stop start AUDI TT ROADSTER 2008 Owner's Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2008Pages: 316, PDF Size: 70.1 MB

Page 222 of 316

-~_C_ h_e _c _ k_ i_n ...:::g::;...._ a_n_ d_ f_ i_ll _in -'g:::;.._ ___________________________________________ _

Closing the engine hood

- Pull the hood down until the pressure from the struts is

reduced.

- Let the hood

drop down and latch in place. Do not try to

push it shut;

it may fail to engage~& .

& WARNING

A hood that is not completely latched could fly up and block your

view while driving.

• When you close the engine hood, check it to make sure the

safety catch has properly engaged. The hood should be flush with

the surrounding vehicle body parts.

• If you notice while driving that the hood is not secured prop

erly, stop at once and close it. •

Working in the engine compartment

Be especially careful whenever you work in the engine

compartment!

Whenever you must perform any work in the engine compartment,

for example checking and filling the different fluids, there is a risk of injury, burns and accidents. To prevent personal injury always

observe the following WARNINGS. The engine compartment of any

vehicle is a hazardous area!

=> &

& WARNING

To help avoid injury, before you check anything under the hood :

• Switch off the engine.

• Remove the ignition key.

• Apply the parking brake.

& WARNING (continued)

• Move selector lever of automatic transmission to "P" {Park);

put manual transmission in Neutral.

• Always let the engine cool down. Hot components will burn

skin on contact.

• To reduce the risk of being burned, never open the hood if you

see or hear steam or coolant escaping from the engine compart

ment. Wait until no steam or coolant can be seen or heard before

carefully opening the hood .

• Keep children away from the engine compartment.

• Never spill fluids on hot engine components. They can cause a

fire.

• Never touch the radiator fan. The auxiliary electric fan is

temperature controlled and can switch on suddenly.

• Never open the coolant reservoir cap when the engine is still

warm. The coolant system is pressurized and hot coolant could

spray out.

• Protect your face, hands and arm from steam or hot engine

coolant by placing a thick rag over the cap when you open the

coolant reservoir.

• If work on the fuel system or the electrical system is necessary:

- Always disconnect the battery .

- Never smoke or work near heaters or open flames. Fluids in

the engine compartment could start a fire.

- Keep an approved fire extinguisher immediately available.

• To avoid electrical shock and personal injury while the engine

is running or being started, never touch :

- Ignition cables

- Other components of the high voltage electronic ignition

system.

• If you must perform a check or repair with the engine running: .,_

Page 268 of 316

11111.___W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? ______________________________________________ _

- Switch the electric air pump off - switch in position

0. If

the required tire pressure of at least 1.8 bar has not been

reached, follow the instructions in the section Re

inflating tire.

Re-inflating tire

-Remove the hose from the valve and pull the plug out of

the socket.

- Drive the vehicle slowly 10 meters backward or forward.

This helps to distribute the sealant better.

- Remove the empty inflation bottle and screw the hose

G)

=> page 265, fig. 169 from the electric pump directly onto

the valve.

- Insert the plug ©=>

page 265, fig. 169 into the socket for

the cigarette lighter.

- Move the switch

@ => page 265, fig. 170 on the electric

air pump

31 to position I. After 5 minutes, tire pressure

must have reached at least

1 .8 bar.

- Switch the electric air pump off - switch in position

0. If

the required tire pressure of at least 1.8 bar has not been reached, it is not possible to make a repair with the tire

sealant. Seek professional assistance.

Disassembling Tire Mobility System

- Remove the hose from the valve and pull the plug out of

the socket.

- Screw the dust cap onto the valve.

- Place the empty sealant bottle back in the original pack-

aging and cl ip it in place under the floor so that no tire

sealant can run out into t he vehicle. -

Place the electric air pump in the luggage compartment

for the time being.

- Start driving right away so that the sealant is distributed

in the tire.

& WARNING

• Follow the manufacturer's safety instructions on the decal for

the air pump and the sealant bottle.

• If a tire pressure of 1.8 bar cannot be achieved after pumping

for 5 minutes, the tire is too severely damaged. Do not continue to

drive.

• Seek professional assistance if it is not possible to repair the

tire with the tire sealant.

[ i] Tips

• Do not operate the electric air pump for more than 8 minutes

without stopping, otherwise it can overheat. When the air pump has

cooled down, you can continue to use it.

• If sealant has escaped, allow it to dry, then you can peel it off. •

Applies to vehic les : with Tire Mobil ity Sys tem

Final check

After driving for a short distance , tire pressure

must be checked

- After driving for about 10 minutes, stop and check the

tire pressure .

- If tir e pressure is still at least 1.3 bar, inflate the tire to

specified pressure (see driveas side B -pillarl, drive to the

next repair shop and have the tire and the sealant bottle

replaced.

~

Page 282 of 316

llll1.--___;E::. m :..:..:. e .::..:..r_,.g ~e:..: n:..:..: c:.!y ;__: s:... i..:.t ..:.u :...a ..:.t:... i..::o ..:.n..:.. s::.... ______________________________________________ _

6. Connect one end of the black jumper cable to the nega

tive term inal

0 of t he booster bat tery @.

7. Connect the other end of the balck jumper cable to the negative terminal (bolt head)

G) in the external starting

point @ of your ve hic le.

8. Route the jumper cables so tha t they cannot catch in any

rotating parts in the engine compartment.

Starting the engin e

9. Start the engine of the vehicle providing assistance and

allow it to run at id le.

10 . Now start t he engine o f the ve hicle wit h the disc harged

battery, wa it for two to three minutes until t he engine

"runs" smoothly.

11 . If the engi ne does not start : Stop tryi ng after 10 seconds

and t hen try ag ain after abo ut 30 secon ds.

12. In the vehicle that has received start assistance, turn on

the heate r blower and the rear window heating to elimi

nate any voltage pea ks when disconnecting. Driving

lights must be switched off!

1 3. Disconnect the cable while the engine is running exactly

in

reverse order to that described in=> page 279,

"Connecting/d isconnecting the jumper cable .". When

doing so, make sure t hat the cable cannot contact

rotating engine parts.

14 . Close the cover on the pos itive terminal.

The battery is vented to the outside to prevent gases from entering

the vehic le interior. Make sure that the jumper clamps are well

connected with their

metal parts in full contact with the battery

termina ls .

& WARNING

To a vo id se riou s pe rso nal in jur y a nd d am age t o the vehi cle, heed

all wa rnings and in stru ction s of th e jumper cable manuf acturer. If

i n doubt , call for r oad ser vic e.

• Jumper c able s mu st be long enough so that the vehicle s do not

t o uch .

• When connecting jumper cable s, make sur e th at they cannot

g et ca ught in any mo ving p arts in the eng ine comp artment .

• Bef ore you che ck anyth ing in the engin e comp artment , alway s

r ea d and heed all WARNING S=:,

page 21 2, "Engine c omp artment ".

0 Note

Improper hook -up of jumper cables can ruin the generator .

• Always connect POS ITIVE ( +l to POSITIVE(+), and NEGAT IVE( -) to

NEGAT IVE( -) ground post of the battery manager control unit .

• Check that al l screw plugs on the battery cells are screwed in

firm ly . I f not, tighten plugs prior to connecting clamp on negative

battery terminal.

• Please note that the procedure for connect ing a jumper cable as

described above applies specifical ly to the case of your vehicle

being jump started. When you are giving a jump start to another

vehicle, do

not connect the negative(-) cable to the negative 1- l

terminal on the discharged battery@. Instead, securely connect

the negative( -) cable to either a sol id metal component that is

firm ly bolted to the engine block or to the engine block itself . If the

battery that is being charged does not vent to the outside, escaping

battery gas could ignite and explode! •

Page 305 of 316

______________________________________________ A_ l_,_ p _h_ a_ b_e _t_i c_ a _ l _in _ d_e _ x __ lllll

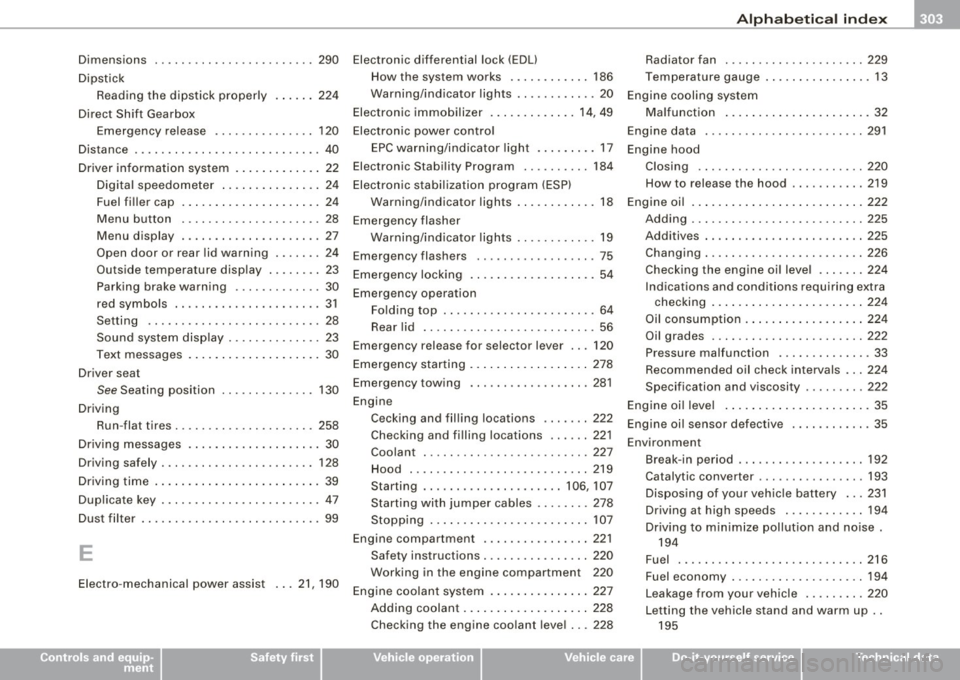

Dimensions ... .. ...... . .... .. .. .... 290 Electronic differential lock (EDU

Dipstick Reading the dipstick properly

Direct Shift Gearbox 224

Emergency release . . . . . . . . . . . . . . . 120

Distance ........ .... ....... ...... ... 40

Driver information system . .... .... ... . 22

Digital speedometer ... .. .... ...... 24

Fuel filler cap ...... ..... .... .... .. 24

Menu button ..................... 28

Menu display ..................... 27

Open door or rear lid warning . ......

24

Outside temperature display .. .... .. 23

Parking brake warning ............. 30

red symbols .. ............. ....... 31

Setting ...... .... ... .... ..... .. .. 28

Sound system disp lay ............ .. 23

Text messages . .... .... .... .... ... 30

Driver seat See Seating position . ............. 130

Driving Run -flat tires . .... .... ....... .... . 258

Dr iving messages ... ..... .. ... .... ... 30

Driving safely . . . . . . . . . . . . . . . . . . . . . . . 128

Driving time ... .... ... ..... .... .... .. 39

Duplicate key .... .... ...... ....... ... 47

Dust filter . ....... .... .... ........ ... 99

E

Electro -mechanical power assist ... 21, 190 How the system works

............ 186

Warning/indicator lights ............ 20

Electronic immobilizer ...... ... .. .. 14, 49

Electronic power cont ro l

EPC warning/indicator light ..... .... 17

Electronic Stability Program .......... 184

Electronic stabilization program (ESP! Warning/indicator lights ........ .... 18

Emergency flasher Warning/ind icator lights .. .... ...... 19

Emergency flashers .................. 75

Emergency locking . ... .... .... ... .. .. 54

Emergency operation Folding top ....................... 64

Rear lid .. .... ....... .... .... .... . 56

Emergency release for selector lever ... 120

Emergency starting ........ ... .... ... 278

Emergency towing .. ............. .. . 281

Engine Cecking and filling locations ... ... . 222

Checking and filling locations ...... 221

Coolant ... .. .... .... ..... .. ... .. 227

Hood . ..... .. ... ... .. .... ..... .. 219

Starting ..................... 106, 107

Starting with jumper cables ........ 278

Stopping .... .... ...... ...... ... . 107

Engine compartment .... ...... ...... 221

Safety instructions ................ 220

Working in the engine compartment 220

Engine coolant sys tem ..... .... ...... 227

Adding coolant .... .... ..... ... ... 228

Checking the engine coolant leve l .. . 228 Radiator fan

... .. .. .. .... .... .... 229

Temperature gauge ................ 13

Engine cooling system Malfunction ... .. .... .... .... ..... 32

Engine data .. ............... .... ... 291

Engine hood Closing .. ... ........ .... ... ..... 220

How to release the hood ... ... ... .. 219

Engine oil . ...... .... .... ... .... .... 222

Adding .... ....... .... ... .... .... 225

Additives .. .... .... ... .... .... ... 225

Changing . .... .... .... ..... ..... . 226

Checking the engine oi l leve l ... .... 224

Indications and conditions requiring extra checking .... .... .... .... .... ... 224

Oil consumption . ...... ..... .. .... 224

Oil grades . ....... .... .... ....... 222

Pressure malfunction .............. 33

Recommended oil check intervals ... 224

Specification and viscosity ......... 222

Engine oi l leve l .. .... .... ... .... .... . 35

Engine oil sensor defective .... ...... .. 35

Environment Break-in period ..... .. ... .... .... . 192

Catalytic converter .......... ... .. . 193

Disposing of your vehic le battery .. . 231

Driving at high speeds . ...... .... . 194

Dr iving to minim ize pollution and noise .

194

Fuel .. .... .... .... ... .... .... ... 216

Fuel economy ......... ........ ... 194

Leakage from your vehicle . .... .... 220

Letting the vehicle stand and warm up ..

195

Controls and equip ment Safety first Vehicle operation

Vehicle care Do-it-yourself service Technical data

Page 311 of 316

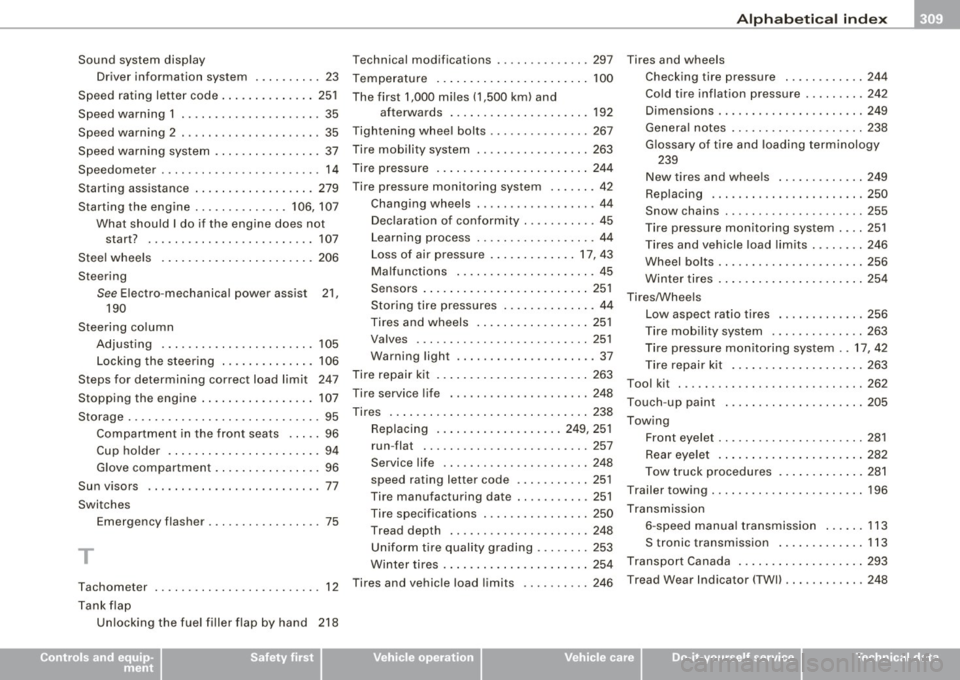

______________________________________________ A_ l_,_ p _h_ a_ b_e _t_ic _ a _ l _in _ d_e _ x __ lll

Sound system display

Driver info rma tion system .... .... .. 23

Speed rating letter code ........... ... 251

Speed warning 1 . .... ...... ... .. .... . 35

Sp eed warning 2 . .... .... ... ... ... .. . 35

Speed warning system ... .... .. .. .... . 37

Speedometer . . . . . . . . . . . . . . . . . . . . . . . . 14

Starting assistance ...... .... ...... .. 279

Starting the engine .. .... .... ... . 106, 107

What should I do if the engine does not

star t? ........ .... .... ... .. ... . 10 7

Stee l wheels .... ....... .... .. . ..... 206

Steering

See Electro-mechanical power assist 21,

190

Steering co lumn

Adjusting .... ... .... .... ...... .. 105

Locking the steering ... .. .... .... . 106

Steps fo r determining co rrect load limit 247

Stopping the engine ...... ....... .... 107

Storage . .... .... .... .... ... .... .... . 95

Compartment in the front seats . .... 96

Cup holder ... .... .... ......... ... 94

Glove compartment ...... .... .... .. 96

Sun visors .. .. .. ..... ... ..... .. ..... 77

Switches Emergency flasher ..... .. .... .... .. 75

T

Tachometer ... .. .... .... ... .... .... . 12

Tank flap

Un locking the fuel filler flap by hand 218

Controls and equip

ment Safety first

Technical

modifications ..... .... ..... 297 Tires and wheels

Tempera ture ............ ... .... .... 100 Checking tire pressure .

.... ...... . 244

The firs t 1,000 miles ( 1,500 kml and Co

ld tire inflation pressure . ... ... .. 242

afterwards ... .. .. .. .... .... .... 192 Dimensions

.. ... .... ... .. .... .... 249

Tightening whee l bolts ... .... .... .... 267 General

notes ...... ... .... ...... . 238

Tire mobility system .... ....... .... .. 263

Tire pressure .... .. ...... .... ....... 244 G

lossary of tire and loading terminology

239

New tires and wh eels . ....... .... . 249

Tire pressure monitor ing system ...... . 42

Changing wheels ........... .... ... 44

Declaration of conform ity . .... .... .. 45

Learning process . ..... ... .... .... . 44

Loss of air pressure ........... .. 17, 43

Malfunctions ... .. .... .... .... ... . 45

Sensors ........... ... .... ....... 251

Storing tire pressures ............. . 44

Tires and wheels ...... .... .... ... 251

Valves ....... .... .... .... .... ... 25 1

Warning light ..... .. .... .... .... .. 37

Tire repair kit ... ... ...... .... .... ... 263

Tire service life ........ .... ... .... .. 248

Tires .... .. . ... ... ................. 238

Replacing .... .... .... .... ... 249, 251

run -flat .. .... ... .... .... .... .... 257

S ervice lif e ..... .... ... .. .... .... 248

speed ra ting let ter code ..... .. ... . 251

Tire manufacturing date . .... ...... 251 Replacing

..... .. .... .... ..... .. . 250

Snow chains ...... .... .. . .. .. .... 255

Ti re pressure monitoring system .... 251

Tires and vehicle load limits ... .... . 246

Wheel bo lts ... .... .... ... .... .... 256

Winter tires ... .... .... ....... .. .. 254

Ti res/Wheels

Low aspect ratio tires . .... ...... .. 256

Tire mob ility system ..... .. .... ... 263

Tire pressure mon itoring system .. 17, 42

Tire repair kit ................ .... 263

Tool kit ..... .... ... .. .... .. .... .... 262

Touch -up paint ... .. .... .... .... .... 205

Towing Front eyelet ... ... ..... ... .... .... 281

Rear eyelet ... .... .... .... ....... 282

Tow truck procedures .. ...... .... . 281

Trailer towing .......... .. ...... .... . 196

Tire specifica tions . ...... ... .... .. 250 Transmission

Tread depth ..... .... ...... .. .... 248 6

-speed manua l transmission ...... 113

Uniform tire quality grading ... ..... 253 S tronic transm

ission ............. 113

Winter tires .... .... ... .... ....... 254 Transport Canada

........ .. .. ....... 293

Tires and vehicle load limits ... ....... 246 Tread

Wear Indicator (TWI) ... .... .... . 248

Vehicle operation Vehicle care Do-it-yourself service Technical data