relays ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 29 of 421

[n:m3^y

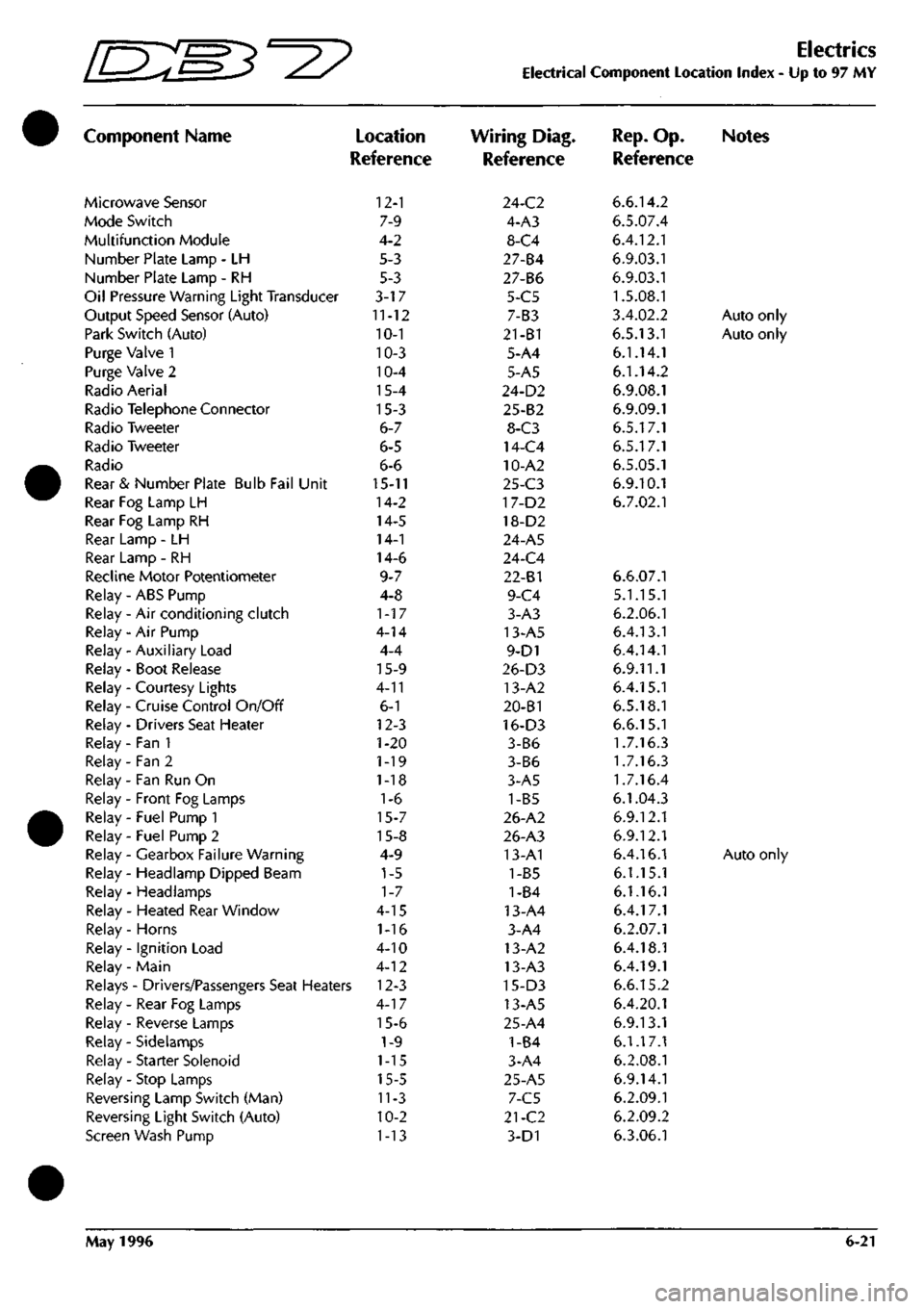

Component Name

Microwave Sensor

Mode Switch

Multifunction Module

Number Plate Lamp - LH

Number Plate Lamp - RH

Oil Pressure Warning Light Transducer

Output Speed Sensor (Auto)

Park Switch (Auto)

Purge Valve 1

Purge Valve 2

Radio Aerial

Radio Telephone Connector

Radio Tweeter

Radio Tweeter

Radio

Rear & Number Plate Bulb Fail Unit

Rear Fog Lamp LH

Rear Fog Lamp RH

Rear Lamp - LH

Rear Lamp - RH

Recline Motor Potentiometer

Relay - ABS Pump

Relay - Air conditioning clutch

Relay - Air Pump

Relay - Auxiliary Load

Relay - Boot Release

Relay - Courtesy Lights

Relay - Cruise Control On/Off

Relay - Drivers Seat Heater

Relay - Fan 1

Relay - Fan 2

Relay - Fan Run On

Relay - Front Fog Lamps

Relay - Fuel Pump 1

Relay - Fuel Pump 2

Relay - Gearbox Failure Warning

Relay - Headlamp Dipped Beam

Relay - Headlamps

Relay - Heated Rear Window

Relay - Horns

Relay - Ignition Load

Relay - Main

)

Location

Reference

12-1

7-9

4-2

5-3

5-3

3-17

11-12

10-1

10-3

10-4

15-4

15-3

6-7

6-5

6-6

15-11

14-2

14-5

14-1

14-6

9-7

4-8

1-17

4-14

4-4

15-9

4-11

6-1

12-3

1-20

1-19

1-18

1-6

15-7

15-8

4-9

1-5

1-7

4-15

1-16

4-10

4-12

Relays - Drivers/Passengers Seat Heaters 12-3

Relay - Rear Fog Lamps

Relay - Reverse Lamps

Relay - Sidelamps

Relay - Starter Solenoid

Relay - Stop Lamps

Reversing Lamp Switch (Man)

Reversing Light Switch (Auto)

Screen Wash Pump

4-17

15-6

1-9

1-15

15-5

11-3

10-2

1-13

Electrics

Electrical Component Location Index - Up to 97 MY

Wiring Diag.

Reference

24-C2

4-A3

8-C4

27-84

27-B6

5-C5

7-B3

21-B1

5-A4

5-A5

24-D2

25-B2

8-C3

14-C4

10-A2

25-C3

17-D2

18-D2

24-A5

24-C4

22-81

9-C4

3-A3

13-A5

9-D1

26-D3

13-A2

20-B1

16-D3

3-B6

3-B6

3-A5

1-B5

26-A2

26-A3

13-A1

1-B5

1-84

13-A4

3-A4

13-A2

13-A3

15-D3

13-A5

25-A4

1-B4

3-A4

25-A5

7-C5

21-C2

3-D1

Rep.

Op. Notes

Reference

6.6.14.2

6.5.07.4

6.4.12.1

6.9.03.1

6.9.03.1

1.5.08.1

3.4.02.2

Auto only

6.5.13.1

Auto only

6.1.14.1

6.1.14.2

6.9.08.1

6.9.09.1

6.5.17.1

6.5.17.1

6.5.05.1

6.9.10.1

6.7.02.1

6.6.07.1

5.1.15.1

6.2.06.1

6.4.13.1

6.4.14.1

6.9.11.1

6.4.15.1

6.5.18.1

6.6.15.1

1.7.16.3

1.7.16.3

1.7.16.4

6.1.04.3

6.9.12.1

6.9.12.1

6.4.16.1

Auto only

6.1.15.1

6.1.16.1

6.4.17.1

6.2.07.1

6.4.18.1

6.4.19.1

6.6.15.2

6.4.20.1

6.9.13.1

6.1.17.1

6.2.08.1

6.9.14.1

6.2.09.1

6.2.09.2

6.3.06.1

May 1996 6-21

Page 131 of 421

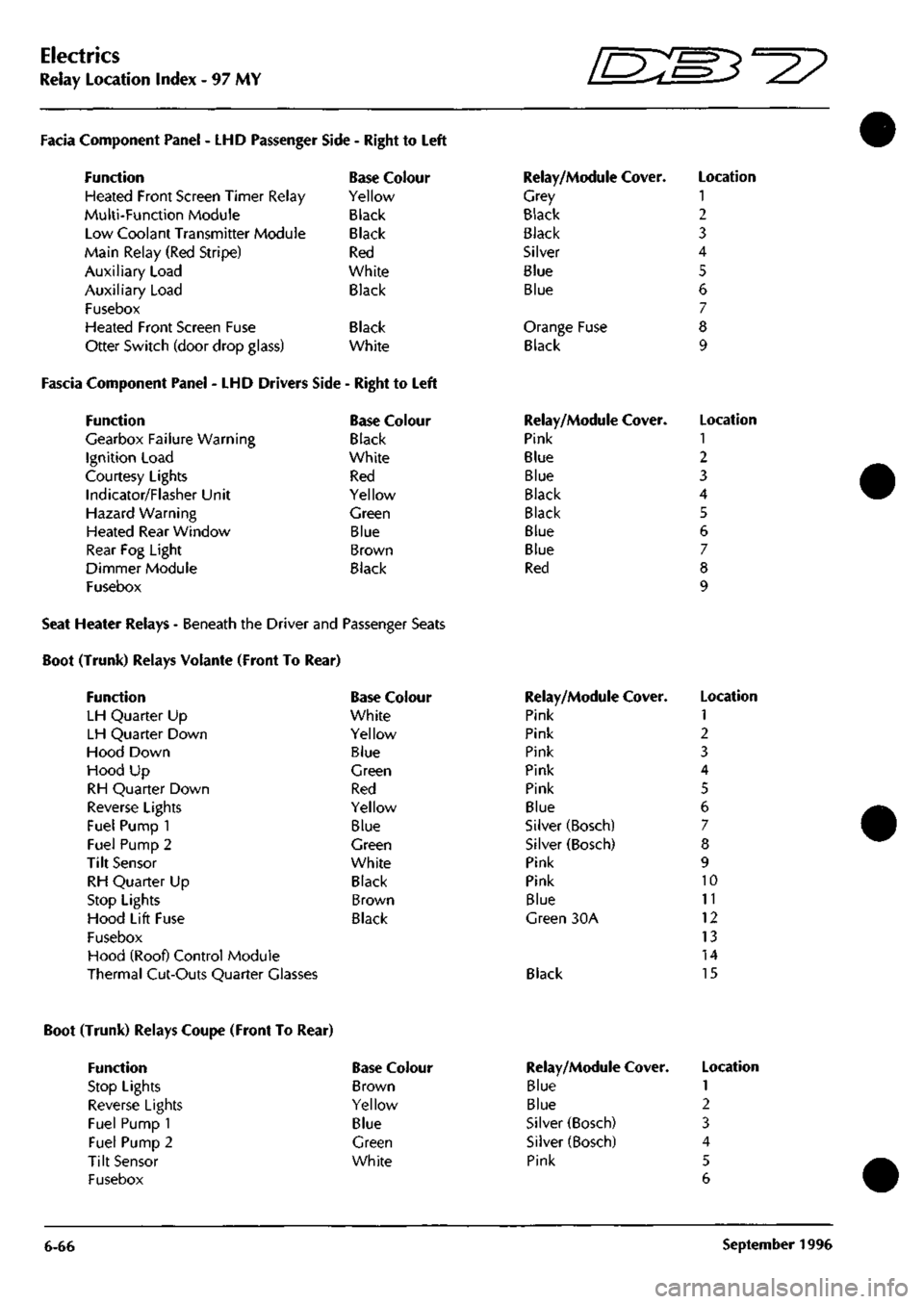

Electrics

Relay Location Index - 97 MY

D^^

Facia Component Panel

- LHD

Passenger

Function

Heated Front Screen Timer Relay

Multi-Function Module

Low Coolant Transmitter Module

Main Relay (Red Stripe)

Auxiliary Load

Auxiliary Load

Fusebox

Heated Front Screen Fuse

Otter Switch (door drop glass)

Side

-

Right

to

Left

Base Colour

Yellow

Black

Black

Red

White

Black

Black

White

Fascia Component Panel

- LHD

Drivers Side

-

Right

to

Left

Function

Gearbox Failure Warning

Ignition Load

Courtesy Lights

Indicator/Flasher Unit

Hazard Warning

Heated Rear Window

Rear

Fog

Light

Dimmer Module

Fusebox

Base Colour

Black

White

Red

Yellow

Green

Blue

Brown

Black

Relay/Module Cover.

Grey

Black

Black

Silver

Blue

Blue

Orange Fuse

Black

Relay/Module Cover.

Pink

Blue

Blue

Black

Black

Blue

Blue

Red

Location

1

2

3

4

5

6

7

8

9

Location

1

2

3

4

5

6

7

8

9

Seat Heater Relays - Beneath the Driver and Passenger Seats

Boot (Trunk) Relays Volante (Front To Rear)

Function

LH Quarter

Up

LH Quarter Down

Hood Down

Hood

Up

RH Quarter Down

Reverse Lights

Fuel Pump

1

Fuel Pump

2

Tilt Sensor

RH Quarter

Up

Stop Lights

Hood Lift Fuse

Fusebox

Hood (Roof) Control Module

Thermal Cut-Outs Quarter Glasses

Base Colour

White

Yellow

Blue

Green

Red

Yellow

Blue

Green

White

Black

Brown

Black

Relay/Module Cover.

Pink

Pink

Pink

Pink

Pink

Blue

Silver (Bosch)

Silver (Bosch)

Pink

Pink

Blue

Green

30A

Black

Location

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Boot (Trunk) Relays Coupe (Front To Rear)

Function

Stop Lights

Reverse Lights

Fuel Pump 1

Fuel Pump 2

Tilt Sensor

Fusebox

Base Colour

Brown

Yellow

Blue

Green

White

6-66

Relay/Module

Blue

Blue

Silver (Bosch)

Silver (Bosch)

Pink

Cover. Location

1

2

3

4

5

6

September

1996

Page 262 of 421

y/--^^^^3^

'—-p "^ Body and Trim

Roof Description

Volante Roof

Description

The system comprises an electrically driven hydraulic pump and two hydraulic rams for raising and lowering the

roof.

The pump is powered via two heavy duty changeover relays. Two further pairs of changeover relays power

the rear quarter windows (one pair for each window). The roof hydraulic pump is protected by a 30A fuse, the

windows by circuit breakers.

An electronic control module (ECM) is actuated by the roof switch on the centre console. The ECM controls the

operation of

both

the roof

and

rear quarter window circuits

so

that they can only be operated in

a

pre-programmed

manned.

When in operation, the ECM provides signals to the roof and to the rear quarter windows.

When the roof

switch

is moved into the open (Roof Down) position, the roof

and

rear windows move together until

approximately four seconds has elapsed. At this time, the ECM will remove power from the rear window circuits,

leaving the roof motor running. The roof motor will stop after 12 seconds (i.e. a further 8 seconds after the rear

window motors stop).

The signals will be removed from the rear window relay after 4 seconds and from the roof relay after 12 seconds

if the roof switch is held in either position for longer than 12 seconds.

In order to comply with legislation, the following features are built into the system:

If the roof switch is operated in either direction and then released before that operation is complete, the roof and

rear quarter windows will stop immediately. If, whilst the system is in operation, the ignition switch

is

turned to the

off position, the system will immediately stop.

If the roof switch is pressed again after pausing during a roof movement, the timing sequence will be as follows:

1.

If the previous direction is selected, the timing recommences from where it left off and will continue to

completion. If the ignition has been turned off, the timing will start from the beginning of its cycle.

2.

If theoppositedirection

is

selected,

the timing sequence will commence

from the beginning

of the newly selected

direction and continue to completion.

Roof and Rear Quarter Light Control

The following diagrams show the component location and the electrical control for the roof and rear quarter light

systems.

May 1996 7-7

Page 287 of 421

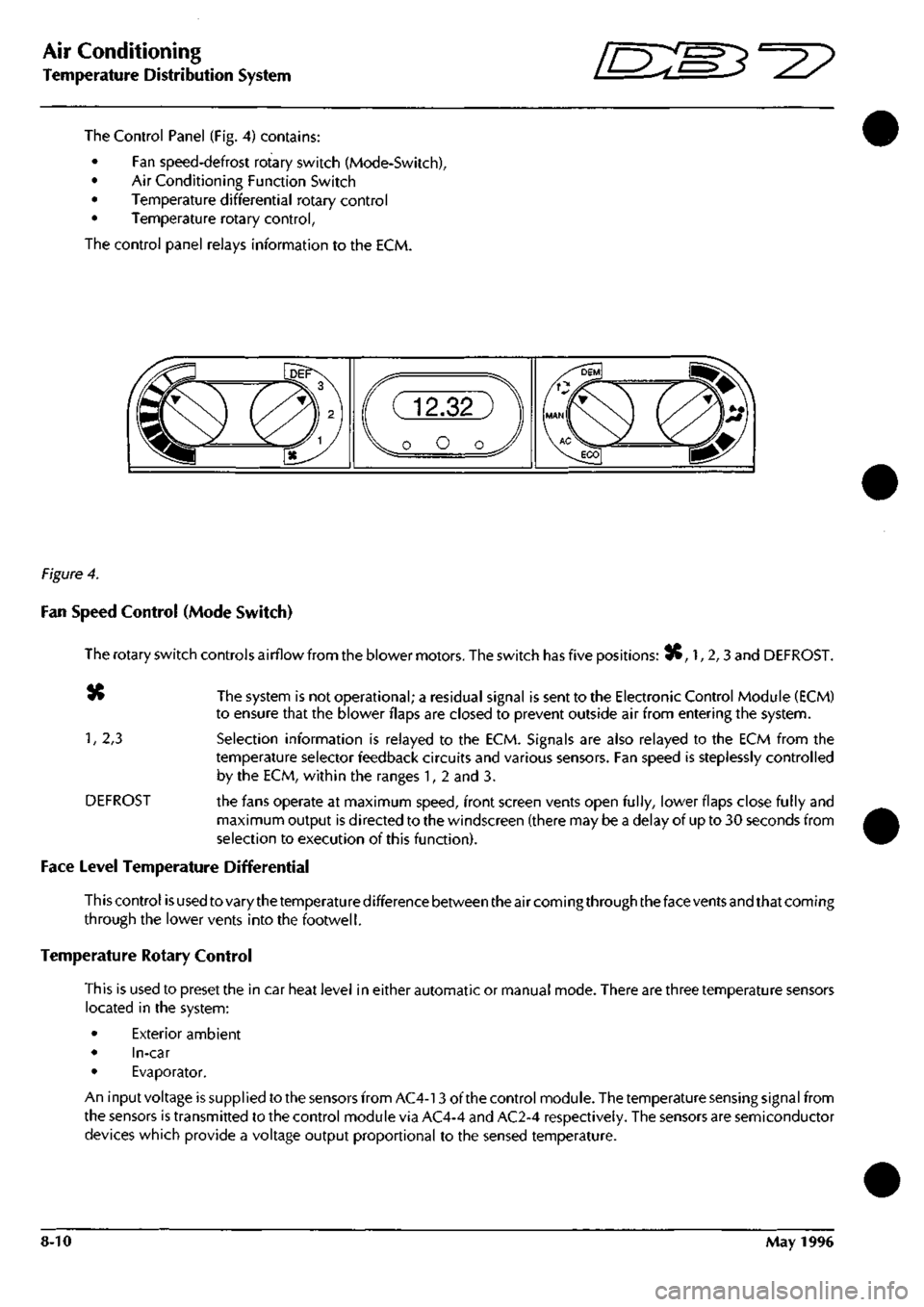

Air Conditioning

Temperature Distribution System

The Control Panel (Fig. 4) contains:

• Fan speed-defrost rotary switch (Mode-Switch),

• Air Conditioning Function Switch

• Temperature differential rotary control

• Temperature rotary control,

The control panel relays information to the ECM.

Figure 4.

Fan Speed Control (Mode Switch)

The rotary switch controls airflow from the blower motors. The switch has five positions: 3C, 1, 2,3 and DEFROST.

«» The system is not operational; a residual signal is sent to the Electronic Control Module (ECM)

to ensure that the blower flaps are closed to prevent outside air from entering the system.

1,

2,3 Selection information is relayed to the ECM. Signals are also relayed to the ECM from the

temperature selector feedback circuits and various sensors. Fan speed is steplessly controlled

by the ECM, within the ranges 1, 2 and 3.

DEFROST the fans operate at maximum speed, front screen vents open fully, lower flaps close fully and

maximum output is directed to the windscreen (there may be a delay of up to 30 seconds from

selection to execution of this function).

Face Level Temperature Differential

This control is used to vary the temperature difference between the air coming through the face vents and that coming

through the lower vents into the footwell.

Temperature Rotary Control

This is used to preset the in car heat level in either automatic or manual mode. There are three temperature sensors

located in the system:

• Exterior ambient

• In-car

• Evaporator.

An input voltage is supplied to the sensors from AC4-13 of the control module. The temperature sensing signal from

the sensors is transmitted to the control module via AC4-4 and AC2-4 respectively. The sensors are semiconductor

devices which provide a voltage output proportional to the sensed temperature.

8-10 May 1996

Page 297 of 421

Air Conditioning

Electronic Control Module r^^?

Description

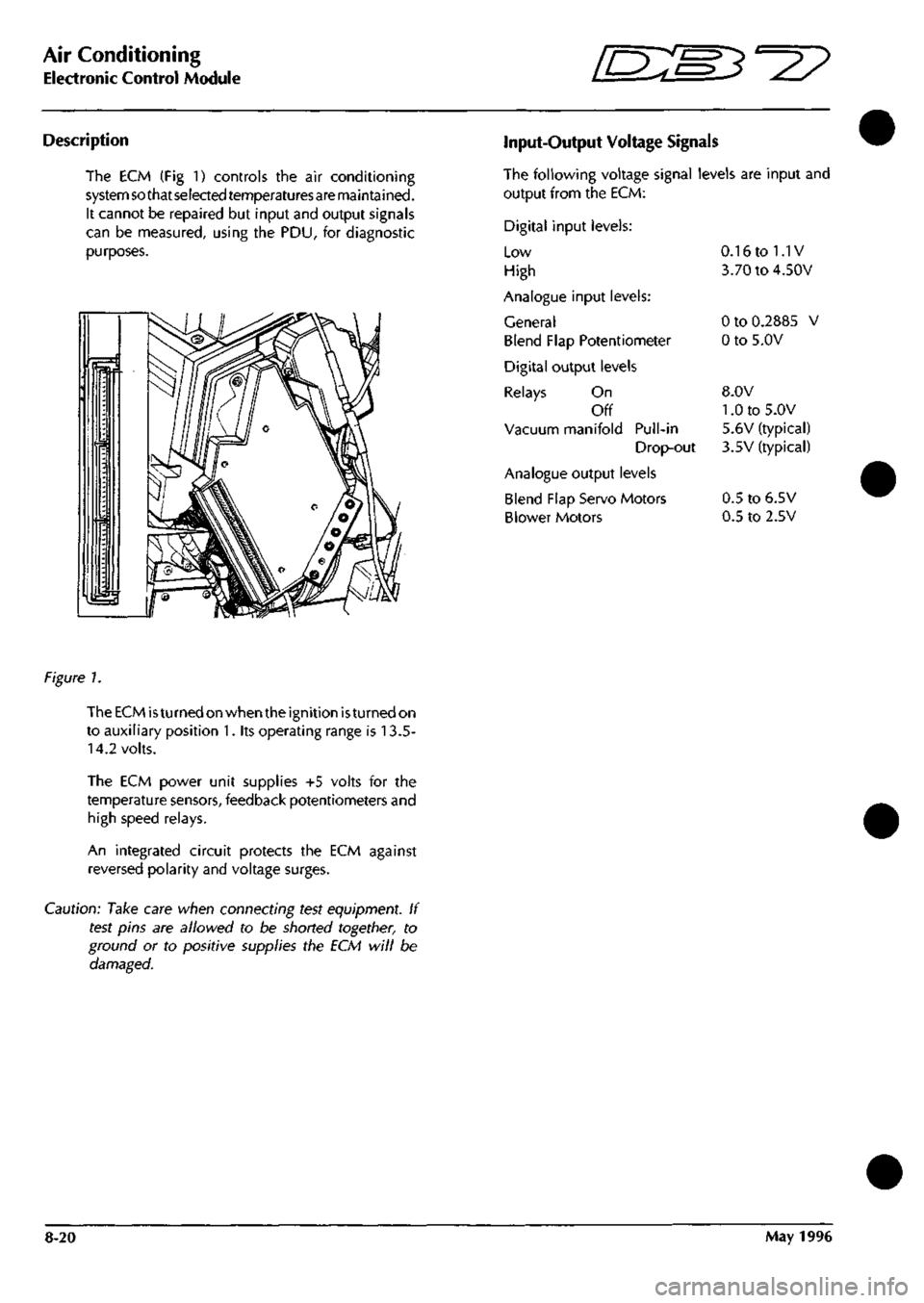

The ECM (Fig 1) controls the air conditioning

system so that selected temperaturesare maintained.

It cannot be repaired but input and output signals

can be measured, using the PDU, for diagnostic

purposes.

Input-Output Voltage Signals

The following voltage signal levels are input and

output from the ECM:

Digital input levels:

Low

High

Analogue input levels:

General

Blend Flap Potentiometer

Digital output levels

Relays On

Off

Vacuum manifold Pull-in

Drop-out

Analogue output levels

Blend Flap Servo Motors

Blower Motors

0.16 to 1.1V

3.70 to 4.50V

0 to 0.2885 V

0 to 5.0V

8.0V

1.0 to 5.0V

5.6V (typical)

3.5V (typical)

0.5 to 6.5V

0.5 to 2.5V

figure 1.

The ECM

is

turned on when the ignition

is

turned on

to auxiliary position 1. its operating range is 13.5-

14.2 volts.

The ECM power unit supplies +5 volts for the

temperature sensors, feedback potentiometers and

high speed relays.

An integrated circuit protects the ECM against

reversed polarity and voltage surges.

Caution: Take care when connecting test equipment. If

test pins are allowed to be shorted together, to

ground or to positive supplies the ECM will be

damaged.

8-20 May 1996

Page 308 of 421

"3^2?

Air Conditioning

System Fault Diagnosis

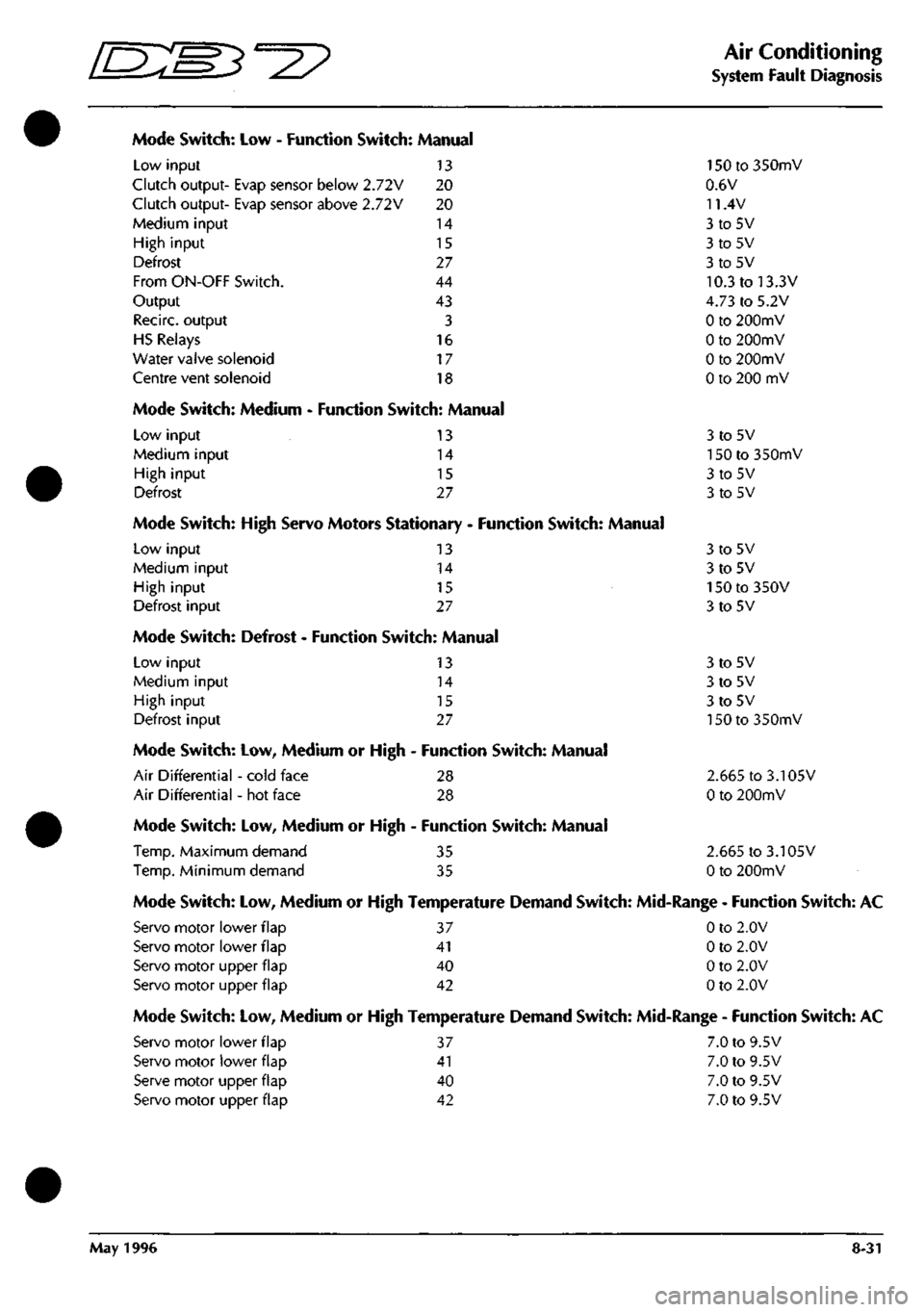

Mode Switch: Low - Function Switch: Manual

Low input 13

Clutch output- Evap sensor below 2.72V 20

Clutch output- Evap sensor above 2.72V 20

Medium input 14

High input 15

Defrost 27

From ON-OFF Switch. 44

Output 43

Recirc. output 3

HS Relays 16

Water valve solenoid 17

Centre vent solenoid 18

Mode Switch: Medium - Function Switch: Manual

Low input

Medium input

High input

Defrost

13

14

15

27

Mode Switch: High Servo Motors Stationary - Function Switch: Manual

Low input 13

Medium input 14

High input 15

Defrost input 27

Mode Switch: Defrost - Function Switch: Manual

Low input

Medium input

High input

Defrost input

13

14

15

27

Mode Switch: Low, Medium or High - Function Switch: Manual

Air Differential - cold face 28

Air Differential - hot face 28

Mode Switch: Low, Medium or High - Function Switch: Manual

Temp.

Maximum demand 35

Temp.

Minimum demand 35

150 to 350mV

0.6V

11.4V

3to5V

3to5V

3to5V

10.3 to 13.3V

4.73 to 5.2V

0 to 200mV

0 to 200mV

0 to 200mV

0 to 200 mV

3to5V

150 to 350mV

3to5V

3to5V

3to5V

3to5V

150 to 350V

3to5V

3to5V

3to5V

3to5V

150 to 350mV

2.665 to 3.105V

0 to 200mV

2.665 to 3.105V

0 to 200mV

Mode Switch: Low, Medium or High Temperature Demand Switch: Mid-Range - Function Switch: AC

Servo motor lower flap 37 0 to 2.0V

Servo motor lower flap 41 0 to 2.0V

Servo motor upper flap 40 0 to 2.0V

Servo motor upper flap 42 0 to 2.0V

Mode Switch: Low, Medium or High Temperature Demand Switch: Mid-Range - Function Switch: AC

Servo motor lower flap 37 7.0 to 9.5V

Servo motor lower flap 41 7.0 to 9.5V

Serve motor upper flap 40 7.0 to 9.5V

Servo motor upper flap 42 7.0 to 9.5V

May 1996 8-31

Page 309 of 421

Air Conditioning

System Fault Diagnosis D^

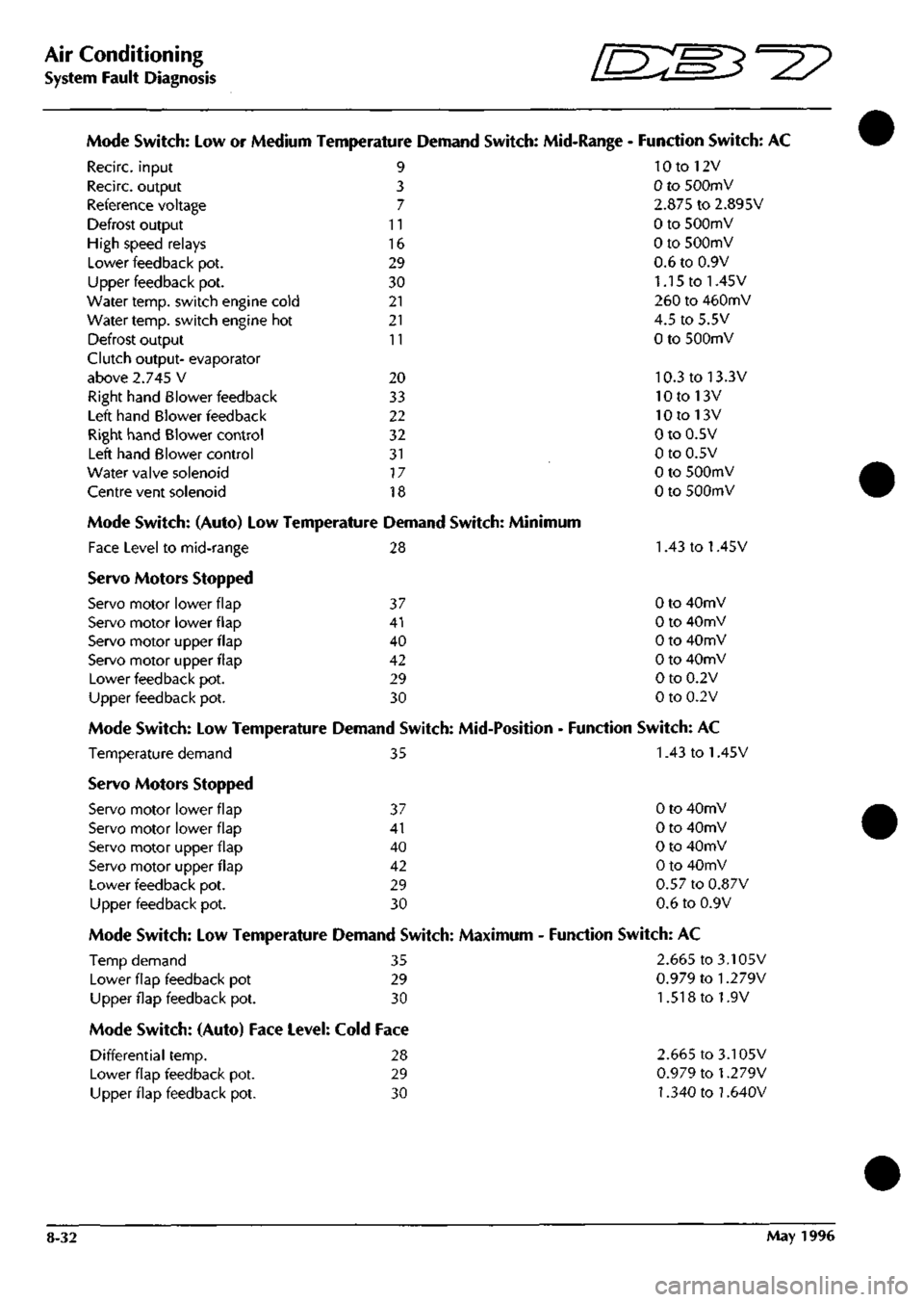

Mode Switch: Low or Medium Temperature Demand Switch: Mid-Range - Function Switch: AC

10 to 12V

0 to SOOmV

2.875 to 2.895V

0 to 500mV

0 to 500mV

0.6 to 0.9V

1.15 to 1.45V

260 to 460mV

4.5 to 5.5V

0 to 500mV

10.3 to 13.3V

10 to 13V

10 to 13V

0 to 0.5V

0 to 0.5V

0 to 500mV

0 to SOOmV

Recirc. input

Recirc. output

Reference voltage

Defrost output

High speed relays

Lower feedback pot.

Upper feedback pot.

Water temp, switch engine cold

Water temp, switch engine hot

Defrost output

Clutch output- evaporator

above 2.745 V

Right hand Blower feedback

Left hand Blower feedback

Right hand Blower control

Left hand Blower control

Water valve solenoid

Centre vent solenoid

9

3

7

11

16

29

30

21

21

11

20

33

22

32

31

17

18

Mode Switch: (Auto) Low Temperature Demand Switch: Minimum

Face Level to mid-range 28 1.43 to 1.45V

Servo Motors Stopped

Servo motor lower flap 37 0 to 40mV

Servo motor lower flap 41 0 to 40mV

Servo motor upper flap 40 0 to 40mV

Servo motor upper flap 42 0 to 40mV

Lower feedback pot. 29 0 to 0.2V

Upper feedback pot. 30 0 to 0.2V

Mode Switch: Low Temperature Demand Switch: Mid-Position - Function Switch: AC

Temperature demand 35 1.43 to 1.45V

Servo Motors Stopped

Servo motor lower flap 37 0 to 40mV

Servo motor lower flap 41 0 to 40mV

Servo motor upper flap 40 0 to 40mV

Servo motor upper flap 42 0 to 40mV

Lower feedback pot. 29 0.57 to 0.87V

Upper feedback pot. 30 0.6 to 0.9V

Mode Switch: Low Temperature Demand Switch: Maximum - Function Switch: AC

Temp demand 35 2.665 to 3.105V

Lower flap feedback pot 29

Upper flap feedback pot. 30

0.979 to

1.279V

1.518 to 1.9V

Mode Switch: (Auto) Face Level: Cold Face

Differential temp. 28

Lower flap feedback pot. 29

Upper flap feedback pot. 30

2.665 to 3.105V

0.979 to

1.279V

1.340 to

1.640V

8-32 May 1996

Page 310 of 421

^7?

Air Conditioning

System Fault Diagnosis

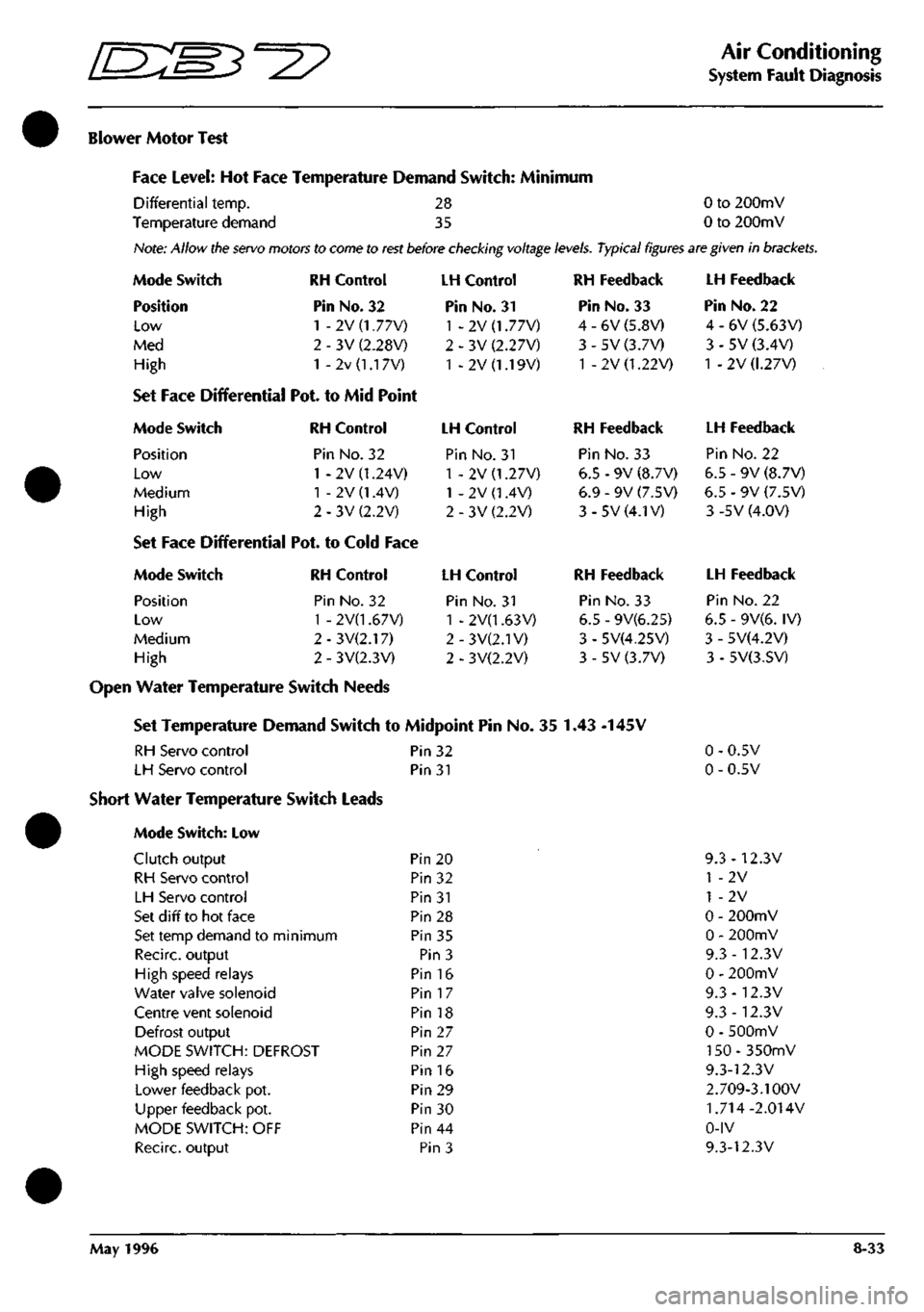

Blower Motor Test

Face Level: Hot Face Temperature Demand Switch: Minimum

Differential temp. 28 0 to 200mV

Temperature demand 35 0 to 200mV

Hote:

Allow

the servo motors

to

come to rest before checking voltage

levels.

Typical figures are given

in

brackets.

Mode Switch

Position

Low

Med

High

RH Control

Pin No. 32

1 - 2V (1.77V)

3V (2.28V)

2v

(1.1

7V)

Set Face Differential Pot. to Mid Point

Mode Switch RH Control

Position Pin No. 32

Low 1 - 2V (1.24V)

Medium 1 - 2V (1.4V)

High 2-3V(2.2V)

Set Face Differential Pot. to Cold Face

Mode Switch

Position

Low

Medium

High

RH Control

Pin No. 32

1 - 2V(1.67V)

2 - 3V(2.17)

2 - 3V(2.3V)

LH Control

Pin No. 31

1 -2V(1.77V)

2 - 3V (2.27V)

1 - 2V (1.19V)

LH Control

Pin No. 31

1 - 2V (1.27V)

1 - 2V (1.4V)

2 - 3V (2.2V)

LH Control

Pin No. 31

1 - 2V(1.63V)

2-3V(2.1V)

2 - 3V(2.2V)

RH Feedback

Pin No. 33

4 - 6V (5.8V)

3 - 5V (3.7V)

1 - 2V (1.22V)

RH Feedback

Pin No. 33

6.5 - 9V (8.7V)

6.9 - 9V (7.5V)

3-5V(4.1V)

RH Feedback

Pin No. 33

6.5 - 9V(6.25)

3 - 5V(4.25V)

3 - 5V (3.7V)

Open Water Temperature Switch Needs

Set Temperature Demand Switch to Midpoint Pin No. 35 1.43 -145V

RH Servo control Pin 32

LH Servo control Pin 31

Short Water Temperature Switch Leads

Mode Switch: Low

Clutch output

RH Servo control

LH Servo control

Set d iff to hot face

Set temp demand to minimum

Recirc. output

High speed relays

Water valve solenoid

Centre vent solenoid

Defrost output

MODE SWITCH: DEFROST

High speed relays

Lower feedback pot.

Upper feedback pot.

MODE SWITCH: OFF

Recirc. output

Pin 20

Pin 32

Pin 31

Pin 28

Pin 35

Pin 3

Pin 16

Pin 17

Pin 18

Pin 27

Pin 27

Pin 16

Pin 29

Pin 30

Pin 44

Pin 3

LH Feedback

Pin No. 22

4 - 6V (5.63V)

3 - 5V (3.4V)

1 -2V (1.27V)

LH Feedback

Pin No. 22

6.5 - 9V (8.7V)

6.5 - 9V (7.5V)

3 -5V (4.0V)

LH Feedback

Pin No. 22

6.5 - 9V(6. IV)

3 - 5V(4.2V)

3 - 5V(3.SV)

0.5V

0.5V

9.3-12.3V

1 -2V

1 -2V

0 - 200mV

0 - 200mV

9.3-12.3V

0 - 200mV

9.3-12.3V

9.3-12.3V

0 - 500mV

150-350mV

9.3-12.3V

2.709-3.1 OOV

1.714-2.014V

0-IV

9.3-12.3V

May 1996 8-33