air conditioning ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 328 of 421

^?

Air Conditioning Repair Procedures

Compressor Removal

8.1.01.1 Compressor Removal/Renewal

Procedure

1.

Open the bonnet and fit a wing cover.

2.

Depressurise the air conditioning system.

3.

6.

7.

8.

9.

Disconnect the low and high pressure hoses from

the rear of the compressor. Plug the hose ends to

prevent the ingress of dirt.

Remove the compressor pivot bolt securing nut.

Carefully separate the muffler from the compressor

and remove and discard the 'O' ring

seal.

Fit a blanking plug to the muffler and a blanking

plate to the compressor, fit and tighten the bolt that

secures blanking plate.

Raise the vehicle to working height on a ramp.

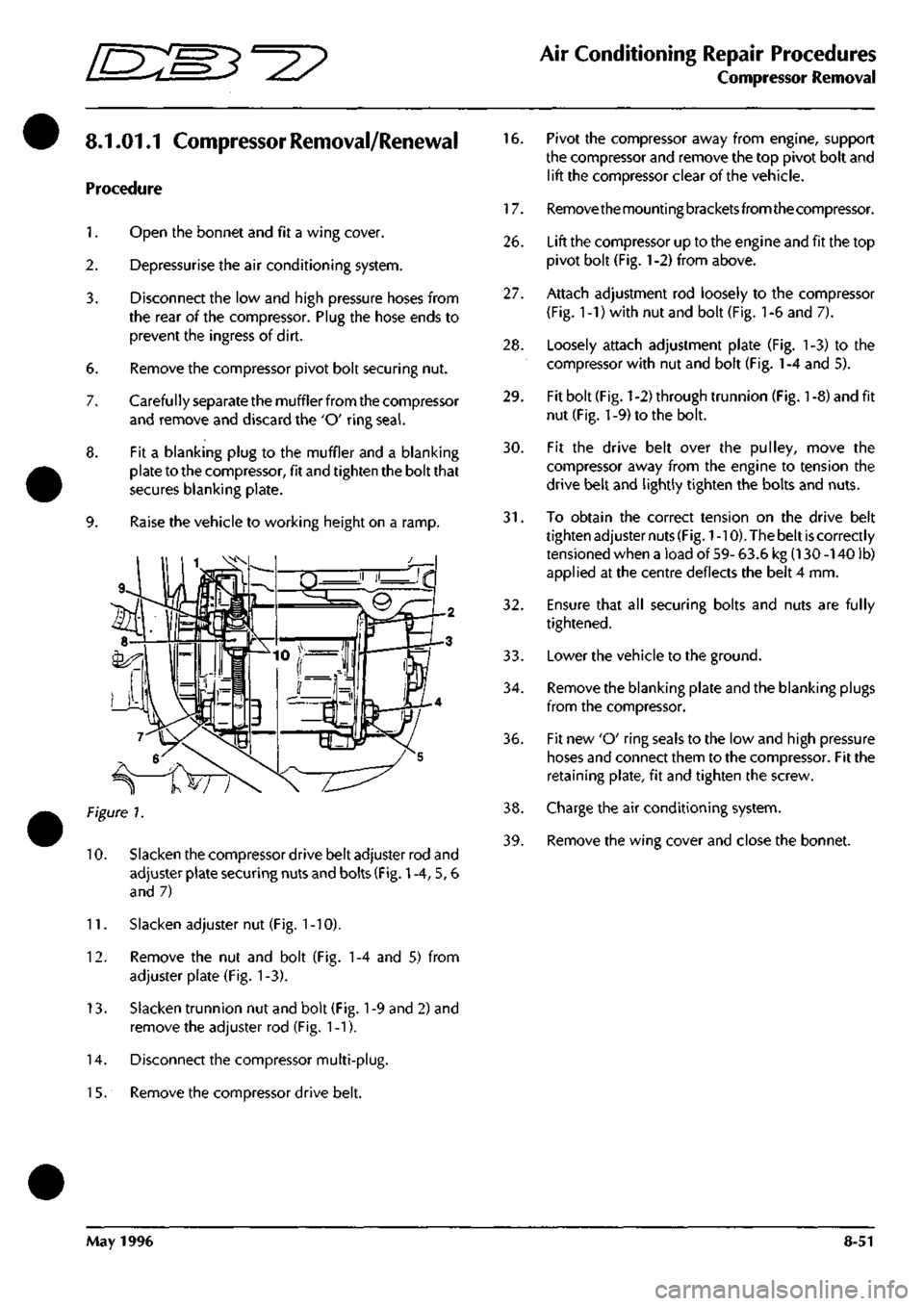

Figure 7.

10.

Slacken the compressor drive belt adjuster rod and

adjuster plate securing nuts and bolts (Fig.

1

-4, 5, 6

and 7)

11.

Slacken adjuster nut (Fig.

1

-10).

12.

Remove the nut and bolt (Fig. 1-4 and 5) from

adjuster plate (Fig. 1-3).

13.

Slacken trunnion nut and bolt (Fig.

1

-9 and 2) and

remove the adjuster rod (Fig. 1-1).

14.

Disconnect the compressor multi-plug.

1

5. Remove the compressor drive belt.

16.

Pivot the compressor away from engine, support

the compressor and remove the top pivot bolt and

lift the compressor clear of the vehicle.

17.

Removethemountingbracketsfromthecompressor.

26.

Lift the compressor up to the engine and fit the top

pivot bolt (Fig.

1

-2) from above.

27.

Attach adjustment rod loosely to the compressor

(Fig.

1

-1) with nut and bolt (Fig.

1

-6 and 7).

28.

Loosely attach adjustment plate (Fig. 1-3) to the

compressor with nut and bolt (Fig.

1

-4 and 5).

29.

Fit bolt (Fig.

1

-2) through trunnion (Fig.

1

-8) and fit

nut (Fig. 1-9) to the bolt.

30.

Fit the drive belt over the pulley, move the

compressor away from the engine to tension the

drive belt and lightly tighten the bolts and nuts.

31.

To obtain the correct tension on the drive belt

tighten adjuster nuts

(Fig.

1

-10). The belt

is

correctly

tensioned when a load of 59- 63.6 kg (130 -140 lb)

applied at the centre deflects the belt 4 mm.

32.

Ensure that all securing bolts and nuts are fully

tightened.

33.

Lowerthe vehicle to the ground.

34.

Remove the blanking plate and the blanking plugs

from the compressor.

36.

Fit new 'O' ring seals to the low and high pressure

hoses and connect them to the compressor. Fit the

retaining plate, fit and tighten the screw.

38.

Charge the air conditioning system.

39.

Remove the wing cover and close the bonnet.

May 1996 8-51

Page 329 of 421

Air Conditioning Repair Procedures

Field Coil Renewal

/

Gasket Kit Renewal ffi^e^'^^

8.1.02.1 Field Coil Renewal 8.1.03.1 Renew Gasket

Kit

Procedure

1.

Open

the

bonnet

and fit a

wing cover.

2.

Depressurise

the air

conditioning system.

3. Remove

the

compressor.

4.

Remove

the

compressor drive clutch.

5. Remove

the

compressor pulley.

6. Slacken

the

field coil wire clamp screw

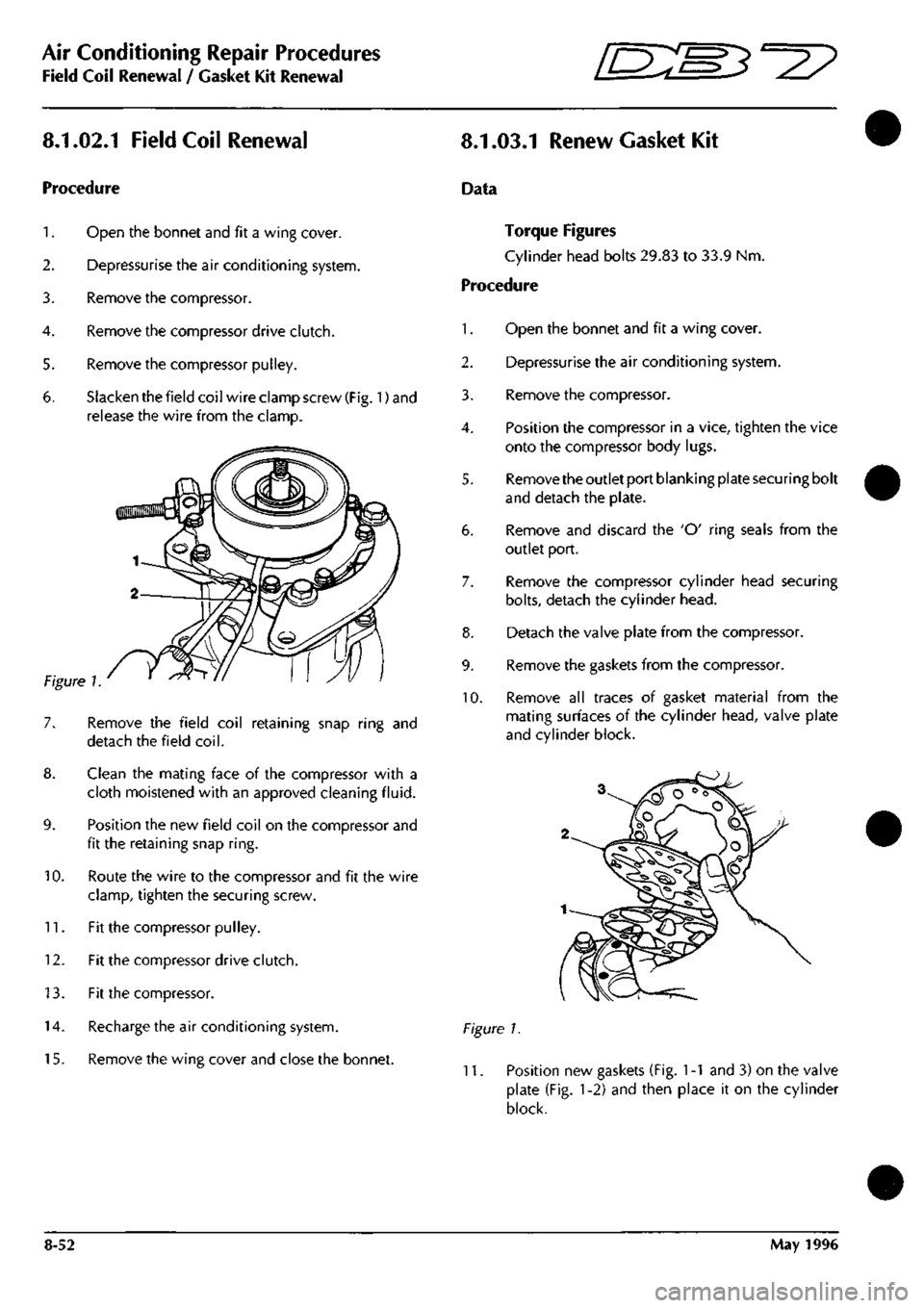

(Fig.

1) and

release

the

wire from

the

clamp.

10.

Remove

the

field coil retaining snap ring

and

detach

the

field

coil.

Clean

the

mating face

of the

compressor with

a

cloth moistened with

an

approved cleaning

fluid.

Position

the new

field coil

on the

compressor

and

fit

the

retaining snap

ring.

Route

the

wire

to the

compressor

and fit the

wire

clamp, tighten

the

securing screw.

11.

Fit the

compressor pulley.

12.

Fit the

compressor drive clutch.

13.

Fit the

compressor.

14.

Recharge

the air

conditioning system.

15.

Remove

the

wing cover

and

close

the

bonnet.

Data

Torque Figures

Cylinder head bolts 29.83

to 33.9 Nm.

Procedure

1.

Open

the

bonnet

and fit a

wing cover.

2.

Depressurise

the air

conditioning system.

3. Remove

the

compressor.

4.

Position

the

compressor

in a

vice, tighten

the

vice

onto

the

compressor body lugs.

5. Remove the outlet port blanking plate securing bolt

and detach

the

plate.

6. Remove

and

discard

the 'O'

ring seals from

the

outlet port.

7. Remove

the

compressor cylinder head securing

bolts,

detach

the

cylinder head.

8. Detach

the

valve plate from

the

compressor.

9. Remove

the

gaskets from

the

compressor.

10.

Remove

all

traces

of

gasket material from

the

mating surfaces

of the

cylinder head, valve plate

and cylinder block.

Figure

1.

11.

Position

new

gaskets (Fig.

1 -1

and 3) on the

valve

plate

(Fig. 1-2) and

then place

it on the

cylinder

block.

8-52 May

1996

Page 330 of 421

ES3^^

Air Conditioning Repair Procedures

Valve Plate Renewal

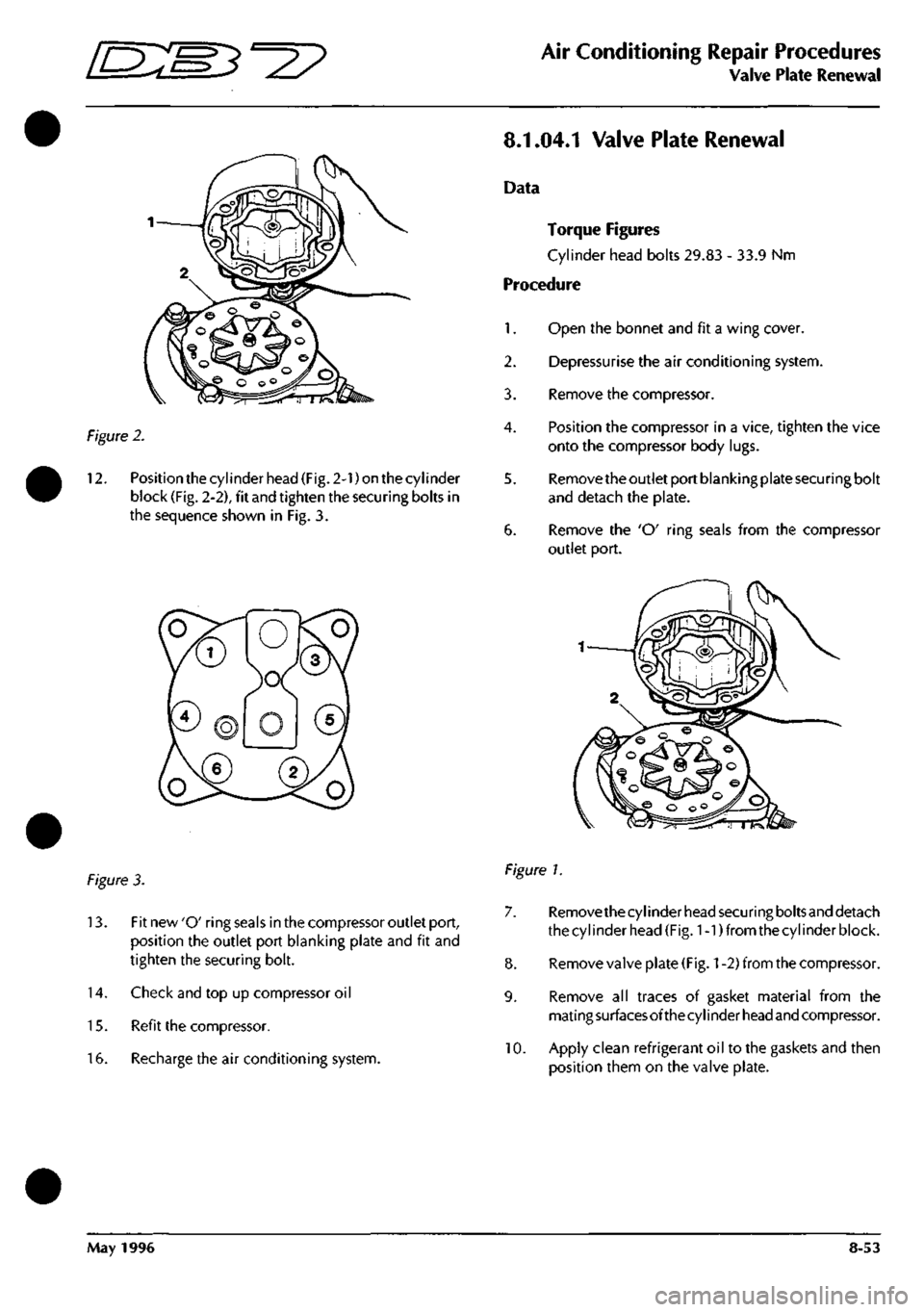

Figure

2.

12.

Position the cylinder head (Fig. 2-1) on the cylinder

block (Fig. 2-2), fit and tighten the securing bolts in

the sequence shown in Fig. 3.

8.1.04.1 Valve Plate Renewal

Data

Torque Figures

Cylinder head bolts 29.83 - 33.9 Nm

Procedure

1.

Open the bonnet and fit a wing cover.

2.

Depressurise the air conditioning system.

3. Remove the compressor.

4.

Position the compressor in a vice, tighten the vice

onto the compressor body lugs.

5. Remove the outlet port blanking plate securing bolt

and detach the plate.

6. Remove the 'O' ring seals from the compressor

outlet port.

figure 3.

13.

Fit new 'O' ring seals in the compressor outlet port,

position the outlet port blanking plate and fit and

tighten the securing bolt.

14.

Check and top up compressor oil

15.

Refit the compressor.

16.

Recharge the air conditioning system.

Figure 1.

7. Removethecylinder head securing boltsand detach

the cylinder head (Fig. 1-1) from the cylinder block.

8. Remove valve plate

(Fig.

1

-2) from the compressor.

9. Remove all traces of gasket material from the

mati

ng

surfaces of the cy

I

i nder

head

and compressor.

10.

Apply clean refrigerant oil to the gaskets and then

position them on the valve plate.

May 1996 8-53

Page 331 of 421

Air Conditioning Repair Procedures

Expansion Valve Renewal

ES^'^?

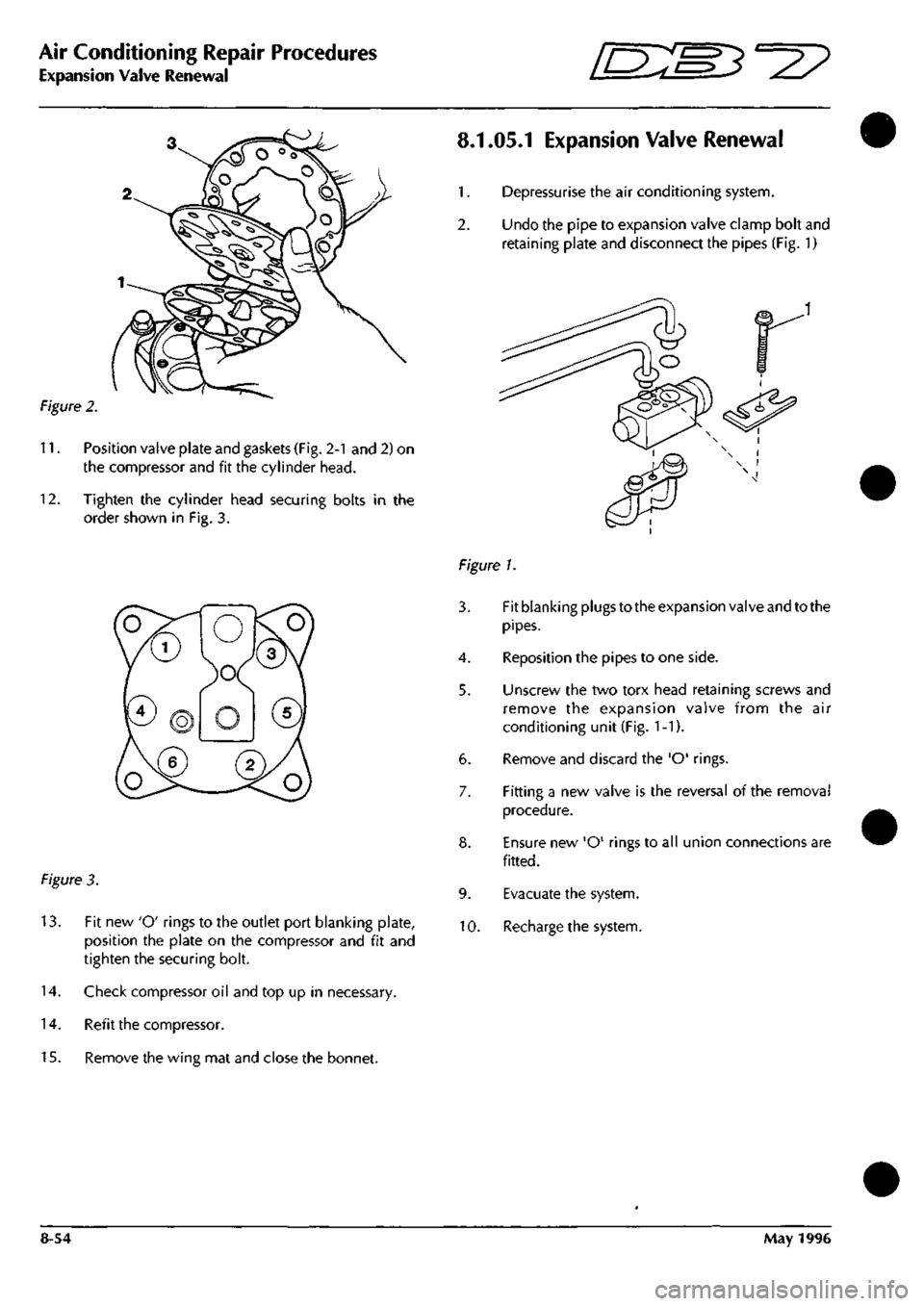

Figure 2.

11.

Position valve plate and gaskets (Fig. 2-1 and 2) on

the compressor and fit the cylinder head.

12.

Tighten the cylinder head securing bolts in the

order shown in Fig. 3.

Figure 3.

13.

Fit new 'O' rings to the outlet port blanking plate,

position the plate on the compressor and fit and

tighten the securing bolt.

14.

Check compressor oil and top up in necessary.

14.

Refit the compressor.

15.

Remove the wing mat and close the bonnet.

8.1.05.1 Expansion Valve Renewal

1.

Depressurise the air conditioning system.

2.

Undo the pipe to expansion valve clamp bolt and

retaining plate and disconnect the pipes (Fig. 1)

Figure 1.

3. Fit blanking plugs to the expansion valve and to the

pipes.

4.

Reposition the pipes to one side.

5. Unscrew the two torx head retaining screws and

remove the expansion valve from the air

conditioning unit (Fig.

1

-1).

6. Remove and discard the 'O' rings.

7. Fitting a new valve is the reversal of the removal

procedure.

8. Ensure new 'O' rings to all union connections are

fitted.

9. Evacuate the system.

10.

Recharge the system.

8-54 May 1996

Page 332 of 421

^2?

Air Conditioning Repair Procedures

Hose - Compressor to Evaporator/Air-Con Unit Renew

8.1.06.1 Hose-Compressor

to

Evaporator

Renewal

Procedure

1.

Open the bonnet and fit a wing cover.

2.

Depressurise the air conditioning systenn.

3. Remove the hose to evaporator valve clamping

plate,

disconnect the hose from the valve, remove

and discard the 'O' ring

seal.

4.

Fit a blanking plug to the evaporator valve. Release

the evaporator hose securing clips.

5. Remove the compressor outlet port retaining bolt.

6. Disconnect the hose from the compressor, discard

the hose complete with 'O' ring seals.

7. Connect the hose to the evaporator valve and

tighten clamp onto the hose.

8. Route the hose to the compressor, fit a new 'O' ring

seal and connect it to the compressor.

9. Position the outlet port retaining plate on the

compressor, fit and tighten the securing bolt.

10.

Refit the hose to the clips.

11.

Charge the air conditioning system.

12.

Remove the wing cover and close the bonnet.

8.2.01.1 Air Conditioning Unit Renewal

1.

Disconnect the battery earth

lead.

2.

Drain the engine coolant into a suitable container.

3. Depressurise the air conditioning system.

4.

Disconnect the high and low pressure hoses and

expansion valve from the air conditioning unit (see

expansion valve renewal).

5. Slacken the coolant hose to the heater matrix pipe

securing clips and disconnect the hoses from the

matrix. (This will require the removal of the air

intake hose for access.)

6. Remove the following items from inside the car:

front seats

underscuttle panels/knee bolsters

glove box assembly

facia trim (walnut trim)

radio and ashtray

centre console switch panel assembly

instrument panel and surround trim

steering wheel and column

facia assembly complete

hoses - distribution box to door vents

facia support frame

Details and drawings of the above operations can

be found in the electrical and trim sections.

Disconnect the vacuum hoses from the blower

motors, water valve and reservoir.

Un-clip the electrical harness from the air

conditioningunit, release theelectrical connections

and reposition the harness to allow removal of the

unit.

Displace and remove the footwell ventilator ducts

and hoses (Fig. 1-1).

May 1996 8-55

Page 333 of 421

Air Conditioning Repair Procedures

Air-Conditioning Unit Renew ^^?

10.

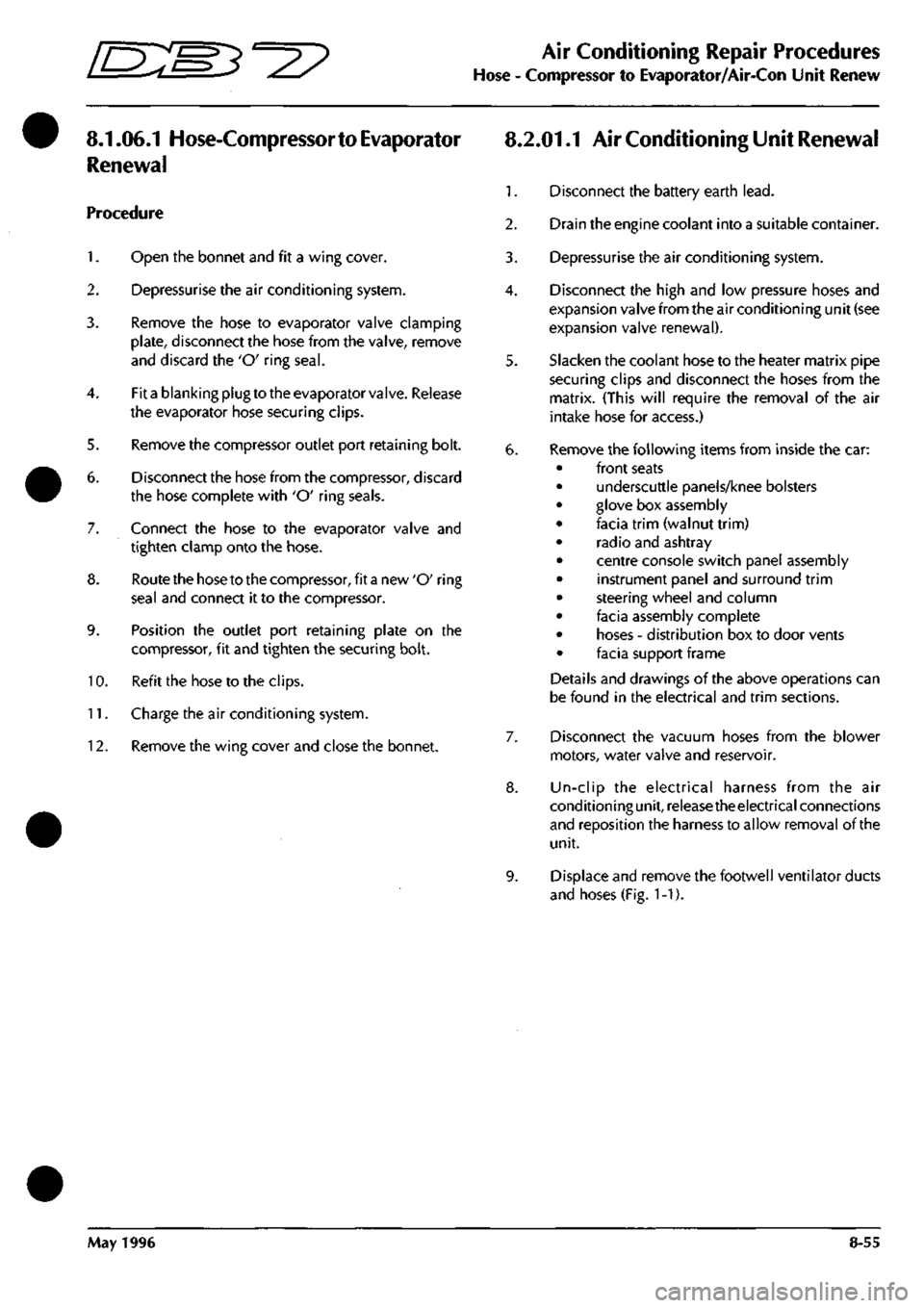

Disconnect the pliable trunking from the unit (Fig.

8.2.02.1

EvaporatOr Unit Renewal

1-2). ^

1.

Remove the air conditioning unit assembly.

2.

Remove the heater pipe guide plate securing screws

and remove the guide plate.

3. Remove the screws secu ri ng evaporator sensor and

withdraw the sensor from the evaporator.

4.

Remove the screws securing the solenoid mounting

plate and displace the mounting plates from the

unit.

5. Removetheharnesstocasingearthboltand displace

the harness.

6. Cut and remove the harness to casing securing

ratchet straps and displace the harness from the

casing.

7. Displace the vacuum hose from the casing.

8. Displace and remove the casing securing clips.

9. Splitthecasingandremovetheevaporatorfromthe

unit.

10.

Remove the expansion valve guide securing screws

and remove the plate.

11.

Displace and remove the plate from the evaporator.

12.

Fitting the new evaporator is the reversal of the

removal procedure.

13.

Refill the engine cooling system with coolant.

14.

Recharge the air conditioning system.

Figure 1

11.

Twistandpulloutthefourairconditioningunitstub

pipes (Fig. 1-3)

12.

Remove the screws securing the air conditioning

unit support stays.

13.

Displace the tunnel carpet for access to the lower

fixing bolts and remove the stays.

14.

Disconnect the condensate drain tubes.

15.

Peel off the tape securing the windscreen demist

duct to the distribution box (Fig.

1

-4).

16.

Remove the air conditioning unit to bulkhead

securing nuts.

1

7. Carefully lift out the air conditioning unit complete

with the distribution box.

18.

Remove the distribution box securing screws and

remove the assembly (Fig.

1

-5).

19.

Reverse the removal procedure to refit the air

conditioning unit.

Note:

Ensure new'O'rings

are

fitted toall air conditioning

tiose connections.

8-56 May 1996

Page 334 of 421

^?

Air Conditioning Repair Procedures

upper/Lower Servo Feedback Potentiometer Renew

8.2.03.1

Upper Servo Feedback

Potentiometer Renewal

8.2.04.1

Lower Servo Feedback

Potentiometer Renew

1.

Disconnect the battery earth

lead.

2.

(On left hand cars) Remove the instrument paci<

and surround

trim.

2.

(On right hand cars) Remove the glove box

assembly.

3.

Remove the

securing screws

and

the potentiometer

assembly. Disconnect the electrical connector.

4.

Fitting a new potentiometer is the reverse of the

removal procedure.

1.

Disconnect the battery earth

lead.

2.

Un-clip and remove the left hand underscuttle

casing.

Figure 1.

3. Disconnect the electrical block connector

(Fig.

1).

4.

Remove the securing screw and the potentiometer

assembly.

5. Fitting a new potentiometer is the reversal of the

removal procedure.

May 1996 8-57

Page 335 of 421

Air Conditioning Repair Procedures

Upper/Lower Flap Motor Renew [EB^^^?

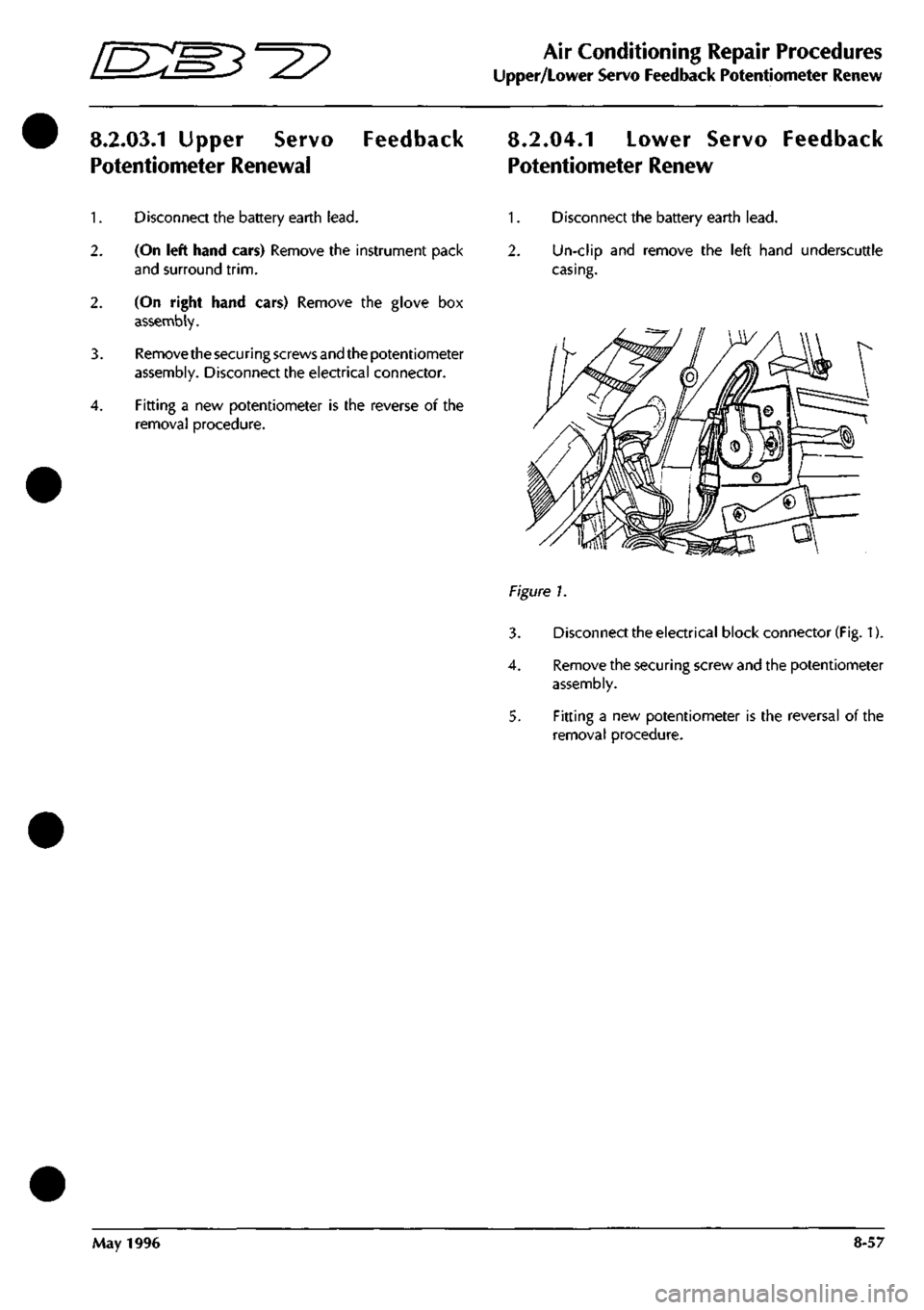

8.2.05.1 Upper Flap Motor Assembly

Renew

8.2.06.1 Lower Flap Motor Assembly

Renew

1.

Disconnect the battery earth

lead.

2.

Remove the electronic control module.

3. Disconnect the motor block connector.

4.

Remove the securing screws and motor assembly

(Figl).

Figure

5.

5. Fitting a new motor is the reverse of the removal

procedure.

1.

Disconnect the battery earth

lead.

2.

Remove the right hand side underscuttle casing.

3. Remove the electronic control unit.

4.

Disconnect the block connector.

5. Remove the screws securing the motor to the air

conditioning unit.

6. Displace the'P'clip.

7. Withdraw and remove the motor from the air

conditioning unit.

8. Fitting a new motor is the reversal of the removal

procedure.

8-58 May 1996

Page 336 of 421

'nzm^=2?

Air Conditioning Repair Procedures

Blower Motor Renewal

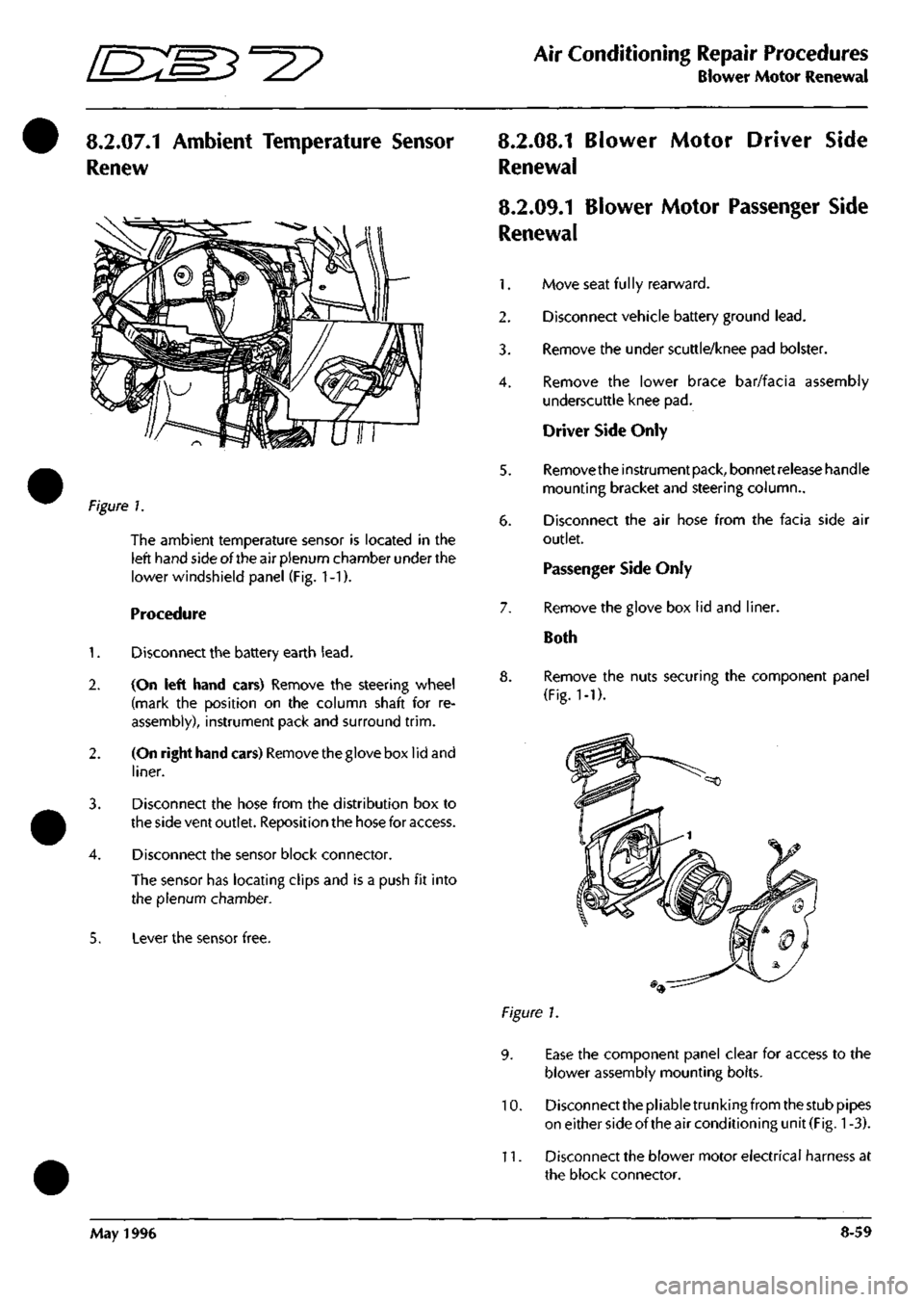

8.2.07.1 Ambient Temperature Sensor

Renew

?\gure

1.

The ambient temperature sensor is located in the

left hand side of the air plenum chamber under the

lower windshield panel (Fig. 1-1).

Procedure

1.

Disconnect the battery earth

lead.

2.

(On left hand cars) Remove the steering wheel

(mark the position on the column shaft for re

assembly), instrument pack and surround

trim.

2.

(On right hand cars) Removethegloveboxlidand

liner.

3. Disconnect the hose from the distribution box to

the side vent outlet. Reposition the hose for access.

4.

Disconnect the sensor block connector.

The sensor has locating clips and is a push fit into

the plenum chamber.

5. Lever the sensor free.

8.2.08.1 Blower Motor Driver Side

Renewal

8.2.09.1 Blower Motor Passenger Side

Renewal

1.

Move seat

fu 1

ly rearward.

2.

Disconnect vehicle battery ground

lead.

3. Remove the under scuttle/knee pad bolster.

4.

Remove the lower brace bar/facia assembly

underscuttle knee pad.

Driver Side Only

5. Removetheinstrumentpack, bonnetreieasehandle

mounting bracket and steering column..

6. Disconnect the air hose from the facia side air

outlet.

Passenger Side Only

7. Remove the glove box lid and liner.

Both

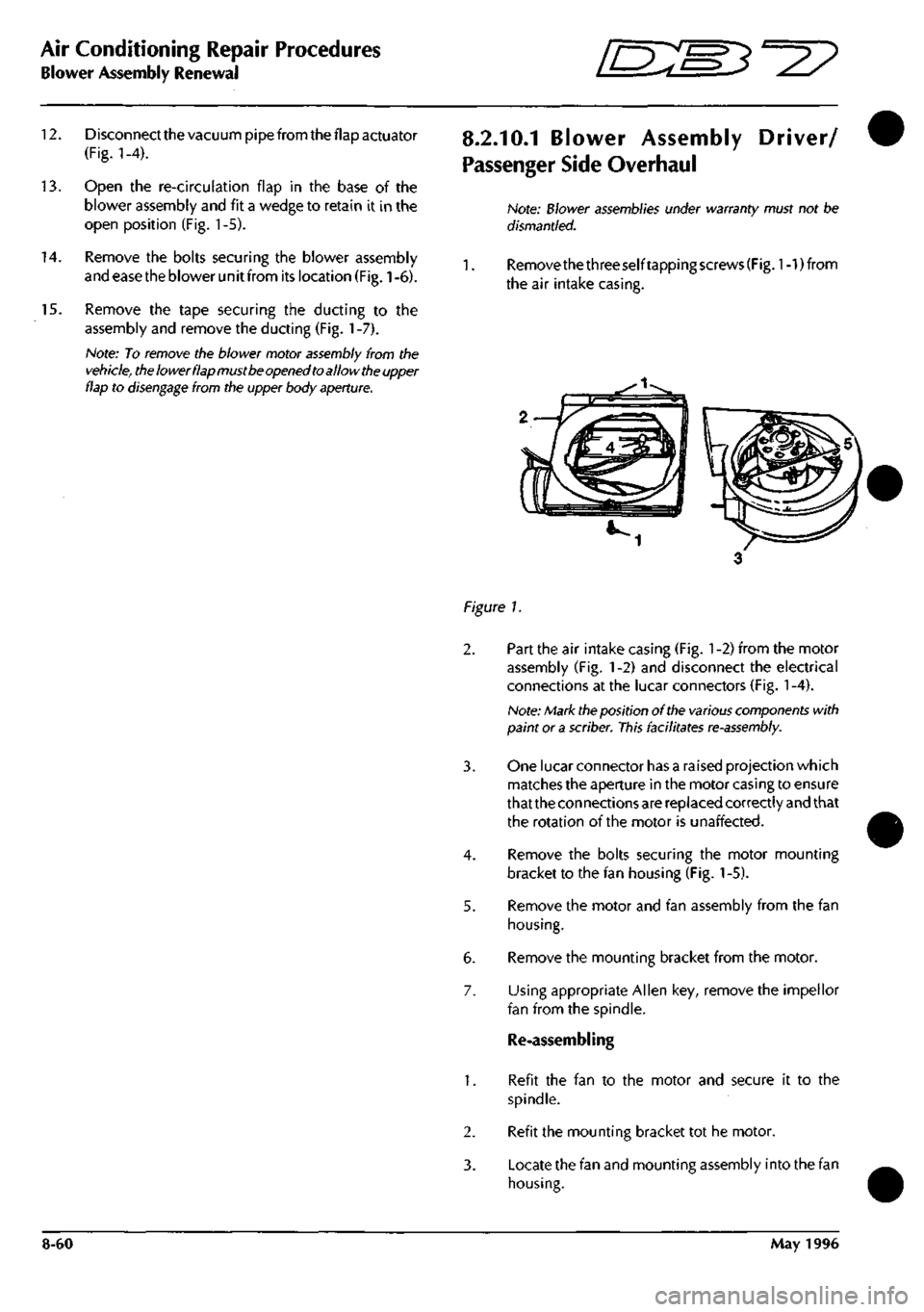

8. Remove the nuts securing the component panel

(Fig.

1-1).

Figure 1.

9. Ease the component panel clear for access to the

blower assembly mounting bolts.

10.

Disconnect the pliable trunking from the stub pipes

on either side of the air conditioning unit

(Fig.

1

-3).

11.

Disconnect the blower motor electrical harness at

the block connector.

May 1996 8-59

Page 337 of 421

Air Conditioning Repair Procedures

Blower Assembly Renewal o^s^-^?

12.

Disconnect the vacuum pipe from the flap actuator

(Fig.

1-4).

13.

Open the re-circulation flap in the base of the

blower assembly and fit a wedge to retain it in the

open position (Fig. 1-5).

14.

Remove the bolts securing the blower assembly

and ease the blower unit from its location (Fig.

1

-6).

15.

Remove the tape securing the ducting to the

assembly and remove the ducting (Fig.

1

-7).

Note: To remove the blower motor

assembly

from the

vehicle,

the

lower flap must be opened to allow the upper

flap to

disengage

from the upper body

aperture.

8.2.10.1 Blower Assembly Driver/

Passenger Side Overhaul

Note:

Blower

assemblies

under warranty must not be

dismantled.

1.

Remove the three selftapping screws

(Fig.

1-1) from

the air intake casing.

Figure 7.

2.

Part the air intake casing (Fig.

1

-2) from the motor

assembly (Fig. 1-2) and disconnect the electrical

connections at the lucar connectors (Fig.

1

-4).

Note: Mark the position of the

various components

with

paint or

a

scriber.

This

facilitates

re-assembly.

3. One lucar connector has a raised projection which

matches the aperture in the motor casing to ensure

that the connections are replaced correctly and that

the rotation of the motor is unaffected.

4.

Remove the bolts securing the motor mounting

bracket to the fan housing (Fig. 1-5).

5. Remove the motor and fan assembly from the fan

housing.

6. Remove the mounting bracket from the motor.

7. Using appropriate Allen key, remove the impellor

fan from the spindle.

Re-assembling

1.

Refit the fan to the motor and secure it to the

spindle.

2.

Refit the mounting bracket tot he motor.

3. Locate the fan and mounting assembly into the fan

housing.

8-60 May 1996