battery ASTON MARTIN DB7 1997 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 136 of 421

NO 66 67 68 61 6I>

COLOUR

NR NU R RU NR

PIN RS 86 87 8« 30

AREA 2.B6

2.B3-I6

2.B4-I9

2.C2 2.D3

NO 75 76 77

74

COLOUR

B U UR

N

PIN 85 86

87 87A

30

AREA

1.03-8

2.82-11

2.B2-I0

2.B4-22

NO 83 M 85

82

COLOUR

8G wr WR

N

PIN B5 86

87 B7A

30

AREA 2.B3 2.86 2.A5

2.84-20

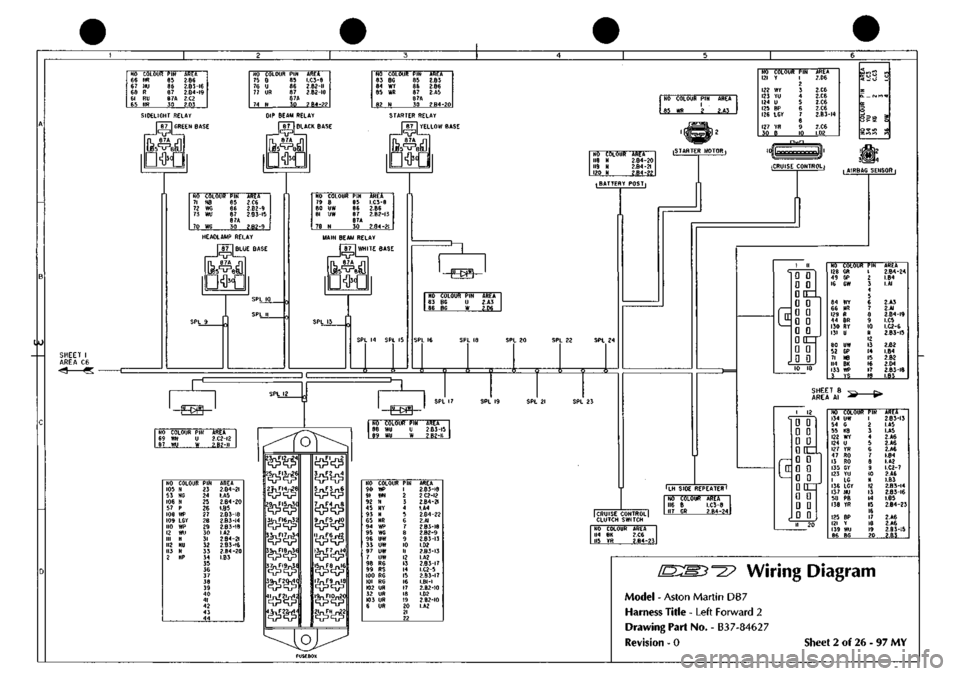

SIDELIGHT RELAY I

87

{GREEN BASE

JqpL L 87A

DW|

OlP BEAM RELAY I 87 I BLACK BASE

87A

'5^BI

lO

SHEET I AREA C6 <4 «

mu

STARTER RELAY I

87 I

YELLOW BASE

87A

'5^ei

NO COLOUR

PIN

I

.

85

WD 2

AREA

2.A3

NO 71 7? 73

70

COLOUR

N8 WG WU

WG

pm 85 86 8/ 87A 30

AREA 2.C6

2.82-9

2.B3-I5

2.B2-9

HEADLAMP RELAY

I

87

I

BLUE BASE

BTA

DW|

NO COLOUR 121

Y

122

WY

123

YU

124

U

125

BP

126

LGY

127

YR

30

B

PIN

1 7

3 4 5 6

7 8

9 10

AREA 2.D6

2.C6 2.C6 2.C6 2.C6

2.B3-I4

2.C6 l,D2

NO 79 80 81

78

COLOUR

B UW UW

N

PIN 85 86

87 87A

30

AREA LC3-e 2.B6

2.82-13

2.84-21

MAIN BEAM RELAY

I 87 I WHITE BASE

87A

SPL 14 SPL 15

HO 118 119 120

COLOUR N N N

AREI 2.84 ?.B4 2.84

20 21 22

iSTARTER MOTOR I

•BATTERY POSTi

^

NO 83 86

COLOUR PIN 8G U BG W

AREA 2.A3 2.D6

SPL 22 SPL 24

xf

3 C

'-Fw^'

NO 69 87

COLOUR

PIN

WN

U

WU

W

AREA

2.C2-I2

2.82-11

^

'-Fag—'

NO COLOUF 105 N 53 NG 106 N 57 P 108 WP 109 LGY 110 WP 12 WU III N 112 NU 113 N 2 NP

PIN 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44

AREA

2.84-21

I.A5

2.84-20

I.B5

2.83-18

2.83-14

2.B3-I8

I.A2

2.84-21

2.B3-I6

2.84-20

1.83

2^n2^.

25nFI3;^6

'^'^^

3lnfl6n32

3^EI7j^.

35nFI8n3e

3^n9^,

,^r2^,

3^.2^

5^F3^6

7^E4^

9^E5^0

1^6^

,3^E7^4

l5j^E8^6

I^P9^8

i9nFiOn20|

2^r,l^2

NO 88 89

COLOUR

PIN

WU

U

WU

W

AREA

2.B3-I5

2.B2-I1

NO COLOUf 90

WP

91

WN

92

N

45

NY

93

N

65

NR

94

WP

95

WG

96

UW

33

UW

97

UW

7

UW

98

RG

99

RS

100

RG

101

RG

102

UR

32

UR

103

UR

6

UR

PIN 1 2 3 4 5 6 7 8 9 10 II 12 13 14 15 16 17 18 19

20 21 22

AREA

2.B3-I8

2.C2-I2

2.B4-2I

I.A4

2.84-22

2.AI

2.83-18

2.82-9

2.83-13

1.02

2.83-13

I.A2

2.B3-I7

I.C2-5

2.83-17

LBI-I

2.B2-IO

1.02

2.82-10

I.A2

iCRUISE CONTROLi

("

D D • D

DDC^

G D D D D D D D DQzr D • D 0

NO COLOUF 128 GR 49 GP 16 GW

84 WY 66 NR 129 R 44 8R 130 RY 131 U

80 UW 52 GP 71 NB 114 8K 133 WP 3 YS

PIN

1 2 3 4 5 6 7 8 9 10 II 12 13 14 15 16 17 18

AREA

2.B4-24

I.B4 I.AI

2.A3 2.AI

2.B4-I9

I.C5

I.C2-6

2.B3-I5

2.B2 1.84 2.B2 2.04

2.83-18

1.83

SHEET 8 AREA Al

-(*•

LH SIDE REPEATER

I

I CRUISE CONTROL] CLUTCH SWITCH

NO COLOUR AREA

116 B

I.C3-8

117

GR

2.84-24

NO 114 115

COLOUR AREA 8K

2.C6

YR 2.B4-23

c

1

12 D 0 0 G D D D[E±

HDD

^ • n Qtrr 0 G D D D D

NO COLOUf 134

UW

54

G

55

KB

122

WY

124

U

127

YR

47

RO

13

RO

135

GY

123

YU

1

LG

136

LGY

137

NU

58

PB

138

YR

125

BP

121

Y

139

WU

86

BG

PIN 1 ? 3 4 5 6 7 8 9 10 II 12 13 14

15 16

17 IB 19 20

AREA

2,B3-I3

I.A5 I.A5 2.A6 2.A6 2.Ae

LB4

I.A2

I.C2-7

2.A6 1.83

2.B3-I4

2.83-16

1.85

2.84-23

2.A6 2.A6

2.83-15

2.83

'^^? Wiring Diagram

Model - Aston Martin DB7

Harness Title - Left Forward 2

Drawing Part No. - B3

7-8462

7

Revision - 0 Sheet 2 of 26 - 97 MY

Page 138 of 421

NO 140 141

COLOUR

PIN

NV

1

B

2

AREA 3.C4 3,A2

NO 14? 143

COLOUR

PIN

NP

1

m

2

AREA 3.05 3.D4

< lOlO

5! —fsi Q: 3 O _J O

(O

omcD

.

f

i^

q

ifll?

< rrt

o

Si

il

*s

H

Jz

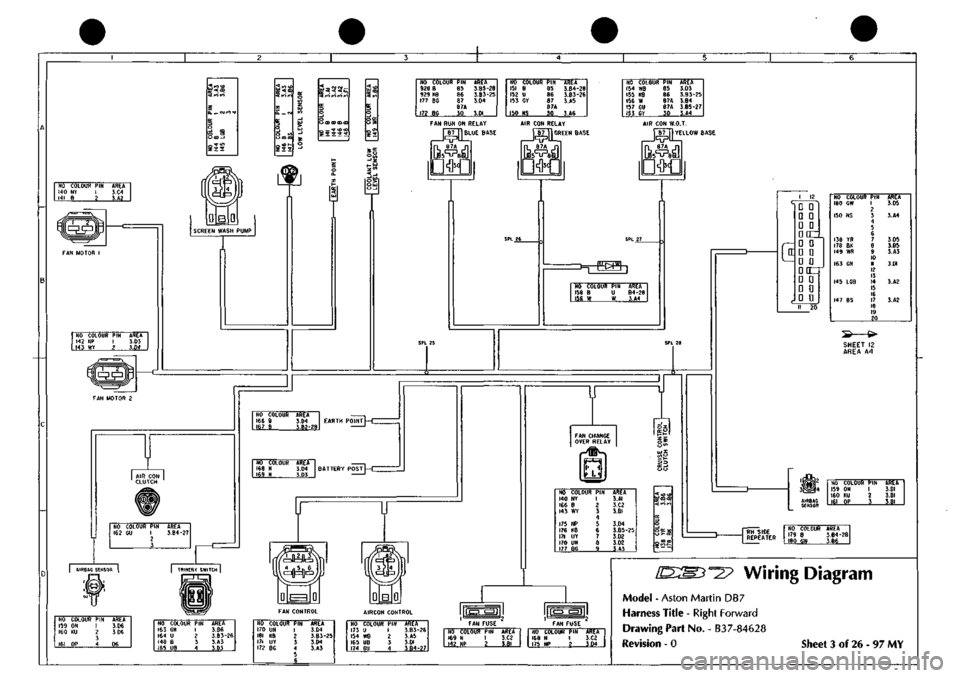

NO COLOUR 928

B

929

KB

177

BO

172

BG

PIN B9 86 87 87A 30

AREA

3.85-28

3.B3-25

3.D4

3.01

NO COLOUR

PIN

151

B 85

152

U 86

153

OY 87

e7A 150

NS 30

AREA

3.B4-28

3.B3-26

3.A5

3.A6

NO COLOUf 154

W8

155

KB

156

W

157

GU

153

BY

PIN 85 86 S7A e7A 30

AREA 3.D3

3.B5-25

3.B4

3.B5-27

3.A4

FAN

RUN

ON

RELAY

I

87

II

BLUE BASE

87A

AIR

CON

RELAY AIR

CON

W.O.T.

DW|

I

87

II

GREEN

BASE

am

I

87 II

YELLOW BASE

Is-^sl

SCREEN WASH PUMP

I

•Wl|

3n-^ai

NO COLOUR

PIN

AREA 158

B U

B4-28 156

W W 3.A4

FAN MOTOR

2

NO COLOUR

PIN

162

GU

1

2 3

AREA

3.B4-27

c

NO COLOUR AREA

166

8 3.D4

167

B

3.B2-28 EARTH POINT

OINT|—c

NO COLOUR 168

N

169

N

AREA 3.04 3.03 BATTERY

PCS

'osTj-c:

TRINERY SWITCH

NO 159 160

161

COLOUR ON KU

OP

PIN 1 2 3 4

AREA 3.D6 3.06

06

NO COLOUR

PIN

163

GN

I

164

U 2

148

B 3

165

ua 4

AREA 3.B6 3.B3-26 3.A3 3.D3

FAN CHANGE OVER RELAY Is

>

\,1

NO COLOUf 140

NY

166

B

143

WY

175

NP

176

KB

171

UY

170

UN

177

BG

PIN 1 2 3 4 5 6 7 8 9

AREA 3.AI 3.C2 3.BI

3.D4

3.B5-25

3.02 3.D2 3.A3 "a

D

D

•

D

D

D

hi

D

Q

Dinr

D

D

D

D

D

•

NO COLOUF 180 GW

150

NS

138

YR

178

BK

149

WR

163

GN

145

LGB

147

BS

PIN 1 ? 3 4 5 6 7 B 9 10 II 12 13 14 15 16 17 18 19 20

AREA 3.05

3.A4

3.D5 3.D5 3.A3

3.DI

3.A2

3.A2

NO COLOUR

PIN

159

ON 1

160

KU 2

161

OP 3

AREA 3.DI 3.DI 3.DI

J RH

Sll

I REPEA SIDE 1 REPEATER NO 179 180

COLOUR B GW

AREA 3.B4-3.B6 28

NO COLOUR

PIN

170

UN I

181

KB 2

171

UY 3

172

BG

4

5

6^

AREA 3.D4

3.B3-25

3.04 3.A3

NO 173 154 165 174

AIRCON CONTROL

COLOUR U WB UB GU

PIN 1 ? 3 4

AREA 3.B3-3.A5 3.01 3.B4-

26

27

r

^2

FAN FUSE NO COLOUR

PIN

169

N 1

142

NP 2

AREA 3.C2 3.BI

NO COLOUR

PIN

168

N 1

175

NP 2

AREA 3.C2 3.D4

Wiring Diagram

Model

-

Aston Martin

DB7

Harness Title

-

Right Forward

Drawing Part No.

-

B37-84628

Revision

- 0

Sheet

3 of 26 - 97 MY

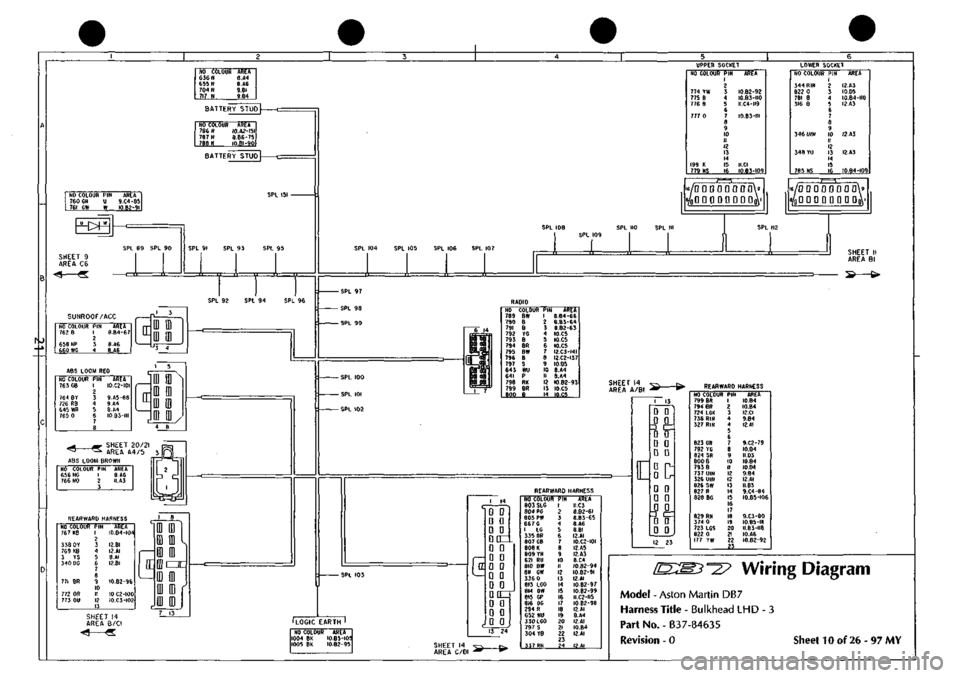

Page 152 of 421

fj

NO COLOUR 636 N 655

N

704

N

7r7 N

AREA e.M S.A6 9.DI 9.04

UPPER SOCKET LOWER SOCKET

BATTERY

STUDt

NO COLOUR 786

N

787

N

788

N

AREA I0.AZ-I5I

8.B6-75

IO.BI-90

BATTERY

STUDt

NO COLOUR

PIN

AREA

760

ON

U

9.C4-85

761 GW W I0.B?-9I

SPL 151

-

^w^

SPL 89 SPL 90

T^

SUNROOF/ACC

NO COLOUR PIN AREA 762 B I

e.B4-67

2 658

NP

3 8.A6 660 WG 4 8.A6

II

[D

fl]

(D

01 ^5 4

ABS LOOM

RED

764

BY

726 RB 645 WR 765 0

AREA

A4/5

ABS

LOOM

BROWN

NO COLOUR

PIN

AREA 656

NG

I 8.A6

766 NO

2

II.A3 3

REARWARD HARNESS NO COLOUR 767 KB

338 OY 769 KB 3

YS

340 OC

771

BR

772 OR 773 OU

PIN 1 2 3 4 5 e

7 8 9 10 II 12 13

AREA I0.B4-I04

I2.BI I2.AI 8.AI 12.81

10.82-96

I0.C2-I00 IO.C3-I02

SHEET

14

AREA

B/CI

-4

«

NO COLOUR

PIN

AREA

774 YW 775 B

776

B

199

K

779 NS

I0.B2-92 I0.B3-IIO II.C4-II9

II.CI I0.B3-ID9

NO COLOUR

344 RIN 822 0 781 8 316 B

346 UIN

348 YU

785

NS

PIN

? 3 4 5 6 7 8 9 10 II 12 13 14 15 16

AREA

I2.A3 I0.D5 I0.B4-II0 I2.A3

I2.A3

I2.A3

10.84-109

'YD 0 0

D D

0

D

a

do DD pan Dap'

SPL 105 SPL 106 SPL 107

16/0 D

0

D

0 0

D

0\'

e/flDDODaODDo\'

SHEET

II

AREA

81

-SPL 97

-SPL 98

-

SPL 99

-

SPL 100

-

SPL 101

-

SPL 102

NO /89 790 791 792 793 794 795 796 797 643 641 798 799 800

COLOUf BW B B YG B BR BW B S

wu

p RK BR B

Pll 1 2 1 4 b 6

/

8 9 10 II 12 13 14

AREA

8.B4-66

8.B3-64

8.B2-63

IOCS I0.C5 I0.C5 I2.C3-14I I2.C2-I37 10.05 8.A4 8.A4 I0.B2-93 I0.C5 I0.C5

ILOGIC

EARTH

'

NO COLOUR AREA

1004 BK I0.B5-I0! 1005 BK I0.B2-95

(f

D

D

•

a

D

•

DOZL

D

D

0

D

0

D

•

D

D

D

DCT D

D

D

a

0

0 13 24

AREA

C/OI

REARWARD HARNESS NO COLOUF 803 SLG 804 PC 805 PW 667 G 1 LC 335 OR 807 GB 808 K 809 YN 621 RU 810 BW 811 GW 336 0 813 LGO 814 OW 815 GP 816 OG 294

R

652

WU

330 LCO 797

S

304

YB

337

RN

PIN 1 ? 3 4 5 6 7 8 9 10 II 12 13 14 15 16 17 18 19 20 21 22 23 24

AREA 11.03

e.B2-6l

8.83-65

8.A6 8.BI I2.AI I0.C2-I0I I2.A5 I2.A5 8.C4 10.62-94 I0.B2-9I

12.

Al

10.82-97 I0.B2-99 II.C2-II5 10,82-98 I2.AI 8.A4 I2.AI I0.B4

12.

Al

I2.AI

c

Q

D

n

n

D

CZ

u

u

D

D

D

0

SC:

D

D

D

D

n

n

3

CZ

u

u

D

D

REARWARD HARNESS NO COLOUf 799

BR

794

BR

724

LGK

736 RIN 327 RIN

823

GR

792 YG 824 SR 800 8 793 8 737 UIN 326 UIN 826

SW

827

R

828

BG

829

RN

374 0 723 LGS 822 0 177 YW

PIN 1 2 3 4 4 5 6 7 8 9 10 II 12 12 13 14 15 16 17 IB 19 20 21 22 23

AREA I0.B4 I0.B4 I2.CI 9.B4 I2.AI

9.C2-79

I0.B4 11.03 I0.B4 I0.D4 9.B4 I2.A1 11.03

9.C4-84

I0.B5-I06

9.C3-80

I0.B5-III I1.B3-I16 I0.A6 10.82-92

Wiring

Diagram

Model

- Aston Martin DB7

Harness

Title - Bulkhead LHD - 3

Part

No. - B37-84635

Revision

- 0

Sheet

10 of 26-97 MY

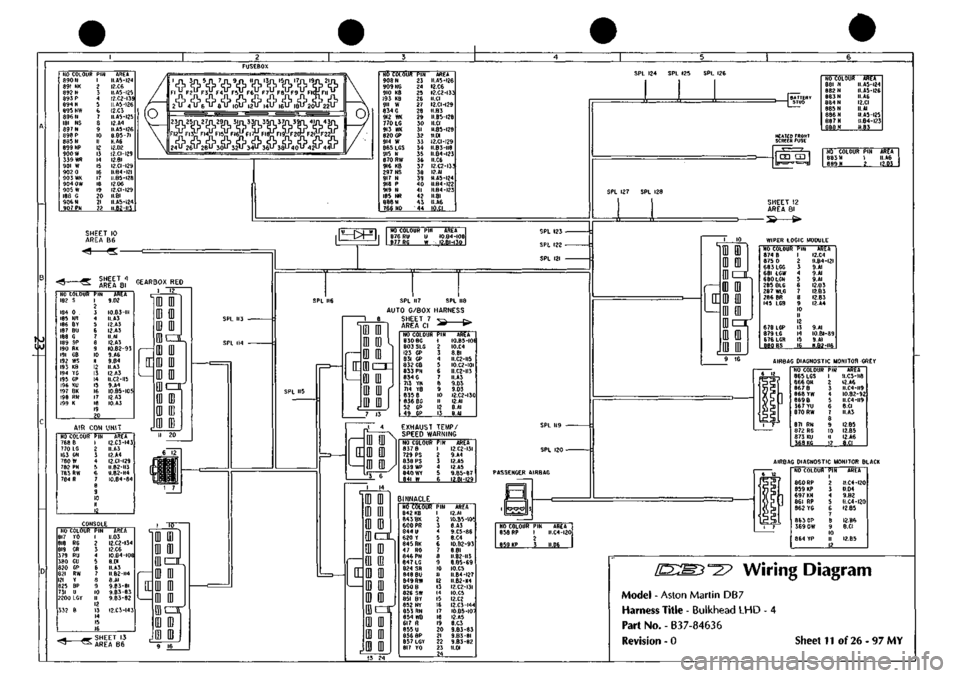

Page 154 of 421

NO COLOUF 890 N 891

NK

892 N 893 P 894 N 895 NW 896 N 131

NS

897 N 898 P 88SN 899 NP 900 W 339 WR 901

W

902

0

903 WK 904 OW 905

W

188

G

906 N 907 PN

PIN 1 ? 3 4 S 6 7 8 9 10 II 1? 13 14 15 16 17 18 19 ?0 21 22

AREA II.A5-I24 I2.C6 II.A5-I25 IZ.C2-I39 II.A5-126 I2.C3 11.45-125 I2.A4 II.A5-I26

e.B5-7l

II.A6 I2.D2 I2.CI~I29 12.81 I2.CH29 II.B4-I2I II.B5-I28 12.06 I2.CI-I29 II.BI II.A5-I24 1I.B2-II3

25JL25n 27n 29n 3in 33n 35n 37n 39n ''ia,''3rL

24V26V28V3oV,2*34V3sV38V4oV42V44V

NO COLOUF 908 N 909 NG 910

KB

193

KB

911

W

834 G 912

WK 770 10

913

WK

820

0?

914

W

865 LGS 915

N

870 RW 916

KB

297 NS 917

N

918

P

919

N

185

NR

888 N 766 NO

PIN ?3 ?4 25 ?6 27 28 29 30 31 3? 33 34 35 36 37 38 39 40 41 4? 43 44

AREA II.A5-I26 I2.C6 I2.C2-I32 II.CI I2.CI-I29 II.B3 II.B5-I28 II.CI II.B5-I28 11.01 12.01-129 II.B3~II8 II.B4-I23 II.C6 I2.C2-I3; I2.A1 II.A5-I24 II.B4-I22 II.B4-I23 11.81 II.Ae lO.CI

SPL

124 SPL 125 SPL 126

SHEET 10 AREA B6 iF^^i

-«-

SHEET

t

AREA

Bl

GEARBOX

RED

NO COLOUF 182

S

184

0

185

NR

186

BY

187

BU

188

G

189

SP

190

RK

191

GB

192

WS

193

KB

194

YG

195

GP

196

KU

197

BK

198

UN

199

K

PIN

1 2 3

4 5 6 / 8 9 10 II 1? 13 14 15 16 17

18 19 20

AREA 9.D2

I0.B3-III II.A3 12.A3 I2.A3 II.AI I2.A3 10.B2-93 9.A6 9.B4 II.A3 I2.A3 1I.C2-II5 9.A4 10,85-105 I2.A3 I0.A3

AIR CON UNIT

NO COLOUR

PIN

768

B

?70

LG

163

GN

780

W

782

PN

783 RW 784 R

1 2 3 4 5 6

7 8 9 10 II 12

AREA 12.03-143 II.A3 I2.A4 12.01-129 II.B2-II3 II.B2-II4 I0.B4-84

NO COLOUF 817

YO

818

RG

819

OR

379

RU

380

GU

820

GP

821

RW

121

Y

825

BP

731

U

2200

LGY

332

B

PIN 1 2 3 4 5 6 7 8 9 10

II 12 13 14 15 16

AREA 11.03 12.02-134 12.06 I0.B4-I0a 8.DI II.A3 II.B2-II4 8.AI

9.B3-8I

9.B3-83

9.B3-82

12.03-143

<^

• SHEET 13 •AREA B6

NO COLOUR

PIN

AREA 876

RU U

IO.B4-10S 877

RG

W -

I2.BI-I30 SPL

123

-

SPL

122

-

SPL 121

-

SPL

117

SPL

118

c

AUTO

G/BOX HARNESS

SHEET

7 v^ r-

AREA

CI -** »"

cx

NO OOLOUF 830 BG 803 SLG 123

GP

831

GP

832

GB

833 PH 834

0

713

YN

714

YB

835

B

836 BG 52

GP 49 GP

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13

AREA lO.BS-IOt 10.04 S.BI ILC2-II5 I0.C2-I0I 11.02-113 II.A3 9.03 9.03 I2.C2-I30 I2.AI

8.AI 8.AI

CO]

01

EXHAUST

TEMP/

SPEED WARNING

NO COLOUR 837

B

729

PS

838 PS 839

WP

840 WY 841

W

PIN 1 2 3 4 5 6

AREA 12.02-131 9.A4 12.A5 I2.A5

9.B5-87

I2.BI-129 PASSENGER AIRBAG

BINNACLE

I

(=3;

era

ra

i(=r

NO OOLOUF 842

KB

843 BK 600 PR 844 U 620

Y

845 RK 47

RO

646 PN e47LG 824 SR 848 BU 649 RW 850

B

826 SW 851

BY

852 NY 853 RN 854

WB

617

R

855

U

856 BP 857

LGY

817

YO

PIN 1 ? 3 4 5 6 / 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

AREA I2.A1

I0.B5-I0!

8.A3

9.05-86

8.04 I0.B2-93 8.BI II.B2-II3

e.B5-69

10.05 II.B4-I27 II.B2-I14 12.02-131 10.05 12.02 12.03-144

I0.B5-10;

I2.A5 8.03

9.B3-83

9.B3-8I

9.B3-82

11.01

SPL

127 SPL 128

c

IcX

|[=r

NO COLOUR

PIN

AREA 858

RP I

11.04-120 2 859 KP

3 11.06

I BATTERY

~| STUD

NO COLOUI 881

N

882 N 883 N 884

N

885

N

886 N 667

N

886 N

AREA II.A5-I24 II.A5-I26 II.A6 I2.CI ILAI I1.A5-I25 II.B4-I23 I1.B3

CB CD NO COLOUR PIN 883 N I 869 N 2

AREA II.A6 I2.D3

WIPER LOGIC NO COLOUF 874

B

875 0 683 LGG 681 LGW 680 LGN 285

BLG

287

WLG

286

BR

145 LGB

678 LGP 879 LC 676 LGR 880 BS

PIN 1 2 i 4 b 6 7 8 9 10 II 12 13 14 15 16

MODULE AREA I2.C4 II.B4-I2I 9.AI 9.AI 9.AI 12.B3 12.B3 12.B3 12.A4

9.AI IO.Bl-89 9.AI 1I.B2-II6

AIRBAG DIAGNOSTIC MONITOR GREY NO COLOUR 865 LGS 866 ON 867 B 868 YW 869 B 367 YU 870

RW

871 RN 672

RG

873

KU

368 KG

PIN 1 2 3 4 5 6 7 8 9 10 II 12

AREA 11.03-118 12.A6 11.04-119 10.82-92 11.04-119 8.CI II.A3

12.85 12.85

12.

A6 8.CI

AIRBAG DIAGNOSTIC MONITOR BLACK NO COLOUR

860 RP 859 KP 697 KN

861

RP

862

YG

863 OP 369 OW

864

YP

PIN

2 3 4 5 S 7 8 9 10 11 12

AREA

I1.C4-120 II.D4 9.B2 ILC4-I20 12.B5

I2.B6

e.oi

I2.B5

""^^ Wiring Diagram

Model - Aston Martin DB7

Harness Title - Bulkhead LHD - 4

Part No. - B37-84636

Revision - 0 Sheet 11 of 26-97 MY

Page 187 of 421

^=2?

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 188 of 421

Electrics

Airbag System =7?

Spillage and Leakage

If material is spilled or released, contact Aston

Martin Technical Support for advice on clean-up

procedures. All personnel must be kept away from

the contaminated area.

Do not dispose of contaminated propellant or

water into storm or sanitary sewers, ground water

or

soil.

Spills may be reportable to state and/or federal

authorities.

Materials must be disposed of by incineration or

chemical oxidation under carefully controlled

conditions by specially trained individuals and in

accordancewith local stateandfederal regulations.

Scrapping Vehicles with Live Airbags

when scrapping a vehicle with live airbags, first

deploy the airbags in accordance with the following

procedure. This procedure assumes that the airbag

wiring is undamaged

See Handling/Safety Information.

If the airbags are to be removed, see the airbag

module assembly/removal/servicing instructions.

Equipment required:

Four insulation displacement connectors

(scotch locks).

Charged 'slave' battery.

Two 10 metre lengths of

1

mm^ wire fitted with

crocodile clips on one end.

Procedure

WARNING: The deployment procedure must be

carried out outdoors away from other personnel.

1.

Remove any loose debris from around the airbag

modules and ensure that no flammable liquids are

present.

2.

Disconnect the vehicle battery.

WARNING: Always connect to the airbag

first,

as

the bag will deploy immediately on connection to

the battery.

3. Remove the passenger side airbag deployment

door and underscuttle panel.

4.

Remove the drivers side underscuttle panel.

5. Disconnect the airbag connector for the spiral

cassette under the fascia and at the wire (drivers

side).

6. Locate the harness connectors and cut the wires

leading from the airbag just above the mating plug

(passengers side).

Note: The harness connected between the driver's

airbag

and the connector

has

one red

feed

wire and

one

grey/orange return

wire.

The

harness

connected between

the

passenger's

airbag and the connector

has

one blue/

orange

feed wire and one

pinl

return wire.

6-72 September1996

Page 189 of 421

^^

Electrics

Airbag System

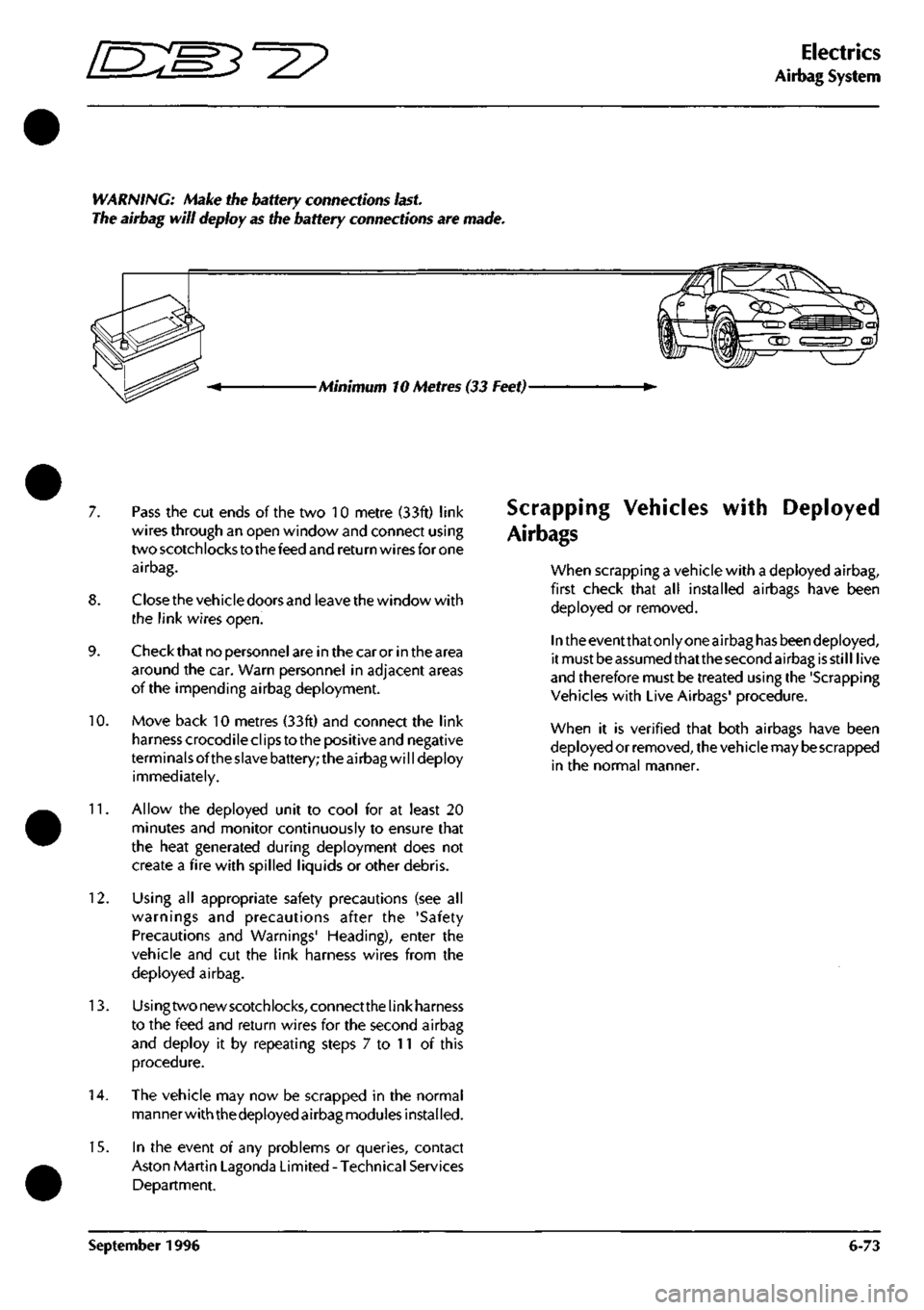

WARNING: Make the battery connections

last.

The airbag will deploy as the battery connections are made.

Minimum 10 Metres (33 Feet)-

7. Pass the cut ends of the two 10 metre (33ft) link

wires through an open window and connect using

two scotchlocks to the feed and return wires for one

airbag.

8. Closethe vehicle doors and leave the window with

the link wires open.

9. Check that no personnel are in the car or in the area

around the car. Warn personnel in adjacent areas

of the impending airbag deployment.

10.

Move back 10 metres (33ft) and connect the link

harness crocodile clips to the positive and negative

terminals ofthe slave battery; the airbag will deploy

immediately.

11.

Allow the deployed unit to cool for at least 20

minutes and monitor continuously to ensure that

the heat generated during deployment does not

create a fire with spilled liquids or other debris.

12.

Using all appropriate safety precautions (see all

warnings and precautions after the 'Safety

Precautions and Warnings' Heading), enter the

vehicle and cut the link harness wires from the

deployed airbag.

13.

Usingtwonewscotchlocks,connectthelinkharness

to the feed and return wires for the second airbag

and deploy it by repeating steps 7 to 11 of this

procedure.

14.

The vehicle may now be scrapped in the normal

manner with thedeployed airbag modules installed.

15.

In the event of any problems or queries, contact

Aston Martin Lagonda Limited - Technical Services

Department.

Scrapping Vehicles

Air bags

with Deployed

when scrapping a vehicle with a deployed airbag,

first check that all installed airbags have been

deployed or removed.

In the eventthatonly one airbag has beendeployed,

it must be assumed thatthe second airbag is still live

and therefore must be treated using the 'Scrapping

Vehicles with Live Airbags' procedure.

when it is verified that both airbags have been

deployed or removed, the vehicle may

be

scrapped

in the normal manner.

September 1996 6-73

Page 190 of 421

Electrics

Airbag System E:m3^2?

Disposal of Live Airbags

Modu

les

removed/renewed by Aston Martin dealers

are to be deployed using the following procedure.

WARNING: Never use a customer's vehicle to

deploy airbags.

Equipment Required:

Link harness

'Slave'

battery

Safety goggles to BS 2092 grade 2 or equivalent

Rubber gloves to PrEN 374 class 2 or equivalent

Ear protectors

Particulate respirator to EN 149 grade FFP 25

Deployment cage

Note: If you do not

have access

to a deployment

cage,

please

contact Aston Martin

Lagonda

Limited

Technical

Support Department for advice.

Procedure

This procedure must be performed outdoors, away

from other personnel.

Remove any loose debris from around the airbag

and ensure that no flammable liquids are present.

Assemble the disposal cabinet and fit the airbag as

shown in figure 1 in line with the following

procedures:

a) Remove the mesh guard from the rig frame.

b) Attach the guard to the frame by bolting the

hinges to the frame.

c) Ensure the relevant plate is fitted and rotate into

position.

d) Fit and secure the airbag module onto the plate.

e) Clamp the plate down using the two toggle

clamps.

f) Close the mesh guard.

Note: The harness connected between the driver's

airbag and

the

connector

has

one red

feed

wire and one

grey/orange return wire. The harness connected between

the

passenger's

airbag and the connector

has

one blue/

orange feed wire and one pink/black return wire.

Connect the 10 metre {33ft) link harness to the

airbag.

Ensure that no personnel are in the vicinity of the

cabinet.

5. Move 10 metres (33ft) and connect the link harness

crocodile clips to the 'slave' battery; the airbag will

deploy immediately.

6. Allow the unit to cool for at least 20 minutes.

7. Open the mesh guard and remove the deployed

airbag module.

Note: Should the

design

of your deployment

cage

differ

from that described above, please contact the cage

manufacturer for advice on mounting the airbag.

8. Seal the deployed module into a plastic bag ready

for disposal.

9. In the event of any problems or queries, contact

Aston Martin Lagonda Limited -Technical Services

Department.

Disposal of Deployed Airbags

Deployed airbags are to be disposed of as special

waste and disposal must comply with local

environmental requirements. If

in

any doubt, contact

the local authority for disposal instructions.

Note; The storage, transportation, disposal and/or

recycling of airbag module components must be

performed in accordance with all applicable federal,

state

and local regulations including, but not limited to,

those

governing building and fire

codes,

environmental

protection, occupational health and safety and

transportation.

Modules removed and deployed by Aston Martin

Dealers are to be returned to Aston Martin Lagonda

Limited for disposal following prior consultation.

6-74 September 1996

Page 191 of 421

'=2?

Electrics

Airbag System

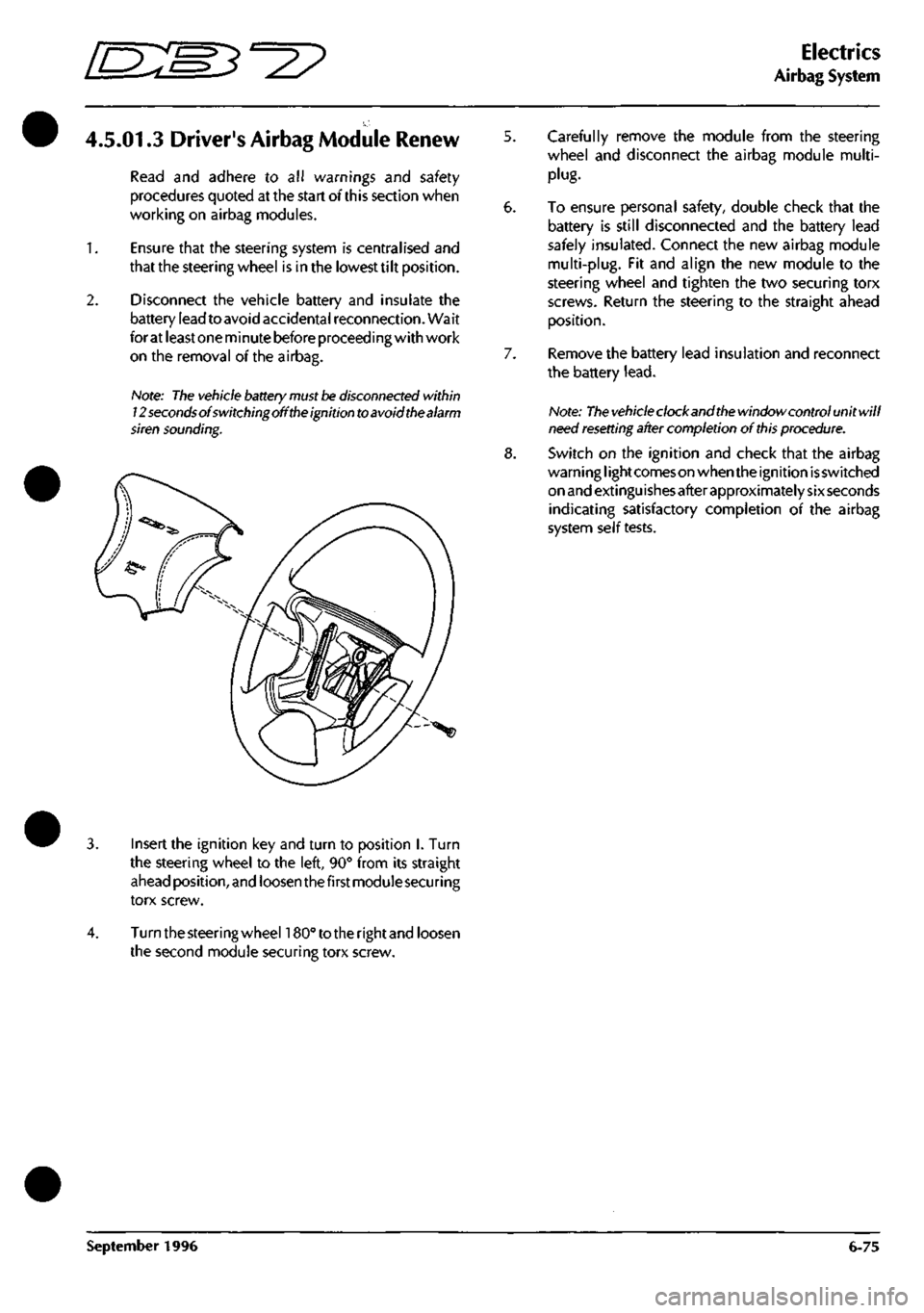

4.5.01.3 Driver's Airbag Module Renew

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on airbag modules.

1.

Ensure that the steering system is centralised and

that the steering wheel is in the lowest tilt position.

2.

Disconnect the vehicle battery and insulate the

battery lead to avoid accidental reconnection. Wait

for at least one minute before proceeding with work

on the removal of the airbag.

Hote: The vehicle battery

must be

disconnected within

12 seconds of switching off

the

ignition to avoid the alarm

siren sounding.

5. Carefully remove the module from the steering

wheel and disconnect the airbag module multi-

plug.

6. To ensure personal safety, double check that the

battery is still disconnected and the battery lead

safely insulated. Connect the new airbag module

multi-plug.

Fit and align the new module to the

steering wheel and tighten the two securing torx

screws. Return the steering to the straight ahead

position.

7. Remove the battery lead insulation and reconnect

the battery

lead.

Note:

The vehicle

clockandthe window control unitwill

need

resetting

after completion of

this

procedure.

8. Switch on the ignition and check that the airbag

warni ng

I

ight comes on when the ignition is switched

on and extinguishes after approximately sixseconds

indicating satisfactory completion of the airbag

system self tests.

Insert the ignition key and turn to position I. Turn

the steering wheel to the left, 90° from its straight

ahead position, and loosen thefirstmoduiesecuring

torx screw.

Turn the steering wheehSO" to the rightand loosen

the second module securing torx screw.

September 1996 6-75

Page 192 of 421

Electrics

Airbag System ^^?

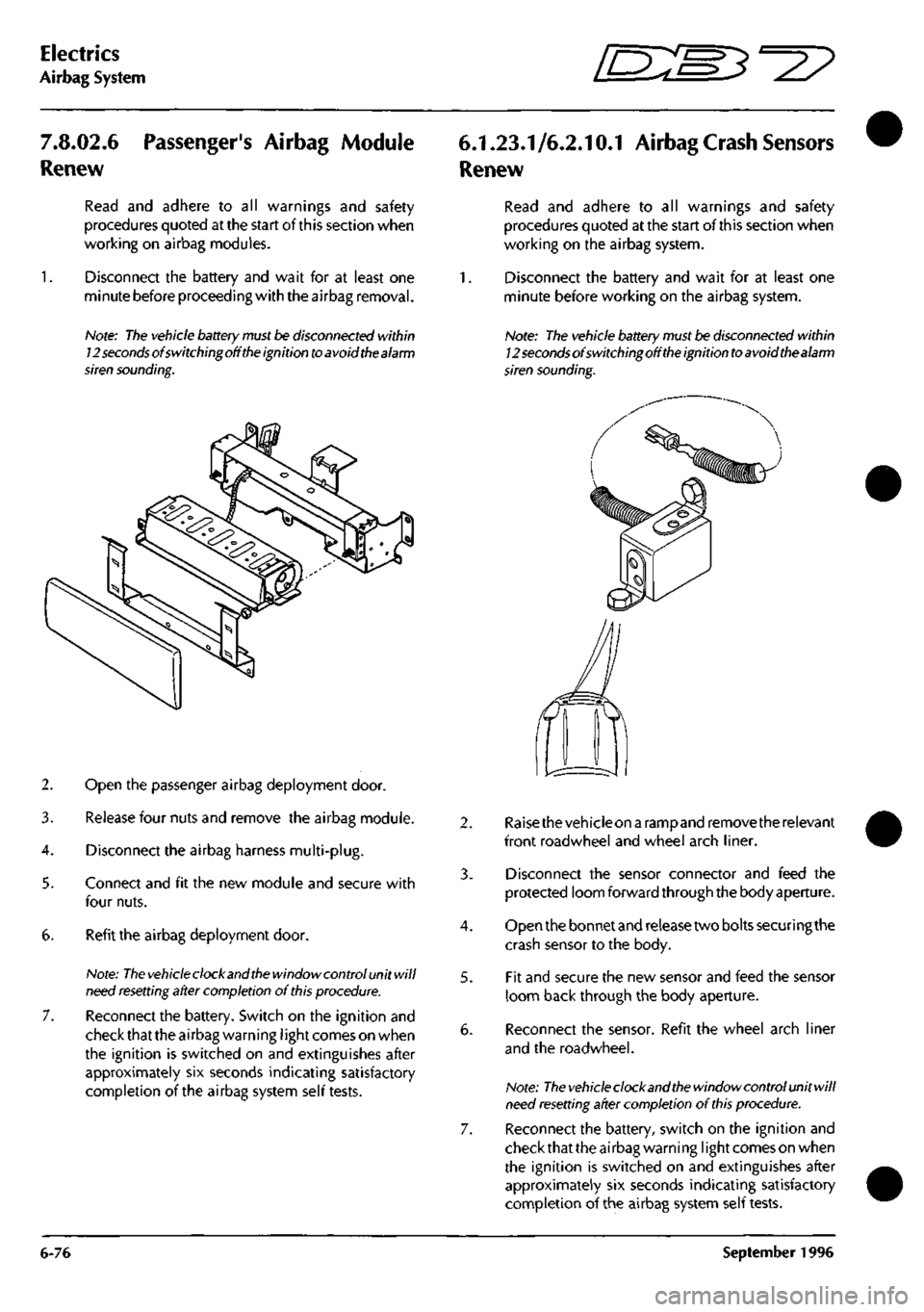

7.8.02.6

Renew

Passenger's Airbag Module

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on airbag modules.

Disconnect the battery and wait for at least one

minute before proceeding with the airbag removal.

Note:

The

vehicle battery

must

be disconnected within

12

seconds

of switchingoff

the

ignition

to

avoid the alarm

siren sounding.

2. Open the passenger airbag deployment door.

3. Release four nuts and remove the airbag module.

4.

Disconnect the airbag harness multi-plug.

5. Connect and fit the new module and secure with

four nuts.

6. Refit the airbag deployment door.

Note:

The vehicle

clock and

the

window control unit will

need

resetting

after completion of

this

procedure.

7. Reconnect the battery. Switch on the ignition and

check that the airbag warning

I

ight comes on when

the ignition is switched on and extinguishes after

approximately six seconds indicating satisfactory

completion of the airbag system self tests.

6.1.23.1/6.2.10.1 Airbag

Crash

Sensors

Renew

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on the airbag system.

1.

Disconnect the battery and wait for at least one

minute before working on the airbag system.

Note: The vehicle

battery

must be disconnected within

12

seconds

of switchingoff

the

ignition

to

avoid thealarm

siren sounding.

4.

5.

Raisethevehicleon a rampand remove the relevant

front roadwheel and wheel arch liner.

Disconnect the sensor connector and feed the

protected loom forward through the body aperture.

Open the bonnet and release two bolts securing the

crash sensor to the body.

Fit and secure the new sensor and feed the sensor

loom back through the body aperture.

Reconnect the sensor. Refit the wheel arch liner

and the roadwheel.

Note:

The vehicle

clock and

the

window control unit will

need

resetting

after completion of

this

procedure.

Reconnect the battery, switch on the ignition and

check that the airbag warning

I

ight comes on when

the ignition is switched on and extinguishes after

approximately six seconds indicating satisfactory

completion of the airbag system self tests.

6-76 September 1996