warning AUDI Q7 2009 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2009, Model line: Q7, Model: AUDI Q7 2009Pages: 426, PDF Size: 97.13 MB

Page 378 of 426

lllftl.,___W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle.

Loosening

Fig . 303 Changing a

wheel: loosening the

wheel bolts

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

the wheel bolts counter-clockwise about

one single turn

in the direction of arrow::::, fig. 303.

Tightening

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

each wheel bolt clockwise until it is seated.

& WARNING

• Do not use force or hurry when changing a wheel -you can

cause the vehicle to slip off the jack and cause serious personal

injuries.

& WARNING (continued)

• Do not loosen the wheel bolts more than one turn before you

raise the vehicle with the jack. -You risk an injury.

[ i] Tips

If a wheel bolt is very tight, you may find it easier to loosen by care

fully pushing down on the end of the wheel bolt wrench with

one

foot only.

As you do so, hold on to the car to keep your balance and

take care not to slip. •

Raising the vehicle

The vehicle must be lifted with the jack first before the

wheel can be removed.

Fig. 304 Changing a

wheel: mounting

points for the jack ..

Page 379 of 426

_____________________________________________ W_ h_ a_t _d_ o_l _ d_o _ n_o_ w_ ? _ __._

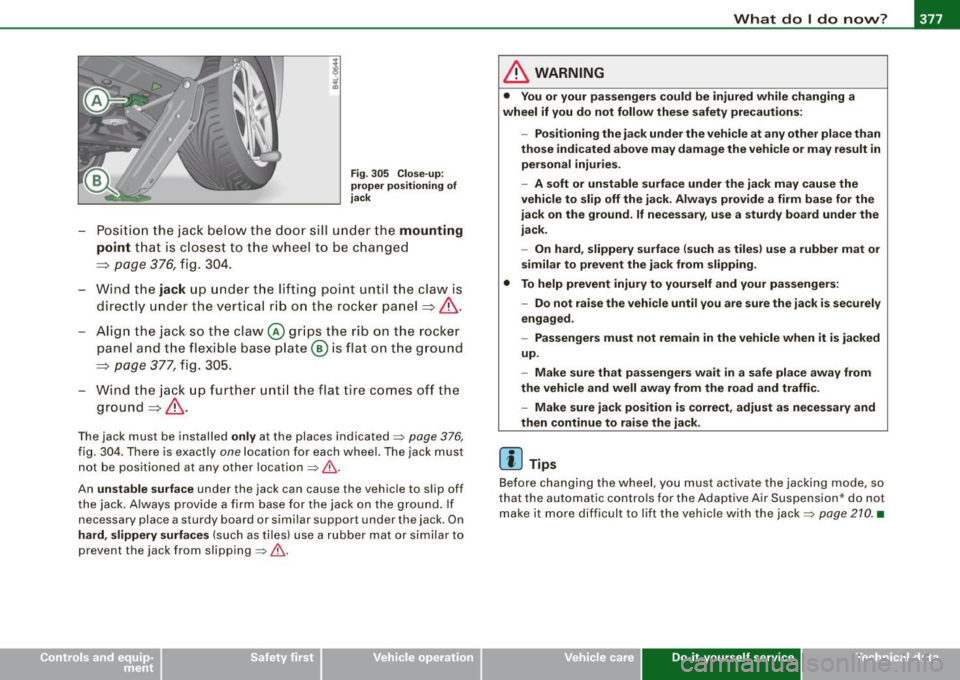

Fig. 30 5 Close- up:

prope r po sit io ning of

jack

- Posi tion the jack b elow the doo r sill u nder t he mounting

point

t ha t is clos est to the w hee l to be cha nged

==> p age 376, fi g. 30 4.

- Wind the jack up un der the liftin g p oint un til the c law is

d ir ect ly un der t he ver tical rib on th e ro cke r pane l==:> & .

- Align t he jack so the claw@ grip s the rib on th e rocke r

pane l and th e fl exible base plate @ is flat o n the gr oun d

==> page 3 77, fig. 30 5.

- Wind t he jack up furt her u ntil the flat ti re come s off the

g roun d==:> & .

The jack must be instal led only at the places indicated=> pa ge 376,

fi g. 30 4. T here is e xactl y on e loca tion for each w heel. The jack must

not be positioned at any oth er location =:>& .

A n

unstable surface under the jack can cause the vehic le to s lip off

the ja c k. Al ways pro vid e a firm base for the jack on t he grou nd. If

necessary place a sturd y board or s imilar sup port under the jack. On

hard , slippery surface s {such as tile s) us e a rub ber mat or s imi lar to

p revent the jack from slipping =:>& .

& WARNING

• You or your passengers could be injured wh ile changing a

wheel if you do not follow these safety precautions:

-Positioning the jack under the vehicle at any othe r place than

those indicated above may damage the vehicle or may result in personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack . Always provide a firm base for the

jack on the ground. If necessary, use a sturdy board under the

jack.

- On hard, slippery surface (such as tiles ) use a rubber mat or

similar to prevent the jack from slipping .

• To help prevent injury to yourself and your passengers:

-Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait

in a safe place away from

the vehicle and well away from the road and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to rai se the jack.

[ i ] Tips

B efore c hang in g the whee l, you must activate the jac king mode, so

that the au tomatic con trols for the Adaptive Air Suspension * do not

m ak e it mo re diff icu lt to lif t the v ehic le wi th t he jack =:>

page 210. •

Vehicle care Do-it-yourself service irechnical data

Page 381 of 426

_______________________________________________ W_ h_ a_t _ d_ o_ l _d _o_ n_ o _ w_ ? __ IIIII

•

- Let the compressor run until it has reached 50 PSI (3.5

bar). Switch the compressor off after running for 8

minutes at the most -danger of overheating!

& WARNING

The compressor and the tire filler hose can become extremely hot

while they are running -danger of burns!

0 Note

Switch the compressor off after running for 8 minutes at the most -

danger of overheating! Allow the compressor to cool down for a few

minutes before you use it again.

[ i] Tips

The compressor must not be connected to the cigarette lighter

socket, as this socket does not provide the required power .•

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their tread pattern pointed in the right direction.

Using a spare tire with a tread pattern intended for use

in a specific direction

When using a spare tire with a tread pattern intended for use in a

specific direction, please note the following:

• The direction of rotation is marked by an arrow on the side of the

tire.

• If the spare tire has to be installed in the incorrect direction, use

the spare tire only temporarily since the tire will not be able to

achieve its optimum performance characteristics with regard to

aquaplaning, noise and wear. •

We recommend that you pay particular attention to this fact

during wet weather and that you adjust your speed to match road

conditions.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible to restore the handling advantages of a

unidirectional tire. •

Notes on wheel changing

Please read the information => page 359, "New tires and replacing

tires and wheels " if you are going to use a spare tire which is

different from the tires on your vehicle.

After you change a tire :

• Check the tire pressure on the spare immediately after installa

tion.

• Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a

qualified workshop.

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 120 ft lb (160 Nm).

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible. Remount the wheel cover.

Until then, drive with extra care and at reduced speeds .

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed, then be sure to read

the information

=> page 359, "New tires and replacing tires and

wheels". ..

Do-it -yourself service

Page 383 of 426

_________________________________________________ F_ u_ s_ e_s _ a_n _d_ b_ u _ lb_ s _ __._

Fuses and bulbs

Fuses

Replacing a fuse

A problem in the electrical system may be caused by a

blown fuse.

Fig . 307 Ins trument

pa nel left: Face c over

F ig . 308 I nst rume nt

pa nel left: Co ntent

F ac e cover

- Locate the fuse which belongs to the component which

failed.

- Switch off the ignition and the e lectr ica l component

affected. - Carefully p

ry t he face cover off the instr umen t pane l

using the ignition key or a screwdriver~ fig. 307.

- Rem ove the plastic clip @ from i ts retainer in the face

cove r~ fig. 308, p lace i t over the questionable fuse and

remove the fuse.

- Replace a blown fuse (recognizable by the melted metal

str ip inside) wi th a f use of the

same amperage.

The individual circuits are protected by fuses. T he fuse panels with

the fuses are located on the left and right front faces of the instru

ment pane l behind a cover and in the right storage area in the

luggage compartment.

There is a plastic clip @ in the cover on the lef t side of the instru

ment pane l, which can be used to remove the fuses . The crank © is

used for emergency operation of the Panoramic sliding sun roof *.

You w ill also find a label on both covers in the instrument panel with

the fuse layout © for the corresponding fuse panel.

& WARNING

Nev er replac e a fuse with one that ha s a high er amperag e rati ng.

• A fu se w ith a to o high ampe rage could damage the ele ctr ical

pa rt a nd cause a fire .

0 Note

• On no account should fuses be repaired (e .g. patched up wi th tin

foil or wire) as this may cause serious damage elsewhere in the e lec

trica l circuit o r cause fire.

• If a fuse blows repeatedly, do not keep replacing it. Instead , have

the cause of the repea ted short circuit or overload located and fixed.

ti>

Vehicle care Do-it-yourself service Technical data

Page 388 of 426

11111.___F_ u_ s _ e_s _ a_n _ d_ b_ u_lb _ s _______________________________________________ _

& WARNING

Contact with high -voltage components of the ele ctrical system

and improper replacement of gas discharge (Xenon ) headlight

bulbs can cause ser ious personal injury and death .

• Xenon bulbs are pressurized and can explode when being

changed .

• Changing Xenon lamp s requires the special training, instruc

tions and equipment .

• Only an authorized Audi dealer or other qualified work shop

should change the bulbs in gas discharge lamps .

& WARNING

There are parts with sharp edges on the openings and on the bulb

holder s that can cause serious cuts.

• If you are uncertain about what to do , have the work performed

by an authorized Audi dealer or other qualified workshop . Serious

personal injury may result from improperly performed work.

[ i ] Tips

• If you must re place the light bulb s yourself, always remember

that the engine compartment of any ve hicle is a hazardous area to

work in . Always read and heed al l WARNI NGS ~

page 324, "Engine

compart ment"~

&-

• It is best to ask your autho rized Audi dea ler whenever you need

to change a bulb .•

Page 389 of 426

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s __ lll

•

Emergency situations

General

This chapter is intended for trained emergency crews and working

pe rsonnel who have the necessary tools and equ ipment to perform

these operations. •

Starting by pushing or towing

(D Note

You r ve hicle is eq uipped w ith an automatic trans missi on. C o nse

quent ly, the engine cannot be started by pushing or towing .•

Starting with jumper cables

If necess ary, the en gine can b e sta rted by conn ectin g it to

the battery of anothe r vehicle.

If th e engine should fail to start because of a discharged or weak

b at te ry, the batt ery ca n be co nnected t o the ba ttery of

another

vehicle, using a pair of jumper cables to start the engine .

Jumper cables

Use

only jumper cables of sufficiently large cross section to carry the

s tarte r curre nt safely. Refer t o the manu fac tu rer 's specif ica tions.

Use only ju mper cabl es with

insulated terminal clamps whic h are

distinct ly marked:

plus (+l cable in mo st cas es c olored red

minus

(- 1 cable in most cases colored black.

& WARNING

Batteries contain electricity, acid , and gas. Any of the se can cause

very ser ious or fatal injury . Follow the instructions below for safe

handling of your vehicle 's battery .

• Always shield your eyes and avoid leaning over the battery

whenever possible .

• A discharged battery can freeze at temperatures just below

32 °F (0 °C l. Before connecting a jumper cable , you must thaw the

frozen battery completely , otherwise it could explode .

• Do not allow battery acid to conta ct eyes or skin. Flush any

contacted area with water immediately.

• Improper use of a booster battery to start a vehicle may cause

an explosion.

• Vehicle batteries generate explosive gases . Keep sparks , flame

and lighted c igarettes away from batteries.

• Do not try to jump start any vehicle with a low acid level in the

battery.

• The voltage of the booster battery must also have a 12-Volt

rating. The capacity (Ah l of the booster battery should not be

lower than that of the discharged battery . Use of batteries of

different voltage or substantially different "Ah" rating may cause

an explosion and personal injury .

• Never charge a frozen battery. Gas trapped in the ice may cause

an explosion.

• Never charge or use a battery that has been frozen . The battery

c ase may have be weakened .

• Use of batter ies of different voltage or substantially different

c apacity (Ah l rating may cause an explosion and injury . The

capacity (Ahl of the booster batte ry should not be lower than that

of the discharged battery. _..

Do-it -yourself service

Page 391 of 426

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s __ lfflll

•

Conn ect POSITIVE (+ ) to PO SITIVE (+ ) (r ed )

- Open the red cover on the pos itive pole => page 388,

fig. 312.

1. Connect one end of the positive cable (red) on the

jump

start bolt=>

page 388, fig. 3 13 G) (Bo lts under red cover

= "positive") of the vehicle to be started @.

2. Connect the other end to the positive terminal@ of the

booster battery ®·

Conn ect NEGATIVE (- ) to NEGATIVE (-) (black )

3. Connect one end to the negat ive termi nal 0 of t he

boos ter battery ®·

4 . Connect the other end of the negative cable (black) to the

jump sta rt bolt 0 (Bolts with hex head = "n egative") of

the vehicle to be s tarted @.

Startin g th e e ngin e

-Start the engine of the veh icle w ith the booster battery .

Run t he engine at a moderate speed .

- Start engine with discharged ve hicle battery in the usual

ma nner.

- If the engine fails to s tart: do not keep the star ter

cranking for longer than 10 seconds. Wait f or about

30 seconds and then try again.

- With engine running, remove jumper cables from both

vehicles in the exact reverse order.

- Close the red cover on the positive pole.

The battery is vented to the outside to prevent gases from entering

the vehic le interior . Make sure that the jumper clamps are well connected with their

metal parts in full contact with the battery

t erminals .

& WARNING

To avoid seriou s per sonal in jur y a nd d amage to the vehicle , heed

a ll wa rning s and in stru ction s o f th e jum per ca ble man ufa cturer . If

in doubt , call for ro ad serv ice.

• Jump er c able s must b e lo ng eno ugh s o that the vehi cle s do not

touch .

• When conne cting jumpe r cable s, ma ke sure th at the y cannot

g et caught in an y mo ving p arts i n the engine comp art m ent .

• Before you che ck anyth ing in the en gin e com partm ent , a lwa ys

r ea d and h eed all W ARNIN GS~ pag e 32 4, "E ngine compa rtm ent ".

0 Note

Improper hook -up of jumper cables can ruin the generato r.

• Always connect POSITIVE(+) to POS ITIVE( +), and NEGATIVE( -) to

NEGATIVE( -) ground post of the battery manager control unit.

• Check that al l screw p lugs on the battery ce lls are screwed in

firm ly . If not, tighten plugs prior to connecting clamp on negative

battery termi nal.

• Please note that the procedure for connecting a jumper cab le as

described above applies specifical ly to the case of your vehicle

being jump started. When you are giving a jump start to another

vehicle, do not connect the negative(-) cable to the negative (-1

terminal on the discharged battery©~ page 388, fig. 313. Instead,

securely connect the negative ( -1 cable to either a solid metal

component that is firmly bolted to the engine b lock or to the engine

block itself . If the battery that is being charged does not vent to the

outside, escap ing battery gas could ignite and exp lode! •

Do-it-yourself service

Page 392 of 426

lllffll.,___E_ m _ e _r.;:g '-e_ n_ c-=y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

Emergency towing with commercial

tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by commercial tow truck

operators who know how to operate their equipment safely.

• Never tow your Audi, towing will cause damage to the engine

and transmission.

• Never wrap the safety chains or winch cables around the brake

lines.

• To prevent unnecessary damage, your Audi must be transported

with a flat bed truck.

• To load the vehicle on to the flat bed, use the towing loop found

in the vehicle tools and attach to the front or rear anchorage

~ page 390 and~ page 391.

& WARNING

A vehicle being towed is not safe for passengers. Never allow

anyone to ride in a vehicle being towed, for any reason. •

Front towing loop

Do not install the front towing loop until it is needed.

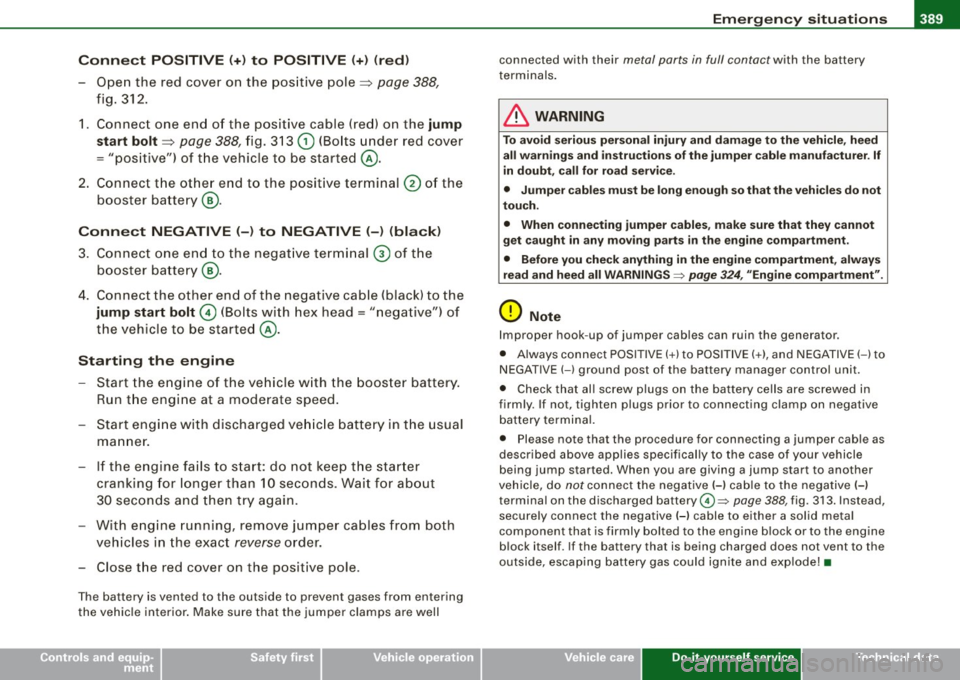

Fig. 314 Right front

bumper: Removing the

air intake grill

Fig . 315 Right front

bumper without grill:

Screwing in towing

loop

At the right front under the bumper, there is a threaded

opening with a

left-hand thread into which the towing loop

is screwed. The threaded hole is concealed behind an air

intake grill.

- Press the upper tab down and the lower tab up~ fig. 314

(i).

- Pull the grill forward and out 0-

- Remove the towing loop from the vehicle tool kit.

Page 393 of 426

________________________________________________ E_ m ___ e_r .::g :...e_ n _ c_,!y:._ s_ i_t _u _a_ t_ i_o _n_ s _--J_

- Screw the towing loop t ightly into the threaded hole as

far as it will go::::>

page 390, fig. 315.

When it is no longer needed, unscrew the towing loop and put it

back into the vehicle toolkit. Be sure to have the towing loop stored

in the vehicle at all times.

When installing the grill for the air duct, be sure that the tabs on the

gril l are first inserted into their guides on the vehicle above the

fog lamp. Then position the opposite side of the grill

=> page 390,

fig. 314 ® and push it firmly into its guide.

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

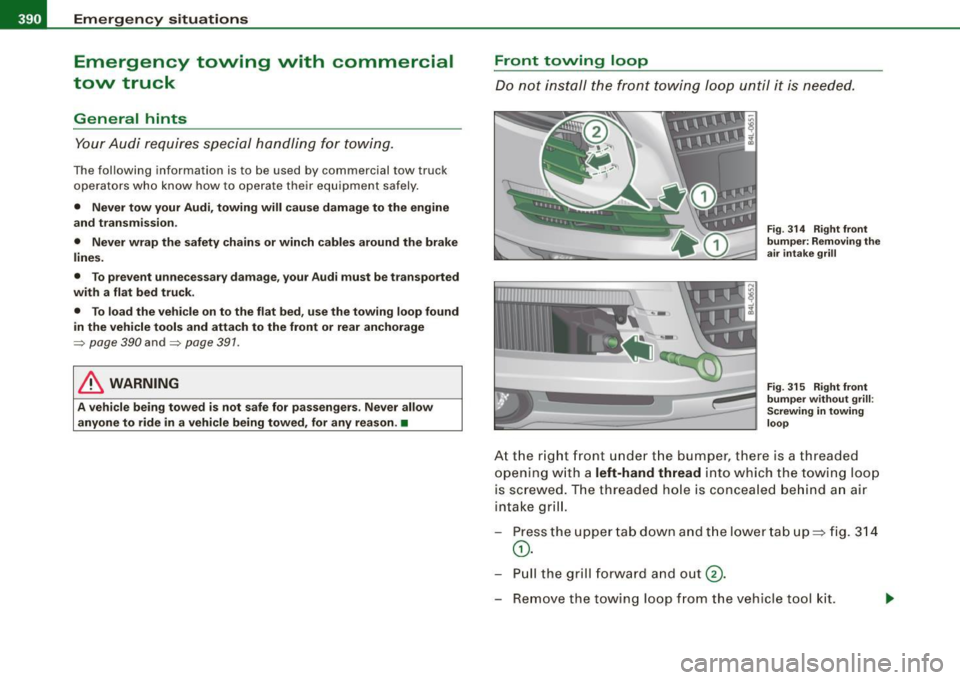

Rear towing loop

Do not install the rear towing loop until it is needed.

Fig. 316 Rear bumper:

Cover Fig

. 317 Rear bumper:

Screwing in towing

loop

At the right rear behind a cover in the bumper, there is a

threaded opening with

a left-hand thread into which the

towing loop is screwed.

- To release the cover from the bumper, press it in by

applying short, sharp pressure to the outer part

==> fig. 316.

- Remove the towing loop from th e vehicle tool kit.

- Screw the towing loop tightly into the threaded hole as

far as it will go ::::> fig. 317.

Unscrew the towing loop again after use and instal l the cover in the

bumper. Return the towing loop to the toolkit. Be sure to have the

towing loop stored in the vehicle at all times .

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

Vehicle care Do-it-yourself service irechnical data

Page 394 of 426

lll9.,___E_ m_ e_ r -'g==-- e_n _ c_ y=--- s_ i_ t _u _a _ t_ i_o _n _ s _____________________________________________ _

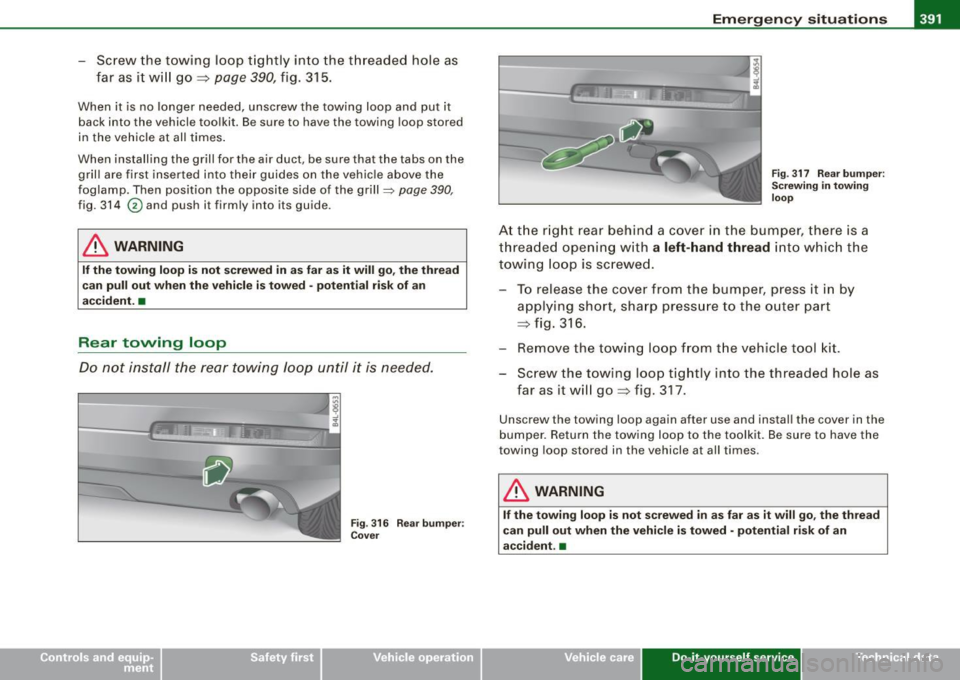

Loading the vehicle onto a flat bed truck

Front hook up

Fig. 318 Vehicle on flat

bed truck

- Align the vehicle w ith the centerline of the car carrier

ramp.

- Attach the winch hook to the front towline eye p reviously

installed.

Rear hook up

- Align the vehicle with the centerline of the car carrier

ramp.

- Attach the winch hook to the rear towline eye prev iously

i nstalled.

[ i ) Tips

Check carefully to make sure the hook -up is secure before moving

the car up the fla tbed truck ramp. •

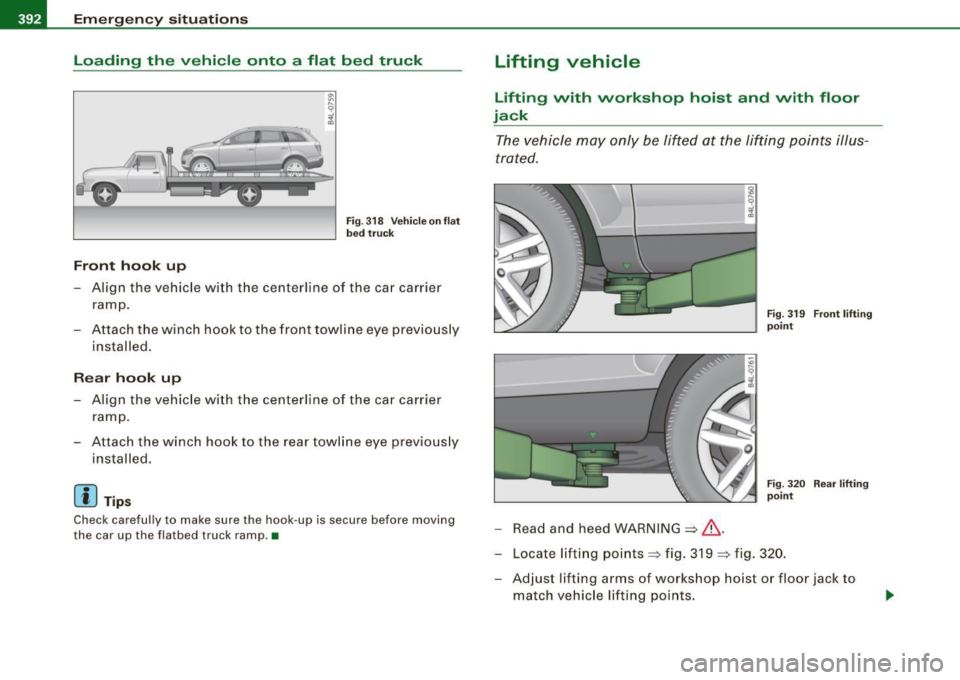

Lifting vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be lifted at the lifting points illus

trated.

- Read and heed WARNING=>& .

Fig. 319 Front lifting

point

Fig. 320 Rear lifting

point

- Locate lifting points=> fig. 319 => fig. 320.

- Adjust lifting arms of workshop hoist or floor jack to

match vehicle lifting points.