coolant ASTON MARTIN V8 VANTAGE 2010 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 385 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-13

5. Remove tensioner assembly (see Figure 2).

Figure 2

6. Remove bolts (x3) securing oil pressure pump to sump.

7. Release chain from oil pressure pump sprocket, remove

oil pump.

8. Remove and discard oil pressure pump gasket.

9. Remove bolts (x3) securing oil scavenge pump to sump

(see Figure 3).

Figure 3

10. Release chain from oil scavenge pump sprocket, remove scavenge pump.

11. Remove and discard oil scavenge pump gasket (see Figure 4).

Figure 4

12. Remove oil pump(s) drive sprocket. 13. Disconnect multiplug from

oil pressure sensor (see

Figure 5).

Figure 5

14. Disconnect multiplug from engine electric coolant

temperature sensor (see Figure 6).

Figure 6

A0302274

A0302274B

A0302276

A030216

A030216A

Page 389 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-17

12. Install piston ring clamp to piston, install piston assembly

in its cylinder bore. Remo ve piston ring clamp (see

Figure 19).

Figure 19

13. Lubricate crankshaft journal with clean engine oil.

14. Carefully pull connecting ro d into place on crankshaft

journal.

15. Install bearing cap to connecting rod. Install and torque tighten retaining bolts (x2).

16. Clean windage tray.

17. Install windage tray, install and torque tighten bolts (x8).

18. Clean old sealant from sump flange and engine bedplate.

19. Ensure that sump flange and mating face on engine bedplate are clean and dry.

20. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

21. Ensure that there are no gaps in sealant track.

22. Install sump, install and torque tighten bolts (x16) in the correct sequence.

23. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

24. Lubricate and install new 'O' ring seals to oil pipes.

25. Install oil pipes in sump, install and torque tighten bolts (x2)

26. Install compressor, install and torque tighten bolts (x4).

27. Connect multiplug to A/C compressor.

28. Install LH and RH HEGO sensor multiplug brackets to sump. Install and torque tighten bolts (x4).

29. Secure harness clips (x6) in sump.

30. Connect multiplug to crankshaft timing sensor.

31. Connect multiplug to engine electric coolant temperature sensor.

32. Connect multiplug to oil pressure sensor.

33. Clean oil scavenge pump and mating face on sump.

34. Install oil pump(s) drive sprocket.

35. Install new oil scavenge pu mp gasket, align on dowels

(x2). 36. Install chain onto oil scavenge pump sprocket.

37. Install oil scavenge pump, align to dowels (x2), Install

and torque tighten bolts (x3).

38. Install chain onto oil pump drive sprocket.

39. Clean oil pressure pump and mating face on sump.

40. Install new gasket to sump, align to dowels (x2).

41. Position oil pressure pump, install chain on pump sprocket.

42. Install oil pressure pump, align to dowels (x2), Install and torque tighten bolts (x3).

43. Install chain tensioner, install and torque tighten bolt, remove guide pin.

44. Install crankshaft timing sprocket.

45. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.01.HW Gasket - Cylinder Head -

Engine Set - Renew With Engine Removed).

Additional Piston-Renew (Each)

Removal

1. Mark bearing caps and connecting rods for correct installation.

2. Remove bolts (x2) securing bearing cap to connecting rod, remove bearing cap.

3. Install special tools (303-535) to the connecting rod to prevent damage to crankshaft journal.

4. Carefully push connecting rod/piston assembly upwards and remove from cylinder bore.

5. Remove special tools from connecting rod.

6. Install bearing cap on connecting rod, install and lightly tighten retaining bolts.

7. Remove circlip (x2) securing gudgeon pin in piston and

connecting rod. Remove piston.

Installation

1. Clean cylinder bore.

2. Install piston rings in cylinder bore to a pre-determined depth and measure ring gaps.

3. Remove piston ring set from cylinder bore and install on piston.

4. Clean connecting rod.

5. Install piston on connecting rod in its correct orientation, install circlip(s).

Caution

Install pistons into cylinder block with the ‘arrow’ on the

piston crown facing to the front of the engine.

A0311337

Repair Operation Time (ROT)

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Caution

Connecting rod bolts are tor que

tightened to yield and

mu st

be replaced.

Page 391 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-19

11. Remove and discard oil scavenge pump gasket (see

Figure 4).

Figure 4

12. Remove oil pump(s) drive sprocket.

13. Disconnect multiplug from oil pressure sensor (see

Figure 5).

Figure 5

14. Disconnect multiplug from engine electric coolant temperature sensor (see Figure 6).

Figure 6

15. Disconnect multiplug from cr ankshaft timing sensor (see

Figure 7).

Figure 7

A0302276

A030216

A030216A

A030206

Page 394 of 947

Power Conversion (03.11)

Engine (03.00)3-11-22 Workshop Manual May 2007

34. Note that piston grade number on crown and thick

flange on connecting rod faces to front of engine on LH

bank (B) (see Figure 16).

Figure 16

Installation

1. Clean cylinder bores.

2. Use an expander and remove and discard piston rings from pistons.

3. Clean pistons.

4. Install new piston rings, (each set), in cylinder bores to a pre-determined depth and measure ring gaps.

5. Remove each piston ring set from cylinder bores and install on pistons

6. Remove connecting rod bearing caps.

7. Install bearings in connecting rods and bearing caps.

8. Lubricate cylinder bores, pistons and rings with clean

engine oil.

9. Install special tools (303-303-535) to the connecting rod to prevent damage to crankshaft journal.

10. Correctly position ring gaps on pistons prior to

installation. 11. Install piston ring clamp to each piston in turn and install

in its respective cylinder bore. Remove piston ring

clamp (see Figure 17).

Figure 17

12. Lubricate crankshaft journa ls with clean engine oil.

13. Carefully pull each connecting rod into place on each crankshaft journal.

14. Install bearing caps to their relevant connecting rods. Install and torque tighten retaining bolts (x16).

15. Clean windage tray.

16. Install windage tray, install and torque tighten bolts (x8).

17. Clean old sealant from sump flange and engine bedplate.

18. Ensure that sump flange and mating face on engine bedplate are clean and dry.

19. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

20. Ensure that there are no gaps in sealant track.

21. Install sump, install and torque tighten bolts (x16) in the correct sequence.

22. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

23. Lubricate and install new O-ring seals to oil pipes.

24. Install oil pipes in sump, install and torque tighten bolts (x2)

25. Install compressor, install and torque tighten bolts (x4).

26. Connect multiplug to A/C compressor.

27. Install LH and RH HEGO sensor multiplug brackets to

sump. Install and torque tighten bolts (x4).

28. Secure harness clips (x6) in sump.

29. Connect multiplug to crankshaft timing sensor.

30. Connect multiplug to engine electric coolant temperature sensor.

31. Connect multiplug to oil pressure sensor.

Caution

Make sure the piston ring gaps are positioned at

different positions opposite th e thrust side of the piston

before installation.

A0311332

Caution

Install pistons into cylinder block with the

Page 396 of 947

Power Conversion (03.11)

Engine (03.00)3-11-24 Workshop Manual May 2007

14.Disconnect multiplug from engine electric coolant

temperature sensor (see Figure 5).

Figure 5

15. Disconnect multiplug from crankshaft timing sensor. (see Figure 6)

Figure 6

16.Release harness clips (x6) from sump (see Figure 7).

Figure 7

A030216A

A030206

A030206B

Page 399 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-27

10. Install special tools (303-535) to the connecting rod to

prevent damage to crankshaft journal.

11. Install piston ring clamp to piston, install piston assembly

in its cylinder bore. Remo ve piston ring clamp (see

Figure 16).

Figure 16

12. Lubricate crankshaft journal with clean engine oil.

13. Carefully pull connecting ro d into place on crankshaft

journal.

14. Install bearing cap to connecting rod. Install and torque tighten retaining bolts (x2).

15. Clean windage tray.

16. Install windage tray, install and torque tighten bolts (x8).

17. Clean old sealant from sump flange and engine bedplate.

18. Ensure that sump flange and mating face on engine bedplate are clean and dry.

19. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

20. Ensure that there are no gaps in sealant track.

21. Install sump, install and torque tighten bolts (x16) in the correct sequence.

22. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

23. Lubricate and install new O-ring seals to oil pipes.

24. Install oil pipes in sump, install and torque tighten bolts (x2)

25. Install compressor, install and torque tighten bolts (x4).

26. Connect multiplug to A/C compressor.

27. Install LH and RH HEGO se nsor multiplug brackets to

sump. Install and torque tighten bolts (x4).

28. Secure harness clips (x6) in sump.

29. Connect multiplug to crankshaft timing sensor.

30. Connect multiplug to engine electric coolant temperature sensor. 31. Connect multiplug to oil pressure sensor.

32. Clean oil scavenge pump and mating face on sump.

33. Install oil pump(s) drive sprocket.

34. Install new oil scavenge pu

mp gasket, align on dowels

(x2).

35. Install chain onto oil scavenge pump sprocket.

36. Install oil scavenge pump, align to dowels (x2), Install and torque tighten bolts (x3).

37. Install chain onto oil pump drive sprocket.

38. Clean oil pressure pump and mating face on sump.

39. Install new gasket to sump, align to dowels (x2).

40. Position oil pressure pump, install chain on pump sprocket.

41. Install oil pressure pump, align to dowels (x2), Install and torque tighten bolts (x3).

42. Install chain tensioner, install and torque tighten bolt, remove guide pin.

43. Install crankshaft timing sprocket.

44. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.01.HW Gasket - Cylinder Head -

Engine Set - Renew With Engine Removed).Piston Ring Set-Additional-Renew (Each)

Removal

1. Mark bearing cap and connecting rod for correct

installation (see Figure 1).

Figure 1

Caution

Install pistons into cylinder block with the ‘arrow’ on the

piston crown facing to the front of the engine.

Caution

Use only a plastic scraper when removing old sealant

and gaskets from engine components.

A0311337

Repair Operation Time (ROT)

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN.

USED ENGINE OIL CAN BE HARMFUL.

A0311329

Page 402 of 947

Power Conversion (03.11)

Engine (03.00)3-11-30 Workshop Manual May 2007

14.Disconnect multiplug from engine electric coolant

temperature sensor (see Figure 6).

Figure 6

15. Disconnect multiplug from crankshaft timing sensor (see Figure 7).

Figure 7

16. Release harness clips (x6) from sump (see Figure 8).

Figure 8

A030216A

A030206

A030206B

Page 405 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-33

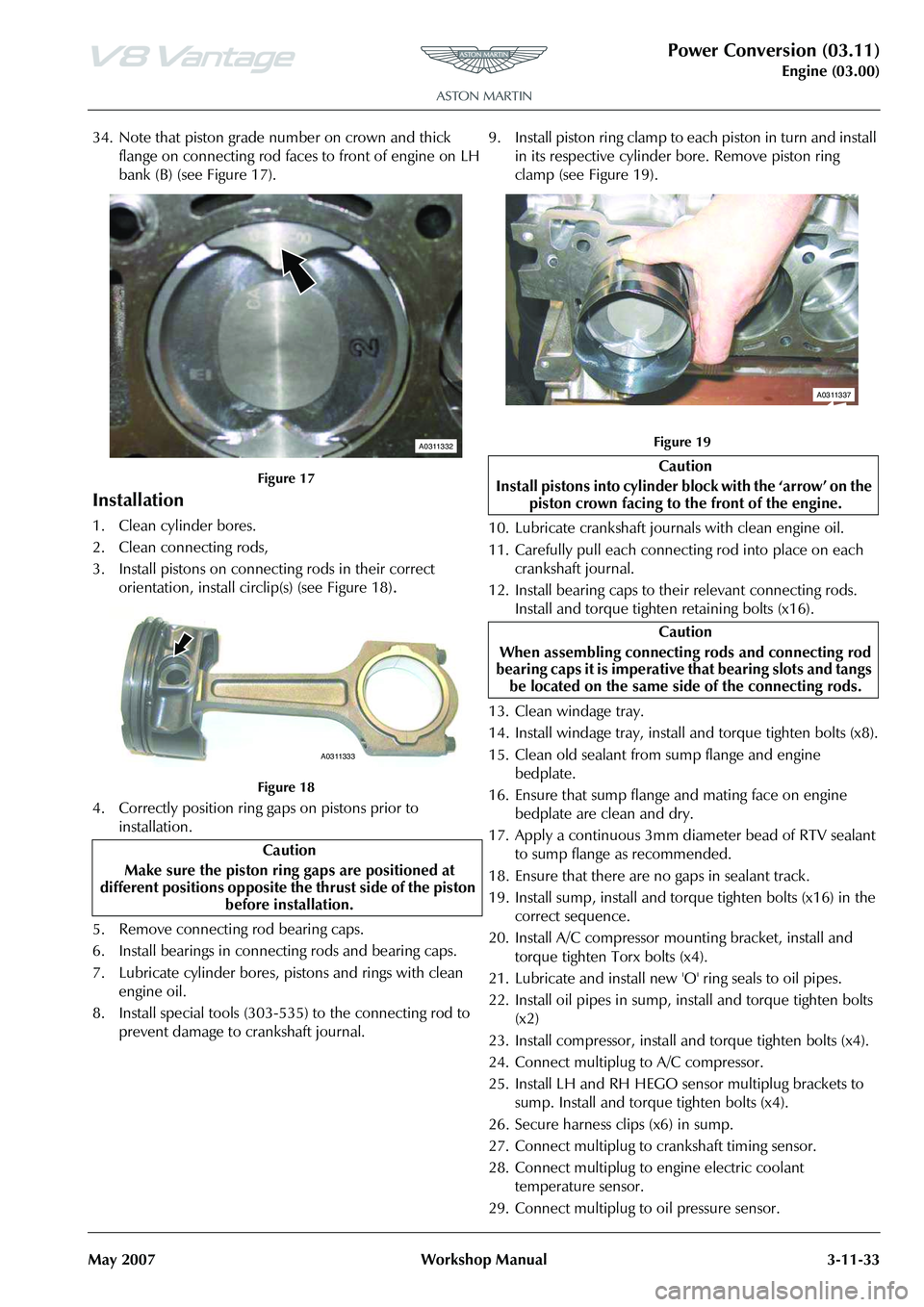

34. Note that piston grade number on crown and thick

flange on connecting rod faces to front of engine on LH

bank (B) (see Figure 17).

Figure 17

Installation

1. Clean cylinder bores.

2. Clean connecting rods,

3. Install pistons on connecting rods in their correct orientation, install circlip(s) (see Figure 18)

.

Figure 18

4. Correctly position ring gaps on pistons prior to installation.

5. Remove connecting rod bearing caps.

6. Install bearings in connecting rods and bearing caps.

7. Lubricate cylinder bores, pistons and rings with clean

engine oil.

8. Install special tools (303-535) to the connecting rod to prevent damage to crankshaft journal. 9. Install piston ring clamp to each piston in turn and install

in its respective cylinder bore. Remove piston ring

clamp (see Figure 19).

Figure 19

10. Lubricate crankshaft journals with clean engine oil.

11. Carefully pull each connecting rod into place on each crankshaft journal.

12. Install bearing caps to their relevant connecting rods. Install and torque tighten retaining bolts (x16).

13. Clean windage tray.

14. Install windage tray, install and torque tighten bolts (x8).

15. Clean old sealant from sump flange and engine bedplate.

16. Ensure that sump flange and mating face on engine bedplate are clean and dry.

17. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

18. Ensure that there are no gaps in sealant track.

19. Install sump, install and torque tighten bolts (x16) in the correct sequence.

20. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

21. Lubricate and install new 'O' ring seals to oil pipes.

22. Install oil pipes in sump, install and torque tighten bolts (x2)

23. Install compressor, install and torque tighten bolts (x4).

24. Connect multiplug to A/C compressor.

25. Install LH and RH HEGO se nsor multiplug brackets to

sump. Install and torque tighten bolts (x4).

26. Secure harness clips (x6) in sump.

27. Connect multiplug to crankshaft timing sensor.

28. Connect multiplug to engine electric coolant temperature sensor.

29. Connect multiplug to oil pressure sensor.

Caution

Make sure the piston ring gaps are positioned at

different positions opposite the thrust side of the piston

before installation.

A0311332

A0311333

Caution

Install pistons into cylinder block with the

Page 489 of 947

Brake Actuation System (06.06)

Brake System (06.00)

May 2007 Workshop Manual 6-6-3

7. Fill reservoir.

8. Bleed Brakes (see Workshop Manual procedure 06.06.AD Pad Kit - Manual Brake and Clutch Pedal -

Renew).

LHD-Brake Master Cylinder Assembly-

Renew

Removal

1. Remove corner cross brace.

2. Move expansion tank aside for access (bolt x1, nut x1, hose clips x2, multiplug x1).

3. Disconnect clutch reservoir feed pipe.

4. Disconnect multiplugs (x2).

5. Disconnect brake pipes from master cylinder (move aside).

6. Remove reservoir holding screw for access to master cylinder retaining nut.

7. Remove master cylinder from booster (nuts x2).

Installation

1. On new master cylinder - Remove reservoir holding screw for access to master cylinder retaining nut.

2. Install master cylinder to booster (nuts x2).

3. Install reservoir holding screw for access to master cylinder retaining nut.

4. Connect brake pipes to master cylinder.

5. Connect clutch reservoir feed pipe. 6. Connect multiplugs (x2).

7. Install expansion tank aside (bolt x1, nut x1, hose clips

x2, multiplug x1).

8. Install corner cross brace (torque) (only fully tighten

when vehicle on level floor).

9. Bleed Brakes (see Workshop Manual procedure 06.06.AD Pad Kit - Manual Brake and Clutch Pedal -

Renew).

10. Top-up coolant.

Clutch Master Cylinder Assembly-Renew

Removal

1. Move drivers seat fully rearward.

2. Remove clevis pin and clip.

3. Remove cylinder securing nuts (x2).

4. Remove fluid (syringe) from brake master cylinder to

below clutch level.

5. Remove corner cross brace.

6. Move expansion tank aside for access (bolt x1, nut x1, hose clips x2, multiplug x1).

7. Disconnect clutch reservoir feed pipe.

8. Disconnect clutch pipe quick fit (pull clip back) and move aside.

9. Remove cylinder assembly.

10. Remove and discard O-ring seal from master cylinder.

11. Split components

12. Remove pipe from cy linder (mark position).

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 490 of 947

Brake Actuation System (06.06)

Brake System (06.00)

6-6-4 Workshop Manual May 2007

13. Re-fit components

14. Install pipe to cylinder.

Installation

1. Install new O-ring seal on master cylinder.

2. Install cylinder assembly.

3. Connect pipe to master cylinder (quickfit).

4. Connect clutch reservoir feed pipe.

5. Install expansion tank aside (bolt x1, nut x1, hose clips x2, multiplug x1).

6. Install corner cross brace (torque) (only fully tighten when vehicle on level floor).

7. Install cylinder retaining nuts (x2) (torque).

8. Install clevis pin and clip.

9. Bleed clutch system (see Workshop Manual procedure 08.00.AF - Clutch Hydraulic System - Bleed).

10. Top-up coolant.

RH/LH Front Caliper Hose Assembly-

Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove RH/LH front wheel arch liner (see Workshop

Manual procedure 01.02.FB/01.02.GB Wheel Arch

Liner - Front - RH/LH - Renew).

4. Remove bleed nipple dust caps.

5. Position bleed container, connect bleed hose to RHR/ LHR Caliper, open bleed nipples (x1).

6. Position bleed container, connect bleed hose to RHF/ LHF Caliper, open bleed nipples (x1).

7. Depress brake pedal >60 mm and secure with support. 8. Tighten RHR/LHR bleed nipple, disconnect bleed hose,

remove bleed container and fit dust cap.

9. Tighten RHF/LHF bleed nipple, disconnect bleed hose, remove bleed container and fit dust cap.

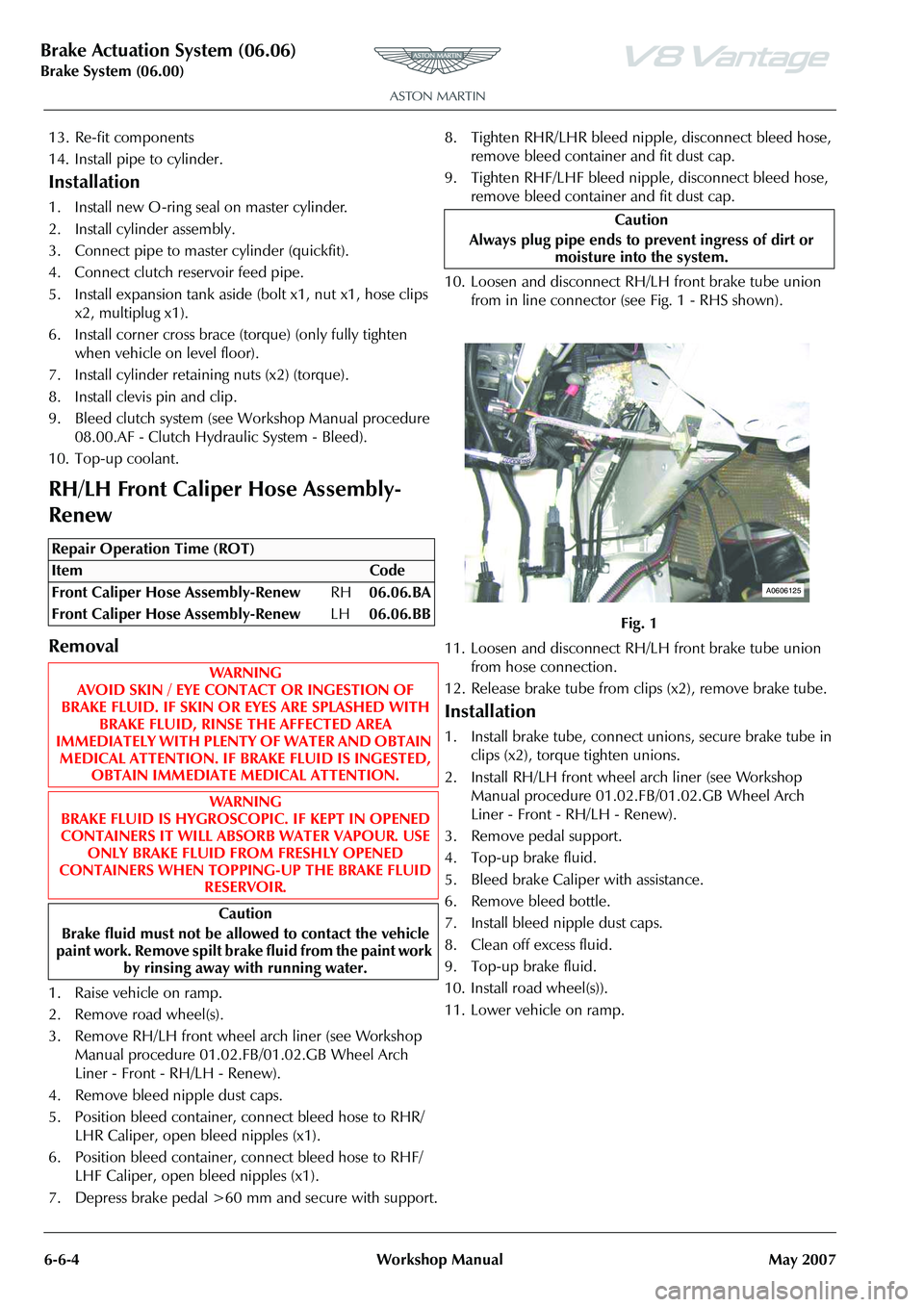

10. Loosen and disconnect RH/LH front brake tube union from in line connector (see Fig. 1 - RHS shown).

11. Loosen and disconnect RH/LH front brake tube union from hose connection.

12. Release brake tube from clips (x2), remove brake tube.

Installation

1. Install brake tube, connect unions, secure brake tube in clips (x2), torque tighten unions.

2. Install RH/LH front wheel arch liner (see Workshop Manual procedure 01.02.FB/01.02.GB Wheel Arch

Liner - Front - RH/LH - Renew).

3. Remove pedal support.

4. Top-up brake fluid.

5. Bleed brake Caliper with assistance.

6. Remove bleed bottle.

7. Install bleed nipple dust caps.

8. Clean off excess fluid.

9. Top-up brake fluid.

10. Install road wheel(s)).

11. Lower vehicle on ramp.

Repair Operation Time (ROT)

Caution

Always plug pipe ends to prevent ingress of dirt or

moisture into the system.

Fig. 1

A0606125