sensor ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 296 of 421

^2?

Air Conditioning

Electronic Control Module

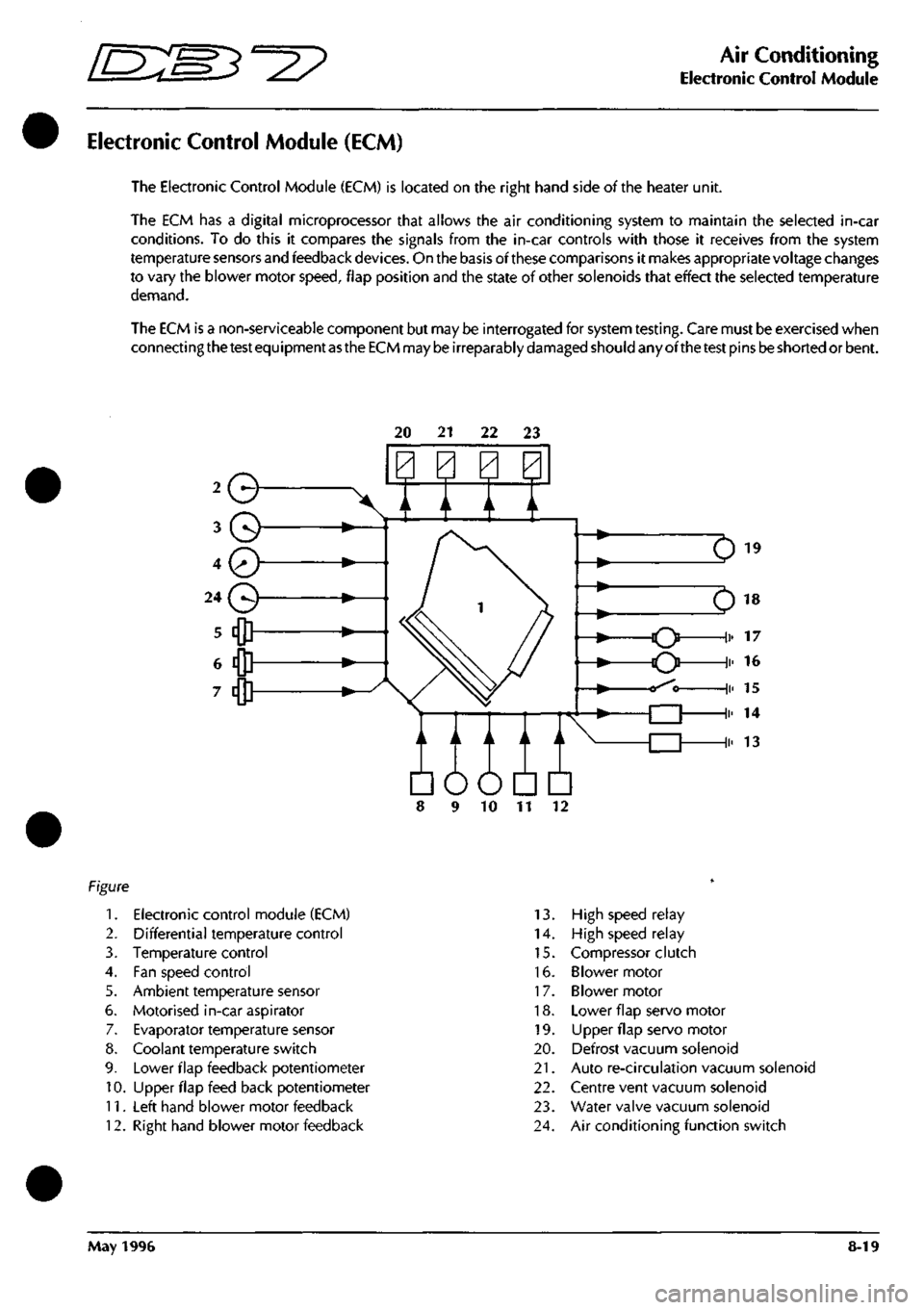

Electronic Control Module (ECM)

The Electronic Control Module (ECM) is located on the right hand side of the heater unit.

The ECM has a digital microprocessor that allows the air conditioning system to maintain the selected in-car

conditions. To do this it compares the signals from the in-car controls with those it receives from the system

temperature sensors and feedback

devices.

On the basis of these comparisons it makes appropriate voltage changes

to vary the blower motor

speed,

flap position and the state of other solenoids that effect the selected temperature

demand.

The ECM is a non-serviceable component but may be interrogated for system

testing.

Care must be exercised when

connecting

the test

equipment

as the ECM

may

be

irreparably

damaged

should any ofthe

test

pins

be

shorted or bent.

20 21 22 23

Q

A / A \/

Em

10 11

1.

Electronic control module (ECM)

2.

Differential temperature control

3. Temperature control

4.

Fan speed control

5. Ambient temperature sensor

6. Motorised in-car aspirator

7. Evaporator temperature sensor

8. Coolant temperature switch

9. Lower flap feedback potentiometer

10.

Upper flap feed back potentiometer

11.

Left hand blower motor feedback

12.

Right hand blower motor feedback

13.

High speed relay

14.

High speed relay

15.

Compressor clutch

16.

Blower motor

17.

Blower motor

18.

Lower flap servo motor

19.

LIpper flap servo motor

20.

Defrost vacuum solenoid

21.

Auto re-circulation vacuum solenoid

22.

Centre vent vacuum solenoid

23.

Water valve vacuum solenoid

24.

Air conditioning function switch

May 1996 8-19

Page 297 of 421

Air Conditioning

Electronic Control Module r^^?

Description

The ECM (Fig 1) controls the air conditioning

system so that selected temperaturesare maintained.

It cannot be repaired but input and output signals

can be measured, using the PDU, for diagnostic

purposes.

Input-Output Voltage Signals

The following voltage signal levels are input and

output from the ECM:

Digital input levels:

Low

High

Analogue input levels:

General

Blend Flap Potentiometer

Digital output levels

Relays On

Off

Vacuum manifold Pull-in

Drop-out

Analogue output levels

Blend Flap Servo Motors

Blower Motors

0.16 to 1.1V

3.70 to 4.50V

0 to 0.2885 V

0 to 5.0V

8.0V

1.0 to 5.0V

5.6V (typical)

3.5V (typical)

0.5 to 6.5V

0.5 to 2.5V

figure 1.

The ECM

is

turned on when the ignition

is

turned on

to auxiliary position 1. its operating range is 13.5-

14.2 volts.

The ECM power unit supplies +5 volts for the

temperature sensors, feedback potentiometers and

high speed relays.

An integrated circuit protects the ECM against

reversed polarity and voltage surges.

Caution: Take care when connecting test equipment. If

test pins are allowed to be shorted together, to

ground or to positive supplies the ECM will be

damaged.

8-20 May 1996

Page 300 of 421

'^^p

Air Conditioning

In Car Controls

Fan Speed Control Switch (Mode Switch)

SC On Mode

The system is not operational, a residual

signal to the ECM ensures that the blower

flaps are closed to prevent air entering the

system.

1.

Low Blower Mode

The fan speed is lowandtheairconditioning

function switch is fully operational. Pin 13

on the ECM is earthed through the switch

and a 12V signal is returned to Pin 44.

2.

Medium Blower Mode

The fan runs at medium speed and the

function switch is fully operational. Pin 14

of the ECM is earthed through the switch

and a 12V signal is returned to Pin 44.

3. High Blower Mode

The fan speed is high and the function

switch is fully operational. Pin 15 at the

ECM is earthed through the switch and a

12V signal is returned to Pin 44.

DEF Defrost Blower Mode

The fan speed is

high,

the function switch

and temperature switch are not operational,

front screen vents are fully open and lower

flaps are fully closed. Pin 27 at the ECM is

earthed through the switch and a 12V signal

is returned to Pin 44.

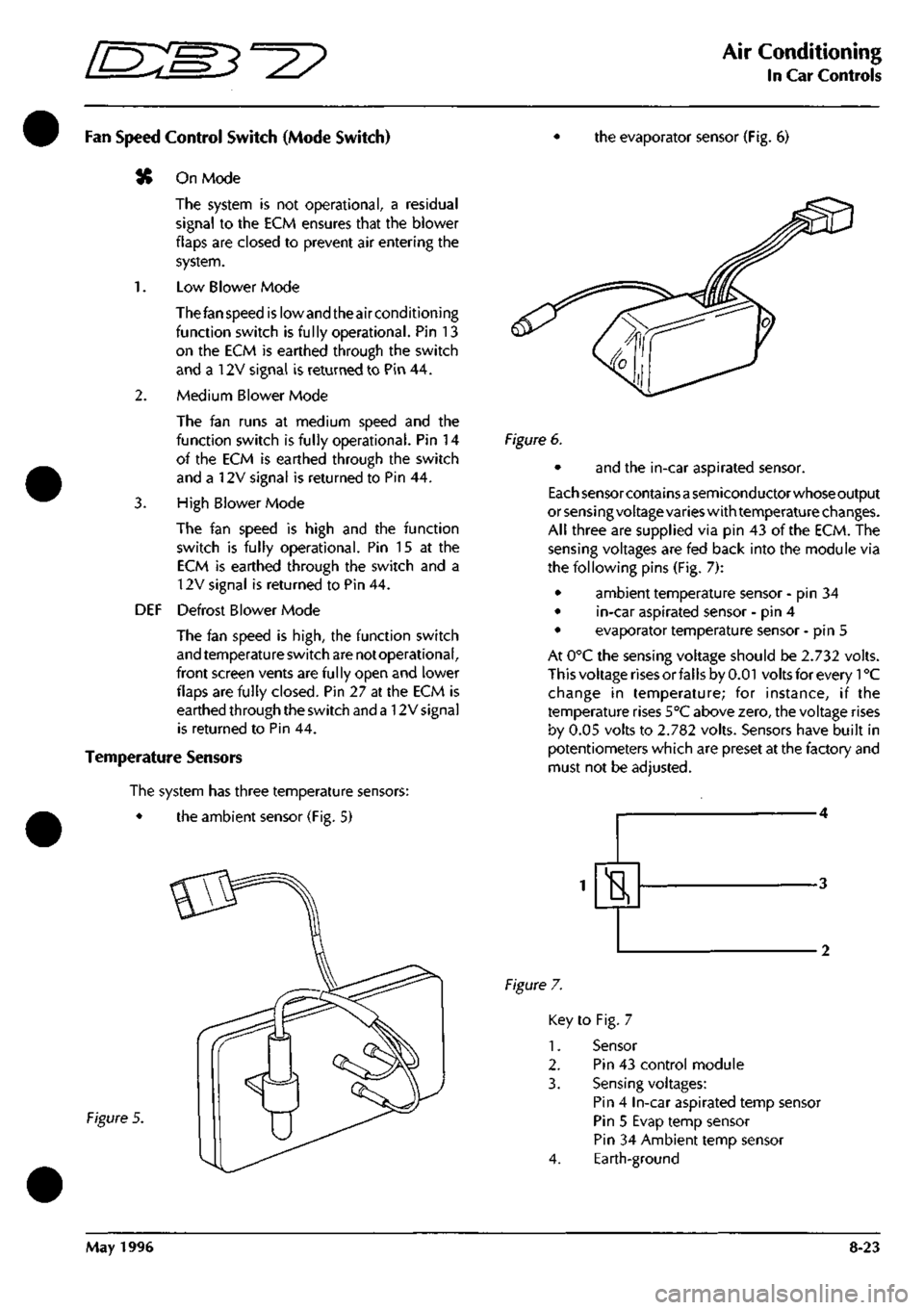

Temperature Sensors

The system has three temperature sensors:

• the ambient sensor (Fig. 5)

the evaporator sensor (Fig. 6)

Figure 5.

Figure 6.

• and the in-car aspirated sensor.

Each sensor containsa semiconductor whose output

or sensing voltage varies with temperature changes.

All three are supplied via pin 43 of the ECM. The

sensing voltages are fed back into the module via

the following pins (Fig. 7):

• ambient temperature sensor - pin 34

• in-car aspirated sensor - pin 4

• evaporator temperature sensor - pin 5

At 0°C the sensing voltage should be 2.732 volts.

This voltage rises or falls by 0.01 volts for every 1°C

change in temperature; for instance, if the

temperature rises 5°C above zero, the voltage rises

by 0.05 volts to 2.782 volts. Sensors have built in

potentiometers which are preset at the factory and

must not be adjusted.

H

Figure 7.

Key to Fig. 7

1.

Sensor

2.

Pin 43 control module

3. Sensing voltages:

Pin 4 In-car aspirated temp sensor

Pin 5 Evap temp sensor

Pin 34 Ambient temp sensor

4.

Earth-ground

May 1996 8-23

Page 301 of 421

Air Conditioning

In Car Controls ^2?

Evaporator Sensor

The evaporator sensor allov^^s the ECM to monitor

the temperature ofthe refrigerant in the evaporator

core continuously. When the temperature falls

below 0°C the ECM de-energises the compressor's

electromagnetic clutch and prevents refrigerant

from flowing through the system. The clutch is re

engaged when the temperature rises.

Motorised In-Car Aspirated Sensor

The motorised aspirator (Fig. 8), which is fitted to

the passenger side facia underscuttle panel,

incorporates a motor driven fan (Fig. 8-1) that

draws air continuously over the in car temperature

sensor (Fig. 8-2).

Figure 8.

Key

1.

2.

3.

4.

5.

to Fig. 8

Motor

Sensor

Fan

Connector SCAO07

Connector SAC030

The motor (Fig. 8-1) is supplied, independently of

the air conditioning

system,

from the ign ition switch

(position 2). Its operating voltage range is 13.5 to

14.2 volts. Maximum current is 120 mA. The sensor

(Fig.

8-2) has a temperature operating range of -

30°C to +85°C. It is fed with 5 volts from the ECM

(pin 43), while the sensing voltage

is

supplied to pin

4 ofthe ECM. At 0°C the sensing voltage is 2.732V

± 0.002V. The rate of change of sensing voltage is

0.01 V± 0.002V per 1°C.

LC/0

0^5

U

Figure 9.

Key to Fig. 9

1.

Ignition switched supply to motor

2.

+5V supply to sensor from pin 43 of ECM

3. Sensor voltage output to pin 10 of ECM

4.

Sensor earth-ground to pin 4 of ECM

5. Motor earth-ground

A. Motor

B. Sensor

Ambient Temperature Sensor

An ambient temperature sensor (Fig. 10-1) is fitted

in the plenum air intake to provide the ECM with

information on the temperature ofthe air entering

the air conditioning unit and so offset the in-car

temperature at extremes of ambient. The voltage

signal output from the sensor is proportional to the

temperature of the surrounding air. The sensor

temperature range is -30°C to 85°C. At 0°C the

output ofthe sensor is 2.732V ± 0.005V. The rate

of change is + 0.01 V ± 0.002V per

1

°C.

Figure 10.

Key to Fig. 10

1.

Ambient temperature sensor

2.

+5 volts from ECM Pin 43

3. Sensing signal to ECM Pin 34

4.

Earth-ground

8-24 May 1996

Page 307 of 421

Air Conditioning

System Fault Diagnosis ^=2?

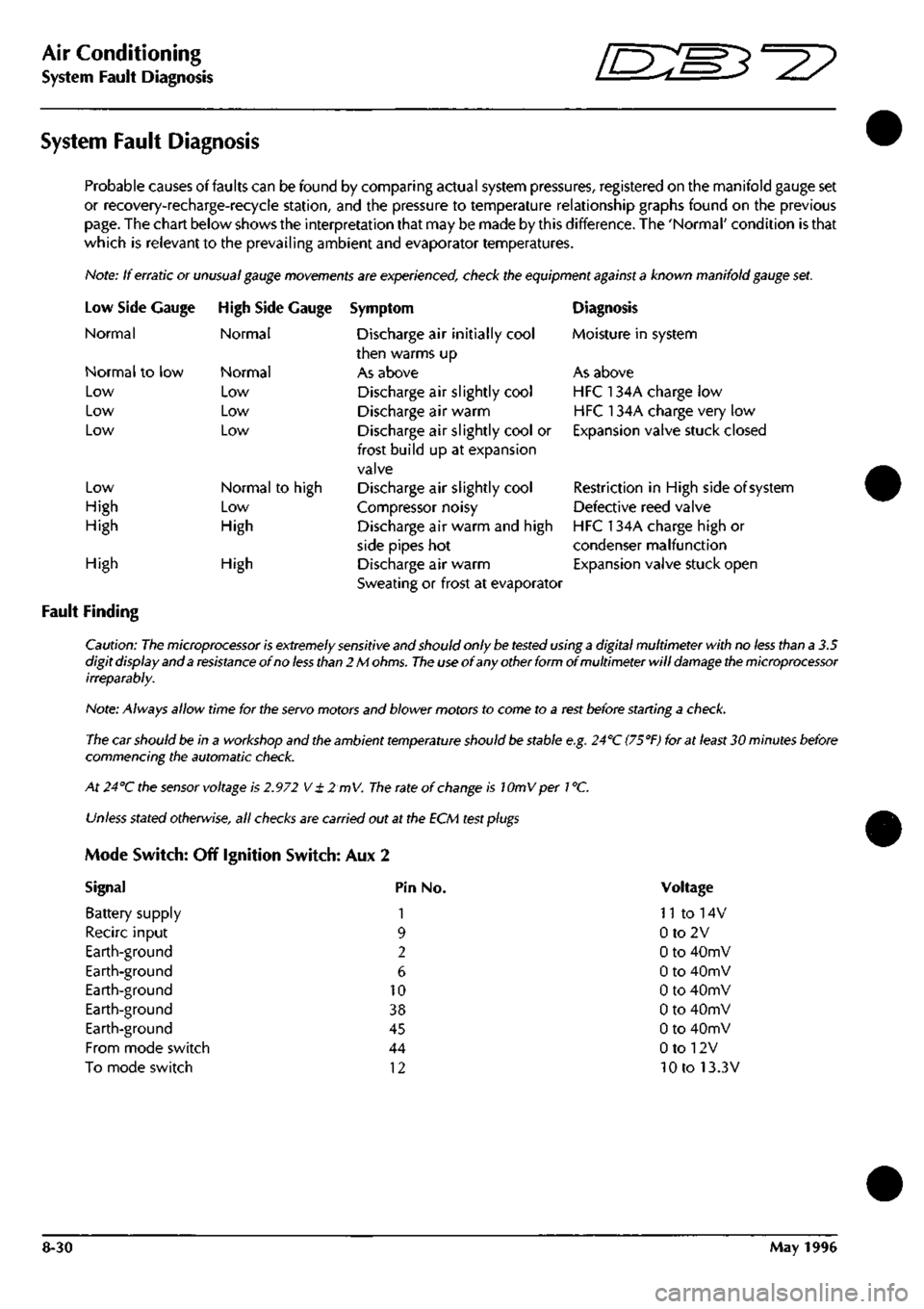

System Fault Diagnosis

Probable causes of faults can be found by comparing actual system pressures, registered on the manifold gauge set

or recovery-recharge-recycie station, and the pressure to temperature relationship graphs found on the previous

page.

The chart below shows the interpretation that may be made by this difference. The 'Normal' condition is that

which is relevant to the prevailing ambient and evaporator temperatures.

Note: If erratic or

unusual gauge movements

are experienced, check the equipment

against a

known manifold

gauge

set.

Low Side

Normal

Gauge

Normal to low

Low

Low

Low

Low

High

High

High Side Gauge

Normal

Normal

Low

Low

Low

Normal to high

Low

High

High

Fault Finding

High

Symptom

Discharge air initially cool

then warms up

As above

Discharge air slightly cool

Discharge air warm

Discharge air slightly cool or

frost build up at expansion

valve

Discharge air slightly cool

Compressor noisy

Discharge air warm and high

side pipes hot

Discharge air warm

Sweating or frost at evaporator

Diagnosis

Moisture in system

As above

HFC 134A charge low

HFC 134A charge very low

Expansion valve stuck closed

Restriction in High side of system

Defective reed valve

HFC 134A charge high or

condenser malfunction

Expansion valve stuck open

Caution:

The microprocessor is extremely sensitive

and should only

be tested

using

a

digital multimeter with no

less

than a 3.5

digit display and a

resistance

of no

less than

2 M

ohms.

The use

of any other form of multimeter will

damage the microprocessor

irreparably.

Note: Always allow time for the

servo

motors and blower motors to come to a

rest

before starting a

check.

The car should be in a workshop and the ambient

temperature

should

be

stable

e.g.

24''C

(75°F)

for at

least

30 minutes before

commencing the automatic

check.

At 24°C the

sensor

voltage is

2.972

V

± 2 mV.

The

rate of

change

is lOmVper

1

°C.

Unless

stated

otherwise,

all

checks

are carried out at the ECM

test plugs

Mode Switch: Off Ignition Switch: Aux 2

Signal Pin No.

Battery supply 1

Recirc input 9

Earth-ground 2

Earth-ground 6

Earth-ground 10

Earth-ground 38

Earth-ground 45

From mode switch 44

To mode switch 12

Voltage

n to 14v

0to2V

0 to 40mV

0 to 40mV

0 to 40mV

0 to 40mV

0 to 40mV

0 to 12V

10 to 13.3V

8-30 May 1996

Page 308 of 421

"3^2?

Air Conditioning

System Fault Diagnosis

Mode Switch: Low - Function Switch: Manual

Low input 13

Clutch output- Evap sensor below 2.72V 20

Clutch output- Evap sensor above 2.72V 20

Medium input 14

High input 15

Defrost 27

From ON-OFF Switch. 44

Output 43

Recirc. output 3

HS Relays 16

Water valve solenoid 17

Centre vent solenoid 18

Mode Switch: Medium - Function Switch: Manual

Low input

Medium input

High input

Defrost

13

14

15

27

Mode Switch: High Servo Motors Stationary - Function Switch: Manual

Low input 13

Medium input 14

High input 15

Defrost input 27

Mode Switch: Defrost - Function Switch: Manual

Low input

Medium input

High input

Defrost input

13

14

15

27

Mode Switch: Low, Medium or High - Function Switch: Manual

Air Differential - cold face 28

Air Differential - hot face 28

Mode Switch: Low, Medium or High - Function Switch: Manual

Temp.

Maximum demand 35

Temp.

Minimum demand 35

150 to 350mV

0.6V

11.4V

3to5V

3to5V

3to5V

10.3 to 13.3V

4.73 to 5.2V

0 to 200mV

0 to 200mV

0 to 200mV

0 to 200 mV

3to5V

150 to 350mV

3to5V

3to5V

3to5V

3to5V

150 to 350V

3to5V

3to5V

3to5V

3to5V

150 to 350mV

2.665 to 3.105V

0 to 200mV

2.665 to 3.105V

0 to 200mV

Mode Switch: Low, Medium or High Temperature Demand Switch: Mid-Range - Function Switch: AC

Servo motor lower flap 37 0 to 2.0V

Servo motor lower flap 41 0 to 2.0V

Servo motor upper flap 40 0 to 2.0V

Servo motor upper flap 42 0 to 2.0V

Mode Switch: Low, Medium or High Temperature Demand Switch: Mid-Range - Function Switch: AC

Servo motor lower flap 37 7.0 to 9.5V

Servo motor lower flap 41 7.0 to 9.5V

Serve motor upper flap 40 7.0 to 9.5V

Servo motor upper flap 42 7.0 to 9.5V

May 1996 8-31

Page 333 of 421

Air Conditioning Repair Procedures

Air-Conditioning Unit Renew ^^?

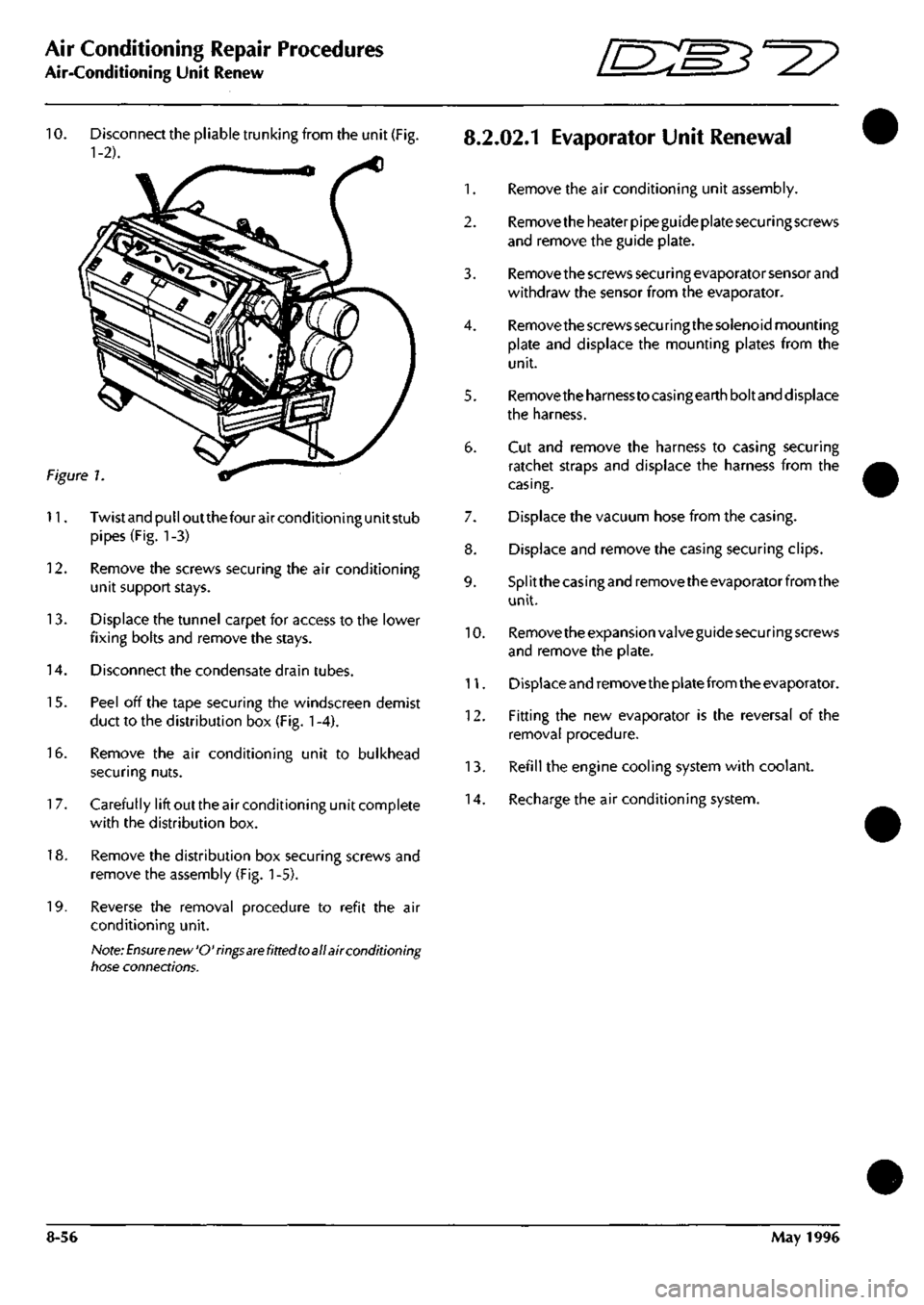

10.

Disconnect the pliable trunking from the unit (Fig.

8.2.02.1

EvaporatOr Unit Renewal

1-2). ^

1.

Remove the air conditioning unit assembly.

2.

Remove the heater pipe guide plate securing screws

and remove the guide plate.

3. Remove the screws secu ri ng evaporator sensor and

withdraw the sensor from the evaporator.

4.

Remove the screws securing the solenoid mounting

plate and displace the mounting plates from the

unit.

5. Removetheharnesstocasingearthboltand displace

the harness.

6. Cut and remove the harness to casing securing

ratchet straps and displace the harness from the

casing.

7. Displace the vacuum hose from the casing.

8. Displace and remove the casing securing clips.

9. Splitthecasingandremovetheevaporatorfromthe

unit.

10.

Remove the expansion valve guide securing screws

and remove the plate.

11.

Displace and remove the plate from the evaporator.

12.

Fitting the new evaporator is the reversal of the

removal procedure.

13.

Refill the engine cooling system with coolant.

14.

Recharge the air conditioning system.

Figure 1

11.

Twistandpulloutthefourairconditioningunitstub

pipes (Fig. 1-3)

12.

Remove the screws securing the air conditioning

unit support stays.

13.

Displace the tunnel carpet for access to the lower

fixing bolts and remove the stays.

14.

Disconnect the condensate drain tubes.

15.

Peel off the tape securing the windscreen demist

duct to the distribution box (Fig.

1

-4).

16.

Remove the air conditioning unit to bulkhead

securing nuts.

1

7. Carefully lift out the air conditioning unit complete

with the distribution box.

18.

Remove the distribution box securing screws and

remove the assembly (Fig.

1

-5).

19.

Reverse the removal procedure to refit the air

conditioning unit.

Note:

Ensure new'O'rings

are

fitted toall air conditioning

tiose connections.

8-56 May 1996

Page 336 of 421

'nzm^=2?

Air Conditioning Repair Procedures

Blower Motor Renewal

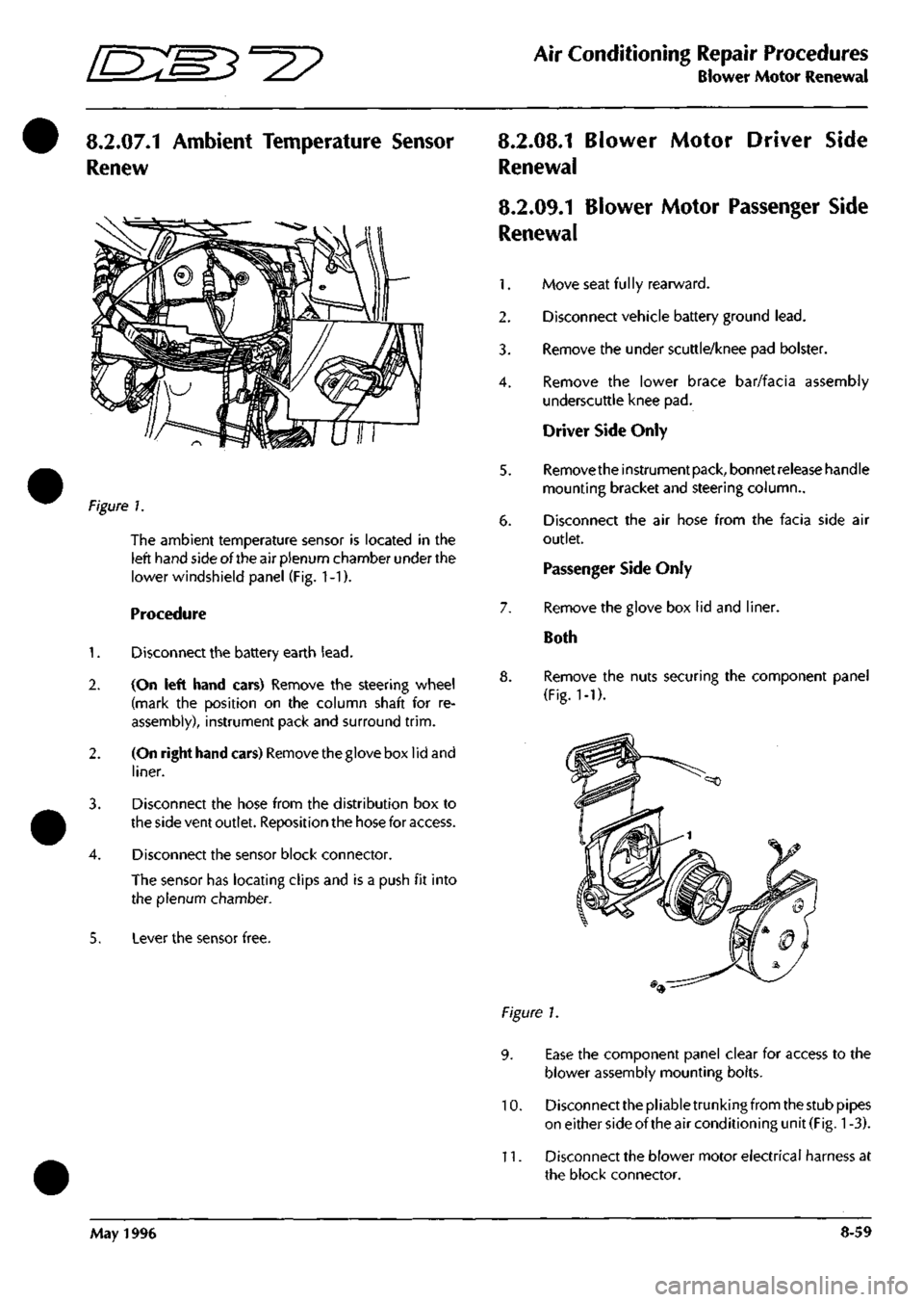

8.2.07.1 Ambient Temperature Sensor

Renew

?\gure

1.

The ambient temperature sensor is located in the

left hand side of the air plenum chamber under the

lower windshield panel (Fig. 1-1).

Procedure

1.

Disconnect the battery earth

lead.

2.

(On left hand cars) Remove the steering wheel

(mark the position on the column shaft for re

assembly), instrument pack and surround

trim.

2.

(On right hand cars) Removethegloveboxlidand

liner.

3. Disconnect the hose from the distribution box to

the side vent outlet. Reposition the hose for access.

4.

Disconnect the sensor block connector.

The sensor has locating clips and is a push fit into

the plenum chamber.

5. Lever the sensor free.

8.2.08.1 Blower Motor Driver Side

Renewal

8.2.09.1 Blower Motor Passenger Side

Renewal

1.

Move seat

fu 1

ly rearward.

2.

Disconnect vehicle battery ground

lead.

3. Remove the under scuttle/knee pad bolster.

4.

Remove the lower brace bar/facia assembly

underscuttle knee pad.

Driver Side Only

5. Removetheinstrumentpack, bonnetreieasehandle

mounting bracket and steering column..

6. Disconnect the air hose from the facia side air

outlet.

Passenger Side Only

7. Remove the glove box lid and liner.

Both

8. Remove the nuts securing the component panel

(Fig.

1-1).

Figure 1.

9. Ease the component panel clear for access to the

blower assembly mounting bolts.

10.

Disconnect the pliable trunking from the stub pipes

on either side of the air conditioning unit

(Fig.

1

-3).

11.

Disconnect the blower motor electrical harness at

the block connector.

May 1996 8-59

Page 342 of 421

Air Conditioning

Air-Conditioning Diagnostics

The Air Conditioning System Diagnostics

The air-conditioning control module (A/CCM) is located at the right end of the air-conditioning unit.

A

digital microprocessor within the

A/CCM

receives

data

signals from

the

operator controlled

switches.

Comparison

of these signals with those returned from the system temperature sensor and feedback devices results in the

appropriate voltage changes necessary to vary: blower motor

speed,

flap positions and system solenoids to respond

to the drivers selected temperature demand.

The air from the two blower motors is passed through the evaporator matrix which, depending on the A/C mode

selected,

removes heat from the incoming air. Depending on the position of

the

two blend

flaps,

the cold air passes

either directly into the vehicle outlet vents, or is passed through the heater matrix to be reheated and then passed

to the vehicle outlet vents.

The amount of air passing through the heater matrix is infinitely variable depending on ambient temperature and

the temperature selected within the vehicle.

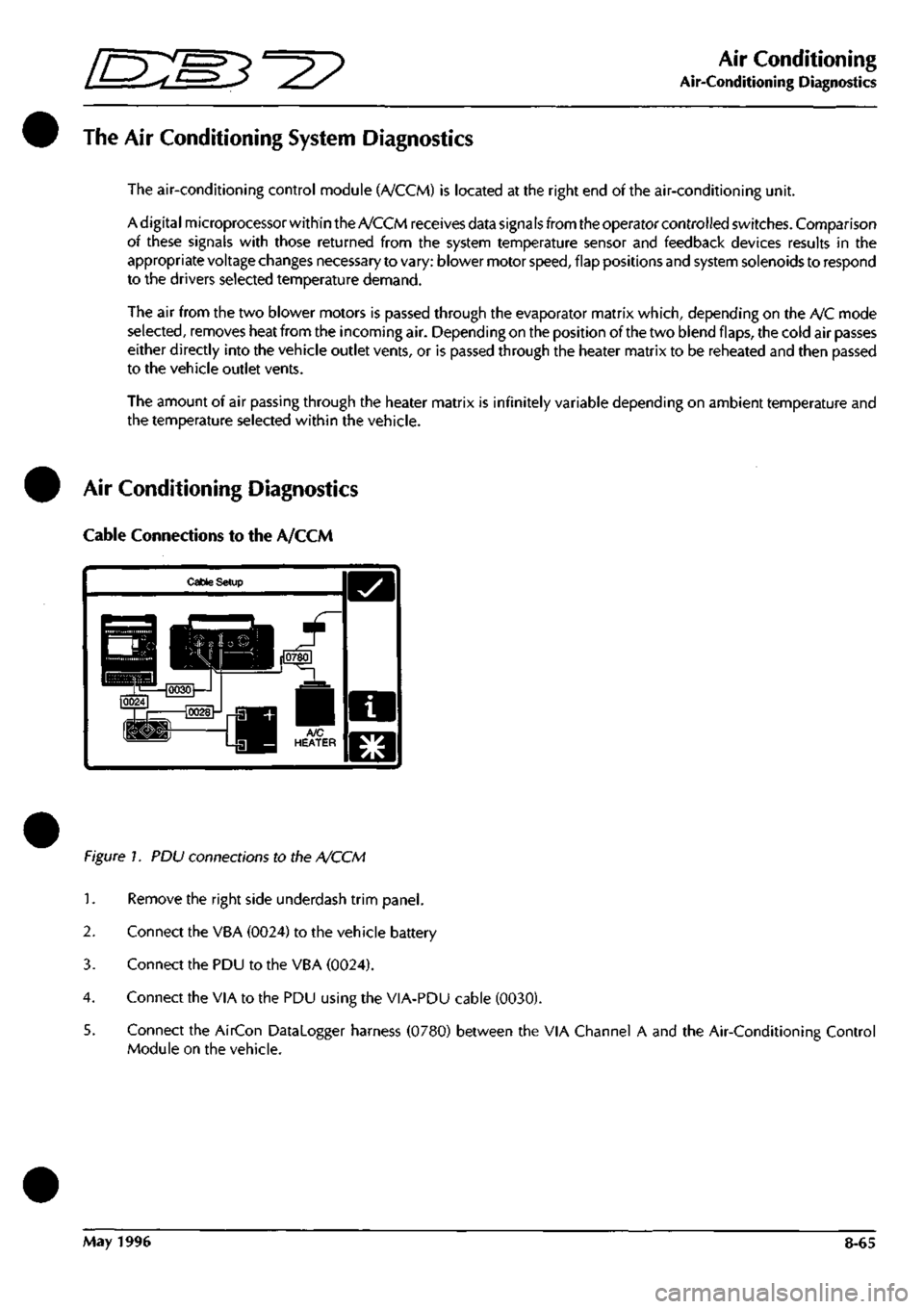

Air Conditioning Diagnostics

Cable Connections to the A/CCM

Cable Setup

Figure 1. PDU connections to the A/CCM

1.

Remove the right side underdash trim panel.

2.

Connect the VBA (0024) to the vehicle battery

3. Connect the PDU to the VBA (0024).

4.

Connect the VIA to the PDU using the VIA-PDU cable (0030).

5. Connect the AirCon Datalogger harness (0780) between the VIA Channel A and the Air-Conditioning Control

Module on the vehicle.

May 1996 8-65

Page 343 of 421

Air Conditioning

Portable Diagnostic Unit - Signal Monitoring 3^^?

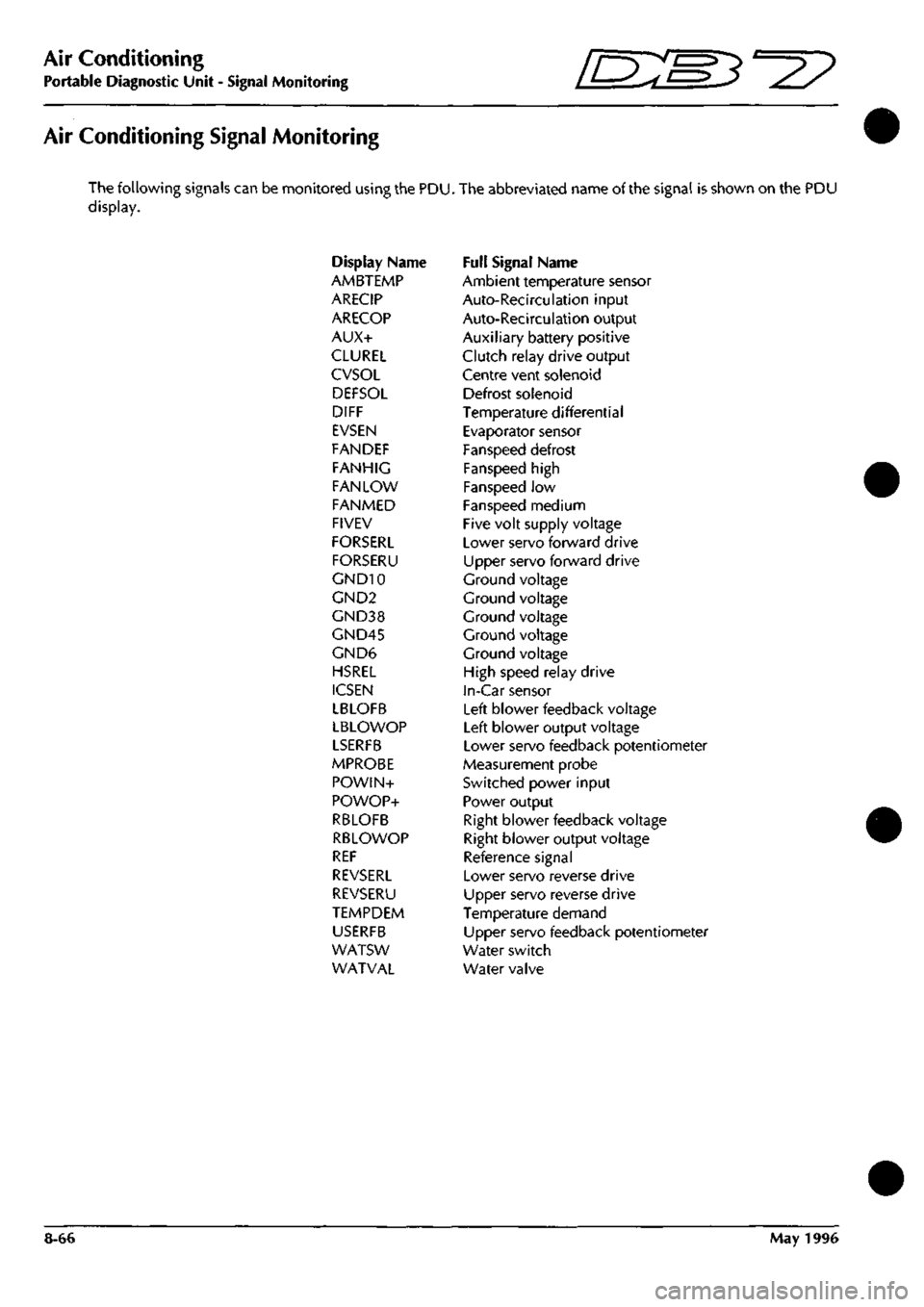

Air Conditioning Signal Monitoring

The following signals can be monitored using the PDU. The abbreviated name of the signal is shown on the PDU

display.

Display Name Full Signal Name

AMBTEMP Ambient temperature sensor

ARECIP Auto-Recirculation input

ARECOP Auto-Recirculation output

AUX+ Auxiliary battery positive

CLUREL Clutch relay drive output

CVSOL Centre vent solenoid

DEFSOL Defrost solenoid

DIFF Temperature differential

EVSEN Evaporator sensor

FANDEF Fanspeed defrost

FANHIG Fanspeed high

FAN LOW Fanspeed low

FANMED Fanspeed medium

FIVEV Five volt supply voltage

FORSERL Lower servo forward drive

FORSERU Upper servo forward drive

GND10 Ground voltage

GND2 Ground voltage

GND38 Ground voltage

GND45 Ground voltage

GND6 Ground voltage

HSREL High speed relay drive

ICSEN In-Car sensor

LBLOFB Left blower feedback voltage

LBLOWOP Left blower output voltage

LSERFB Lower servo feedback potentiometer

MPROBE Measurement probe

POWIN+ Switched power input

POWOP+ Power output

RBLOFB Right blower feedback voltage

RBLOWOP Right blower output voltage

REF Reference signal

REVSERL Lower servo reverse drive

REVSERU Upper servo reverse drive

TEMPDEM Temperature demand

USERFB Upper servo feedback potentiometer

WATSW Water switch

WATVAL Water valve

8-66 May 1996