height ASTON MARTIN V8 VANTAGE 2010 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 433 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-7

8. Install caliper and Allen bolts (x2) and tighten.

9. Install ABS speed sensor, install and torque tighten.

10. Install sensor multiplug.

11. Install pad wear sensors.

12. Install track rod end to vertical link, install and torque tighten nut.

13. Install road wheel(s).

14. Pump brake pedal.

15. Lower vehicle on ramp.

16. 4 wheel alignment - check/adjust (see Workshop Manual procedure 04.00.AD 4 Wheel Alignment -

Check & Adjust).

Front Suspension Sensor Assembly-

Renew

Removal

1. Raise vehicle on ramp

2. Remove nut/bolt securing ride height sensor link to

lower suspension arm (see Figure 1).

3. Remove nut/Torx bolt, ride height sensor to subframe.

4. Disconnect ride heig ht sensor multiplug.

5. Remove bolts (x2) securing sensor to sensor bracket.

Installation

1. Align sensor to bracket and install bolts (x2).

2. Connect ride height sensor multiplug.

3. Position sensor to subframe, install and torque tighten nut/Torx bolt.

4. Align sensor link to lower suspension arm, install and torque tighten nut/bolt.

5. Lower vehicle on ramp.

Repair Operation Time (ROT)

Page 436 of 947

Rear Suspension (04.02)

Suspension (04.00)4-2-2 Workshop Manual May 2007

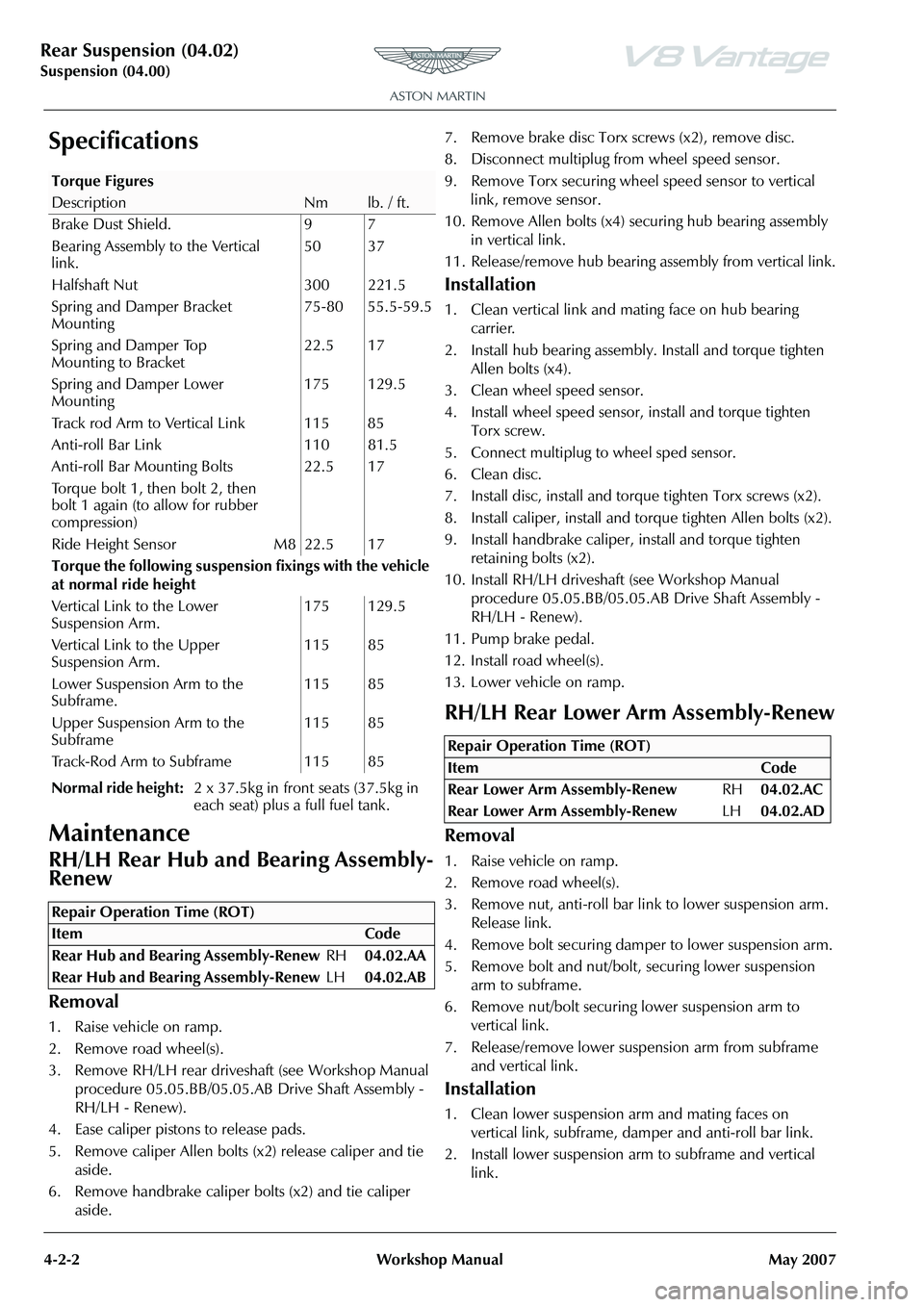

Specifications

Maintenance

RH/LH Rear Hub and Bearing Assembly-

Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove RH/LH rear drivesha ft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

4. Ease caliper pistons to release pads.

5. Remove caliper Allen bolts (x2) release caliper and tie aside.

6. Remove handbrake caliper bolts (x2) and tie caliper aside. 7. Remove brake disc Torx screws (x2), remove disc.

8. Disconnect multiplug fr

om wheel speed sensor.

9. Remove Torx securing wheel speed sensor to vertical link, remove sensor.

10. Remove Allen bolts (x4) se curing hub bearing assembly

in vertical link.

11. Release/remove hub bearing a ssembly from vertical link.

Installation

1. Clean vertical link and mating face on hub bearing

carrier.

2. Install hub bearing assembly. Install and torque tighten Allen bolts (x4).

3. Clean wheel speed sensor.

4. Install wheel speed sensor, install and torque tighten Torx screw.

5. Connect multiplug to wheel sped sensor.

6. Clean disc.

7. Install disc, install and torq ue tighten Torx screws (x2).

8. Install caliper, install and torque tighten Allen bolts (x2).

9. Install handbrake caliper, install and torque tighten

retaining bolts (x2).

10. Install RH/LH driveshaft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

11. Pump brake pedal.

12. Install road wheel(s).

13. Lower vehicle on ramp.

RH/LH Rear Lower Arm Assembly-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut, anti-roll bar li nk to lower suspension arm.

Release link.

4. Remove bolt securing damper to lower suspension arm.

5. Remove bolt and nut/bolt, securing lower suspension arm to subframe.

6. Remove nut/bolt securing lower suspension arm to

vertical link.

7. Release/remove lower suspension arm from subframe and vertical link.

Installation

1. Clean lower suspension arm and mating faces on vertical link, subframe, damper and anti-roll bar link.

2. Install lower suspension ar m to subframe and vertical

link.

Torque Figures

DescriptionNmlb. / ft.

Brake Dust Shield. 9 7

Bearing Assembly to the Vertical

link. 50 37

Halfshaft Nut 300 221.5

Spring and Damper Bracket

Mounting 75-80 55.5-59.5

Spring and Damper Top

Mounting to Bracket 22.5 17

Spring and Damper Lower

Mounting 175 129.5

Track rod Arm to Vertical Link 115 85

Anti-roll Bar Link 110 81.5

Anti-roll Bar Mounting Bolts

Torque bolt 1, then bolt 2, then

bolt 1 again (to allow for rubber

compression) 22.5 17

Ride Height Sensor M8 22.5 17

Torque the following suspensi on fixings with the vehicle

at normal ride height

Vertical Link to the Lower

Suspension Arm. 175 129.5

Vertical Link to the Upper

Suspension Arm. 115 85

Lower Suspension Arm to the

Subframe. 115 85

Upper Suspension Arm to the

Subframe 115 85

Track-Rod Arm to Subframe 115 85

Normal ride height: 2 x 37.5kg in front seats (37.5kg in

each seat) plus a full fuel tank.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Rear Lower Arm Assembly-Renew RH04.02.AC

Rear Lower Arm Assembly-Renew LH04.02.AD

Page 437 of 947

Rear Suspension (04.02)

Suspension (04.00)

May 2007 Workshop Manual 4-2-3

3. Install bolt and bolts/nuts (x2), lower suspension arm to subframe and vertical link. Do not torque tighten at this

stage.

4. Align damper to lower suspension arm, install bolt. Do not torque tighten at this stage.

5. Align anti-roll bar link to lower suspension arm, install

nut. Do not torque tighten at this stage.

6. Install road wheel(s).

7. Lower vehicle on ramp.

8. Torque tighten suspension nuts/bolts.

9. 4 wheel alignment - check/adjust (see Workshop Manual procedure 04.00.AD 4 Wheel Alignment -

Check and Adjust).

RH/LH Upper Rear Arm Assembly-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nuts/bolts (x2), upper suspension arm to subframe.

4. Remove nut/bolt securing upper suspension arm to vertical link.

5. Release and remove upper suspension arm assembly.

Installation

1. Clean upper suspension arm and mating faces on subframe and vertical link.

2. Install upper suspension arm in subframe.

3. Install bolts/nuts (x2), upper suspension arm to subframe. Do not torque tighten at this stage.

4. Install upper suspension arm in vertical link, install bolt/

nut. Do not torque tighten at this stage.

5. Install road wheel(s).

6. Lower vehicle on ramp.

7. Torque tighten nuts/bolts, upper suspension arm to vertical link and subframe.

RH/LH Toe Control Rear Arm Assembly-

Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Release ABS sensor harness clips (x2) from toe control arm.

4. Remove nut/bolt securing toe control arm to subframe.

5. Remove nut/bolt securing toe control arm to vertical link.

6. Release/remove toe control arm.

Installation

1. Clean toe control arm and mating faces on vertical link and subframe.

2. Install toe control arm in vertical link and subframe.

3. Install bolts/nuts (x2). toe control arm to vertical link and subframe. Do not torque tighten at this stage.

4. Install ABS sensor harness clips in toe control arm.

5. Install road wheel(s).

6. Lower vehicle on ramp.

7. 4 wheel alignment - check/adjust(see Workshop Manual procedure 04.00.AD 4 Whee l Alignment - Check and

Adjust).

Rear Anti-Roll Bar-Renew

Removal

1. Raise vehicle on ramp.

2. Remove rear undertray (see Workshop Manual procedure 01.02.PB Undertray - Rear - Renew).

3. Remove nuts (x2), anti-roll bar links to lower arms.

4. Remove bolts (x4), bush straps (x2), anti-roll bar to subframe.

5. Remove anti-roll bar. Note cut-off section at top.

6. Remove bushes (x2) from anti-roll bar.

7. Remove nuts (x2), washers (x2), remove links from anti- roll bar.

Caution

Final tightening of suspension components must be

carried out with the suspensi on arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum upward travel.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 438 of 947

Rear Suspension (04.02)

Suspension (04.00)4-2-4 Workshop Manual May 2007

Installation

1. Clean anti-roll bar, bushes, bush straps and links.

2. Install links (x2), to anti-roll bar. Install washers (x2) and nuts (x2). Do not torque tighten.

3. Install bushes (x2) on anti-roll bar.

4. Position anti-roll bar, align bushes (x2), install straps (x2), install bolts (x4). Do not torque tighten.

5. Position anti-roll bar drop links to lower arms, install

nuts (x2). Do not torque tighten.

6. Install rear undertray (see Workshop Manual procedure 01.02.PB Undertray - Rear - Renew).

7. Lower vehicle on ramp.

8. Torque tighten link nuts (x4).

9. Torque tighten bush strap bolts (x4).

Rear Pair-Anti-Roll Bar Bushing-Renew

Removal

1. Raise vehicle on ramp.

2. Remove rear undertray(see Workshop Manual procedure01.02.PB Undertray - Rear - Renew).

3. Remove bolts (x4) securing anti-roll bar bush straps (x2) to subframe.

4. Release/remove bush straps.

5. Remove bushes (x2) from anti-roll bar.

Installation

1. Clean anti-roll bar and bush straps.

2. Install bushes onto anti-roll bar.

3. Install bush straps (x2), install bolts (x4). Do not torque tighten at this stage.

4. Install rear undertray(see Workshop Manual procedure 01.02.PB Undertray - Rear - Renew).

5. Lower vehicle on ramp.

6. Torque tighten all suspension nuts/bolts.

RH/LH Rear Anti-Roll Bar Link-Renew

Removal

1. Raise vehicle on ramp.

1. Remove nut, collect wash er, link to anti-roll bar.

1. Remove nut, link to lower suspension arm. Remove link.

Installation

1. Clean link and mating faces on anti-roll bar and lower suspension arm.

2. Install link to anti-roll bar, install washer and nut. Do not

torque tighten at this stage.

3. Position link to lower suspension arm, install nut). Do not torque tighten at this stage.

4. Lower vehicle on ramp.

5. Torque tighten link nuts (x2).

RH/LH Rear Hub Vertical Link-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel/s

3. With assistance, remove rear hub nut.

4. Remove nut/bolt, securing toe rod to vertical link, release toe rod.

5. Disconnect ABS sensor multiplug.

6. Remove Torx screw securing ABS sensor, remove sensor

7. Ease caliper pistons to release pads.

8. Remove caliper Allen bolts (x2) release caliper and tie aside.

9. Remove handbrake caliper bolts (x2) and tie caliper aside.

10. Remove brake disc Torx screws (x2) remove disc.

11. Remove nut/bolt securing lower suspension arm to

vertical link.

12. Remove nut/bolt securing vertical link to upper

suspension arm.

13. Release vertical link from driveshaft, remove vertical

link.

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this will over stress the suspension bushes when the suspension is deflected to maximum

upward travel.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Rear Anti-Roll Bar Link-Renew RH04.02.BD

Rear Anti-Roll Bar Link-Renew LH04.02.BE

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum

upward travel.

Repair Operation Time (ROT)

ItemCode

Rear Hub Vertic al Link-Renew RH04.02.HB

Rear Hub Vertic al Link-Renew LH04.02.GB

Page 442 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-2 Workshop Manual May 2007

7. Position suspension arm aside (see Fig. 4).

8. Remove nuts (x3 each side) from damper top mounting. and remove engine cross br ace support (see Fig. 5). 9. Remove nuts and bolts each side from damper lower

mountings (see Fig, 6).

10. Remove spring and damper assembly.

Installation

1. Install spring and damper assembly and engine cross brace support.

2. Install top mounting nuts (x3) each side (do not torque tighten).

3. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

4. Position upper suspension arm to body and install bolts and nuts (x2) each side (do not torque tighten).

5. Connect ABS sensor multiplug and install harness clips in upper suspension ar m and vertical link.

6. Install road wheel(s).

7. Lower vehicle on ramp.

8. Tighten upper arm nuts and bolts.

9. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

10. Install engine cross brace and install and torque tighten

Torx bolts (x4).

Allow the upper suspension ar

m and vertical link to fall

back, giving access to remo ve the spring and damper

assembly.

Caution

Make sure that the brake flex hose is not over stretched.

Fig. 4

Fig. 5

If removing both spring and damper units - the engine bay

cross brace will be released.

Fig. 6

If removed, place the engine ba y cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum

upward travel.

Page 444 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-4 Workshop Manual May 2007

8. Remove nuts (x3 each side) from damper top mounting and remove engine cross br ace support (see Fig. 5).

9. Remove nuts and bolts (each side) from damper lower mountings (see Fig. 6).

10. Remove spring and damper assembly.

11. Position spring compressor to spring and compress spring.

12. Hold damper shaft and remove top mounting retaining nut.

13. Remove top mounting and spring assembly.

14. Remove spring compressor from spring.

Installation

1. Clean spring and top mounting.

2. Position spring compressor to new spring and compress spring.

3. Install spring and top mounting and install and torque tighten retaining nut.

4. Remove spring compressor. 5. Install spring and damper assembly and install engine

cross brace support.

6. Install top mounting nuts (x3) each side (do not torque tighten).

7. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

8. Position upper suspension arm and install bolts and nuts (x2) each side (do not torque tighten).

9. Connect ABS sensor multiplug and install harness clips in upper suspension ar m and vertical link.

10. Install road wheel(s).

11. Lower vehicle on ramp.

12. Torque tighten upper arm nuts and bolts.

13. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

14. Align engine cross brace and install Torx bolts (x2).

15. Tighten Torx bolts (x4) to correct torque.

Front Damper-Pair-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Disconnect ABS sensor multiplug.

4. Release sensor harness clips (x3) from upper suspension arm and vertical link.

5. Remove Torx bolts (x4) from LH and RH side securing

engine cross brace and remove cross brace.

6. Remove nuts and bolts (x2 each side) from upper suspension arm to body and position suspension arm

aside.

Fig. 5

Fig. 6

If removed, place the engine ba

y cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum

upward travel.

Repair Operation Time (ROT)

ItemCode

Front Damper-Pair-Renew 04.03.AC

If removing both spring and damper units - the engine bay

cross brace will be released.

Allow the upper suspension arm and vertical link to fall back, giving access to remo ve the spring and damper

assembly.

Caution

Ensure that the brake flex hose is not over stretched.

Page 445 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-5

7. Remove nuts (x3 each side) from damper top mounting and remove engine cross brace support.

8. Remove nuts and bolts each side from damper lower mountings.

9. Remove spring and damper assembly.

10. Position spring compresso r to spring and compress

spring.

11. Hold damper shaft, and remove top mounting retaining nut.

12. Remove top mounting and spring assembly.

13. Remove dust shield from rebound bumper and spring seat flange.

Installation

1. Clean spring , spring seat flange, bumper, dust shield and top mounting .

2. Install spring seat flange, rebound bumper and dust shield onto damper.

3. Install spring and top mounting and install and tighten retaining nut.

4. Remove spring compressor.

5. Install spring and damper assembly and install engine cross brace support.

6. Install top mounting nuts (x3) each side (do not torque tighten).

7. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

8. Position upper suspension arm and install bolts and nuts (x2) each side (do not torque tighten).

9. Connect ABS sensor multiplug and install harness clips in upper suspension arm and vertical link.

10. Install road wheel(s).

11. Lower vehicle on ramp.

12. Tighten upper arm nuts an d bolts to correct torque.

13. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

14. Align engine cross brace, install Torx bolts (x2) and

tighten Torx bolts (x4) to correct torque.

Rear Spring and Damper Assembly-Pair-

Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to shock

absorber mounting bracket.

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

8. Disconnect ABS sensor multiplug (see Fig. 2).

If removed, place the engine

bay cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspension components must be

carried out with the suspensi on arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum upward travel.

Repair Operation Time (ROT)

Page 521 of 947

Manual Transmission (07.03)

Transmission (07.00)

Issue 5, January 2010 Workshop Manual 7-3-5

31. Put a transmission jack be low the transaxle (refer to

Figure 12).

Figure 12

32. Adjust the height of the tran smission jack until it holds

the transaxle.

33. Remove and discard the four bolts that attach the right

side transaxle mount bracket to the transaxle. (see

Figure 13).

Figure 13

34. Remove and discard the four bolts that attach the left side transaxle mount bracket to the transaxle.

Figure 14

35. Remove the transaxle mount assemblies.

Figure 15

36. Use an applicable strap to attach the transaxle to the transmission jack.

37. Lower the transaxle on the transmission jack by approximately 420 mm.

38. Release the wiring harness for the reverse lamp switch from the clip.

39. Release the electrical connector for the reverse lamp switch from the mount.

Figure 16

40. Disconnect the electrical connector from the reverse lamp switch.

Page 522 of 947

Manual Transmission (07.03)

Transmission (07.00)7-3-6 Workshop Manual Issue 5, January 2010

41. Use the special tool to release the gear selector cables from the ball joints.

Figure 16

42. Release the gear selector cables from the bracket.

Figure 17

Put a transmission jack in position below the torque tube.

Figure 18

43. Adjust the height of the transmission jack to hold the torque tube. 44. Remove the eight bolts that attach the torque tube to

the transaxle.

Figure 19.

45. Move the transaxle rearward to give clearance between the torque tube and the transaxle

46. Carefully lower the transaxle on the transmission jack to

remove the transaxle from the vehicle.

Figure 20

47. Clean the mating faces of the components.

Install

1. Move the transaxle on th e transmission jack, into

position below the vehicle.

2. Use the transmission jack to adjust the height of the transaxle to align the transaxle with the torque tube.

3. Install and torque the eight bolts that attach the torque tube to the transaxle.

4. Lower the transmission jack away from the torque tube.

5. Connect the gear selector cables to the ball joints.

6. Install the gear selector cables into the bracket.

WAR NI NG

THE TRANSAXLE ASSEMBLY IS VERY HEAVY. GET THE

AID OF ONE MORE PERSON WHEN YOU MOVE THE

TRANSAXLE. IF YOU DO NOT, PERSONAL INJURY CAN OCCUR.

WAR NI NG

THE TRANSAXLE ASSEMBLY IS VERY HEAVY. GET THE AID OF ONE MORE PERSON WHEN YOU MOVE THE

TRANSAXLE. IF YOU DO NOT, PERSONAL INJURY CAN

OCCUR.

Page 523 of 947

Manual Transmission (07.03)

Transmission (07.00)

Issue 5, January 2010 Workshop Manual 7-3-7

7. Connect the electrical connector to the reverse lamp switch.

8. Install the electrical connector for the reverse lamp switch into the mount.

9. Install the wiring harness for the reverse lamp switch to the clip.

10. Adjust the height of the transmission jack to lift the transaxle into the correct position.

11. Remove the strap from the transaxle and the transmission jack.

12. Install the transaxle mount assemblies.

Figure 21

13. Install and torque the four bolts that attach the left side transaxle mount bracket to the transaxle.

Figure 22

14. Install and torque the four bolts that attach the right side transaxle mount bracket to the transaxle.

Figure 23

15. Lower the transmission jack to align the transaxle mounts to the rear subframe.

16. Move the transmission jack away from the vehicle.

17. Install and tighten the nut that attaches the left side transaxle mount to the rear subframe.

18. Install and tighten the nut that attaches the right side transaxle mount to the rear subframe.

19. Remove and the sealing plugs from the transaxle and the breather pipe.

20. Connect breather pipe to the transaxle.

21. Remove and discard the sealing plugs from the oil cooler matrix and the pipes.

22. Connect and tighten the pipes to the oil cooler matrix.

23. Put the driveshafts into position on the transaxle shaft flanges. Align the marks on the flanges that you made

during removal.

24. Install and torque the six new bolts that attach the left side driveshaft flange to the transaxle flange. If

necessary, turn the driveshaft to get access to all of the

bolts.

25. Install and torque the six new bolts that attach the right side driveshaft flange to the transaxle flange. If

necessary, turn the driveshaft to get access to all of the

bolts.

26. Put the ground cable into position.

27. Install and tighten the nut that attaches the ground cable to the body.

28. Install the tunnel reinforcement plate.

29. Install and torque the eight bolts that attach the tunnel reinforcement plate to the body.

30. Install floor heatshield.

31. Install and tighten the four bolts that attach the floor heat shield to the body.

Note: Put the three driveshaft bolt plates in position when

you install the bolts in the step that follows.

Note: Put the three driveshaft bolt plates in position when

you install the bolts in the step that follows.