instrument panel ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 9 of 421

[Em^^^?

Electrics

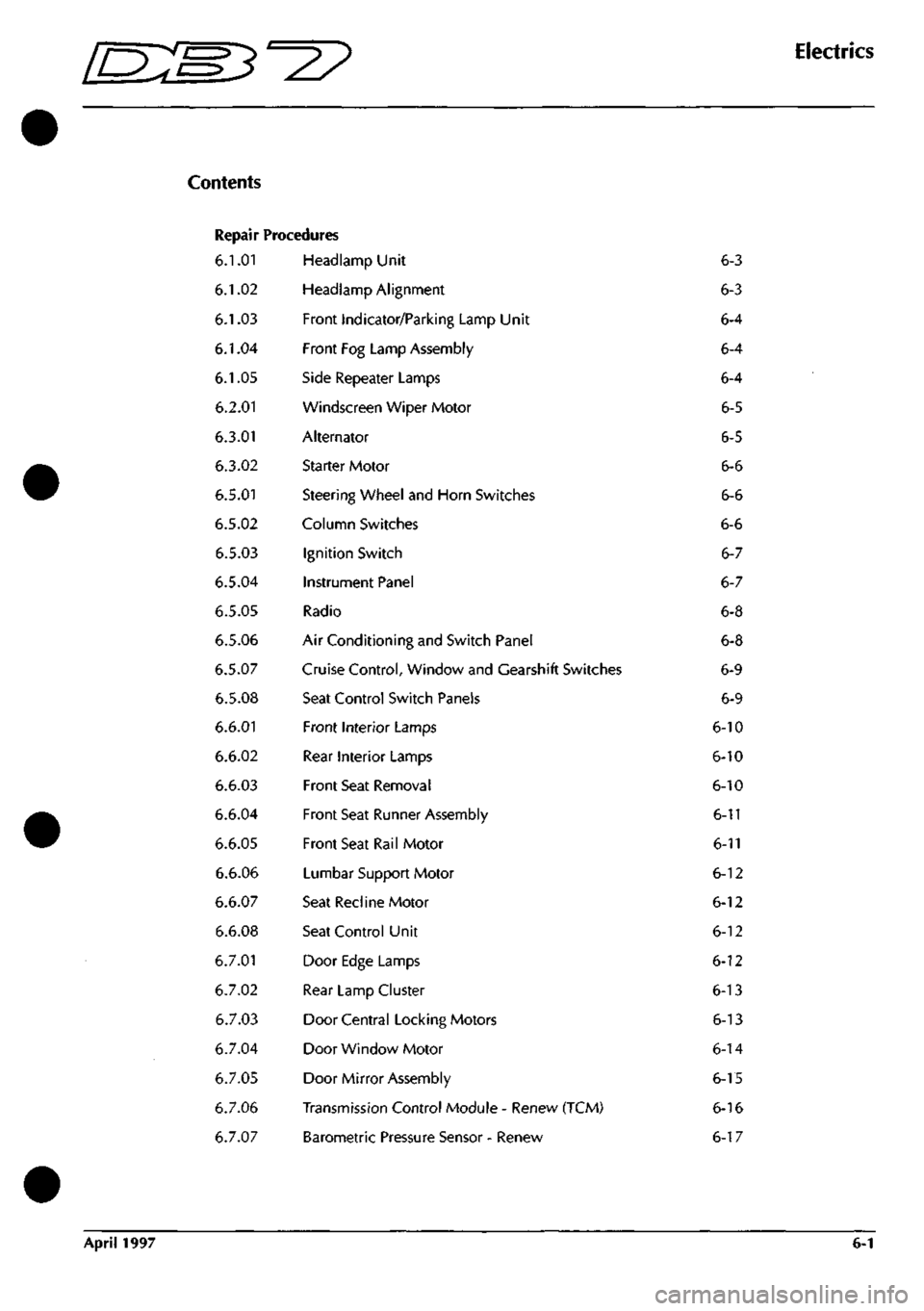

Repair Procedures

6.1.01

6.1.02

6.1.03

6.1.04

6.1.05

6.2.01

6.3.01

6.3.02

6.5.01

6.5.02

6.5.03

6.5.04

6.5.05

6.5.06

6.5.07

6.5.08

6.6.01

6.6.02

6.6.03

6.6.04

6.6.05

6.6.06

6.6.07

6.6.08

6.7.01

6.7.02

6.7.03

6.7.04

6.7.05

6.7.06

6.7.07

Headlamp Unit

Headlamp Alignment

Front Indicator/Parking Lamp Unit

Front Fog Lamp Assembly

Side Repeater Lamps

Windscreen Wiper Motor

Alternator

Starter Motor

Steering Wheel and Horn Switches

Column Switches

Ignition Switch

Instrument Panel

Radio

Air Conditioning and Switch Panel

Cruise Control, Window and Gearshift Switches

Seat Control Switch Panels

Front Interior Lamps

Rear Interior Lamps

Front Seat Removal

Front Seat Runner Assembly

Front Seat Rail Motor

Lumbar Support Motor

Seat Recline Motor

Seat Control Unit

Door Edge Lamps

Rear Lamp Cluster

Door Central Locking Motors

Door Window Motor

Door Mirror Assembly

Transmission Control Module - Renew (TCM)

Barometric Pressure Sensor - Renew

6-3

6-3

6-4

6-4

6-4

6-5

6-5

6-6

6-6

6-6

6-7

6-7

6-8

6-8

6-9

6-9

6-10

6-10

6-10

6-11

6-11

6-12

6-12

6-12

6-12

6-13

6-13

6-14

6-15

6-16

6-17

April 1997 6-1

Page 15 of 421

Em3^^^

Electrics

Ignition Switch / Instrument Panel - Removal Procedures

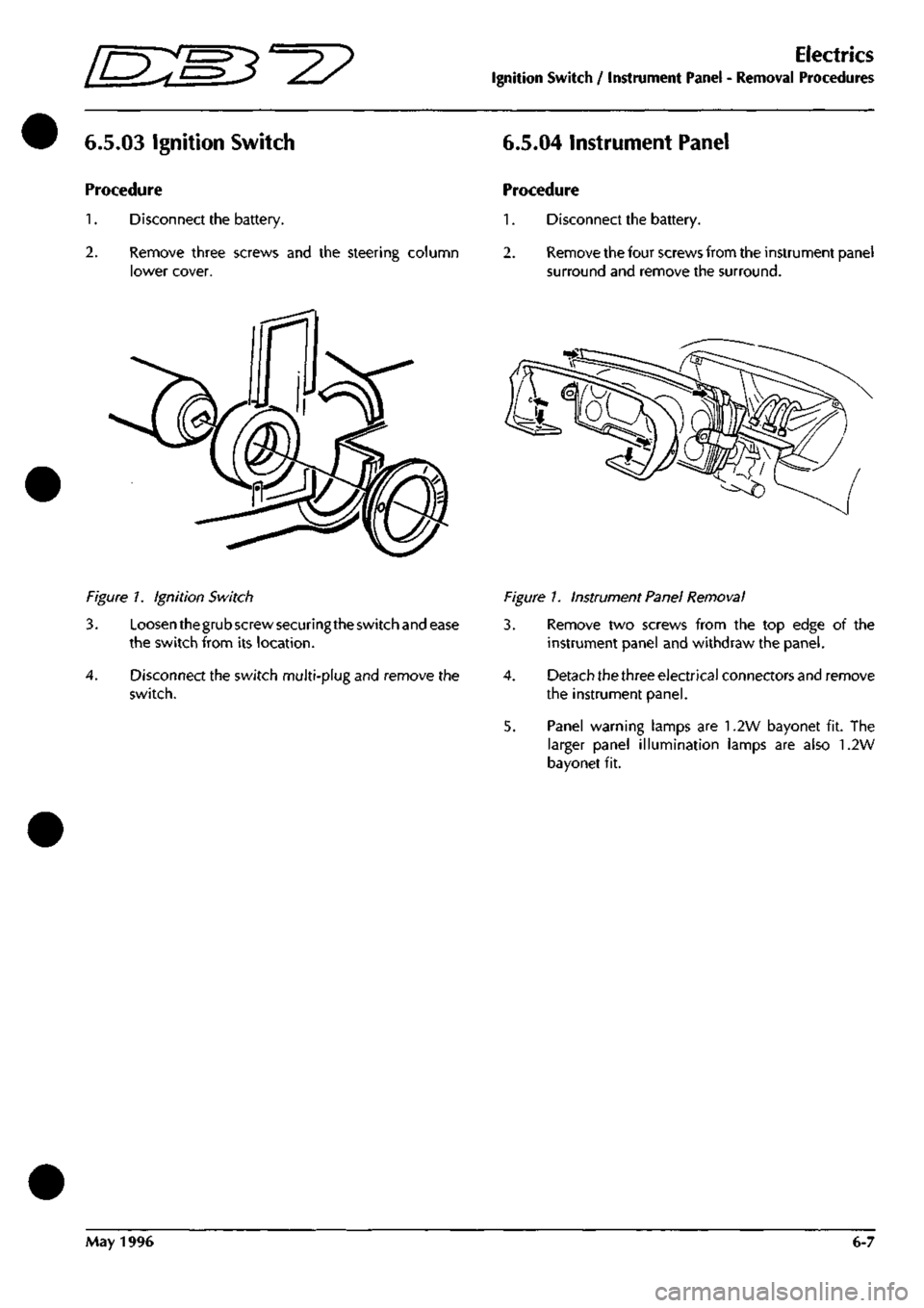

6.5.03 Ignition Switch 6.5.04 Instrument Panel

Procedure

1.

Disconnect the battery.

2.

Remove three screws and the steering column

lower cover.

Procedure

1.

Disconnect the battery.

2.

Remove the four screws from the instrument pane!

surround and remove the surround.

Figure 7. Ignition Switch

3.

4.

Loosen thegrub screw securing the switch and ease

the switch from its location.

Disconnect the switch multi-plug and remove the

switch.

Figure 1. Instrument Panel Removal

3. Remove two screws from the top edge of the

instrument panel and withdraw the panel.

4.

Detach the three electrical connectors and remove

the instrument panel.

5. Panel warning lamps are 1.2W bayonet fit. The

larger panel illumination lamps are also 1.2W

bayonet fit.

May 1996 6-7

Page 28 of 421

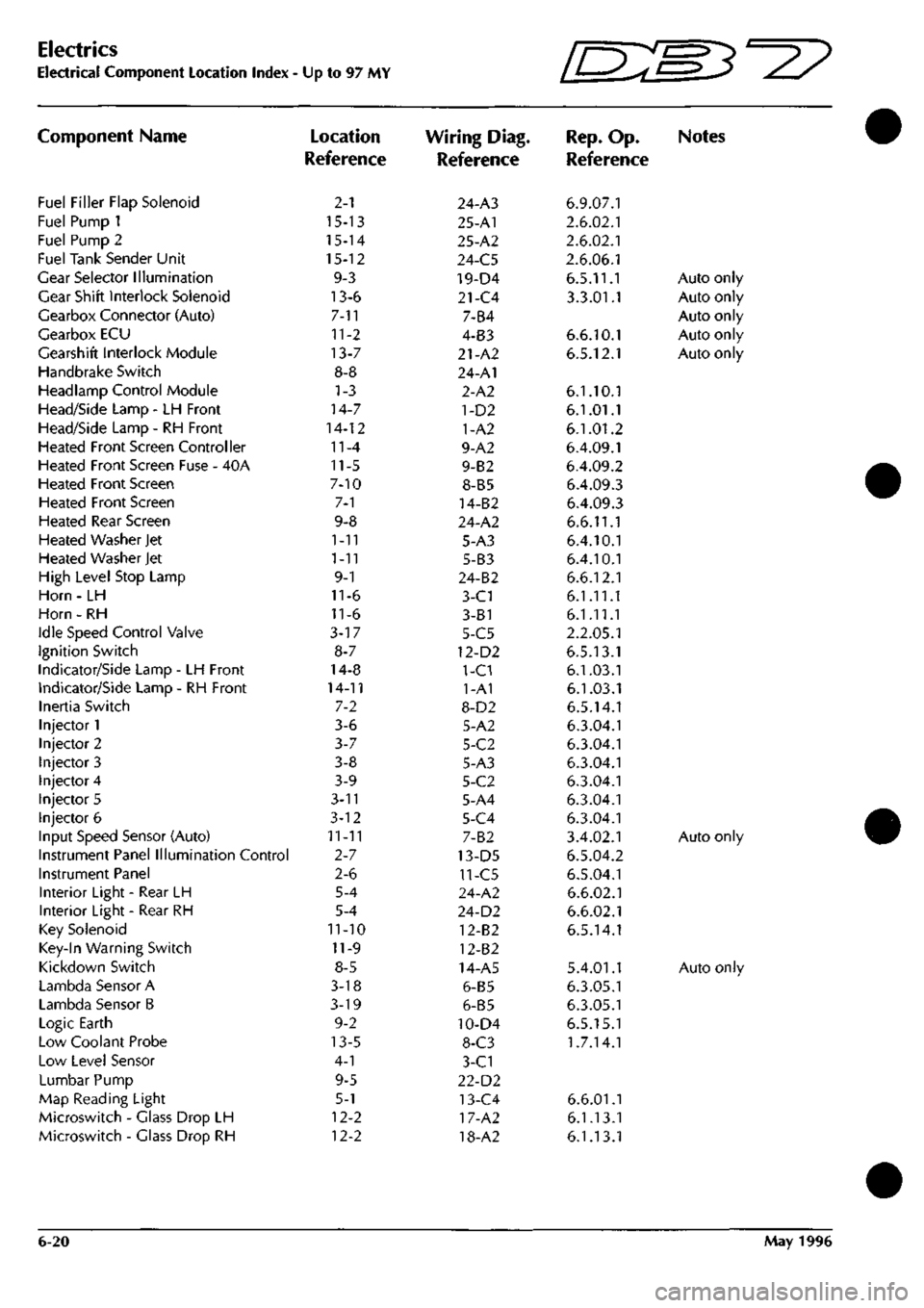

Electrics

Electrical Component Location Index •

Component Name

Fuel Filler Flap Solenoid

Fuel Pump 1

Fuel Pump 2

Fuel Tank Sender Unit

Gear Selector Illumination

Gear Shift Interlock Solenoid

Gearbox Connector (Auto)

Gearbox ECU

Gearshift Interlock Module

Handbrake Switch

Headlamp Control Module

Head/Side Lamp - LH Front

Head/Side Lamp - RH Front

Heated Front Screen Controller

Heated Front Screen Fuse - 40A

Heated Front Screen

Heated Front Screen

Heated Rear Screen

Heated Washer Jet

Heated Washer Jet

High Level Stop Lamp

Horn - LH

Horn - RH

Idle Speed Control Valve

Ignition Switch

Indicator/Side Lamp - LH Front

Indicator/Side Lamp - RH Front

Inertia Switch

Injector 1

Injector 2

Injector 3

Injector 4

Injector 5

Injector 6

Input Speed Sensor (Auto)

Instrument Panel Illumination Control

Instrument Panel

Interior Light - Rear LH

Interior Light - Rear RH

Key Solenoid

Key-In Warning Switch

Kickdown Switch

Lambda Sensor A

Lambda Sensor B

Logic Earth

Low Coolant Probe

Low Level Sensor

Lumbar Pump

Map Reading Light

Microswitch - Glass Drop LH

Microswitch - Glass Drop RH

Up to 97 MY

Location

Reference

2-1

15-13

15-14

15-12

9-3

13-6

7-11

11-2

13-7

8-8

1-3

14-7

14-12

11-4

11-5

7-10

7-1

9-8

1-11

1-11

9-1

11-6

11-6

3-17

8-7

14-8

14-11

7-2

3-6

3-7

3-8

3-9

3-n

3-12

11-11

2-7

2-6

5-4

5-4

11-10

11-9

8-5

3-18

3-19

9-2

13-5

4-1

9-5

5-1

12-2

12-2

Wiring Diag.

Reference

24-A3

25-A1

25-A2

24-C5

19-D4

21-C4

7-B4

4-B3

21-A2

24-A1

2-A2

1-D2

1-A2

9-A2

9-B2

8-B5

14-B2

24-A2

5-A3

5-B3

24-B2

3-C1

3-81

5-C5

12-D2

1-C1

1-A1

8-D2

5-A2

5-C2

5-A3

5-C2

5-A4

5-C4

7-B2

13-D5

11-C5

24-A2

24-D2

12-B2

12-B2

14-A5

6-B5

6-B5

10-D4

8-C3

3-C1

22-D2

13-C4

17-A2

18-A2

Ini^'

IL-^^'^

Rep.

Op.

Reference

6.9.07.1

2.6.02.1

2.6.02.1

2.6.06.1

6.5.11.1

3.3.01.1

6.6.10.1

6.5.12.1

6.1.10.1

6.1.01.1

6.1.01.2

6.4.09.1

6.4.09.2

6.4.09.3

6.4.09.3

6.6.11.1

6.4.10.1

6.4.10.1

6.6.12.1

6.1.11.1

6.1.11.1

2.2.05.1

6.5.13.1

6.1.03.1

6.1.03.1

6.5.14.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

3.4.02.1

6.5.04.2

6.5.04.1

6.6.02.1

6.6.02.1

6.5.14.1

5.4.01.1

6.3.05.1

6.3.05.1

6.5.15.1

1.7.14.1

6.6.01.1

6.1.13.1

6.1.13.1

W3^y

Notes

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

6-20 May 1996

Page 109 of 421

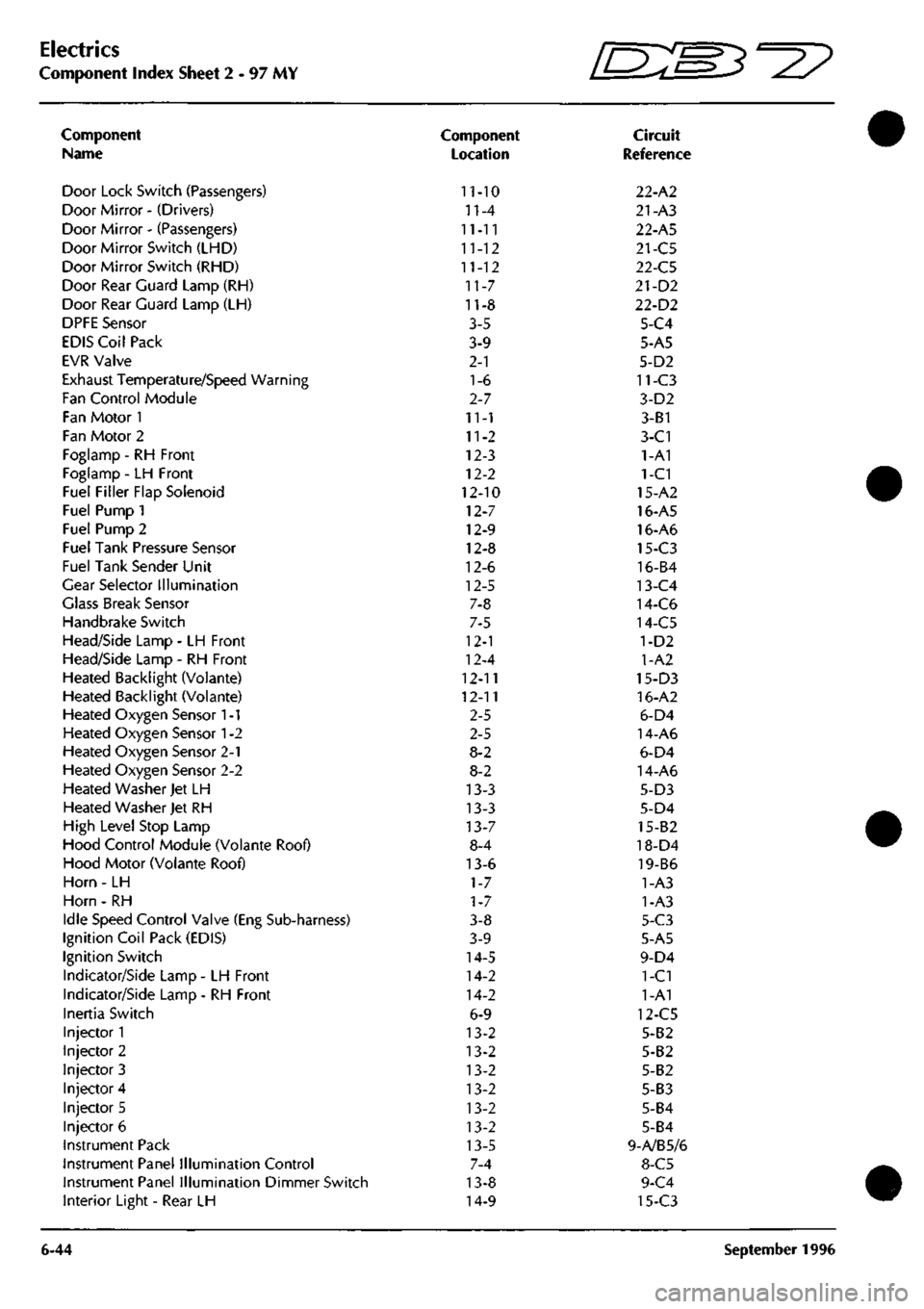

Electrics

Component Index Sheet 2 - 97 MY

Component

Name

Door Lock Switch (Passengers)

Door Mirror - (Drivers)

Door Mirror - (Passengers)

Door Mirror Switch (LHD)

Door Mirror Switch (RHD)

Door Rear Guard Lamp (RH)

Door Rear Guard Lamp (LH)

DPFE Sensor

EDIS Coil Pack

EVR Valve

Exhaust Temperature/Speed Warning

Fan Control Module

Fan Motor 1

Fan Motor 2

Foglamp - RH Front

Foglamp - LH Front

Fuel Filler Flap Solenoid

Fuel Pump 1

Fuel Pump 2

Fuel Tank Pressure Sensor

Fuel Tank Sender Unit

Gear Selector Illumination

Glass Break Sensor

Handbrake Switch

Head/Side Lamp - LH Front

Head/Side Lamp - RH Front

Heated Backlight (Volante)

Heated Backlight (Voiante)

Heated Oxygen Sensor

1

-1

Heated Oxygen Sensor

1

-2

Heated Oxygen Sensor 2-1

Heated Oxygen Sensor 2-2

Heated Washer Jet LH

Heated Washer Jet RH

High Level Stop Lamp

Hood Control Module (Volante Roof)

Hood Motor (Volante Roof)

Horn - LH

Horn - RH

Idle Speed Control Valve (Eng Sub-harness)

Ignition Coil Pack (EDIS)

Ignition Switch

Indicator/Side Lamp - LH Front

Indicator/Side Lamp - RH Front

Inertia Switch

Injector 1

Injector 2

Injector 3

Injector 4

Injector 5

Injector 6

Instrument Pack

Instrument Panel Illumination Control

Instrument Panel Illumination Dimmer Switch

Interior Light - Rear LH

6-44

Component

Location

11-10

n-4

11-11

11-12

11-12

11-7

11-8

3-5

3-9

2-1

1-6

2-7

11-1

11-2

12-3

12-2

12-10

12-7

12-9

12-8

12-6

12-5

7-8

7-5

12-1

12-4

12-11

12-11

2-5

2-5

8-2

8-2

13-3

13-3

13-7

8-4

13-6

1-7

1-7

3-8

3-9

14-5

14-2

14-2

6-9

13-2

13-2

13-2

13-2

13-2

13-2

13-5

7-4

13-8

14-9

fEB^-^?

Circuit

Reference

22-A2

21-A3

22-A5

21-C5

22-C5

21-D2

22-D2

5-C4

5-A5

5-D2

11-C3

3-D2

3-B1

3-C1

1-A1

1-C1

15-A2

16-A5

16-A6

15-C3

16-B4

13-C4

14-C6

14-C5

1-D2

1-A2

15-D3

16-A2

6-D4

14-A6

6-D4

14-A6

5-D3

5-D4

15-82

18-D4

19-B6

1-A3

1-A3

5-C3

5-A5

9-D4

1-C1

1-A1

12-C5

5-B2

5-B2

5-B2

5-B3

5-B4

5-B4

9-A/B5/6

8-C5

9-C4

15-C3

September 1996

Page 224 of 421

Electrics

Seat Belt Pretensioner ^?

060C Warning Lamp Short Circuit

060C will be logged if the nnonitor current flow

through the SRS/Airbag warning lamp is excessive.

The warning lamp circuit is normally at 12 volts and

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

If either control module connector is displaced and

the ignition is switched on, the warning lamp will

be illuminated via the ground shorting link between

pins!

and 2 ofthe pretensioner controller connector

or pins 4 and 5 of the airbag controller connector,

both control modules must be checked for the

appropriate DTC to isolate which circuit is at fault.

Procedure

1.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060C code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

If fault code 060C is not logged, go to the diagnostics

section of the airbag system.

2.

Check the security of the pretensioner control

module connector.

If the connector is secure, go to step 3.

If the connector isdisplaced,resecu re theconnector.

Clear all logged DTCs and retest the vehicle to

ensure that the problem is resolved.

3. Access the SRS/Airbag warning lamp and check the

lamp resistance.

If the resistance is approximately

120£2,

the lamp is

good.

Refit the lamp and go to step 4.

If the resistance of the lamp is significantly less than

approximately 120^, fit a new lamp and refit the

instrument panel. Clear the logged DTCs from the

pretensioner control module and retest the vehicle

to ensure that the problem is resolved.

4.

If the checks in step 3 are good, the low circuit

resistance must be in the instrument pack or in the

control module. Replace the pretensioner control

module and reconnect all components.

6. Switch on the ignition and then test the vehicle.

If the 060C code is logged again, replace the

instrument pack.

060D Warning lamp open circuit

060D will be logged if the monitor current flow

through the SRS/Airbag warning lamp is below the

normal monitor level.

The warning lampcircuit is normally at 12 voltsand

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

Procedure

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060D code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

lffaultcode060D is not

logged,

gotothediagnostics

section of the airbag system.

Switch off the ignition. Access the SRS/Airbag

warning lamp and check the lamp resistance. The

resistance should be approximately 120Q.

If the resistance is 120i2, go to step 3.

If the lamp resistance is significantly lower than

120^2,

replace the lamp. Retest the vehicle to

ensure that the problem is resolved.

Wait 10 minutes after switching off the ignition to

ensure that the pretensioner firing capacitors have

fully discharged.

Disconnect the pretensioner control module and

temporarily cheat the warning lamp shorting link.

Note: The control module harness connector has a

shorting link which short circuits the warning lamp line

(pin 2)to ground

(pin

Dwhen

the

connector

is

displaced.

Carefully insert a suitable non-metallic cheater to remove

the

short

circuit

between

pins

1

and 2 before continuing

with fault

diagnosis.

ooooooooooooo o o poo

i^i

^ ^ ^ 1^1

Insert cheater hare

6-108

September

1996

Page 229 of 421

O" D^?

Body and Trim

Contents

Contents

Body and Trim

Body Repair

Potential Risks

Precautions

General Repair Notes

Steel Body Parts - Repair, Remove and Replace

RTM Body Parts

Body Panel and Trim Removal

Front Apron

Front Undertray

Wheel Arch Liners

Side Sills (top fixings)

Side Sills (bottom fixings)

Rear Bumper

Doors

Door Liners

Door Liner (components)

Steering Wheel

Column Switches

Instrument Panel (surround)

Instrument Panel

Facia Underscuttles

Glove Box

Facia Mountings (1)

Facia Mountings (2)

Console Instruments

Radio

Front Seats

Ashtray

Centre Console

Seat ECU Covers

Rear Console

Rear Seats and C Post Trim

Quarter Panels, B Post Panels, Parcel Shelf

Headlining

Roof System Description and Repair Procedures

Vol ante Roof

Roof and Rear Quarter Light Control

Roof Component Location

Roof Control System

9.0.02.1

Roof Removal/Replacement

9.0.02.3

Roof Hydrailic Control System

9.0.02.5

Bleeding the Roof Hydraulic System

9.1.01.1

Rear Quarter Window Renewal

9.1.01.2

Rear Quarter Glass Adjustment

9.1.01.4

Rear Quarter Window Lift Motor - LH

9.1.01.5

Rear Quarter Window Lift Motor - RH

Roof Sealing and Wind Noise

9.2.01.5

'A' Post/Header Sealing and Lock Adj

9.2.01.6

Roof Seals - Adjustment

9.2.01.7

Cheater Plate Seals - Adjust/Renew

9.2.01.8

Door Glass Adjustment

Alcantara Cleaning

7-1

7-2

7-2

7-3

7-3

7-4

7-5

7-6

Sheet 1

Sheet 2

Sheet 3

Sheet 4

Sheet 5

Sheet 6

Sheet 7

Sheet 8

Sheet 9

Sheet 10

Sheet 11

Sheet 12

Sheet 13

Sheet 14

Sheet 15

Sheet 16

Sheet 17

Sheet 18

Sheet 19

Sheet 20

Sheet 21

Sheet 22

Sheet 23

Sheet 24

Sheet 25

Sheet 26

Sheet 27

7-7

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-17

7-18

7-19

7-20

7-21

May 1996 7-1

Page 234 of 421

Body and Trim

Body Panel and Trim Removal 5^7

Body Panel and Trim Removal

The following diagrams show the fixings for all

removeable body and trim panels.

Sheet 1. Front Apron

Sheet 2. Front Undertray

Sheet 3. Wheel Arch Liners

Sheet 4. Side Sills (top fixings)

Sheets. Side Sills (bottom fixings)

Sheet 6. Rear Bumper

Sheet 7. Doors

Sheet 8. Door Liners

Sheet 9. Door Liner (components)

Sheet 10. Steering Wheel

Sheet 11. Column Switches

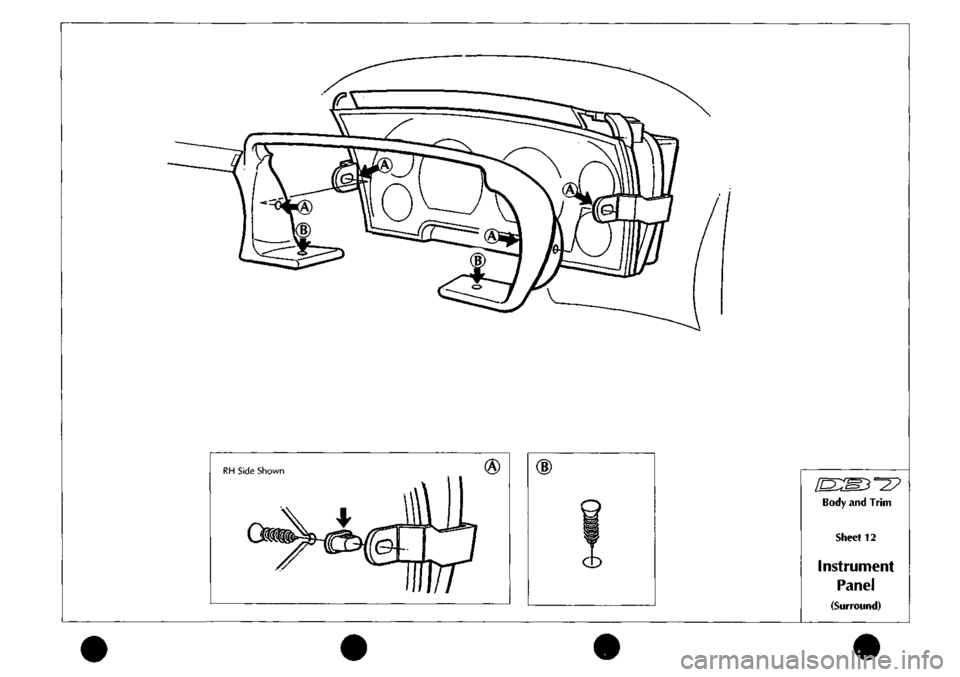

Sheet 12. Instrument Panel (surround)

Sheet 13. Instrument Panel

Sheet 14. Facia Underscuttles

Sheet 15. Glove Box

Sheet 16. Facia Mountings (1)

Sheet

1

7. Facia Mountings (2)

Sheet 18. Console Instruments

Sheet 19. Radio

Sheet 20. Front Seats

Sheet

21.

Ashtray

Sheet 22. Centre Console

Sheet 23. Seat ECU Covers

Sheet 24. Rear Console

Sheet 25. Rear Seats and C Post Trim

Sheet 26. Quarter Panels, B Post Panels, Parcel Shelf

Sheet 27. Headlining

7-6 May 1996

Page 246 of 421

Body

and

Trim

Sheet

12

Instrument

Panel

(Surround)

Page 332 of 421

^2?

Air Conditioning Repair Procedures

Hose - Compressor to Evaporator/Air-Con Unit Renew

8.1.06.1 Hose-Compressor

to

Evaporator

Renewal

Procedure

1.

Open the bonnet and fit a wing cover.

2.

Depressurise the air conditioning systenn.

3. Remove the hose to evaporator valve clamping

plate,

disconnect the hose from the valve, remove

and discard the 'O' ring

seal.

4.

Fit a blanking plug to the evaporator valve. Release

the evaporator hose securing clips.

5. Remove the compressor outlet port retaining bolt.

6. Disconnect the hose from the compressor, discard

the hose complete with 'O' ring seals.

7. Connect the hose to the evaporator valve and

tighten clamp onto the hose.

8. Route the hose to the compressor, fit a new 'O' ring

seal and connect it to the compressor.

9. Position the outlet port retaining plate on the

compressor, fit and tighten the securing bolt.

10.

Refit the hose to the clips.

11.

Charge the air conditioning system.

12.

Remove the wing cover and close the bonnet.

8.2.01.1 Air Conditioning Unit Renewal

1.

Disconnect the battery earth

lead.

2.

Drain the engine coolant into a suitable container.

3. Depressurise the air conditioning system.

4.

Disconnect the high and low pressure hoses and

expansion valve from the air conditioning unit (see

expansion valve renewal).

5. Slacken the coolant hose to the heater matrix pipe

securing clips and disconnect the hoses from the

matrix. (This will require the removal of the air

intake hose for access.)

6. Remove the following items from inside the car:

front seats

underscuttle panels/knee bolsters

glove box assembly

facia trim (walnut trim)

radio and ashtray

centre console switch panel assembly

instrument panel and surround trim

steering wheel and column

facia assembly complete

hoses - distribution box to door vents

facia support frame

Details and drawings of the above operations can

be found in the electrical and trim sections.

Disconnect the vacuum hoses from the blower

motors, water valve and reservoir.

Un-clip the electrical harness from the air

conditioningunit, release theelectrical connections

and reposition the harness to allow removal of the

unit.

Displace and remove the footwell ventilator ducts

and hoses (Fig. 1-1).

May 1996 8-55

Page 336 of 421

'nzm^=2?

Air Conditioning Repair Procedures

Blower Motor Renewal

8.2.07.1 Ambient Temperature Sensor

Renew

?\gure

1.

The ambient temperature sensor is located in the

left hand side of the air plenum chamber under the

lower windshield panel (Fig. 1-1).

Procedure

1.

Disconnect the battery earth

lead.

2.

(On left hand cars) Remove the steering wheel

(mark the position on the column shaft for re

assembly), instrument pack and surround

trim.

2.

(On right hand cars) Removethegloveboxlidand

liner.

3. Disconnect the hose from the distribution box to

the side vent outlet. Reposition the hose for access.

4.

Disconnect the sensor block connector.

The sensor has locating clips and is a push fit into

the plenum chamber.

5. Lever the sensor free.

8.2.08.1 Blower Motor Driver Side

Renewal

8.2.09.1 Blower Motor Passenger Side

Renewal

1.

Move seat

fu 1

ly rearward.

2.

Disconnect vehicle battery ground

lead.

3. Remove the under scuttle/knee pad bolster.

4.

Remove the lower brace bar/facia assembly

underscuttle knee pad.

Driver Side Only

5. Removetheinstrumentpack, bonnetreieasehandle

mounting bracket and steering column..

6. Disconnect the air hose from the facia side air

outlet.

Passenger Side Only

7. Remove the glove box lid and liner.

Both

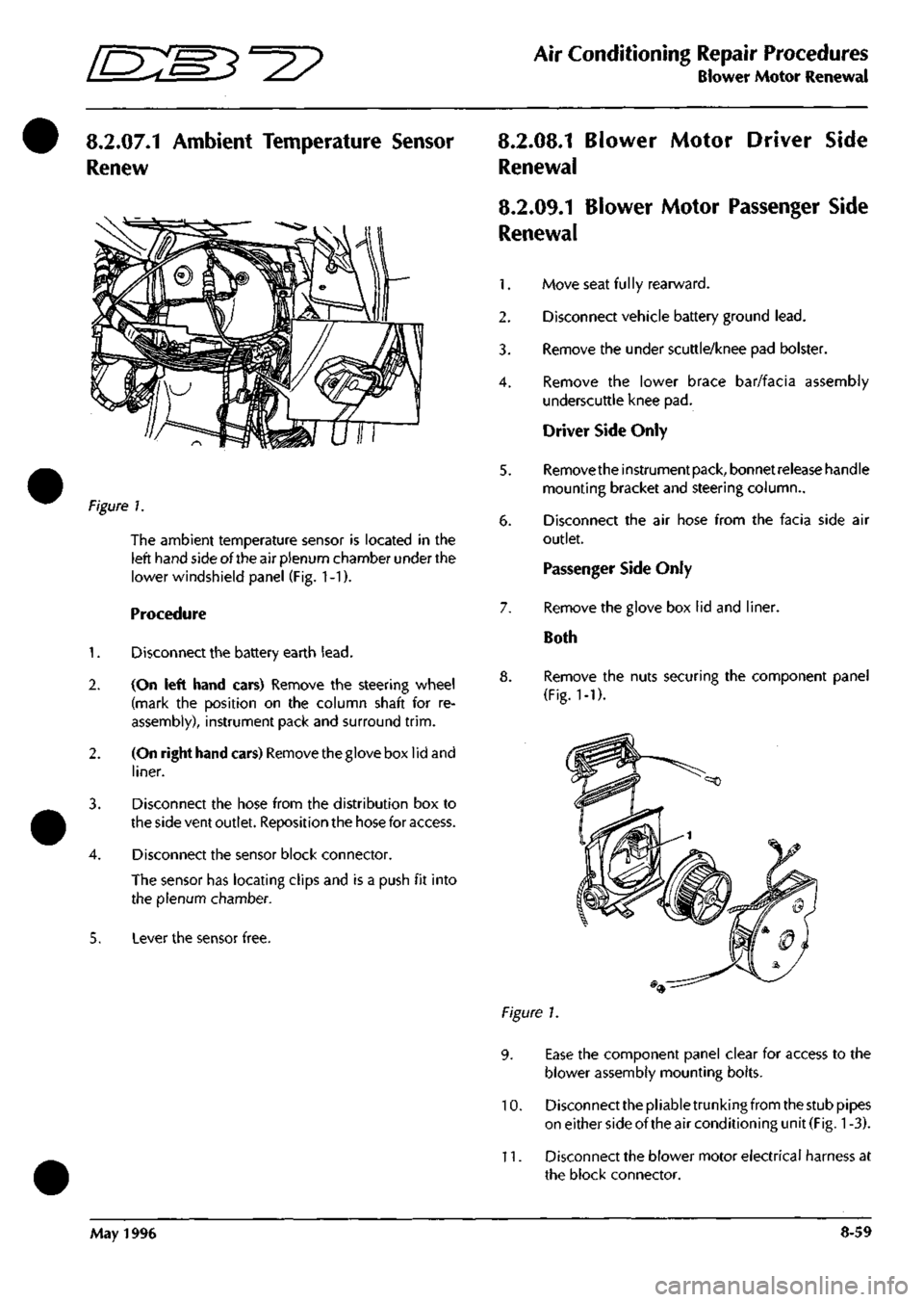

8. Remove the nuts securing the component panel

(Fig.

1-1).

Figure 1.

9. Ease the component panel clear for access to the

blower assembly mounting bolts.

10.

Disconnect the pliable trunking from the stub pipes

on either side of the air conditioning unit

(Fig.

1

-3).

11.

Disconnect the blower motor electrical harness at

the block connector.

May 1996 8-59