AUDI S3 SEDAN 2015 Owners Manual

Manufacturer: AUDI, Model Year: 2015, Model line: S3 SEDAN, Model: AUDI S3 SEDAN 2015Pages: 282, PDF Size: 71.14 MB

Page 251 of 282

....,

N

0 > co

rl I.O

"'

"'

"'

rl

-Some of the equipment listed in the follow

ing tables applies only to certain model

versions or certain opt ional equ ipment.

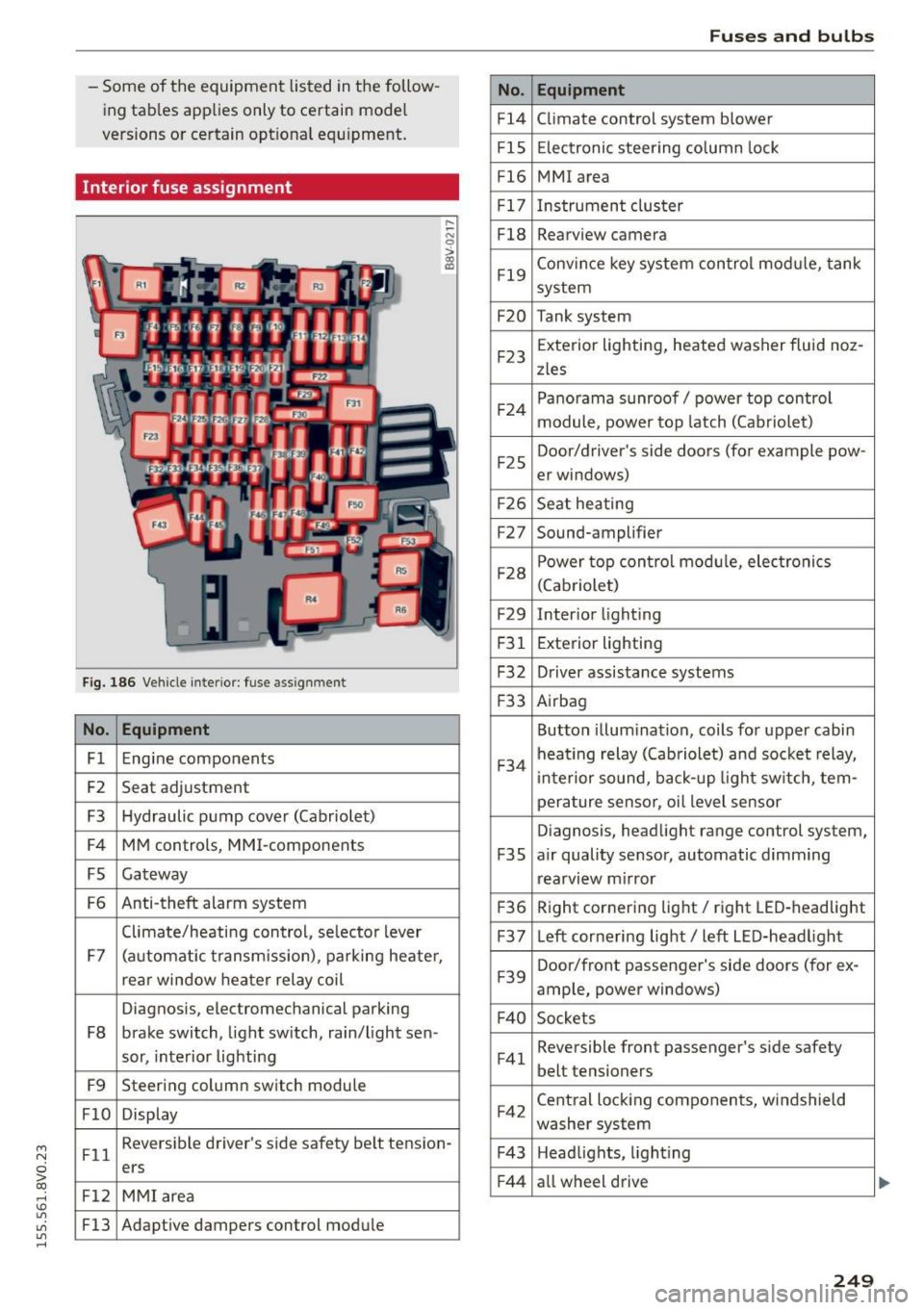

Interior fuse ass ignment

F ig. 186 Vehicle interior: fuse assignment

No. Equipment

Fl Engine components

F2 Seat

adjustment

F3 Hydraulic pump cover (Cabriolet)

F4 MM

controls, MMI-components

FS Gateway

F6 Anti-theft

alarm system

Climate/heati ng control, selector lever

F7 (automat ic transm ission), parking heater,

rear window heater relay coil

Diagnosis, electromechanical parking

F8 brake switch, light switch, rain/light sen-

sor, interior lighting

F9 Steering column switch module

FlO Display

.... ~ N

0

>

"' (0

Fll Reversible

driver's side safety belt tension-

ers

F12 MMI area

F13 Adapt ive dampers control module

No.

Fl4

FlS

Fl6

F 1 7

F18

F19

F20

F23

F 24

F 25

F 26

F27

F28

F29

F 31

F32

F 33

F34

F3S

F 36

F37

F 39

F 40

F 41

F42

F43

F 44

Fu ses a nd bulb s

Equipment

Climate control system blower

Electronic steering co lumn lock

MMI area

Instrument cluster

Rearview camera

Conv ince key system control mod ule, tank

system

Tank system

Exterior lighting, heated washer fluid noz-

zles

Panorama sunroof/ power top control

module, power top latch (Cabriolet)

Door/driver 's side doors (for example pow-

er windows)

Se at heating

Sound-amplifier

Power top control modu le, electronics

(Cab riolet)

Inter ior light ing

E xterior lighting

Driver assistance systems

Airbag

Button illumination, coils for upper cabin

heating relay (Cab riolet) and socket relay,

i nte rior sound, back- up light sw itch, tern-

perature sensor, oi l level sensor

Diagnosis, headlight range control system,

a ir quality sensor, automatic d imming

rearview m irror

Right cornering light/ right LED-headlight

Left cornering light/ left LED-headlight

Door/front passenger's side doors (for ex-

ample, power windows)

Sockets Reversible front passenger's side safety

belt tensioners

Central locking components, windshield

washer system

Head lights, l ight ing

a ll wheel drive

249

Page 252 of 282

Fuses and bulbs

No. Equipment

F49 Starter, clutch sensor,

headlight relay coil

F53 Rear window defogger

The power seats* are protected via

circuit break

ers

that automatically switch on after a few sec

onds after the overload has been reduced.

(0 Tips

Note that the following table was accurate at

the time of printing and is subject to change.

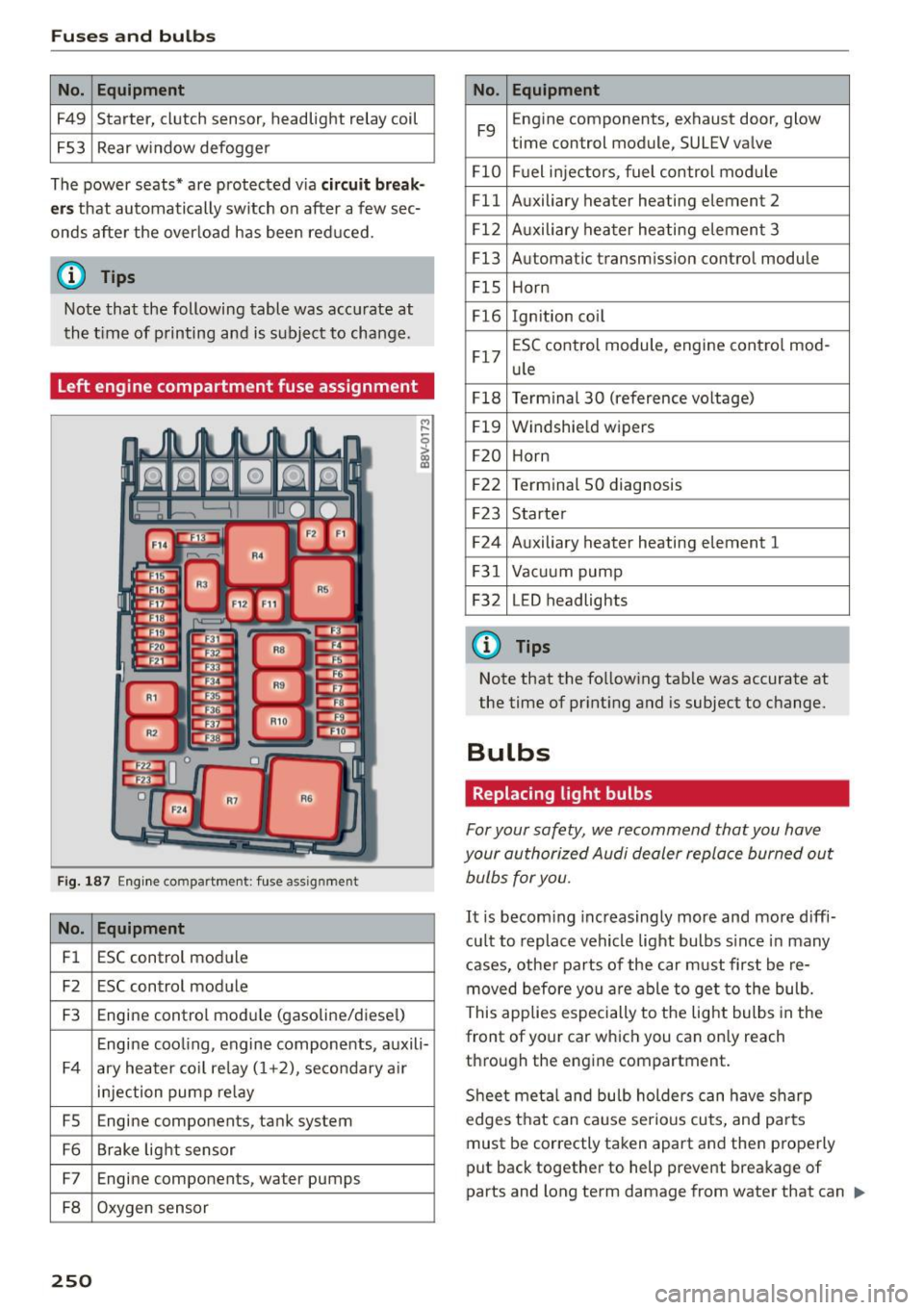

Left engine compartment fuse assignment

Fig. 187 Engine compartmen t: fuse assig nme nt

No. Equipment

Fl ESC control module

F2 ESC control module

F3 Engine control module (gasoline/diesel)

Engine cooling, engine components, auxili-

F4 ary heater coil relay (1+2), secondary a ir

injection pump relay

FS Engine components, tank system

F6 Brake light sensor

F7 Engine components, water pumps

F8 Oxygen sensor

250

No. Equipment

F9 E

ngine components, exhaust door, glow

time control module, SULEV valve

Fl0 Fuel injectors, fuel control module

Fll Auxiliary heater heating element 2

F12 Auxiliary heater heating element 3

F13 Automatic transmission control module

FlS Horn

F16 Ign ition coil

F17 ESC

control module, engine contro l mod-

ule

F18 Terminal 30 (reference voltage)

F19 Windshie

ld wipers

F20 Horn

F22 Terminal 50 diagnosis

F23 Starter

F24 Auxiliary heater heating element 1

F31 Vacuum pump

F32 L

ED headlights

(!') Tips

Note that the following tab le was accurate at

the time of printing and is subject to change.

Bulbs

Replacing light bulbs

For your safety , we recommend that you have

your authorized Audi dealer replace burned out

bulbs for you.

It i s becoming increasingly more and more diffi

cu lt to replace vehicle light bulbs s ince in many

cases, other parts of the car must first be re

moved before you are able to get to the bulb.

This applies especially to the light bulbs in the

front of your car which you can only reach

through the engine compartment.

Sheet meta l and bulb holders can have sharp

edges that can cause serious cuts, and pa rts

must be correctly taken apart and then properly

put back together to help prevent breakage of

parts and long term damage from water that can .,,_

Page 253 of 282

M N

0 > co ,...., \!) ..,.,

..,.,

..,., ,....,

enter housings that have not been properly re

sealed .

F or your safety, we recommend that you have

your author ized Audi dealer replace any bulbs for

you, since your dealer has the proper tools, the

correct bulbs and the expertise .

Gas disc har ge la mps (X enon li g ht s):

Due to the high electrical voltage, have the bulbs

replaced by a qualif ied techn ician . H eadlights

with Xenon light can be identified by the high

voltage sticke r.

L ED headlights* requ ire no ma intenance . Please

contact your authorized Audi dealer if a bulb needs to be replaced .

_& WARNING

Contact with high-voltage components of the

electrical system and improper replacement

o f gas discharge (Xenon) headlight bu lbs can

cause serious personal injury and death.

- Xenon bulbs are pressurized and can ex -

plode when being changed.

- C hang ing Xenon lamps requires the spe cial

training, instructions and equipment .

- Only an authorized Aud i dea ler or othe r

qualified workshop shou ld change the bulbs

in gas discharge lamps.

_& WARNING

There are parts with sharp edges on the open ings and on the b ulb holders that can cause

ser ious c uts.

- If you are uncertain about what to do, have

the work performed by an author ized Audi

dealer or other qualif ied workshop. Ser ious

persona l injury may result from improperly

performed work .

- If you still pre fer to replace the light bulbs

yourself, be aware that the engine compart

ment is a hazardous area to work in

i:> page l 98 i:> .&

-It is best to ask your authorized A udi dealer

whenever you need to change a bulb.

Fu ses a nd bulb s

251

Page 254 of 282

Emerg enc y s it uat ion s

Emergency situations

General

T his c hapt er is inte nded fo r tra ined e merg ency

c rews a nd worki ng p ers onn el w ho h ave the nec

e ssa ry tool s and equipm ent t o perf orm the se

op era tion s.

Starting by pushing or

towing

CD Note

Veh icles w ith an automatic transmission can

not be started by push ing or tow ing.

Starting with jumper

cables

If necessary, the engine con be started by con

necting it to the battery of another vehicle .

If the engine should fail to start because of a d is

charged or weak battery, the battery can be con

nected to the battery of

another vehicle, using a

p air o f jump er ca bles to start the engine.

Jump er c able s

Use only jumper cables of sufficiently large cr oss

se ction

to carry the starter current safely. Refer

to the manufacturer's specifications.

Use on ly jumper cables with

insulated term inal

clamps which are d istinctly mar ked:

pl us( +) cabl e in most cases co lored re d

minu s(-) cable

in most cases colored black .

A WARNING

Batteries contain electricity, ac id, and gas.

Any of these can cause very ser ious or fatal in

jury . Follow the inst ruct ions be low for safe

hand ling of your veh icle's battery.

- Always shield your eyes and avoid leaning

over the battery w henever possible.

- A discharged battery can freeze at tempera

tures just below 32

°F (0 °C). Before con

nect ing a jumper cab le, you must thaw the

25 2

frozen battery completely, otherwise it

could explode.

- Do not allow battery acid to contact eyes or

skin. Flush any contacted area with water immediately.

- Improper use of a booster battery to start a

veh icle may cause an explosion.

- Vehicle batteries generate explosive gases .

Keep sparks, flame and lighted cigarettes

away from batteries.

- Do not try to jump start any vehicle with a

low acid level in the battery.

- The voltage of the booster battery must al

so have a 12-volt rating. The capacity (Ah) of

the booster battery should not be lower

than that of the discharged battery. Use of

batter ies of different voltage or substantial

ly different "Ah" rating may cause an explo

sion and personal injury.

- Never charge a frozen battery. Gas trapped in the ice may cause an explosion .

- Never charge or use a battery that has been

frozen. The battery case may have be weak

ened .

- Use of batter ies of different voltage or sub

stantially d ifferent capacity (Ah) rating may

cause an explosion and injury. The capacity

(Ah) of the booster battery should not be

lowe r than that of the discharged battery.

- Before you check anything in the engine

compartment, always read and heed a ll

WARNINGS

qpoge 198.

CD Note

-App lying a higher voltage booster battery

wi ll cause expensive damage to sensitive

elec tronic components, such as control

units, re lays, radio, etc.

- T here must be no electrical contact between

the vehicles as otherwise cu rrent cou ld al

ready start to flow as soon as the positive

(+) termina ls are connected.

@ Tips

The discharged battery must be properly con-

nected to the vehicle's electrical system. .,.

Page 255 of 282

....,

N

0 > co

rl I.O

"'

"'

"'

rl

When jump starting or charging the battery,

never connect the negative ground cable to

the battery negat ive post because the battery

manager system must be able to detect the

battery's state of charge. Always connect the

negative g round cab le to the negative ground

post of the battery manager control unit.

Using jump start cables

Connect the jump start cables in the exact order

described below.

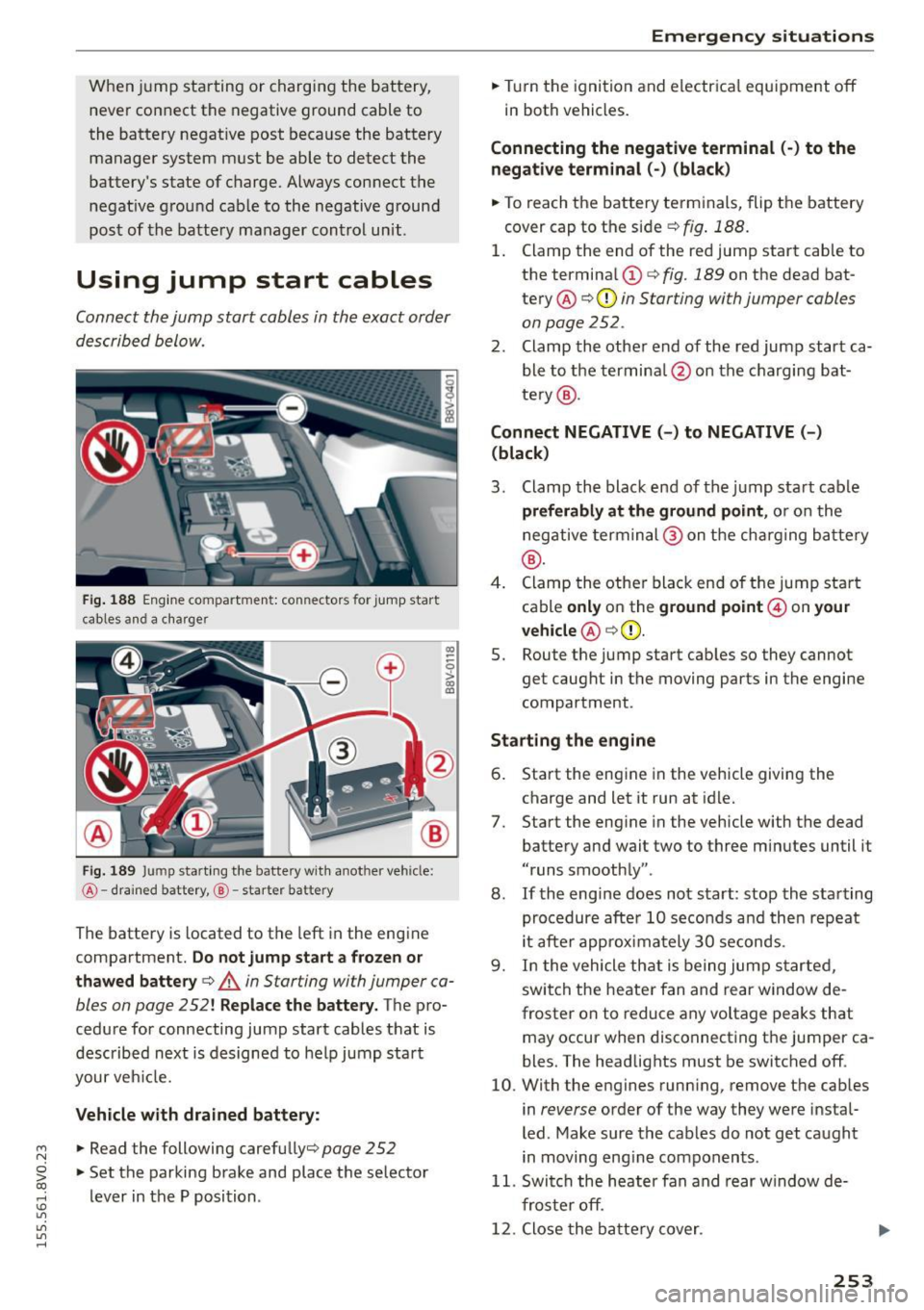

Fig. 188 Engine compa rtment: connectors for jump start

cables and a charger

Fig. 189 Ju m p sta rting the battery with anot her veh icle:

@ -drained battery, @-starter battery

The battery is located to the left in the eng ine

compartment.

Do not jump start a frozen or

thawed battery

c> A in Starting with jumper ca

bles on page

252! Replace the battery. The pro

cedure for connecting jump start cables that is

described next is designed to help jump start

your veh icle.

Vehicle with drained battery: .. Read the following carefullyc>

page 252

.. Set the parking brake and place the selector

lever in the P position .

Emergency situations

.. Turn the ignition and electrica l equipment off

in both vehicles.

Connecting the negative terminal(-) to the

negative terminal(-) (black)

.. To reach the battery terminals, flip the battery

cover cap to the side

c> fig . 188 .

1. Clamp the end of the red jump start cable to

the terminal © c>

fig. 189 on the dead bat

tery ®

¢0) in Starting with jumper cables

on page 252 .

2. Clamp the other end of the red jump start ca

ble to the terminal@on the charging bat

tery @.

Connect NEGATIVE (-) to NEGATIVE (-)

(black)

3 . Clamp the black end of the jump start cable

preferably at the ground point , or on the

negative term inal @ on the charg ing battery

® ·

4. Clamp the other black end of the jump start

cable

only on the ground point@) on your

vehicle ®

¢(D.

5. Route the jump start cab les so they cannot

get caught in the moving parts in the engine

compartment .

Starting the engine

6. Start the engine in the vehicle giving the

charge and let it run at idle.

7. Start the engine in the vehicle with the dead

battery and wait two to three minutes until it

"runs smoothly" .

8. If the engine does not start: stop the starting

procedure after

10 seconds and then repeat

it after approximately

30 seconds .

9. In the vehicle that is being jump started,

switch the heater fan and rear window de

froster on to reduce any voltage peaks that

may occur when disconnecting the jumper ca

bles. The headlights must be switched off .

10. With the engines running, remove the cables

in

reverse orde r of the way they were instal

led . Make sure the cables do not get caught

in moving eng ine components .

11. Switch the heater fan and rear w indow de

froster off .

12 . Close the battery cover .

253

Page 256 of 282

Emerg enc y s it uat ion s

The battery is vented to the outside so that not

gases enter the passenger compartment. Make

sure that the connected pos itive terminal clamps

on the jump start cable have sufficient contact

with metal.

A WARNING

Follow the warnings and instructions from

the jump start cable manufacturer to reduce

the risk of ser ious injuries and vehicle dam

age. If you are unsure about anyth ing, call

roadside assistance.

- The jump start cables must be long enough

so that the vehicles do not touch.

-

- Route the jump start cab les so they cannot

get caught in the moving parts in the engine

compartment.

- Always read and follow the warni ngs befo re

c he ck ing anything in t he engine compa rt

ment

¢page 198.

(D Note

Connecting jump start cables incorrectly can

destroy the alter nator.

- Always connect the positive term inal(+) to

the positive te rm inal(+) and the negative

te rmi nal(-) to the negat ive termina l(-) on

the body ground point, b ut no t the negat ive

te rminal on t he ba ttery.

- M ake sure the screw pl ugs on the batte ry

ce lls are insta lled securely.

If no t, tighten

the plugs before connec ting the clamps to

the negat ive termina l on the battery.

- Please note that the conne ct ing p rocess de

scribed below for the jump start cables is in

tended for when your ve hicle is being jump

started. If you are jump starting another ve

hicle, do not connect the negative cable to

the negat ive termina l(·) on the drained bat

tery, but rather connect it to a large metal

component that is bol ted secu rely to the en

g ine block, o r to the engine bloc k itself. If

the battery in the vehicle being jump start

ed is no t vente d to the outs ide, there is a

risk of explosion due to hyd rogen gas.

- M ake sure tha t the connected positive ter

min al cl amps h ave sufficie nt contact with

me tal.

254

- Do not use the battery negative terminal for

jump starting or a ma lfunction co uld occur

in the vehicle electrica l system.

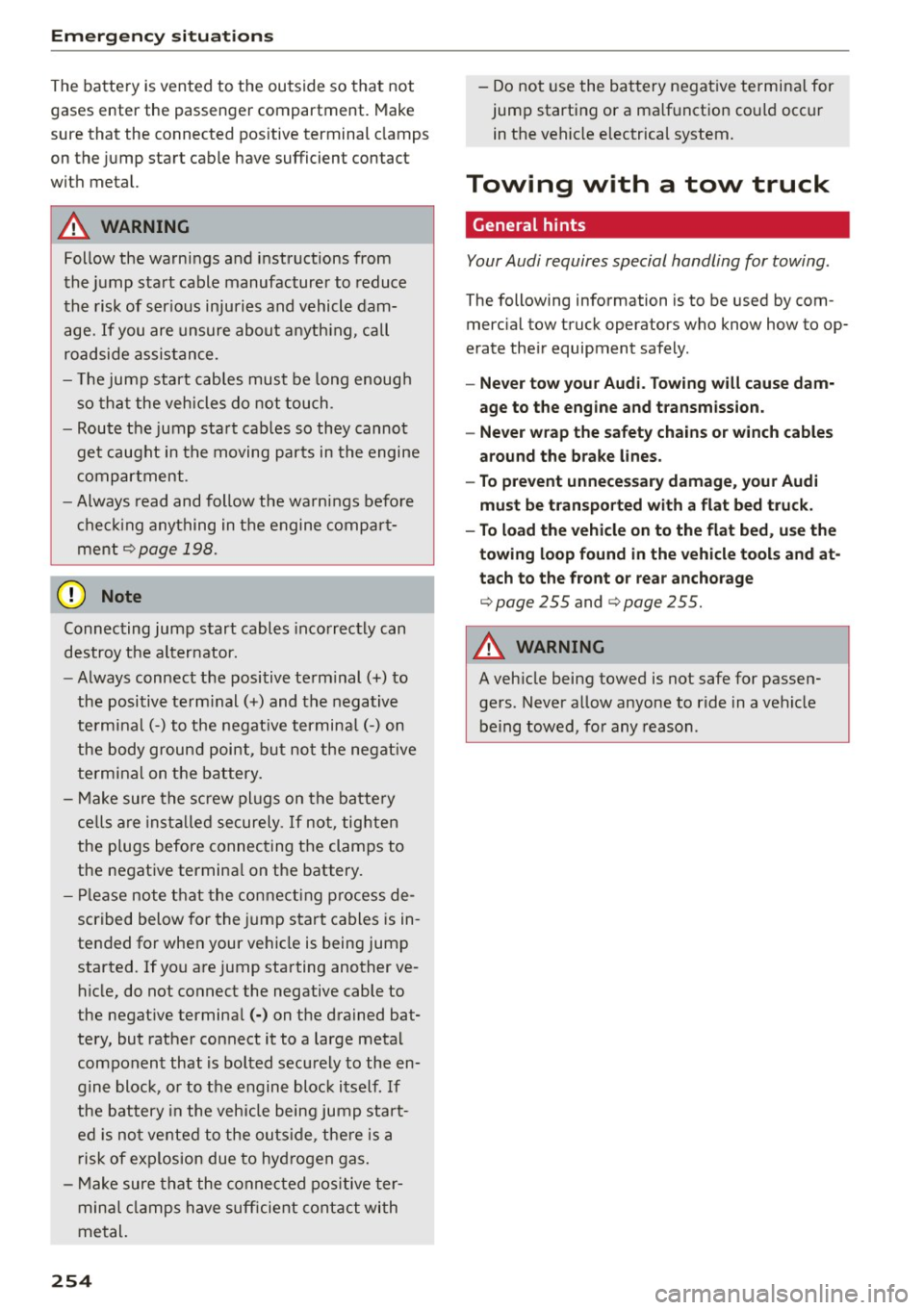

Towing with a tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by com

merc ial tow truck operators who know how to op

erate their equipment safely.

- Never tow yo ur Audi. Towing will cau se dam·

a ge to the engine and t ransmission.

- Never wrap the safet y chain s or winch cables

around the brake line s.

- To prevent unnece ssary damage, your Audi

must be t ran spo rted with a flat bed truck.

- To load the vehicle on to the fl at bed , u se the

towing loop found in the veh icle tools and at

t a ch to the front o r rear an chorage

¢page 255 and ¢page 255.

A WARNING

A vehicle being towed is not safe for passen

gers. Never a llow anyone to ride in a vehicle

being towed, fo r any reason.

Page 257 of 282

....,

N

0 > co

rl I.O

"'

"'

"'

rl

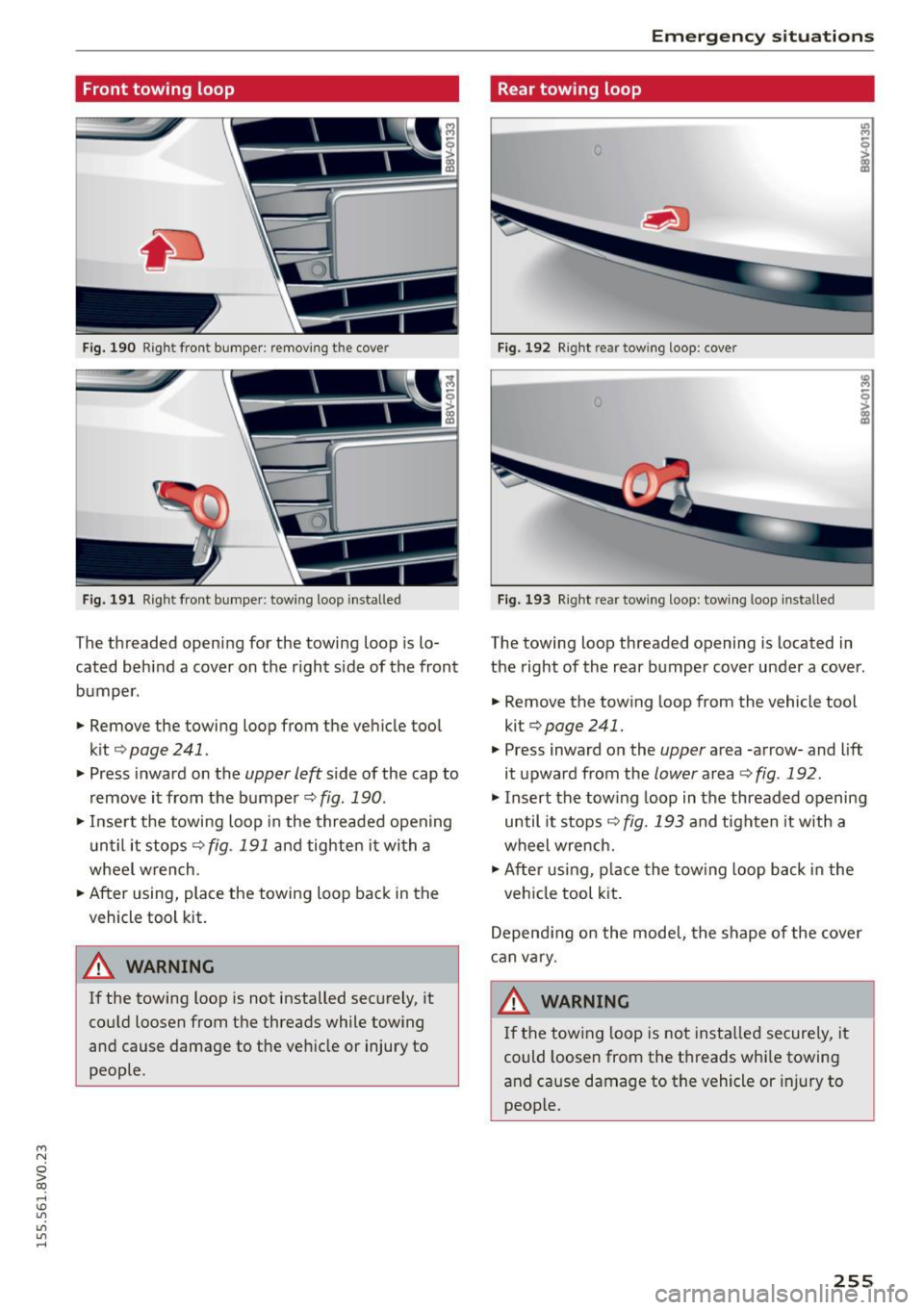

Front towing loop

Fig. 190 Right front bumper: removing the cove r

Fig. 191 Right front bumpe r: tow ing loop installed

The threaded opening for the towing loop is lo

cated behind a

cover on the right side of the front

bumper .

• Remove the towing loop from the vehicle tool

kit

¢ page 241 .

• Press inward on the upper le~ side of the cap to

remove it from the bumper

r::::> fig. 190.

• Inse rt the towing loop in the threaded open ing

u ntil it stops ¢

fig. 191 and tighten i t with a

wheel w rench.

• After using, place the towing loop back in the

vehicle tool kit.

A WARNING

If the towing loop is not installed securely, it

could loosen from the threads while towing

and cause damage to the veh icle or injury to

people.

Emergency situations

Rear towing loop

Fig. 192 Right rea r tow ing loop: cove r

Fig. 193 Righ t rea r tow ing loop: towing loop installed

The towing loop threaded opening is located in

the right of the rear bumper cover under a cover .

• Remove the towing loop from the vehicle tool

kit¢

page 241 .

.,. Press inward on the upper area -arrow- and lift

it upward from the

lower area¢ fig. 192.

.,. Insert the tow ing loop in the threaded opening

until it stops ¢

fig. 193 and tighten it with a

wheel wrench.

• After using, pla ce the towing loop back in the

vehicle tool kit.

Depending on the model, the shape of the

cover

can vary.

WARNING

If the towing loop is not installed securely, it

could loosen from the threads while towing

and cause damage to the vehicle or injury to

people .

255

Page 258 of 282

Emergency situation s

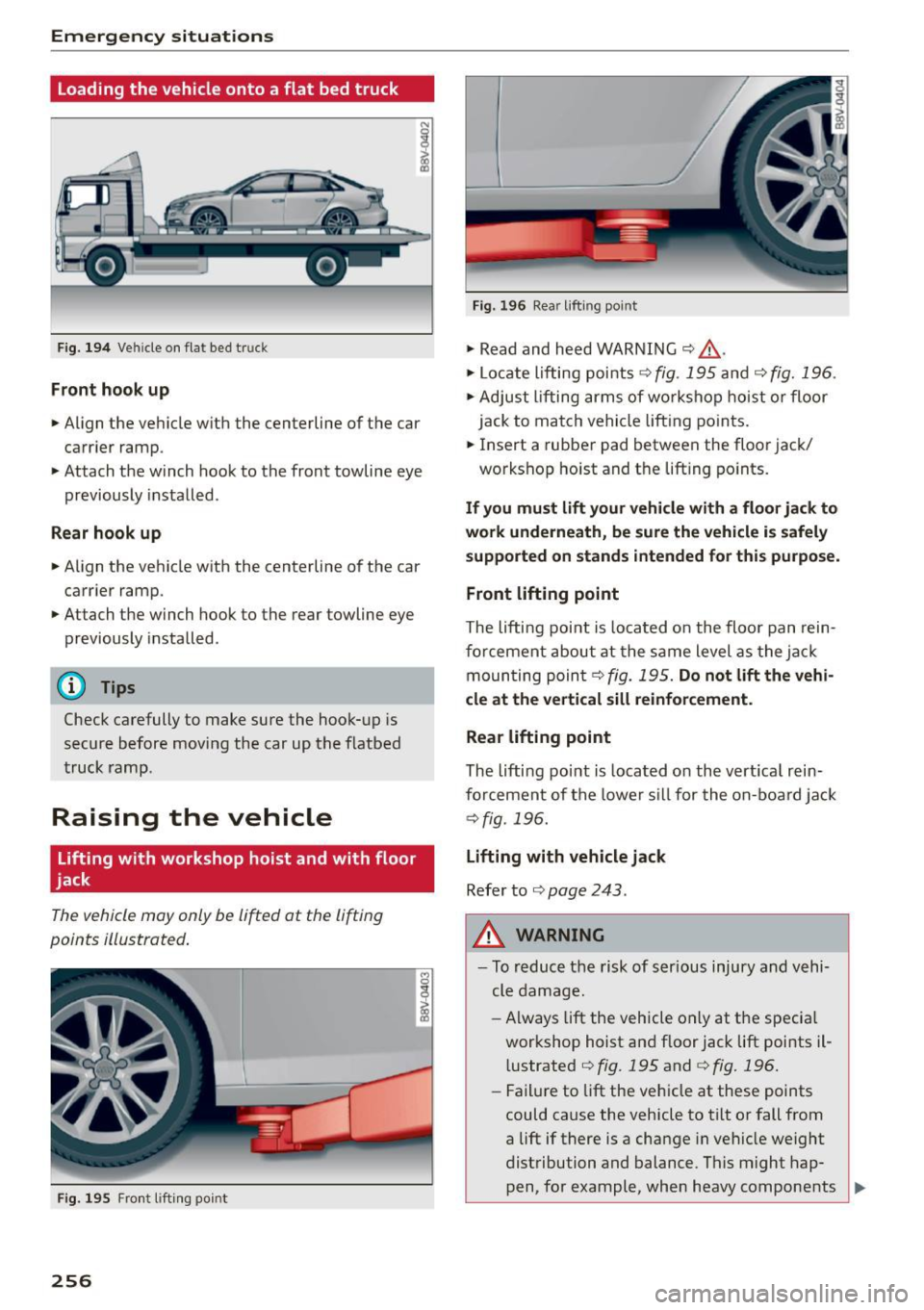

Loading the vehicle onto a flat bed truck

Fig. 194 Ve hicle on flat bed tr uck

Front hook up

.. Align the vehicle w ith the centerline of the car

carrier ramp.

.. Attach the winch hook to the front towline eye

previously installed .

Rear hook up

.. Align the vehicle with the centerline of the car

carr ier ramp .

.. At tach the winch hook to the rear towline eye

previously installed .

@ Tips

Check carefully to make sure the hook-up is

secure before moving the car up the flatbed

truck ramp .

Raising the vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be lifted at the lifting

points illustrat ed .

F ig . 19 5 Fron t lifti ng po int

256

Fig . 19 6 Rear lift ing po int

.. Read and heed WARNING ¢ .&, .

.. Locate lifting poi nts ¢ fig . 195 and ¢ fig. 196 .

.. Adjust lifting arms of wo rkshop hoist o r floor

jack to match vehicle lift ing points .

.. Insert a rubbe r pad between the floor jack/

workshop hoist and the lift ing po ints .

If you mu st lift your vehicle with a floor jack to

work underneath, be sure the vehicle is safely

supported on stands intended for this pu rpose .

Front lifting point

The lifti ng point is located o n the floo r pan rein

fo rcement about at the same level as the ja ck

moun ting poin t¢

fig. 195. Do not lift the vehi·

cle at the ve rtical sill reinfor cement.

Rear lifting point

The lifting po int is located o n the vert ica l re in

forcement of the lower s ill for the on -boa rd ja ck

¢ fig . 196.

Lifting with vehicle jack

Refer to ¢ page 243.

,&. WARNING

-To reduce the risk of serious injury and vehi

cle damage.

- Always lift the vehicle only at the specia l

wor kshop hoist and f loor jack lift points il

l ustrated ¢

fig. 195 and¢ fig. 196.

-Fail ure to lift the veh icle at these points

could cause the vehicle to tilt or fall from

a lift if there is a cha nge in vehicle weight

distributi on and balance . This might hap-

pen, for example, when heavy components .,,_

Page 259 of 282

M N

0 > co ,...., \!) 1.1"1

1.1"1

1.1"1

,....,

such as the engine b lock or transmission

are removed .

- When removing heavy components like

these, anchor vehicle to ho ist o r add corre

sponding weights to maintain the center of

gravity . Otherwise, the vehicle might tilt or

s li p off the hoist , causi ng se rious pe rsonal

injury .

([) Note

-Be awa re of the fo llowing points befo re lift

i ng t he ve hicle:

-The vehicle should never be lifted or

jacked up from underneath the engine oil pan, the transmission housing, the front

or rear axle or the body side members.

This could lead to serious damage.

- To avoid damage to the underbody or

chassis frame , a rubber pad must be in·

serted between the floo r jack and the lift

points.

- Before driving over a wo rkshop hoist,

check that the veh icle weight does not

e xceed the permiss ible lift ing capacity of

the hoist.

- Before driv ing over a workshop hoist, en

sure that there is sufficient clearance be

tween the hoist and low parts of the ve

hicle .

Emergency s ituations

257

Page 260 of 282

Technical data

Technical data

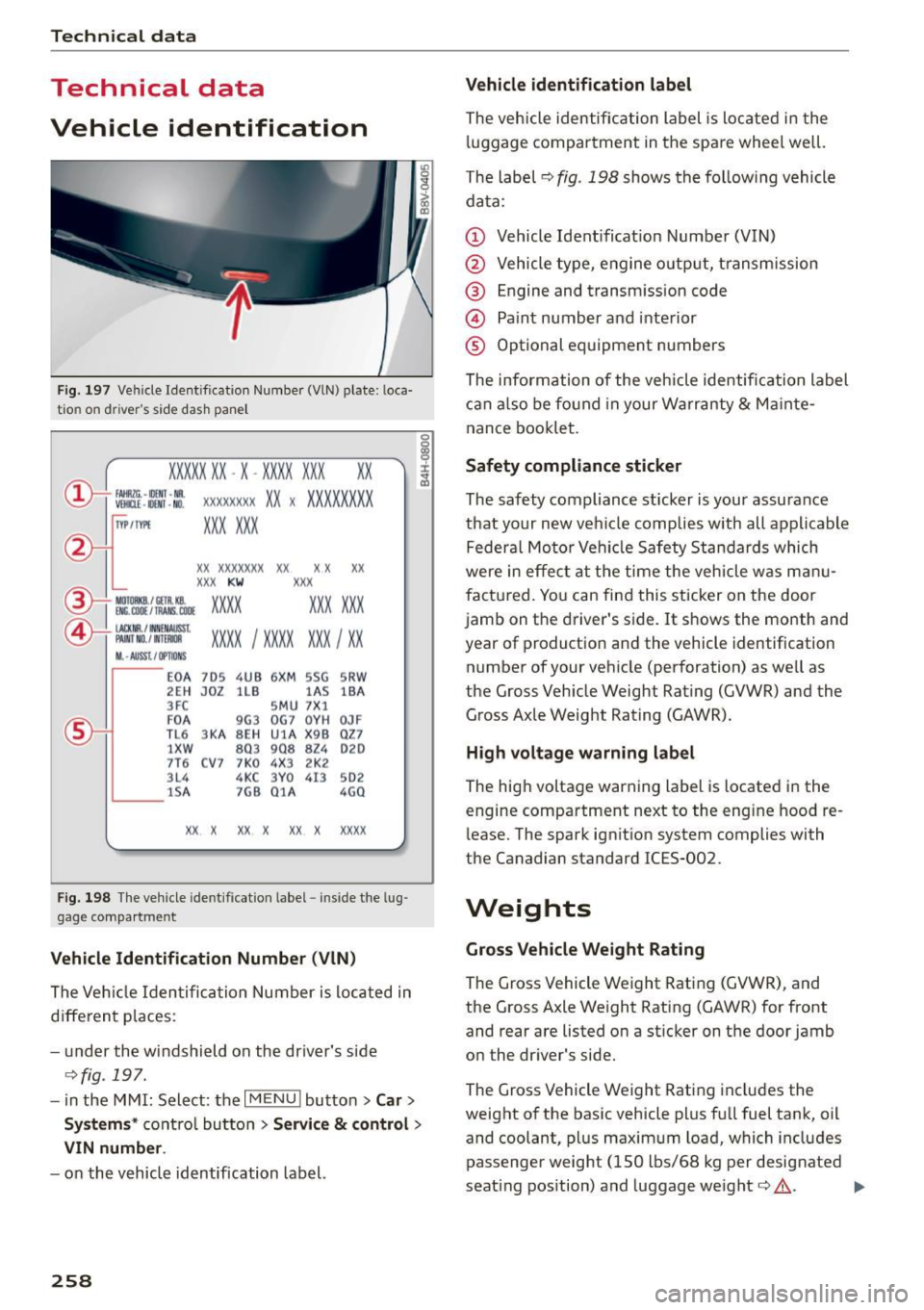

Vehicle identification

F ig. 197 Ve hicle Ident if icat ion Number (VlN) p late: loca·

tio n on d river 's side dash pane l

XXXXX XX -X -XX XX XXX XX

@-+ ~J:~t::1 ::: xxxxxxxx xx x xxxx xxx x

IYP lf'VPE XXX X XX

XX XXXXXXX XX X X XX

XXX KW XXX

\YT IM:.COll/fAANS ,COOE XXX XXX 15\_L I MOIOlll

@-+ ~~

1

:tr:~i XXXX I XXXX XXX I XX

II. -AUSST . / OPTIO NS

EO A 7D5 4UB 6X

M SSG SR W

2EH JOZ lLB lAS

1BA

3FC SM U 7 X1

FO A

9G3 O

G7 OY H

OJF

TL 6 3 KA BEH UlA X 9B Q

Z7

l XW

803 908

8Z4 020

7T6 C V7 7 KO 4X3 2K2

3L4 4KC 3YO 413

502

lS A 7GB 01A

4GO

XX X XX X

XX X xxxx

Fig. 198 The ve hicle ide ntif ic ati on label - inside t he lug ·

gage compar tmen t

Vehicle Identificat ion Number (VlN )

The Veh icle Iden tifica tion Number is located in

differen t places :

- u nder the windshield on the driver's side

¢ fig . 197.

- in the MMI: Select: the I MENU I button> Car >

System s* cont ro l button > Service & control >

VIN number .

-on the vehicl e identification label.

258

Vehicle identification label

The vehicle identification label is located i n the

l uggage compartment in the spare whee l we ll.

The label

9 fig . 198 shows the follow ing vehicle

da ta:

(D Vehicle Ident ificat ion Number (VIN)

@ Vehicle type, engine o utput, transmission

@ Engine and transm ission code

@ Pa int number and interior

® Optional equipment numbers

The information of the vehicle identification label

can also be fo und in your Warranty

& Ma inte

nance booklet.

Safety complianc e sticker

The safety compliance sticker is your assurance

that your new vehicle complies with all applicable

Federa l Mo to r Ve hicl e Safety Standards which

were in e ffect at the time the vehicle w as m anu

factured. You can find this sticker on the door

jamb on the d river's s ide. It shows the month and

year of production and the vehicle identification number of your veh icle (perforation) as we ll as

the Gross Veh icle Weight Rating (GVWR) and the

Gross Axle Weight Rating (GAWR).

H igh volt age warning label

The hig h voltage warning label is located i n the

engine compartment next to the engine hood re

l ease. The spark ignition system complies with

the Canadian standard ICES-002 .

Weights

Gross Vehicle Weight Rating

The Gross Vehicle Weight Rating (GVWR), and

the Gross Axle We ight Rating (GAWR) for front

and rear are listed on a st icker on the door jamb

o n the dr iver 's side.

The Gross Vehicle Weight Rating includes the

weight of the basic vehicle plus fu ll fuel tank, oil

and coolant, plus maxim um load, which includes

passenger weight (150 lbs/68 kg per designated

seat ing pos ition) and luggage weight ¢,&. . ..,_