coolant ASTON MARTIN V8 VANTAGE 2010 Manual Online

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 885 of 947

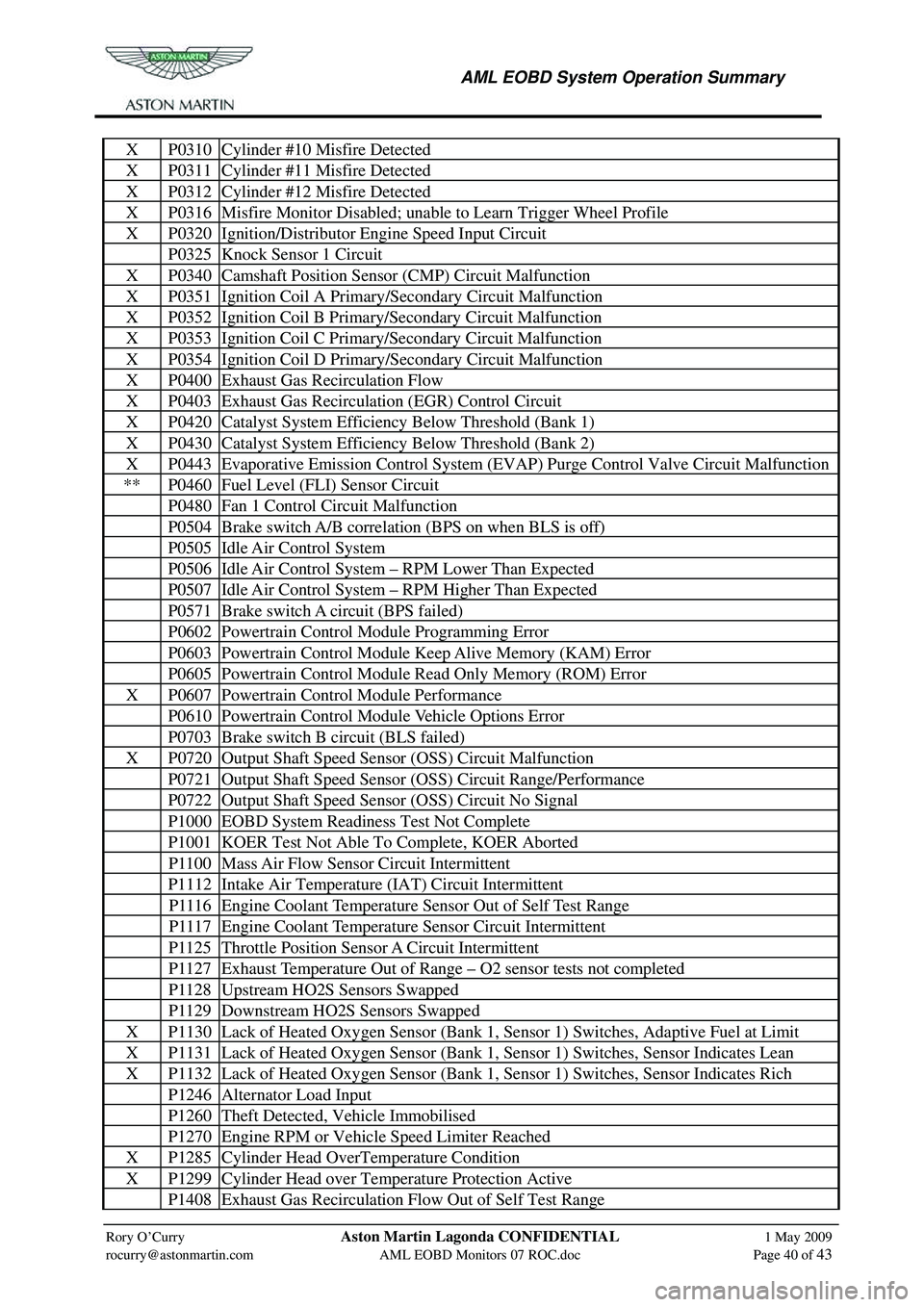

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 40 of 43

X P0310 Cylinder #10 Misfire Detected

X P0311 Cylinder #11 Misfire Detected

X P0312 Cylinder #12 Misfire Detected

X P0316 Misfire Monitor Disabled; unable to Learn Trigger Wheel Profile

X P0320 Ignition/Distributor Engine Speed Input Circuit

P0325 Knock Sensor 1 Circuit

X P0340 Camshaft Position Sens or (CMP) Circuit Malfunction

X P0351 Ignition Coil A Primary/Secondary Circuit Malfunction

X P0352 Ignition Coil B Primary/Secondary Circuit Malfunction

X P0353 Ignition Coil C Primary/Secondary Circuit Malfunction

X P0354 Ignition Coil D Primary/Secondary Circuit Malfunction

X P0400 Exhaust Gas Recirculation Flow

X P0403 Exhaust Gas Recirculation (EGR) Control Circuit

X P0420 Catalyst System Efficiency Below Threshold (Bank 1)

X P0430 Catalyst System Efficiency Below Threshold (Bank 2)

X P0443 Evaporative Emission Control System (EVAP) Purge Control Valve Circuit Malfunction

** P0460 Fuel Level (FLI) Sensor Circuit

P0480 Fan 1 Control Circuit Malfunction

P0504 Brake switch A/B correlation (BPS on when BLS is off)

P0505 Idle Air Control System

P0506 Idle Air Control System – RPM Lower Than Expected

P0507 Idle Air Control System – RPM Higher Than Expected

P0571 Brake switch A circuit (BPS failed)

P0602 Powertrain Control Module Programming Error

P0603 Powertrain Control Module Keep Alive Memory (KAM) Error

P0605 Powertrain Control Module Read Only Memory (ROM) Error

X P0607 Powertrain Control Module Performance

P0610 Powertrain Control Module Vehicle Options Error

P0703 Brake switch B circuit (BLS failed)

X P0720 Output Shaft Speed Sensor (OSS) Circuit Malfunction

P0721 Output Shaft Speed Sensor (OSS) Circuit Range/Performance

P0722 Output Shaft Speed Sensor (OSS) Circuit No Signal

P1000 EOBD System Readiness Test Not Complete

P1001 KOER Test Not Able To Complete, KOER Aborted

P1100 Mass Air Flow Sensor Circuit Intermittent

P1112 Intake Air Temperature (IAT) Circuit Intermittent

P1116 Engine Coolant Temperature Sensor Out of Self Test Range

P1117 Engine Coolant Temperature Sensor Circuit Intermittent

P1125 Throttle Position Sensor A Circuit Intermittent

P1127 Exhaust Temperature Out of Range – O2 sensor tests not completed

P1128 Upstream HO2S Sensors Swapped

P1129 Downstream HO2S Sensors Swapped

X P1130 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Adaptive Fuel at Limit

X P1131 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Lean

X P1132 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Rich

P1246 Alternator Load Input

P1260 Theft Detected, Vehicle Immobilised

P1270 Engine RPM or Vehicle Speed Limiter Reached

X P1285 Cylinder Head OverTemperature Condition

X P1299 Cylinder Head over Temperature Protection Active

P1408 Exhaust Gas Recirculation Flow Out of Self Test Range

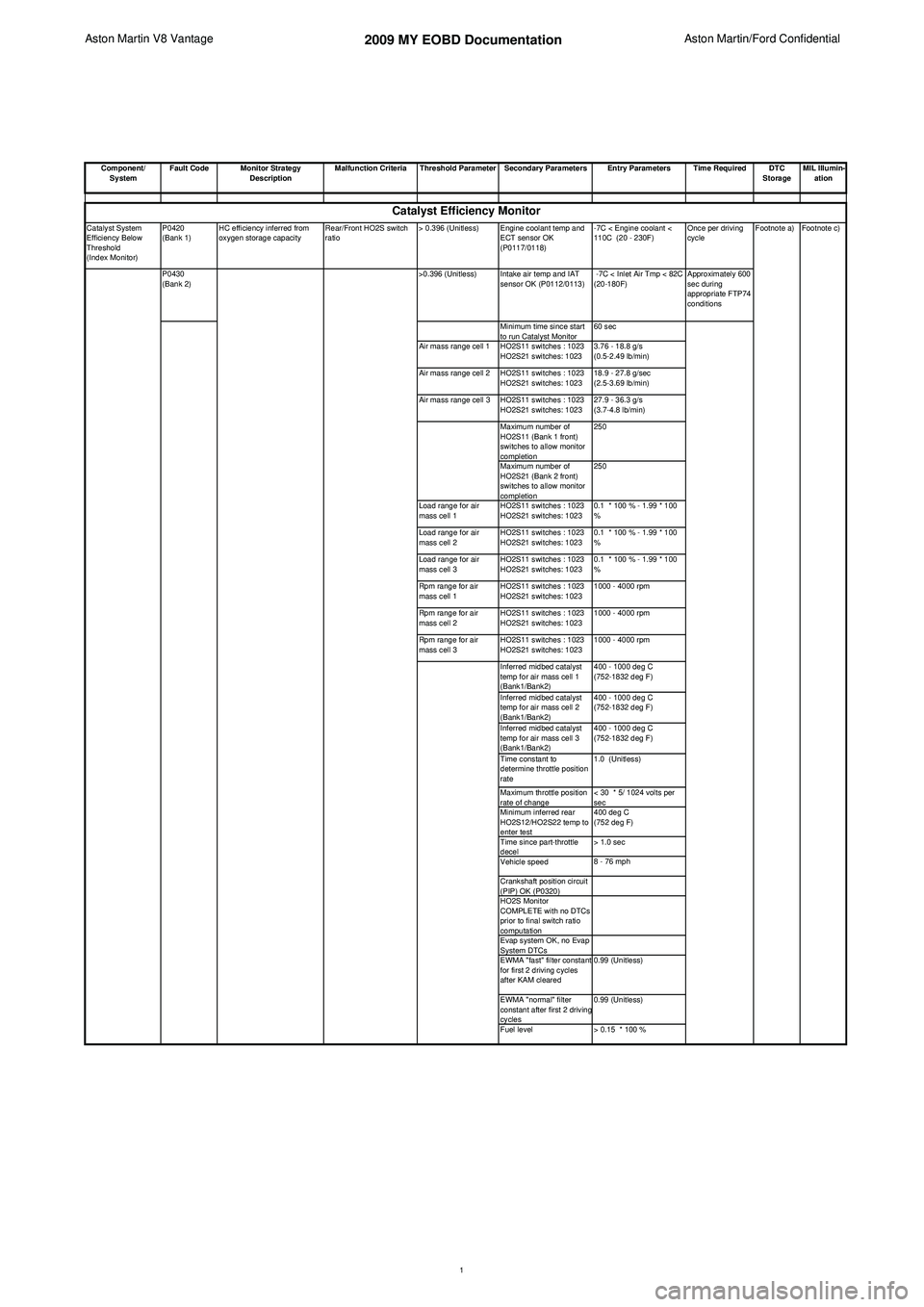

Page 889 of 947

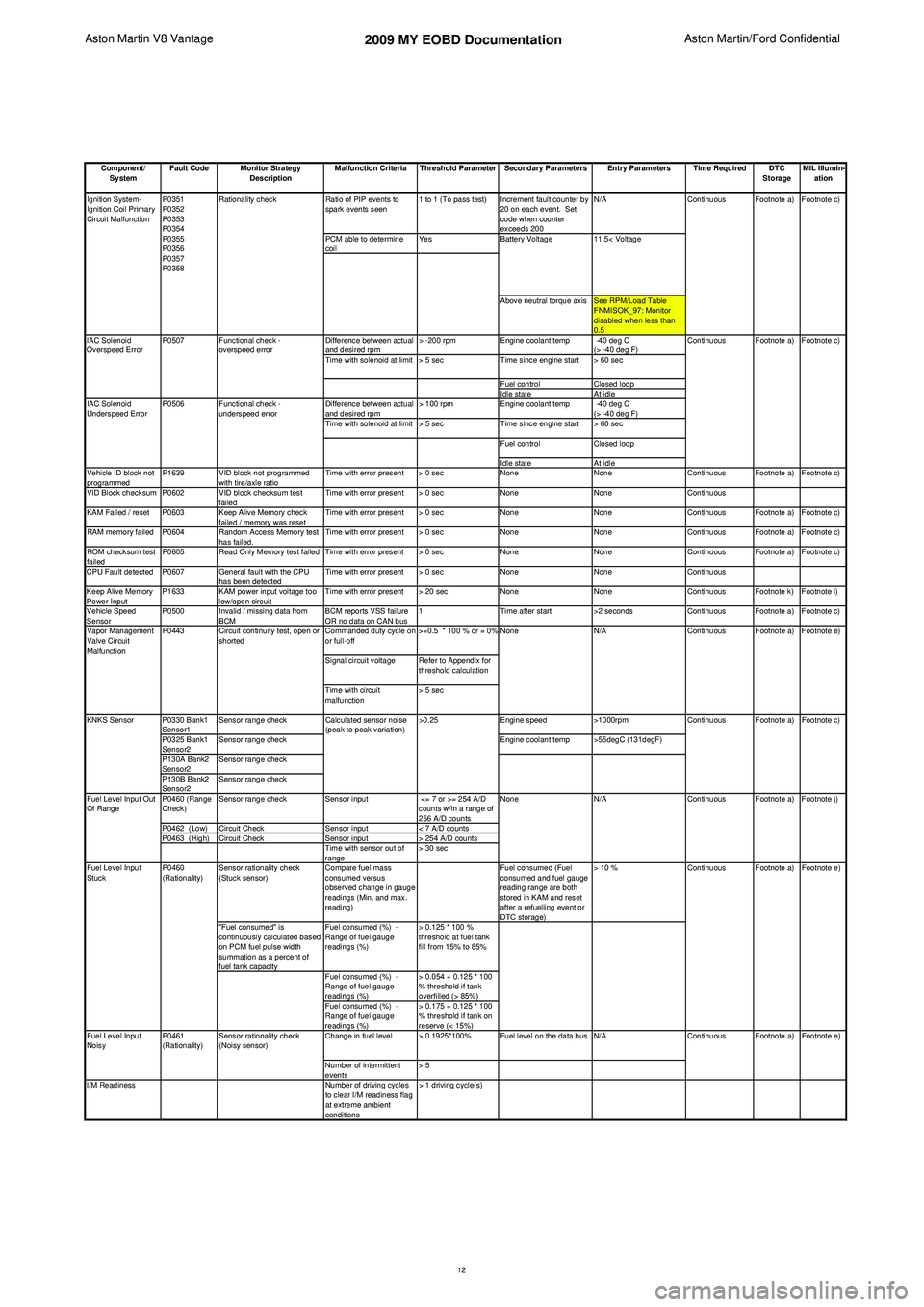

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Catalyst System

Efficiency Below

Threshold

(Index Monitor) P0420

(Bank 1)

HC efficiency inferred from

oxygen storage capacity Rear/Front HO2S switch

ratio> 0.396 (Unitless) Engine coolant temp and

ECT sensor OK

(P0117/0118) -7C < Engine coolant <

110C (20 - 230F)

Once per driving

cycle

P0430

(Bank 2) >0.396 (Unitless) Intake air temp and IAT

sensor OK (P0112/0113) -7C < Inlet Air Tmp < 82C

(20-180F) Approximately 600

sec during

appropriate FTP74

conditions

Minimum time since start

to run Catalyst Monitor 60 sec

Air mass range cell 1 HO2S11 switches : 1023 HO2S21 switches: 1023 3.76 - 18.8 g/s

(0.5-2.49 lb/min)

Air mass range cell 2 HO2S11 switches : 1023 HO2S21 switches: 1023 18.9 - 27.8 g/sec

(2.5-3.69 lb/min)

Air mass range cell 3 HO2S11 switches : 1023 HO2S21 switches: 1023 27.9 - 36.3 g/s

(3.7-4.8 lb/min)

Maximum number of

HO2S11 (Bank 1 front)

switches to allow monitor

completion 250

Maximum number of

HO2S21 (Bank 2 front)

switches to allow monitor

completion 250

Load range for air

mass cell 1 HO2S11 switches : 1023

HO2S21 switches: 1023 0.1 * 100 % - 1.99 * 100

%

Load range for air

mass cell 2 HO2S11 switches : 1023

HO2S21 switches: 1023 0.1 * 100 % - 1.99 * 100

%

Load range for air

mass cell 3 HO2S11 switches : 1023

HO2S21 switches: 1023 0.1 * 100 % - 1.99 * 100

%

Rpm range for air

mass cell 1 HO2S11 switches : 1023

HO2S21 switches: 1023 1000 - 4000 rpm

Rpm range for air

mass cell 2 HO2S11 switches : 1023

HO2S21 switches: 1023 1000 - 4000 rpm

Rpm range for air

mass cell 3 HO2S11 switches : 1023

HO2S21 switches: 1023 1000 - 4000 rpm

Inferred midbed catalyst

temp for air mass cell 1

(Bank1/Bank2) 400 - 1000 deg C

(752-1832 deg F)

Inferred midbed catalyst

temp for air mass cell 2

(Bank1/Bank2) 400 - 1000 deg C

(752-1832 deg F)

Inferred midbed catalyst

temp for air mass cell 3

(Bank1/Bank2) 400 - 1000 deg C

(752-1832 deg F)

Time constant to

determine throttle position

rate 1.0 (Unitless)

Maximum throttle position

rate of change < 30 * 5/ 1024 volts per

sec

Minimum inferred rear

HO2S12/HO2S22 temp to

enter test 400 deg C

(752 deg F)

Time since part-throttle

decel > 1.0 sec

Vehicle speed 8 - 76 mph

Crankshaft position circuit

(PIP) OK (P0320)

HO2S Monitor

COMPLETE with no DTCs

prior to final switch ratio

computation

Evap system OK, no Evap

System DTCs

EWMA "fast" filter constant

for first 2 driving cycles

after KAM cleared 0.99 (Unitless)

EWMA "normal" filter

constant after first 2 driving

cycles 0.99 (Unitless)

Fuel level > 0.15 * 100 % Footnote a)

Footnote c)

Catalyst Efficiency Monitor

1

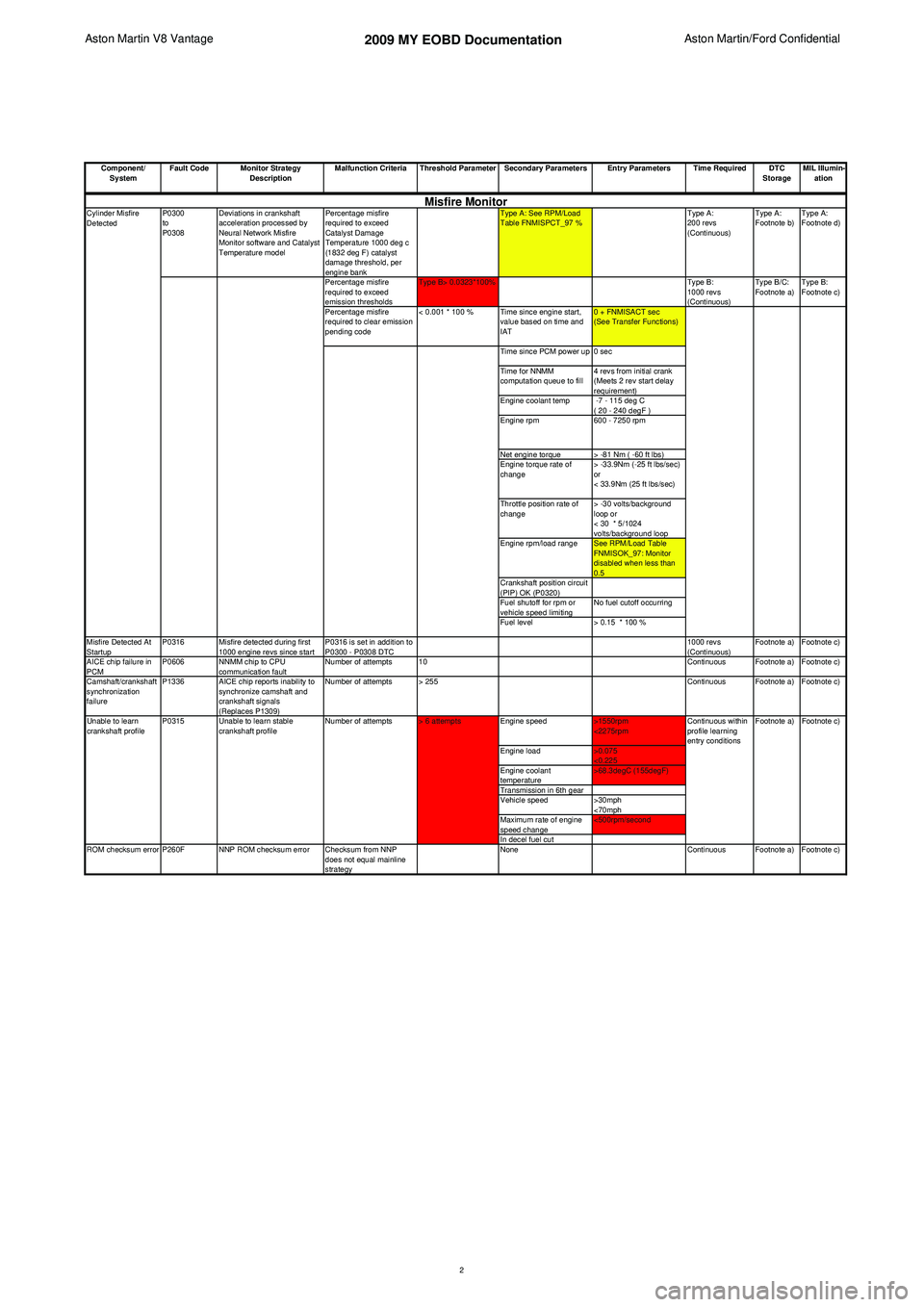

Page 890 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0300

to

P0308 Deviations in crankshaft

acceleration processed by

Neural Network Misfire

Monitor software and Catalyst

Temperature model Percentage misfire

required to exceed

Catalyst Damage

Temperature 1000 deg c

(1832 deg F) catalyst

damage threshold, per

engine bank Type A: See RPM/Load

Table FNMISPCT_97 %

Type A:

200 revs

(Continuous)Type A:

Footnote b)

Type A:

Footnote d)

Percentage misfire

required to exceed

emission thresholds Type B> 0.0323*100% Type B:

1000 revs

(Continuous)Type B/C:

Footnote a)

Type B:

Footnote c)

Percentage misfire

required to clear emission

pending code < 0.001 * 100 % Time since engine start,

value based on time and

IAT 0 + FNMISACT sec

(See Transfer Functions)

Time since PCM power up 0 sec

Time for NNMM

computation queue to fill 4 revs from initial crank

(Meets 2 rev start delay

requirement)

Engine coolant temp -7 - 115 deg C ( 20 - 240 degF )

Engine rpm 600 - 7250 rpm

Net engine torque > -81 Nm ( -60 ft lbs)

Engine torque rate of

change > -33.9Nm (-25 ft lbs/sec)

or

< 33.9Nm (25 ft lbs/sec)

Throttle position rate of

change > -30 volts/background

loop or

< 30 * 5/1024

volts/background loop

Engine rpm/load range See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Crankshaft position circuit

(PIP) OK (P0320)

Fuel shutoff for rpm or

vehicle speed limiting No fuel cutoff occurring

Fuel level > 0.15 * 100 %

Misfire Detected At

Startup P0316 Misfire detected during first

1000 engine revs since start P0316 is set in addition to

P0300 - P0308 DTC 1000 revs

(Continuous)Footnote a) Footnote c)

AICE chip failure in

PCM P0606 NNMM chip to CPU

communication fault Number of attempts 10

Continuous Footnote a) Footnote c)

Camshaft/crankshaft

synchronization

failure P1336 AICE chip reports inability to

synchronize camshaft and

crankshaft signals

(Replaces P1309) Number of attempts > 255

Continuous Footnote a) Footnote c)

Engine speed >1550rpm

<2275rpm

Engine load >0.075

<0.225

Engine coolant

temperature >68.3degC (155degF)

Transmission in 6th gear

Vehicle speed >30mph

<70mph

Maximum rate of engine

speed change <500rpm/second

In decel fuel cut

ROM checksum error P260F NNP ROM checksum error Checksum from NNP does not equal mainline

strategyNone

Continuous Footnote a) Footnote c)

Cylinder Misfire

DetectedMisfire Monitor

Footnote c)

Unable to learn

crankshaft profile P0315 Unable to learn stable

crankshaft profile Number of attempts > 6 attempts Continuous within

profile learning

entry conditionsFootnote a)

2

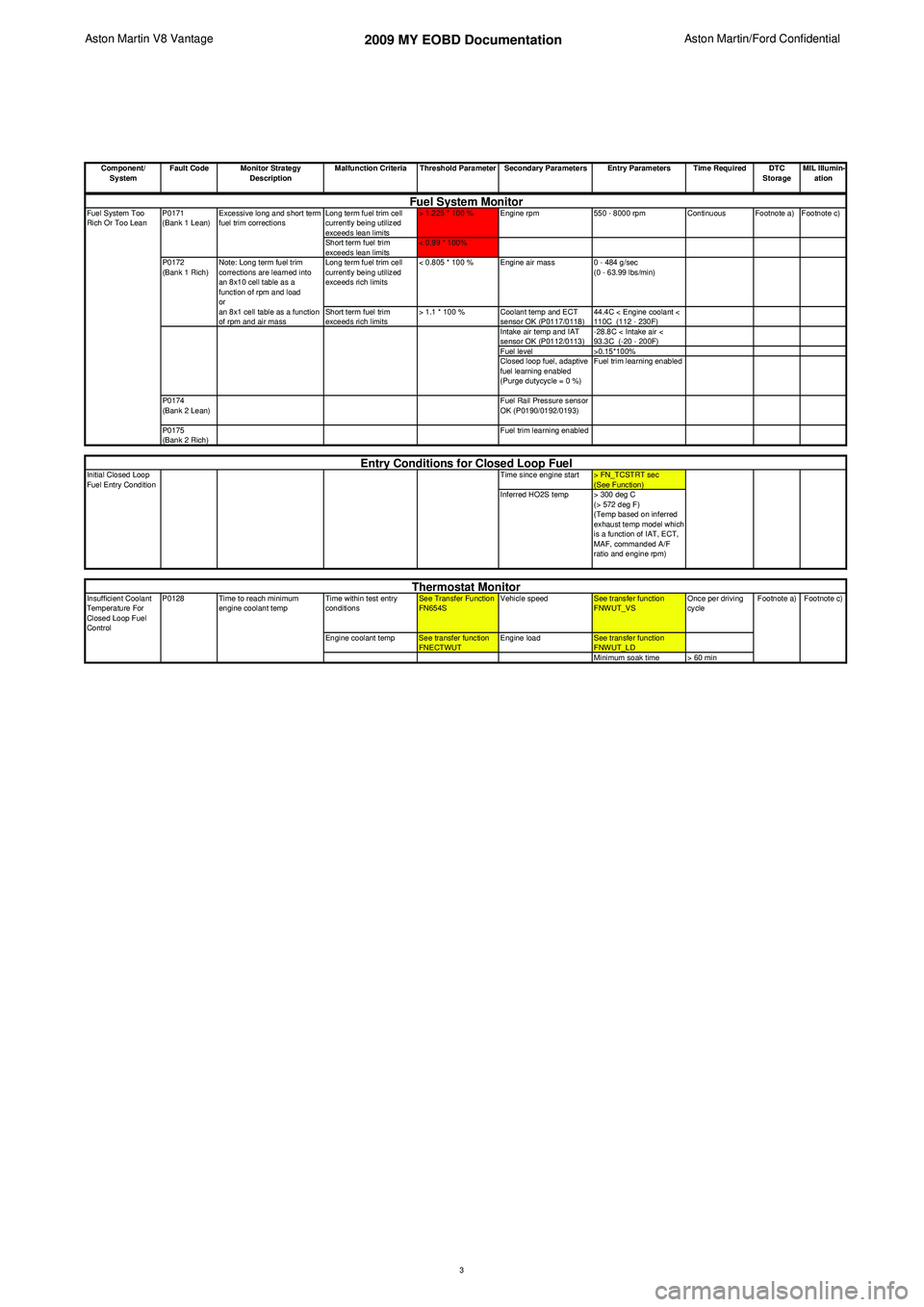

Page 891 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Long term fuel trim cell

currently being utilized

exceeds lean limits > 1.225 * 100 % Engine rpm

550 - 8000 rpmContinuous Footnote a) Footnote c)

Short term fuel trim

exceeds lean limits < 0.99 * 100%

Long term fuel trim cell

currently being utilized

exceeds rich limits < 0.805 * 100 % Engine air mass

0 - 484 g/sec

(0 - 63.99 lbs/min)

Short term fuel trim

exceeds rich limits > 1.1 * 100 % Coolant temp and ECT

sensor OK (P0117/0118) 44.4C < Engine coolant <

110C (112 - 230F)

Intake air temp and IAT

sensor OK (P0112/0113) -28.8C < Intake air <

93.3C (-20 - 200F)

Fuel level >0.15*100%

Closed loop fuel, adaptive

fuel learning enabled

(Purge dutycycle = 0 %) Fuel trim learning enabled

P0174

(Bank 2 Lean) Fuel Rail Pressure sensor

OK (P0190/0192/0193)

P0175

(Bank 2 Rich) Fuel trim learning enabled

Time since engine start > FN_TCSTRT sec

(See Function)

Inferred HO2S temp > 300 deg C (> 572 deg F)

(Temp based on inferred

exhaust temp model which

is a function of IAT, ECT,

MAF, commanded A/F

ratio and engine rpm)

Time within test entry

conditions See Transfer Function

FN654SVehicle speed

See transfer function

FNWUT_VS Once per driving

cycle

Engine coolant temp See transfer function FNECTWUTEngine load

See transfer function

FNWUT_LD

Minimum soak time > 60 min

Entry Conditions for Closed Loop Fuel

Thermostat MonitorInitial Closed Loop

Fuel Entry Condition Note: Long term fuel trim

corrections are learned into

an 8x10 cell table as a

function of rpm and load

or

an 8x1 cell table as a function

of rpm and air mass

P0172

(Bank 1 Rich)

Fuel System MonitorFuel System Too

Rich Or Too Lean

P0171

(Bank 1 Lean)Excessive long and short term

fuel trim corrections

Footnote c)

Insufficient Coolant

Temperature For

Closed Loop Fuel

Control P0128 Time to reach minimum

engine coolant temp Footnote a)

3

Page 892 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

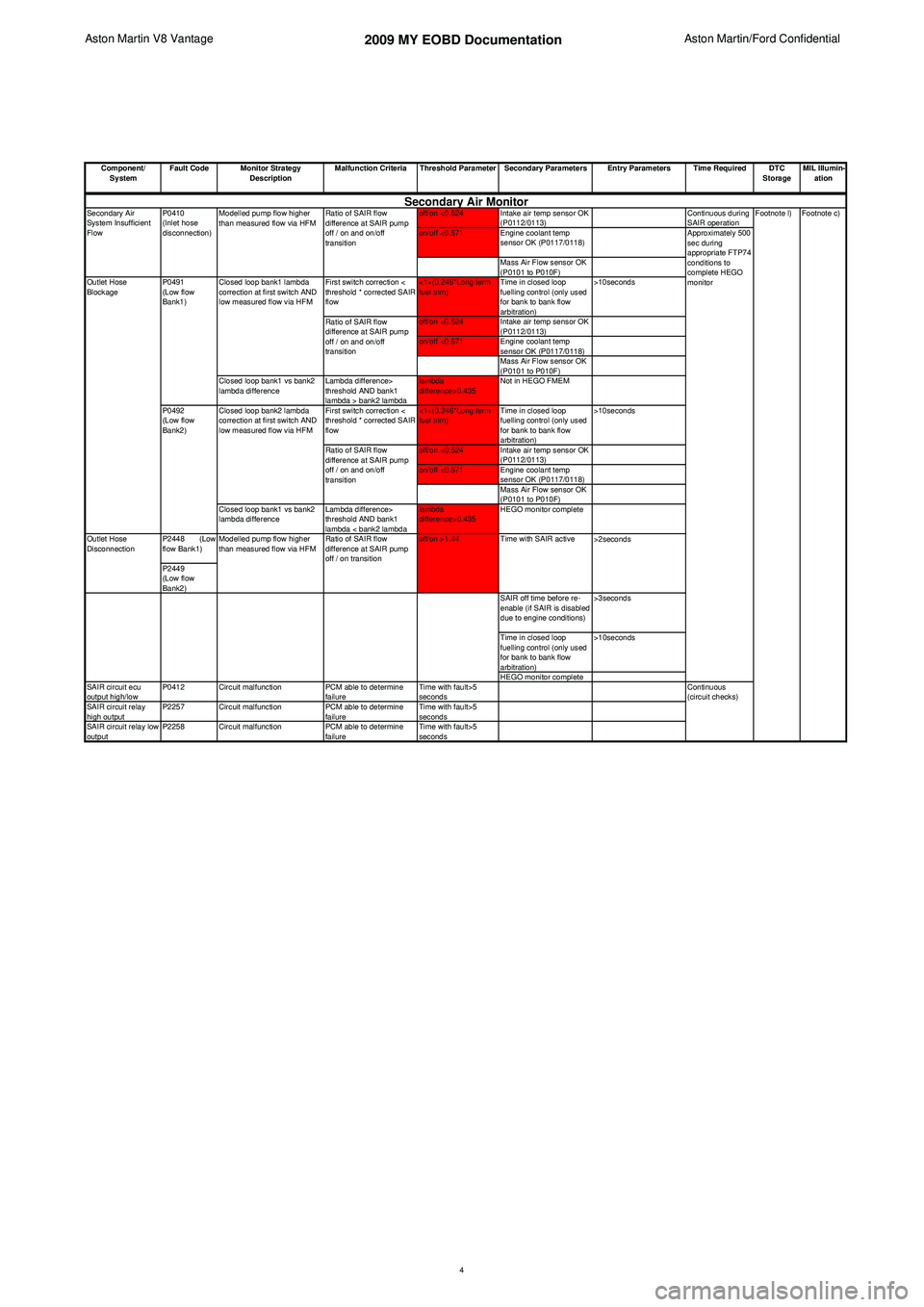

off/on <0.524 Intake air temp sensor OK (P0112/0113) Continuous during

SAIR operation

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda > bank2 lambdalambda

difference>0.435

Not in HEGO FMEM

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda < bank2 lambdalambda

difference>0.435

HEGO monitor complete

P2448 (Low

flow Bank1)

P2449

(Low flow

Bank2) SAIR off time before re-

enable (if SAIR is disabled

due to engine conditions)>3seconds

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

HEGO monitor complete

SAIR circuit ecu

output high/low P0412 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay

high output P2257 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay low

output P2258 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Modelled pump flow higher

than measured flow via HFM

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

>2secondsFootnote c)

Approximately 500

sec during

appropriate FTP74

conditions to

complete HEGO

monitorSecondary Air Monitor

Modelled pump flow higher

than measured flow via HFM Ratio of SAIR flow

difference at SAIR pump

off / on transitionoff/on >1.44

Outlet Hose

Disconnection Footnote l)

Continuous

(circuit checks)

Outlet Hose

Blockage

P0492

(Low flow

Bank2)

P0410

(Inlet hose

disconnection)

Secondary Air

System Insufficient

Flow

Closed loop bank1 lambda

correction at first switch AND

low measured flow via HFM

Closed loop bank2 lambda

correction at first switch AND

low measured flow via HFM

P0491

(Low flow

Bank1)

Time with SAIR active

4

Page 894 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

PCM able to determine

failure

Time with failure >5seconds

PCM able to determine

failure

Time with failure >5seconds

P0011 (Bank1) Cam position error vs

target >12.4deg CRK Engine coolant

temperature >-7c (20f)

P0021 (Bank2) Cam position error bank1

vs bank2 >16deg CRK Engine oil temperature >-7c (20f)

<121c (250f)

Time exceeding threshold >5 seconds Cam angle sensitivity

modifier for cam position

bank1 vs bank2 CAM_RANGE_SENS

(See function)

Cam angle error filter for

target error calculation FNCAM_ACT_FK

(See function)

Filter for target error

calculation 0.25*100%

Intake air temp sensor OK

(P0112/0113)

Engine coolant temp

sensor OK (P0117/0118)

Engine oil temp sensor OK

(P0197/0198)

Throttle Position Sensor

OK (P0122/0123)

Crankshaft position circuit

(PIP) OK (P0320)

Mass Air Flow sensor OK

(P0101 to P010F)

Camshaft ID circuit (CMP)

OK (P0340)

P0012

(Bank1) Cam position error vs

target>12.4deg CRK Engine coolant

temperature >-7c (20f)

P0022 (Bank2) Cam position error bank1

vs bank2 >16deg CRK Engine oil temperature >-7c (20f)

<121c (250f)

Time exceeding threshold >5 seconds Cam angle sensitivity

modifier for cam position

bank1 vs bank2 CAM_RANGE_SENS

(See function)

Cam angle error filter for

target error calculation FNCAM_ACT_FK

(See function)

Filter for target error

calculation 0.25*100%

Intake air temp sensor OK

(P0112/0113)

Engine coolant temp

sensor OK (P0117/0118)

Engine oil temp sensor OK

(P0197/0198)

Throttle Position Sensor

OK (P0122/0123)

Crankshaft position circuit

(PIP) OK (P0320)

Mass Air Flow sensor OK

(P0101 to P010F)

Camshaft ID circuit (CMP)

OK (P0340)

P0016

(Bank1) Engine speed

>600rpm

<1100rpm

P0018

(Bank2) Indicated torque

>25 Nm (18.4ftlb)

<95 Nm (70ftlb)

Time after start >25sec

<16383sec

Engine coolant

temperature >71.1degC (160degF)

<104.4degC (220degF)

Filter for position error 1.5

Air charge temperature >-17.7degC (0degF) <65.5degC (150degF)

Circuit MalfunctionVariable Cam Timing MonitorContinuous Footnote a) Footnote c)

VCT actuator

malfunction P0010 (Bank1)

P0020(Bank2)

VCT target error Measured Cam Position Over

advanced

VCT target error Measured Cam Position Over

retarded

Footnote c)

>8deg CRK Once per driving

cycle Footnote a)

Circuit Malfunction

CAM / CRANK

Misalignment Cam position error

Measured Cam Position with

VCT locked fully retarded

6

Page 895 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

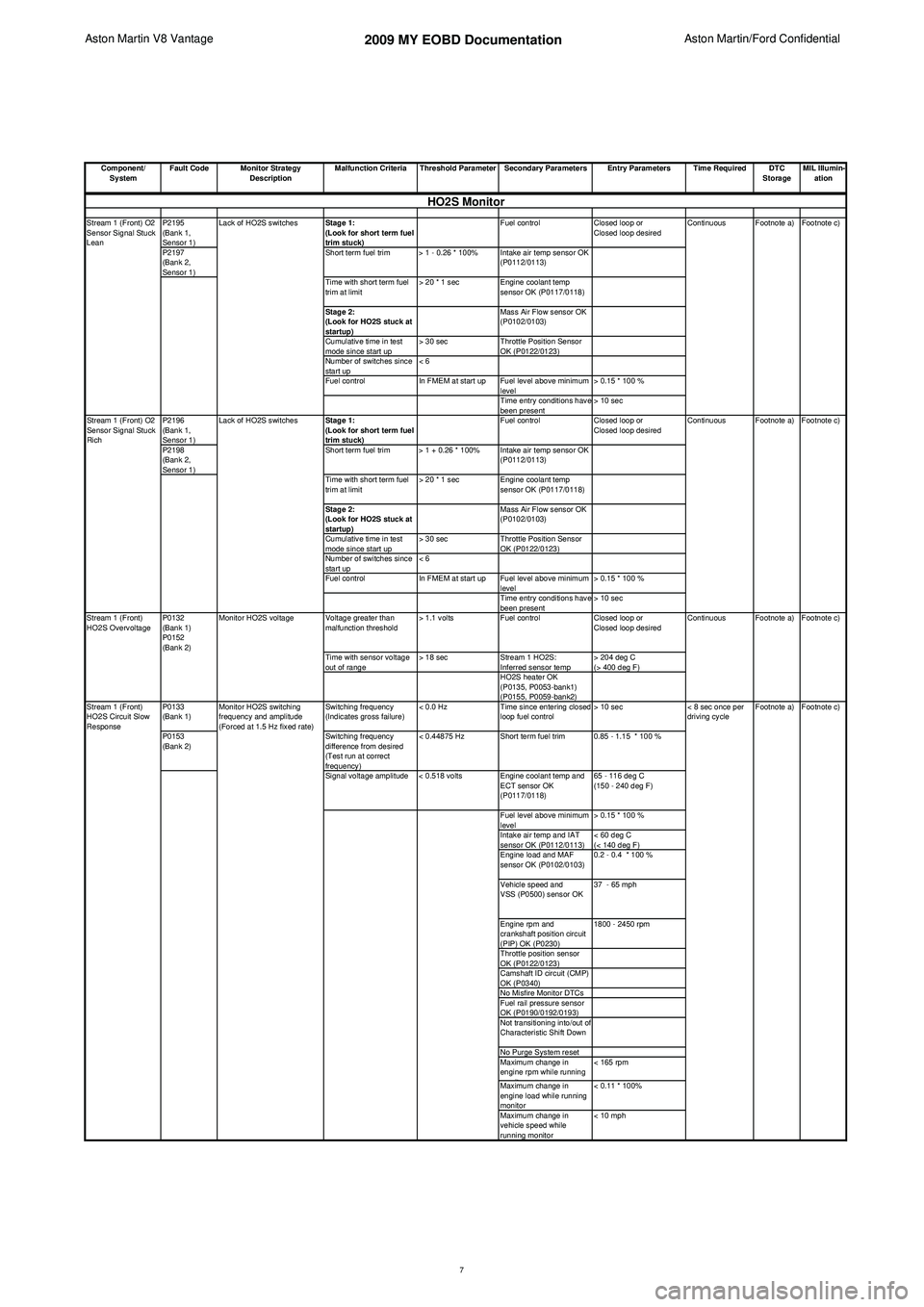

P2195

(Bank 1,

Sensor 1) Stage 1:

(Look for short term fuel

trim stuck) Fuel control Closed loop or

Closed loop desired

P2197

(Bank 2,

Sensor 1) Short term fuel trim > 1 - 0.26 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 20 * 1 sec

Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startup) Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec

Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 6

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Time entry conditions have

been present > 10 sec

P2196

(Bank 1,

Sensor 1) Stage 1:

(Look for short term fuel

trim stuck) Fuel control

Closed loop or

Closed loop desired

P2198

(Bank 2,

Sensor 1) Short term fuel trim > 1 + 0.26 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 20 * 1 sec

Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startup) Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec

Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 6

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Time entry conditions have

been present > 10 sec

Voltage greater than

malfunction threshold > 1.1 volts

Fuel control Closed loop or

Closed loop desired

Time with sensor voltage

out of range > 18 sec

Stream 1 HO2S:

Inferred sensor temp > 204 deg C

(> 400 deg F)

HO2S heater OK

(P0135, P0053-bank1)

(P0155, P0059-bank2)

P0133

(Bank 1) Switching frequency

(Indicates gross failure)< 0.0 Hz

Time since entering closed

loop fuel control > 10 sec

P0153

(Bank 2) Switching frequency

difference from desired

(Test run at correct

frequency)< 0.44875 Hz Short term fuel trim 0.85 - 1.15 * 100 %

Signal voltage amplitude < 0.518 volts Engine coolant temp and ECT sensor OK

(P0117/0118)65 - 116 deg C

(150 - 240 deg F)

Fuel level above minimum

level > 0.15 * 100 %

Intake air temp and IAT

sensor OK (P0112/0113) < 60 deg C

(< 140 deg F)

Engine load and MAF

sensor OK (P0102/0103) 0.2 - 0.4 * 100 %

Vehicle speed and

VSS (P0500) sensor OK 37 - 65 mph

Engine rpm and

crankshaft position circuit

(PIP) OK (P0230) 1800 - 2450 rpm

Throttle position sensor

OK (P0122/0123)

Camshaft ID circuit (CMP)

OK (P0340)

No Misfire Monitor DTCs

Fuel rail pressure sensor

OK (P0190/0192/0193)

Not transitioning into/out of

Characteristic Shift Down

No Purge System reset

Maximum change in

engine rpm while running

it

< 165 rpm

Maximum change in

engine load while running

monitor < 0.11 * 100%

Maximum change in

vehicle speed while

running monitor < 10 mphContinuous

Footnote a)

Footnote a)

Monitor HO2S voltage Footnote a) Footnote c)

Stream 1 (Front)

HO2S Overvoltage

< 8 sec once per

driving cycle

Stream 1 (Front)

HO2S Circuit Slow

Response Monitor HO2S switching

frequency and amplitude

(Forced at 1.5 Hz fixed rate)

P0132

(Bank 1)

P0152

(Bank 2)

Continuous Footnote a) Footnote c)Footnote c)

Continuous

Stream 1 (Front) O2

Sensor Signal Stuck

Lean

Lack of HO2S switches

Lack of HO2S switches

HO2S Monitor

Footnote c)

Stream 1 (Front) O2

Sensor Signal Stuck

Rich

7

Page 898 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

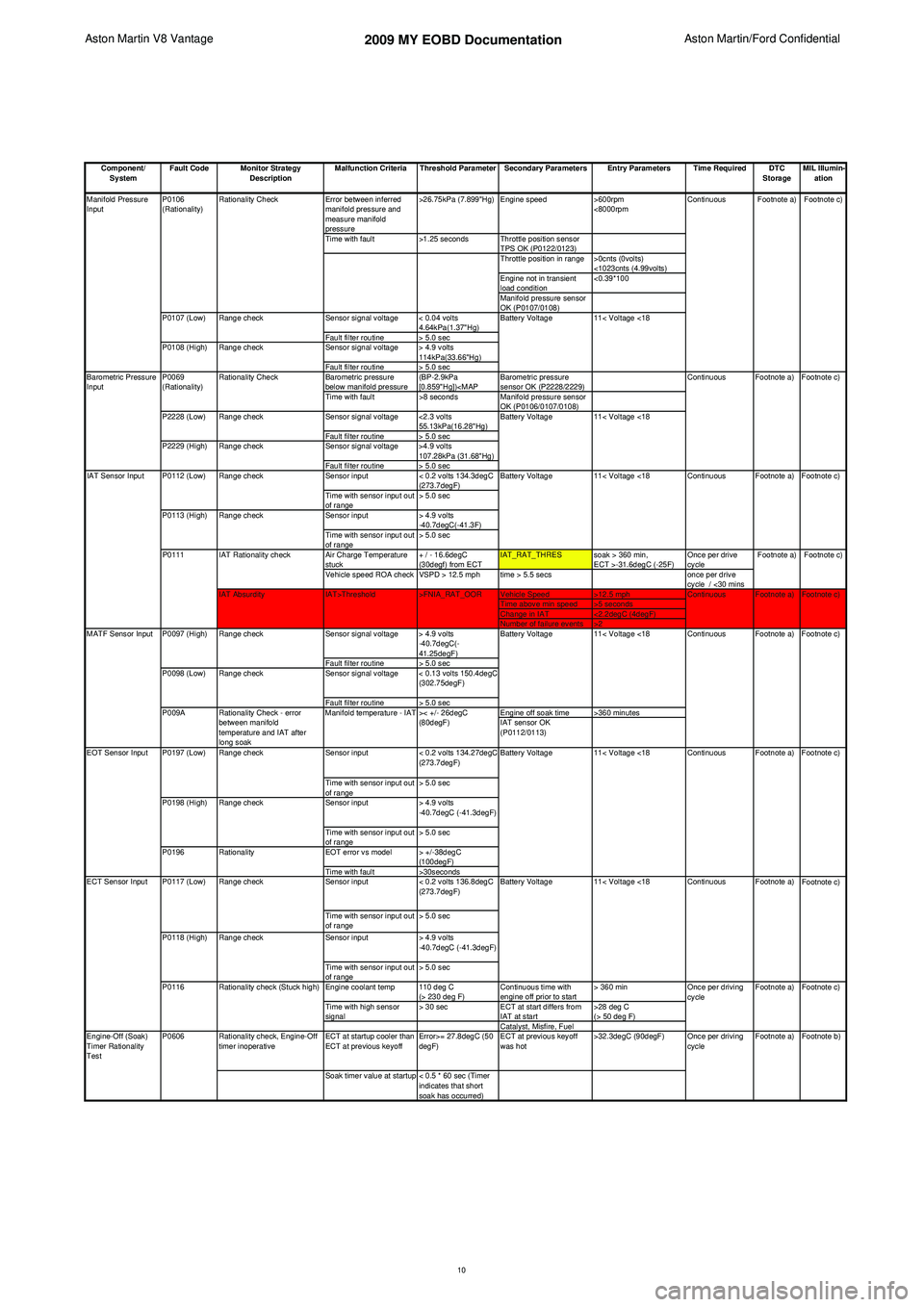

Error between inferred

manifold pressure and

measure manifold

pressure >26.75kPa (7.899"Hg) Engine speed

>600rpm

<8000rpm

Time with fault >1.25 seconds Throttle position sensor

TPS OK (P0122/0123)

Throttle position in range >0cnts (0volts) <1023cnts (4.99volts)

Engine not in transient

load condition <0.39*100

Manifold pressure sensor

OK (P0107/0108)

Sensor signal voltage < 0.04 volts 4.64kPa(1.37"Hg)

Fault filter routine > 5.0 sec

Sensor signal voltage > 4.9 volts 114kPa(33.66"Hg)

Fault filter routine > 5.0 sec

Barometric pressure

below manifold pressure (BP-2.9kPa

[0.859"Hg])

Time with fault >8 secondsManifold pressure sensor

OK (P0106/0107/0108)

Sensor signal voltage <2.3 volts 55.13kPa(16.28"Hg)

Fault filter routine > 5.0 sec

Sensor signal voltage >4.9 volts 107.28kPa (31.68"Hg)

Fault filter routine > 5.0 sec

Sensor input < 0.2 volts 134.3degC

(273.7degF)

Time with sensor input out

of range > 5.0 sec

Sensor input > 4.9 volts

-40.7degC(-41.3F)

Time with sensor input out

of range > 5.0 sec

Air Charge Temperature

stuck + / - 16.6degC

(30degf) from ECT IAT_RAT_THRES soak > 360 min,

ECT >-31.6degC (-25F)Once per drive

cycle

Vehicle speed ROA check VSPD > 12.5 mph time > 5.5 secs once per drive

cycle / <30 mins

Vehicle Speed >12.5 mph

Time above min speed >5 seconds

Change in IAT <2.2degC (4degF)

Number of failure events >2

Sensor signal voltage > 4.9 volts -40.7degC(-

41.25degF)

Fault filter routine > 5.0 sec

Sensor signal voltage < 0.13 volts 150.4degC (302.75degF)

Fault filter routine > 5.0 sec Engine off soak time >360 minutes

IAT sensor OK

(P0112/0113)

Sensor input < 0.2 volts 134.27degC

(273.7degF)

Time with sensor input out

of range > 5.0 sec

Sensor input > 4.9 volts

-40.7degC (-41.3degF)

Time with sensor input out

of range > 5.0 sec

EOT error vs model > +/-38degC (100degF)

Time with fault >30seconds

Sensor input < 0.2 volts 136.8degC

(273.7degF)

Time with sensor input out

of range > 5.0 sec

Sensor input > 4.9 volts

-40.7degC (-41.3degF)

Time with sensor input out

of range > 5.0 sec

Engine coolant temp 110 deg C (> 230 deg F)Continuous time with

engine off prior to start > 360 min

Time with high sensor

signal > 30 sec

ECT at start differs from

IAT at start >28 deg C

(> 50 deg F)

Catalyst, Misfire, Fuel

Rationality check, Engine-Off

timer inoperative ECT at startup cooler than

ECT at previous keyoffError>= 27.8degC (50

degF)ECT at previous keyoff

was hot >32.3degC (90degF)

Soak timer value at startup < 0.5 * 60 sec (Timer indicates that short

soak has occurred)

IAT Sensor Input

P0111IAT Absurdity >FNIA_RAT_OOR

IAT Rationality check

Footnote a) Footnote c)

IAT>Threshold

Footnote c)

Footnote c)

Footnote b)

Once per driving

cycle

Footnote a)

Footnote a)

Footnote a)

Footnote c)

Footnote a)

Footnote a)

>< +/- 26degC

(80degF)

Continuous

Battery Voltage

ECT Sensor Input

Engine-Off (Soak)

Timer Rationality

Test P0606

Once per driving

cycle

Range check

11< Voltage <18

Continuous

P0116 Rationality check (Stuck high) Battery Voltage

P0117 (Low)

P0118 (High) Range check 11< Voltage <18

Battery Voltage 11< Voltage <18 Continuous

P0197 (Low)

P0198 (High) Range check

Range check

EOT Sensor Input

P0196 Rationality

P0112 (Low)

P0113 (High)

Range check

Range check

MATF Sensor Input P009A Rationality Check - error between manifold

temperature and IAT after

long soak Footnote a) Footnote c)

P0106

(Rationality) Rationality Check

Manifold Pressure

Input

P0108 (High) Range check Continuous

Battery Voltage 11< Voltage <18

P0107 (Low) Range check

Barometric Pressure

Input P2228 (Low)

P2229 (High)Range check

Range check

P0069

(Rationality)

Rationality Check

Battery Voltage11< Voltage <18

Battery Voltage 11< Voltage <18 Footnote c)

Footnote a)

Continuous Footnote a) Footnote c)

Footnote c)Footnote c)

Footnote a)

Continuous

Continuous

Manifold temperature - IAT

P0097 (High)

P0098 (Low)

Range check

Range check

10

Page 899 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

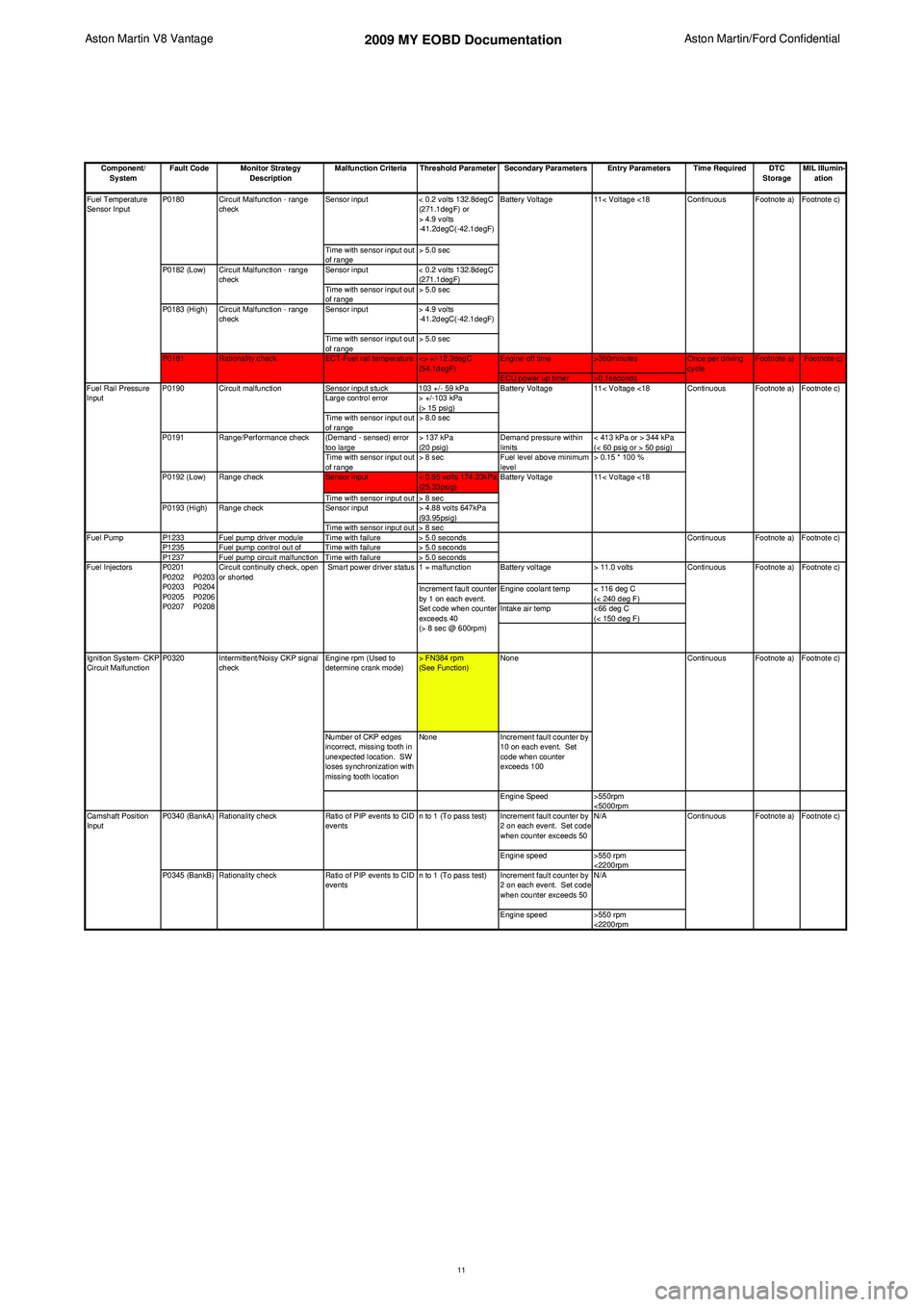

Sensor input < 0.2 volts 132.8degC

(271.1degF) or

> 4.9 volts

-41.2degC(-42.1degF)

Time with sensor input out

of range > 5.0 sec

Sensor input < 0.2 volts 132.8degC

(271.1degF)

Time with sensor input out

of range > 5.0 sec

Sensor input > 4.9 volts

-41.2degC(-42.1degF)

Time with sensor input out

of range > 5.0 sec

Engine off time >360minutes

ECU power up timer >0.1seconds

Sensor input stuck 103 +/- 59 kPa

Large control error > +/-103 kPa (> 15 psig)

Time with sensor input out

of range > 8.0 sec

(Demand - sensed) error

too large > 137 kPa

(20 psig)Demand pressure within

limits < 413 kPa or > 344 kPa

(< 60 psig or > 50 psig)

Time with sensor input out

of range > 8 sec

Fuel level above minimum

level > 0.15 * 100 %

Sensor input < 0.95 volts 174.23kPa

(25.33psig)

Time with sensor input out > 8 sec

Sensor input > 4.88 volts 647kPa

(93.95psig)

Time with sensor input out > 8 sec

P1233 Fuel pump driver module Time with failure > 5.0 seconds

P1235 Fuel pump control out of Time with failure > 5.0 seconds

P1237 Fuel pump circuit malfunction Time with failure > 5.0 seconds 1 = malfunction Battery voltage> 11.0 volts

Engine coolant temp < 116 deg C (< 240 deg F)

Intake air temp <66 deg C

(< 150 deg F)

Engine rpm (Used to

determine crank mode) > FN384 rpm

(See Function)None

Number of CKP edges

incorrect, missing tooth in

unexpected location. SW

loses synchronization with

missing tooth location None

Increment fault counter by

10 on each event. Set

code when counter

exceeds 100

Engine Speed >550rpm

<5000rpm

Increment fault counter by

2 on each event. Set code

when counter exceeds 50 N/A

Engine speed >550 rpm

<2200rpm

Increment fault counter by

2 on each event. Set code

when counter exceeds 50 N/A

Engine speed >550 rpm

<2200rpm Footnote a) Footnote c)

Continuous

<> +/-12.3degC

(54.1degF) Once per driving

cycle

Fuel Temperature

Sensor Input

ECT-Fuel rail temperature

Circuit Malfunction - range

check

Circuit Malfunction - range

check

Circuit Malfunction - range

check

P0180

P0182 (Low)

P0181 Rationality check

P0183 (High)

Ignition System- CKP

Circuit Malfunction P0320 Intermittent/Noisy CKP signal

check Footnote c)

Footnote c)

Ratio of PIP events to CID

events Continuous Footnote a) Footnote c)

n to 1 (To pass test)

n to 1 (To pass test)

Increment fault counter

by 1 on each event.

Set code when counter

exceeds 40

(> 8 sec @ 600rpm)

Smart power driver status

P0340 (BankA)

P0345 (BankB) Circuit continuity check, open

or shorted

P0201

P0202 P0203

P0203 P0204

P0205 P0206

P0207 P0208

Camshaft Position

Input Rationality check

Rationality checkRatio of PIP events to CID

events Continuous

Footnote a)

Footnote c)

Continuous Footnote a) Footnote c) Footnote a)

Battery Voltage 11< Voltage <18

11< Voltage <18 Continuous Footnote a) Footnote c)

11< Voltage <18

Circuit malfunction

Battery Voltage

Battery Voltage

Range check

Continuous Footnote a)

Fuel Injectors

Fuel Rail Pressure

Input

P0190

P0191

P0192 (Low)

P0193 (High)

Fuel Pump Range check

Range/Performance check

11

Page 900 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Ratio of PIP events to

spark events seen 1 to 1 (To pass test) Increment fault counter by

20 on each event. Set

code when counter

exceeds 200 N/A

PCM able to determine

coil Yes

Above neutral torque axis See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Difference between actual

and desired rpm > -200 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Difference between actual

and desired rpm > 100 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Vehicle ID block not

programmed P1639 VID block not programmed

with tire/axle ratio Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

VID Block checksum P0602 VID block checksum test failedTime with error present > 0 sec

NoneNoneContinuous

KAM Failed / reset P0603 Keep Alive Memory check failed / memory was resetTime with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

RAM memory failed P0604 Random Access Memory test has failed.Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

ROM checksum test

failed P0605 Read Only Memory test failed Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

CPU Fault detected P0607 General fault with the CPU has been detectedTime with error present > 0 sec

NoneNoneContinuous

Keep Alive Memory

Power Input P1633 KAM power input voltage too

low/open circuit Time with error present > 20 sec

NoneNoneContinuous Footnote k) Footnote i)

Vehicle Speed

Sensor P0500 Invalid / missing data from

BCM BCM reports VSS failure

OR no data on CAN bus1

Time after start >2 secondsContinuous Footnote a) Footnote c)

Commanded duty cycle on

or full-off >=0.5 * 100 % or = 0%

Signal circuit voltage Refer to Appendix for threshold calculation

Time with circuit

malfunction > 5 sec

P0330 Bank1

Sensor1 Sensor range check

Engine speed>1000rpm

P0325 Bank1

Sensor2 Sensor range check

Engine coolant temp >55degC (131degF)

P130A Bank2

Sensor2 Sensor range check

P130B Bank2

Sensor2 Sensor range check

P0460 (Range

Check) Sensor range check

Sensor input <= 7 or >= 254 A/D

counts w/in a range of

256 A/D counts

P0462 (Low) Circuit Check Sensor input< 7 A/D counts

P0463 (High) Circuit Check Sensor input> 254 A/D counts

Time with sensor out of

range > 30 sec

Sensor rationality check

(Stuck sensor) Compare fuel mass

consumed versus

observed change in gauge

readings (Min. and max.

reading) Fuel consumed (Fuel

consumed and fuel gauge

reading range are both

stored in KAM and reset

after a refuelling event or

DTC storage)> 10 %

"Fuel consumed" is

continuously calculated based

on PCM fuel pulse width

summation as a percent of

fuel tank capacity Fuel consumed (%) -

Range of fuel gauge

readings (%)

> 0.125 * 100 %

threshold at fuel tank

fill from 15% to 85%

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.054 + 0.125 * 100

% threshold if tank

overfilled (> 85%)

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.175 + 0.125 * 100

% threshold if tank on

reserve (< 15%)

Change in fuel level > 0.1925*100% Fuel level on the data bus N/A

Number of intermittent

events > 5

I/M Readiness Number of driving cycles

to clear I/M readiness flag

at extreme ambient

conditions > 1 driving cycle(s) Footnote e)

Footnote a)

Footnote c)

Footnote a) Footnote j) Footnote e)

Fuel Level Input

Noisy Continuous Footnote a)

Continuous Footnote a)

P0461

(Rationality) Sensor rationality check

(Noisy sensor)

Fuel Level Input

Stuck

P0460

(Rationality) Continuous

N/A Continuous

Calculated sensor noise

(peak to peak variation)

>0.25

KNKS Sensor

Fuel Level Input Out

Of Range NoneFootnote a) Footnote e)

Vapor Management

Valve Circuit

Malfunction P0443 Circuit continuity test, open or

shorted None

N/A Continuous

11.5< Voltage

Ignition System-

Ignition Coil Primary

Circuit Malfunction

IAC Solenoid

Underspeed Error P0507

P0506

Functional check -

overspeed error

Functional check -

underspeed error

IAC Solenoid

Overspeed Error

Footnote a) Footnote c)

Continuous

P0351

P0352

P0353

P0354

P0355

P0356

P0357

P0358

Rationality check

Continuous Footnote a) Footnote c)

Battery Voltage

12