AUDI TT 1998 8N / 1.G ATW Engine Motronic Fuel Injection Syst

Manufacturer: AUDI, Model Year: 1998, Model line: TT, Model: AUDI TT 1998 8N / 1.GPages: 81, PDF Size: 1.03 MB

Page 1 of 81

24-1

Motronic fuel injection

system, servicing

Safety precautions

If special testing equipment is required during

road test, note the following:

WARNING!

Test equipment must always be secured to

the rear seat and operated from there by a

second person.

If test and measuring equipment is operated

from the passenger seat, the person seated

there could be injured in the event of an

accident involving deployment of the

passenger-side airbag.

To reduce the risk of personal injury and/or

damage to the fuel injection and ignition system,

always observe the following:

Only disconnect and reconnect wires for

injection and ignition system, including test

leads, when ignition is turned off.

If engine is to be cranked at starting RPM

without starting (e.g. for compression testing),

Pa

ge 1 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 2 of 81

disconnect connector from ignition coils and

from fuel injectors.

Pa

ge 2 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 3 of 81

24-2

It is possible that the control module will

recognize a malfunction and store a DTC during

some tests. After completing all tests and

repairs, DTC memory should therefore be

checked and erased if necessary. Readiness

code must be generated after DTC memory is

erased Page 01

-73

.

Always switch ignition off before cleaning

engine.

The battery should only be disconnected and

reconnected when the ignition is turned off,

since otherwise the Engine Control Module

(ECM) can be damaged.

WARNING!

Fuel system is under pressure! Before

opening system, place rags around the

connection point. Then release pressure by

carefully loosening connection.

Pa

ge 3 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 4 of 81

24-3

Rules of cleanliness

When working on the fuel supply or fuel injection

systems, the following "6 rules of cleanliness"

should be carefully observed:

Thoroughly clean all connections and the

surrounding area before disconnecting.

Place parts that have been removed on a clean

surface and cover. Use lint-free cloths only!

Carefully cover over opened components or

seal, if repairs are not carried out immediately.

Only install clean components:Only unpack

replacement parts immediately prior to

installation. Do not use parts that have been

stored loose (in tool boxes etc.)

When the system is open:Do not work with

compressed air if it can be avoided. Do not

move vehicle unless absolutely necessary.

Disconnected electrical harness

connectors:Protect from dirt and moisture. Be

sure harness connector is dry before

connecting.

Pa

ge 4 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 5 of 81

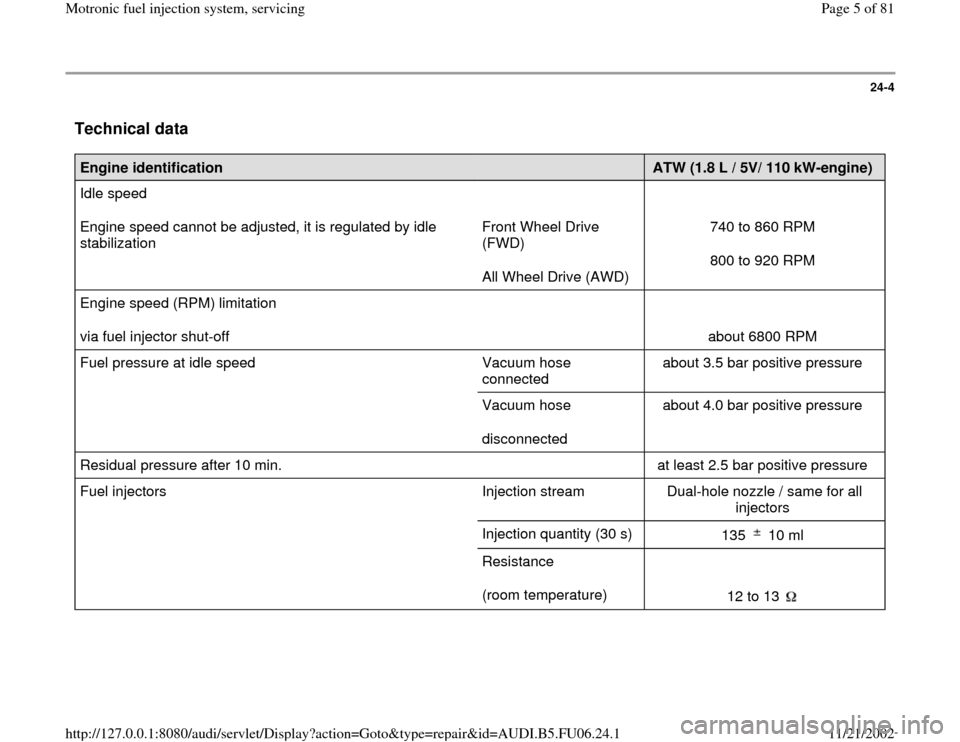

24-4

Technical data

Engine identification

ATW (1.8 L / 5V/ 110 kW-engine)

Idle speed

Engine speed cannot be adjusted, it is regulated by idle

stabilization

Front Wheel Drive

(FWD)

All Wheel Drive (AWD)

740 to 860 RPM

800 to 920 RPM

Engine speed (RPM) limitation

via fuel injector shut-off

about 6800 RPM

Fuel pressure at idle speed Vacuum hose

connected about 3.5 bar positive pressure

Vacuum hose

disconnected about 4.0 bar positive pressure

Residual pressure after 10 min. at least 2.5 bar positive pressure

Fuel injectors Injection stream Dual-hole nozzle / same for all

injectors

Injection quantity (30 s)

135 10 ml

Resistance

(room temperature)

12 to 13

Pa

ge 5 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 6 of 81

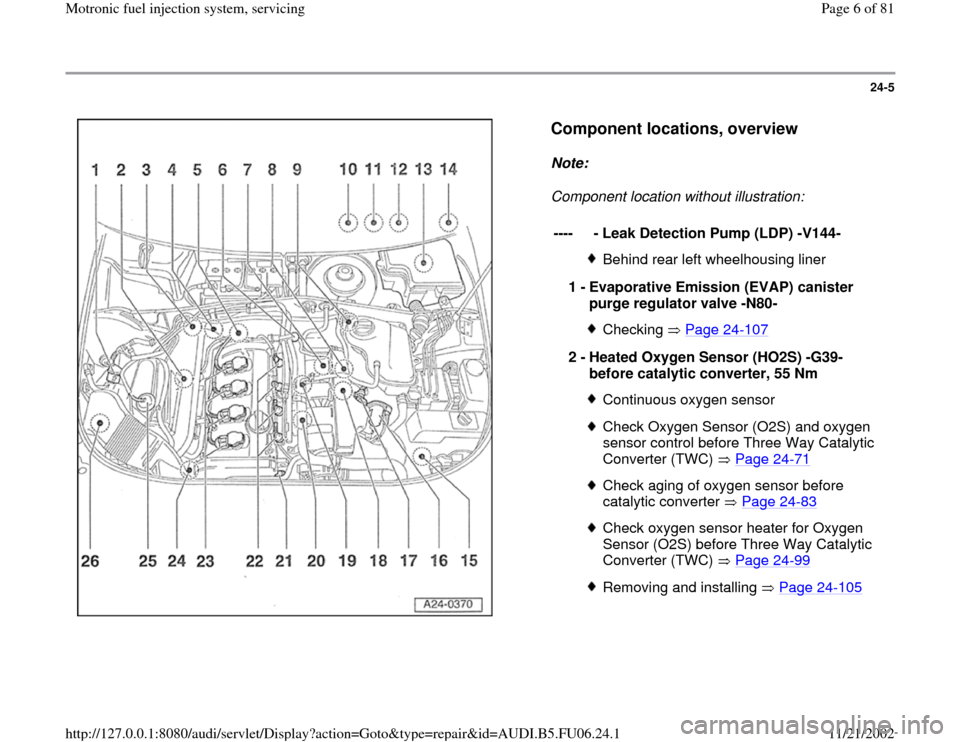

24-5

Component locations, overview

Note:

Component location without illustration:

----

- Leak Detection Pump (LDP) -V144-

Behind rear left wheelhousing liner

1 -

Evaporative Emission (EVAP) canister

purge regulator valve -N80- Checking Page 24

-107

2 -

Heated Oxygen Sensor (HO2S) -G39-

before catalytic converter, 55 Nm

Continuous oxygen sensorCheck Oxygen Sensor (O2S) and oxygen

sensor control before Three Way Catalytic

Converter (TWC) Page 24

-71

Check aging of oxygen sensor before

catalytic converter Page 24

-83

Check oxygen sensor heater for Oxygen

Sensor (O2S) before Three Way Catalytic

Converter (TWC) Page 24

-99

Removing and installing Page 24

-105

Pa

ge 6 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 7 of 81

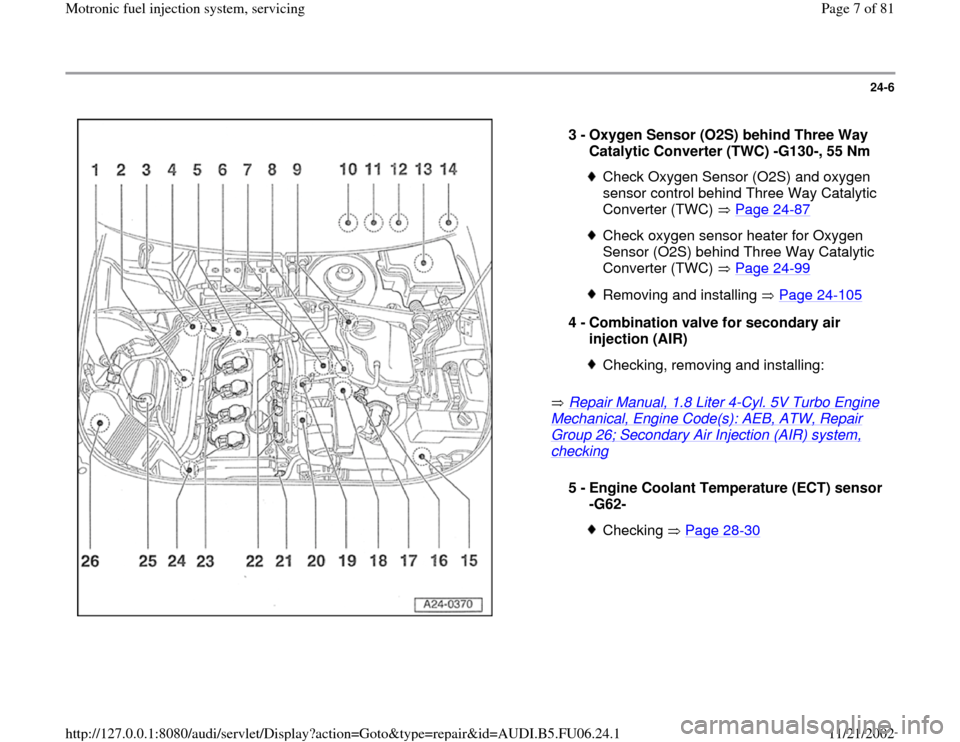

24-6

Repair Manual, 1.8 Liter 4

-Cyl. 5V Turbo Engine

Mechanical, Engine Code(s): AEB, ATW, Repair Group 26; Secondary Air Injection (AIR) system, checking

3 -

Oxygen Sensor (O2S) behind Three Way

Catalytic Converter (TWC) -G130-, 55 Nm Check Oxygen Sensor (O2S) and oxygen

sensor control behind Three Way Catalytic

Converter (TWC) Page 24

-87

Check oxygen sensor heater for Oxygen

Sensor (O2S) behind Three Way Catalytic

Converter (TWC) Page 24

-99

Removing and installing Page 24

-105

4 -

Combination valve for secondary air

injection (AIR)

Checking, removing and installing:

5 -

Engine Coolant Temperature (ECT) sensor

-G62-

Checking Page 28

-30

Pa

ge 7 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 8 of 81

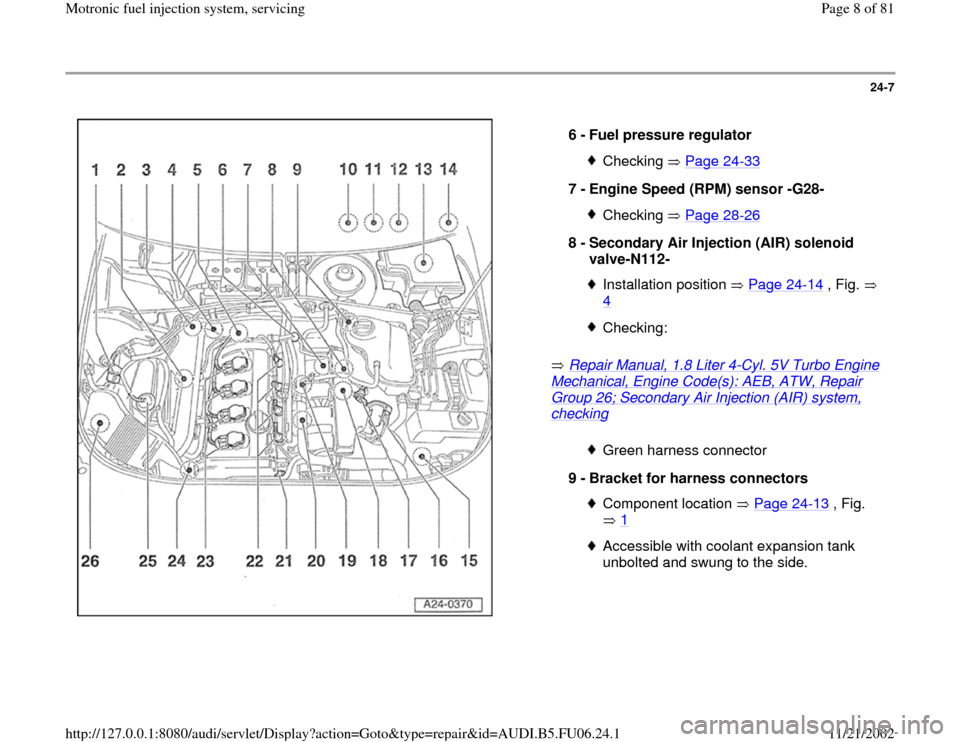

24-7

Repair Manual, 1.8 Liter 4

-Cyl. 5V Turbo Engine

Mechanical, Engine Code(s): AEB, ATW, Repair Group 26; Secondary Air Injection (AIR) system, checking

6 -

Fuel pressure regulator Checking Page 24

-33

7 -

Engine Speed (RPM) sensor -G28-

Checking Page 28

-26

8 -

Secondary Air Injection (AIR) solenoid

valve-N112-

Installation position Page 24

-14

, Fig.

4

Checking:Green harness connector

9 -

Bracket for harness connectors Component location Page 24

-13

, Fig.

1

Accessible with coolant expansion tank

unbolted and swung to the side.

Pa

ge 8 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 9 of 81

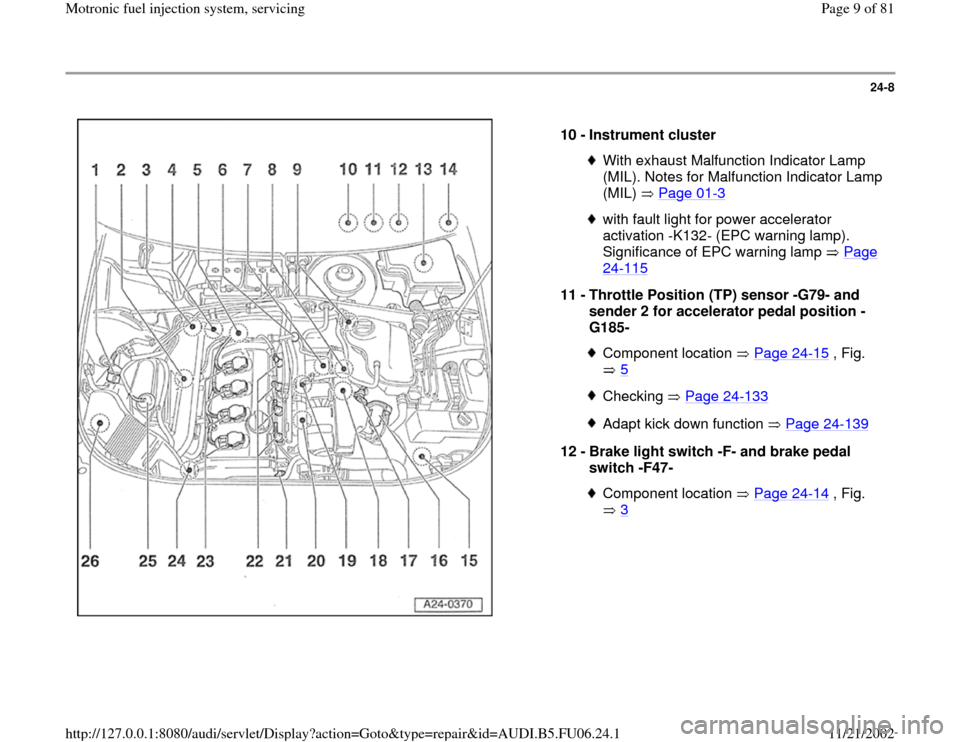

24-8

10 -

Instrument cluster

With exhaust Malfunction Indicator Lamp

(MIL). Notes for Malfunction Indicator Lamp

(MIL) Page 01

-3

with fault light for power accelerator

activation -K132- (EPC warning lamp).

Significance of EPC warning lamp Page 24

-115

11 -

Throttle Position (TP) sensor -G79- and

sender 2 for accelerator pedal position -

G185-

Component location Page 24

-15

, Fig.

5

Checking Page 24

-133

Adapt kick down function Page 24

-139

12 -

Brake light switch -F- and brake pedal

switch -F47-

Component location Page 24

-14

, Fig.

3

Pa

ge 9 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1

Page 10 of 81

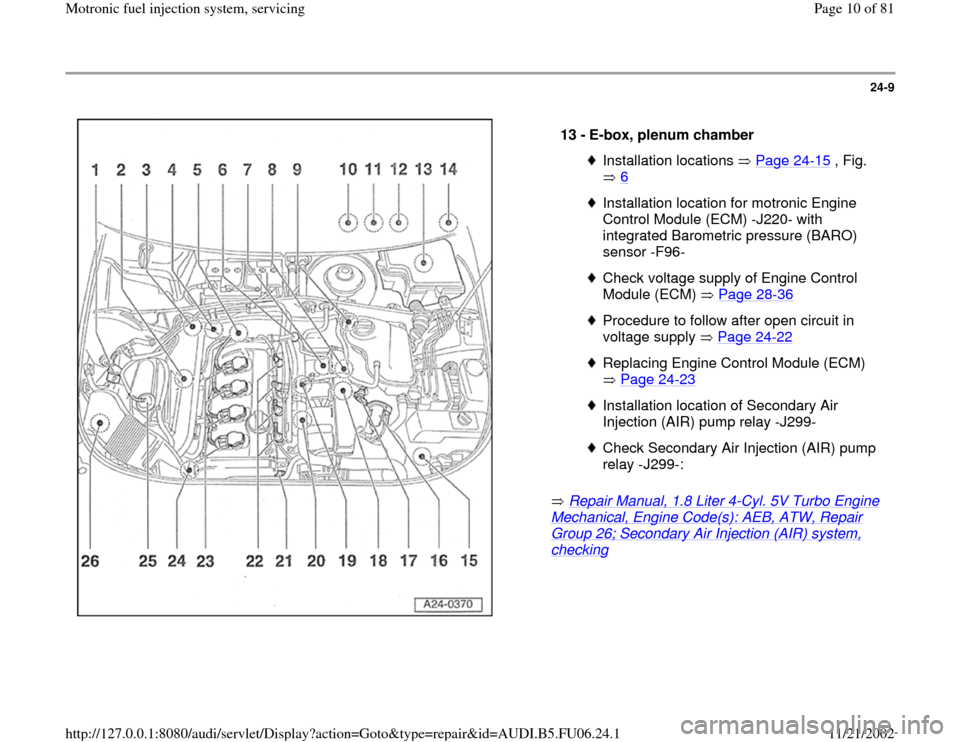

24-9

Repair Manual, 1.8 Liter 4

-Cyl. 5V Turbo Engine

Mechanical, Engine Code(s): AEB, ATW, Repair Group 26; Secondary Air Injection (AIR) system, checking

13 -

E-box, plenum chamber Installation locations Page 24

-15

, Fig.

6

Installation location for motronic Engine

Control Module (ECM) -J220- with

integrated Barometric pressure (BARO)

sensor -F96- Check voltage supply of Engine Control

Module (ECM) Page 28

-36

Procedure to follow after open circuit in

voltage supply Page 24

-22

Replacing Engine Control Module (ECM)

Page 24

-23

Installation location of Secondary Air

Injection (AIR) pump relay -J299- Check Secondary Air Injection (AIR) pump

relay -J299-:

Pa

ge 10 of 81 Motronic fuel in

jection s

ystem, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.FU06.24.1