AUDI A4 2001 B5 / 1.G Technical Features Design And Function

Manufacturer: AUDI, Model Year: 2001, Model line: A4, Model: AUDI A4 2001 B5 / 1.GPages: 88, PDF Size: 10.42 MB

Page 21 of 88

Downloaded from www.Manualslib.com manuals search engine

21

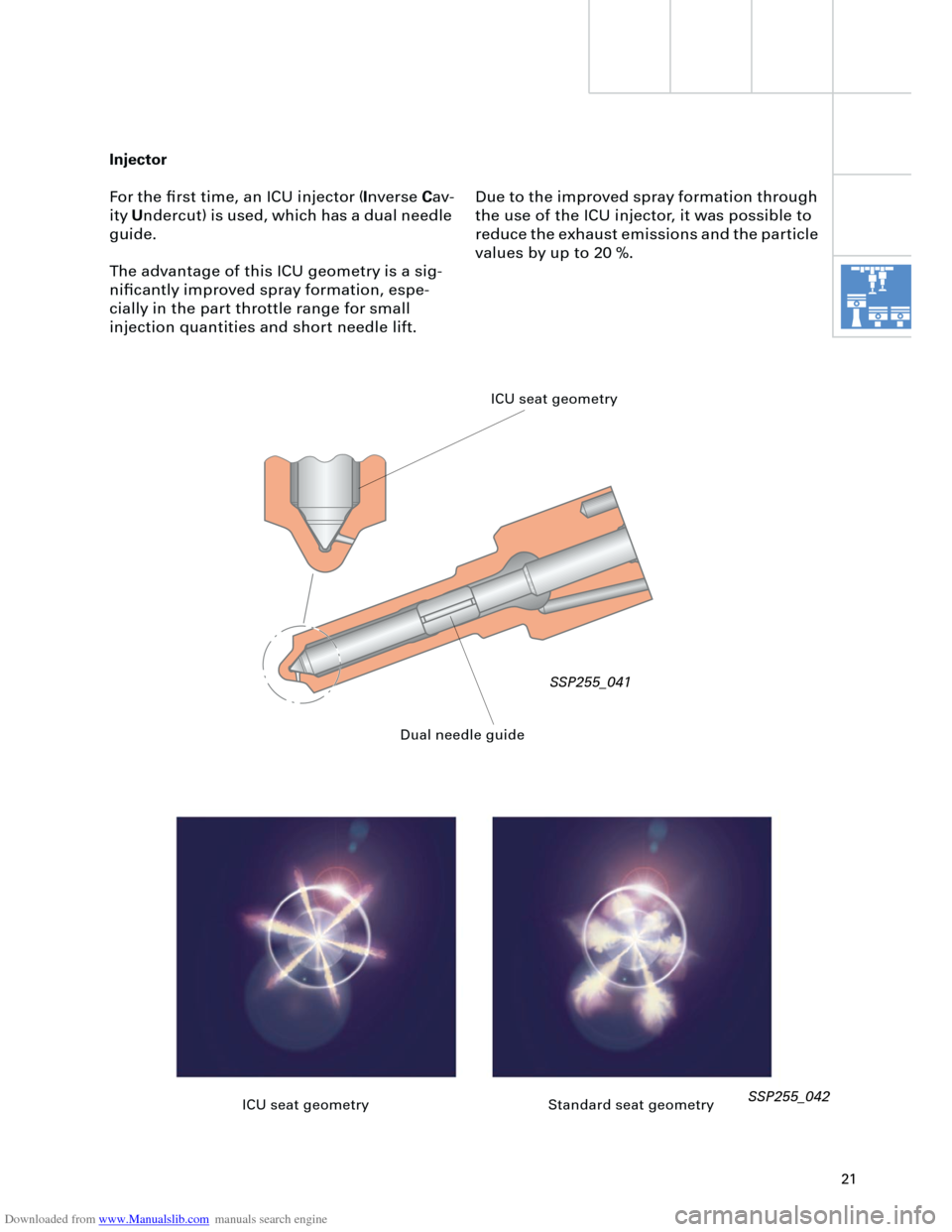

Injector

For the first time, an ICU injector (

I

nverse

C

av-

ity

U

ndercut) is used, which has a dual needle

guide.

The advantage of this ICU geometry is a sig-

nificantly improved spray formation, espe-

cially in the part throttle range for small

injection quantities and short needle lift.

SSP255_042

ICU seat geometry

Dual needle guide

Due to the improved spray formation through

the use of the ICU injector, it was possible to

reduce the exhaust emissions and the particle

values by up to 20 %.

ICU seat geometry Standard seat geometry

SSP255_041

Page 22 of 88

Downloaded from www.Manualslib.com manuals search engine

22

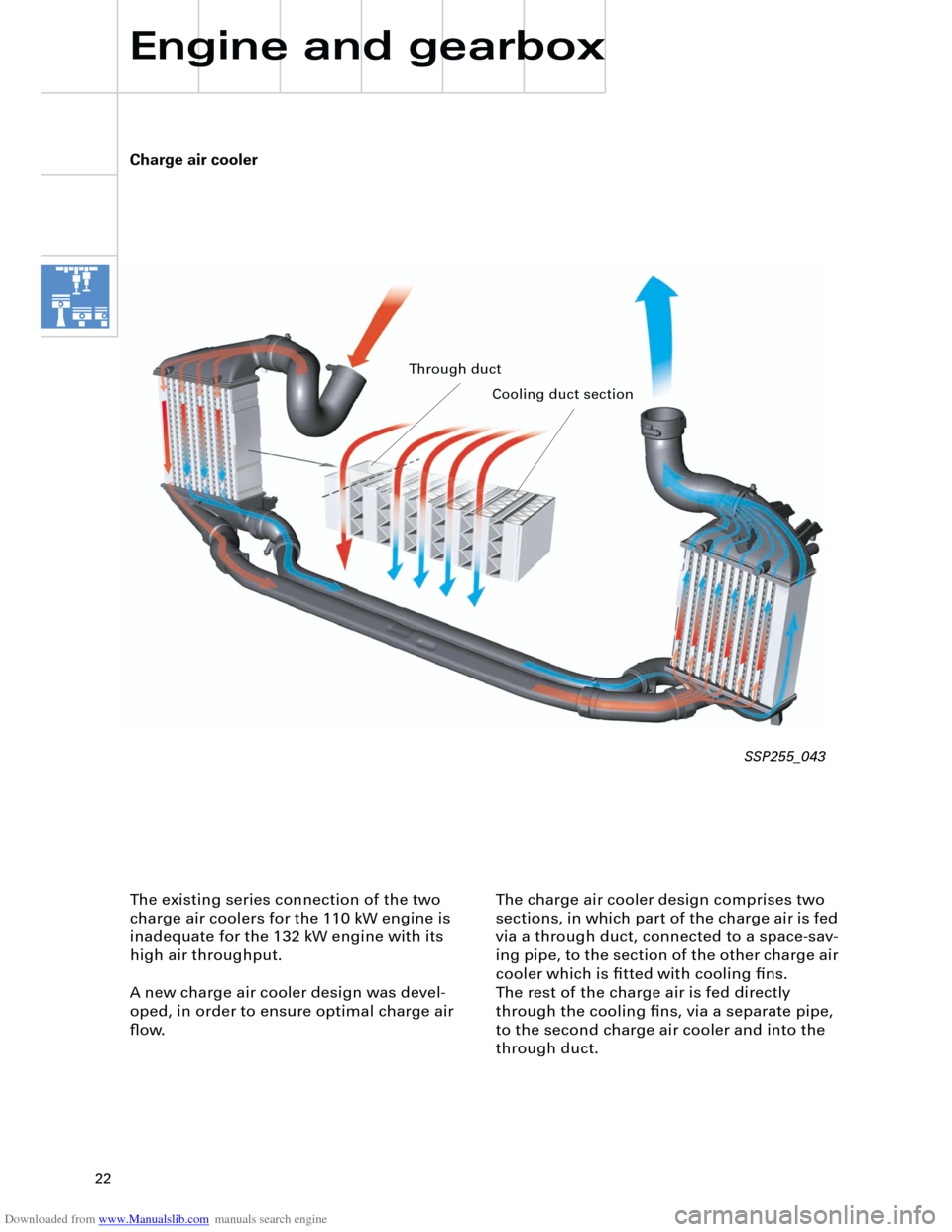

The charge air cooler design comprises two

sections, in which part of the charge air is fed

via a through duct, connected to a space-sav-

ing pipe, to the section of the other charge air

cooler which is fitted with cooling fins.

The rest of the charge air is fed directly

through the cooling fins, via a separate pipe,

to the second charge air cooler and into the

through duct.

Charge air cooler

Engine and gearbox

The existing series connection of the two

charge air coolers for the 110 kW engine is

inadequate for the 132 kW engine with its

high air throughput.

A new charge air cooler design was devel-

oped, in order to ensure optimal charge air

flow.

SSP255_043

Through duct

Cooling duct section

Page 23 of 88

Downloaded from www.Manualslib.com manuals search engine

23

P

R+NDS

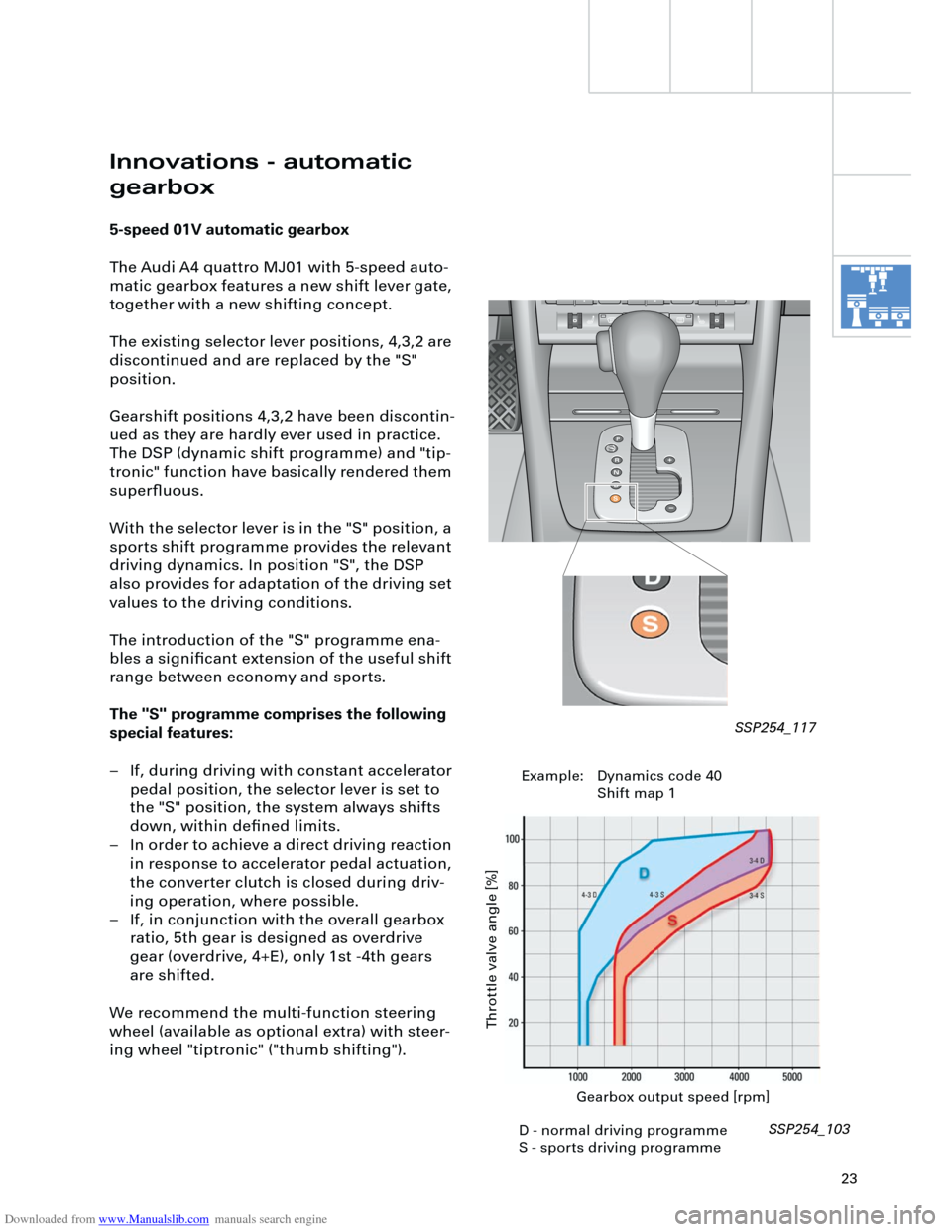

Innovations - automatic

gearbox

5-speed 01V automatic gearbox

The Audi A4 quattro MJ01 with 5-speed auto-

matic gearbox features a new shift lever gate,

together with a new shifting concept.

The existing selector lever positions, 4,3,2 are

discontinued and are replaced by the "S"

position.

Gearshift positions 4,3,2 have been discontin-

ued as they are hardly ever used in practice.

The DSP (dynamic shift programme) and "tip-

tronic" function have basically rendered them

superfluous.

With the selector lever is in the "S" position, a

sports shift programme provides the relevant

driving dynamics. In position "S", the DSP

also provides for adaptation of the driving set

values to the driving conditions.

The introduction of the "S" programme ena-

bles a significant extension of the useful shift

range between economy and sports.

The "S" programme comprises the following

special features:

– If, during driving with constant accelerator

pedal position, the selector lever is set to

the "S" position, the system always shifts

down, within defined limits.

– In order to achieve a direct driving reaction

in response to accelerator pedal actuation,

the converter clutch is closed during driv-

ing operation, where possible.

– If, in conjunction with the overall gearbox

ratio, 5th gear is designed as overdrive

gear (overdrive, 4+E), only 1st -4th gears

are shifted.

We recommend the multi-function steering

wheel (available as optional extra) with steer-

ing wheel "tiptronic" ("thumb shifting").

Gearbox output speed [rpm]

Throttle valve angle [%]

SSP254_103 SSP254_117

D - normal driving programme

S - sports driving programmeExample: Dynamics code 40

Shift map 1

Page 24 of 88

Downloaded from www.Manualslib.com manuals search engine

24

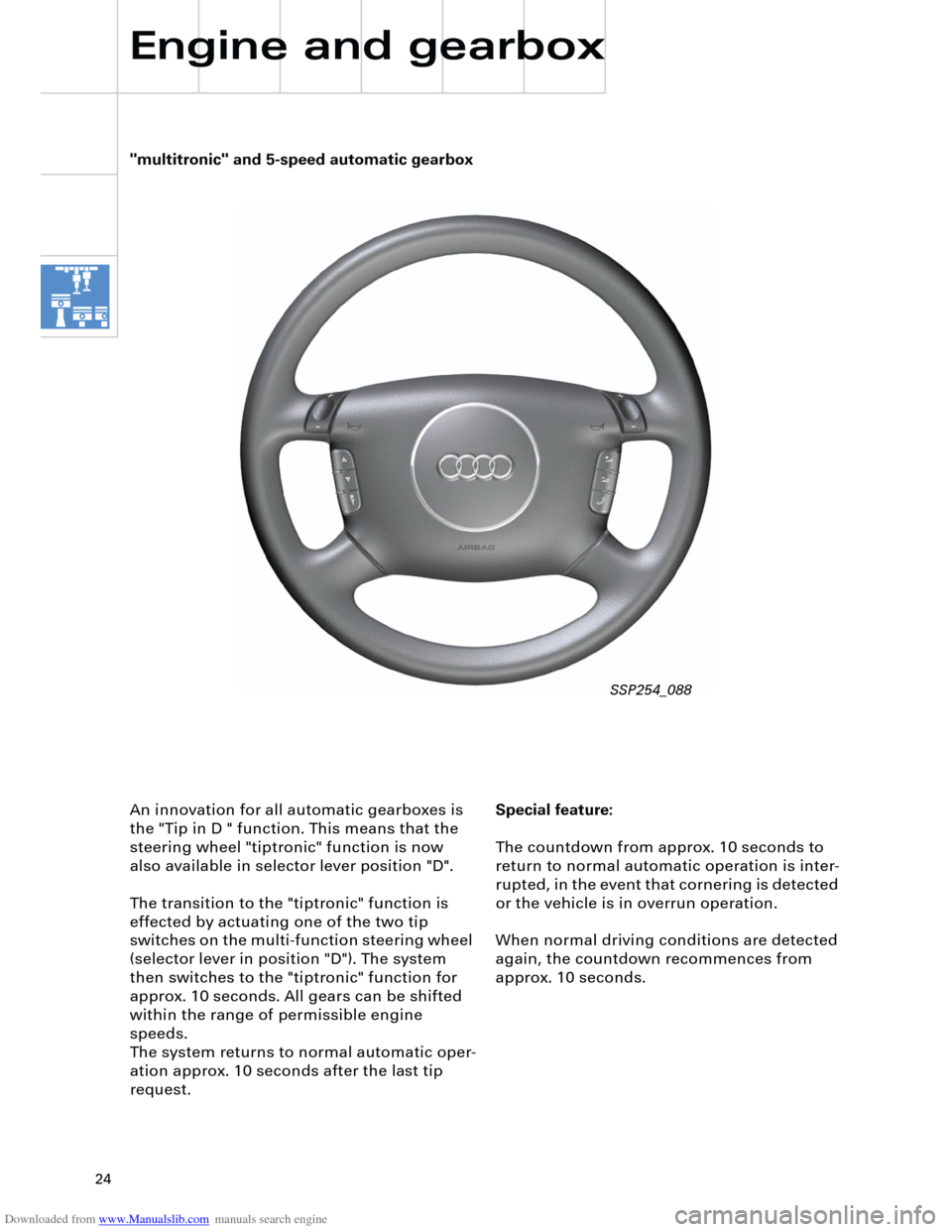

Special feature:

The countdown from approx. 10 seconds to

return to normal automatic operation is inter-

rupted, in the event that cornering is detected

or the vehicle is in overrun operation.

When normal driving conditions are detected

again, the countdown recommences from

approx. 10 seconds. An innovation for all automatic gearboxes is

the "Tip in D " function. This means that the

steering wheel "tiptronic" function is now

also available in selector lever position "D".

The transition to the "tiptronic" function is

effected by actuating one of the two tip

switches on the multi-function steering wheel

(selector lever in position "D"). The system

then switches to the "tiptronic" function for

approx. 10 seconds. All gears can be shifted

within the range of permissible engine

speeds.

The system returns to normal automatic oper-

ation approx. 10 seconds after the last tip

request.

Engine and gearbox

"multitronic" and 5-speed automatic gearbox

SSP254_088

Page 25 of 88

Downloaded from www.Manualslib.com manuals search engine

25

Notes

Page 26 of 88

Downloaded from www.Manualslib.com manuals search engine

26

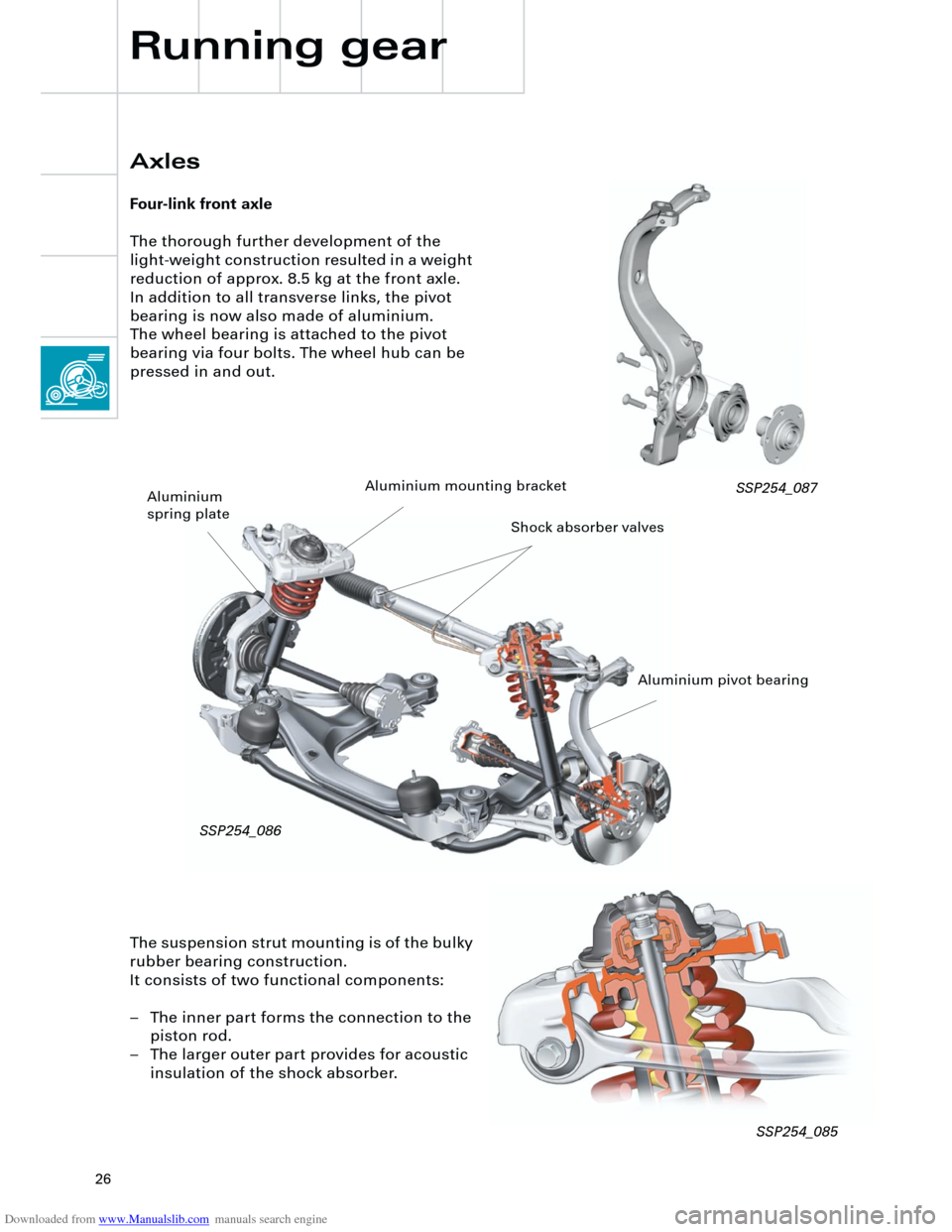

The suspension strut mounting is of the bulky

rubber bearing construction.

It consists of two functional components:

– The inner part forms the connection to the

piston rod.

– The larger outer part provides for acoustic

insulation of the shock absorber.

Axles

Four-link front axle

The thorough further development of the

light-weight construction resulted in a weight

reduction of approx. 8.5 kg at the front axle.

In addition to all transverse links, the pivot

bearing is now also made of aluminium.

The wheel bearing is attached to the pivot

bearing via four bolts. The wheel hub can be

pressed in and out.

Running gear

SSP254_087

Aluminium pivot bearing Aluminium mounting bracket

Aluminium

spring plate

Shock absorber valves

SSP254_086

SSP254_085

Page 27 of 88

Downloaded from www.Manualslib.com manuals search engine

27

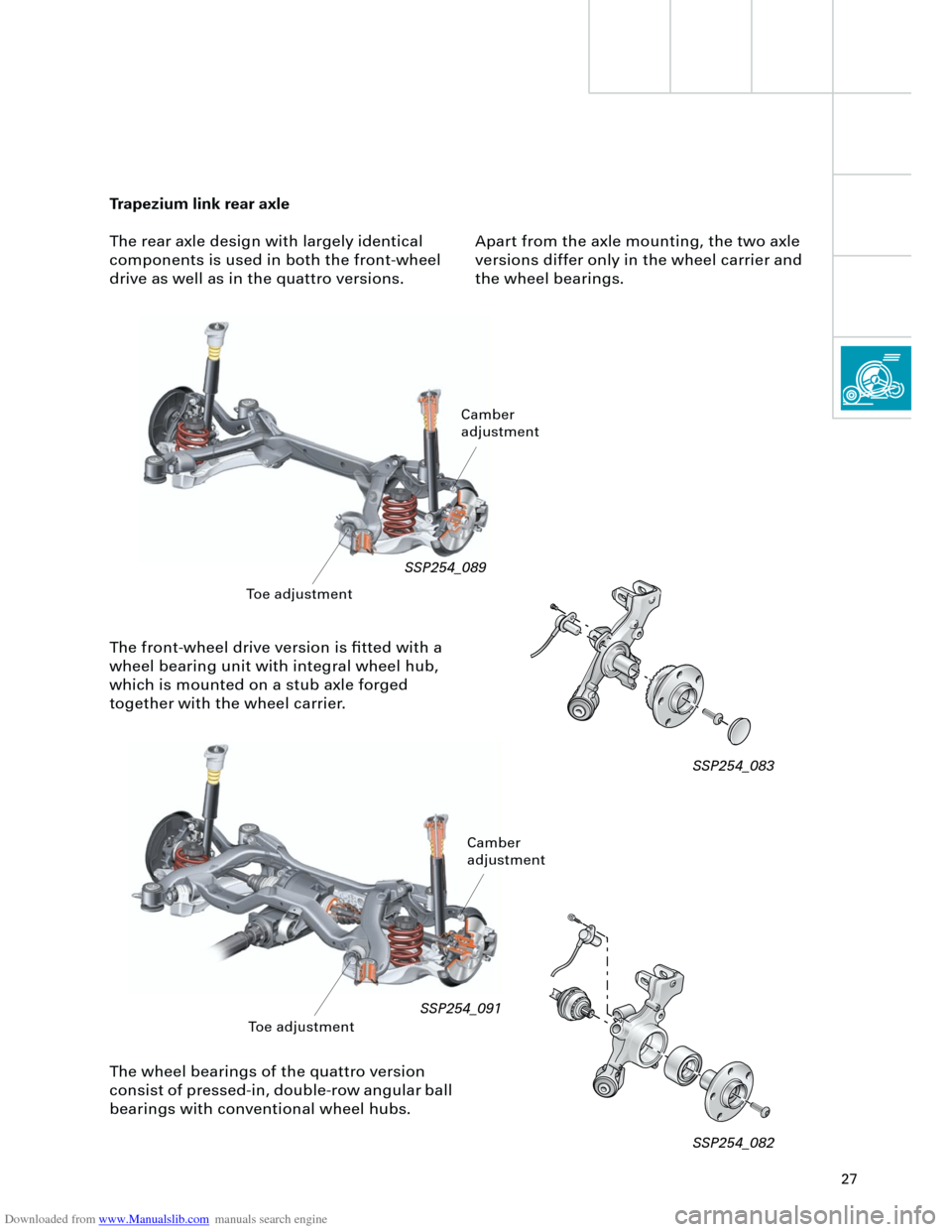

The front-wheel drive version is fitted with a

wheel bearing unit with integral wheel hub,

which is mounted on a stub axle forged

together with the wheel carrier.

Trapezium link rear axle

The rear axle design with largely identical

components is used in both the front-wheel

drive as well as in the quattro versions.

The wheel bearings of the quattro version

consist of pressed-in, double-row angular ball

bearings with conventional wheel hubs.

SSP254_089

SSP254_091

Toe adjustmentCamber

adjustment

SSP254_082 SSP254_083

Apart from the axle mounting, the two axle

versions differ only in the wheel carrier and

the wheel bearings.

Toe adjustment

Camber

adjustment

Page 28 of 88

Downloaded from www.Manualslib.com manuals search engine

28

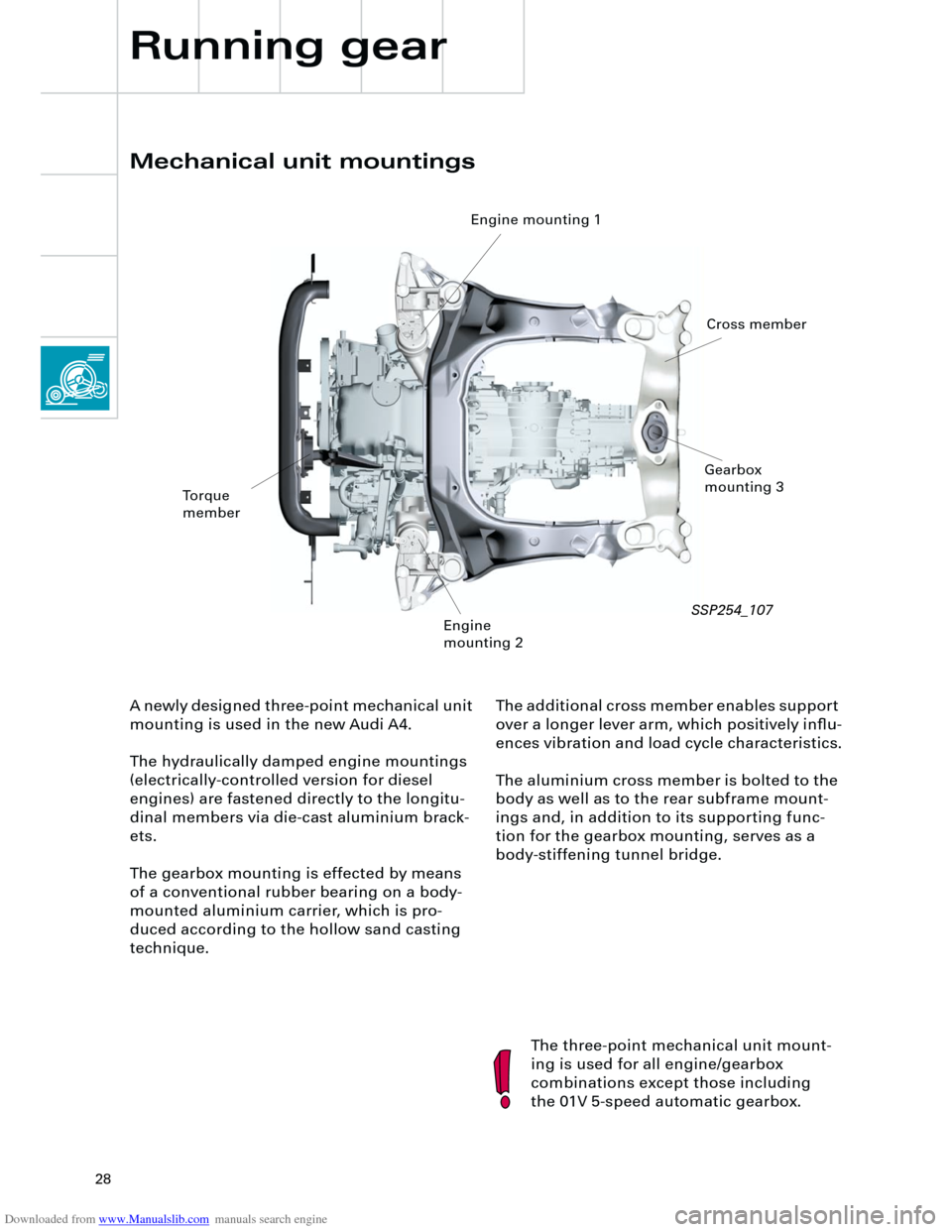

The additional cross member enables support

over a longer lever arm, which positively influ-

ences vibration and load cycle characteristics.

The aluminium cross member is bolted to the

body as well as to the rear subframe mount-

ings and, in addition to its supporting func-

tion for the gearbox mounting, serves as a

body-stiffening tunnel bridge.

Mechanical unit mountings

Running gear

The three-point mechanical unit mount-

ing is used for all engine/gearbox

combinations except those including

the 01V 5-speed automatic gearbox. A newly designed three-point mechanical unit

mounting is used in the new Audi A4.

The hydraulically damped engine mountings

(electrically-controlled version for diesel

engines) are fastened directly to the longitu-

dinal members via die-cast aluminium brack-

ets.

The gearbox mounting is effected by means

of a conventional rubber bearing on a body-

mounted aluminium carrier, which is pro-

duced according to the hollow sand casting

technique.

Torque

member

Engine mounting 1

Engine

mounting 2Gearbox

mounting 3

Cross member

SSP254_107

Page 29 of 88

Downloaded from www.Manualslib.com manuals search engine

29

Brake system

The new Bosch ESP 5.7 is introduced in the

Audi A4. The ESP 5.7 is distinguished by the

following special features:

– The hydraulic unit and control unit form a

single unit.

– The charging pump (actuation of ESP

hydraulic pump V156) is discontinued.

– A brake assistant is included.

Hydraulic modulator

Due to the increased brake fluid viscosity at

extremely low ambient temperatures, the

required delivery rate for the return pump for

ABS V39 could not be achieved without a

charging pump (resulting from the increased

suction resistance in the system).

The purpose of the development of the

ESP 5.7 was to improve the suction of the ABS

return pump so that the charging pump was

no longer necessary.

The charging pump could be discontinued

through the use of a two-stage ABS return

pump, enlarging the cross-section of the

brake lines and the use of a larger-dimen-

sioned central valve in the brake master cylin-

der.

SSP254_094

Page 30 of 88

Downloaded from www.Manualslib.com manuals search engine

30

UTUTOTOTUT

UTUTOTOTUT

Running gear

The graphic shows a comparison of the

suction volumes of both pump versions.

In the single-stage ABS return pump, the

entire suction volume must be drawn in and

flow through the suction line during one

piston stroke (piston stroke from TDC to BDC). The suction pressure is correspondingly high

and increases with increasing viscosity.

Cavitation and the associated drop in

performance on the pressure side, are the

results.

Single-stage ABS return pump

Suction volumes

SSP254_095

Suction volumes