 is correct but only one fan responds, suspect a fault in the

harness or relay.

A/CCM Pin 4 ref Pin 6

The in-car temperature sensor operates in the range 0-5 volts. Actual output is

2.732 volts at 0 degrees Celsius ±0.01 volts for every degree Celsius above or

below zero. The sensor signal forms a reference point for the whole system.

If the signal on this pin remains at less than

1

volt, suspect either a short to ground

on the signal wire or an open circuit on the 5 volt supply line to the sensor.

If the signal rises to approximately 3 volts, then suspect an open circuit on the

ground supply to the sensor.

8-70 May 1996

Page 349 of 421

Air Conditioning

Portable Diagnostic Unit Signal Definitions ~3^^?

Measurement Probe

(MPROBE)

Switched Power Input

(POWIN+)

Power Output

(POWOP+)

Right Blower Feedback Voltage

(RBLOFB)

Right Blower Output Voltage

(RBLOWOP)

Measurement probe (RED) with reference to measurement probe (BLACK).

A/CCM Pin 44 ref Pin 6

Switched power-in is a signal from the control module. Unlike the unswitched

power available on pins 1 and 12, this signal is only available when the A/C is

switched on.

A/CCM Pin 12 ref vehicle battery +ve

This is the ignition power for the whole A/C system. It passes through the A/CCM

via pins 1 and 12 (and a feedback protection diode) before supplying the fan

control switch. Pin 12 should normally read battery voltage with the ignition

switch in positions I or

II.

With the ignition switch off, pin 12 should read 0 volts.

A/CCM Pin 33 ref Pin 6

The purpose of the blower feedback is to inform the control module of the present

blower speed. This enables the control module to directly monitor and control

blower motor speed. With Manual selected, the blower operates in four basic

ranges:

Low Speed

Temp Min:

Temp Med:

Temp Max:

Medium Speed

Temp Min:

Temp Med:

Temp Max:

High Speed

Pin 33 = 1±1 volt at all temperature settings

Defrost

Pin 33 = 1±1 volt at all temperature settings

pin 33 = 5±1 volt

pin 33 = 9±1volt

pin 33 = 5±1 volt

pin 33 = 2±1 volt

pin 33 = 6±1volt

pin 33 = 2±1 volt

A/CCM Pin 32 ref Pin 6

This signal is produced by the control module to drive the blower motor. The signal

can vary from 0-3 volts depending on blower motor

speed.

The higher the voltage,

the higher the blower motor speed. This signal is amplified by a simple amplifier

circuit inside the blower motor. This circuit also supplies the feedback signals to

pins 22 and 33.

Note: If

the

signal

rises

above 5 volts, then

suspect a

fault in the amplifier circuit.

8-72 May 1996

Page 354 of 421

'=^

The Aston Martin Lagonda Diagnostic System

Installation Instructions

12 10

19 22 21 20

VIA A / /^^>^ I B T

A-XA^I'A® QA

13

16

18 29

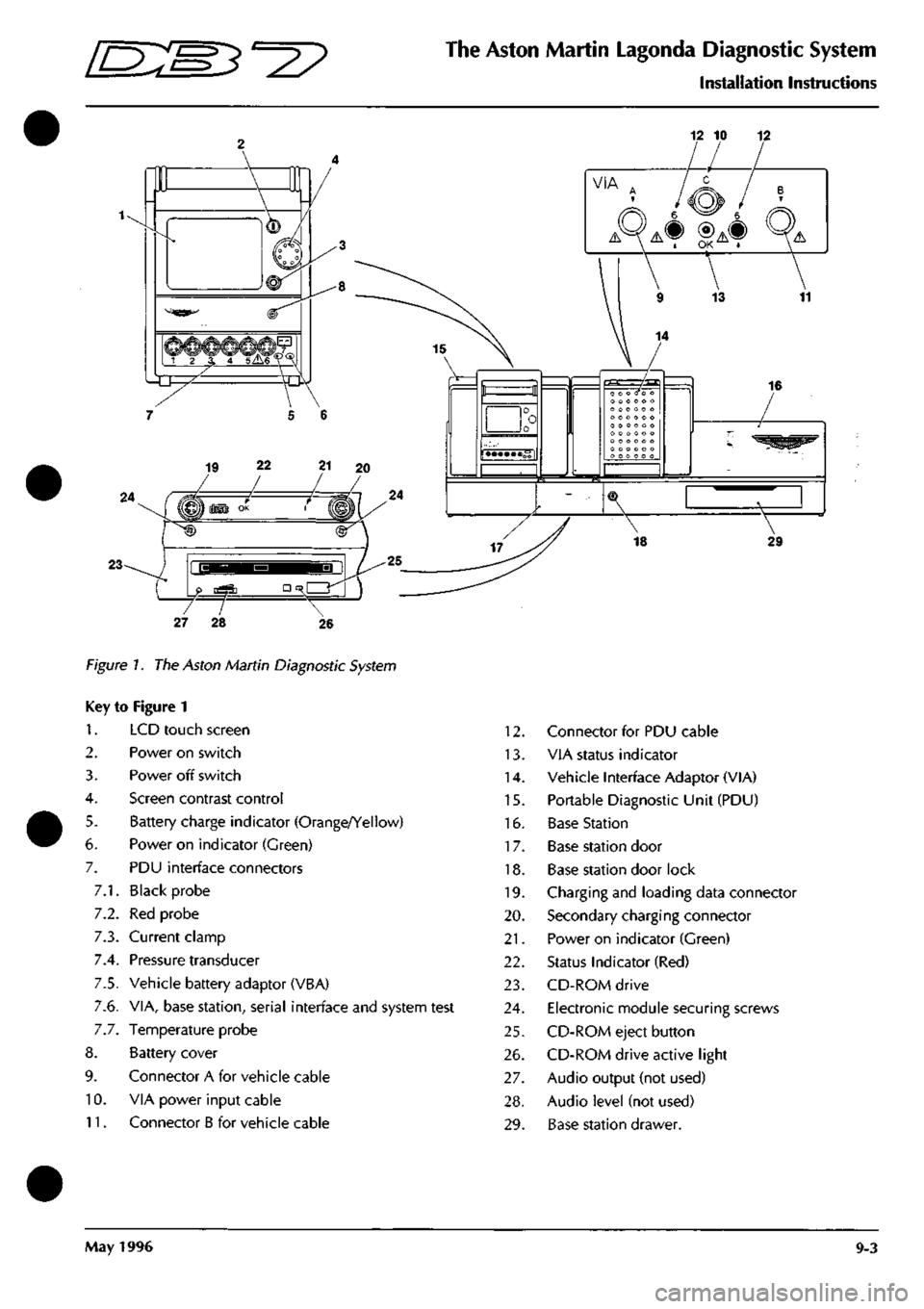

Figure 7. The Aston Martin Diagnostic System

Key to Figure 1

1.

2.

3.

4.

5.

6.

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

7.7.

8.

9.

10.

11.

LCD touch screen

Power on switch

Power off switch

Screen contrast control

Battery charge indicator (Orange/Yellow)

Power on indicator (Green)

PDU interface connectors

Black probe

Red probe

Current clamp

Pressure transducer

Vehicle battery adaptor (VBA)

VIA, base station, serial interface and system test

Temperature probe

Battery cover

Connector A for vehicle cable

VIA power input cable

Connector B for vehicle cable

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

Connector for PDU cable

VIA status indicator

Vehicle Interface Adaptor (VIA)

Portable Diagnostic Unit (PDU)

Base Station

Base station door

Base station door lock

Charging and loading data connector

Secondary charging connector

Power on indicator (Green)

Status Indicator (Red)

CD-ROM drive

Electronic module securing screws

CD-ROM eject button

CD-ROM drive active light

Audio output (not used)

Audio level (not used)

Base station drawer.

May 1996 9-3

Page 355 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions "^P

Component Identification

Base Station (Fig

1

-16)

The Base Station is a wall or bench mounted steel

unit on which up to two Portable Diagnostic Units

and a Vehicle Interface Adaptor can be stored.

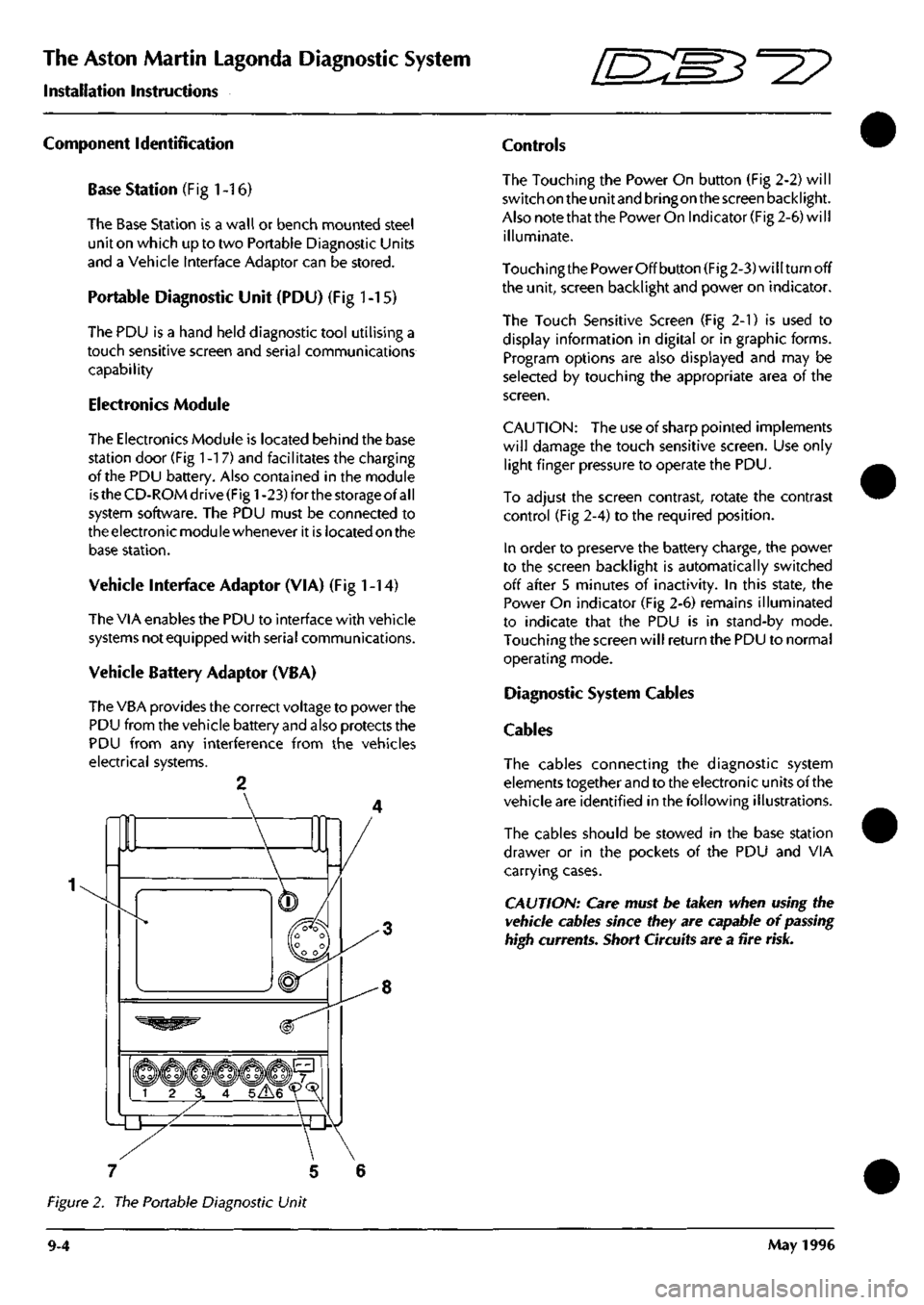

Portable Diagnostic Unit (PDU) (Fig 1-15)

The PDU is a hand held diagnostic tool utilising a

touch sensitive screen and serial communications

capability

Electronics Module

The Electronics Module is located behind the base

station door (Fig

1

-17) and facilitates the charging

of the PDU battery. Also contained in the module

is

the CD-ROM drive (Fig

1

-23) for the storage of

al I

system software. The PDU must be connected to

the electronic modu le whenever it is located on the

base station.

Vehicle interface Adaptor (VIA) (Fig

1

-14)

The VIA enables the PDU to interface with vehicle

systems not equipped with serial communications.

Vehicle Battery Adaptor (VBA)

The VBA provides the correct voltage to power the

PDU from the vehicle battery and also protects the

PDU from any interference from the vehicles

electrical systems.

Controls

The Touching the Power On button (Fig 2-2) will

switch on the unit and bringon the screen backlight.

Also note that the Power On Indicator (Fig 2-6) will

illuminate.

Touching the Power Off button (Fig 2-3) will turn off

the unit, screen backlight and power on indicator.

The Touch Sensitive Screen (Fig 2-1) is used to

display information in digital or in graphic forms.

Program options are also displayed and may be

selected by touching the appropriate area of the

screen.

CAUTION:

The use of sharp pointed implements

will damage the touch sensitive screen. Use only

light finger pressure to operate the PDU.

To adjust the screen contrast, rotate the contrast

control (Fig 2-4) to the required position.

In order to preserve the battery charge, the power

to the screen backlight is automatically switched

off after 5 minutes of inactivity. In this state, the

Power On indicator (Fig 2-6) remains illuminated

to indicate that the PDU is in stand-by mode.

Touching the screen will return the PDU to normal

operating mode.

Diagnostic System Cables

Cables

The cables connecting the diagnostic system

elements together and to the electronic units of the

vehicle are identified in the following illustrations.

The cables should be stowed in the base station

drawer or in the pockets of the PDU and VIA

carrying cases.

CAUTION: Care must be taken when using the

vehicle cables since they are capable of

passing

high currents. Short Circuits are a fire

risk.

7 5 6

Figure 2. The Portable Diagnostic Unit

9-4 May 1996

Page 357 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions mm^^?

Diagnostic System Cables

311

^ri M

r 1

3130-0030-01 VIA-PDU Cable

^

ctfa

3130-0778-00-B Anti-Lock Brakes

3130-0064-01 Base Station-PDU Cable

3130-0475-00 Test Probes

VBA

3130-0024-01 Vehicle Battery Adapti

3130-0764-00 Road Test Ext Cable

9-6 May 1996

Page 361 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions

[ES^'^?

Powering-Up the Base Station

When first operating the System or when first using

a PDU fitted with substitute batteries, it will take up

to36 hourstoachievefull charge. Inthemeantime,

the PDU can be used whilst connected to the base

station or to the vehicle battery.

Vi/\RNmGS:

When using the system equipment, basic safety

precautions should always be followed, including:

Carefully read and follow all instructions.

Care should be taken as burns can occur from

touching hot parts.

Do not operate the appliance with a damaged

mains lead or if the appliance has been dropped or

damaged. Call your local GenRad Service Centre

immediately for a substitute

part.

Do not let the mains lead hang over the

edge

of the

table, bench or counter or come into contact with

hot manifolds or moving fan blades.

The Aston Martin Portable Diagnostic Unit

is

fitted with an

auto switching power supply suitable for voltage supplies

of 100 - 240 VAC 50 - 60 Hz. You need only check that

the power cord connector is of the correct type for your

power outlets.

1.

Connect the mains lead to the mains outlet.

2.

Check that the green indicator lamp above the base

station door is illuminated. If the green lamp does

not come on, see the problem solving section for

advice.

3. After a few seconds, during which the electronics

module completes its self-test, the red OK indicator

lamp should illuminate. If the red lamp does not

come on, see the problem solving section for

advice.

4.

Allow the base station electronics module to reach

working temperature. This will take approximately

BOminutes, after which time the base station will be

ready to accept the software on CD-ROM.

5. Slide the PDU into its carrying case and place the

associated cables and probes in the carrying case

compartments.

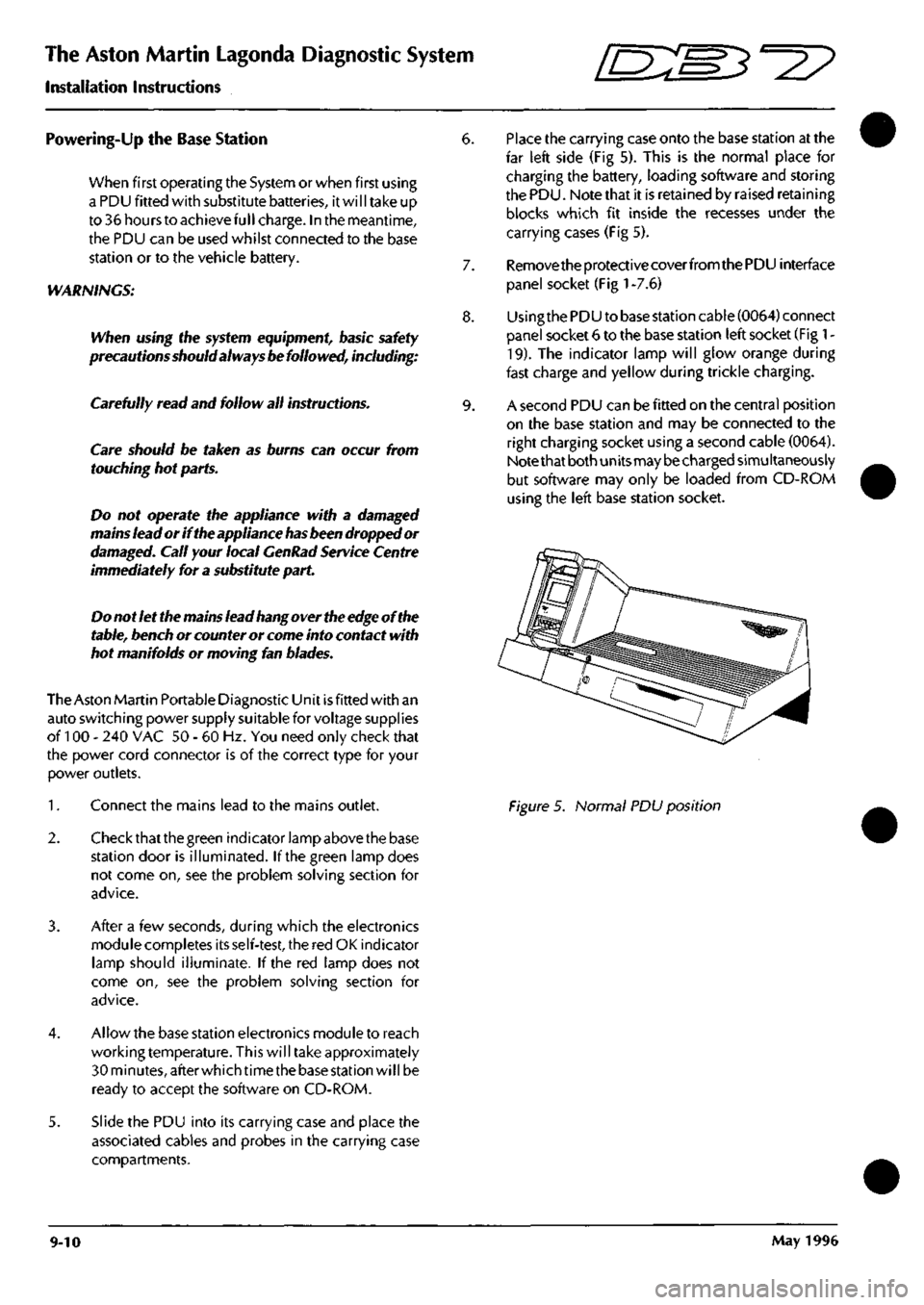

6. Place the carrying case onto the base station at the

far left side (Fig 5). This is the normal place for

charging the battery, loading software and storing

the PDU. Note that it is retained by raised retaining

blocks which fit inside the recesses under the

carrying cases (Fig 5).

7. Remove the protective coverfromthe PDU interface

panel socket (Fig

1

-7.6)

8. Usingthe PDU to base station cable (0064) connect

panel socket 6 to the base station left socket (Fig

1

-

19).

The indicator lamp will glow orange during

fast charge and yellow during trickle charging.

9. A second PDU can be fitted on the central position

on the base station and may be connected to the

right charging socket using a second cable (0064).

Note that both units may be charged simultaneously

but software may only be loaded from CD-ROM

using the left base station socket.

Figure 5. Normal PDU position

9-10 May 1996

Page 365 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions 5^27

Battery Charging

The PDU is fitted with internal NICAD batteries

which allow the PDU to be transported whilst

retaining programs. The batteries are not designed

to be used as a general power source. A special

circuit monitorstheamountofcharge in the batteries

so that they cannot be overcharged.

From the time when first operating the system or a

PDU fitted with substitute batteries, it will take up

to 36 hours to achieve full charge. In the meantime,

the PDU can be used whilst connected to the base

station or to the vehicle battery. Keep transit times

to and from the vehicle as short as reasonably

possible to preserve battery charge.

Subsequent battery charges

shou Id

take six to seven

hours from fully discharged. The PDU must always

be left connected to the base station when not in

use in order to keep the batteries fully charged.

CAUTION: The rechargeable NICAD batteries

fitted to the PDU are of a special type and must

only be replaced with GenRad approved parts. Do

not substitute the batteries with any other type.

Always

dispose

of old batteries in compliance with

local recycling regulations. The procedure for

changing the battery pack

is

described later in this

installation guide.

Operating Procedures

Refer to the Aston Martin Diagnostic System Users

Guide for detail on each of the PDU software

options

Selecting Diagnostics

1.

Switch on the PDU, the main menu will be

displayed.

2.

Select 'Run Diagnostic' from the main menu and

confirm the selection by pressing the 'tick'

icon.

A

sequence of menus will be displayed requesting

identification of the vehicle under test.

3. The system will load the appropriate software.

4.

On completion of software loading, disconnect the

PDU from the base station and transfer it in its

carrying case to the vehicle. The additional pockets

in the carrying case may be used for carrying any

interface cables required.

5. If the VIA is required, also transfer it in its carrying

case to the vehicle together with any vehicle

interface cable required.

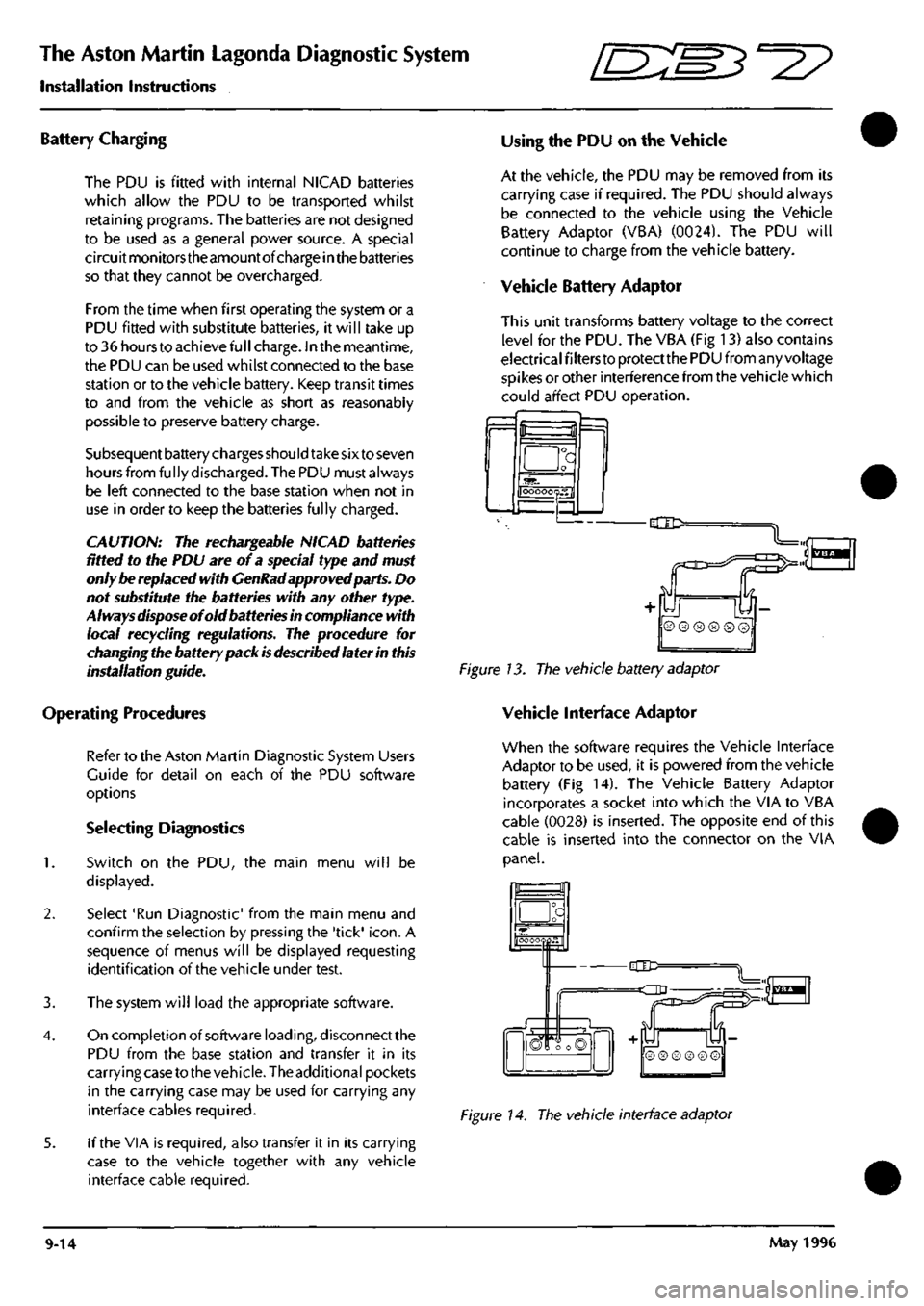

Using the PDU on the Vehicle

At the vehicle, the PDU may be removed from its

carrying case if required. The PDU should always

be connected to the vehicle using the Vehicle

Battery Adaptor (VBA) (0024). The PDU will

continue to charge from the vehicle battery.

Vehicle Battery Adaptor

This unit transforms battery voltage to the correct

level for the PDU. The VBA (Fig 13) also contains

electrical filters to protect the PDU from any voltage

spikes or other interference from the vehicle which

could affect PDU operation.

f=l

a

OOOOOQS.fl

-dlD:

Figure 13. The vehicle battery adaptor

Vehicle Interface Adaptor

When the software requires the Vehicle Interface

Adaptor to be used, it is powered from the vehicle

battery (Fig 14). The Vehicle Battery Adaptor

incorporates a socket into which the VIA to VBA

cable (0028) is inserted. The opposite end of this

cable is inserted into the connector on the VIA

panel.

_a

hOOOOQpH"

-CIC=

=dD

n

S

© ® ® ® © ©

Figure 14. The vehicle interface adaptor

9-14 May 1996

Page 368 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Installation Instructions

Step 4

Connect the mains power to the base station. Is the base station red indicator illuminated?

YES - Go to step 5

NO - Renew the electronic module (0019)

Steps

Switch off the PDU and disconnect

al I

cables. Set up the PDU to charge from the left charge socket on the base station

using one of the PDU to base station cables. Is the PDU charge indicator (Fig 1-5) illuminated.

YES - Go to step 9

NO - Go to step 6

Step 6

Set up the PDU to charge from the right socket on the base station using the same PDU to base station cable. Is the

PDU charge indicator (Fig 1-5) illuminated.

YES - Co to step 8

NO - Go to step 7

Step 7

Using the VBA, connect the PDU to a charged vehicle battery. Is the PDU charge indicator illuminated?

YES - Go to step 8

NO - Renew the PDU (001 7)

Steps

Switch off the PDU and disconnect all cables. Connect the PDU to the base station left connector using the second

PDU to base station cable (0064). Is the PDU charge indicator illuminated?

YES - The first PDU to base station cable (0064) is faulty, renew the cable.

NO - Renew the electronic module (0019).

Step 9

Switch on the PDU. Is the PDU power indicator (Fig 1-6) illuminated?

YES - Go to step 10.

NO - Renew the PDU (001 7).

Step 10

Is the PDU touch screen illuminated?

YES - Go to step 12.

NO - Go to step 11.

May 1996 9-17