fuse ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 5 of 421

//—-^

^^^^5~^

' -^ ^ Introduction

Safety Precautions

Safety Precautions (continued)

Electrical Equipment

1.

Ensure that electrical equipment is in safe working order before use.

2.

Inspect power leads of all mains electrical equipment for damage and security, and check that it is properly

earthed.

3. Ensure that electrical equipment is protected by a fuse of the correct current rating.

4.

Disconnect the battery before commencing repair operations to the electrical system, fuel system and engine

or when working beneath the vehicle.

Exhaust Fumes

Engines should not be run in confined spaces, exhaust fumes contain harmful and toxic substances including carbon

monoxide which can prove fatal if inhaled. Engines must only be run where there is fume extraction equipment in

operation or where there is adequate ventilation.

Fire Precautions

1.

Ensure that a suitable form of fire extinguisher is conveniently located near the work area.

2.

Keep oils, solvents and combustible materials away from naked flames and other sources of ignition.

3. Ensure that NO SMOKING signs are posted around areas where combustible materials and vapour may be

present and ensure that the warnings are strictly observed.

4.

Ensure that dry sand is available to soak up any spillage of fuel or other flammable solutions.

5. Fume extraction equipment must be available and in full working order to remove combustible and toxic

vapours.

6. All personnel should be aware of the fire drill procedures and precautions.

Jacking and Lifting

1.

The recommended procedures for lifting, jacking and towing are included latefin this seetion-and must be

strictly observed to ensure personal safety.

2.

Always use a vehicle hoist, ramp or pit for working beneath the car in preferencetd^&^cking

3. Never rely on a jack to support a car independently, use axle stands or blocks carefully pJaQed at the jacking

points to provide rigid support.

4.

When working beneath a vehicle, chock the wheels as well as applying the handbrake.

5. Ensure that the vehicle is standing on firm level ground before jacking or lifting.

5. Check any lifting equipment used has adequate capacity for the load being lifted and is ih"fdll working order.

Tools and Equipment

1.

Do not leave tools, equipment, spilt oil, etc. around or on the work area.

2.

Ensure that tools and equipment used are in good condition; do not use damaged or defective tools or

equipment.

3. Do not apply heat in an attempt to free stiff nuts or fittings; as well as causing damage to protective coatings,

there is a risk of damage to electronic equipment and brake lines from stray heat.

4.

Use the recommended service tool where instructed to do so.

April 1997 v

Page 10 of 421

Electrics

Electrical Component Location and Wiring Information - Up to 97 MY

Component Index 6-19

Component Location Diagrams 6-23

Electronic Control Unit Location Diagram 6-38

Relay Panel, Fusebox and Earth Point Location Diagram 6-39

Loom Location Diagrams 6-40

Wiring Diagrams and Splice Lists 6-42

Electrical Component Location and Wiring Information - 97 MY

Component Index 6-43

Component Location Diagrams 6-47

Relay Location Diagrams 6-64

Wiring Diagrams and Splice Lists 6-68

Airbag System - Repair and Diagnostic Procedures 6-69

Seat Belt Pretensioner System - Repair and Diagnostic Procedures 6-101

Security System (Restricted Circulation) 6-111

PATS System (Restricted Circulation) 6-121

97.5 Model Year

6.6.03 Seat Removal (97.5 MY)

6.6.08 Seat Control Module (97.5 MY)

6-127

6-128

6-2 April! 997

Page 22 of 421

Electrics

Electric Windows - Fault Analysis / Window Motor Removal

[n:m3^^

Electric Windows

Description

Power to the window wind circuits is available

when the ignition switch is on and is supplied

through a thermal cut-out to the left and right

window switches. The switches are double pole

plus earth so that the current through a window

motor may be switched in either direction to raise

or lower the window.

DB7 uses frameless door windows which seal

against rubber strips around the body shell door

opening.

To avoid damaging these seals during

door opening, the door glass must be lowered

before the door can be opened. This function is

controlled by the window control units. The units

are mounted on the inside of each door frame and

will sense if a door handle is pulled to open the

door. Before releasing the door lock, the control

unit will drive the window wind motor briefly to

lower the door window glass down until it clears

the window seals. Similarly, after closing a door,

the window motor will be run to raise the door glass

to seat the glass against the body seals.

Fault Analysis Procedure

a) If a window fails to operate, check for fuse failure

and the connectors for poor or open contacts.

b) Check the thermal cut-out by shorting across it and

operating either window. If the windows operate

with the short

ci rcu

it but not without, the cut-out is

faulty.

c) With the ignition on, battery voltage should be

available between the inputterminalsof the switches

and chassis. Operate each switch and ensure that

battery voltage is available between the switch

output terminals and chassis.

d) Measure voltagefrom each switch inputterminalto

the switch earth return terminal. If no voltage is

measured,

the earth return line is open circuit.

e) Measure continuity through the wiring from the

switches to each motor. If continuity is correct,

remove the motor for bench testing.

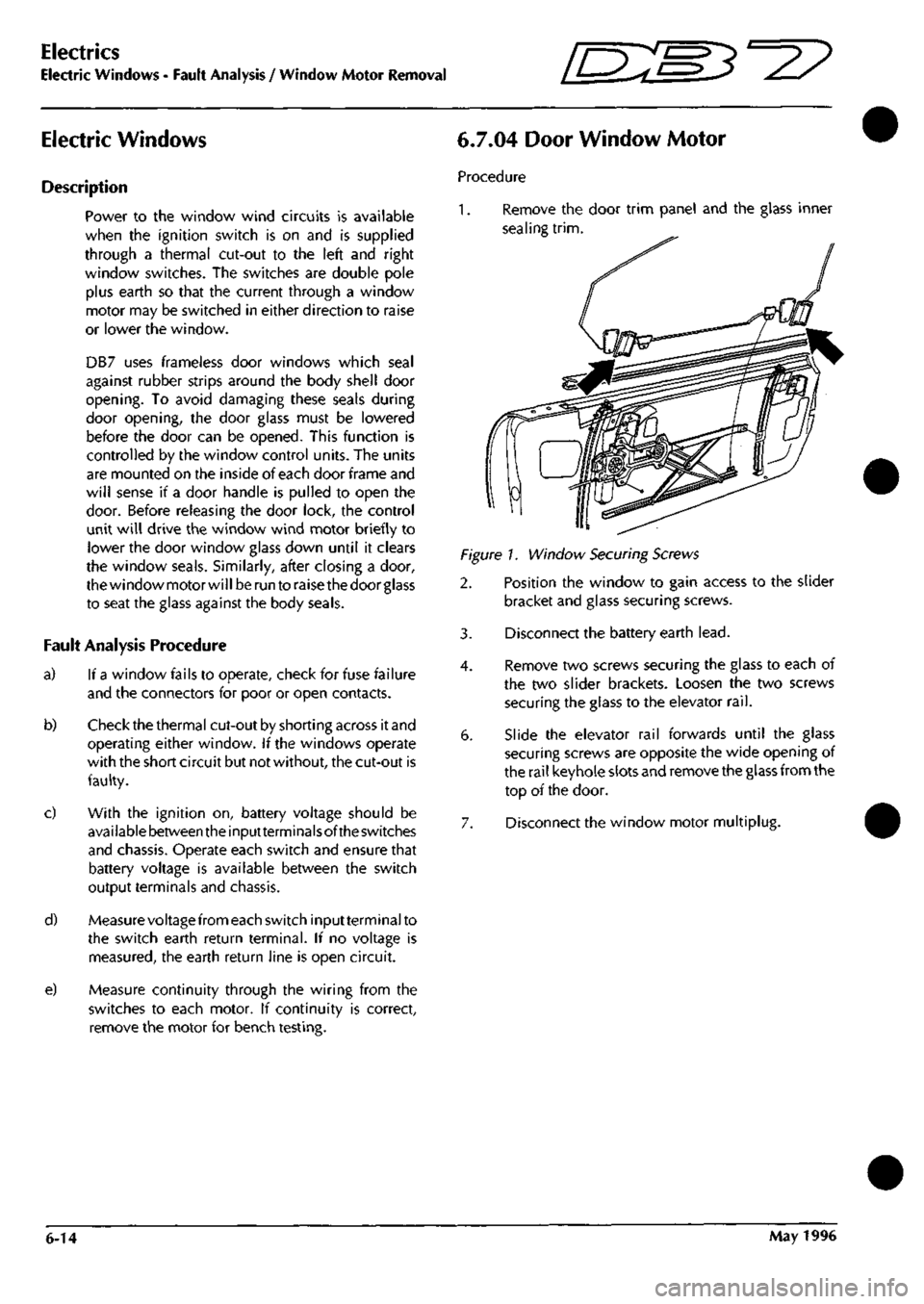

6.7.04 Door Window Motor

Procedure

1.

Remove the door trim panel and the glass inner

sealing

trim.

Figure!. Window Securing Screws

2. Position the window to gain access to the slider

bracket and glass securing screws.

3. Disconnect the battery earth

lead.

4.

Remove two screws securing the glass to each of

the two slider brackets. Loosen the two screws

securing the glass to the elevator

rail.

6. Slide the elevator rail forwards until the glass

securing screws are opposite the wide opening of

the rail keyhole slots and remove the glass from the

top of the door.

7. Disconnect the window motor multiplug.

6-14 May 1996

Page 27 of 421

Electrics

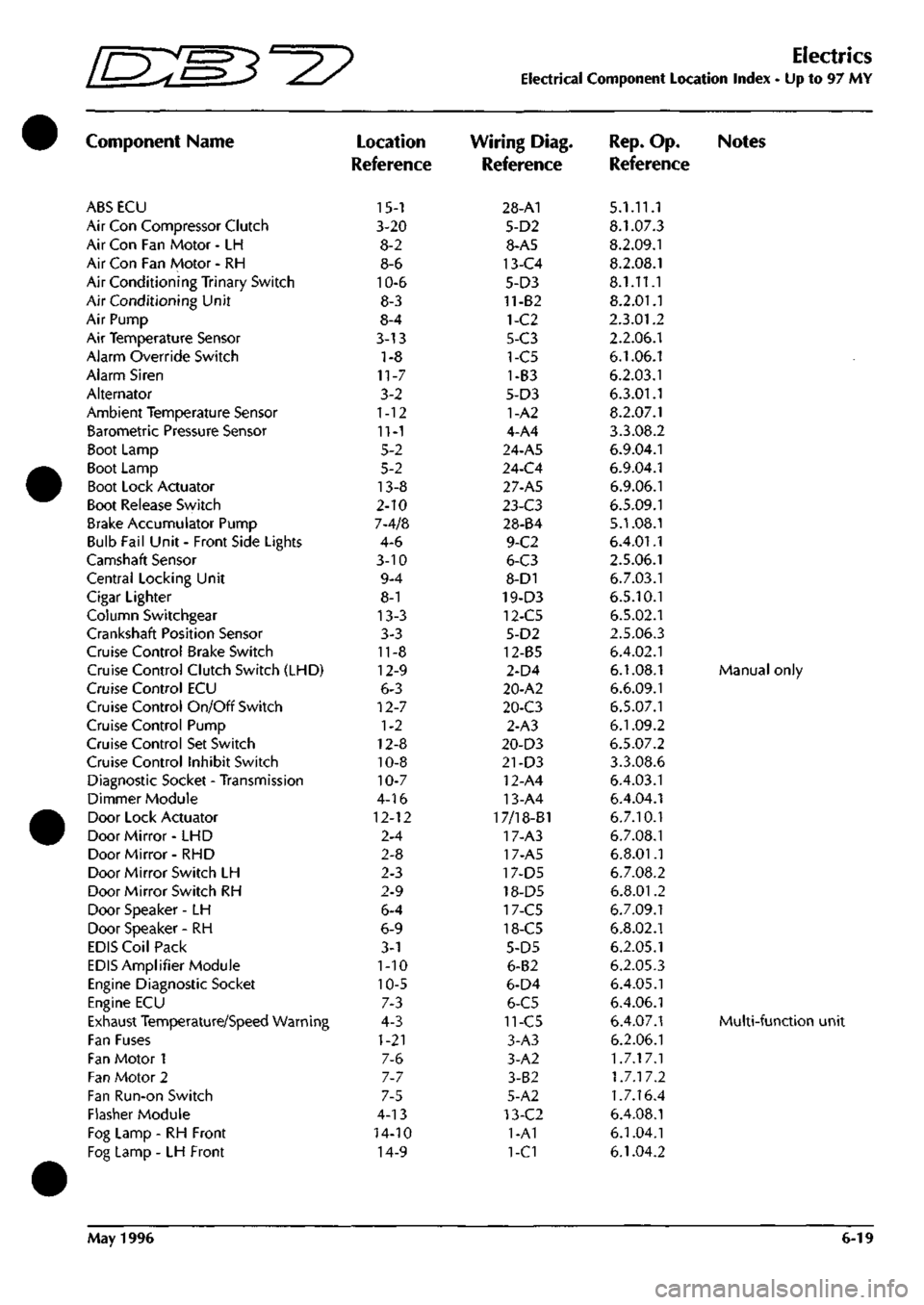

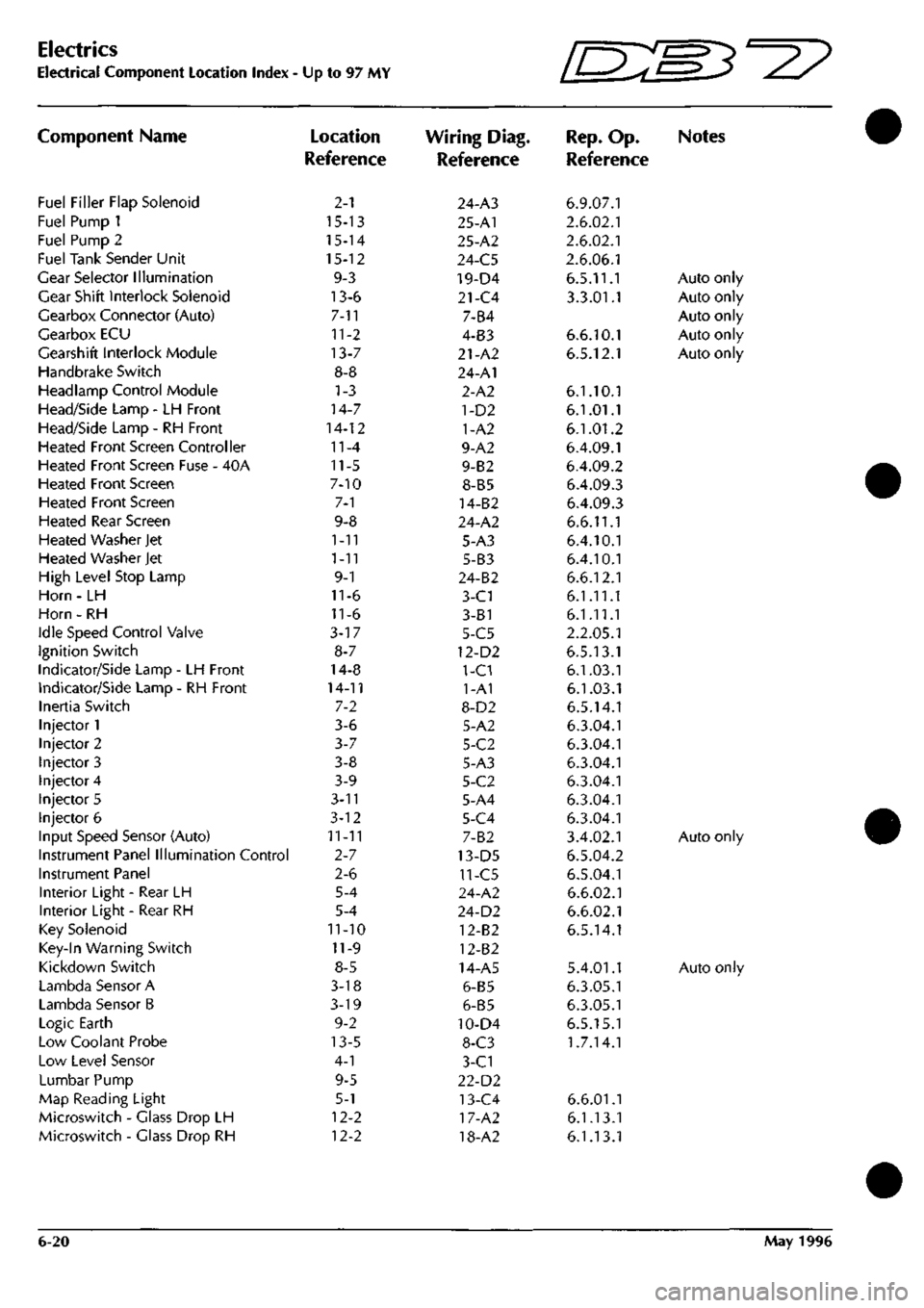

Electrical Component Location Index - Up to 97 MY

Component Name

ABS ECU

Air Con Compressor Clutch

Air Con Fan Motor - LH

Air Con Fan Motor - RH

Air Conditioning Trinary Switch

Air Conditioning Unit

Air Pump

Air Temperature Sensor

Alarm Override Switch

Alarm Siren

Alternator

Ambient Temperature Sensor

Barometric Pressure Sensor

Boot Lamp

Boot Lamp

Boot Lock Actuator

Boot Release Switch

Brake Accumulator Pump

Bulb Fail Unit - Front Side Lights

Camshaft Sensor

Central Locking Unit

Cigar Lighter

Column Switchgear

Crankshaft Position Sensor

Cruise Control Brake Switch

Cruise Control Clutch Switch (LHD)

Cruise Control ECU

Cruise Control On/Off Switch

Cruise Control Pump

Cruise Control Set Switch

Cruise Control Inhibit Switch

Diagnostic Socket - Transmission

Dimmer Module

Door Lock Actuator

Door Mirror- LHD

Door Mirror- RHD

Door Mirror Switch LH

Door Mirror Switch RH

Door Speaker -LH

Door Speaker - RH

EDIS Coil Pack

EDIS Amplifier Module

Engine Diagnostic Socket

Engine ECU

Exhaust Temperature/Speed Warning

Fan Fuses

Fan Motor 1

Fan Motor 2

Fan Run-on Switch

Flasher Module

Fog Lamp - RH Front

Fog Lamp - LH Front

Location

Reference

15-1

3-20

8-2

8-6

10-6

8-3

8-4

3-13

1-8

11-7

3-2

1-12

11-1

5-2

5-2

13-8

2-10

7-4/8

4-6

3-10

9-4

8-1

13-3

3-3

11-8

12-9

6-3

12-7

1-2

12-8

10-8

10-7

4-16

12-12

2-4

2-8

2-3

2-9

6-4

6-9

3-1

1-10

10-5

7-3

4-3

1-21

7-6

7-7

7-5

4-13

14-10

14-9

Wiring Diag.

Reference

28-A1

5-D2

8-A5

13-C4

5-D3

11-82

1-C2

5-C3

1-C5

1-B3

5-D3

1-A2

4-A4

24-A5

24-C4

27-A5

l-i-C3

28-84

9-C2

6-C3

8-D1

19-D3

12-C5

5-D2

12-85

2-D4

20-A2

20-C3

2-A3

20-D3

21-D3

12-A4

13-A4

17/18-B1

17-A3

17-A5

17-D5

18-D5

17-C5

18-C5

5-D5

6-B2

6-D4

6-C5

11-C5

3-A3

3-A2

3-B2

5-A2

13-C2

1-A1

1-C1

Rep.

Op. Notes

Reference

5.1.11.1

8.1.07.3

8.2.09.1

8.2.08.1

8.1.11.1

8.2.01.1

2.3.01.2

2.2.06.1

6.1.06.1

6.2.03.1

6.3.01.1

8.2.07.1

3.3.08.2

6.9.04.1

6.9.04.1

6.9.06.1

6.5.09.1

5.1.08.1

6.4.01.1

2.5.06.1

6.7.03.1

6.5.10.1

6.5.02.1

2.5.06.3

6.4.02.1

6.1.08.1 Manual only

6.6.09.1

6.5.07.1

6.1.09.2

6.5.07.2

3.3.08.6

6.4.03.1

6.4.04.1

6.7.10.1

6.7.08.1

6.8.01.1

6.7.08.2

6.8.01.2

6.7.09.1

6.8.02.1

6.2.05.1

6.2.05.3

6.4.05.1

6.4.06.1

6.4.07.1 Multi-functio

6.2.06.1

1.7.17.1

1.7.17.2

1.7.16.4

6.4.08.1

6.1.04.1

6.1.04.2

May 1996 6-19

Page 28 of 421

Electrics

Electrical Component Location Index •

Component Name

Fuel Filler Flap Solenoid

Fuel Pump 1

Fuel Pump 2

Fuel Tank Sender Unit

Gear Selector Illumination

Gear Shift Interlock Solenoid

Gearbox Connector (Auto)

Gearbox ECU

Gearshift Interlock Module

Handbrake Switch

Headlamp Control Module

Head/Side Lamp - LH Front

Head/Side Lamp - RH Front

Heated Front Screen Controller

Heated Front Screen Fuse - 40A

Heated Front Screen

Heated Front Screen

Heated Rear Screen

Heated Washer Jet

Heated Washer Jet

High Level Stop Lamp

Horn - LH

Horn - RH

Idle Speed Control Valve

Ignition Switch

Indicator/Side Lamp - LH Front

Indicator/Side Lamp - RH Front

Inertia Switch

Injector 1

Injector 2

Injector 3

Injector 4

Injector 5

Injector 6

Input Speed Sensor (Auto)

Instrument Panel Illumination Control

Instrument Panel

Interior Light - Rear LH

Interior Light - Rear RH

Key Solenoid

Key-In Warning Switch

Kickdown Switch

Lambda Sensor A

Lambda Sensor B

Logic Earth

Low Coolant Probe

Low Level Sensor

Lumbar Pump

Map Reading Light

Microswitch - Glass Drop LH

Microswitch - Glass Drop RH

Up to 97 MY

Location

Reference

2-1

15-13

15-14

15-12

9-3

13-6

7-11

11-2

13-7

8-8

1-3

14-7

14-12

11-4

11-5

7-10

7-1

9-8

1-11

1-11

9-1

11-6

11-6

3-17

8-7

14-8

14-11

7-2

3-6

3-7

3-8

3-9

3-n

3-12

11-11

2-7

2-6

5-4

5-4

11-10

11-9

8-5

3-18

3-19

9-2

13-5

4-1

9-5

5-1

12-2

12-2

Wiring Diag.

Reference

24-A3

25-A1

25-A2

24-C5

19-D4

21-C4

7-B4

4-B3

21-A2

24-A1

2-A2

1-D2

1-A2

9-A2

9-B2

8-B5

14-B2

24-A2

5-A3

5-B3

24-B2

3-C1

3-81

5-C5

12-D2

1-C1

1-A1

8-D2

5-A2

5-C2

5-A3

5-C2

5-A4

5-C4

7-B2

13-D5

11-C5

24-A2

24-D2

12-B2

12-B2

14-A5

6-B5

6-B5

10-D4

8-C3

3-C1

22-D2

13-C4

17-A2

18-A2

Ini^'

IL-^^'^

Rep.

Op.

Reference

6.9.07.1

2.6.02.1

2.6.02.1

2.6.06.1

6.5.11.1

3.3.01.1

6.6.10.1

6.5.12.1

6.1.10.1

6.1.01.1

6.1.01.2

6.4.09.1

6.4.09.2

6.4.09.3

6.4.09.3

6.6.11.1

6.4.10.1

6.4.10.1

6.6.12.1

6.1.11.1

6.1.11.1

2.2.05.1

6.5.13.1

6.1.03.1

6.1.03.1

6.5.14.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

3.4.02.1

6.5.04.2

6.5.04.1

6.6.02.1

6.6.02.1

6.5.14.1

5.4.01.1

6.3.05.1

6.3.05.1

6.5.15.1

1.7.14.1

6.6.01.1

6.1.13.1

6.1.13.1

W3^y

Notes

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

6-20 May 1996

Page 46 of 421

I

00

n m o

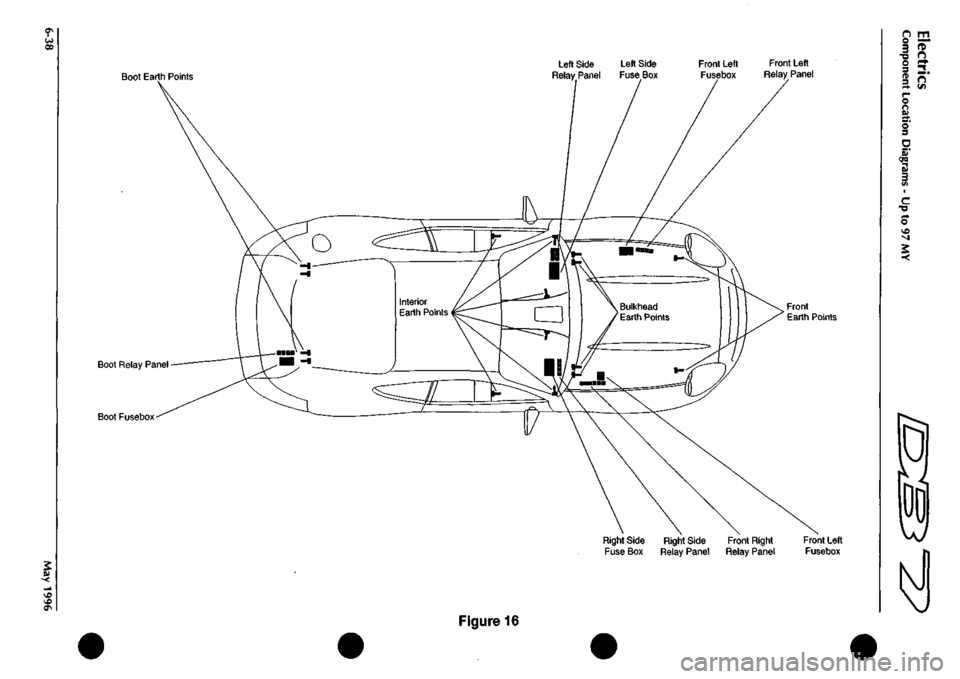

Boot Earth Points

Left Side Relay Panel

Left Side Fuse Box Front Left Fusebox

Front Left Relay Panel

n

Boot Relay Panel

Boot Fusebox

3

I =•

r-O ft

5' 3

cro

C •a

o

-<

Front Earth Points

Right Side Fuse Box Right Side Relay Panel Front Right Relay Panel

Front Left Fusebox

2

&<

^

I7>

Figure 16

Page 49 of 421

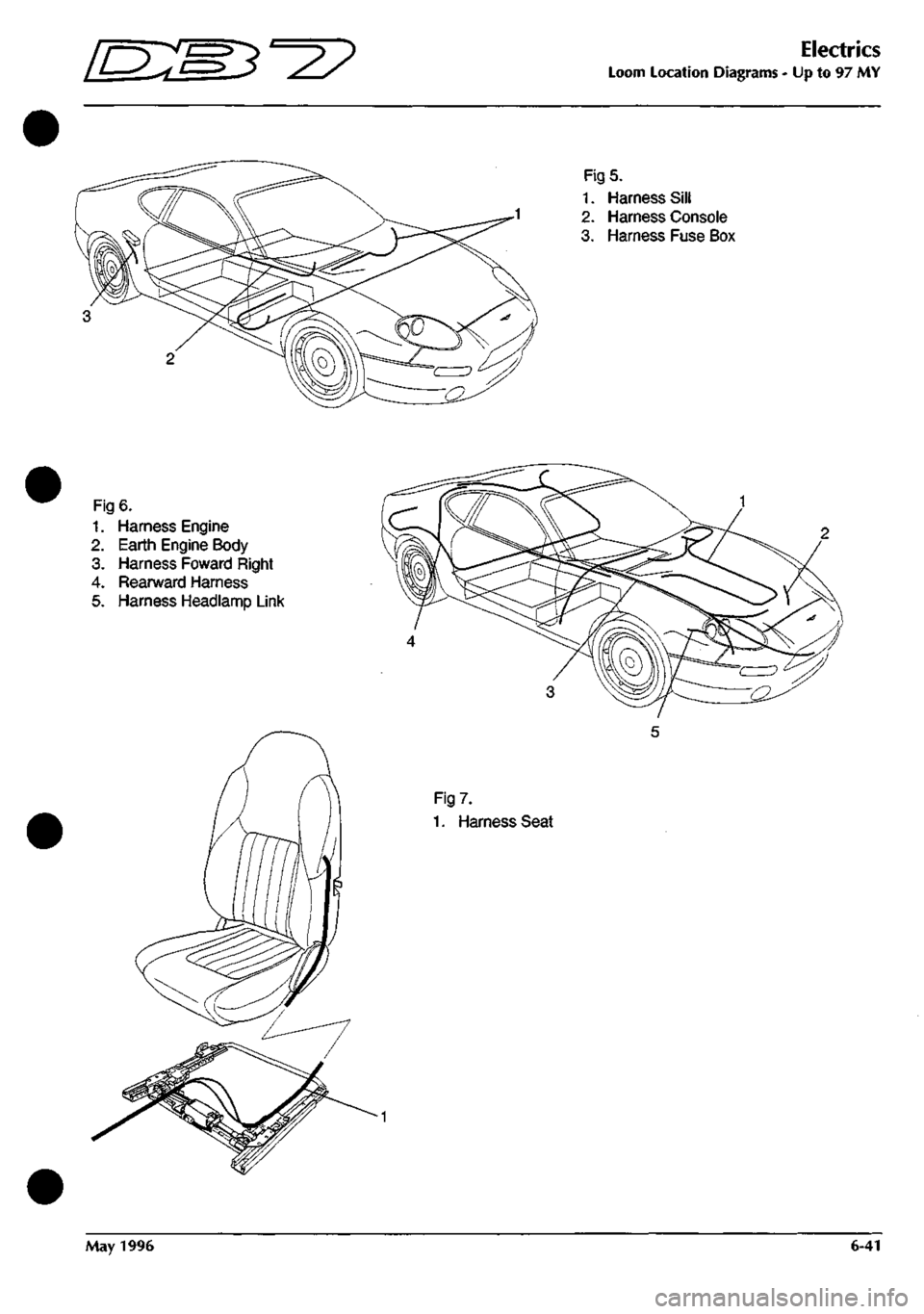

Electrics

Loom Location Diagrams - Up to 97 MY

Fig 5.

1.

Harness Sill

2.

Harness Console

3. Harness Fuse Box

Fig 6.

1.

Harness Engine

2.

Earth Engine Body

3. Harness Foward Right

4.

Rearward Harness

5. Harness Headlamp Link

Fig 7.

1.

Harness Seat

May 1996 6-41

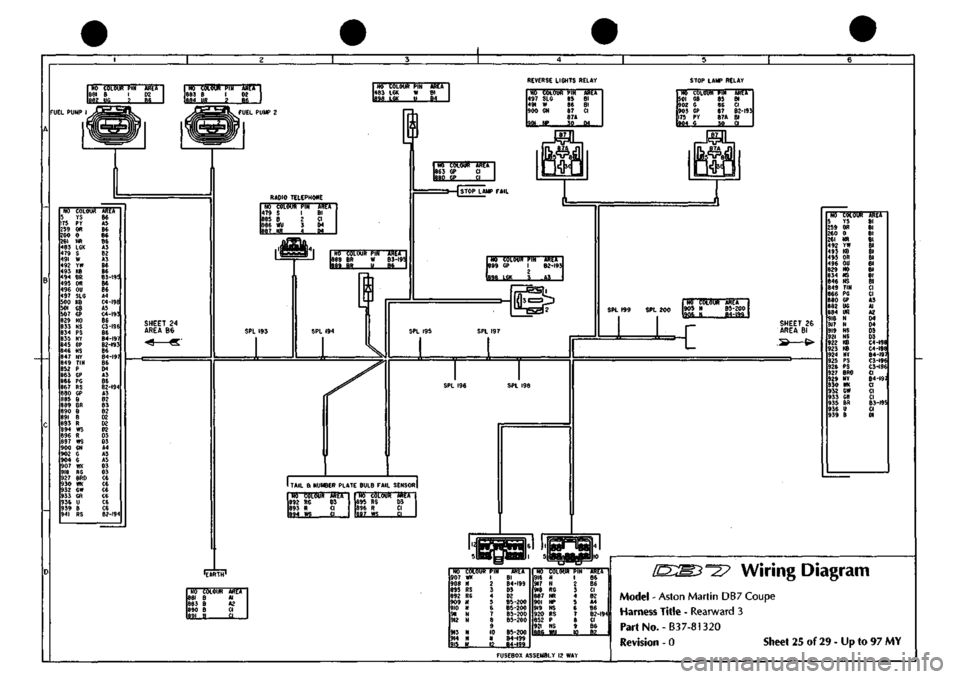

Page 99 of 421

NO COLOUR PIN 1881 B I m vi i

REVERSE LIGHTS RELAY STOP LAMP RELAY

KO COLOUn 497 SLG 491 W 900 GN

901 NP

PIK 85 88 87 e7A

-iS-

AREA Bl Bl CI

-Id-..

NO COLOUR PIN 901 GB 85 90Z G 8G 903 GP 87 ITS PY 87A ?« 5 59

Ml Bl CI B2-I93 Bl CI

law

NO COLOUR 5 YS 175 PY 259 OR 260 0 261 NR 483 LGK 479 S 491 W 492 YW 493 KB 494 BR 495 OR 496 OU 497 SLG 500 KB 501 GB 507 GP 829 NO 833 NS 834 PS 835 NY 845 CP 646 NS 847 NY 849 TIN 852 P 863 GP 866 PC 867 RS 880 GP 885 B 889 BR 890 B 891 B 893 R 894 WS 896 R 697 WS 900 GH 902 G 904 G 907 WK 918 RG 927 BRD 930 WK 932 GW 933 GR 936 U 939 B 941 RS

AREA B6 A5 B6 BG 86 A3 B2 A3 86 86

B3-I9:

B6 66 A4 C4-I98 A5

C4-I9;

B6 C3-I96 B6 B4-I97 B2-I95 B6 B4-I97 86 D4 A3 B6 B2-I94 A3 82 83 82 D2 D2 D2 03 D3 A4 A3 A5 D3 03 C6 C6 C6 C6 C6 C6 B2-I94

NO COLOUR 5 YS 259 OR 260 0 261 NR 492 YW 493 KB 495 OR 496 OU 829 NO 834 NS 846 NS 849 TIN 866 PG 880 GP 882 UG 884 UR 916 N 917 N 919 NS 921 NS 922 KB 923 KB 924 NY 925 PS 926 PS 927 BRD 929 HY 930 WK 952 GW 933 CR 935 BR 936 U 939 B

-ma'

Bl Bl Bl Bl Bl Bl Bl 61 61 Bl Bl CI CI A3 Al K 04 04 03 03 C4-I9t 04-198 B4-I91 C3-I96 C3-I96 CI 64-191 CI CI CI

63-19!

CI 01

NO COLOUR 881 8 883 6 890 6

9?i

B

AREA Al A2 a a

FUSEBOX ASSEMBLY 12 WAY

Wiring Diagram

Model - Aston Martin DB7 Coupe

Harness Title - Rearward 3

PartNo.-B37-81320

Revision - 0 Sheet 25 of 29 - Up to 97 MY

Page 103 of 421

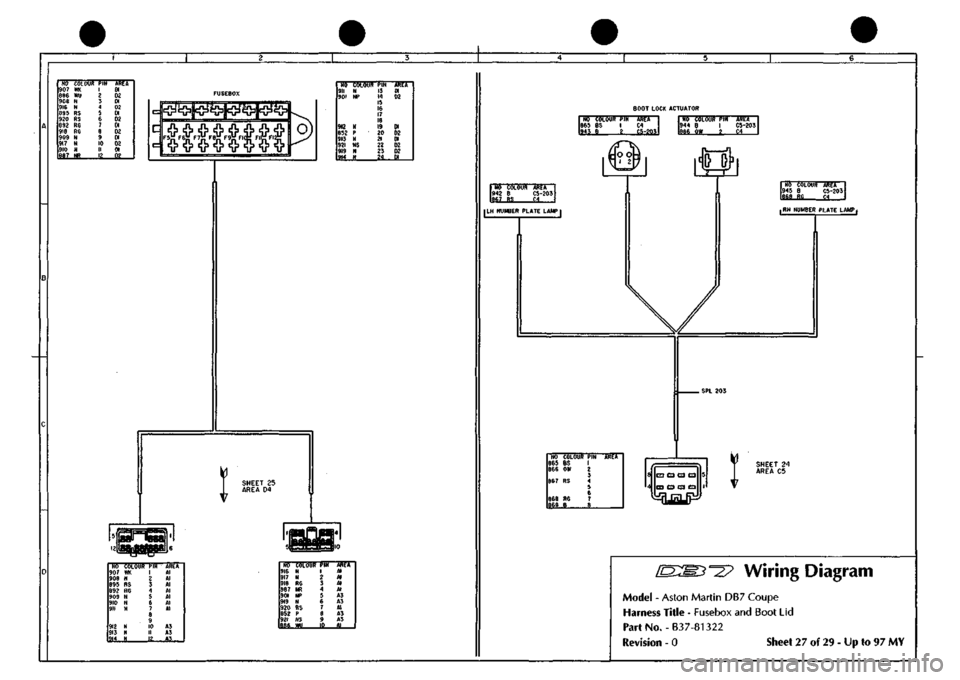

NO COLOUf 907

m

886

WU

908

N

916

N

895

RS

920

RS

692

RG

918

RC

909

N

917

N

910

N

887

NR

PIN 1 •/ 3 4 5 6 7 e 9 10 II IS

AREA 01 02 01 02 01 02 01 02 01 02 01 02

^^c^ldrjiiQJ^i^i^^

ti6

911 901

912 8S? 915 921 919

V<

COLOU!

N HP

N P N NS N N

I*1N 13

15 16 17

m

19 20 21 22 23

24

Mi

a 02

Dl 02 01 02 D2 Dl

SHEET

25

AREA

D4

IB

PBflHBlPPtiJ

NO COLOUf 907

IK

908

N

895

RS

892

RG

909

N

910

N

911

N

912

N

913

N

914

N

PIN 1 2 3 4 5 6 7 8 9 10 II 12...

AREA Al Al

Al

Al Al Al Al

A3 A3

flj

NO COLOUR

PIN

916

N

917

N

918

RC

987

KR

901

NP

919

N

920

RS

852

P

)ZI

NS

886

WU

1 2 3 4 5 e 7 8 9 IB-

AREA Al Al Al Al A3 A3 Al A3 A3 Al

BOOT LOCK ACTUATOR

865

BS I C4 ?

Ho ioLm

M

mi

944

B I

C5-203 966

OW ? C4

M C6L0Ut) ARtA

942

B

C5-203 867

RS C4

ILH NUMBER PLATE LAMP

I

11

NO 945 COLOUR B RO C5-203 ?4

...

,RH NUMBER PLATE LAMP,

NO COLOUf 865

BS

866

OW

867

RS

868

RO

869

B

PIN 1 2 3 4 5 6 7

?

AREA

8

o a Q a 5

4

C3

Q Q a I

SHEET 24 AREA C5

'^? Wiring Diagram

Model

-

Aston Martin DB7 Coupe

Harness Title

-

Fusebox and Boot Lid

PartNo.-B37-81322

Revision

- 0

Sheet 27 of 29

-

Up to 97 MY

Page 129 of 421

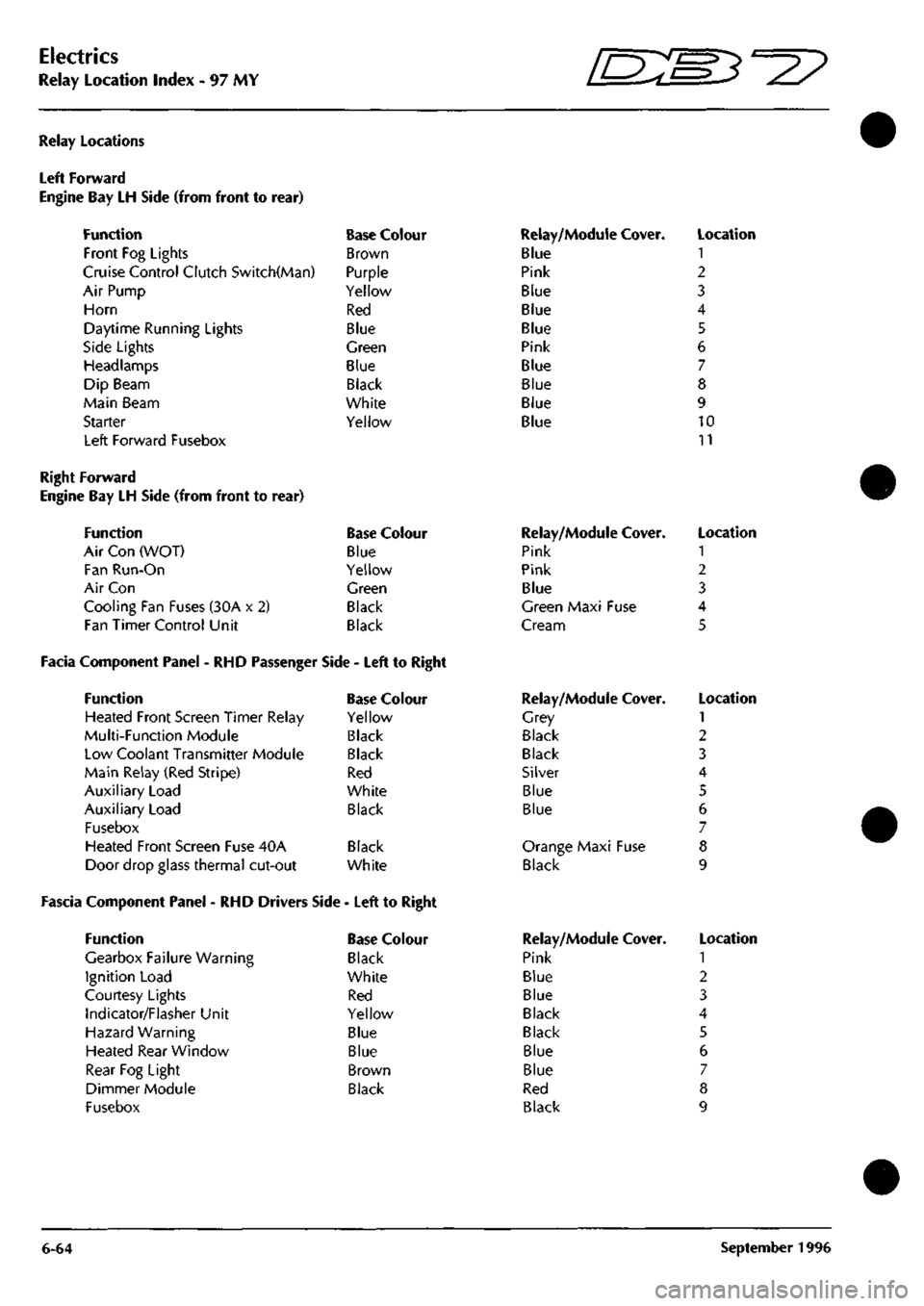

Electrics

Relay Location Index - 97 MY 5^^?

Relay Locations

Left Forward

Engine Bay LH Side (from front to

Function

Front Fog Lights

rear)

Cruise Control Clutch Switch(Man)

Air Pump

Horn

Daytime Running Lights

Side Lights

Headlamps

Dip Beam

Main Beam

Starter

Left Forward Fusebox

Base Colour

Brown

Purple

Yellow

Red

Blue

Green

Blue

Black

White

Yellow

Relay/Module Cover.

Blue

Pink

Blue

Blue

Blue

Pink

Blue

Blue

Blue

Blue

Location

1

2

3

4

5

6

7

8

9

10

11

Right Forward

Engine Bay LH Side (from front to rear)

Function Base Colour

Air Con (WOT) Blue

Fan Run-On Yellow

Air Con Green

Cooling Fan Fuses (30A x 2) Black

Fan Timer Control Unit Black

Facia Component Panel - RHD Passenger Side - Left to Right

Function Base Colour

Heated Front Screen Timer Relay Yellow

Multi-Function Module Black

Low Coolant Transmitter Module Black

Main Relay (Red Stripe) Red

Auxiliary Load White

Auxiliary Load Black

Fusebox

Heated Front Screen Fuse 40A Black

Door drop glass thermal cut-out White

Fascia Component Panel - RHD Drivers Side - Left to Right

Function

Gearbox Failure Warning

Ignition Load

Courtesy Lights

Indicator/Flasher Unit

Hazard Warning

Heated Rear Window

Rear Fog Light

Dimmer Module

Fusebox

Base Colour

Black

White

Red

Yellow

Blue

Blue

Brown

Black

Relay/Module

Pink

Pink

Blue

Cover.

Green Maxi Fuse

Cream

Relay/Module

Grey

Black

Black

Silver

Blue

Blue

Cover.

Orange Maxi Fuse

Black

Relay/Module

Pink

Blue

Blue

Black

Black

Blue

Blue

Red

Black

Cover.

Location

1

2

3

4

5

Location

1

2

3

4

5

6

7

8

9

Location

1

2

3

4

5

6

7

8

9

6-64 September 1996