ECU AUDI S3 SEDAN 2018 Repair Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2018, Model line: S3 SEDAN, Model: AUDI S3 SEDAN 2018Pages: 404, PDF Size: 62.3 MB

Page 363 of 404

LL co ..... N

" N ..... 0 N > co

"To open the side panel, turn the lock and re

move the cover

unt il the cargo floor engages beh ind the tabs

@ in both s ide panels¢ fig. 281 (upper im

age) .

" Fold the cargo floor back befo re closing the

luggage compartment lid .

Veh icle tool kit and cargo floor co ve r

App lies to: ve hicles with vers ion 2

The vehicle tool kit, tire mobility kit* and com

pressor* are stored in the luggage compartment

u nder the cargo floor

cover @¢ fig. 280.

"Engage the plastic hook ® in the luggage com-

partment

seal ¢ fig. 281.

" Fold the cargo floor back before closing the

luggage compartment lid .

..&, WARNING

Applies to: vehicles w ith jack

Improper use of the vehicle jac k can ca use se

rious personal injuries.

- Never use the screw drive r hex head to

t ighten whee l bolts, since the bolts cannot

attain the necessary tightening torque if you

use the hex head, potentially causing an ac

cident.

-The factory -supplied jack is intended only

for your vehicle model. Under no circum

stances should it be used to lift heavy

vehicles or other loads; you r isk injuring

yourself.

-Never start the engine when the vehicle is

ra ised, which could cause a n accident.

-Support the veh icle secure ly with appropri

ate stands if work is to be performed under

neath the vehicle; otherwise, there is a po

tent ial risk for injury .

-Never use the jack supplied with your Audi

on another vehicle, particularly on a heav ier

one . The jack is only suitable for use on the

vehicl e it came w ith.

@ Tips

The vehicle jack* in your vehicle is mainte

nance-free.

Em ergen cy as sis tanc e

Tire mobility kit

Preparation

Applies to: veh icles w it h tire mob ility kit

" Read and follow the important safety precau-

tions i n

¢page 360.

"Se t the park ing brake.

" Move the selector lever into the P position .

"Check if a repair with the tire mobi lity kit is pos -

sible

¢ page 361.

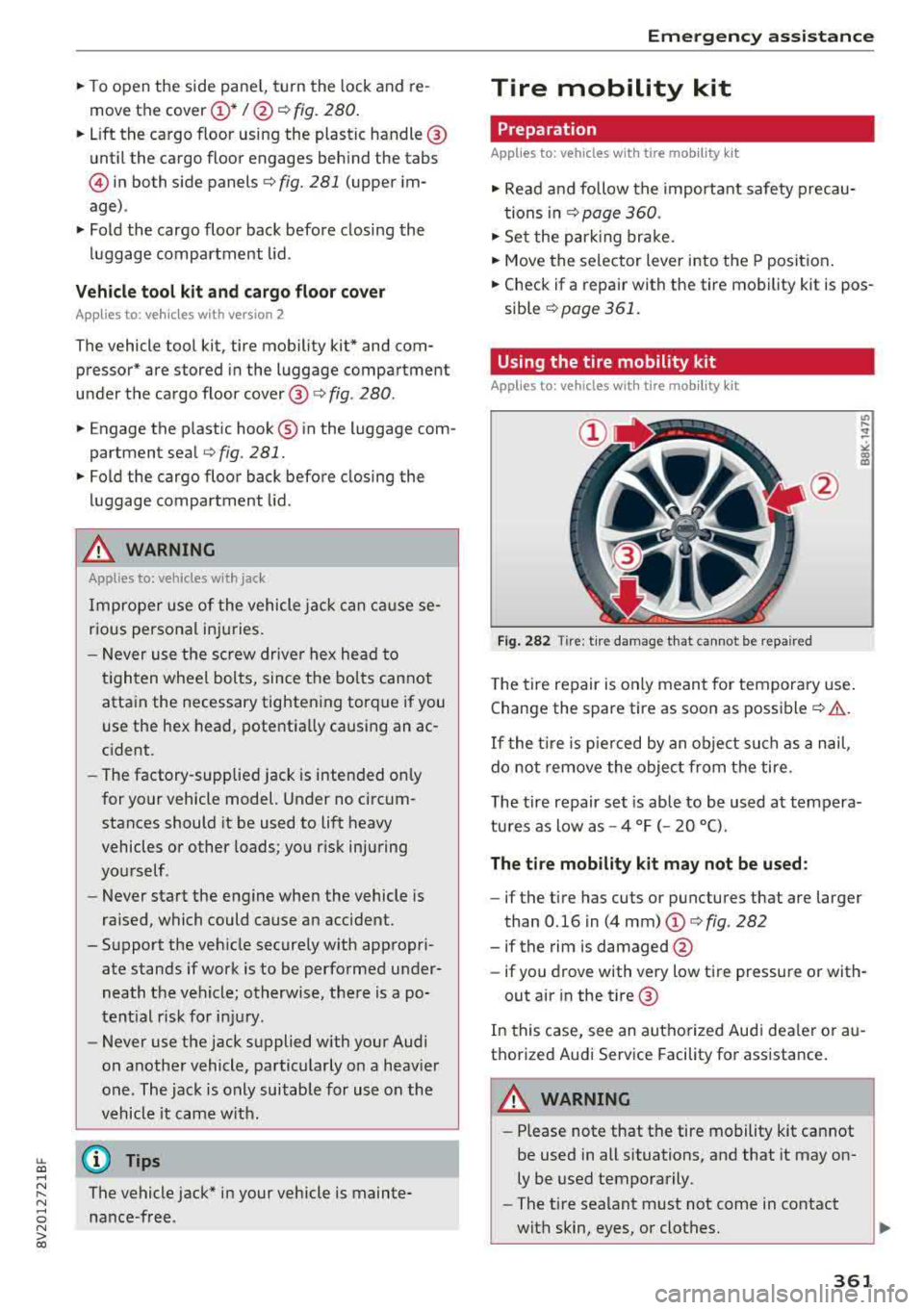

Using the tire mobility kit

Applies to: veh icles w it h tire mob ility kit

Fig. 282 Tire : tire damage t hat cannot be repaired

The tire repair is only meant for temporary use .

Change the spare tire as soon as

possible¢ &.

If the t ire is p ie rced by an object su ch as a nail,

do not remove the objec t from t he tire.

The tire repair set is able to be used at tempera

tures as low as -4 °F ( -20 °C) .

The tire mobility kit may not be us ed :

-if the t ire has cuts or punctures that are larger

than 0.16 in (4 mm)

(D ¢ fig. 282

-if the rim is damaged @

-if you drove with very low tire pressure or with-

out air in the tire @

In this case, see an authorized Aud i dea ler o r au

thorized Audi Serv ice Facility for ass istance.

.&_ WARNING

-Please note that the tire mobility kit cannot

be used in all situations, and that it may on

ly be used temporarily .

-The tire sealant must not come in contact

with skin, eyes, or clothes.

361

Page 368 of 404

Emergency assistance

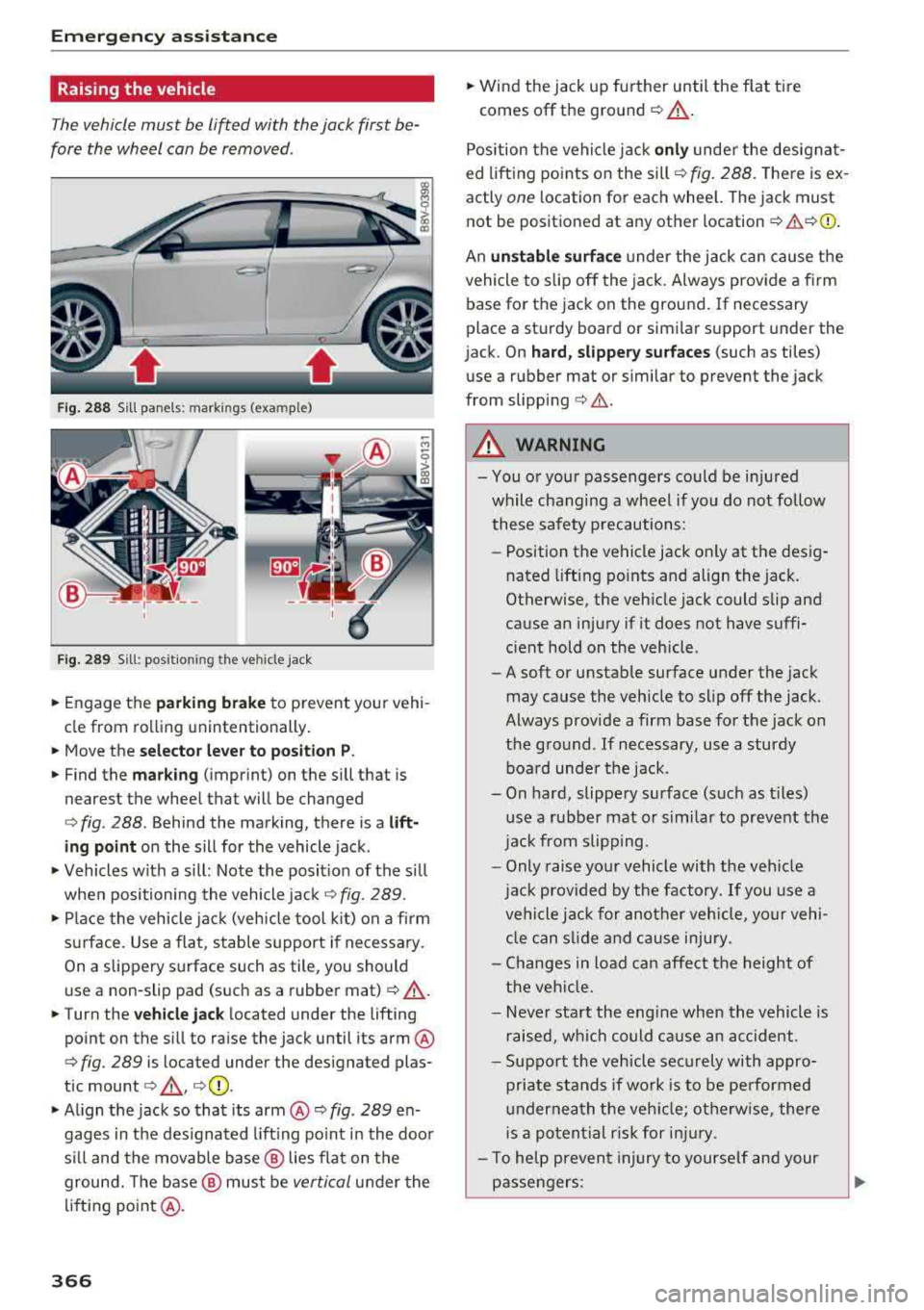

Raising the vehicle

The vehicle must be li~ed with the jack first be

fore the wheel can be removed.

Fig. 288 Sill panels : mark in gs (exa mple)

Fig. 289 Sill : positio nin g th e ve hicle jack

,.. Engage the parking brake to prevent your vehi

cle from rolling unintentionally.

,.. Move the selector lever to position P.

,.. Find the marking (imprint) on the sill that is

nearest the wheel that will be changed

c> fig . 288 . Behind the marking, there is a lift

ing point on the sill for the vehicle jack.

,.. Vehicles with a sill: Note the position of the sill

when positioning the vehicle jack

c::> fig. 289.

,.. Place the vehicle jack (vehicle tool kit) on a firm

surface. Use a flat, stable support if necessary.

On a slippery surface such as tile, you should

use a non-slip pad (such as a rubber mat)

c::> ,&..

,.. Turn the vehicle jack located under the lifting

point on the sill to raise the jack until its arm @

c> fig. 289 is located under the designated plas

tic mount

c::> ,& , c::>G) .

,.. Align the jack so that its arm@ c::> fig. 289 en

gages in the designated lifting point in the door

sill and the movable base @ lies flat on the

ground. The base @ must be

vertical under the

lifting point @.

366

,.. Wind the jack up further until the flat tire

comes off the ground

c::> ,&. .

Position the vehicle jack only under the designat

ed lifting points on the sill

c::>fig. 288. There is ex

actly

one location for each wheel. The jack must

not be positioned at any other location

c::> & c::>(I) .

An unstable surface under the jack can cause the

vehicle to slip off the jack. Always provide a firm

base for the jack on the ground. If necessary

place a sturdy board or similar support under the

jack. On

hard, slippery surfaces (such as tiles)

use a rubber mat or similar to prevent the jack

from slipping

c::> & .

A WARNING -

-You or your passengers could be injured

while changing a wheel if you do not follow

these safety precautions :

-Position the vehicle jack only at the desig

nated lifting points and align the jack.

Otherwise, the vehicle jack could slip and

cause an injury if it does not have suffi

cient hold on the vehicle .

-A soft or unstable surface under the jack

may cause the vehicle to slip off the jack.

Always provide a firm base for the jack on

the ground . If necessary, use a sturdy

board under the jack.

-On hard, slippery surface (such as tiles)

use a rubber mat or similar to prevent the

jack from slipping.

-Only raise your vehicle with the vehicle

jack provided by the factory. If you use a

vehicle jack for another vehicle, your vehi

cle can slide and cause injury.

-Changes in load can affect the height of

the vehicle.

-Never start the engine when the vehicle is

raised, which could cause an accident.

-Support the vehicle securely with appro

priate stands if work is to be performed

underneath the vehicle; otherwise, there

is a potential risk for injury .

-To help prevent injury to yourself and your

passengers:

Page 369 of 404

LL co .... N

" N .... 0 N > co

-Do not raise the v ehicl e until you are sure

the jack is securely engaged .

- Passengers must not rema in in the vehicle

when it is jacked up.

- Make sure that passengers wait in a safe

p lace away from the vehicle and well away

from the road and traff ic.

- Make sure jack position is correct, adjust

as necessary and then cont inue to raise

the jack.

CD Note

Do not li ft the vehicle by the sill. Position the

vehicle jack on ly at the designated lifting

points on the sil l. Otherwise, your vehicle will

be damaged.

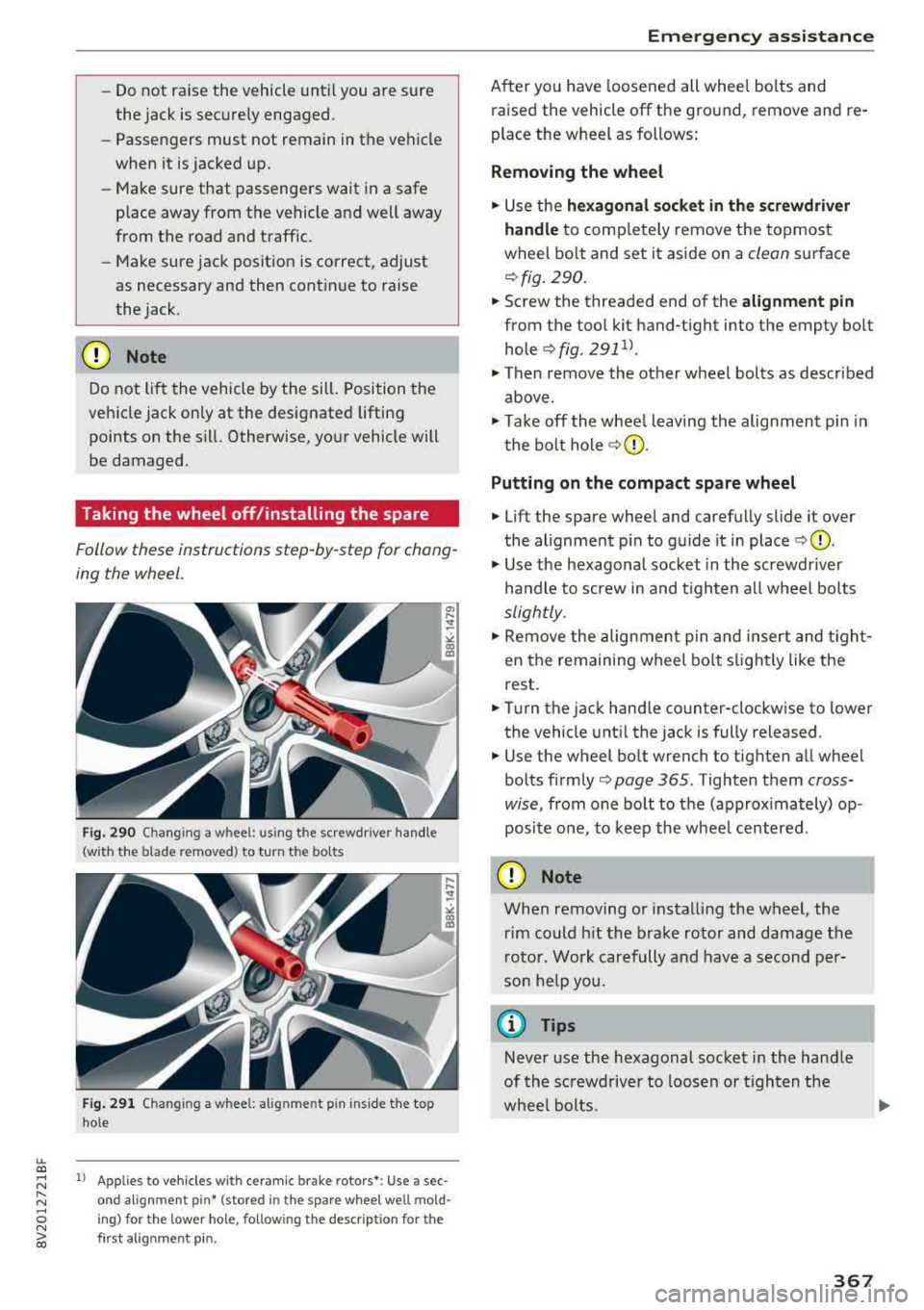

Taking the wheel off/installing the spare

Follow th ese instructions st ep-by-step for chang

ing the wheel .

Fig . 2 90 Ch angin g a w hee l: u sin g th e screwdr ive r ha ndle

(with t he bla de remo ved} t o turn t he bolts

F ig. 291 C h anging a w hee l: ali gnm en t pi n in side the to p

h ol e

1l Appli es to veh icles with ceram ic br ake rot ors•: Use a sec

on d alig nme nt pin * (sto re d in t he s pare w hee l we ll mo ld

ing} for the lo w er hole , fo ll o w ing the de scr ip tion for t he

firs t alig nmen t pin .

Em ergen cy as sis tanc e

After you have loosened all whe el bo lts and

raised the vehicle off the gro und, remove and re

place the wheel as follows:

Removing the wheel

.,. Use the hexagonal socket in the screwdriver

handle

t o comp letely remove the topmost

wheel bo lt and set i t aside on a

clean su rface

r=> fig. 290.

.,. Screw the threaded end of the alignment pin

from the too l kit hand-tight into the empty bo lt

hole

c> fig . 2911>.

.,. Then remove the other wheel bolts as descr ibed

above .

.,. Take off the whee l leaving the alignment p in in

the bolt hole

~ 0-

Putting on the comp act spare wheel

.,. Lift the spare wheel and carefully slide it over

the alignment p in to guide it in

place r=>@.

.,. Use the hexagonal socket in the screwdr iver

ha ndle to screw in and t igh ten all wheel bolts

slightly .

.,. Remove the alignmen t pin and insert and t igh t

en the remaining wheel bo lt s light ly like the

rest .

.,. Tu rn the jack hand le counter-clockwise to lowe r

the vehicle until the jack is fully released .

.,. Use the wheel bolt wrench to tighten a ll wheel

bolts firmly

c> page 365 . Tighten them cross

wise,

from one bo lt to the (approx imately) op

posite one , to keep the wheel centered .

CD Note

When removing or installing the wheel , the

r im could h it the brake rotor and damage the

r otor. Work carefully and have a second per

son help you.

@ Tips

Never use the hexagonal socket in the handle

of the sc rewdrive r to loosen or t ighten the

whee l bolts.

367

Page 370 of 404

Emergency assistance

-Pull th e revers ible blade from the sc rew driv

e r before you use the he xag onal socket in

the handle t o turn the w heel bo lts .

- W hen mounting ti res w ith

unidirectional

tread design

make sure the t read pattern is

po inted the r igh t way

c> page 36 8.

-The wheel bolts should be clea n and easy to

turn . C heck for di rt and c orros io n on t he

mating surfaces o f both the wheel an d the

hu b. Remove all dirt from t hese surfaces be

fo re r emo untin g the wheel.

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mount ed with th eir tread pattern pointed in the

right direction .

Using a spare tire with a tread pattern

intended for use in a specific direction

W hen using a spare ti re with a tread patte rn in

tended fo r use in a spec ific d ir e ction, please note

t he following:

- The direct ion of rotat io n is marked by an a rrow

o n the side of the tire.

- If the spare tire has to be installed in the incor

r ect d irection, use the spare tire only tempora

r ily s ince the t ire w ill not be ab le to achieve its

o pti mum p erf ormance c harac ter istics wi th re

gard to a quaplaning, noise and wea r.

- We recommen d that you pay particular atten

t ion to this fac t during wet weathe r and that

yo u adju st yo ur spe ed to match roa d condi

tio ns.

- Replace t he flat t ire with a new one and have i t

in stall ed on yo ur vehicle as soon as possible to

r e stor e th e han dling adv antage s of a un id ir e c

ti on al ti re.

Notes on wheel changing

Please read the info rmation c> page 33 7 if you

are going to use a spare tire which is different

from the tires on yo ur vehicle .

Afte r you change a tire:

-Check the tire pressure on the spare immedi

ately after installation.

368

- Have the wheel bolt tightening torque

checked with a torque wrench as soon as pos

sible by your authorized Audi dealer or a

qualified service station.

- With steel and alloy wheel rims, the wheel

bolts are correctly tightened at a torque of

90 ft lbs (120 Nm).

- If you notice that the wheel bolts are corroded

and difficult to turn while changing a tire ,

they should be replaced before you check the

tightening torque .

- Replace the flat tire with a new one and have

it installed on your vehicle as soon as possi

ble. Remount the wheel cover.

Until then, drive with extra care and at reduced

speeds.

A WARNING

- If you are goi ng t o equip yo ur vehicle with

t ires or r ims which diffe r from those which

wer e fac to ry install ed, th en be su re to read

t he infor matio n

c> pag e 33 7.

- Always mak e sure th e damag ed wheel or

e ve n a fl at tire and th e jack and to ol kit ar e

pr op erl y se cure d in t he l uggage com part

me nt a nd are no t loos e in the pass eng er

c omp artment.

- In a n ac cide nt or sudde n maneuver they

co uld fly forw ard, i njuring a nyon e in the ve

h icle.

- Alway s store damage d wheel, j ack a nd too ls

secure ly in the lu g gage compa rt ment. O th

erwise, in an a cci den t or sudden maneuve r

they cou ld fly forwar d, cau sing injury to pas

sen gers in the veh icle.

-

Page 372 of 404

Emergency assistance

Removing the subwoofer

• Lift up the cargo floor ¢ page 369, fig. 292 .

• Press the connector tabs @¢ fig. 294 togeth

er.

• Remove the connector @and set the discon-

nected cab le aside.

• Remove the bo lt @ .

• Carefu lly remove t he subwoofer .

Installing the subwoofe r

• Carefully place the subwoofer in the rim we ll.

The word

"FRONT" on the subwoofer must face

f orward.

• Inse rt the connector that was removed .

• Secure the subwoofer with the bolt .

• Fold the cargo floo r cover bac k into p lace.

(D Tips

The subwoofer can also be mounted w hen t he

spare tire is not in the spare wheel well.

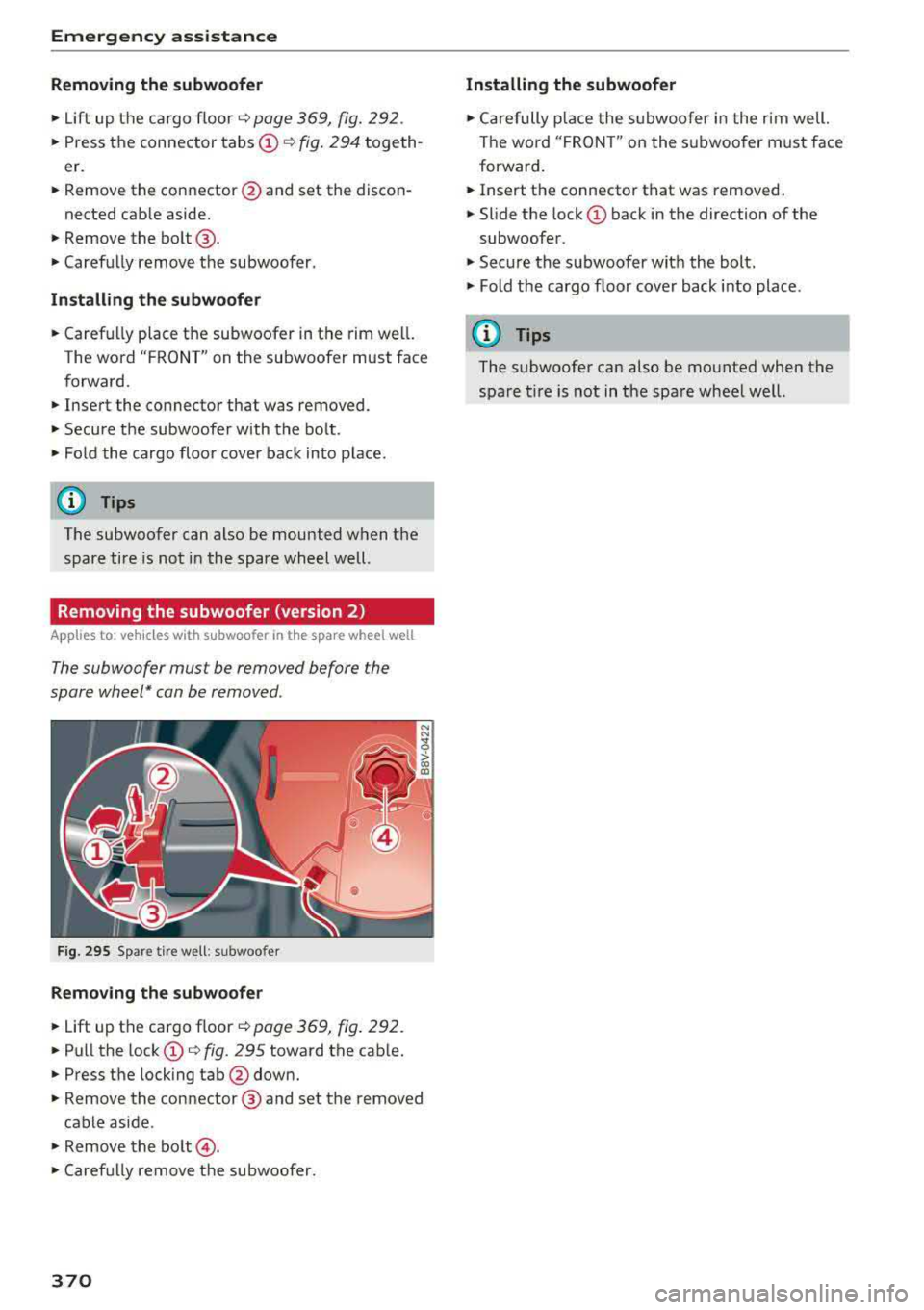

Removing the subwoofer (version 2)

Applies to: vehicles w ith s ubwoofer in the spare wheel well

The subwoofer must be removed before the

spare wheel* can be removed .

Fig . 295 Spare t ire well : su bwoofer

Remov ing the subwoofer

• Lift up the cargo floor ¢ page 369 , fig . 292 .

• Pull the lock (D ¢ fig. 295 toward the cab le.

• Press t he lock ing tab @down.

• Remove the connector @and set the removed

cable aside .

• Remove the bolt @.

• Caref ull y remove t he subwoofer.

370

Installing the subwoofer

• C arefully p lace the s ubwoofer i n the r im well.

The word "F RONT" on the s ubwoofer m ust face

forward .

• Insert the connecto r that was removed .

• Slide the lock (D back in the direction of the

subwoofe r.

• Secure the subwoo fer wit h the bolt.

• Fold the cargo floor cover back into place .

(D Tips

The subwoofer can also be mounted when the

spare t ire is not in the spa re whee l wel l.

Page 375 of 404

LL co .... N

" N .... 0 N > co

No. Equipment

F49 Clutch sensor (relay 1+2),

high-voltage

battery, power electronics

F52 Control module for suspension control

F53 Rear window defogger

The power seats* are protected via

circuit break

ers

that automatically switch on after a few sec

onds after the overload has been reduced.

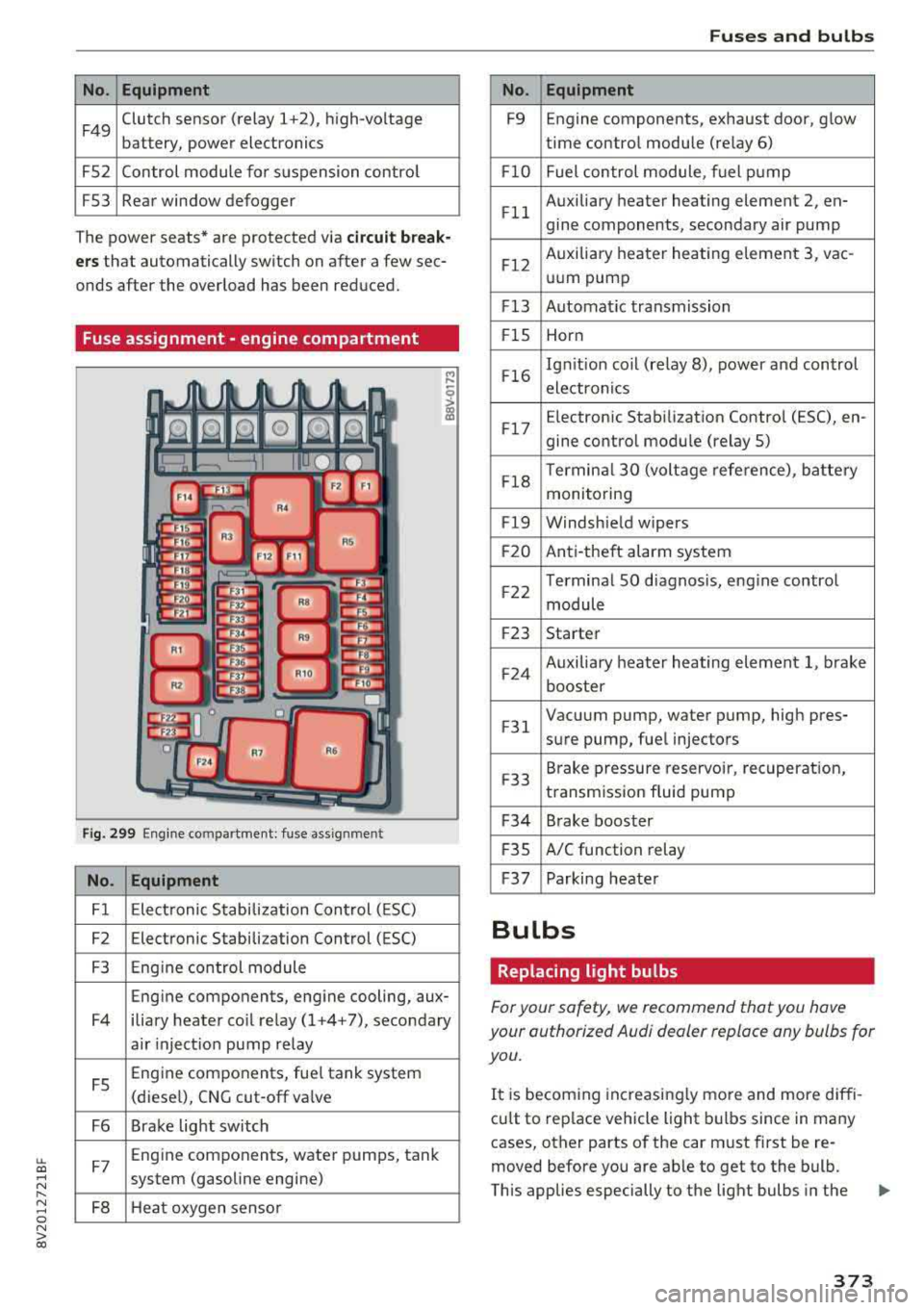

Fuse assignment -engine compartment

Fig. 299 Engine compartme nt: fuse assignment

No. Equipment

Fl Electronic Stabilization Control (ESC)

F2 Electronic Stabilization Control (ESC)

F3 Engine control module

Eng ine components, engine cooling, aux-

F4 iliary heater co il relay (1+4+7), secondary

air inject ion pump relay

FS Engine components, fue

l tank system

(diesel), CNG cut-off va lve

F6 Brake light switch

F7 Eng

ine components, water pumps, tank

system (gasoline engine)

FB Heat oxygen sensor

Fuses and bulbs

No. Equipment

F9 Engine

components, exhaust door, glow

time control module (relay 6)

F lO Fuel control module, fuel pump

F ll Auxiliary

heater heating element 2, en-

gine components, secondary air pump

F12 Auxiliary

heater heating element 3, vac-

uum pump

F13 Automat ic transmission

F lS Horn

F16 Ign

it ion coil (relay 8), power and control

electronics

F17 E

lectroni c Stabilization Control (ESC), en-

gine control module (relay S)

F18 Terminal

30 (voltage reference), battery

monitoring

Fl9 Windshield wipers

F20 Anti-theft alarm system

F22 Terminal

SO diagnos is, engine control

module

F23 Starter

F24 Auxiliary

heater heating element 1, brake

booster

F 31 Vacuum pump, water pump, high pres-

sure pump, fuel injectors

F33 Brake

pressure reservoir, recuperation,

transmission fluid pump

F34 Brake booster

F 35 A/C function

relay

F37 Parking heater

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for

you.

It is becom ing increasingly more and more diffi

cu lt to replace vehicle light bulbs since in many

cases, other parts of the car must first be re

moved before you are ab le to get to the bulb.

This applies especially to the light bulbs in the

373

Page 377 of 404

u. 00 .-< N l' N .-< 0 N > 00

Emergency situations

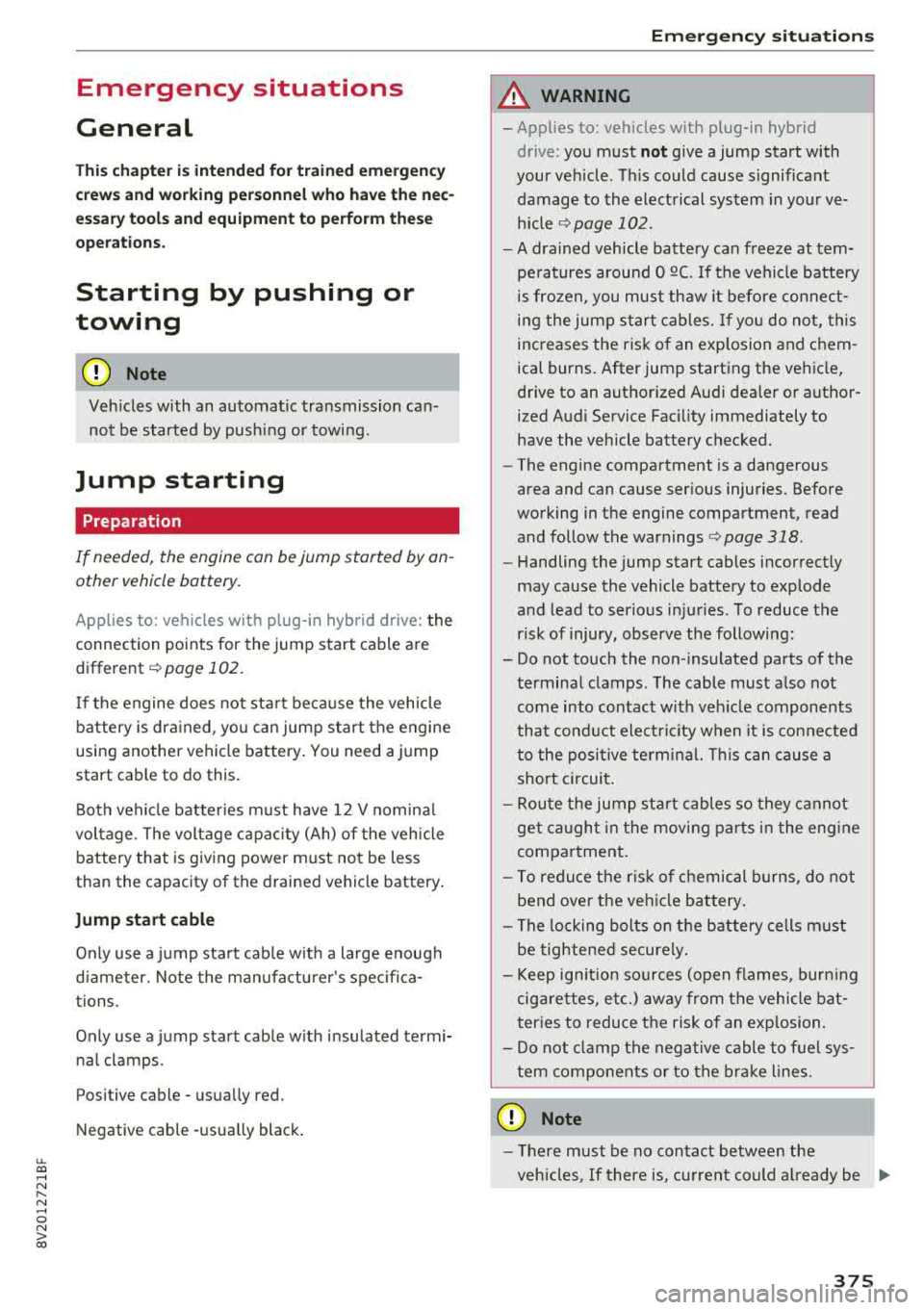

General

This chapter is intended for trained emergency

crews and working personnel who have the nec

essary tools and equipment to perform these

operations.

Starting by pushing or

towing

~ Note

Vehicles with an automatic transmission can

not be started by pushing or towing.

Jump starting

Preparation

If needed, the engine can be jump started by an

other vehicle battery.

Applies to: vehicles with plug-in hybrid drive: the

connection points for the jump start cable are

different

q page 102.

If the engine does not start because the vehicle

battery is drained, you can jump start the engine

using another vehicle battery. You need a jump

start cable to do this.

Both vehicle batteries must have 12 V nominal

voltage . The voltage capacity (Ah) of the vehicle

battery that is giving power must not be less

than the capacity of the drained vehicle battery.

Jump start cable

Only use a jump start cable with a large enough

diameter. Note the manufacturer's specifica

tions .

Only use a jump start cable with insulated termi

nal clamps.

Positive cable - usually red .

Negative cable -usually black.

Emergency situations

A WARNING

--

- Applies to: vehicles with plug-in hybrid

drive: you must

not give a jump start with

your vehicle . This could cause significant

damage to the electrical system in your ve

hicle

Q page 102.

-A drained vehicle battery can freeze at tem

peratures around 0

Q(. If the vehicle battery

is frozen, you must thaw it before connect

ing the jump start cables. If you do not, this

increases the risk of an explosion and chem

ical burns. After jump starting the vehicle,

drive to an authorized Audi dealer or author

ized Audi Service Facility immediately to

have the vehicle battery checked.

- The engine compartment is a dangerous

area and can cause serious injuries. Before

working in the engine compartment, read

and follow the warnings

Qpage 318.

- Handling the jump start cables incorrectly

may cause the vehicle battery to explode

and lead to serious injuries . To reduce the

risk of injury, observe the following:

- Do not touch the non-insulated parts of the

terminal clamps. The cable must also not

come into contact with vehicle components

that conduct electricity when it is connected

to the positive terminal. This can cause a

short circuit.

- Route the jump start cables so they cannot

get caught in the moving parts in the engine

compartment.

- To reduce the risk of chemical burns, do not

bend over the vehicle battery.

- The locking bolts on the battery cells must

be tightened securely.

- Keep ignition sources (open flames, burning

cigarettes, etc.) away from the vehicle bat

teries to reduce the risk of an explosion.

- Do not clamp the negative cable to fuel sys tem components or to the brake lines.

(LlJ} Note

- There must be no contact between the

vehicles, If there is, current could already be

.,.

375

Page 378 of 404

Emergency situations

flowing when connecting the positive termi

nals and the vehicle battery in the vehicle

providing the jump start cou ld be drained.

- Jump start cables can cause considerab le

damage to the vehicle electrical system if

they are connected incorrectly.

- The drained vehicle battery must be con

nected correctly to the electrical system.

- P lease note that the connecting process de

scribed below for the jump start cables is in

tended for when your vehicle is being jump

started. If you are jump starting another ve

hicle, do not connect the negative cable to

the negat ive terminal( -) on the drained ve

hicle battery, but rather connect it to a large

metal component that is bolted securely to

the engine block, or to the engine block it

se lf. If the vehicle battery in the vehicle be

ing jump started is not vented to the out

side, there is a risk of explosion due to hy

drogen gas.

@ Tips

If a car phone is installed, switch it off or

check the operating guide for what to do in

this situation.

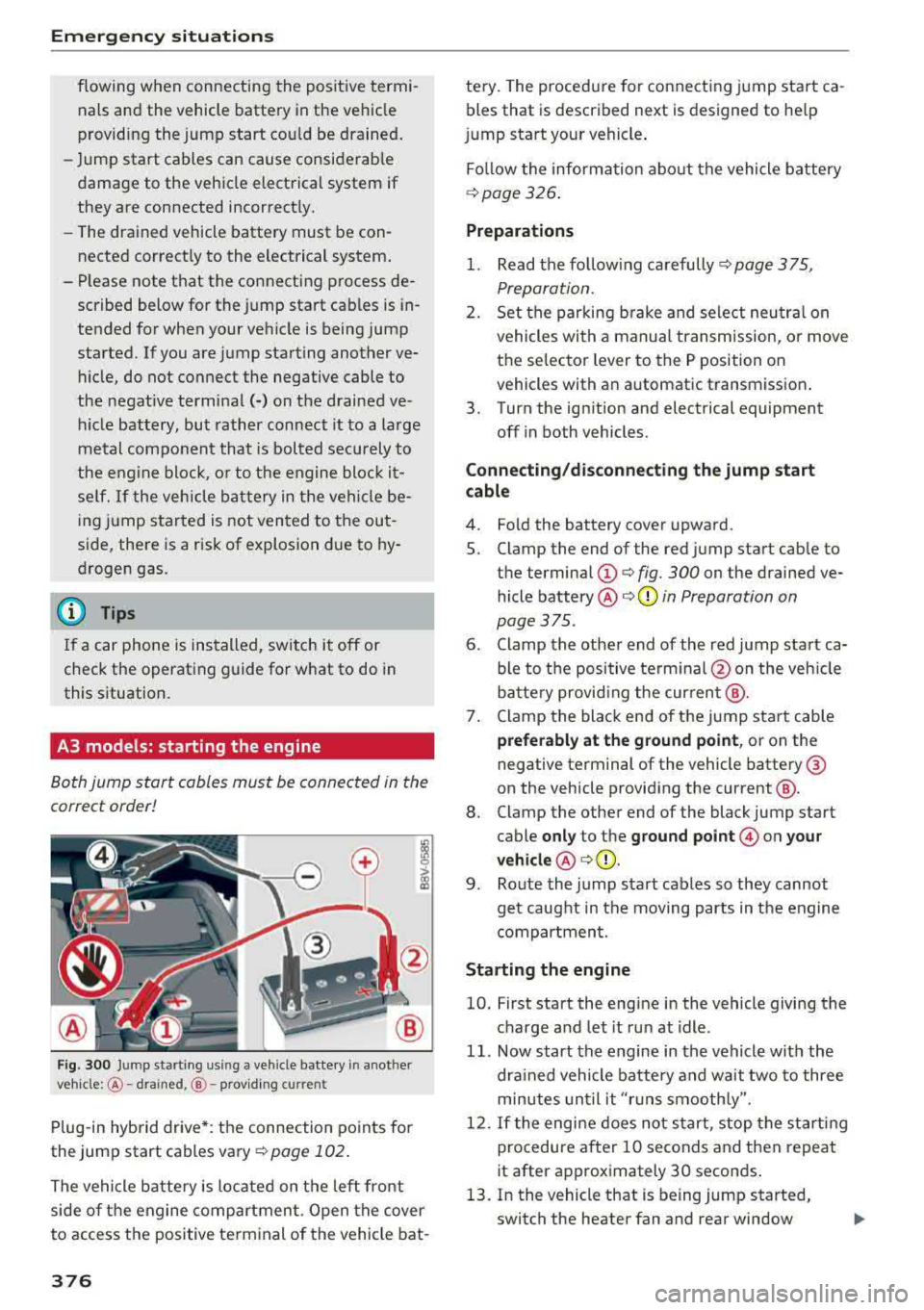

A3 models: starting the engine

Both jump start cables must be connected in the

correct order!

F ig. 300 Ju mp starting using a vehicle batte ry in anot her

vehicle :@ - dra ined, @- providing cu rrent

Plug-in hybrid drive *: the connection points for

the jump start cables vary Q

page 102.

The vehicle battery is located on the left front

side of the engine compartment . Open the cover

to access the positive terminal of the vehicle bat-

376

tery. The procedure for connecting jump start ca

bles that is described next is designed to help

j ump start your vehicle .

Follow the information about the vehicle battery

Qpage 326 .

Preparations

1. Read the following carefully ¢ page 375,

Preparation.

2. Set the parking brake and select neutral on

vehicles with a manual transmission, or move

the selector lever to the P position on

vehicles with an automatic transmission .

3. Turn the ignition and electrical equipment

off in both vehicles.

Connecting/disconnecting the jump start

cable

4. Fold the battery cover upward.

5. Clamp the end of the red jump start cable to

the termina l

(D ¢ fig. 300 on the drained ve

hicle

battery @Q(D in Preparation on

page

375 .

6. Clamp the other end of the red jump start ca

ble to the positive terminal @on the vehicle

battery providing the current @.

7. Clamp the black end of the jump start cab le

preferably at the ground point, or on the

negative terminal of the vehicle battery@

on the vehicle providing the current @.

8. Clamp the other end of the black jump start

cable

only to the ground point © on your

vehicle @Q(D .

9. Route the jump start cables so they cannot

get caught in the moving parts in the engine

compartment.

Starting the engine

10. First start the engine in the vehicle giving the

charge and let it run at idle.

11. Now start the engine in the vehicle with the

dra ined vehicle battery and wait two to three

minutes until it "r uns smoothly".

12. If the engi ne does not start, stop the starting

procedure after 10 seconds and then repeat

it after approximately 30 seconds .

13. In the vehicle that is being jump started, switch the heater fan and rear window

..,,

Page 381 of 404

LL co .... N

" N .... 0 N > co

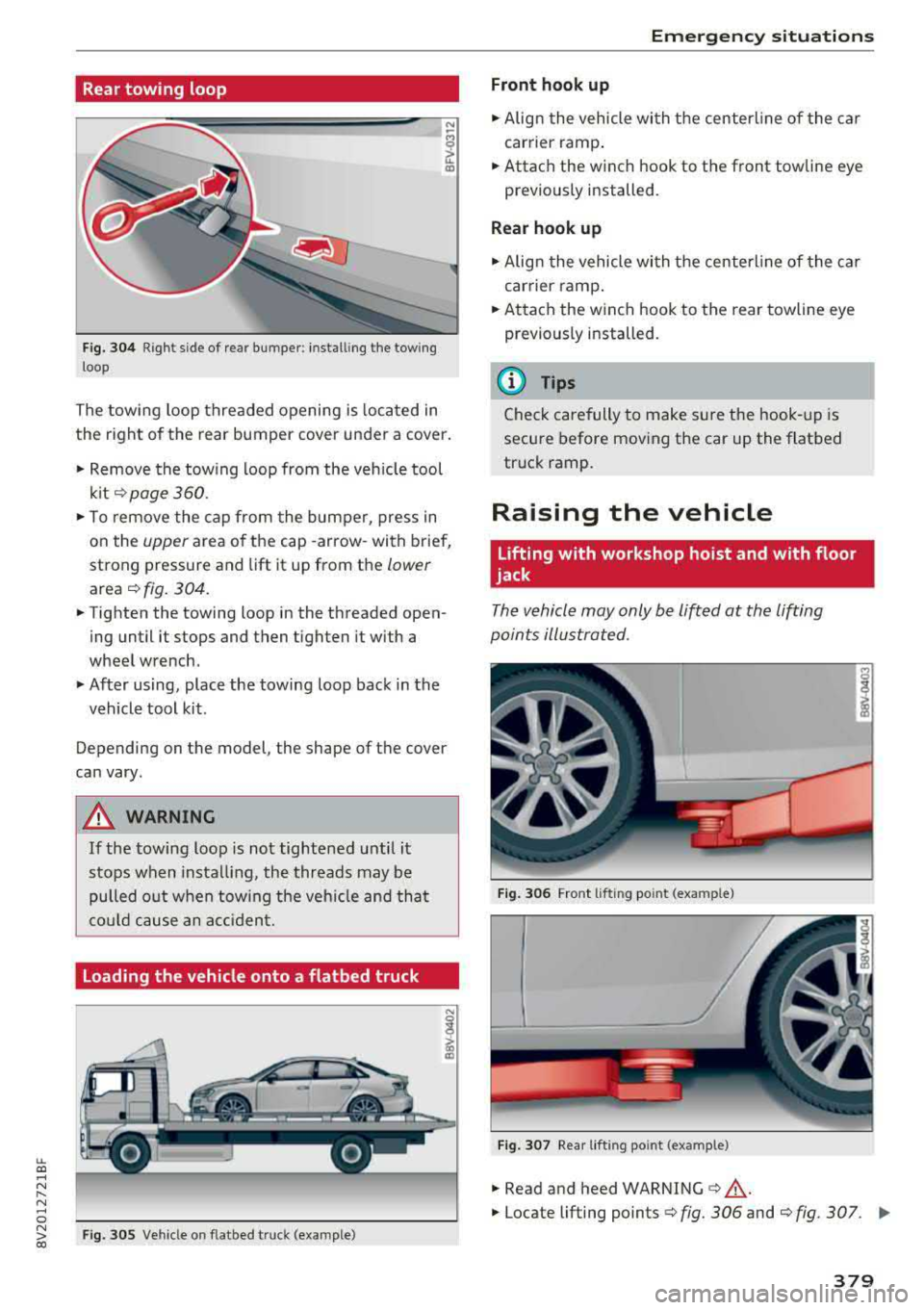

Rear towing loop

Fig. 304 Right side of rear bumper: installing the towing

loop

The towing loop threaded opening is located in

the right of the rear bumper cover under a cover.

.. Remove the towing loop from the vehicle tool

kit¢ page 360.

.. To remove the cap from the bumper, press in

on the

upper area of the cap -arrow-with brief,

strong pressure and lift it up from the

lower

area ¢ fig. 304.

.. Tighten the towing loop in the threaded open

ing until it stops and then tighten it with a

wheel wrench .

.. After using, place the towing loop back in the

vehicle tool kit .

Depending on the model, the shape of the cover

can vary .

& WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the vehicle and that

could cause an accident.

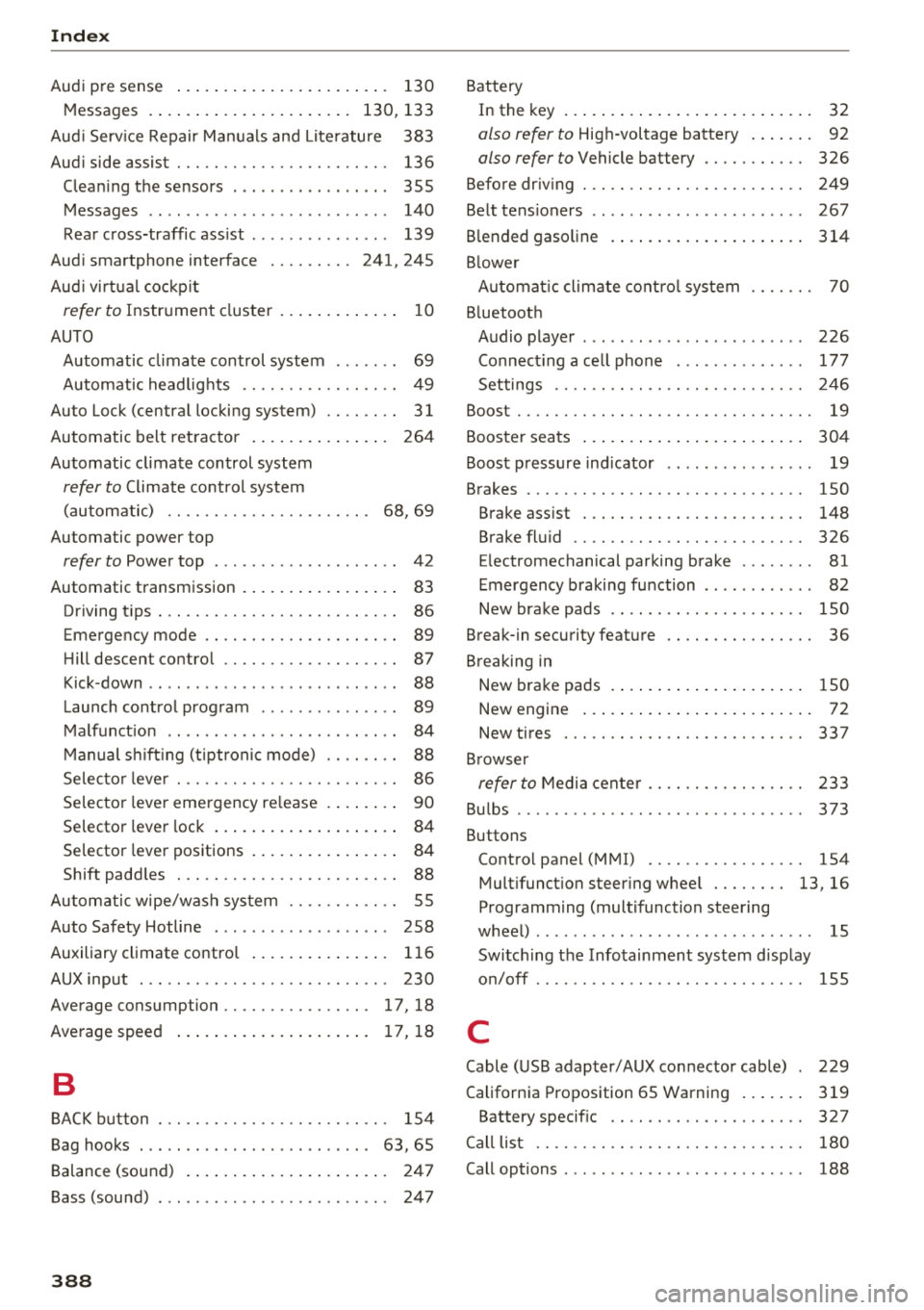

Loading the vehicle onto a flatbed truck

Fig. 305 Vehicle on flatbed t ruck (example)

Emergency situations

Front hook up

.. Align the vehicle with the centerline of the car

carrier ramp .

.. Attach the winch hook to the front towline eye

previously installed .

Rear hook up

.. Align the vehicle with the centerline of the car

carrier ramp .

.. Attach the winch hook to the rear towline eye

previously installed.

(D Tips

Check carefully to make sure the hook-up is

secure before moving the car up the flatbed

truck ramp .

Raising the vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be lifted at the lifting

points illustrated .

Fig. 306 Front lifting po int (exa mple)

Fig. 307 Rear lifting point (exa mple)

" Read and heed WARNING ¢&, .

.. Locate lifting points ¢ fig. 306 and ¢ fig. 307. ..,

379

Page 390 of 404

Index

Audi pre sense . . . . . . . . . . . . . . . . . . . . . . . 130

Messages . . . . . . . . . . . . . . . . . . . . . . 130, 133

Aud i Service Repair Manuals and Literature 383

Audi side assist . . . . . . . . . . . . . . . . . . . . . . . 136

Cleaning the sensors . . . . . . . . . . . . . . . . . 355

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Rear cross-traffic assist . . . . . . . . . . . . . . . 139

Audi smartphone interface . . . . . . . . . 241, 245

Aud i virtual cockp it

refer to Instrument cluster . . . . . . . . . . . . . 10

AUTO

Automatic climate control system . . . . . . .

69

Automatic headlights . . . . . . . . . . . . . . . . . 49

Auto Lock (centr al locking system) . . . . . . . . 31

Automatic belt retractor . . . . . . . . . . . . . . . 264

Automatic climate control system

refer to Climate control system

(automatic) . . . . . . . . . . . . . . . . . . . . . .

68, 69

Automatic power top

refer to Power top . . . . . . . . . . . . . . . . . . . . 42

Automatic transmission . . . . . . . . . . . . . . . . . 83

Driving tips . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Emergency mode . . . . . . . . . . . . . . . . . . . . . 89

Hill descent control . . . . . . . . . . . . . . . . . . . 87

Kick -down . . . . . . . . . . . . . . . . . . . . . . . . . . .

88

Launch control program . . . . . . . . . . . . . . . 89

Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . 84

Manual shift ing (tiptronic mode) . . . . . . . . 88

Selector lever . . . . . . . . . . . . . . . . . . . . . . . . 86

Selector lever emergency re lease . . . . . . . . 90

Selector lever lock . . . . . . . . . . . . . . . . . . . . 84

Selector lever positions . . . . . . . . . . . . . . . . 84

Shift padd les . . . . . . . . . . . . . . . . . . . . . . . . 88

Automatic wipe/wash system . . . . . . . . . . . . 55

Auto Safety Hotline . . . . . . . . . . . . . . . . . . .

258

Auxiliary climate contro l . . . . . . . . . . . . . . . 116

AUX input . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Average consumption ........... .... . 17, 18

Average speed . . . . . . . . . . . . . . . . . . . . . 17, 18

B

BACK button . . . . . . . . . . . . . . . . . . . . . . . . . 154

Bag hooks . . . . . . . . . . . . . . . . . . . . . . . . .

63, 65

Balance (sound) . . . . . . . . . . . . . . . . . . . . . . 247

Bass (sound) . . . . . . . . . . . . . . . . . . . . . . . . . 247

388

Battery

In the key . . . . . . . . . . . . . . . . . . . . . . . . . . .

32

also refer to High-voltage battery . . . . . . . 92

also refer to Vehicle battery . . . . . . . . . . . 326

Before driv ing . . . . . . . . . . . . . . . . . . . . . . . . 249

Belt tensioners . . . . . . . . . . . . . . . . . . . . . . . 267

Blended gasoline . . . . . . . . . . . . . . . . . . . . . 314

Blower

Automat ic climate control system . . . . . . .

70

Bluetooth

Audio player . . . . . . . . . . . . . . . . . . . . . . . .

226

Connecting a cell phone . . . . . . . . . . . . . . 177

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Boost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Booster seats . . . . . . . . . . . . . . . . . . . . . . . . 304

Boost pressure indicator . . . . . . . . . . . . . . . . 19

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Brake assist . . . . . . . . . . . . . . . . . . . . . . . . 148

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . 326

Electromechanical parking brake . . . . . . . . 81

Emergency braking function . . . . . . . . . . . . 82

New brake pads . . . . . . . . . . . . . . . . . . . . . 150

Break-in security feature . . . . . . . . . . . . . . . . 36

Breaking in

New brake pads . . . . . . . . . . . . . . . . . . . . .

150

New engine . . . . . . . . . . . . . . . . . . . . . . . . . 72

New tires . .... .. .. .. ............. .. 337

Browser

refer to Media center . . . . . . . . . . . . . . . . . 233

Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Buttons

Control panel (MMI) . . . . . . . . . . . . . . . . .

154

Multifunction steering wheel . . . . . . . . 13, 16

Programming (multifunction steering

wheel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Switching the Infotainment system display

on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

155

C

Cable (USB adapter/AUX connector cable) 229

California Proposition 65 Warning . . . . . . . 319

Battery specific . . . . . . . . . . . . . . . . . . . . . 327

Call list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Call options . . . . . . . . . . . . . . . . . . . . . . . . . . 188