AUDI S4 1998 B5 / 1.G Engine Manual

Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 61 of 72

62

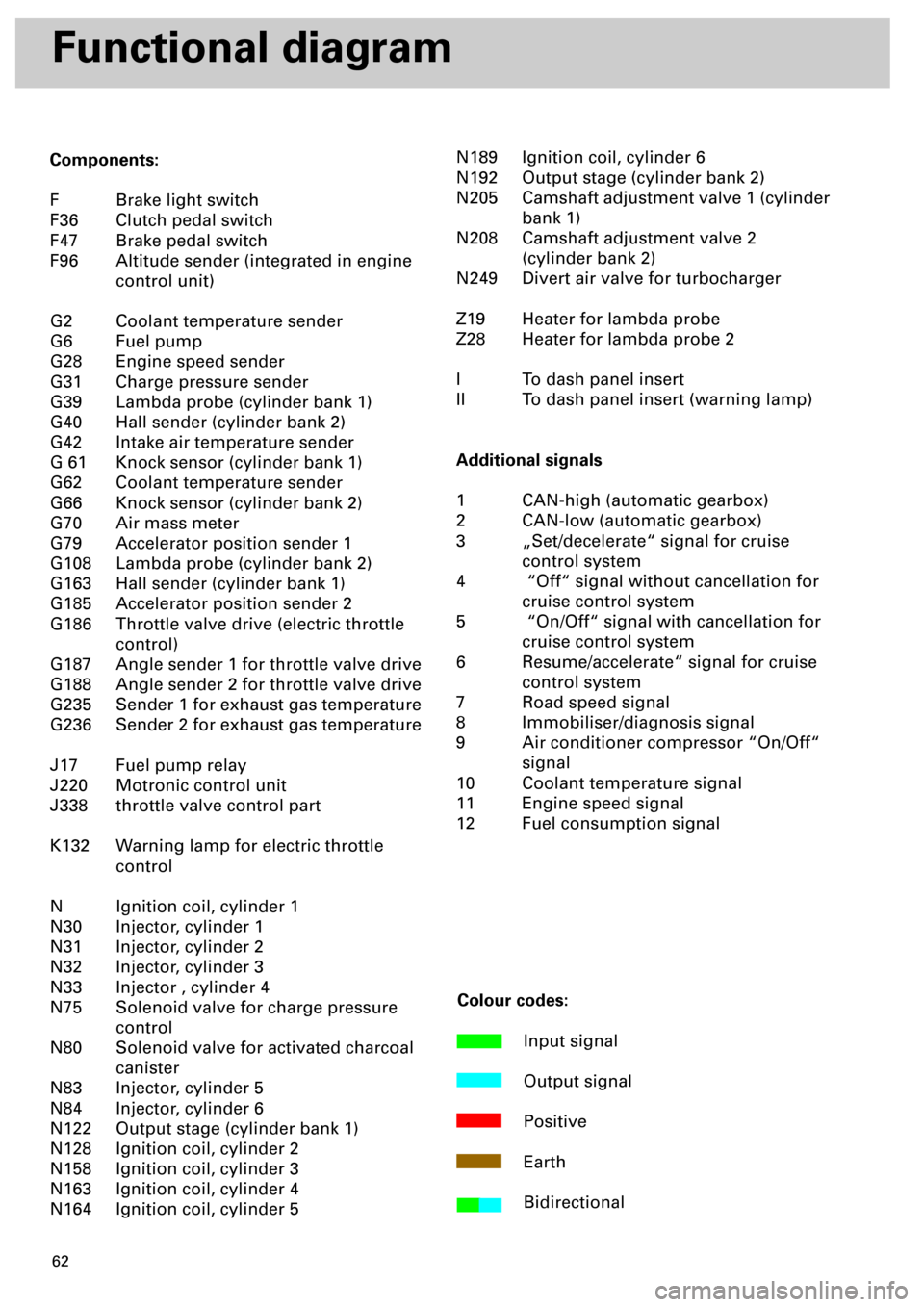

Functional diagram

Components:

F Brake light switch

F36 Clutch pedal switch

F47 Brake pedal switch

F96 Altitude sender (integrated in engine

control unit)

G2 Coolant temperature sender

G6 Fuel pump

G28 Engine speed sender

G31 Charge pressure sender

G39 Lambda probe (cylinder bank 1)

G40 Hall sender (cylinder bank 2)

G42 Intake air temperature sender

G 61 Knock sensor (cylinder bank 1)

G62 Coolant temperature sender

G66 Knock sensor (cylinder bank 2)

G70 Air mass meter

G79 Accelerator position sender 1

G108 Lambda probe (cylinder bank 2)

G163 Hall sender (cylinder bank 1)

G185 Accelerator position sender 2

G186 Throttle valve drive (electric throttle

control)

G187 Angle sender 1 for throttle valve drive

G188 Angle sender 2 for throttle valve drive

G235 Sender 1 for exhaust gas temperature

G236 Sender 2 for exhaust gas temperature

J17 Fuel pump relay

J220 Motronic control unit

J338 throttle valve control part

K132 Warning lamp for electric throttle

control

N Ignition coil, cylinder 1

N30 Injector, cylinder 1

N31 Injector, cylinder 2

N32 Injector, cylinder 3

N33 Injector , cylinder 4

N75 Solenoid valve for charge pressure

control

N80 Solenoid valve for activated charcoal

canister

N83 Injector, cylinder 5

N84 Injector, cylinder 6

N122 Output stage (cylinder bank 1)

N128 Ignition coil, cylinder 2

N158 Ignition coil, cylinder 3

N163 Ignition coil, cylinder 4

N164 Ignition coil, cylinder 5N189 Ignition coil, cylinder 6

N192 Output stage (cylinder bank 2)

N205 Camshaft adjustment valve 1 (cylinder

bank 1)

N208 Camshaft adjustment valve 2

(cylinder bank 2)

N249 Divert air valve for turbocharger

Z19 Heater for lambda probe

Z28 Heater for lambda probe 2

I To dash panel insert

II To dash panel insert (warning lamp)

Additional signals

1 CAN-high (automatic gearbox)

2 CAN-low (automatic gearbox)

3 „Set/decelerate“ signal for cruise

control system

4 “Off“ signal without cancellation for

cruise control system

5 “On/Off“ signal with cancellation for

cruise control system

6 Resume/accelerate“ signal for cruise

control system

7 Road speed signal

8 Immobiliser/diagnosis signal

9 Air conditioner compressor “On/Off“

signal

10 Coolant temperature signal

11 Engine speed signal

12 Fuel consumption signal

Colour codes:

Input signal

Output signal

Positive

Earth

Bidirectional

Page 62 of 72

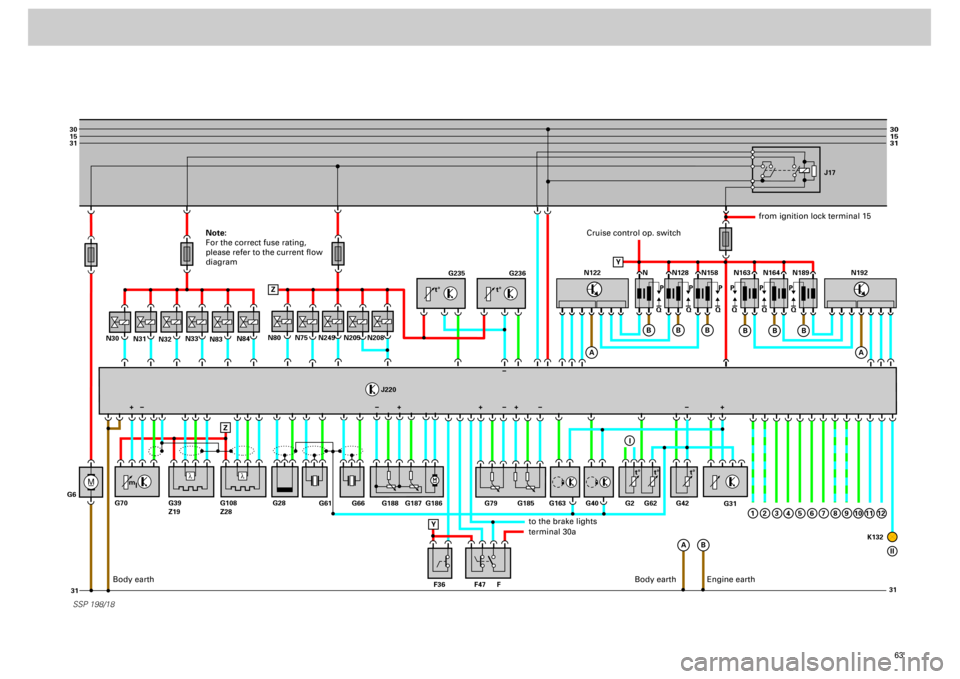

63

M

30

15

31

31 31

30

15

31

_

G6N31

N32N33N80

J220

N83N84

N30

N75

N249

N205

N208

SSP 198/18

G235

G236

G31

N N128J17

N158 N163 N164 N189

Q PPPPPP

QQ QQQ

A

A

B Z

ZB

B

B

N122

A

B

B

B

1

N192

G61

G66 G188 G187 G186 G79

F47 F36 FG163 G40 G62G2 G42

K132 G185

G28 G70 G39

Z19G108

Z28

Y

+

Y

I

2

3

4

5

6

7

8

9

10

11

12

II

l

l

t° t°

m

lt° t° t°

+++ +

Cruise control op. switch

from ignition lock terminal 15

to the brake lightsterminal 30a

Body earth

Engine earth

Note:

For the correct fuse rating,

please refer to the current flow

diagram

Body earth

Page 63 of 72

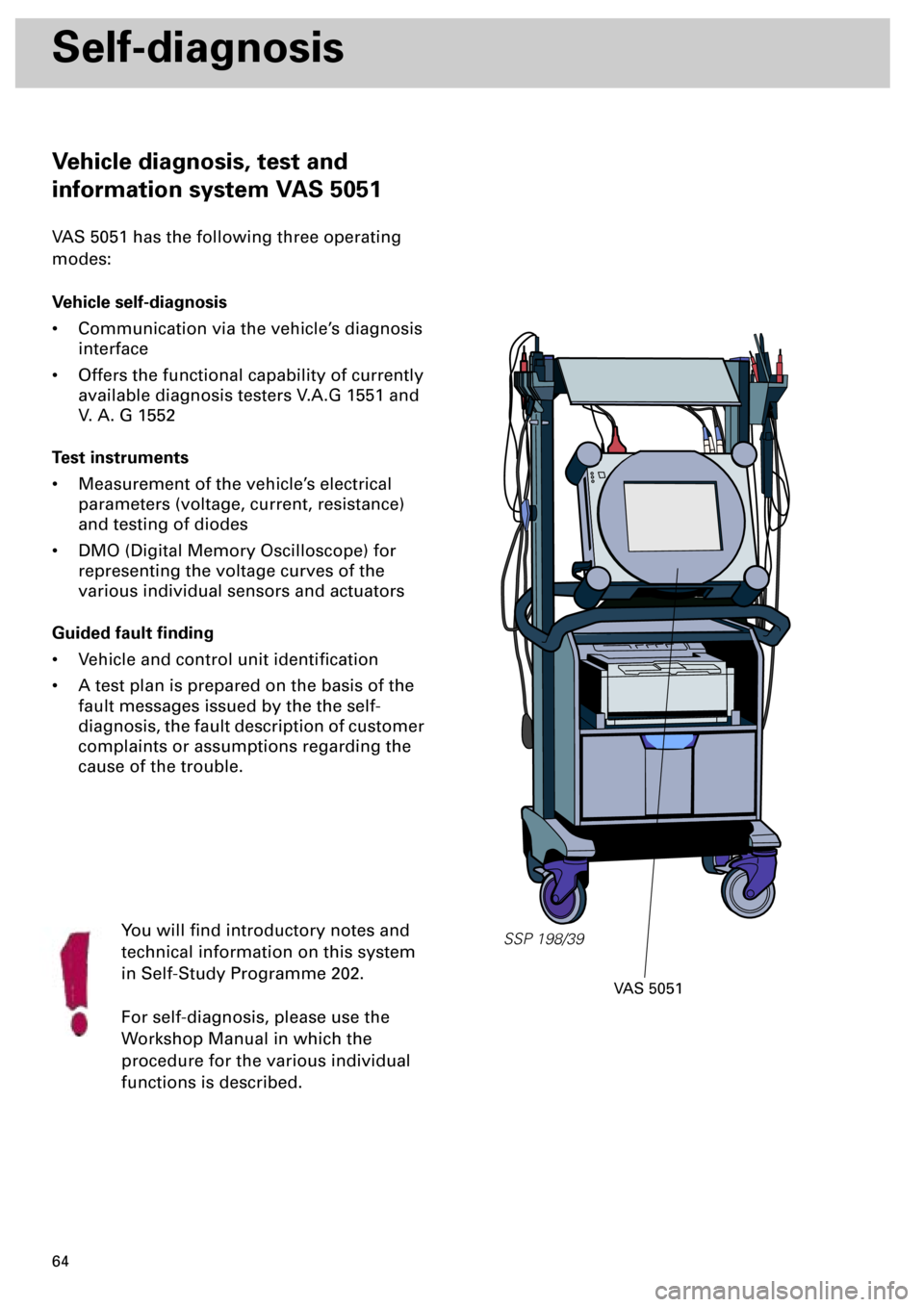

64

SSP 198/39

Self-diagnosis

Vehicle diagnosis, test and

information system VAS 5051

VAS 5051 has the following three operating

modes:

Vehicle self-diagnosis

• Communication via the vehicle’s diagnosis

interface

• Offers the functional capability of currently

available diagnosis testers V.A.G 1551 and

V. A. G 1552

Test instruments

• Measurement of the vehicle’s electrical

parameters (voltage, current, resistance)

and testing of diodes

• DMO (Digital Memory Oscilloscope) for

representing the voltage curves of the

various individual sensors and actuators

Guided fault finding

• Vehicle and control unit identification

• A test plan is prepared on the basis of the

fault messages issued by the the self-

diagnosis, the fault description of customer

complaints or assumptions regarding the

cause of the trouble.

You will find introductory notes and

technical information on this system

in Self-Study Programme 202.

For self-diagnosis, please use the

Workshop Manual in which the

procedure for the various individual

functions is described.

VAS 5051

Page 64 of 72

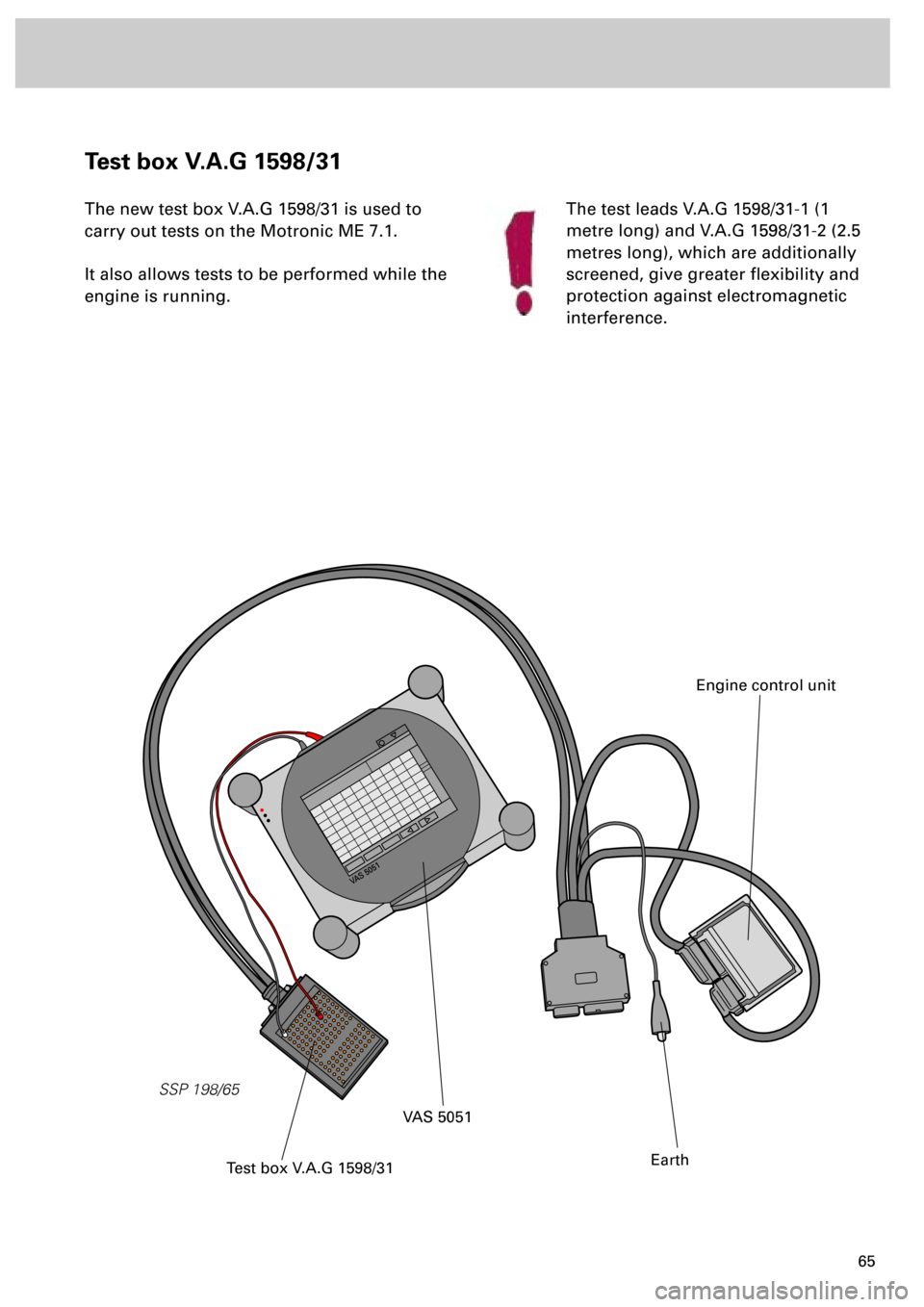

65

Test box V.A.G 1598/31

The new test box V.A.G 1598/31 is used to

carry out tests on the Motronic ME 7.1.

It also allows tests to be performed while the

engine is running.

VAS 5051VAS 5051

SSP 198/65

VAS 5051

Test box V.A.G 1598/31

Engine control unit

Earth

The test leads V.A.G 1598/31-1 (1

metre long) and V.A.G 1598/31-2 (2.5

metres long), which are additionally

screened, give greater flexibility and

protection against electromagnetic

interference.

Page 65 of 72

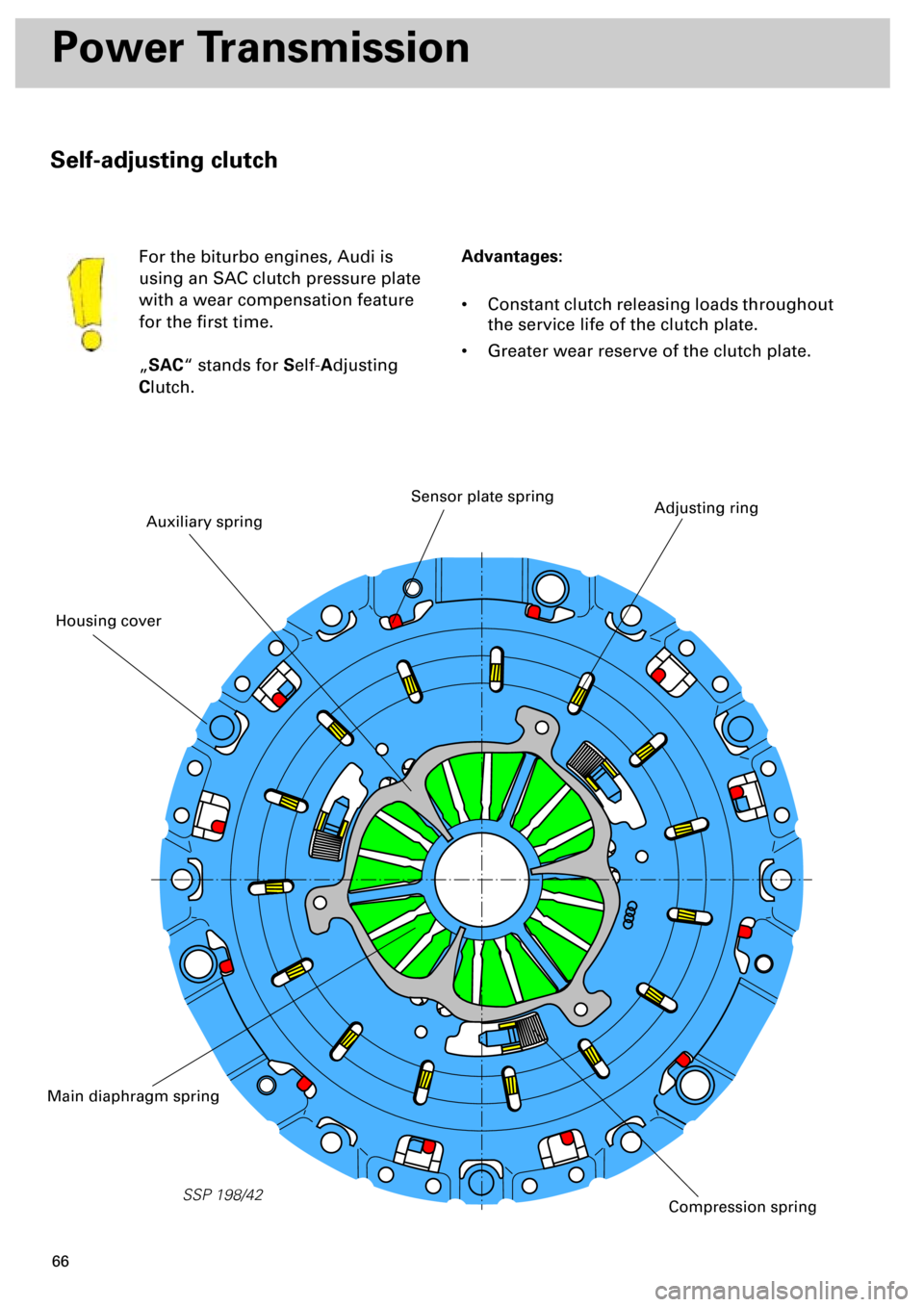

66

Power Transmission

Self-adjusting clutch

Advantages:

• Constant clutch releasing loads throughout

the service life of the clutch plate.

• Greater wear reserve of the clutch plate. For the biturbo engines, Audi is

using an SAC clutch pressure plate

with a wear compensation feature

for the first time.

„

SAC

“ stands for

S

elf-

A

djusting

C

lutch.

SSP 198/42

Auxiliary spring

Adjusting ringSensor plate spring

Main diaphragm spring

Compression spring

Housing cover

Page 66 of 72

67

Problem:

As the clutch plate wears, the position of the

main diaphragm spring changes, as do the

characteristics for contact pressure and

releasing load.

The main diaphragm spring has a digressive

characteristic. To prevent the contact pressure

of the pressure plate dropping too low over a

wear range of approx. 1.5 - 2 mm, the

characteristic of the main diaphragm spring is

such that the forces initially increase as a

factor of distance travelled.

This has the knock-on effect of producing

uncomfortably high pedal forces.

The clutch in the biturbo engine is required to

transmit high levels of torque.

Higher contact pressures have to be applied to

compensate for the limitations on the surface

area of the clutch lining for design reasons.

This in turn results in higher releasing loads

(particularly as wear progresses).

Solution to problem:

If the position of the main diaphragm spring

remains constant over the entire wear range,

the associated forces will also remain

unchanged.

This effect is achieved using the new SAC

clutch pressure plate.

SSP 198/41

Housing cover

SSP 198/72

0 -1 -2 1 2 3 4

Pressure plate travel in mm

Contact pressure

Fitting location

Wear reserve

Contact pressure characteristic

(conventional clutch )

Sensor plate spring

Main diaphragm spring

Adjusting ring

Auxiliary spring

Disengaging stop

Page 67 of 72

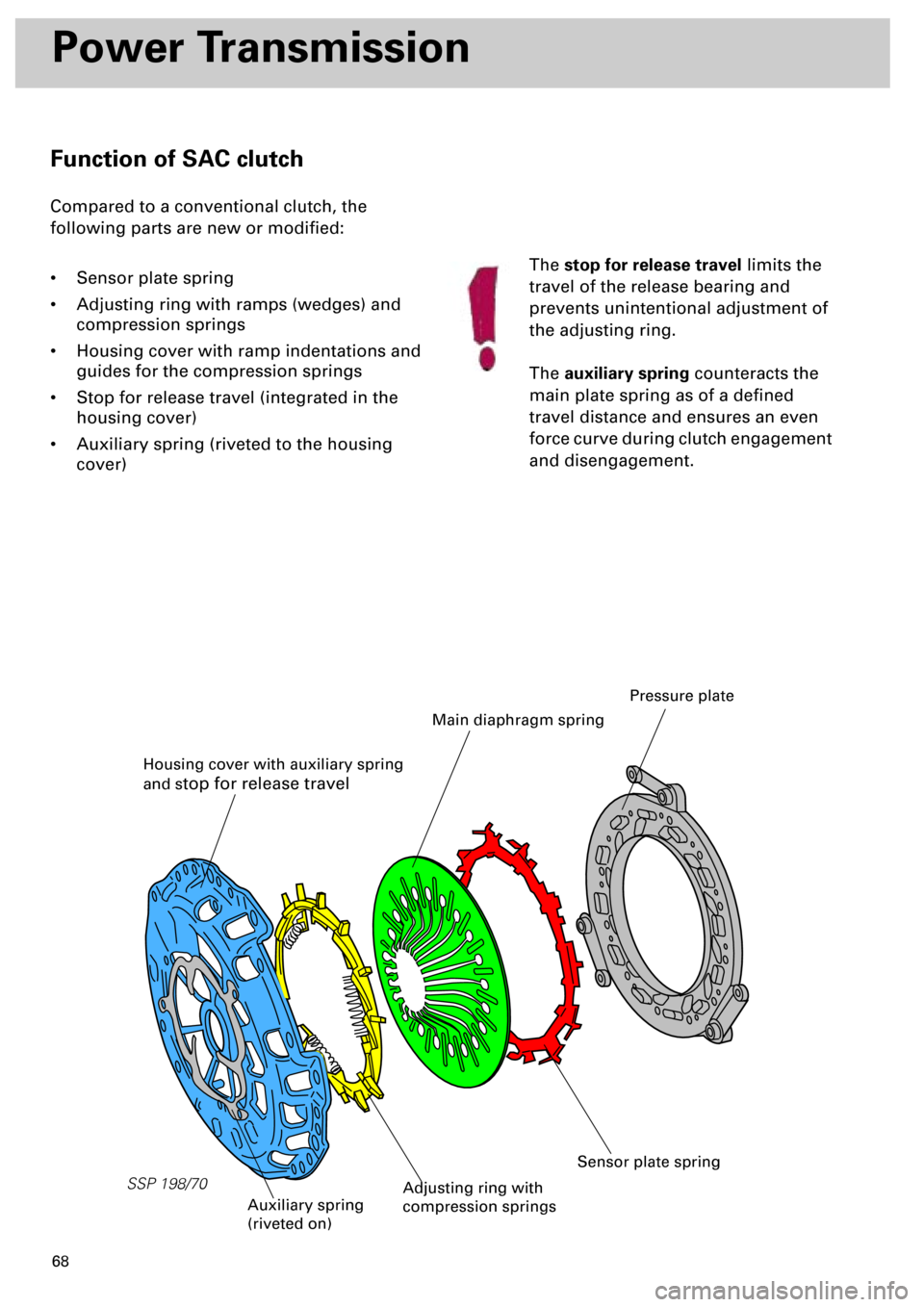

68

Power Transmission

Function of SAC clutch

Compared to a conventional clutch, the

following parts are new or modified:

• Sensor plate spring

• Adjusting ring with ramps (wedges) and

compression springs

• Housing cover with ramp indentations and

guides for the compression springs

• Stop for release travel (integrated in the

housing cover)

• Auxiliary spring (riveted to the housing

cover)The

stop for release travel

limits the

travel of the release bearing and

prevents unintentional adjustment of

the adjusting ring.

The

auxiliary spring

counteracts the

main plate spring as of a defined

travel distance and ensures an even

force curve during clutch engagement

and disengagement.

SSP 198/70

Housing cover with auxiliary spring

and s

top for release travel

Main diaphragm spring

Pressure plate

Auxiliary spring

(riveted on)

Sensor plate spring

Adjusting ring with

compression springs

Page 68 of 72

69

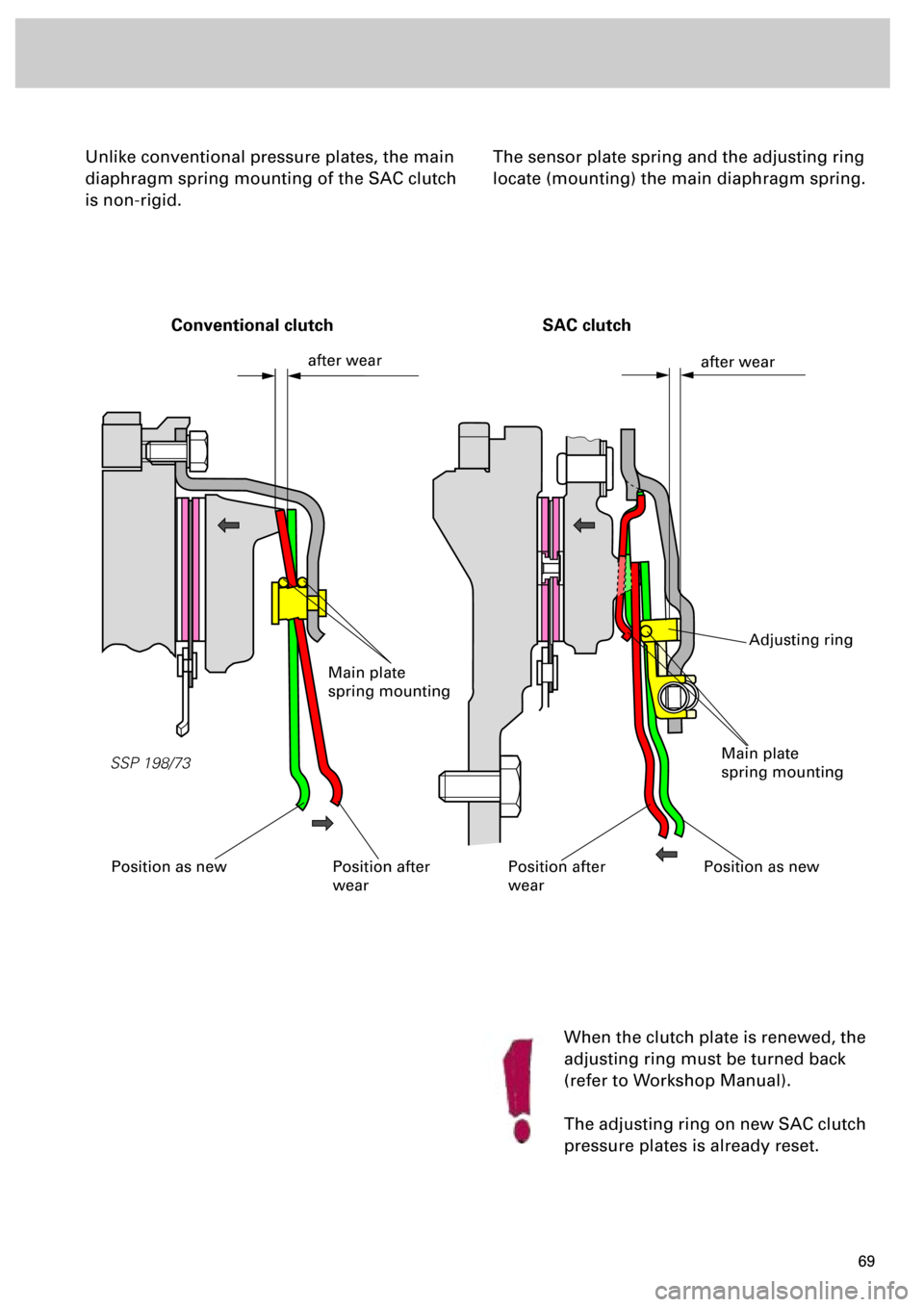

Unlike conventional pressure plates, the main

diaphragm spring mounting of the SAC clutch

is non-rigid.

When the clutch plate is renewed, the

adjusting ring must be turned back

(refer to Workshop Manual).

The adjusting ring on new SAC clutch

pressure plates is already reset.

The sensor plate spring and the adjusting ring

locate (mounting) the main diaphragm spring.

SSP 198/73

after wear

after wear

Position as newPosition after

wearPosition as newPosition after

wear

Main plate

spring mounting

Main plate

spring mounting

Conventional clutch

SAC clutch

Adjusting ring

Page 69 of 72

70

Power transmission

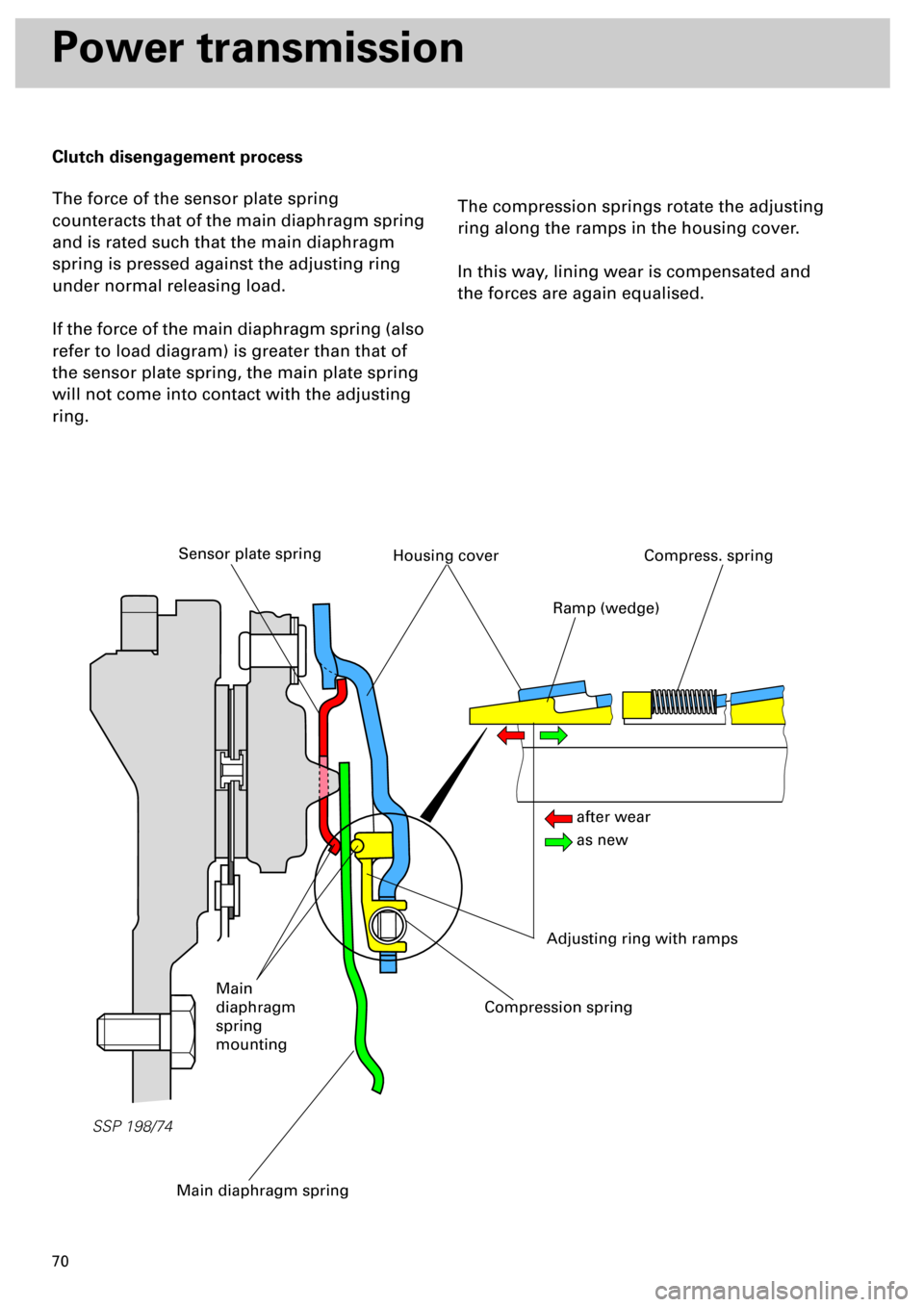

Clutch disengagement process

The force of the sensor plate spring

counteracts that of the main diaphragm spring

and is rated such that the main diaphragm

spring is pressed against the adjusting ring

under normal releasing load.

If the force of the main diaphragm spring (also

refer to load diagram) is greater than that of

the sensor plate spring, the main plate spring

will not come into contact with the adjusting

ring.

The compression springs rotate the adjusting

ring along the ramps in the housing cover.

In this way, lining wear is compensated and

the forces are again equalised.

SSP 198/74

Main diaphragm spring

Sensor plate springHousing cover

Adjusting ring with ramps

Compress. spring

Compression spring

Main

diaphragm

spring

mounting

Ramp (wedge)

after wear

as new

Page 70 of 72

71

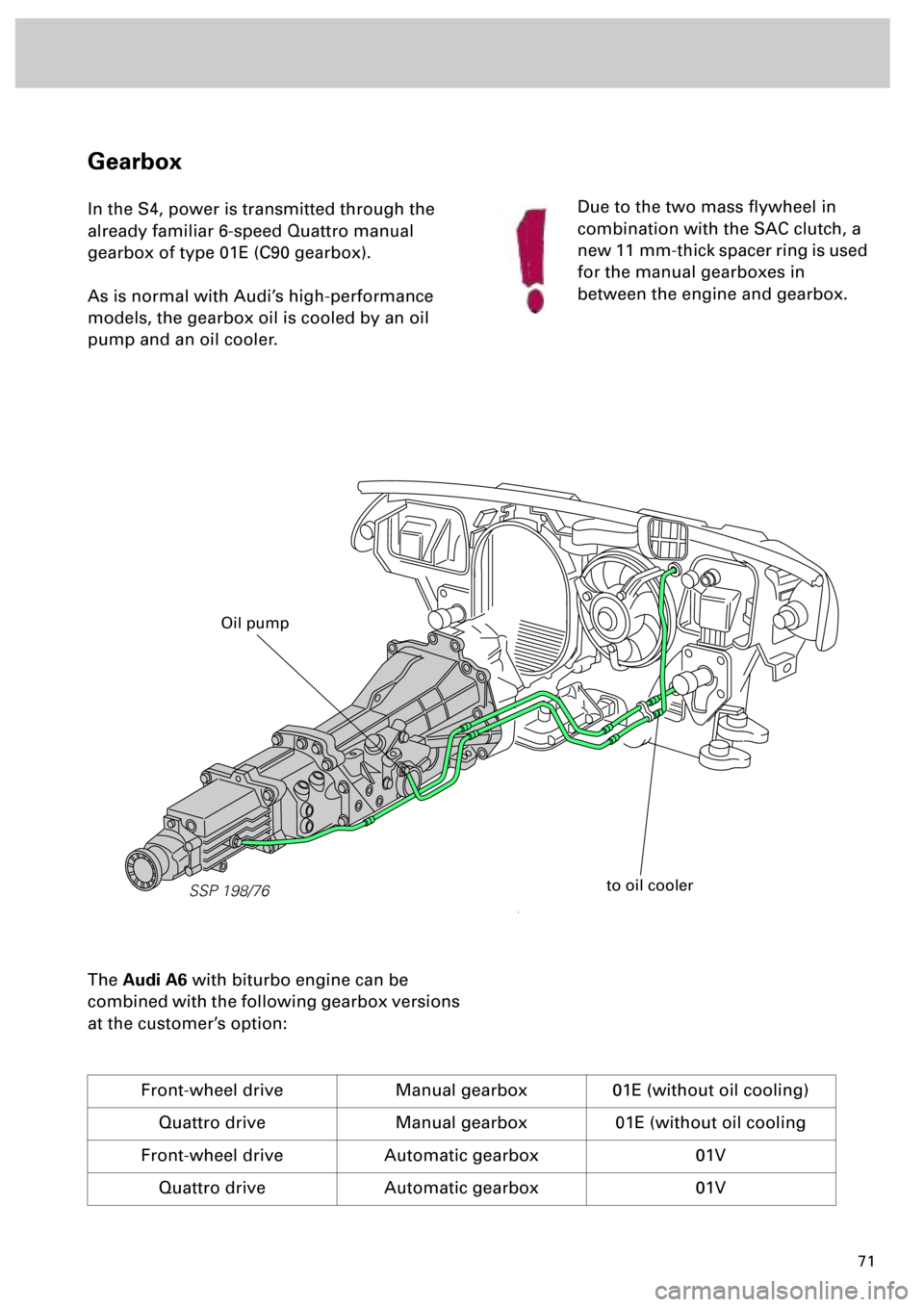

Gearbox

In the S4, power is transmitted through the

already familiar 6-speed Quattro manual

gearbox of type 01E (C90 gearbox).

As is normal with Audi’s high-performance

models, the gearbox oil is cooled by an oil

pump and an oil cooler.

The

Audi A6

with biturbo engine can be

combined with the following gearbox versions

at the customer’s option:

Front-wheel drive Manual gearbox 01E (without oil cooling)

Quattro drive Manual gearbox 01E (without oil cooling

Front-wheel drive Automatic gearbox 01V

Quattro drive Automatic gearbox 01V

Due to the two mass flywheel in

combination with the SAC clutch, a

new 11 mm-thick spacer ring is used

for the manual gearboxes in

between the engine and gearbox.

SSP 198/76

to oil cooler

Oil pump