AUDI S6 2010 Owners Manual

Manufacturer: AUDI, Model Year: 2010, Model line: S6, Model: AUDI S6 2010Pages: 368, PDF Size: 86.82 MB

Page 331 of 368

_______________________________________________ F_u _s_ e_ s_ a_ n_ d_ b_u _ l_ b _ s __ _

No. Equipment

11 Pa rk in g System

12 Cigare tt e lig ht er r ea r

Fuse holder (brown)

1 Rear view

2 El ectr ic re ar lid (A va nt)

3 Electric rear lid (Avant)

4 Electric rear lid (Avant)

5 Co mmuni cation, An te n na amplifie r

6 Not used

7 M MI

8 Not used

9 Digital Tuner

10 Not used

11 Not used

12 No t used

Bulbs

Replacing Light bulbs

Amps

5

20

5

30

30

20

5

5

5

5

For your safety, we recommend that you have your autho

rized Audi dealer replace burned out bulbs for you.

It is becoming increas ingly more and mo re difficu lt to replace veh icle

light b ulbs since in many cases, other parts of t he car must first be

removed before yo u are able to get to the bu lb. This ap plies espe cially

to the light bu lbs in the front of your car which you can on ly reach

through the engi ne compa rtment.

Safety first

•

Sheet metal and bulb holders can have sharp edges that can cause

ser io us c uts, and parts mus t be cor re ct ly ta ken apar t and the n prop

erly put back together to he lp prevent breakage of parts and long

term damage from water t hat ca n enter housings that have not been

properly resealed .

For your safety, we recommend that you have your a uthorized Audi

dealer replace any bulbs fo r yo u, since yo ur dealer has t he pr oper

too ls, the correct bu lbs and t he expertise.

Gas discharge lamp s (Xenon lights) *:

Due to the high electr ica l voltage, have the bulbs replaced by a qual

ified technician. Headlights with Xenon light can be identified by the

high vol tage s ticker.

& WARNING

Contact with high-voltage components of the electrical system

and improper repla cement of g as discharge (Xenon ) headlight

bulb s can cause serious personal injury and dea th .

• Xenon bulbs are pres surized and can e xplode when being

c hanged.

• Changing Xenon lamp s requires the special training , instruc

tions and equipm ent .

• Only an authorized Audi dealer

or oth er qualified work shop

should change the bulbs in gas discharge lamps .

& WARNING

There are parts with sharp edge s on the opening s and on the bulb

holder s that can cau se serious cuts.

• If you are unce rtain about what to do, have the work

performed by an authorized Audi dealer or other qualified work

shop . Se rious personal injury m ay result from improperly

performed work. ..

Vehicle care Do-it-yourself service Technical data

Page 332 of 368

![AUDI S6 2010 Owners Manual lffl!I.___F_ u_ s_e _s_ a_n_ d_ b_u _ l_ b_ s _______________________________________________ _

(I] Tips

• If you must rep lace the light bulbs yourself, a lways remember

that the eng AUDI S6 2010 Owners Manual lffl!I.___F_ u_ s_e _s_ a_n_ d_ b_u _ l_ b_ s _______________________________________________ _

(I] Tips

• If you must rep lace the light bulbs yourself, a lways remember

that the eng](/img/6/57594/w960_57594-331.png)

lffl!I.___F_ u_ s_e _s_ a_n_ d_ b_u _ l_ b_ s _______________________________________________ _

(I] Tips

• If you must rep lace the light bulbs yourself, a lways remember

that the engine compartment of any vehicle is a hazardous area to

work in. Always read and heed all WARNINGS~

page 269, "Engine

compartment"~

& -

• It is best to ask your author ized Audi dea le r w henever you need to

change a bulb. •

Page 333 of 368

Emergency situations --------------=----EWI

Emergency situations

General

This chapter is intended for trained emergency crew s and working

personnel who ha ve the necessar y tools and equipment to perform

the se operations . •

Starting by pushing or towing

(D Note

Your vehicle is equipped with an a utomat ic transmission. Conse

que ntly, the eng ine can not be started by pushing or towing. •

Starting with jumper cables

If necess ary, the engine can be started by connecting it to

the battery of an other vehicle .

If the engine shou ld fai l to start because of a discharged or weak

battery, the battery can be co nnecte d to the battery of

another

vehicle, using a pair of jumper cable s to start the engine .

Jumper cables

Use only jumper cables of suffic ient ly large cross section to carry the

sta rter cur ren t safely . Refe r to the manufacture r's specifications.

Use on ly j umper cab les with

insulated te rm ina l clamps w hich are

distinct ly marked :

plus(+) cable in most cases colo red red

minus (-) cable i n most cases colored black.

Safety first

& WARNING

Batterie s contain electricity, acid, and gas . Any of these can cause

very serious or fatal injury . Follow the inst ructions below for safe

handling of your vehicle 's battery .

• Always shield your eyes and avoid leaning over the battery

whenever possible.

• A discharged battery can freeze at temperatures just below

32 °F (0 °C). Before connecting a jumper cable, you must thaw the

frozen battery completely , otherwise it could explode.

• Do not allow battery acid to contact eyes or skin . Flush any

contacted area with water immediately .

• Improper use of a booster battery to start a vehicle may cause

an explosion.

• Vehicle batteries generate e xplos ive gases. Keep spa rks, flame

and lighted cigarettes away from batteries.

• Do not try to jump start any vehicle with a low acid level in the

battery.

• The voltage of the booster battery must also h ave a 12 -Volt

rating. The capacity (Ah) of the booster battery should not be

lower than that of the discharged battery. Use of batter ies of

different voltage or sub stantially different "Ah " rating may cau se

an explosion and personal injury.

• Never charge a frozen battery . Ga s trapped in the ice may cause

an e xplosion.

• Never charge or use a battery that has been frozen. The battery

case may have be weakened.

• Use of batteries of different voltage or substantially different

capacity (Ah ) rating may cause an explosion and injury . The

capacity (Ah ) of the booster battery should not be lower than that

of the discharged battery. _..

Vehicle care Do-it-yourself service Technical data

Page 334 of 368

-Emergency situations PW..._-=----='----------------

& WARN ING (con tin ue d)

• Before you che ck anything in the engine compartment, always

read and heed all WARNINGS~

page 269, "Engine compart

ment ".

0 Note

• App lying a higher vo ltage booster battery will cause expens ive

damage t o sens it ive e lec tron ic compone nts, such as contro l units,

re lays, rad io, etc.

• The re must be no elect rical contact between the veh icles as othe r

w ise current could already start to flow as soon as the pos it ive( +)

t erminals a re connected.

[ i ] Tips

• T he discha rged ba ttery mus t be p roper ly connec ted to the

vehicle's electrical system. Whe n jump starting or charging the

b att ery, never connec t the negat ive g round cable to the batte ry nega

tive post because the battery manager system must be ab le to detect

the ba ttery's state of charge . Always connect the negative gro und

cable to the negative ground post of the batte ry manager contro l

unit. •

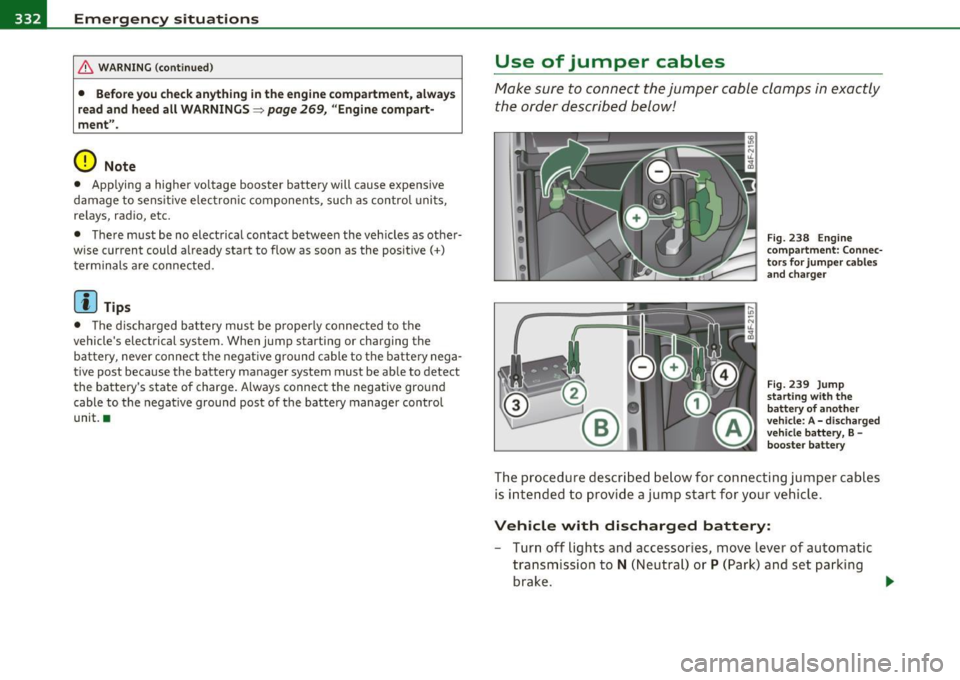

Use of jumper cables

fvfake sure t o con nect the j umpe r ca ble clamps i n ex a ctly

the order describ ed belo w!

Fig. 2 38 Engine

c omp artment : Co nnec

t o rs f or jump er cab les

a nd c harger

Fig. 239 Jump

st art in g wi th the

b att ery of ano th er

v eh icle : A -disch arged

v ehicle batt ery, B -

boo ste r battery

Th e p ra ced u re descri bed belo w for c onn ect ing jump er ca ble s

is int ende d to prov ide a jump star t for your veh icle.

Vehicle with d ischarged battery:

- Tur n off lights and accesso ries, move leve r of automatic

tra nsm ission to

N ( N eutral) o r P (P ark) and set pa rking

b rake.

~

Page 335 of 368

Emergency situations --------------=----Efffll

Connect POSITIVE (+) to POSITIVE (+) (red)

- Open the red cover on the posi tive po le ~ page 332,

fig . 238.

1. Connect one e nd of the pos itive cable (red) on the

jump

start bolt~

page 332, fig. 239 © (Bolts under red cover

= "positive") of the vehicle to be started @.

2 . Connect the other end to the pos itive terminal @ of the

booster battery ®·

Connect NEGATIVE(-) to NEGATIVE(-)

(black)

3 . Connec t one end to the negative te rmi nal @ of the

booster battery ®·

4. Conn ect t he other end o f the n ega tive cabl e (black) to t he

jump start bolt© (Bolts w it h hex head = "n egat ive") of

the vehic le to be s tarte d

@.

Starting the engine

- Start the engine of t he vehicle w ith the booster battery.

Run the engi ne at a moderate speed.

- Start e ng ine w it h discharged ve hicle battery in the usu al

ma nner .

- If the engine fai ls to star t: do no t ke ep the s tar ter

crank ing for lo nger than 10 secon ds. W ait for abou t

30 seco nds and then t ry again .

- Wi th engine running, remove jum per cable s from bot h

v eh icle s in t he exact

re vers e order.

- C lose the re d cove r on the positive pole.

Safety first

T he battery is vented to the outside to prevent gases from entering

t he ve hicl e inter ior. Make su re t hat t he ju mper clamps are we ll

connected with the ir

metal parts in full contact with the battery

terminals .

& WARNING

To avoid serious per sonal injury and damage to the vehicle, heed

all warnings and instructions of the jumper cable manufacturer . If

in doubt, call for road service .

• Jumper cables must be long enough so that the vehicles do not

tou ch.

• When connecting jumper cables , make sure that they cannot

get caught in any moving part s in the engine compartment .

• Before you che ck anything in the engine compartment , always

read and heed all WARNINGS~

page 269, "Engine compart

ment ".

0 Note

Improper hook-up of j umper cab les can ruin the generator.

• Always co nnect POSITIVE(+) to POSI TIVE(+), and NEGATIV E(- )

to NEGA TIVE( -) ground post of the battery manager cont rol unit.

• Check that all screw p lugs on the battery ce lls are sc rewed in

firmly. If not, tighten p lugs prior to connecting clamp on negative

battery terminal.

• Please note that the proced ure for connecting a jumper cable as

described above applies specifically to t he case of your vehicle being

jump started . When you a re giving a jump start to another vehicle, do

not connect the negative( -) cab le to the nega tive (-) te rm inal on the

discharged battery©~

page 332, fig. 239. Instead, securely

c onne ct the negative (- ) cab le to ei ther a so lid met al componen t th at

is f irm ly bolted to the eng ine b lock or to the eng ine b lock itself. If the

ba ttery tha t is bei ng charged does not ven t to t he ou tside, escap ing

battery gas could ignite and explode! •

Vehicle care Do-it-yourself service Technical data

Page 336 of 368

,..,___E_ m_ e_r -=g :.. e_ n_c -=y '-- s_i_t _u _a _ t_ i_ o _ n_ s ____________________________________________ _

Emergency towing with

commercial tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by commercial tow truck

operators who know how to operate their equipment safely.

• Never tow your Audi, towing will cause damage to the engine

and transmission.

• Never wrap the safety chains or winch cables around the brake

lines.

• To prevent unnecessary damage, your Audi must be transported

with a flat bed truck.

• To load the vehicle on to the flat bed, use the towing loop found

in the vehicle tools and attach to the front or rear anchorage

~ page 334 and~ page 335 .

& WARNING

A vehicle being towed is not safe for passengers. Never allow

anyone to ride in a vehicle being towed, for any reason. •

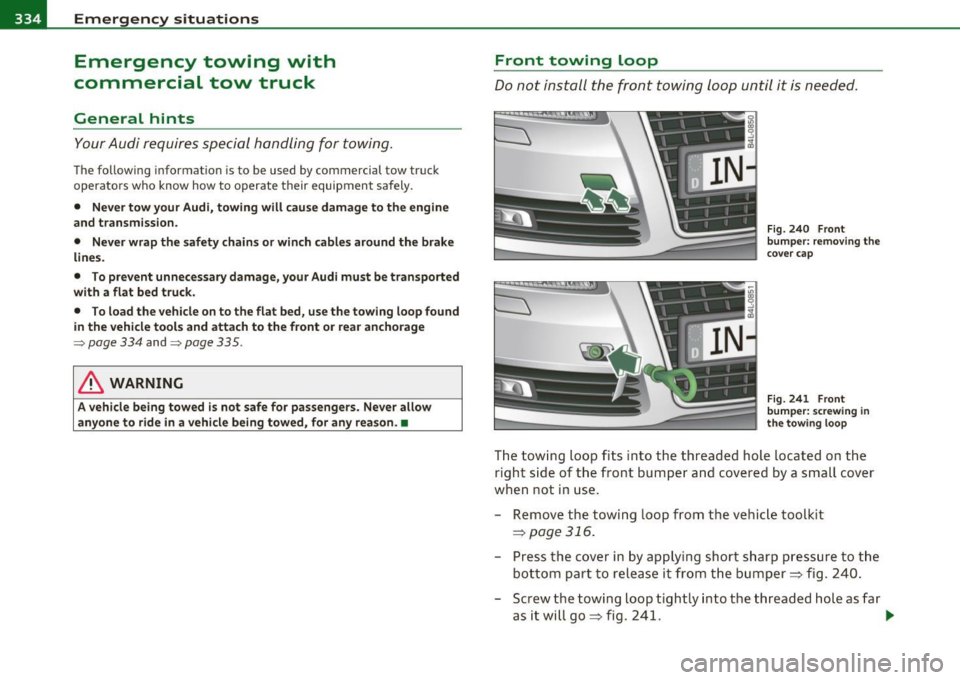

Front towing Loop

Do not install the front towing loop until it is needed.

Fig. 240 Front

bumper: removing the

cover cap

Fig. 241 Front

bumper: screwing in

the towing loop

The towing loop fits into the threaded hole located on the

right side of the front bumper and covered by a small cover

when not in use.

- Remove the towing loop from the vehicle toolkit

=> page 316.

-Press the cover in by applying short sharp pressure to the

bottom part to release it from the bumper=> fig. 240.

- Screw the towing loop tightly into the threaded hole as far

as it will go=> fig. 241 . ..,

Page 337 of 368

Emergency situations --------------=---:.--___.VPII

When it is no longer needed, unscrew the towing loop and put it back

into the vehicle toolkit. Be sure to have the towing loop stored in the

vehicle at all times .

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

ca n pull out when the vehicle is towed -potential risk of an

accident. •

Rear towing loop

Do not install the rear towing loop until it is needed.

Fig. 242 Rear

bumper: screwing in

the tow ing loop

On the right side under the rear bumper there is a threaded

hole for the towing loop. The threaded hole is protected by a

cover.

- Remove the towing loop from the vehicle toolkit

=::;, page 316.

-Pull the protective cover out of the threaded hole

=;, fig. 242.

-Screw the towing loop tightly into the threaded hole as far

as it will go.

Vehicle OP-eration

When it is no longer needed, unscrew the towing loop and put it back

into the vehicle toolk it. Be sure to have the towing loop stored in the

vehicle at all times.

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

c an pull out when the vehicle is towed · potential risk of an

accident. •

Loading the vehicle onto a flat bed truck

Front hook up

Fig. 243 Vehicle on

fl at bed truck

-Align the vehicle w ith the centerline of the car carrier

ramp.

- Attach the winch hook to the front towline eye previously

installed.

Rear hook up

- Align the vehicle with the centerline of the car carrier

ramp .

Vehicle care Do-it-yourself service iTechnical data

Page 338 of 368

lffll.,___E_ m_ e_r-=g :.. e_ n_c -=y '-- s_i_t _u _a _ t_ i_ o _ n_ s ____________________________________________ _

-Attach the winch hoo k to the rear towline eye previously

i n stalled.

[I) Tips

Check carefu lly to make s ure the hook -up is secure before moving the

car up the flatbed truck ramp .•

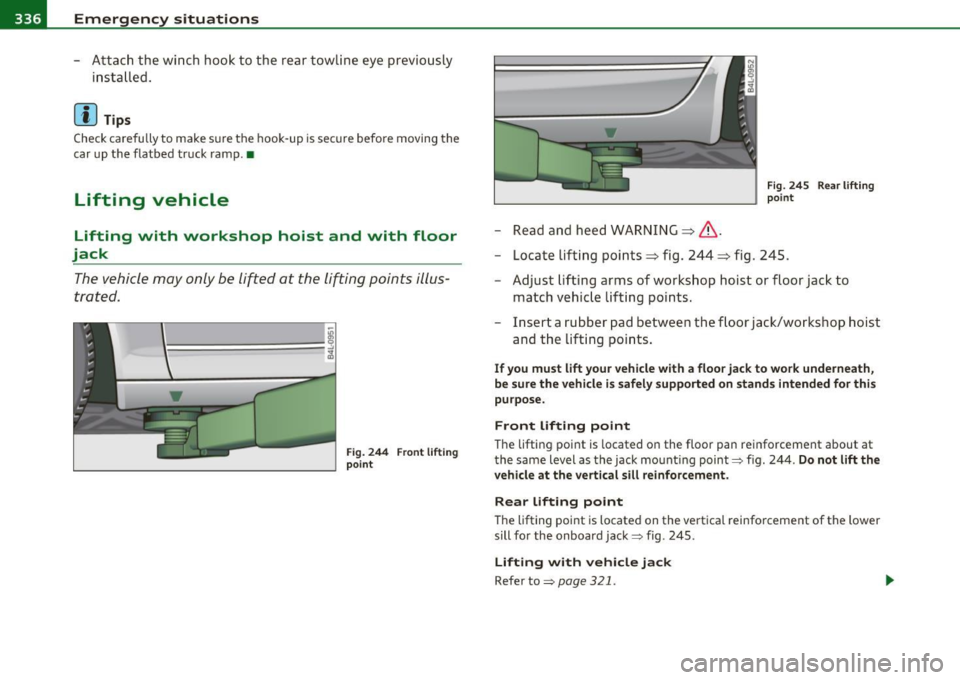

Lifting vehicle

Lifting with workshop hoist and w ith floor

jack

The vehicle may only be lifted at the lifting points illus

trated.

~ ~

\ == ============= ~ ;_

Fig. 244 Fron t lift ing

p oi nt

- Read and heed WAR NIN G ~ & .

Fig. 24 5 Rear li fting

p o int

- Loca te lifting points ~ fig. 244 ~ fig . 2 45 .

- Adjust lifting arms of workshop hoist or floor jack to

match vehic le lift ing poi nts.

- Insert a rubber pad between the floor jac k/wo rks hop hoist

and t he lift ing poi nts .

If you must lift your vehicle with a floor jack to work underneath ,

be sure the vehicle is safely supported on stand s intended for this

purpose .

Front lifting point

The lifti ng point is located o n the floor pan re inforcement about at

t he same level as the jack mount ing point=> fig. 244 .

Do not lift the

vehicle at the verti cal sill reinforcement .

Rear lifting point

The lifting point is located on the vertica l reinforcement of the lower

sill for the onboard jack=> fig. 245 .

Lifting with vehicle jack

Refer to=> page 321.

Page 339 of 368

_____________________________________________ E_ m_ e_r-= g ::.. e_ n_c-= y'- s_ i_t _u _a_ t_ i_ o _ n_ s __ ffl'II

& WARNING

• To reduce the risk of serious injury and vehicle damage.

-Always lift the vehicle only at the special workshop hoist and

floor jack lift points illustrated=>

page 336, fig. 244 and

=> page 336, fig. 245.

- Failure to lift the vehicle at these points could cause the

vehicle to tilt or fall from a lift if there is a change in vehicle

weight distribution and balance. This might happen, for

example, when heavy components such as the engine block or

transmission are removed .

• When removing heavy components like these, anchor vehicle

to hoist or add corresponding weights to maintain the center of

gravity. Otherwise , the vehicle might tilt or slip off the hoist ,

causing serious personal injury.

0 Note

• B e aw are of the following poi nts b efo re li fting the ve hicl e:

- The vehicle should never be lifted or jacked up from under

neath the engine oil pan, the transmission housing , the front or

rear axle or the body side members . This could lead to serious

damage.

- To avoid damage to the underbody or chassis frame, a rubber

pad must be inserted between the floor jack and the lift points.

- Before driving over a workshop hoist, check that the vehicle

weight does not exceed the permissible lifting capacity of the hoist.

- Before driving over a workshop hoist, ensure that there is

sufficient clearance between the hoist and low parts of the

vehicle. •

Safety first Vehicle care Do-it-yourself service Technical data

Page 340 of 368

___ G_ e_n_ e_r _a _ l_ in_ f_o _r_ m_ a_ t_io _ n _______________________________________________ _

General information

Explanation of technical data

Some of the technical data listed in this manual requires

further explanation.

The technical data for your vehicle is listed in the charts starting on

~ page 341 . This sect ion prov ides genera l information, notes and

restrictions which app ly to this data .•

Veh icle identification

The key data is given on the vehicle identification number

(VIN) plate and the vehicle data sticker.

F ig. 2 46 V ehicle I den

t ifi ca tion Nu mbe r

(V IN ) plate: locat io n

o n d river's s id e d ash

p an el Fi

g. 2 47 The vehi cle

i d enti ficati on l abel -

in side the l ugga ge

co mpa rtme nt

The Vehicle Id ent ifi cat ion Number (VlN )

is located on the driver's s ide so that it is visible from the outside

through the windshield~ fig. 246. You can also d isp lay the Vehicle

Identification Number of your vehicle in the MMI. Se lect funct ion

button [CAR]>

S yst em s*> Vehicle ID number (VIN ).

The vehicle identifica tion lab el

is located in the luggage compartment near the battery .

The label~ fig. 247 shows the following vehicle data:

© Production control No.

@ Vehicle identification No.

® Type code n umber

@ Type designat io n/eng ine output in Kilow atts

© Engine and transmission code letter

© Paint No./Interior

(j) Optional equipment No.'s

Vehicle data 2 to 7 are also found in your Warranty

& Maintenance

booklet . .,,