lock AUDI A4 2008 B8 / 4.G Repair Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: A4, Model: AUDI A4 2008 B8 / 4.GPages: 342, PDF Size: 13.14 MB

Page 229 of 342

Intelligent technology227

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data current even when the ignition is off. In some cases there may not

be enough power available to start the engine.

Your vehicle is equipped with an intelligent power management

system to control the distribution of electrical energy. This signifi-

cantly improves reliability when starting the engine, and also

prolongs the life of the battery.

The main functions incorporated in the power management system

are battery diagnosis, residual current management and dynamic

power management.

Battery diagnosis

The battery diagnosis function constantly registers the condition of

the battery. Sensors detect the battery voltage, battery current and

battery temperature. This enables the system to calculate the

current power level and charge condition of the battery.

Residual current management

The residual current management reduces power consumption

while the vehicle is parked. It controls the supply of power to the

various electrical components while the ignition is switched off. The

system takes the battery diagnosis data into consideration.

Depending on the power level of the battery, the individual electrical

components are switched off one after the other to prevent the

battery from losing too much charge and to ensure that the engine

can be started reliably.

Dynamic power management

While the vehicle is moving, this function distributes the available

power to the various electrical components and systems according

to their requirements. The power management ensures that on-

board systems do not consume more electrical power than the

alternator can supply, and thus maintains the maximum possible

battery power level.

Note

•

The power management system is not able to overcome the

given physical limits. Please remember that the power and life of

the battery are limited.

•

A warning message will appear ⇒page 228, “Driver message in

the instrument cluster display” if the battery power has dropped to

a level where reliable starting is impaired.

Points to remember

Starting ability has first priority.Short trips, city traffic and low temperatures all place a heavy load

on the battery. In these conditions a large amount of power is

consumed, but only a small amount is supplied. The situation is also

critical if electrical equipment is in use when the engine is not

running. In this case power is consumed when none is being gener-

ated.

In these situations you will be aware that the power management

system is intervening to control the distribution of electrical power.

When the vehicle is parked for long periods

If you do not drive your vehicle for a period of several days or weeks,

the power management will gradually shut off the on-board

systems one by one, or reduce the amount of current they are using.

This limits the amount of power consumed and helps to ensure reli-

able starting even after a long period.

Please note that certain convenience features, such as the Audi

advanced key*, the remote control key or the electrical seat adjust-

ment may not be available when you unlock the vehicle. These func-

tions will be restored when you switch on the ignition and start the

engine.

document_0900452a81b1b9de.book Seite 227 Donnerstag, 26. Juli 2007 9:16 09

Page 236 of 342

Towing a trailer 234•

The trailer overrun brake must be set correctly. This is important

to ensure that the trailer can be braked correctly, to avoid the vehicle

and trailer “jack-knifing” and to prevent excess braking of the trailer.

•

At low outside temperatures, both the towing vehicle and the

trailer should be fitted with winter tyres.

WARNING

It is essential that you adjust your speed to suit the weather, road

and traffic conditions. Do not let the trailer stabilisation system

tempt you into taking any risks when driving – this can cause acci-

dents.•

The ESP and trailer stabilisation system cannot defy the laws

of physics. This should be kept in mind, particularly on slippery

and wet roads and when towing a trailer with a light load.

•

The trailer stabilisation system is functional, regardless of

whether the trailer has a mechanical overrun brake or not.

•

The trailer stabilisation system is not always able to detect

swaying of trailers with a light load and will therefore not inter-

vene.

•

A trailer can still “jack-knife” on slippery roads with little grip,

even if the towing vehicle is equipped with the trailer stabilisation

system.

•

Trailers with a high centre of gravity may even tip over before

they start to sway sideways.

•

If you are not towing a trailer, but the trailer socket is being

used (e.g. for an illuminated bicycle rack), the trailer stabilisation

system may be activated in extreme driving conditions.

•

Please note the additional information and warnings

⇒page 234.

Notes on towing

Driving with a trailer always requires extra care.Weight distribution

Try to avoid towing a loaded trailer with an unladen vehicle. If this

cannot be avoided, drive extra slowly to allow for the unbalanced

weight distribution.

Speed

The stability of the car and trailer is reduced with increasing speed.

For this reason it is advisable not to drive at the maximum permis-

sible top speed in unfavourable road, weather or wind conditions.

This applies especially on a downhill gradient.

You should always reduce speed immediately if the trailer shows

the slightest sign of swaying. Never try to stop the swaying by accel-

erating further.

Always brake in good time. If the trailer has an overrun brake, apply

the brakes gently at first and then firmly. This will prevent the jerking

that can be caused by the trailer wheels locking. Change down in

good time before going down a steep hill so that you can use the

engine braking effect to slow down the vehicle.

Swaying and pitching can be reduced by stabiliser aids. We recom-

mend having stabiliser aids installed when towing trailers with a

high trailer weight. They can be purchased and installed at an Audi

dealer.

Overheating

When climbing long hills in hot weather with the engine running

fast in low gear, you should keep an eye on the coolant temperature

gauge ⇒page 11. Reduce speed immediately if the needle moves to

the top end of the scale. If the temperature warning lamp

in the

instrument cluster should start flashing, stop the car and let the

engine cool down by running it at idling speed for a few minutes.

document_0900452a81b1b9de.book Seite 234 Donnerstag, 26. Juli 2007 9:16 09

Page 237 of 342

Towing a trailer235

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

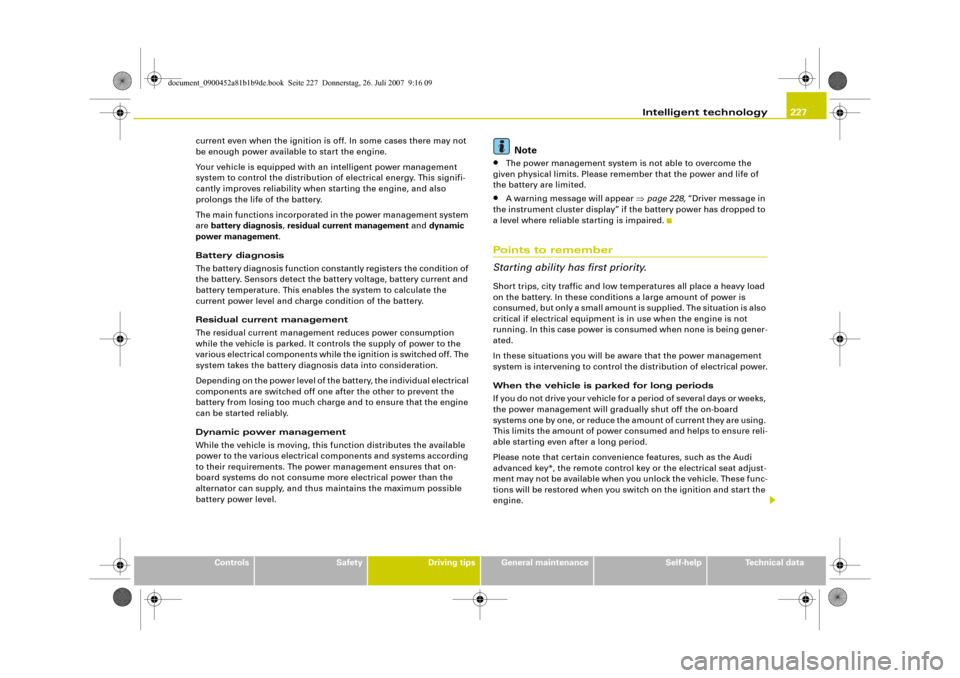

Applies to vehicles: with towing bracketAccessories

Before mounting equipment and accessories (e.g. bicycle

rack) please observe the following notes.The equipment/accessories mounted must not protrude more than

700 mm from the ball joint .

The total weight (mounted equipment plus the load) must not

exceed 75 kg.

The maximum load depends on where the centre of gravity lies.

The maximum weight decreases as the distance between the centre

of gravity and the ball joint increases.

The following limits apply:

If the distance is 300 mm, the total weight (incl. the equipment

mounted) must not exceed 75 kg.

If the distance is 600 mm, the total weight (incl. the equipment

mounted) must not exceed 35 kg.

Only bicycle racks for a maximum of three bicycles may be used.

Equipment mounted on the towing bracket

We recommend that you only mount equipment (e.g. bicycle rack)

which has been approved by Audi on the ball joint. If you wish to

attach other equipment please make sure that it has been approved by the manufacturer for use on the ball joint. If you mount unsuit-

able equipment, this can cause damage to the towing bracket. In an

extreme case, damage to the towing bracket could cause it to break

⇒.

WARNING

•

If you wish to mount equipment which has not been approved

by Audi please ensure that it is suitable for use on Audi vehicles.

•

Use of unsuitable equipment can result in severe damage to

the towing bracket. The towing bracket could then break while

pulling a trailer and cause an accident.

•

Never use tools of any kind when fitting and removing the ball

joint. This could damage the mechanism which locks the ball joint

in place and impair its safety (accident risk).

Removable towing bracketApplies to vehicles: with removable towing bracketIntroduction

Special care is required when fitting and removing the

towing bracket.

Fig. 234 Load distribu-

tion of equipment and

accessories

A1A1

AAAB

Fig. 235 Luggage

compartment with

towing bracket

document_0900452a81b1b9de.book Seite 235 Donnerstag, 26. Juli 2007 9:16 09

Page 238 of 342

Towing a trailer 236The removable ball joint attachment for the towing bracket is

carried under the floor panel on the left-hand side of the luggage

compartment and is secured by a strap.

The ball joint can be fitted and removed by hand.

WARNING

•

Never use tools of any kind when fitting and removing the ball

joint. This could damage the mechanism which locks the ball joint

in place and impair its safety (accident risk).

•

Secure the ball joint again with the strap when you have

finished using it.Note

•

Do not attempt to modify or repair the ball joint or other towing

bracket components.

•

Should you have any difficulties when using the towing bracket,

or suspect that it is not fitted properly, contact a qualified workshop.

•

Before setting off, always check that the ball joint is secured

properly ⇒page 238.

•

Never disengage the ball joint with the caravan / trailer still

hitched or with a bicycle rack or similar accessory still attached.

•

It is advisable to remove the ball joint when you are not towing a

trailer. Fold the socket back to its original position so that the

mounting fixture is properly closed.

•

The ball joint must be removed if you intend to clean the car with

a steam cleaning attachment. Make sure that the mounting fixture

is properly closed.

•

For installation and removal of the ball joint we recommend that

the gloves provided be used.

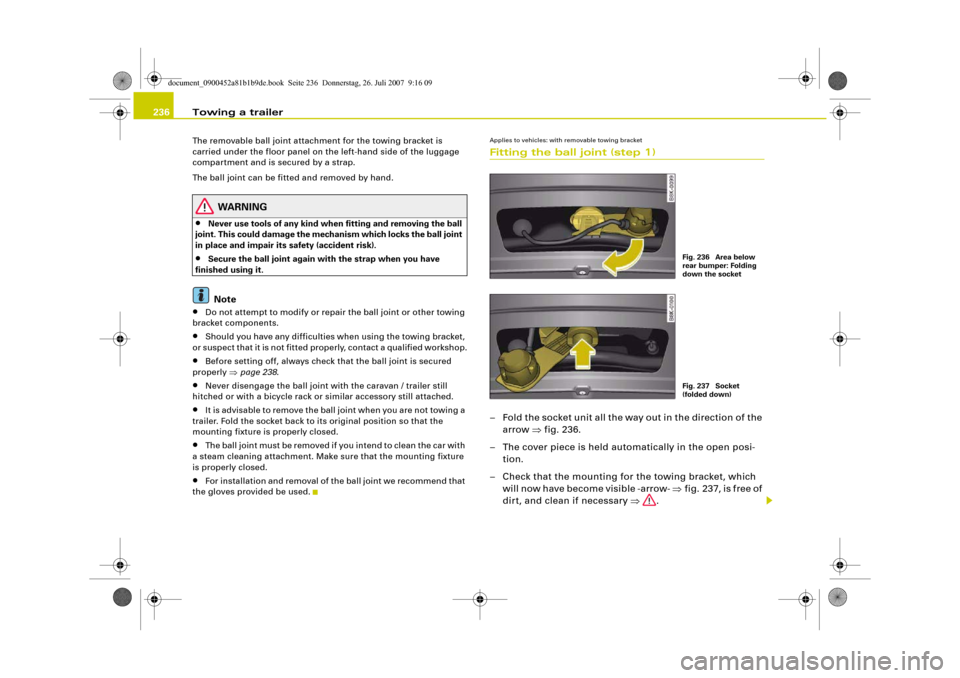

Applies to vehicles: with removable towing bracketFitting the ball joint (step 1)– Fold the socket unit all the way out in the direction of the

arrow ⇒fig. 236.

– The cover piece is held automatically in the open posi-

tion.

– Check that the mounting for the towing bracket, which

will now have become visible -arrow- ⇒fig. 237, is free of

dirt, and clean if necessary ⇒.

Fig. 236 Area below

rear bumper: Folding

down the socketFig. 237 Socket

(folded down)

document_0900452a81b1b9de.book Seite 236 Donnerstag, 26. Juli 2007 9:16 09

Page 239 of 342

Towing a trailer237

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Also check the shaft section of the ball joint and its asso-

ciated mechanical parts to make sure they are clean and

undamaged.Continued ⇒page 237, “Fitting the ball joint (step 2)”.

WARNING

It is important to keep the mounting fixture clean. Otherwise the

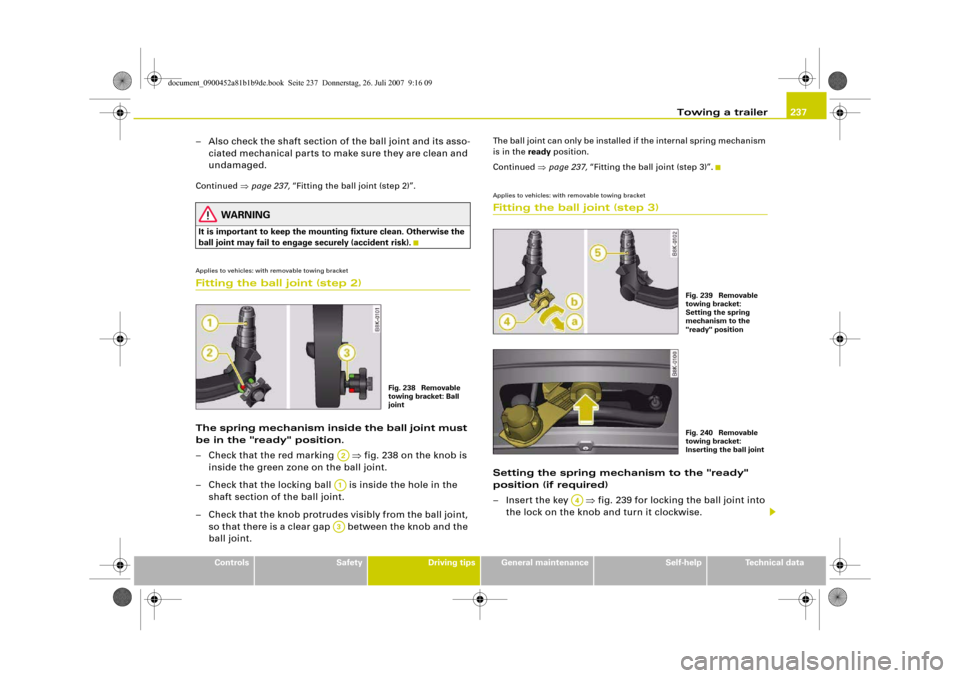

ball joint may fail to engage securely (accident risk).Applies to vehicles: with removable towing bracketFitting the ball joint (step 2)The spring mechanism inside the ball joint must

be in the "ready" position.

– Check that the red marking ⇒fig. 238 on the knob is

inside the green zone on the ball joint.

– Check that the locking ball is inside the hole in the

shaft section of the ball joint.

– Check that the knob protrudes visibly from the ball joint,

so that there is a clear gap between the knob and the

ball joint.

The ball joint can only be installed if the internal spring mechanism

is in the ready position.

Continued ⇒page 237, “Fitting the ball joint (step 3)”.Applies to vehicles: with removable towing bracketFitting the ball joint (step 3)Setting the spring mechanism to the "ready"

position (if required)

– Insert the key ⇒fig. 239 for locking the ball joint into

the lock on the knob and turn it clockwise.

Fig. 238 Removable

towing bracket: Ball

joint

A2A1A3

Fig. 239 Removable

towing bracket:

Setting the spring

mechanism to the

"ready" positionFig. 240 Removable

towing bracket:

Inserting the ball joint

A4

document_0900452a81b1b9de.book Seite 237 Donnerstag, 26. Juli 2007 9:16 09

Page 240 of 342

Towing a trailer 238

– Pull out the knob in direction , hold and turn in direc-

tion until the locking ball engages ⇒.

Inserting the ball joint

– With the spring mechanism in the “ready” position,

insert the ball joint into the mounting fixture and push it

upwards ⇒page 237, fig. 240 in the direction indicated

(arrow) ⇒. The spring mechanism should then

engage automatically with an audible click.

– Lock the ball joint by turning the key anti-clockwise.

– Take out the key and press the cover cap provided onto

the lock.Continued ⇒page 238, “Fitting the ball joint (step 4)”.

WARNING

•

If it is not possible to set the spring mechanism to the "ready"

position as described above, do not use the ball joint. Please take

your vehicle to a qualified workshop.

•

To avoid injury, keep your hands away from the knob and the

cover piece when inserting the ball joint into the mounting fixture.Note

Make sure that the knob can turn freely when the ball joint is

inserted.

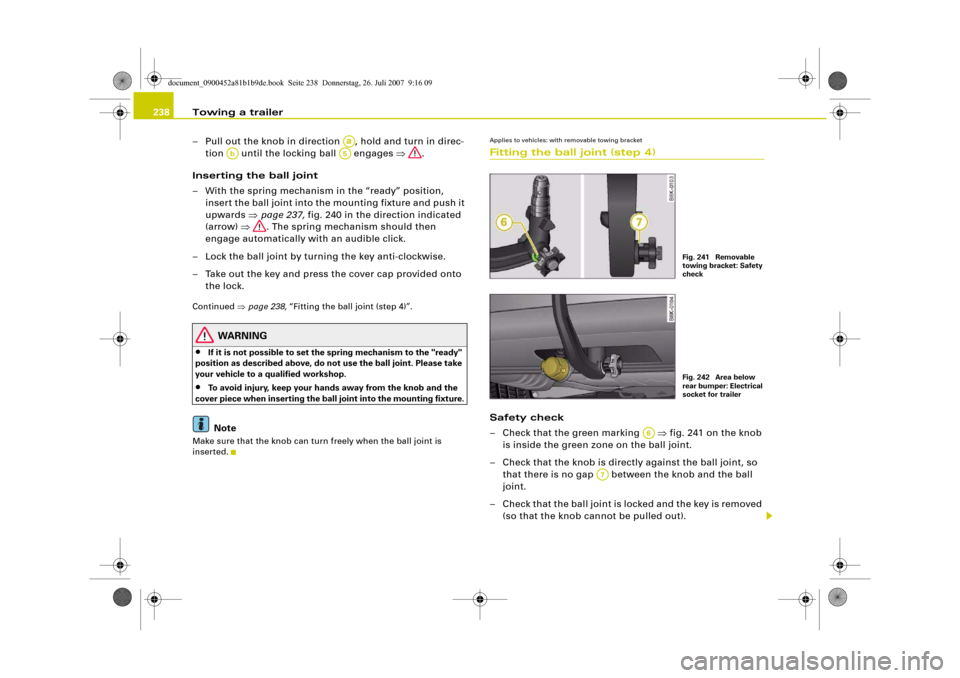

Applies to vehicles: with removable towing bracketFitting the ball joint (step 4)Safety check

– Check that the green marking ⇒fig. 241 on the knob

is inside the green zone on the ball joint.

– Check that the knob is directly against the ball joint, so

that there is no gap between the knob and the ball

joint.

– Check that the ball joint is locked and the key is removed

(so that the knob cannot be pulled out).

Aa

Ab

A5

Fig. 241 Removable

towing bracket: Safety

checkFig. 242 Area below

rear bumper: Electrical

socket for trailer

A6

A7

document_0900452a81b1b9de.book Seite 238 Donnerstag, 26. Juli 2007 9:16 09

Page 241 of 342

Towing a trailer239

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Check that the ball joint fits tightly in the mounting

fixture (try moving it about to check).

Electrical socket for trailer

– The cable of the towing bracket can be connected to the

socket ⇒page 238, fig. 242.If the safety check is not satisfactory, the ball joint must be fitted

again properly.

WARNING

To avoid accidents, the ball joint must meet all the safety require-

ments listed in the safety check. The towing bracket must not be

used if any one of these requirements is not met. If this is the case,

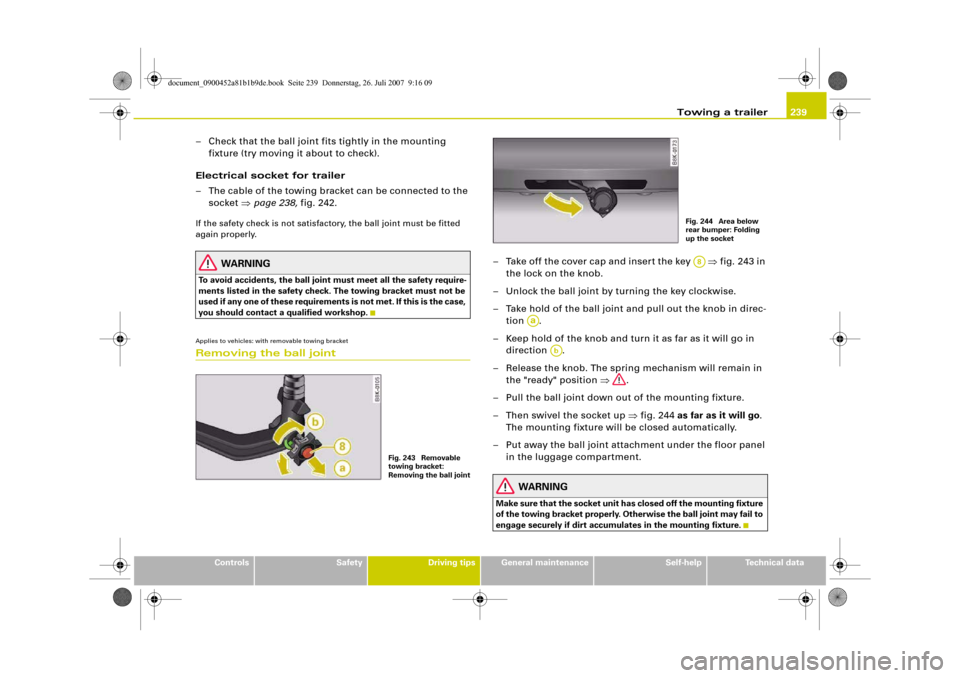

you should contact a qualified workshop.Applies to vehicles: with removable towing bracketRemoving the ball joint

– Take off the cover cap and insert the key ⇒fig. 243 in

the lock on the knob.

– Unlock the ball joint by turning the key clockwise.

– Take hold of the ball joint and pull out the knob in direc-

tion .

– Keep hold of the knob and turn it as far as it will go in

direction .

– Release the knob. The spring mechanism will remain in

the "ready" position ⇒.

– Pull the ball joint down out of the mounting fixture.

– Then swivel the socket up ⇒fig. 244 as far as it will go.

The mounting fixture will be closed automatically.

– Put away the ball joint attachment under the floor panel

in the luggage compartment.

WARNING

Make sure that the socket unit has closed off the mounting fixture

of the towing bracket properly. Otherwise the ball joint may fail to

engage securely if dirt accumulates in the mounting fixture.

Fig. 243 Removable

towing bracket:

Removing the ball joint

Fig. 244 Area below

rear bumper: Folding

up the socketA8

Aa

Ab

document_0900452a81b1b9de.book Seite 239 Donnerstag, 26. Juli 2007 9:16 09

Page 254 of 342

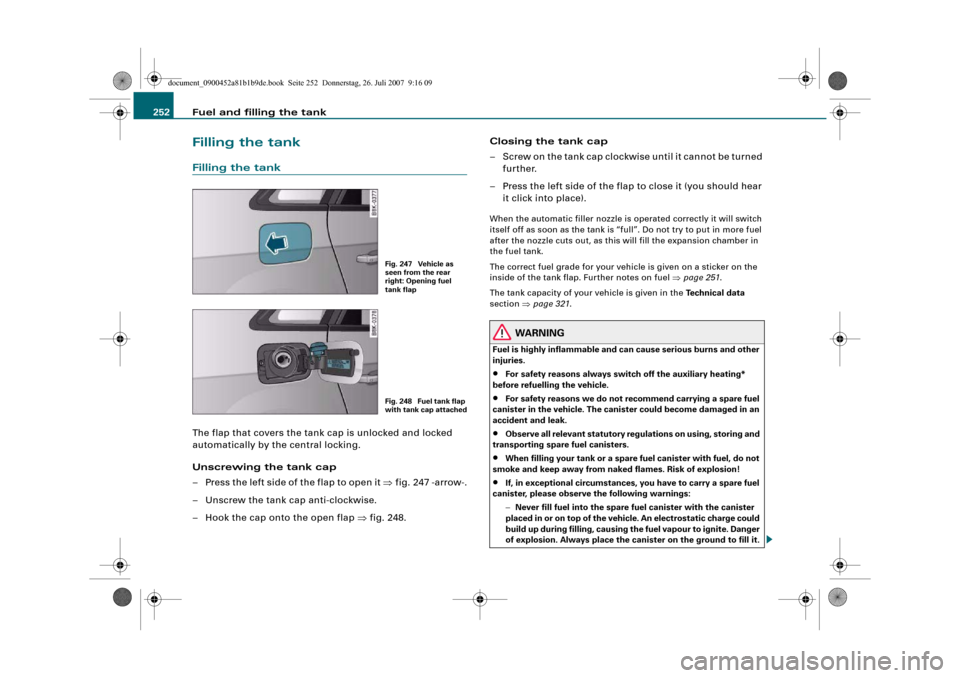

Fuel and filling the tank 252Filling the tankFilling the tankThe flap that covers the tank cap is unlocked and locked

automatically by the central locking.

Unscrewing the tank cap

– Press the left side of the flap to open it ⇒fig. 247 -arrow-.

– Unscrew the tank cap anti-clockwise.

– Hook the cap onto the open flap ⇒fig. 248.Closing the tank cap

– Screw on the tank cap clockwise until it cannot be turned

further.

– Press the left side of the flap to close it (you should hear

it click into place).

When the automatic filler nozzle is operated correctly it will switch

itself off as soon as the tank is “full”. Do not try to put in more fuel

after the nozzle cuts out, as this will fill the expansion chamber in

the fuel tank.

The correct fuel grade for your vehicle is given on a sticker on the

inside of the tank flap. Further notes on fuel ⇒page 251.

The tank capacity of your vehicle is given in the Technical data

section ⇒page 321.

WARNING

Fuel is highly inflammable and can cause serious burns and other

injuries.•

For safety reasons always switch off the auxiliary heating*

before refuelling the vehicle.

•

For safety reasons we do not recommend carrying a spare fuel

canister in the vehicle. The canister could become damaged in an

accident and leak.

•

Observe all relevant statutory regulations on using, storing and

transporting spare fuel canisters.

•

When filling your tank or a spare fuel canister with fuel, do not

smoke and keep away from naked flames. Risk of explosion!

•

If, in exceptional circumstances, you have to carry a spare fuel

canister, please observe the following warnings:

−Never fill fuel into the spare fuel canister with the canister

placed in or on top of the vehicle. An electrostatic charge could

build up during filling, causing the fuel vapour to ignite. Danger

of explosion. Always place the canister on the ground to fill it.

Fig. 247 Vehicle as

seen from the rear

right: Opening fuel

tank flapFig. 248 Fuel tank flap

with tank cap attached

document_0900452a81b1b9de.book Seite 252 Donnerstag, 26. Juli 2007 9:16 09

Page 255 of 342

Fuel and filling the tank253

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data −Insert the filler nozzle as far as possible into the spare fuel

canister.

−If the spare fuel canister is made of metal, the filler nozzle

must be in contact with the canister during filling. This helps

prevent an electrostatic charge building up.

−Make sure you never spill fuel in the vehicle or in the luggage

compartment. Fuel vapour is explosive. Risk of fatal accident!

Caution

•

If any fuel is spilt onto the vehicle, it should be removed immedi-

ately, as it could otherwise damage the paintwork.

•

Never run the tank completely dry. If there is an irregular fuel

supply, misfiring can occur. As a result unburnt fuel can enter the

exhaust system and cause damage to the catalytic converter(s).

•

When filling the fuel tank after having run it completely dry on a

vehicle with a diesel engine the ignition must be switched on for at

least 30 seconds without starting the engine. When you then start

the engine it may take longer than normal (up to one minute) for the

engine to start firing. This is because air needs to be bled from the

fuel system while starting.For the sake of the environment

Do not try to put in more fuel after the automatic filler nozzle has

switched off; this may cause the fuel to overflow if it becomes warm.

Note

The tank flap is not locked when you lock the vehicle from the

inside.

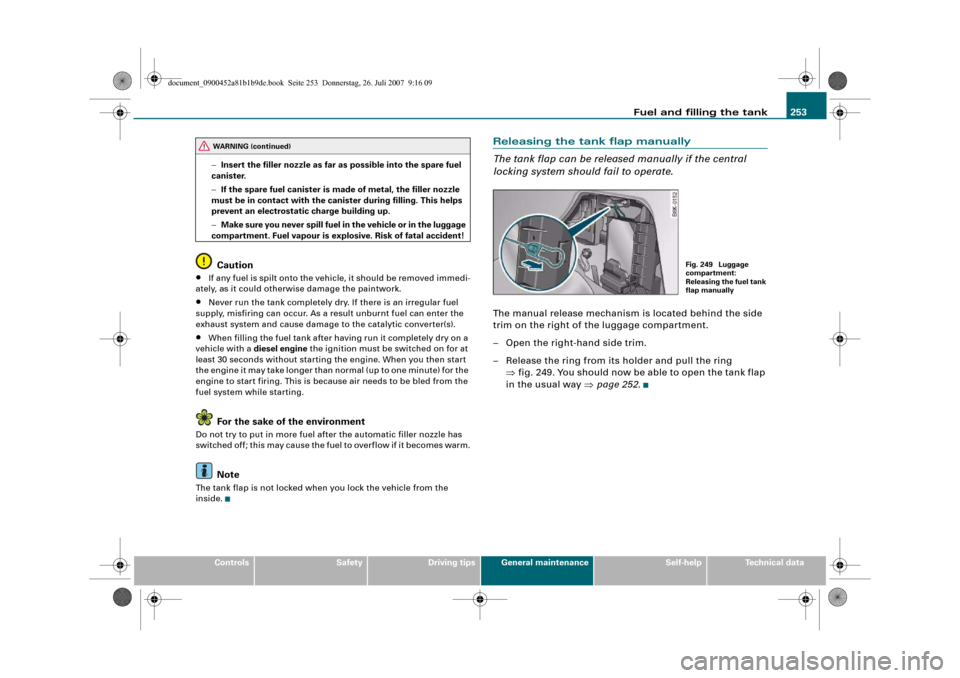

Releasing the tank flap manually

The tank flap can be released manually if the central

locking system should fail to operate.The manual release mechanism is located behind the side

trim on the right of the luggage compartment.

– Open the right-hand side trim.

– Release the ring from its holder and pull the ring

⇒fig. 249. You should now be able to open the tank flap

in the usual way ⇒page 252.

WARNING (continued)

Fig. 249 Luggage

compartment:

Releasing the fuel tank

flap manually

document_0900452a81b1b9de.book Seite 253 Donnerstag, 26. Juli 2007 9:16 09

Page 256 of 342

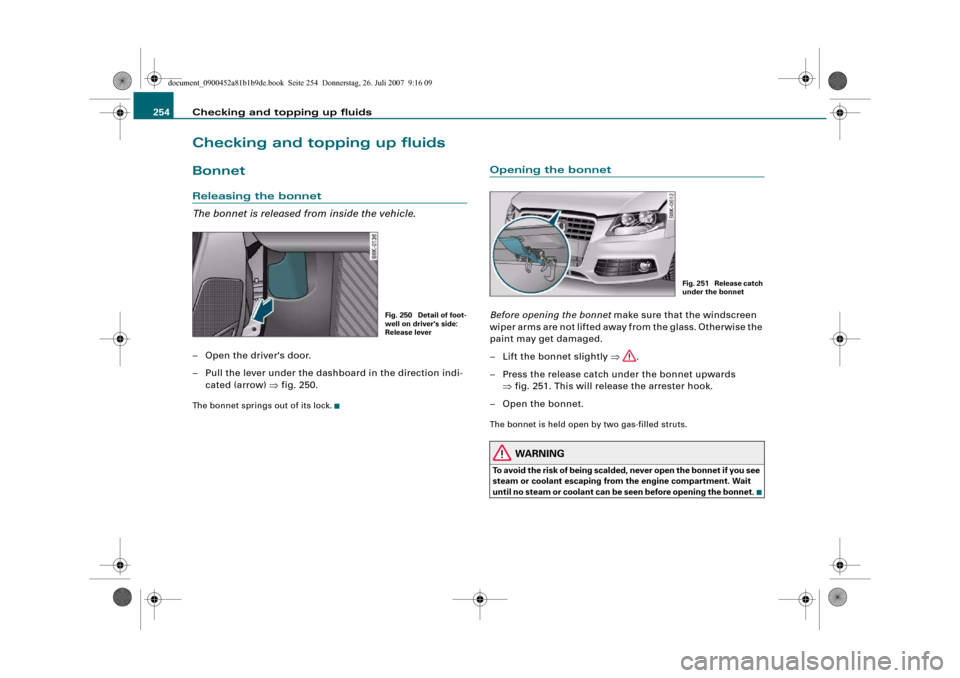

Checking and topping up fluids 254Checking and topping up fluidsBonnetReleasing the bonnet

The bonnet is released from inside the vehicle.– Open the driver's door.

– Pull the lever under the dashboard in the direction indi-

cated (arrow) ⇒fig. 250.The bonnet springs out of its lock.

Opening the bonnetBefore opening the bonnet make sure that the windscreen

wiper arms are not lifted away from the glass. Otherwise the

paint may get damaged.

– Lift the bonnet slightly ⇒.

– Press the release catch under the bonnet upwards

⇒fig. 251. This will release the arrester hook.

– Open the bonnet.The bonnet is held open by two gas-filled struts.

WARNING

To avoid the risk of being scalded, never open the bonnet if you see

steam or coolant escaping from the engine compartment. Wait

until no steam or coolant can be seen before opening the bonnet.

Fig. 250 Detail of foot-

well on driver's side:

Release lever

Fig. 251 Release catch

under the bonnet

document_0900452a81b1b9de.book Seite 254 Donnerstag, 26. Juli 2007 9:16 09