weight AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 5 of 72

5

The technical data

•

Configuration:

V6 engine with 90° V-angle and twin

turbochargers

•

Engine code:

S4: AGB

A6: AJK

•

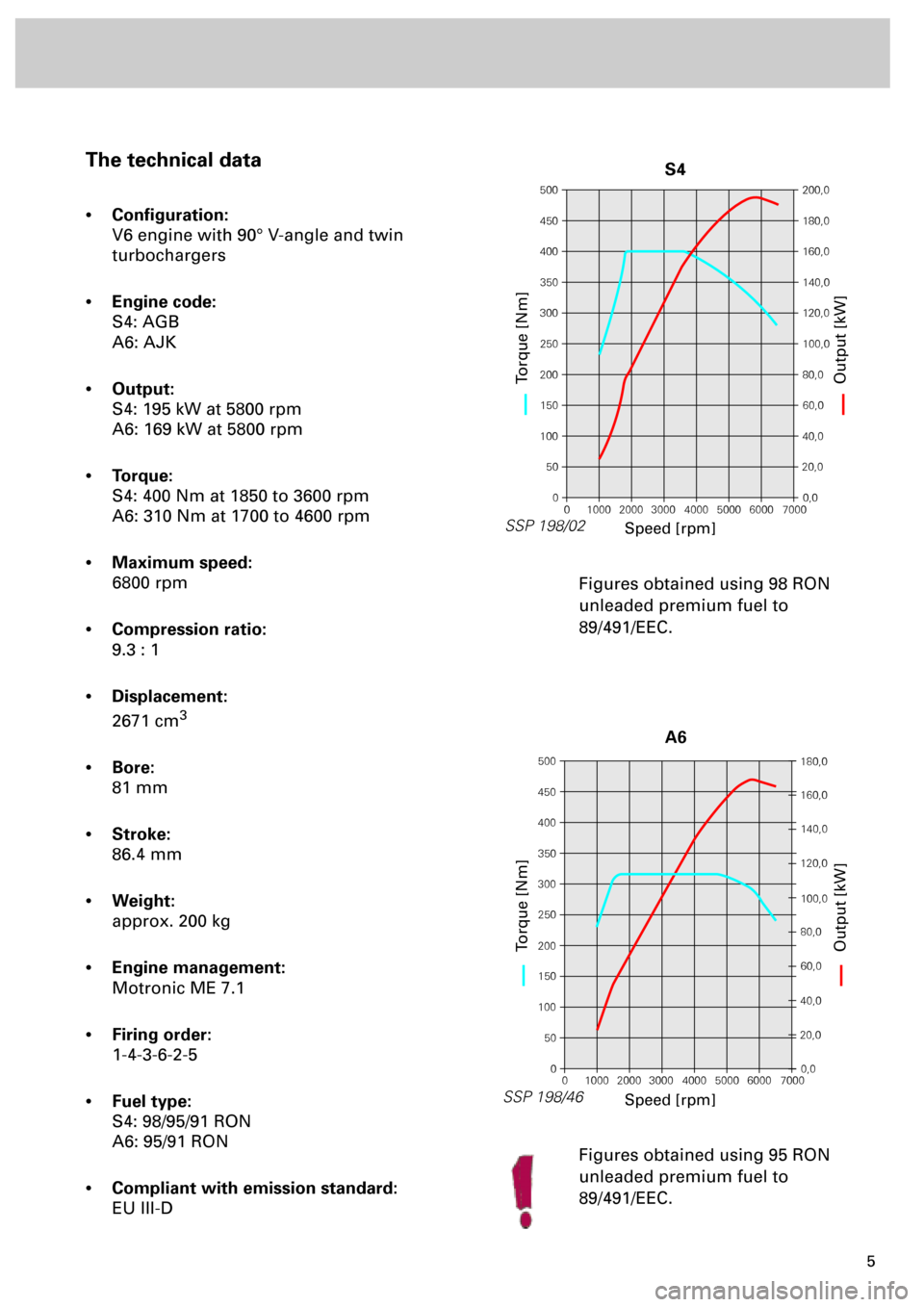

Output:

S4: 195 kW at 5800 rpm

A6: 169 kW at 5800 rpm

•

Torque:

S4: 400 Nm at 1850 to 3600 rpm

A6: 310 Nm at 1700 to 4600 rpm

•

Maximum speed:

6800 rpm

•

Compression ratio:

9.3 : 1

•

Displacement:

2671 cm

3

•

Bore:

81 mm

•

Stroke:

86.4 mm

•

Weight:

approx. 200 kg

•

Engine management:

Motronic ME 7.1

•

Firing order:

1-4-3-6-2-5

•

Fuel type:

S4: 98/95/91 RON

A6: 95/91 RON

•

Compliant with emission standard:

EU III-DFigures obtained using 98 RON

unleaded premium fuel to

89/491/EEC.

Figures obtained using 95 RON

unleaded premium fuel to

89/491/EEC.

500

450

400

350

300

250

200

150

100

50

0200,0

180,0

160,0

140,0

120,0

100,0

80,0

60,0

40,0

20,0

0,0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/02

Speed [rpm]

Torque [Nm]Output [kW]

S4

500

450

400

350

300

250

200

150

100

50

0180,0

160,0

140,0

120,0

100,0

80,0

60,0

40,0

20,0

0,0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/46

Speed [rpm]

Torque [Nm]Output [kW]

A6

Page 21 of 72

22

SSP 198/04

Engine

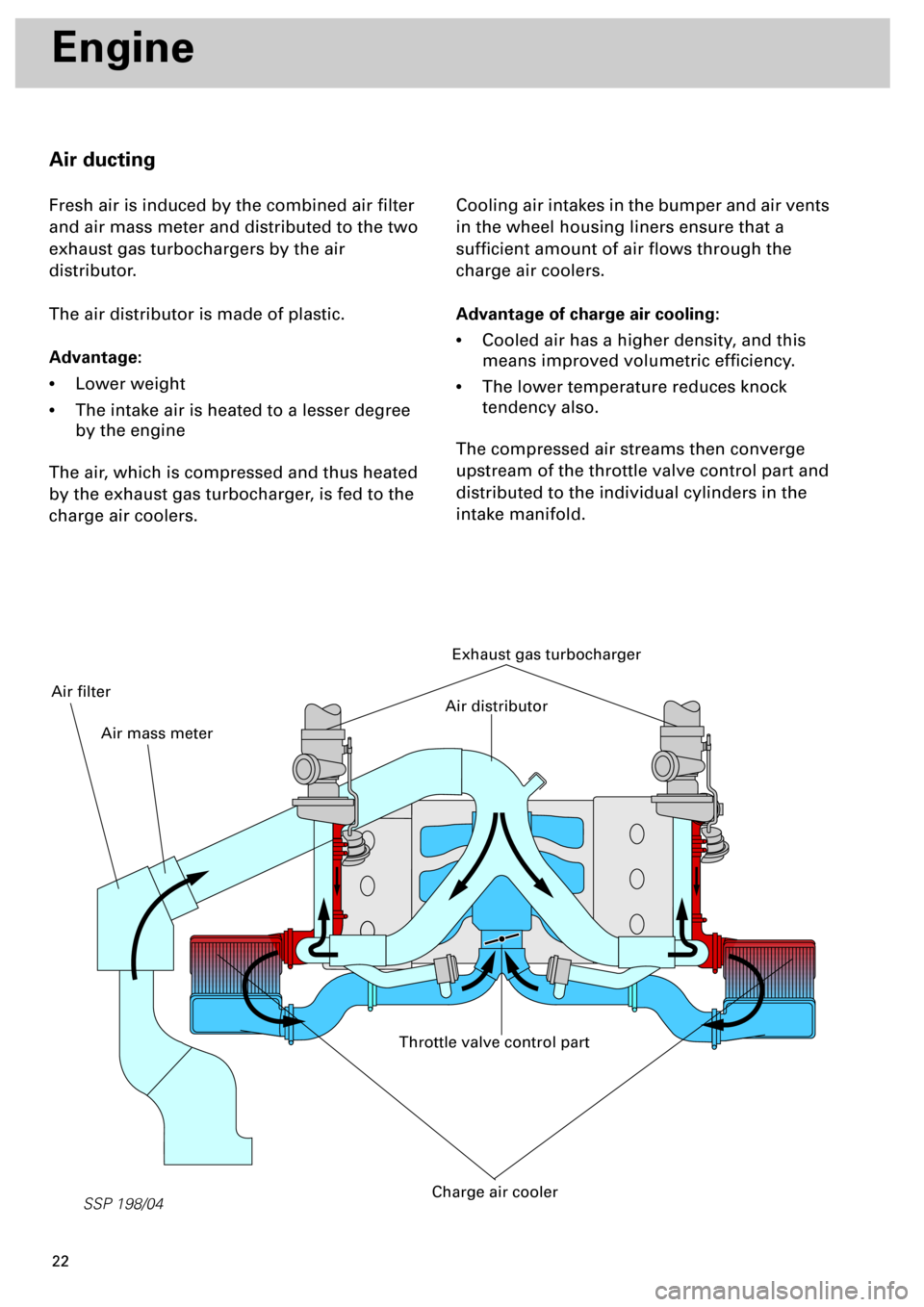

Air ducting

Fresh air is induced by the combined air filter

and air mass meter and distributed to the two

exhaust gas turbochargers by the air

distributor.

The air distributor is made of plastic.

Advantage:

•

Lower weight

•

The intake air is heated to a lesser degree

by the engine

The air, which is compressed and thus heated

by the exhaust gas turbocharger, is fed to the

charge air coolers.Cooling air intakes in the bumper and air vents

in the wheel housing liners ensure that a

sufficient amount of air flows through the

charge air coolers.

Advantage of charge air cooling:

•

Cooled air has a higher density, and this

means improved volumetric efficiency.

•

The lower temperature reduces knock

tendency also.

The compressed air streams then converge

upstream of the throttle valve control part and

distributed to the individual cylinders in the

intake manifold.

Exhaust gas turbocharger

Throttle valve control part

Charge air cooler

Air distributor

Air mass meter

Air filter

Page 23 of 72

24

SSP 198/33

Engine

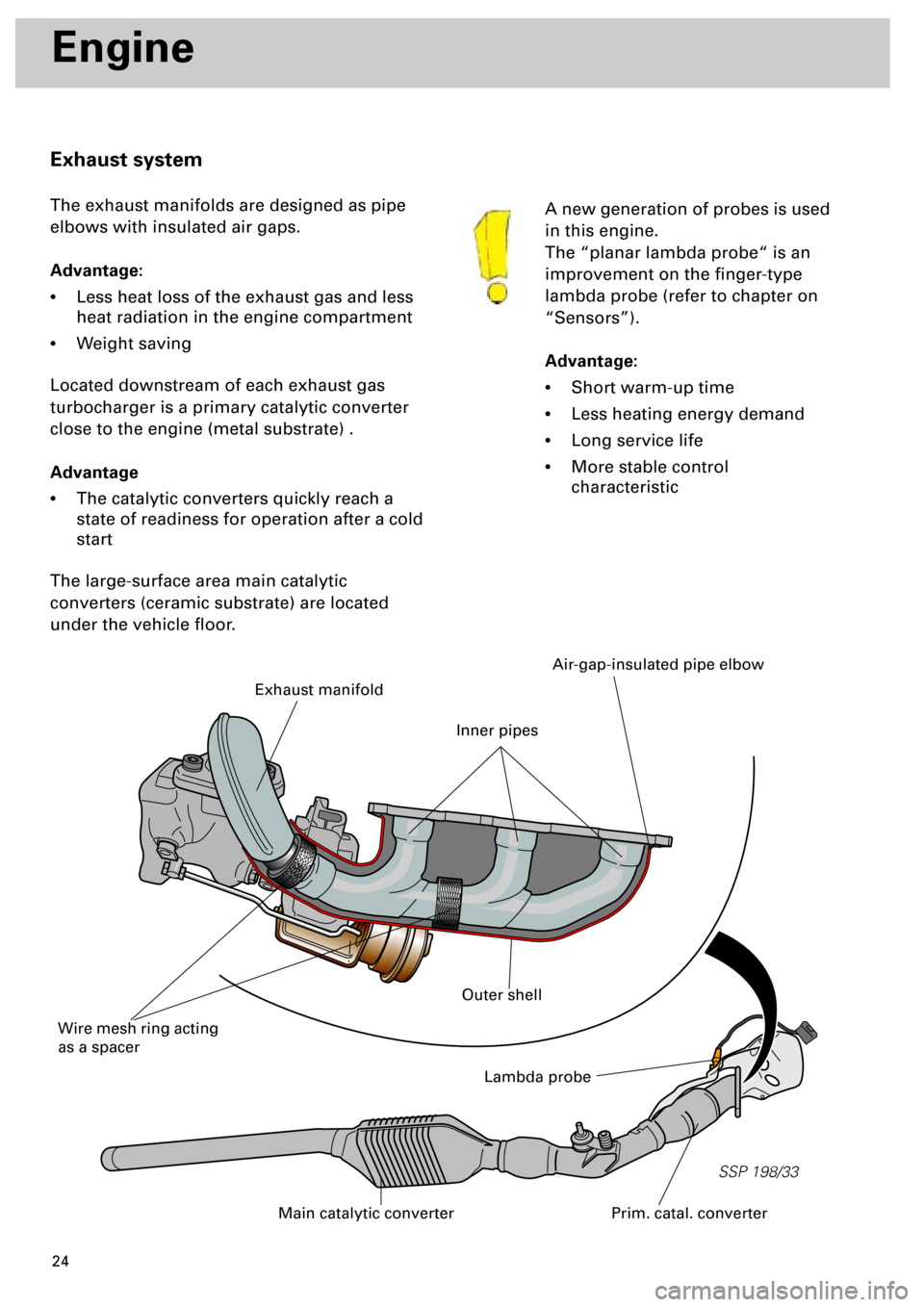

A new generation of probes is used

in this engine.

The “planar lambda probe“ is an

improvement on the finger-type

lambda probe (refer to chapter on

“Sensors”).

Advantage:

•

Short warm-up time

•

Less heating energy demand

•

Long service life

•

More stable control

characteristic

Exhaust system

The exhaust manifolds are designed as pipe

elbows with insulated air gaps.

Advantage:

•

Less heat loss of the exhaust gas and less

heat radiation in the engine compartment

•

Weight saving

Located downstream of each exhaust gas

turbocharger is a primary catalytic converter

close to the engine (metal substrate) .

Advantage

•

The catalytic converters quickly reach a

state of readiness for operation after a cold

start

The large-surface area main catalytic

converters (ceramic substrate) are located

under the vehicle floor.

Lambda probe

Prim. catal. converterMain catalytic converter

Exhaust manifold

Wire mesh ring acting

as a spacer

Air-gap-insulated pipe elbow

Outer shell

Inner pipes

Page 44 of 72

45

SSP 198/34

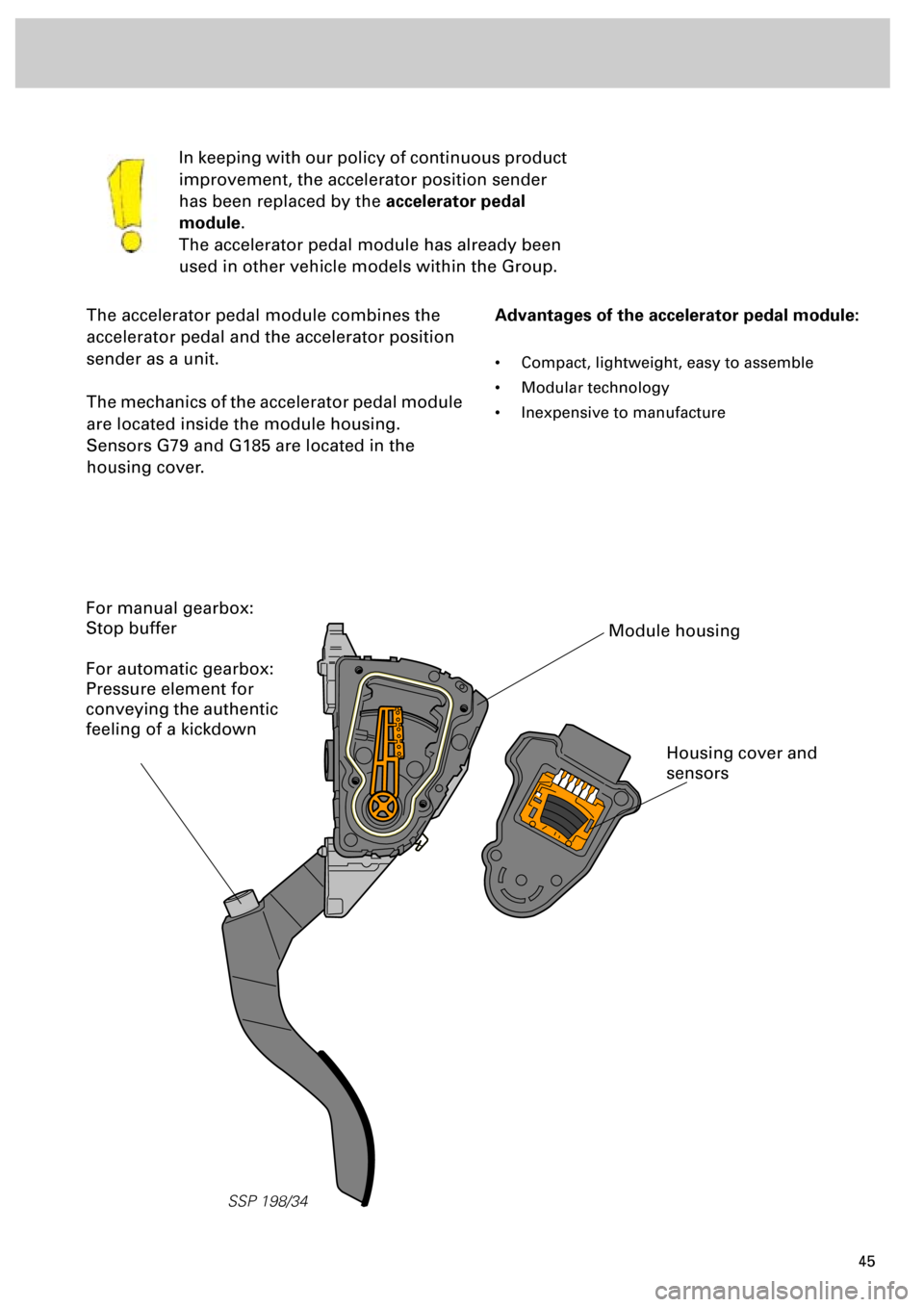

The accelerator pedal module combines the

accelerator pedal and the accelerator position

sender as a unit.

The mechanics of the accelerator pedal module

are located inside the module housing.

Sensors G79 and G185 are located in the

housing cover.In keeping with our policy of continuous product

improvement, the accelerator position sender

has been replaced by the

accelerator pedal

module

.

The accelerator pedal module has already been

used in other vehicle models within the Group.

Advantages of the accelerator pedal module:

• Compact, lightweight, easy to assemble

• Modular technology

• Inexpensive to manufacture

Module housing

Housing cover and

sensors

For manual gearbox:

Stop buffer

For automatic gearbox:

Pressure element for

conveying the authentic

feeling of a kickdown