AUDI S6 2010 Owners Manual

Manufacturer: AUDI, Model Year: 2010, Model line: S6, Model: AUDI S6 2010Pages: 368, PDF Size: 86.82 MB

Page 321 of 368

_____________________________________________ W __ h_a_ t_ d_o_ I_ d_o _ n_ o_ w _ ? __ _

& WARN ING (con tinued)

Trans missio n in "P " (Pa rk) w ill not pre ve nt the vehicle from

mo ving .

• Befo re you ch an ge a wheel , be s ure the ground i s le ve l an d

firm . If ne cess ary, us e a sturdy b oard und er the jack.

• Aft er in st a llin g the sp are wheel , make sure that you repl ace

the flat tire /wheel in it s storage area prop erly and tight en the

knurled ret ain ing s crew se cu rel y.•

Changing a wheel

When you change a wheel, follow the sequence described

below step-by-step and in exactly that order .

1. Activate the vehicle jack mode (only vehicles with Adaptive

Air Suspension) =>

page 168.

2. Remove the decorative wheel cover *. For more details see

also =>

page 320, "Decorative wheel covers" .

3 . Loosen the

wheel bolts => page 320.

4. Locate the proper mo unti ng point for the jack and align

the jack below that point=>

page 321.

5. Lift the car with the jack => page 321.

6. Remove the wheel with the flat tire and then install the

spare =>

page 322.

7. Tighten all wheel bolts lightly.

8 .

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly t ighten all wheel

bolts =>

page 320.

10. Replace the decorative wheel cover *.

Safety first

1 1. Deactivate the vehicle jack mode (only vehicles with

Adaptive Air Suspens ion)=>

page 168 .

& WARNING

Alwa ys re ad and f ollow all WARNINGS and information ~ & in

" Ra ising the vehicl e" on pag e

321 and ~ pag e 323. •

After changing a wheel

A wheel change is not complete without the doing the

following .

-Store and secure the wheel you replaced in the spare

wheel well .

- Replace the tools and the jack in the ir proper location.

- Check the tir e pr essur e on the spare wheel immediately

after mounting it .

- As soon as possib le, have the

tighten ing torques on a ll

wheel bolts checked with a torque wrench . The correct

tightening torque is 90 ft lb (120 Nm) .

- Have the flat tire

replaced as soon as possible.

[ i ] Tips

• If you not ic e that the wheel bolts are corroded and difficu lt to turn

wh ile chang ing a tire, they should be replaced before you check the

tightening torque .

• Drive at reduced speed until you have the tighten ing torques

checked. •

Vehicle care Do-it-yourself service Technical data

Page 322 of 368

lffl!IL--....:..:W:..:..; h:..:.:: a:..:t :... d.:.:..: o:.:...:. I..;d:.:...:. o....:..: n:..:o :...w:..:..:. ? ___________________________________________ _

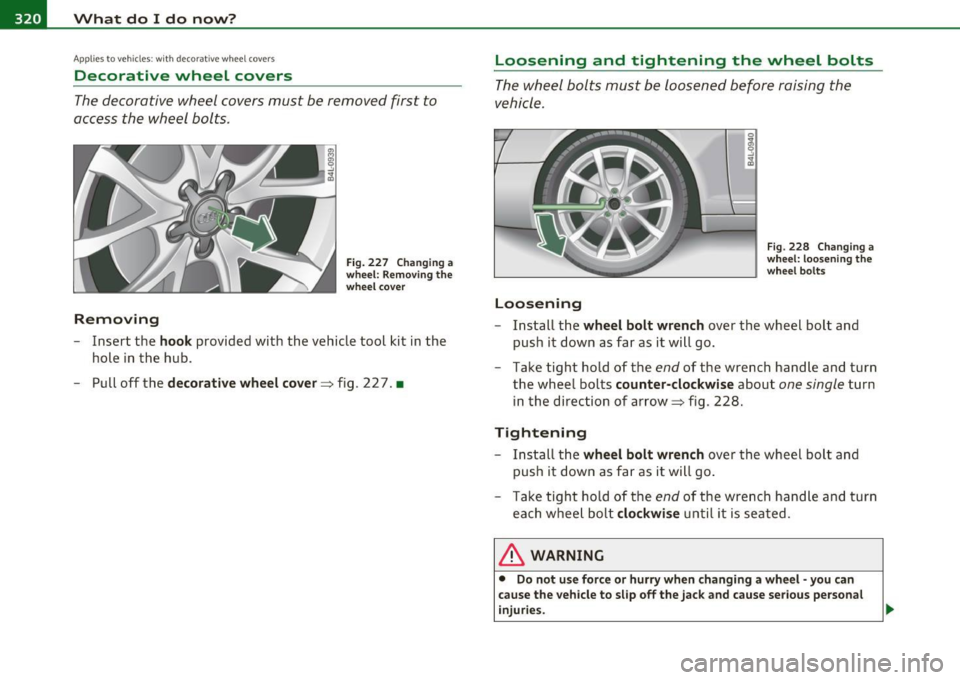

Applies to veh icles : w ith deco rat ive wheel covers

Decorative wheel covers

The decorative wheel covers must be removed first to

access the wheel bolts .

Removing

Fig. 227 Changing a

wheel: Removing the

wheel cover

-Insert the hook provided with the vehicle tool kit in the

hole in the hub .

- Pull off the

decorative wheel cover => fig . 2 2 7. •

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle.

Loosening

Fig. 228 Changing a

wheel: loosening the

wheel bolts

-Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

the wheel bolts

counter-clockwise about one single turn

in the direction of arrow=> fig . 228.

Tightening

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end of the wrench handle and turn

each wheel bolt

clockwise until it is seated.

& WARNING

• Do not use force or hurry when changing a wheel -you can

cause the vehicle to slip off the jack and cause serious personal

injuries.

Page 323 of 368

What do I do now? -

------------------

& WARNING (continued)

• Do not loosen the wheel bolts more than one turn before you

raise the vehicle with the jack. -You risk an injury.

(I) Tips

• Never use the hexagonal socket in the handle of the screwdriver to

loosen o r tighten the wheel bolts .

• If a wheel bolt is very tight, you may find it easier to loosen by

carefully pushing down on the end of th e wheel bolt wrench with

one

foot only .

As you do so, hold on to the car to keep your balance and

take ca re not to slip .•

Raising the vehicle

The vehicle must be li~ed with the jack first before the

wheel can be removed.

Fig. 229 Changing a

wheel: mounting

points for the jack

Vehicle OP-eration

Fig. 230 Close-up:

proper positioning of

jack

- Activate the vehicle jack mode* (only vehicles with Adap

tive Air Suspension)=>

page 168.

-Engage the parking brake to prevent your vehicle from

rolling unintentionally.

- Move the

selector lever to position P.

-Position the jack below the door sill under the mounting

point

that is closest to the wheel to be changed

=> fig . 229.

- Extend the

jack under the lifting point on the door sill until

its arm is positioned directly under the lifting point=>& .

- Align the jack so that its arm©=> fig. 230 engages in the

designated lifting point in the door sill and the movable

base ® lies flat on the ground. The base® must be

vertical under the lifting point@.

- Wind the jack up further until the flat tire comes off the

ground =>& .

The jack must be installed only at the places indicated=> fig . 229.

There is exactly

one location for each wheel. The jack must not be

positioned at any other location

~ & .

Vehicle care Do-it-yourself service iTechnical data

Page 324 of 368

-What do I do now? .,,,.,__ ______________ _

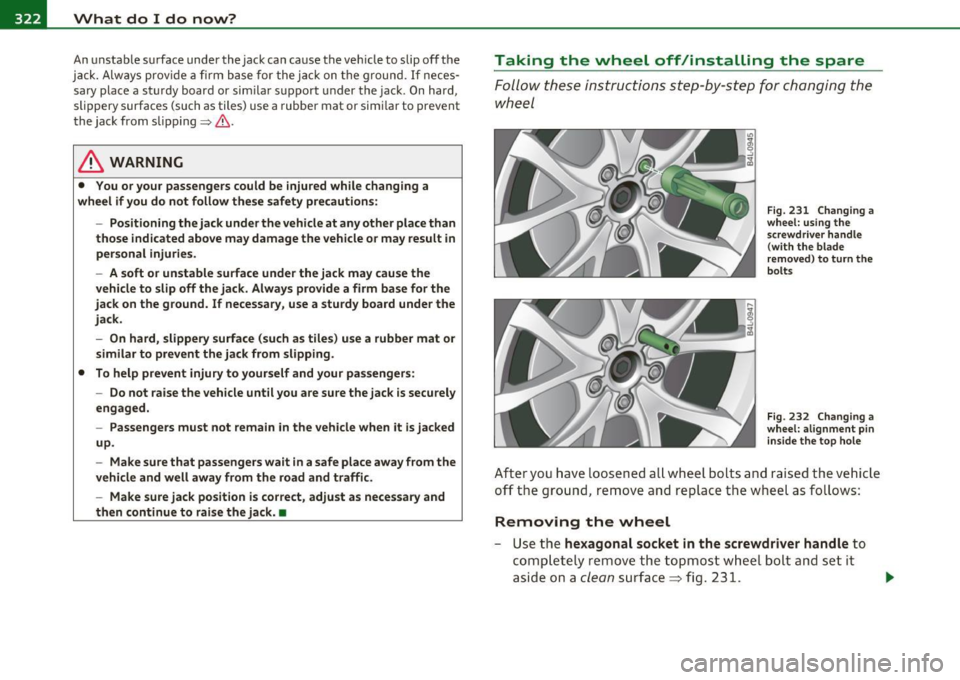

An unstable surface under the jack can cause the vehicle to slip off the

jack. Always provide a firm base for the jack on the ground .

If neces

sary place a sturdy board or similar support under the jack. On hard,

slippery surfaces (such as tiles) use a rubber mat or similar to prevent

the jack from slipping=> &.

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow these safety precautions:

-Positioning the jack under the vehicle at any other place than

those indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack. Always provide a firm base for the

jack on the ground. If necessary, use a sturdy board under the

jack.

- On hard, slippery surface (such as tiles) use a rubber mat or

similar to prevent the jack from slipping.

• To help prevent injury to yourself and your passengers:

- Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait

in a safe place away from the

vehicle and well away from the road and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to raise the jack. •

Taking the wheel off/installing the spare

Follow these instructions step-by -step for changing the

wheel

Fig. 231 Changing a

wheel: using the

screwdriver handle

(with the blade

removed) to turn the

bolts

Fig. 232 Changing a

wheel: alignment pin inside the top hole

After you have loosened all wheel bolts and raised the vehicle

off the ground, remove and replace the wheel as follows:

Removing the wheel

- Use the hexagonal socket in the screwdriver handle to

completely remove the topmost wheel bolt and set it

aside on a

clean surface => fig. 231.

Page 325 of 368

What do I do now? -________________ PfWII

- Screw the threaded end of the alignment pin from the

tool kit hand-tight into the empty bo lt hole~

page 322,

fig. 232.

- Then re m ove the o ther wheel bolts as described above.

- Take off t he w heel leaving the alignment pin i n the bolt

hole.

Putting on the spare wheel

- Lift the spare wheel and carefully slide it over the alig n

ment pi n to guide it in p lace .

- Use the hexagona l socket in the screwdriver handle to

screw in and tighte n all w heel bolts

slightly.

- Remove the alig nment pi n and inse rt an d tighten the

remaining wheel bolt slig htly like the rest.

- Turn the jac k han dle counter-c lockwise to lower the

ve hicle u ntil the jack is fully released.

- Use the wheel bolt wrench to t ighten all whee l bolts firmly

~ page 320 . Tighten them crosswise, from one bolt to

the (approximately) opposite one, to keep the w heel

centered.

[I] Tips

Never use the hexagonal socket i n the handle of the screwdriver to

loosen or tighten the wheel bolts.

• Pull the reve rsible blade from the screwdriver before yo u use the

hexagonal socket in the handle to t urn the whee l bolts.

• When mounting tires with

unidirectional tread design make sure

t he tread pa ttern is po inted the right way~

page 323.

Safety first

• The wheel bolts should be clea n and easy to turn. Check for dirt

and cor rosion on the mat ing surfa ces o f bo th the whee l and the hub.

Remove all d irt from these surfaces before remounting the wheel. •

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their trea d pattern pointed in the right direction .

Using a spare tire with a tread pattern intended for

use in a specific direction

When using a spare tire w ith a tread pattern intended for use in a

specific direction, p lease note the fo llow ing:

• T he direct ion of rotation is marked by an ar row on the s ide of the

tire.

• If the spare tire has to be installed in the incor rect d irect ion, use

the spare tire only tempo rari ly since the tire wi ll not be ab le to

achieve its optimum pe rforma nce charact erist ics with rega rd to

aquaplaning, noise and wear.

• We recommend that you pay particular attention to this fact

during wet weather and that you adjust your speed to match road

condit ions.

• Replace the flat t ire with a new one and have it installed on your

vehicle as soon as possible to restore the handling advantages of a

unidirect iona l tire .•

Notes on wheel changing

Please read the information~ page 305, "New tires and replacing

t ires and wheels" if yo u are go ing to use a spa re t ire wh ich is d iffe rent

from the tires on yo ur vehicle .

After you c hange a ti re:

• Check the tire pressure on the spa re immediately after installa-

tion. ..,

Vehicle care Do-it-yourself service Technical data

Page 326 of 368

lffll.___W __ h_a_ t_ d_ o_ I_ d_o_ n_ o_w _ ? _____________________________________________ _

• Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a qual ified service station.

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 90

ft lb (120 Nm).

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible. Remount the wheel cover.

Until then, drive with extra care and at reduced speeds.

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed, then be sure to

read the information =>

page 305, "New tires and replacing tires

and wheels".

• Always make sure the damaged wheel or even a flat tire and

the jack and tool kit are properly secured in the luggage compart

ment and are not loose in the passenger compartment.

• In an accident or sudden maneuver they could fly forward,

injuring anyone in the vehicle.

• Always store damaged wheel, jack and tools securely in the

luggage compartment. Otherwise, in an accident or sudden

maneuver they could fly forward, causing injury to passengers in

the vehicle. •

Page 327 of 368

Fuses and bulbs -_______________ __.PfWII

Fuses and bulbs

Fuses

Replacing a fuse

A problem in the electrical system may be caused by a

blown fuse.

Fig. 233 Instrument

panel left: Face cover

Fig. 234 Instrument

panel left: Content

Face cover

-Locate the fuse which belongs to the component which

failed.

- Switch off the ignition and the electrical component

affected.

Vehicle OP-eration

- Carefully pry the face cover off the instrument panel using

the ignition key or a screwdriver::::::, fig. 233.

- Remove the plastic clip @from its retainer in the face

cover==> fig. 234, place it over the questionable fuse and

remove the fuse.

- Replace a blown fuse (recognizable by the melted metal

strip inside) with a fuse of the

same amperage.

The individual circuits are protected by fuses. The fuse panels with

the fuses are located on the left and right front faces of the instru

ment panel behind a cover and in the right storage area in the

luggage compartment.

Ther e is a plastic clip@ in the cover on the left side of the instrument

panel, which can be used to remove the fuses. The crank @ is used for

eme rgency operation of the power roof*. You will also find a label on

both covers in the instrument panel with the fuse layout © for the

corresponding fuse panel.

& WARNING

Never replace a fuse with one that has a higher amperage rating.

• A fuse with a too high amperage could damage the electrical

part and cause a fire.

0 Note

• On no account should fuses be repaired (e.g. patched up with tin

foil or wire) as this may cause serious damage elsewhere in the elec

trical circuit or cause fire.

• If a fuse blows repeatedly, do not keep replacing it. Instead, have

the cause of the repeated short circuit or overload located and fixed.

ti>

Vehicle care Do-it-yourself service iTechnical data

Page 328 of 368

m.___F_ u_ s_e _s _ a _ n_d_ b_ u_ lb_ s _____________________________________________ _

(I) Tips

You are well advised to keep a supply of spare fuses in your vehicle .

Fuses with the proper ampere ratings are available at your Audi

dealer. •

Fuse Location, Instrument Panel left

Fig. 23S Fuse pan el

layout

Some of the equipment items listed a re optiona l or only avai lable on

certain mode l configurat ions.

Note that the following t able i s accu rate at the time of going to

pre ss and is subject to change. In the event of discrepancies, the

label on the in side of the cover alwa ys takes precedence.

T he power seats are p rotected by circuit br eaker s, which a utomat i

cally reset after a few seconds after the overload has been remedied .

No. Equipment

1 Not use d

2 Not used

3 Eng ine management

4 Oil level sensor

Amps

s

5

..

No . Equipment

5

6

7

8

9

10

11

12

1 3

14

1 5

16

17

18

1 9

20

21

22

23

24

25

26

27

28

Climate control, tire pressure mon itoring sys

tem

Electronic Stabilization Program (ESP), clutch

sensor

Di agnost ic co nnector

Homelink control unit

A utom atic dimming in ter ior m irr or

Adaptive Cruise Control

Not used

Diagnostic connector

Sw itch module stee ring col umn

Not used

I ns trumen t cluste r, contro l modu le Gatew ay

Telephone, cell phone Elect ronic Stabilization Program (ESP)

Headlight electronics, left-side

Ra in s ensor

Heated washer nozzles

Se at adjus tment ( drive r)

MMI display

Electromec hanical park ing brake

Not used

N ot used

No t used

No t used

Not used

Amps

5

5

5

5

5

5

10

10

10

5

10

5

5

5

1 0

5

5

-

Page 329 of 368

______________________________________________ F _u_s _e_ s_ a_ n_ d _ b _u_l_b _ s _ ___.9I

No. Equipment

29 Not used

30 Not used

31 Back-up

light switch, transmission, engine com-

ponents

Intelligent power module driver (footwell light

32 and front headlights, horn, wiper system, elec-

trically adjustable steering wheel)

-

33 Intelligent power module dr

iver

(lights left-side)

34 Intelligent power module driver

(lights right-side)

35 Not used

36 Headlight

washer system

37 Electronic Stabilization Program (ESP)

38 Wiper system

39 Door control module

left-side

Horn

41 Heater fan

42 Control module electronic ignition lock/electri-

cally adjustable steering wheel

43 Rear

windshie ld wiper (Avant)

44 Power window opener (left-side)

Amps

15

30

25

25

30

25

30 15

25

40

30

15

-

-

35 •

Vehicle OP-eration

Fuse Location, Instrument Panel right

Fig. 236 Fuse panel

l ayou t

Some of the equipment items listed are optional or only available on

certain model configurations.

Note that the following table is accurate at the time of going to

press and is subject to change. In the event of discrepancies, the

label on the inside of the cover always takes precedence.

The power seats are protected by circuit breakers , which automati

cally reset afte r a few seconds after the overload has been remedied.

No. Equipment Amps

Fuse holder (black)

1 Control module Convenience

key

15

2 Cigarette lighter front 20

3 Tire pressure monitoring system

5

4 Electrical outlet front (center console)

20

-

5 Intelligent power module passenger

15

(glove box lock)

6 Door control module right-s ide

15

Sunroof 20

A/C controls 10

Vehicle care Do-it-yourself service iTechnical data

Page 330 of 368

.,.,___F_ u_ s_e _ s_ a_n_ d_ b_u _ l_ b_ s _______________________________________________ _

No. Equipment Amps

9 Heated seats, front 30

10 MMI

7,5

11 Seat adjustment (passenger) 10

12 Communication 5

Fuse holder (brown)

1 Electric fuel pump 20/30

2 Adaptive Air Suspension

15

3 Lane assist 10

4 Audi side assist

5

5 Adaptive Air Suspension 5

6 Shift gate automatic transmission/clutch switch 5

7 Parking System 5

8 Control module Gateway 5

9

Automatic headlight range control (auxiliary 5

driving lights), headlight electronics, right-side

10 Airbag 5

11 Heated rear seats 5

12 Telephone

5 •

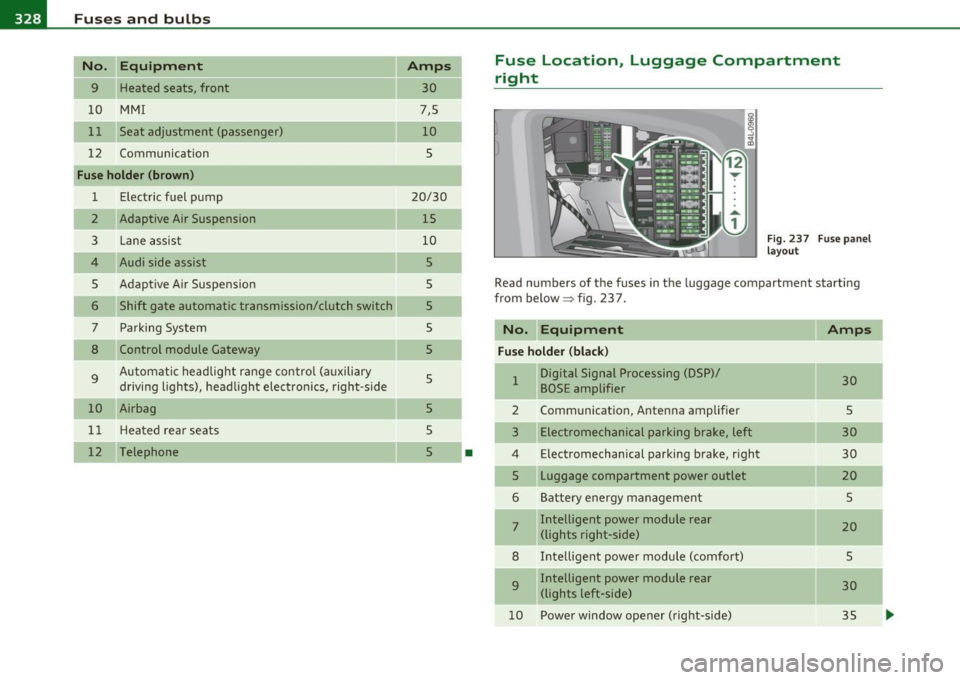

Fuse Location, Luggage Compartment

right

Fig. 237 Fuse panel

layout

Read numbers of the fuses in the luggage compartment starting

from below :::::> fig. 23 7.

No. Equipment

Amps

Fuse holder (black)

1 Digital Signal Processing (DSP)/ 30 BOSE amplifier

2 Communication, Antenna amplifier 5

3 Electromechanical parking brake, left 30

4 Electromechanical parking brake, right

30

5 Luggage compartment power outlet

20

6 Battery energy management 5

7 Intelligent power module rear

20 (lights right-side)

8 Intelligent power module (comfort)

5

9 Intelligent power module rear

30

(lights left-side)

10 Power window opener (right-side)

35

-

-

-

...