engine oil AUDI A8 1996 D2 / 1.G AHA ATQ Engines Lubrication System Components Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1996, Model line: A8, Model: AUDI A8 1996 D2 / 1.GPages: 34, PDF Size: 0.68 MB

Page 1 of 34

17-1

Lubrication system

components, removing and

installing

WARNING!

Do not re-use any fasteners that are worn or

deformed in normal use.

Some fasteners are designed to be used only

once, and are unreliable and may fail if used

again. This includes, but is not limited to,

nuts, bolts, washers, circlips and cotter pins.

Always follow the recommendations in this

manual-replace these fasteners with new

parts where indicated, and any other time it

is deemed necessary by inspection.

CAUTION!

If large quantities of metal particles or other

deposits (caused, i.e. by partial seizure of the

crankshaft or connecting rod bearings) are

found in engine oil, thoroughly clean oil

passages and replace oil cooler to prevent

damage from re-occuring.

Do not overfill with oil past the MAX mark on

the oil dipstick. Damage to the Three Way

Catalytic Converter (TWC) could result.

Pa

ge 1 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 6 of 34

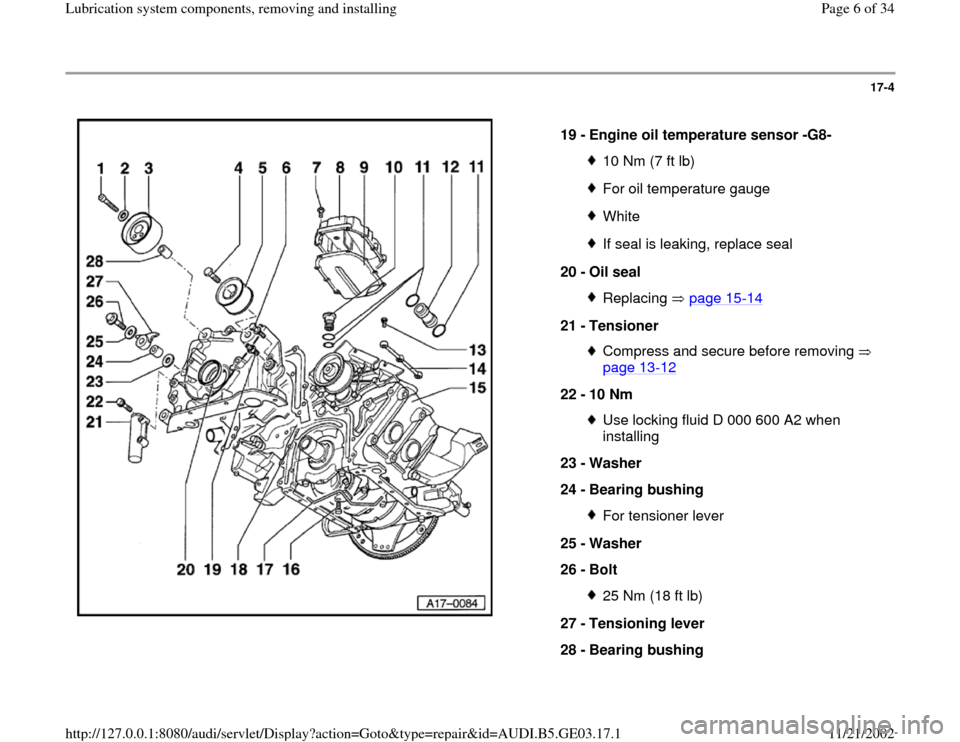

17-4

19 -

Engine oil temperature sensor -G8-

10 Nm (7 ft lb)For oil temperature gaugeWhiteIf seal is leaking, replace seal

20 -

Oil seal Replacing page 15

-14

21 -

Tensioner

Compress and secure before removing

page 13

-12

22 -

10 Nm

Use locking fluid D 000 600 A2 when

installing

23 -

Washer

24 -

Bearing bushing For tensioner lever

25 -

Washer

26 -

Bolt 25 Nm (18 ft lb)

27 -

Tensioning lever

28 -

Bearing bushing

Pa

ge 6 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 8 of 34

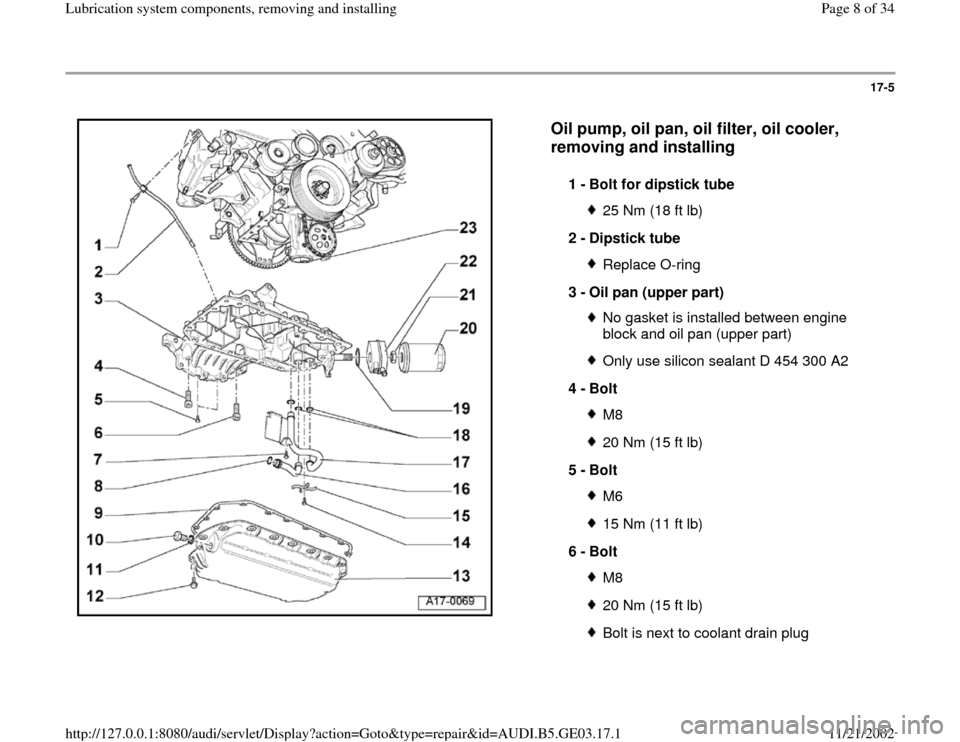

17-5

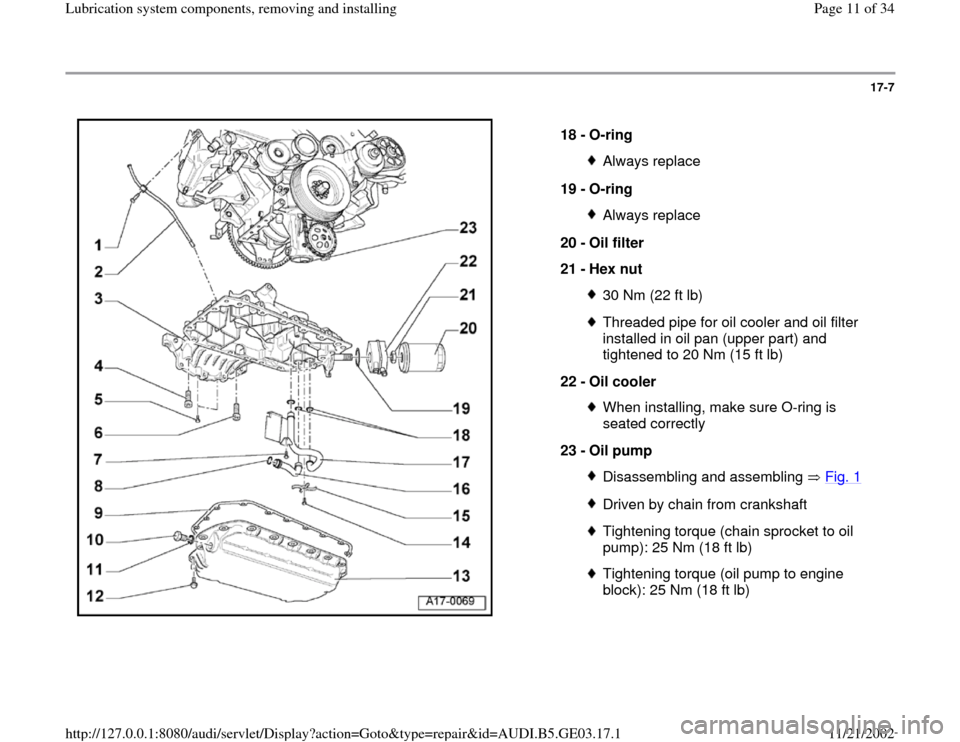

Oil pump, oil pan, oil filter, oil cooler,

removing and installing

1 -

Bolt for dipstick tube

25 Nm (18 ft lb)

2 -

Dipstick tube Replace O-ring

3 -

Oil pan (upper part) No gasket is installed between engine

block and oil pan (upper part) Only use silicon sealant D 454 300 A2

4 -

Bolt M820 Nm (15 ft lb)

5 -

Bolt M615 Nm (11 ft lb)

6 -

Bolt M820 Nm (15 ft lb)Bolt is next to coolant drain plug

Pa

ge 8 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 10 of 34

From pump to oil filter

17 -

Oil supply line From oil filter to engine oil circulation

Pa

ge 10 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 11 of 34

17-7

18 -

O-ring

Always replace

19 -

O-ring Always replace

20 -

Oil filter

21 -

Hex nut 30 Nm (22 ft lb)Threaded pipe for oil cooler and oil filter

installed in oil pan (upper part) and

tightened to 20 Nm (15 ft lb)

22 -

Oil cooler When installing, make sure O-ring is

seated correctly

23 -

Oil pump Disassembling and assembling Fig. 1Driven by chain from crankshaftTightening torque (chain sprocket to oil

pump): 25 Nm (18 ft lb) Tightening torque (oil pump to engine

block): 25 Nm (18 ft lb)

Pa

ge 11 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 15 of 34

17-11

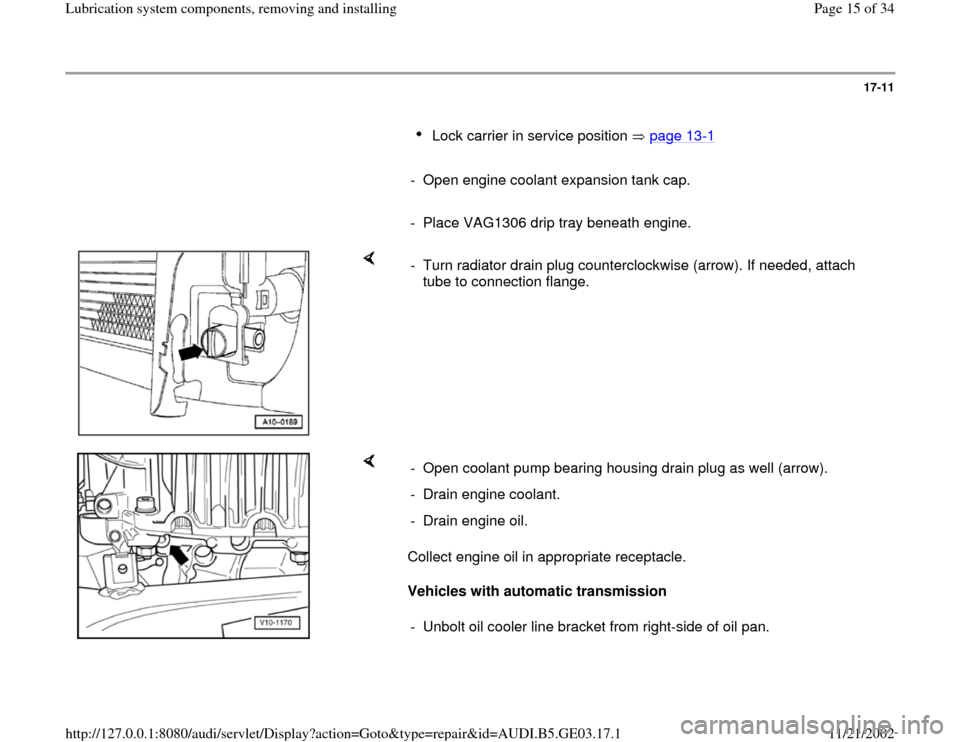

Lock carrier in service position page 13

-1

- Open engine coolant expansion tank cap.

- Place VAG1306 drip tray beneath engine.

- Turn radiator drain plug counterclockwise (arrow). If needed, attach

tube to connection flange.

Collect engine oil in appropriate receptacle.

Vehicles with automatic transmission - Open coolant pump bearing housing drain plug as well (arrow).

- Drain engine coolant.

- Drain engine oil.

- Unbolt oil cooler line bracket from right-side of oil pan.

Pa

ge 15 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 16 of 34

17-12

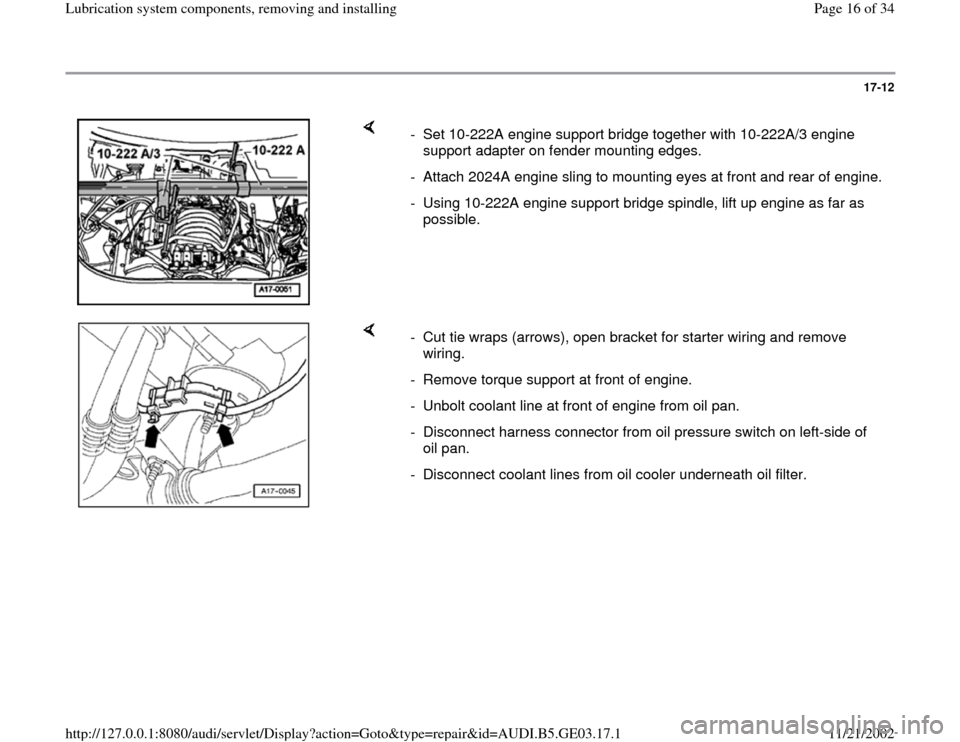

- Set 10-222A engine support bridge together with 10-222A/3 engine

support adapter on fender mounting edges.

- Attach 2024A engine sling to mounting eyes at front and rear of engine.

- Using 10-222A engine support bridge spindle, lift up engine as far as

possible.

- Cut tie wraps (arrows), open bracket for starter wiring and remove

wiring.

- Remove torque support at front of engine.

- Unbolt coolant line at front of engine from oil pan.

- Disconnect harness connector from oil pressure switch on left-side of

oil pan.

- Disconnect coolant lines from oil cooler underneath oil filter.

Pa

ge 16 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 19 of 34

17-15

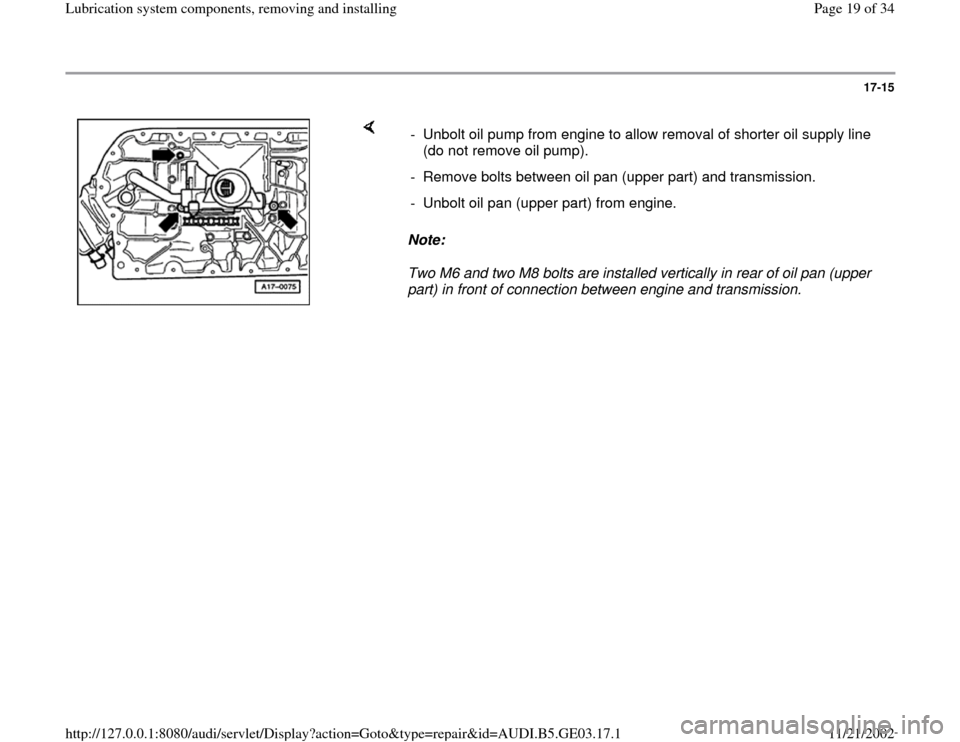

Note:

Two M6 and two M8 bolts are installed vertically in rear of oil pan (upper

part) in front of connection between engine and transmission. - Unbolt oil pump from engine to allow removal of shorter oil supply line

(do not remove oil pump).

- Remove bolts between oil pan (upper part) and transmission.

- Unbolt oil pan (upper part) from engine.

Pa

ge 19 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 21 of 34

17-17

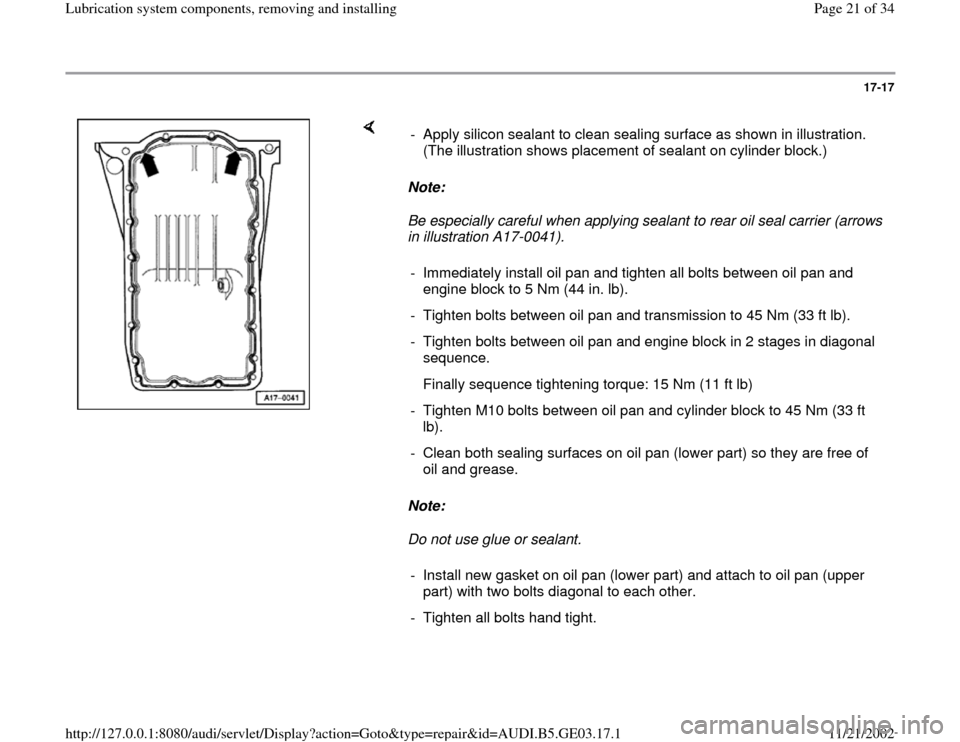

Note:

Be especially careful when applying sealant to rear oil seal carrier (arrows

in illustration A17-0041).

Note:

Do not use glue or sealant. - Apply silicon sealant to clean sealing surface as shown in illustration.

(The illustration shows placement of sealant on cylinder block.)

- Immediately install oil pan and tighten all bolts between oil pan and

engine block to 5 Nm (44 in. lb).

- Tighten bolts between oil pan and transmission to 45 Nm (33 ft lb).

- Tighten bolts between oil pan and engine block in 2 stages in diagonal

sequence.

Finally sequence tightening torque: 15 Nm (11 ft lb)

- Tighten M10 bolts between oil pan and cylinder block to 45 Nm (33 ft

lb).

- Clean both sealing surfaces on oil pan (lower part) so they are free of

oil and grease.

- Install new gasket on oil pan (lower part) and attach to oil pan (upper

part) with two bolts diagonal to each other.

- Tighten all bolts hand tight.

Pa

ge 21 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 22 of 34

17-18

- Starting in center and moving toward outside,

tighten bolts to 10 Nm (7 ft lb).

- Install new seal on oil drain plug and tighten to

30 Nm (22 ft lb).

Notes:

When installing oil pan on removed engine,

make sure oil pan is aligned with cylinder block

on flywheel side.

After installing oil pan, allow sealant to dry for

approx. 30 minutes. Only after allowing sealant

to dry may engine oil be added.

- Install subframe.

Repair Manual, Suspension, Wheels,

Steering, Repair Group 40

- Install lock carrier.

Pa

ge 22 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1