battery ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 370 of 421

^^

The Aston Martin Lagonda Diagnostic System

Installation Instructions

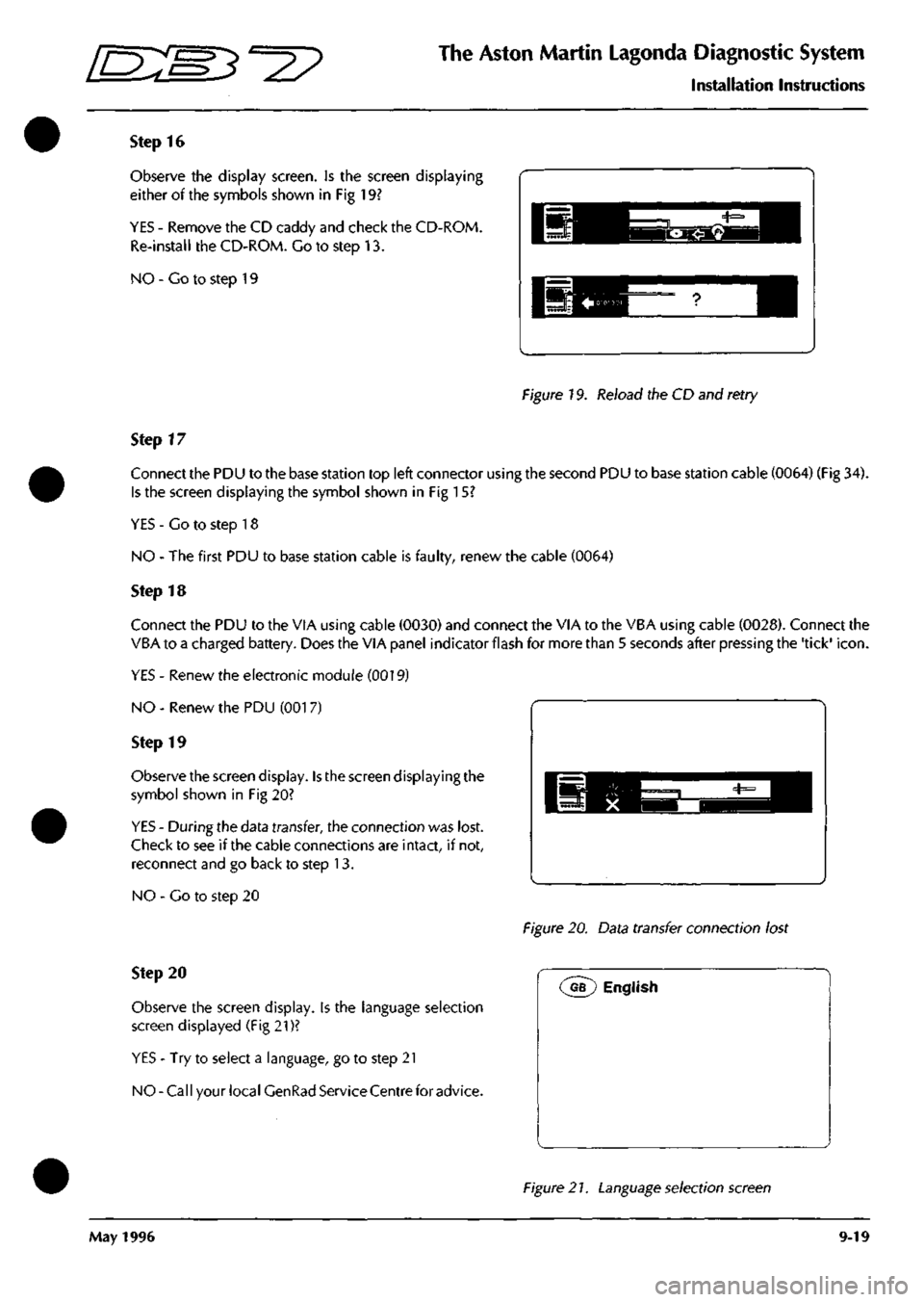

Step 16

Observe the display screen. Is the screen displaying

either of the symbols shown in Fig 19?

YES - Remove the CD caddy and check the CD-ROM.

Re-install the CD-ROM. Go to step 13.

NO - Co to step 19

Figure 19. Reload the CD and retry

Step 17

Connect the PDU to the base station top left connector using the second PDU to base station cable (0064) (Fig 34).

Is the screen displaying the symbol shown in Fig 15?

YES - Go to step 18

NO - The first PDU to base station cable is faulty, renew the cable (0064)

Step 18

Connect the PDU to the VIA using cable (0030) and connect the VIA to the VBA using cable (0028). Connect the

VBA to a charged battery. Does the VIA panel indicator flash for more than 5 seconds after pressing the 'tick'

icon.

YES - Renew the electronic module (0019)

NO - Renew the PDU (001 7)

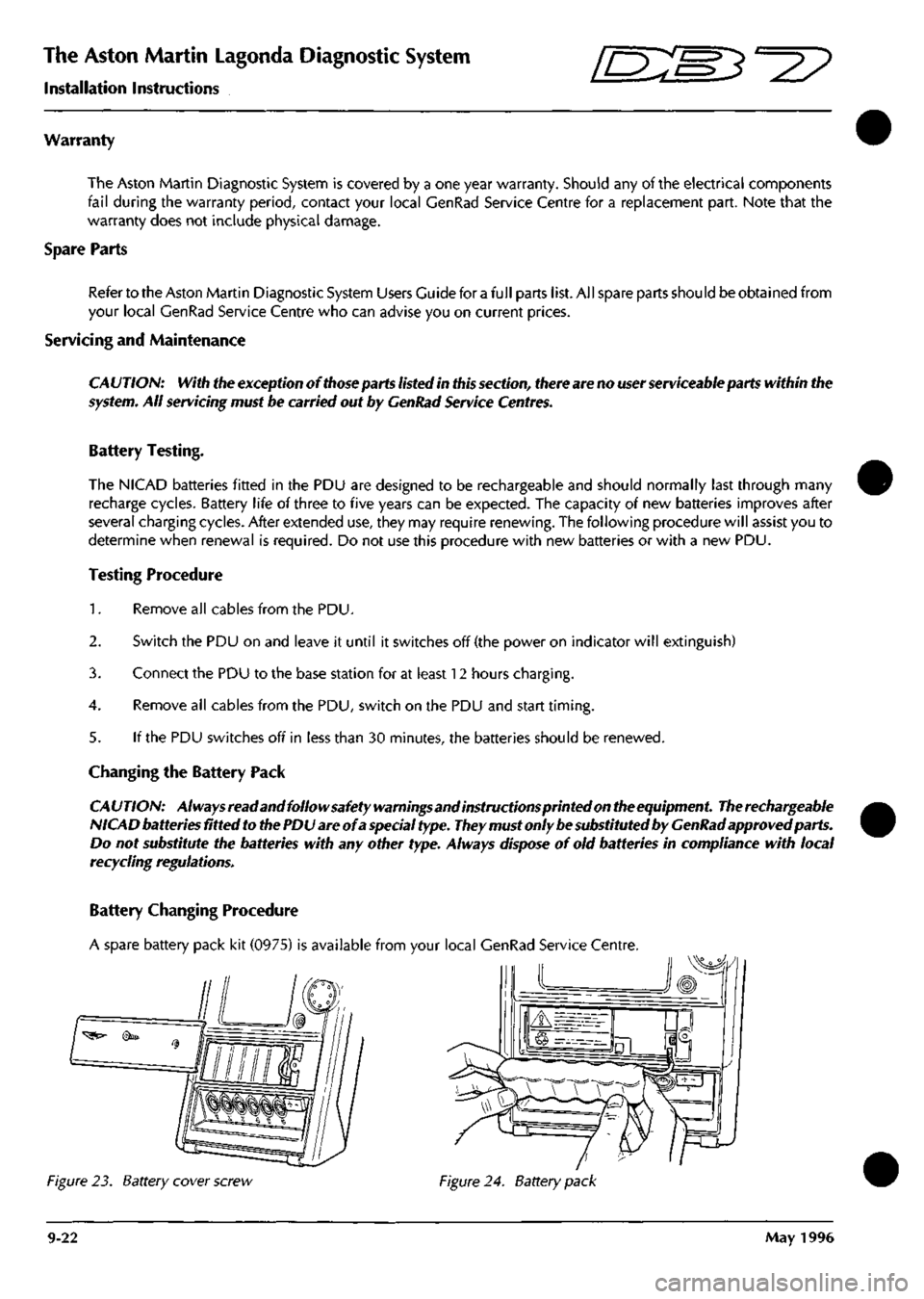

Step 19

Observe the screen display. Is the screen displaying the

symbol shown in Fig 20?

YES - During the data transfer, the connection was lost.

Check to see if the cable connections are intact, if not,

reconnect and go back to step 13.

NO - Go to step 20

Figure 20. Data transfer connection lost

Step 20

Observe the screen display, is the language selection

screen displayed (Fig 21)?

YES - Try to select a language, go to step 21

NO-Call your local GenRad Service Centre for advice.

(^G?) English

Figure 2

7.

Language selection screen

May 1996 9-19

Page 373 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions ^=2?

Warranty

The Aston Martin Diagnostic System is covered by a one year warranty. Should any of the electrical components

fail during the warranty period, contact your local GenRad Service Centre for a replacement part. Note that the

warranty does not include physical damage.

Spare Parts

Refer to the Aston Martin Diagnostic System Users Guide for a full parts list. All spare parts should be obtained from

your local GenRad Service Centre who can advise you on current prices.

Servicing and Maintenance

CA UTION: With the exception of those parts listed in this section, there are no user serviceable parts within the

system. All servicing must be carried out by GenRad Service Centres.

Battery Testing.

The NICAD batteries fitted in the PDU are designed to be rechargeable and should normally last through many

recharge cycles. Battery life of three to five years can be expected. The capacity of new batteries improves after

several charging cycles. After extended use, they may require renewing. The following procedure will assist you to

determine when renewal is required. Do not use this procedure with new batteries or with a new PDU.

Testing Procedure

1.

Remove all cables from the PDU.

2.

Switch the PDU on and leave it until it switches off (the power on indicator will extinguish)

3. Connect the PDU to the base station for at least 12 hours charging.

4.

Remove all cables from the PDU, switch on the PDU and start timing.

5. If the PDU switches off in less than 30 minutes, the batteries should be renewed.

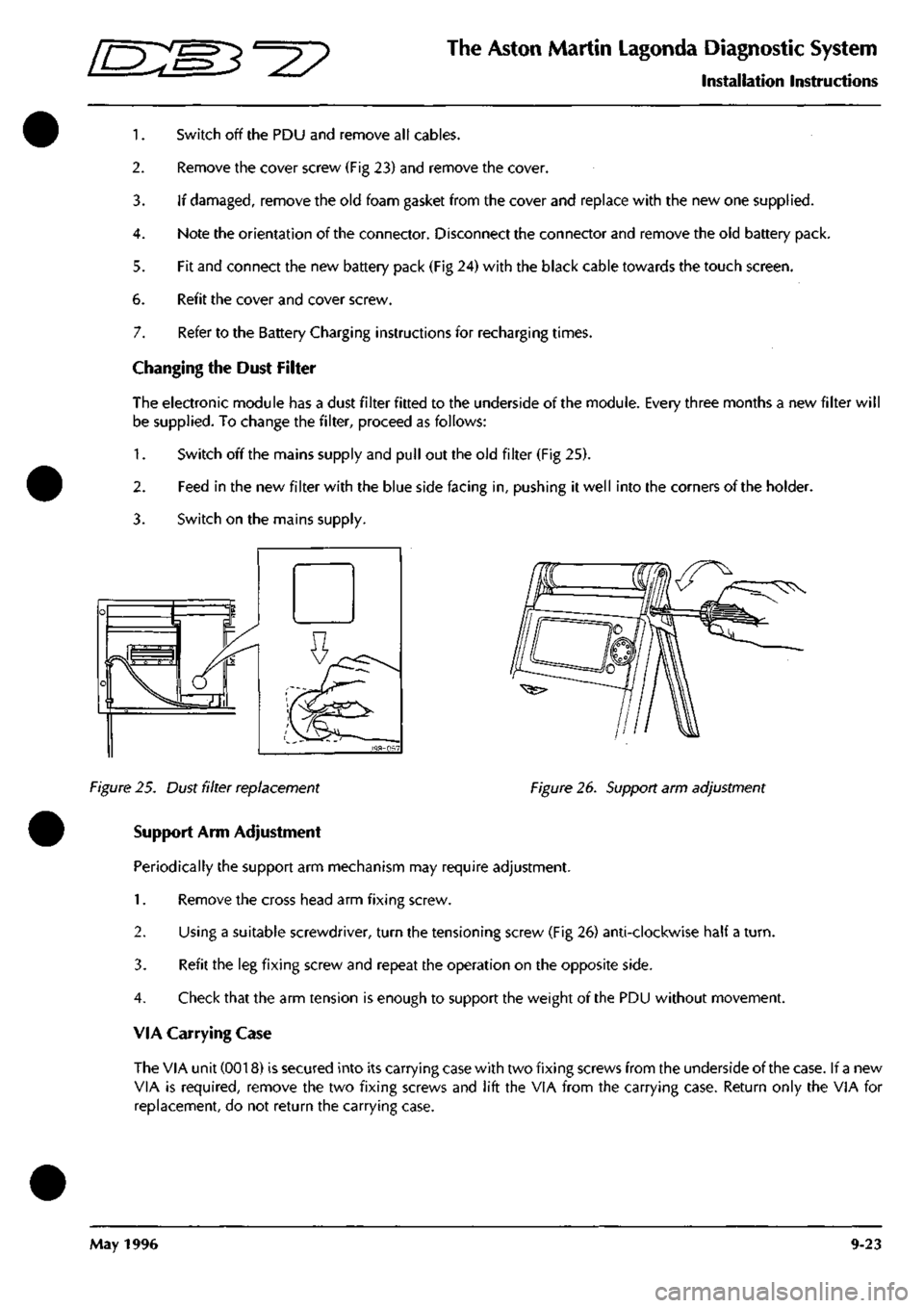

Changing the Battery Pack

CAUTION: Always read and follow safety warnings and instructions printed on the equipment. The rechargeable

NICAD batteries fitted to the PDU are of a special type. They must only be substituted by GenRad approved parts.

Do not substitute the batteries with any other type. Always dispose of old batteries in compliance with local

recycling regulations.

Battery Changing Procedure

A spare battery pack kit (0975) is available from your local GenRad Service Centre.

Figure 23. Battery cover screw Figure 24. Battery pack

9-22 May 1996

Page 374 of 421

^?

The Aston Martin Lagonda Diagnostic System

Installation Instructions

1.

Switch off the PDU and remove all cables.

2.

Remove the cover screw (Fig 23) and remove the cover.

3. If damaged, remove the old foam gasket from the cover and replace with the new one supplied.

4.

Note the orientation of the connector. Disconnect the connector and remove the old battery pack.

5. Fit and connect the new battery pack (Fig 24) with the black cable towards the touch screen.

6. Refit the cover and cover screw.

7. Refer to the Battery Charging instructions for recharging times.

Changing the Dust Filter

The electronic module has a dust filter fitted to the underside of the module. Every three months a new filter wil

be supplied. To change the filter, proceed as follows:

1.

Switch off the mains supply and pull out the old filter (Fig 25).

2.

Feed in the new filter with the blue side facing in, pushing it well into the corners of the holder.

3. Switch on the mains supply.

Figure 25. Dust filter replacement Figure 26. Support arm adjustment

Support Arm Adjustment

Periodically the support arm mechanism may require adjustment.

1.

Remove the cross head arm fixing screw.

2.

Using a suitable screwdriver, turn the tensioning screw (Fig 26) anti-clockwise half a

turn.

3. Refit the leg fixing screw and repeat the operation on the opposite side.

4.

Check that the arm tension is enough to support the weight of the PDU without movement.

VIA Carrying Case

The VIA unit (0018) is secured into its carrying case with two fixing screws from the underside of the case. If a new

VIA is required, remove the two fixing screws and lift the VIA from the carrying case. Return only the VIA for

replacement, do not return the carrying case.

May 1996 9-23

Page 379 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide o: "3^^?

PDU Functions

The PDU main menu provides access into the following functions:

Diagnostics

Training

Digital Multimeter

User Self Test

Diagnostics

On selecting'Diagnostics'from the main

menu,

the user will be prompted to enter the features and market specification

of the vehicle to be tested. Use of the diagnostics in each of the above areas is described later in this guide.

Diagnostics Menu - 95 Model Year

Engine

Anti-Lock Braking System

Vlenu - 97 Model Year

Engine Diagnostics

OBD II Scan Tool

Airbag

Seat Belt Pretensioner

•

•

•

•

Transmission

Engine Datalogger

Climate Control

PATS System

Climate Control

Transmission

Anti-Lock Braking System

Security

Digital Multimeter

The Digital Multimeter function provides the capabilityto measure voltage, current, resistance, frequency, pulse width,

pulse period, and duty cycle. These measurements are usually made using the PDU measurement probes. Measurements

may also be made using the module pin selection function on the Teves Mk

II

braking system and on the Air Conditioning

system.

Training

An on-screen programme is provided to train new users in the use of screen icons and in the use of the digital multi

meter and datalogger functions.

User Self Test

In order to prove that the equpment is functioning correctly, a complete user self test is incorporated. The user is directed

to test the PDU and then to progressively connect each part of the PDU system which will be tested by the software.

Any fault identified during the test is notified to the user. If no faults are identified, the user is advised on the correct

functioning of the system.

PDU Power

Power for the PDU is supplied via an internal rechargeable battery pack which can keep the PDU operational for

approximately one hour when disconnected from the base station and the vehicle. In order to preserve PDU battery

charge, power to the screen backlight is automatically cut after five minutes of inactivity. The power ON indicator

remains lit, indicating that the PDU is in 'stand-by' mode. One touch of the screen will restore backlight power.

When connected to the base station, power is supplied to the PDU from the Electronic Module to recharge the PDU

battery pack as necessary.

On 95 MY vehicles, the Vehicle Battery Adaptor (VBA) is used to maintain PDU power.

On 97 MY vehicles, when connected via the MPA to either diagnostic socket on the vehicle, power is supplied via pin

4 (chassis ground) and pin 16 (battery power) to maintain PDU power at all times even when the vehicle ignition is

switched off.

On all model years, when connected to the air conditioning system using the VIA, the vehicle battery adaptor (VBA)

must also be used to maintain PDU power.

9-28 September 1996

Page 380 of 421

^=2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Software

Software for the PDU system is supplied on CD ROM

discs and supports diagnosis on the following control

units:

Zytek Engine Management System (95 MY)

EEC-V Engine Management System (97 MY)

CM 4L80-E Transmission Controller

PATS - Passive Anti Theft System

Teves Mk II ABS System (95 MY)

Teves Mk IV ABS System (97 MY)

Valeo Air Conditioning System

PMC Airbag System

Megamoss Security System

Autoliv Drivers Seat Belt Pretensioner

(where fitted)

All of these systems are supported in English, French,

Italian,

German and Japanese.

In addition to the specific system software listed above,

thePDU isalsoequipped with general purpose software

to provides multimeter, printing and PDU training

options.

Software for 95 and 97 Model Year Vehicles

Software for both the 95 and 97 model year vehicles is

provided.

The PDU system requires a Vehicle Interface Adaptor

(VIA) to communicate with the control units of 95

model year vehicles.

Communication with 97 model year control units is

principally via an Aston Martin multi-protocol adaptor

to 2 inbuilt diagnostic sockets in the vehicle. Only the

air conditioning unit requires the VIA on 97 model year

vehicles.

If the multimeter function is used, the Vehicle Battery

Adaptor (VBA) will be required to provide the basic

supply and ground levels for the multimeter.

Software Loading and Selection

Ensure that the system is powered up and that the PDU is

correctly connected to the base station. Check and if

necessary load the DB7 software CD Revision 002. (see

the installation guide)

Switch 'on' the PDU which will run through two front

screens and then load the following initial PDU software.

Operating System

Main Menu

Selector

Digital Multimeter

Interactive Training

September 1996 9-29

Page 387 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ffi:S5'=2?

Engine Datalogger

The datalogger software is designed to aid the technician in identifying permanent or intermittent faults in the DB7's

electrical and electronic systems. It can provide a recorded view of selected signals over a chosen time period. This

recording may be captured in a static, rolling road or road test situation. Data recorded during such tests may then be

analysed on completion of the test or printed out for later analysis.

Datalogger operation is described using a fully worked example at the end of this PDU Users Guide.

The full list of datalogger signal names and descriptions is provided in the DB7 OBDII Diagnostic Manual and on the PDU

screen.

The following list is a summary of the PCM signals which may be monitored.

Signal Description

ACCS Air-Con Control Switch - 1 = A/C On

ACP Air-Con Pressure Sensor - 1 = A/C pressure high

ACT MAX Maximum Intake Air Temperature signal during normal running

Adap Fuel 1 Current Adaptive Fuel Correction - (% of range)

Adap Fuel 2 Current Adaptive Fuel Correction - (% of range)

ADPT1F Adaptive Fuel - Table 1 failure mode

ADPT2F Adaptive Fuel - Table 2 failure mode

AIR Air Pump On/Off - 1 = Pump On

AIRM Air Pump Monitor -1 =

high,

pump on

B+ Battery Positive - Volts

BARO Barometric Pressure

CID Cylinder Identification - Cam sensor status

CMP STAT Cam Position Sensor -1 = CID mis, not currently reliable

DRVCNT Number of OBDll Drive Cycles Completed

DSDRPM Desired engine speed (RPM)

DTCCNT Diagnostic Trouiale Codes Count (Fault codes + pending codes. MIL and non-MIL)

ECT MAX Maximum Engine Coolant Temperature signal during normal running

ECT STAT Engine Coolant Temperature - in or out of range

ECT-C Engine Coolant Temperature - "C or raw counts

ECT-V Engine Coolant Temperature - Volts or raw counts

EGR STAT EVP EGR sensor failure

ENGLOAD Engine Load (Ratio of air charge over standard)

ENGRPM Engine Speed - RPM

EPT DPFE Sensor feedback

EVAP DC Cannister Purge Duty Cycle (% on)

EVAPCVA Vapour Management Valve (VMV) fault detected

Evts HI Cumulative cylinder events total carried over from previous background logic executions

Evts LO Cumulative cylinder events total carried over from previous background logic executions

FPM Fuel Pump Monitor - 0 = pump off, 1 = pump on

FPUMP DC Desired Fuel Pump Duty Cycle - 0% or 100%

H02S12 Sensor Output - Volts

H02S21 Sensor Output - Volts

H02S22 Sensor Output - Volts

H02S1I Sensor Output - Volts

HFC High Speed Fan Status

Htrl

1

ret Highest number of retries seen on the H02S 11 heater

Htrl 2 ret Highest number of retries seen on the H02S 12 heater

Htr21 ret Highest number of retries seen on the H02S 21 heater

Htr22 ret Highest number of retries seen on the H02S 22 heater

HTRCM11 H02S n heater current

HTRCM12 H02S 12 heater current

HTRCM21 H02S 21 heater current

HTRCM22 H02S 22 heater current

9-36 September 1996

Page 397 of 421

The Aston Martin Lagonda Diagnostic System //~~^ ^?~?^ " ^ ^

Users Guide

Airbag Diagnostic Trouble Code Monitor

The following diagnostic trouble codes are supported by the Airbag Control Module:

12 Low battery voltage

13 Air bag circuit shorted to ground

14 Front inpact sensor circuit shorted to ground

21 Safing impact sensor incorrectly mounter to vehicle

22 Safing impact sensor output shorted to battery voltage

23 Safing impact sensor input feed / return open circuit

24 Safing impact sensor output feed / return open circuit

32 Driver side airbag circuit high resistance or open

33 Passenger side airbag circuit high resistance or open

34 Driver side airbag circuit low resistance or short circuit

41 Front right impact sensor feed / return open circuit

42 Front left impact sensor feed / return open circuit

44 Front right impact sensor incorrectly mounted to vehicle

45 Front left impact sensor incorrectly mounted to vehicle

51 Airbag CM internal thermal fuse - intermittent short to ground

52 Back up power supply - voltage boost fault

53 Front impact sensor circuits resistance to ground or internal Airbag CM failure

9-46 September 1996

Page 398 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Seat Belt Pretensioner Diagnostics

(where fitted)

Description

The DB7 seat belt pretensioner system operates the

drivers seat belt pretensioner in conjunction with the

Airbag system. The seat belt pretensioner control

module is located underthe right hand seat, beside the

seat control module.

The pretensioner control module calculates changes

in vehicle speed using an input signal from an

accelerometer. When a collision is detected (Rapid

reduction in vehicle speed) the pretensioner charge is

fired using electrical energy stored in a capacitor

within the pretensioner control module. Firing of the

pretensioner charge applies additional tension to the

drivers seat belt.

The airbag and seat belt pretensioner systems share the

SRS (Airbag) warning lamp. Any fault detected by the

pretensioner control module is indicated by constant

illumination ofthe

SRS

(Airbag) warning

lamp.

Flashing

of the SRS warning lamp indicates a fault in the airbag

system.

Should both systems develop faults, the pretensioner

system will permanently illuminate the warning lamp.

This would mask the airbag system warning indication.

Therefore, rectify the pretensioner fault and then retest

for faults in the airbag system

The pretensioner control module can log up to 10

diagnostic trouble codes together with a time since

each fault was alerted to the driver. Each fault will be

identified as 'Permanent' or 'Intermittent' on the PDU

diagnostic trouble codes screen.

System Connections

The Autoliv RC5 Pretensioner Control Module has an

18 pin connector featuring six shorting bridges. The

mating halves ofthe connector may be securely locked

using a double mechanical locking system.

The following pins on the control module connector

are used in the Aston Martin seat belt pretensioner

system:

Pin 1

Pin 2

Pin n

Pin 12

Pin 14

Pin 15

Case

September 1996

Ground

SRS/Airbag Warning Lamp

Drivers airbag positive

Drivers airbag negative

Serial communications

12 volt positive feed

Ground

System Fault Strategy

No single fault may cause an unexpected deployment.

The controller will supervise the airbag/pretensioner

electrical system in order to warn the driver should a

fault occur. Any fault detected by the self diagnostics

shall cause the airbag warning lamp to be activated,

and in some cases the pretensioner control module to

enter shutdown mode. In shutdown mode, the energy

ofthe reserve capacitors shall be discharged to avoid

unintended deployment.

As the ignition is switched on, the pretensioner

controller will directly discharge theenergy capacitors.

When the start up procedure is completed without

detecting any faults, the converter will be activated

allowing the capacitors to be

charged.

The system shall

be fully active within 11 seconds after switching the

ignition on providing that no faults are detected.

All system faults monitored by the controller are filtered

in software to avoid fault warnings due to transient

electrical disturbances.

If a fault which could lead to inadvertent deployment

bedetectedbythemicroprocessor,asoftwareshutdown

will be generated. However, a leakage to an earth or

positive potential in the pretensioner output circuit

shall not cause the controller to enter shutdown mode.

If

a

permanent short of the ignition transistor occurs, a

shutdown shall be generated by the hardware circuit.

If a shutdown occurs, the system shall be unable to

deploy the pretensioner after a period of

3

seconds (i.e.

capacitors discharged to under minimum deployment

voltage).

WARNING: To avoid the possibility of personal

injury caused by accidental deployment of the

pretensioner, disconnect the vehicle battery and

wait at least 10 minutes for all voltages to fully

discharge before working on the pretensioner

system. This covers the possibility of the normal

capacitor discharge circuits being inopera tive and

failing to discharge the capacitor when instructed

to do so.

If the module enters shutdown mode, all diagnostic

functions are stopped, but the communications link

remains active. A fault code corresponding to the

cause of the problem may be read by the PDU.

9-47

Page 399 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^?

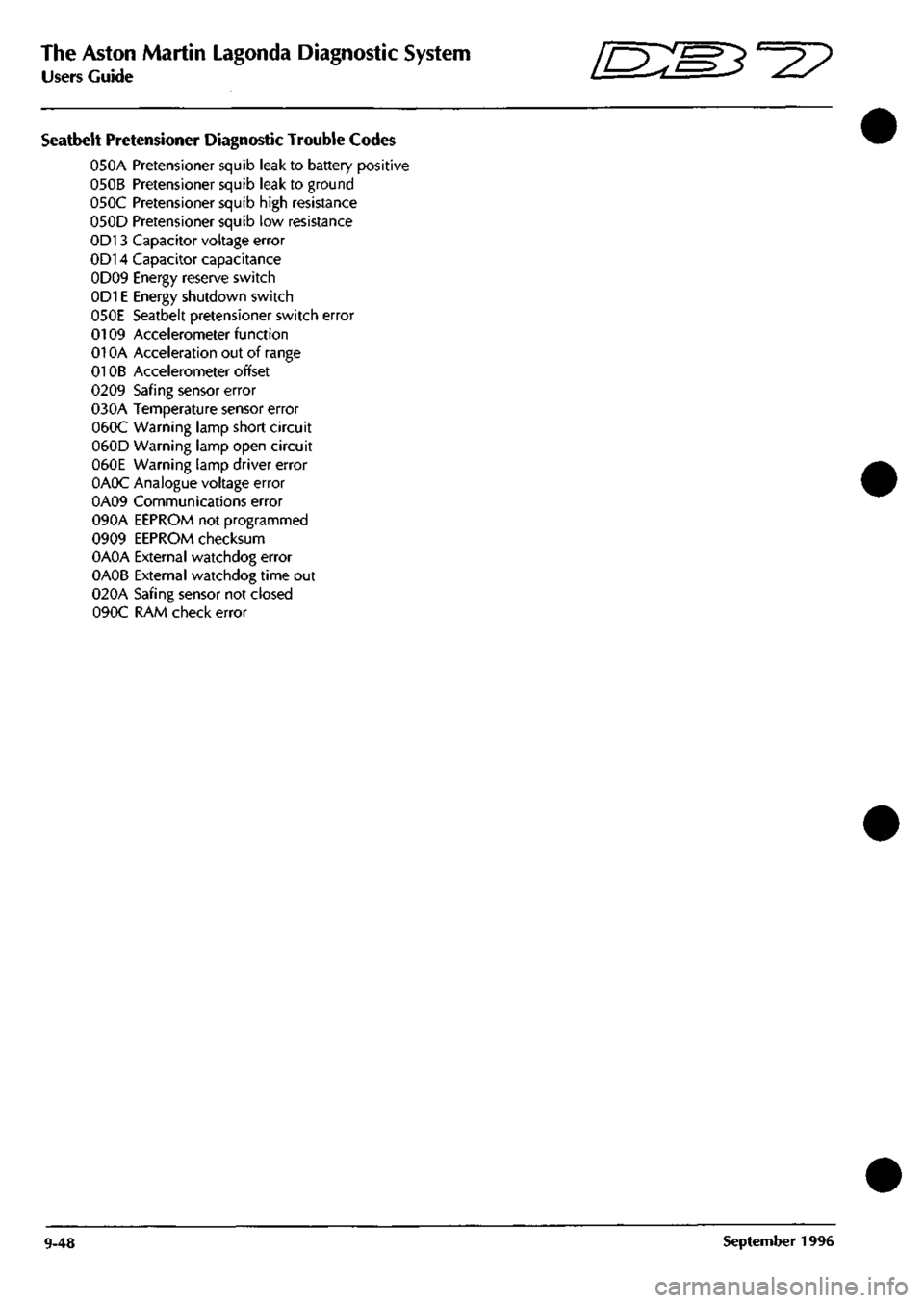

Seatbelt Pretensioner Diagnostic Trouble Codes

050A Pretensioner squib leak to battery positive

050B Pretensioner squib leak to ground

050C Pretensioner squib high resistance

050D Pretensioner squib low resistance

0D13 Capacitor voltage error

0D14 Capacitor capacitance

0D09 Energy reserve switch

0D1E Energy shutdown switch

050E Seatbelt pretensioner switch error

0109 Accelerometer function

01OA Acceleration out of range

01

OB Accelerometer offset

0209 Safing sensor error

030A Temperature sensor error

060C Warning lamp short circuit

060D Warning lamp open circuit

060E Warning lamp driver error

OAOC Analogue voltage error

0A09 Communications error

090A EEPROM not programmed

0909 EEPROM checksum

OAOA External watchdog error

OAOB External watchdog time out

020A Safing sensor not closed

090C RAM check error

9-48 September 1996

Page 402 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

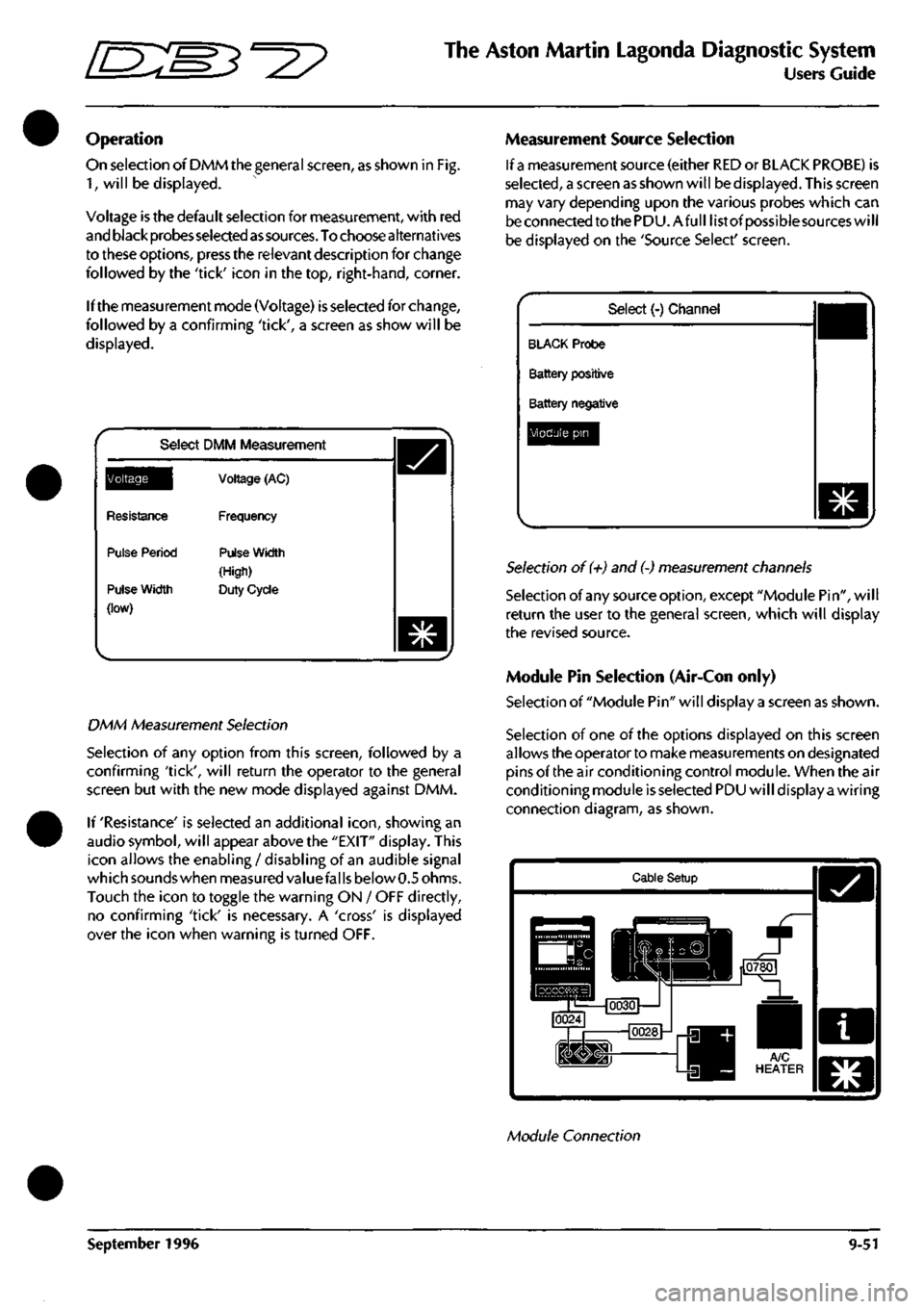

Operation

On selection of DMM the general screen, as shown in Fig.

1,

will be displayed.

Voltage is the default selection for measurement, with red

and black probes selected

as

sources.

To choose alternatives

to these options, press the relevant description for change

followed by the 'tick' icon in the top, right-hand, corner.

If the measurement mode (Voltage) is selected for change,

followed by a confirming 'tick', a screen as show will be

displayed.

Select DMM Measurement

^Q^||[

Resistance

Pulse Period

Pulse Width

(low)

Voltage (AC)

Frequency

Pulse Width

(High)

Duty Cycle

DMM Measurement Selection

Selection of any option from this screen, followed by a

confirming 'tick', will return the operator to the general

screen but with the new mode displayed against DMM.

If 'Resistance' is selected an additional

icon,

showing an

audio symbol, will appear above the "EXIT" display. This

icon allows the enabling / disabling of an audible signal

which sounds when measured valuefal

Is

below 0.5 ohms.

Touch the icon to toggle the warning ON / OFF directly,

no confirming 'tick' is necessary. A 'cross' is displayed

over the icon when warning is turned OFF.

Measurement Source Selection

If

a

measurement source (either RED or BLACK PROBE) is

selected,

a screen as shown will be displayed. This screen

may vary depending upon the various probes which can

be connected to the PDU.Afull list of possiblesources will

be displayed on the 'Source Select' screen.

Select (-) Channel

BLACK Probe

Battery positive

Battery negative

Module pin

Selection of (+) and (-) measurement channels

Selection of any source option, except "Module Pin", will

return the user to the general screen, which will display

the revised source.

Module Pin Selection (Air-Con only)

Selection of "Module Pin" will display a screen as shown.

Selection of one of the options displayed on this screen

allows the operator to make measurements on designated

pins of the air conditioning control module. When the air

conditioning module is selected PDU will display a wiring

connection diagram, as shown.

Cable Setup

Module Connection

September 1996 9-51