air conditioning ASTON MARTIN DB7 1997 Manual Online

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 348 of 421

Air Conditioning

Portable Diagnostic Unit - Signal Definitions

Left Blower Feedback Voltage

(LBLOFB)

Left Blower Output Voltage

(LBLOWOP)

pin 22 = 5±1 volt

pin22 = 9±lvolt

pin 22 = 5±1 volt

pin 22 = 2±1 volt

pin22 = 6±1volt

pin 22 = 2±1 volt

A/CCM Pin 22 ref Pin 6

This signal informs the control module of the present voltage applied to the left

blower. The control module can then monitor and vary this voltage to change

blower motor speed. With Manual selected, the blower operates in four basic

ranges:

Low Speed

Temp Min:

Temp Med:

Temp Max:

Medium Speed

Temp Min:

Temp Med:

Temp Max:

High Speed

Pin 22 = 1±1 volt at all temperature settings

Defrost

Pin 22 = 1±1 volt at all temperature settings

A/CCM Pin 31 ref Pin 6

This signal is produced by the control moduleto drive the blower motor. The signal

can vary from 0-3 volts depending on blower motor

speed.

The higher the voltage,

the higher the blower motor speed. This signal is amplified by a simple amplifier

circuit inside the blower motor. This circuit also supplies the feedback signals to

pins 22 and 33.

Note: If the signal

rises

above 5

volts,

then

suspect a

fault in the amplifier circuit.

Lower Servo Feedback Potentiometer

(LSERFB) A/CCM Pin 29 ref Pin 6

This feedback signal informs the control module of the exact position of the flaps,

enabling accurate control of flap position.

Defrost - Lower flap signal should be 2.9 volts (flap closed) upper flap signal

should read 1.9 volts.

Max Temp - Lower flap signal should read 1.14 volts, upper flap signal should

read 1.9 volts.

Min Temp- Both lower and upper flap signals should read 130± 80 millivolts.

Note: If the

feedback sticks

low, with the fan continually running,

suspect an

open circuit

in the 5 volts supply to the

feedback

potentiometer or

the

potentiometer

itself.

May 1996 8-71

Page 349 of 421

Air Conditioning

Portable Diagnostic Unit Signal Definitions ~3^^?

Measurement Probe

(MPROBE)

Switched Power Input

(POWIN+)

Power Output

(POWOP+)

Right Blower Feedback Voltage

(RBLOFB)

Right Blower Output Voltage

(RBLOWOP)

Measurement probe (RED) with reference to measurement probe (BLACK).

A/CCM Pin 44 ref Pin 6

Switched power-in is a signal from the control module. Unlike the unswitched

power available on pins 1 and 12, this signal is only available when the A/C is

switched on.

A/CCM Pin 12 ref vehicle battery +ve

This is the ignition power for the whole A/C system. It passes through the A/CCM

via pins 1 and 12 (and a feedback protection diode) before supplying the fan

control switch. Pin 12 should normally read battery voltage with the ignition

switch in positions I or

II.

With the ignition switch off, pin 12 should read 0 volts.

A/CCM Pin 33 ref Pin 6

The purpose of the blower feedback is to inform the control module of the present

blower speed. This enables the control module to directly monitor and control

blower motor speed. With Manual selected, the blower operates in four basic

ranges:

Low Speed

Temp Min:

Temp Med:

Temp Max:

Medium Speed

Temp Min:

Temp Med:

Temp Max:

High Speed

Pin 33 = 1±1 volt at all temperature settings

Defrost

Pin 33 = 1±1 volt at all temperature settings

pin 33 = 5±1 volt

pin 33 = 9±1volt

pin 33 = 5±1 volt

pin 33 = 2±1 volt

pin 33 = 6±1volt

pin 33 = 2±1 volt

A/CCM Pin 32 ref Pin 6

This signal is produced by the control module to drive the blower motor. The signal

can vary from 0-3 volts depending on blower motor

speed.

The higher the voltage,

the higher the blower motor speed. This signal is amplified by a simple amplifier

circuit inside the blower motor. This circuit also supplies the feedback signals to

pins 22 and 33.

Note: If

the

signal

rises

above 5 volts, then

suspect a

fault in the amplifier circuit.

8-72 May 1996

Page 350 of 421

O" D'^?

Air Conditioning

Portable Diagnostic Unit - Signal Definitions

Reference Signal

(REF) A/CCM Pin 7 ref Pin 6

This is the main reference signal for the A/CCM. All the sensors reference against

this voltage. Drift in this signal will cause inconsistent temperature control.

Normal voltage should read 2.885 ±10 millivolts

Temperature Demand

(TEMPDEM)

Temperature demand control either selects the required temperature of the system

(auto mode) or the outlet temperature of the vents (manual mode). Pin 35 will vary

from 0 volts at full cooling up to 2.885 volts at full heating.

Note: When

defrost is

selected,

the

signal at pin 35

is

ignored.

The system

will go into full

heating through the upper flaps

only.

Upper Servo Feedback Potentiometer

(USERFB) A/CCM Pin 30 ref Pin 6

The feedback signal informs the control module ofthe exact position of the flaps,

enabling accurate control ofthe flap position.

Defrost - Lower flap signal should read 2.9 volts (flap closed, the upper flap

signal should read 1.9 volts.

Max Temperature - Lower flap signal should read 1.14 volts, upper flap signal

should read 1.9 volts.

Min Temperature - Both upper and lower flap signals should read

1

30 ±80

millivolts.

Note: If the

feedback sticks

low, with the

fan

continually running,

suspect an

open circuit

in the 5 volt supply to the feedback potentiometer or the potentiometer itself

Water Switch

(WATSW)

Water Valve

(WATVAL)

A/CCM Pin 21 ref Pin 6

The water switch monitors the temperature ofthe coolant and inhibits heating by

restricting fan operation at coolant temperatures below 30 degrees Celsius. This

enables the vehicle to warm up at a faster rate. It can be overridden by selecting

Defrost.

A/CCM Pin

1

7 ref Pin 6

The water valve controls thef low of hot coolant to the heater matrix. When manual

full cooling is selected, the valve will close inhibiting the heating effort ofthe

matrix, thus enhancing the cooling effect

Full cooling selected; pin

1

7 should read 10+volts and the water valve should be

closed.

All other conditions, pin

1

7 should read below 0.5 volts and the water valve should

be open.

May 1996 8-73

Page 351 of 421

Air Conditioning

[Dm^'^2?

8-74 May 1996

Page 379 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide o: "3^^?

PDU Functions

The PDU main menu provides access into the following functions:

Diagnostics

Training

Digital Multimeter

User Self Test

Diagnostics

On selecting'Diagnostics'from the main

menu,

the user will be prompted to enter the features and market specification

of the vehicle to be tested. Use of the diagnostics in each of the above areas is described later in this guide.

Diagnostics Menu - 95 Model Year

Engine

Anti-Lock Braking System

Vlenu - 97 Model Year

Engine Diagnostics

OBD II Scan Tool

Airbag

Seat Belt Pretensioner

•

•

•

•

Transmission

Engine Datalogger

Climate Control

PATS System

Climate Control

Transmission

Anti-Lock Braking System

Security

Digital Multimeter

The Digital Multimeter function provides the capabilityto measure voltage, current, resistance, frequency, pulse width,

pulse period, and duty cycle. These measurements are usually made using the PDU measurement probes. Measurements

may also be made using the module pin selection function on the Teves Mk

II

braking system and on the Air Conditioning

system.

Training

An on-screen programme is provided to train new users in the use of screen icons and in the use of the digital multi

meter and datalogger functions.

User Self Test

In order to prove that the equpment is functioning correctly, a complete user self test is incorporated. The user is directed

to test the PDU and then to progressively connect each part of the PDU system which will be tested by the software.

Any fault identified during the test is notified to the user. If no faults are identified, the user is advised on the correct

functioning of the system.

PDU Power

Power for the PDU is supplied via an internal rechargeable battery pack which can keep the PDU operational for

approximately one hour when disconnected from the base station and the vehicle. In order to preserve PDU battery

charge, power to the screen backlight is automatically cut after five minutes of inactivity. The power ON indicator

remains lit, indicating that the PDU is in 'stand-by' mode. One touch of the screen will restore backlight power.

When connected to the base station, power is supplied to the PDU from the Electronic Module to recharge the PDU

battery pack as necessary.

On 95 MY vehicles, the Vehicle Battery Adaptor (VBA) is used to maintain PDU power.

On 97 MY vehicles, when connected via the MPA to either diagnostic socket on the vehicle, power is supplied via pin

4 (chassis ground) and pin 16 (battery power) to maintain PDU power at all times even when the vehicle ignition is

switched off.

On all model years, when connected to the air conditioning system using the VIA, the vehicle battery adaptor (VBA)

must also be used to maintain PDU power.

9-28 September 1996

Page 380 of 421

^=2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Software

Software for the PDU system is supplied on CD ROM

discs and supports diagnosis on the following control

units:

Zytek Engine Management System (95 MY)

EEC-V Engine Management System (97 MY)

CM 4L80-E Transmission Controller

PATS - Passive Anti Theft System

Teves Mk II ABS System (95 MY)

Teves Mk IV ABS System (97 MY)

Valeo Air Conditioning System

PMC Airbag System

Megamoss Security System

Autoliv Drivers Seat Belt Pretensioner

(where fitted)

All of these systems are supported in English, French,

Italian,

German and Japanese.

In addition to the specific system software listed above,

thePDU isalsoequipped with general purpose software

to provides multimeter, printing and PDU training

options.

Software for 95 and 97 Model Year Vehicles

Software for both the 95 and 97 model year vehicles is

provided.

The PDU system requires a Vehicle Interface Adaptor

(VIA) to communicate with the control units of 95

model year vehicles.

Communication with 97 model year control units is

principally via an Aston Martin multi-protocol adaptor

to 2 inbuilt diagnostic sockets in the vehicle. Only the

air conditioning unit requires the VIA on 97 model year

vehicles.

If the multimeter function is used, the Vehicle Battery

Adaptor (VBA) will be required to provide the basic

supply and ground levels for the multimeter.

Software Loading and Selection

Ensure that the system is powered up and that the PDU is

correctly connected to the base station. Check and if

necessary load the DB7 software CD Revision 002. (see

the installation guide)

Switch 'on' the PDU which will run through two front

screens and then load the following initial PDU software.

Operating System

Main Menu

Selector

Digital Multimeter

Interactive Training

September 1996 9-29

Page 381 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide D-^?

Vehicle Features

The vehicle features screen illustrated below is used to

identify the vehicle particulars and the model year.

If Airbag - NO is selected, the vehicle is assumed to be 95

model year.

If Airbag - YES is selected, 97 model year is assumed. On

completing entries in the vehicle features screen, the

appropriate vehicle area screen will be displayed.

Vehicle Features

Transmission MANUAL IIBIE^^I

Airbag IDS^I NO

D

Vehicle Area

This screen allows selection of the vehicle system to be

accessed.

Only 4 systems may be accessed on 95 model

year vehicles, on 97 model year cars, 8 systems may be

accessed as follows:

Vehicle Areas

• Engine Diagnostic

• Engine Datalogger

• Transmission

• OBDII Scan Tool

• Climate Control

• Anti-Lock Braking System

• Airbag

. lb Axol

o

PI

mLM

n

WLM

El

Ku^

95 model year software

Zytek Engine Management

GM 4L80-E Transmission Controller

Teves Mk II Anti-Lock Braking System

Valeo Air Conditioning

97 model year software

EEC-V Engine Management

CM 4L80-E Transmission Controller with OBDII

Teves Mk IV Anti-Lock Braking System

Valeo Air Conditioning

PATS Engine Immobiliser

Megamoss security system

FMC Airbag system

Autoliv seatbelt pretensioner

9-30 September 1996

Page 382 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

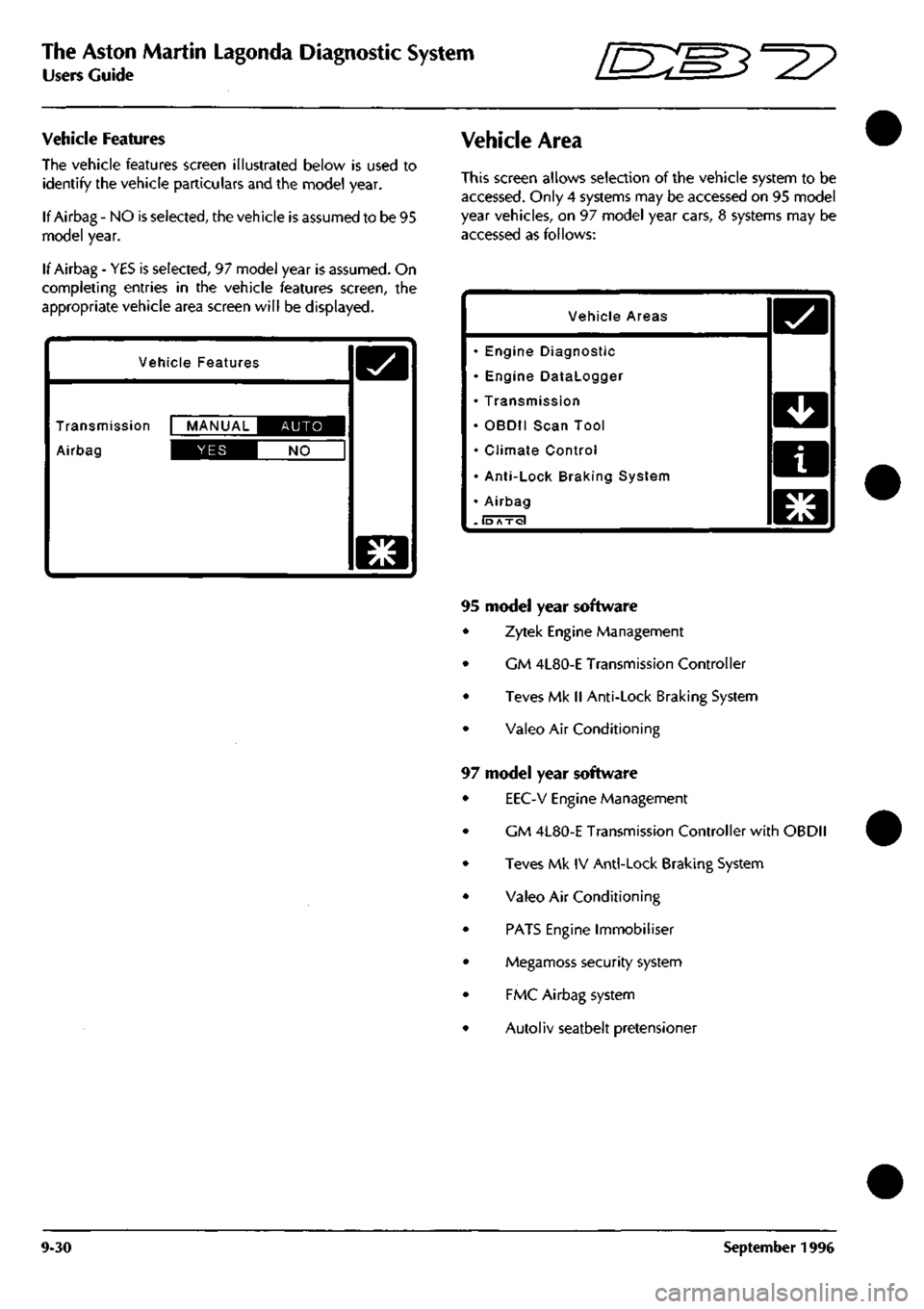

Cable Setup - 95 MY

On

selectingthe

required

vehiclearea,

the selected

software

will be loaded and then the Cable Setup screen will

appear.

Connections will

be

shown directly

to the selected

control

unit

on

95 nnodel year vehicles

using

the vehicle interface

adaptor (VIA) and appropriate cables from the PDU kit.

Select the specified interface devices and cables from the

PDU kit and connect as shown in the diagram.

Cable Setup - 97 MY

On 97 model year

vehicles,

connections

to the

vehicle are

made via the Aston Martin Multi-Protocol Adaptor and

two diagnostic sockets for most vehicle systems.

Cable Setup

Upper Diagnostic Socket

o

Diagnostic Sockets - 97 MY

The diagnostic sockets are located behind the passenger

side underscuttle panel.

Upper Diagnostic Socket

Lower Diagnostic Socket

The

sockets are

mounted on

a

bracket

and

labelled Upper

and Lower. The following lists describe the systems

accessed from each socket.

Upper Diagnostic Socket

Transmission Control Module (TCM)

Megamoss Security System

FMC Airbag System

Teves Mk IV Anti-Lock Braking System

Lower Diagnostic Socket

EEC V Powertrain Control Module (PCM)

PATS Passive Anti-Theft System

Autoliv Seatbelt Pretensioner System

Air Conditioning Diagnostics

The Valeo air-conditioning system uses a unique

communications protocol and therefore the vehicle

interface adaptor (VIA) is required and is connected

directlytotheair-conCPU inordertocarryout diagnostics

work on the system.

September 1996 9-31

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

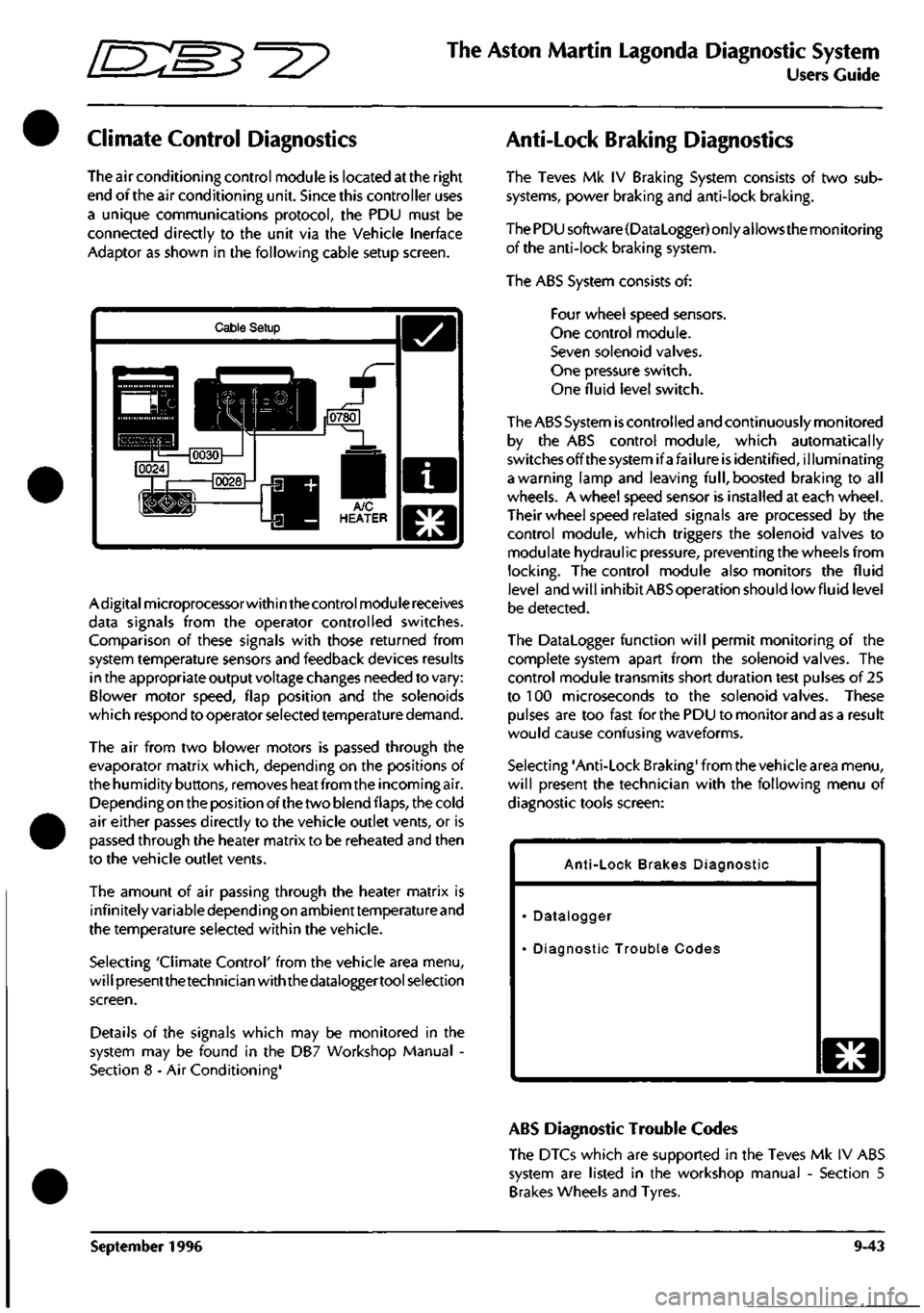

Climate Control Diagnostics

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43

Page 401 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^=2?

Printer Use Digital Multimeter

Print Trace

The Trace Buffer is used to record technician use of the

PDU.As the diagnostics are executed, the following

information is written to trace:

Screen Title

Menu options selected

Operator questions selected

Operator actions

Control module information

Test limits and results

P codes detected by the DTC monitor

Snapshot data from the datalogger

OBD II freeze frame data

Set up the printer and load with paper. Select Print

Trace and confirm the selection. All recorded

information in the above list will be printed.

Printtrace is supported in English, French, German and

Italian.

Print Screen

The Print Screen function dumps a bitmap image of the

current screen display to the printer. This function is

particularly useful for recordingdata such as waveforms

captured by the datalogger application.

The print screen function is supported in English,

French,

German, Italian and Japanese.

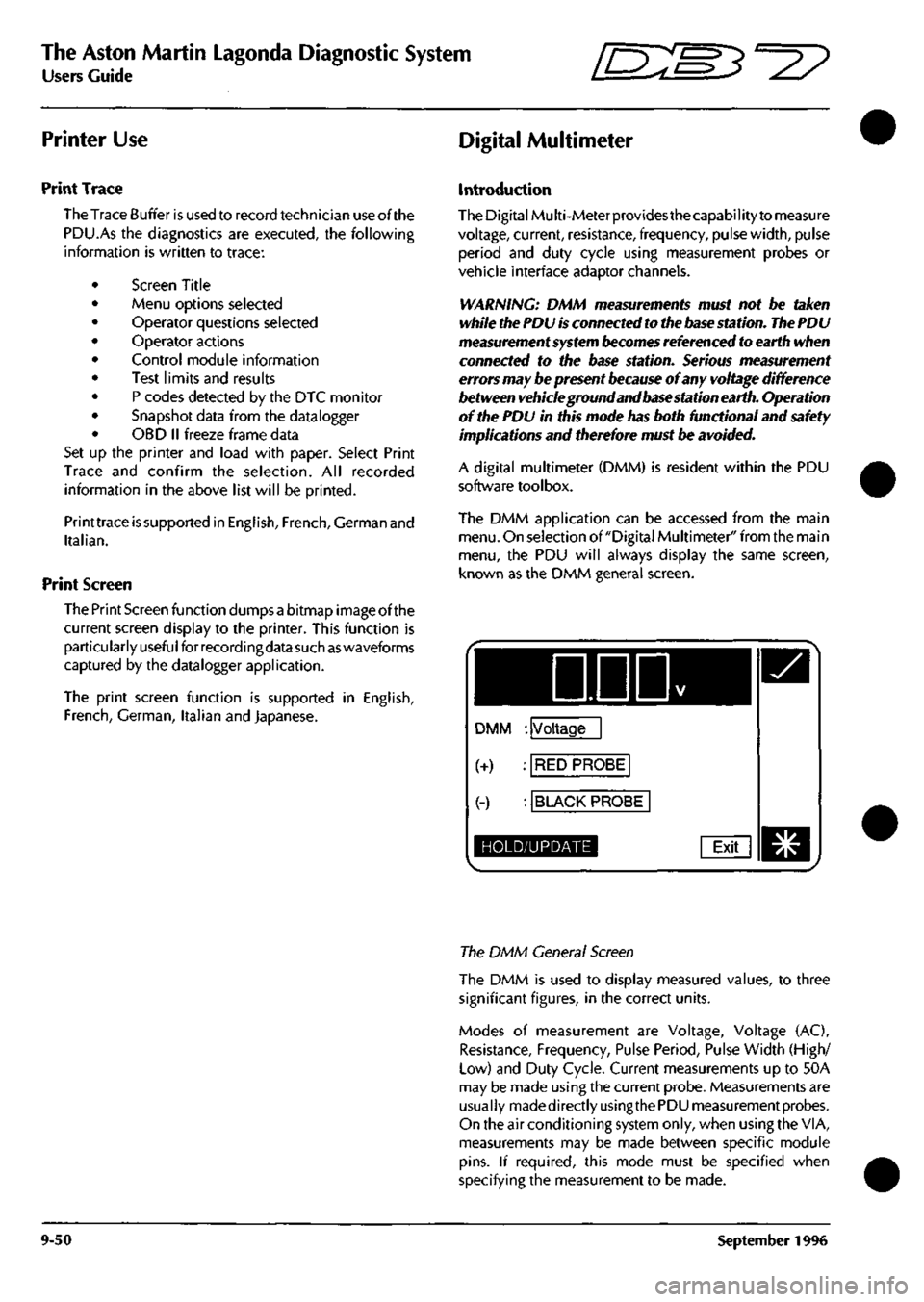

Introduction

The Digital Multi-Meterprovidesthecapability to measure

voltage, current, resistance, frequency, pulse width, pulse

period and duty cycle using measurement probes or

vehicle interface adaptor channels.

WARNING: DMM measurements must not be taken

while the PDU

is

connected to the

base

station. The PDU

measurement system

becomes

referenced to earth when

connected to the base station. Serious measurement

errors may be present

because

of any voltage difference

between vehicle ground and base station earth. Operation

of the PDU in this mode has both functional and safety

implications and therefore must be

avoided.

A digital multimeter (DMM) is resident within the PDU

software toolbox.

The DMM application can be accessed from the main

menu.

On selection of "Digital Multimeter" from the main

menu,

the PDU will always display the same screen,

known as the DMM general screen.

DDD

DMM : Voltage

(+) : RED PROBE

(-) : BLACK PROBE

HOLD/UPDATE Exit

The DMM General Screen

The DMM is used to display measured values, to three

significant figures, in the correct units.

Modes of measurement are Voltage, Voltage (AC),

Resistance, Frequency, Pulse Period, Pulse Width (High/

Low) and Duty Cycle. Current measurements up to 50A

may be made using the current probe. Measurements are

usually madedirectlyusingthe PDU measurement probes.

On the air conditioning system only, when using the VIA,

measurements may be made between specific module

pins.

If required, this mode must be specified when

specifying the measurement to be made.

9-50 September 1996