change wheel AUDI TT ROADSTER 2011 User Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2011, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2011Pages: 260, PDF Size: 64.11 MB

Page 224 of 260

222 What do I do now ?

@ Tips

After a tire repair, have the sealant bottle

rep laced at a dealership . This restores full

functionality to the Tire Mob ility System.

What should I be

aware of when

changing a tire?

General information

The follow ing sections will provide you with

important information o n how to change a

tire using the vehicle tool kit.

However , we recommend that you have a

qua lified service center change the tire and

pe rform all work associated with changing it .

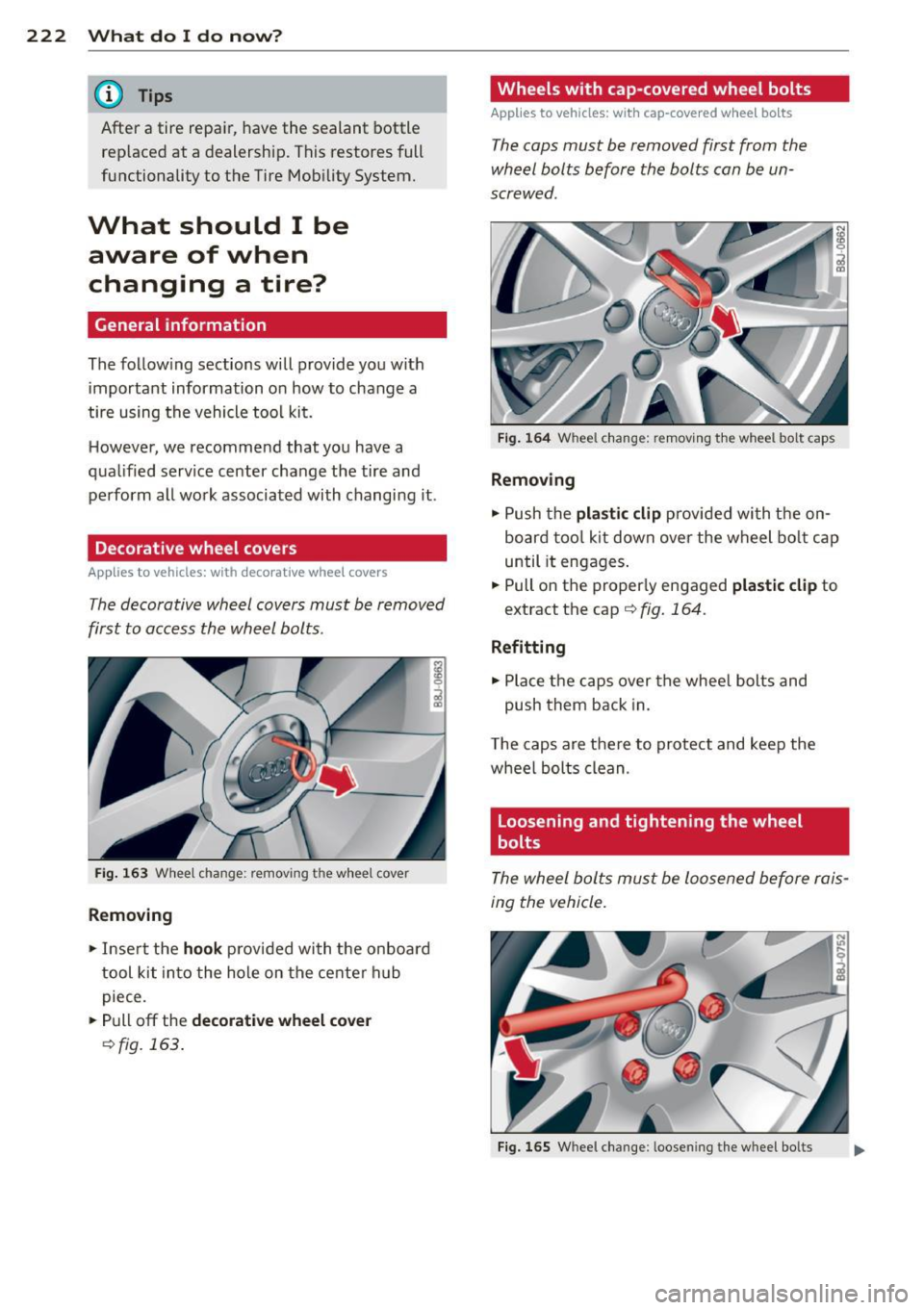

Decorative wheel covers

Applies to vehicles: with decorative wheel covers

The decorative wheel covers must be removed

first to access the wheel bolts .

Fig. 1 63 Wheel ch an ge : remo ving th e wh eel cove r

Removing

,.. In se rt the hook provided wi th t he on board

tool kit into the hole on the center h ub

piece .

,.. Pull

off the decorat ive wheel cover

Q fig . 163 .

' Wheels with cap-covered wheel bolts

Applies to vehicles: with cap-covered wheel bolts

The caps must be removed first from the

wheel bolts before the bolts can be un

screwed .

Fig . 164 W heel c hange: re moving th e wh eel bolt cap s

Removing

,.. Push the plasti c clip provided wi th the on

board too l kit down over the wheel bo lt cap

until it engages .

,.. Pull on th e properly engaged

pla stic clip to

extract the cap

Q fig. 164 .

Refitting

,.. Place the c aps over the whee l bolts and

push them back in.

T he caps are the re to protect and keep the

whee l bolts clean .

Loosening and tightening the wheel

bolts

The wheel bolts must be loosened before rais

ing the vehicle.

Fi g. 16 5 W hee l cha nge : loose ning t he wh eel bol ts

Page 225 of 260

Loosening

• Fit the wheel bolt wrench over the wheel

bolt and push it down as far as it will go .

• Close your grip aro und the

end of the

wrench handle for maximum torque and

turn the wheel bolts

counter-clockwise

about one single turn in the direction of ar

row

¢ fig . 165.

Tightening

• Fit the wheel bolt wrench over the wheel

bo lt and push it down as far as it will go .

• Close your gr ip around the

end of the

wrench handle for max imum torque and

turn each wheel bolt

clockwise until it sits

t ight .

& WARNING

-Using force without cont rol to speed the

wheel change up can cause the vehicle to

slip off the jack and cause serious per

sonal inj uries.

-Do not loosen the wheel bolts more than

one turn

before you raise the veh icle with

the jack. -Risk of inj ury!

(j) Tips

-Never try and use the hexagonal socket

in the handle of the screwdriver to loos

en or tighten the wheel bolts.

- If a whee l bolt sits very tight, you may

find it easier to loosen by carefully push

ing down on the end of the whee l bolt

wrench w ith

one foot only . As you do,

hold on to the car to keep yourse lf stable

and take care not to slip.

What do I do now? 223

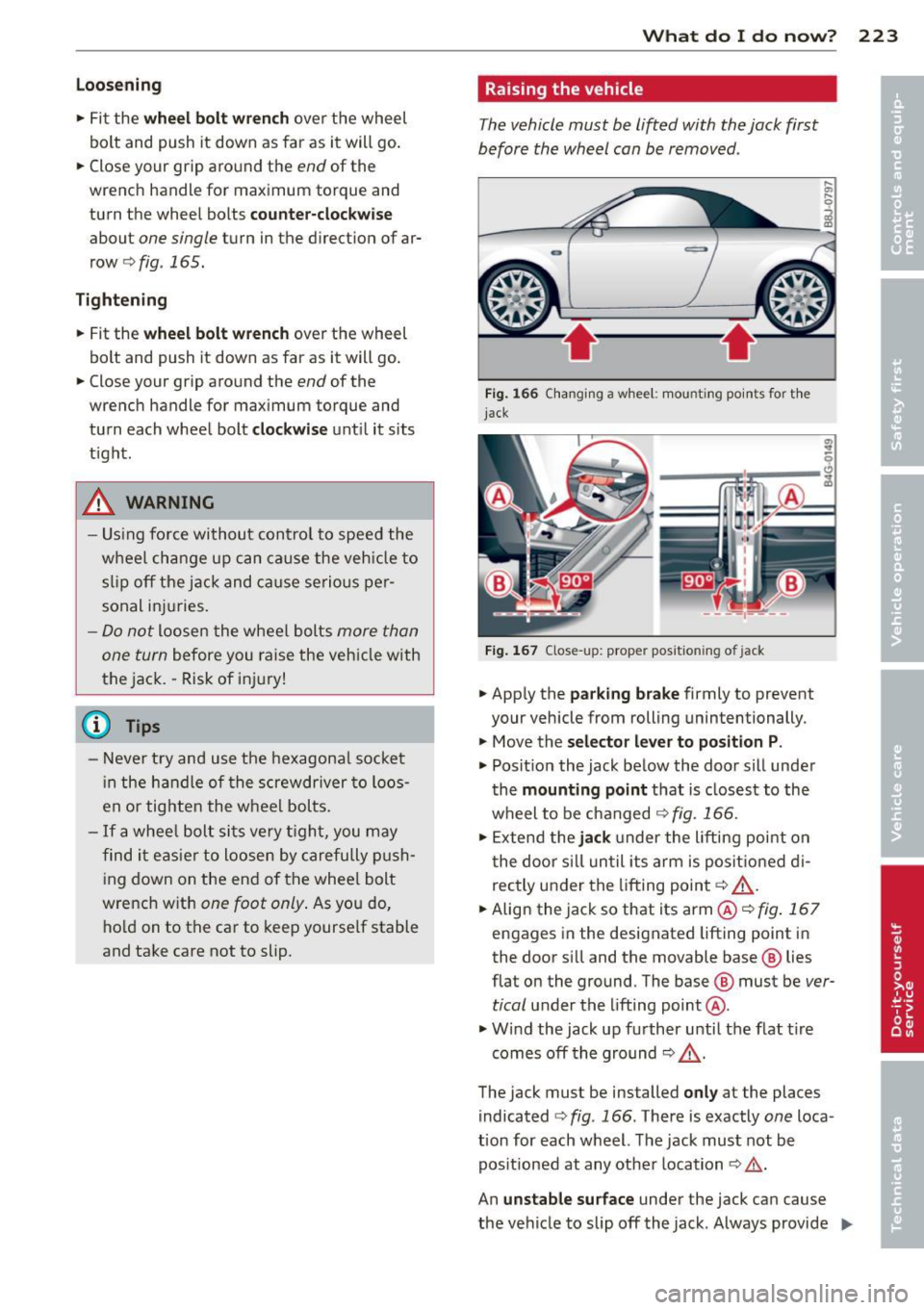

Raising the vehicle

The vehicle must be lifted with the jack first

before the wheel can be removed .

Fig . 166 Chang ing a w hee l: mo unting points for t he

jack

Fig. 1 67 Close-up: proper position ing of jack

• App ly the parking brake firmly to prevent

your vehicle from rolling unintentionally.

• Move the

selector lever to position P.

• Posit ion the jack below the door sill under

the

mounting point that is closest to the

wheel to be changed

¢ fig. 166.

• Extend the jack under the lifting poi nt on

the door sill until its arm is posit ioned di

rectly under the lifting point ¢.&_ .

• Align the jack so that its arm ®¢

fig. 167

engages in the designated lifting point in

the door s ill and the movable base ® lies

flat on the ground. The base @ must be

ver

tical

under the lifting point@.

• Wind the jack up further until the flat tire

comes off the ground ¢

_&.

The jack must be installed only at the places

indicated ¢

fig. 166 . Ther e is exactly one loca

tion for each wheel. The jack must not be

positioned at any othe r location

¢ .& .

An unstable surface under the jack ca n cause

the vehicle to slip off the jack. Always provide .,._

Page 226 of 260

224 What do I do now?

a firm base for the jack on the ground. If nec

essary place a sturdy board or similar support

under the jack. On

hard, slippery surfaces

(such as tile s) use a rubber mat or similar to

prevent the jack from slipping¢,&.

A WARNING

- You or your passengers could be injured

wh ile changing a wheel if you do not fol

low safety p recautions:

- Positioning the jack under the vehicle

at any other place than those indicated

above may damage the vehicle or may result in personal injuries.

- A soft or unstable surface under the

jack may ca use the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground . If necessary,

use a sturdy board under the jack.

- On hard, slippery surface (such as tiles)

use a rubber mat or s imilar to prevent

the jack from slipping.

- To help prevent injury to yourself and

your passengers:

- Do not raise the vehicle unti l yo u are

sure the jack is securely engaged.

- Passengers must not remain in the ve

hicle when it is jacked up.

- Make sure that passengers wait in a

safe p lace away from the vehicle and

well away from the roadway and traffic.

- Make sure jack position is correct, ad

just as necessa ry and then continue to

raise the jack .

@ Note

A floor jack or the pads on the hoist arms

must

not be positioned at the points

shown

-arrows-.

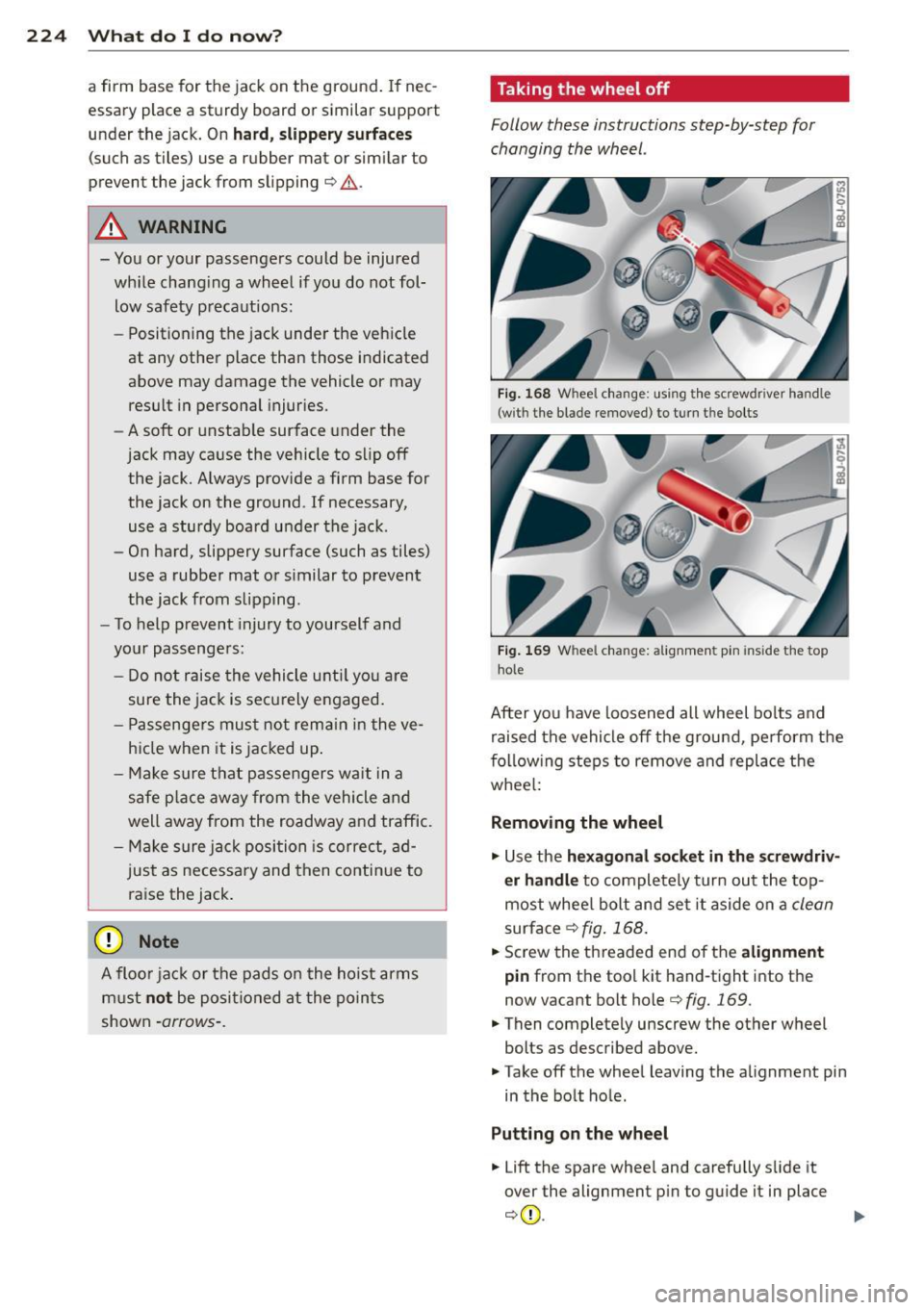

Taking the wheel off

F ollow these instructions step-by-step for

changing the wheel .

Fig. 168 Whee l cha nge: us ing th e screwd river ha nd le

(with the blad e removed ) to turn t he bolts

Fig. 169 Whee l change: alignment pin inside the top

h ole

After you have loosened all wheel bolts and

raised the vehicle off the ground, pe rform the

f ol low ing steps to remove and replace the

whee l:

Removing the wheel

.,. Use the hexagonal socket in the screwdriv

er handle

to completely turn out the top

most whee l bolt and set it aside on a

clean

surface ¢fig. 168.

... Screw the threaded end of the alignment

pin

from the tool kit hand-tight into the

now vacant bolt hole¢

fig. 169 .

.. Then completely unscrew the other wheel

bolts as described above .

.. Take off the wheel leaving the alignment pin

in the bolt hole .

Putting on the wheel

... Lift the spare wheel and carefully s lide it

over the alignment pin to guide it in place

¢(0.

Page 227 of 260

~ Use the hexagonal socket in the screwdriver

handle to screw in and tighten all wheel

bo lts

slightly .

~ Unscrew the alignment pin and insert and

t ighten the remaining wheel bolt s light ly

like the rest.

~ T urn the jack handle counter-clockw ise to

l ower the vehicle unti l the jack is fully re

leased .

~ Use the whee l bolt w rench to t ighten al l

whee l bolts firmly <=>

page 222 . Tighten

them

crosswise, from one bolt to the (ap

proximate ly) opposite one, to keep the

whee l cente red.

Q;) Note

When removing or installing the wheel,

the rim could hit the brake rotor and dam

age the rotor. Work carefully and have a

second person help you.

(D} Tips

Never use the hexagonal socket in the han

dle of the screwdriver to loosen or t ighten

the wheel bolts .

- Pull the reversib le b lade from the screw

driver before yo u use the hexagonal

socket in the handle to t urn the whee l

bo lts .

- When mounting tires with

unid irectional

tread design

make su re the tread pat

te rn is poi nted the r ight way

<=> page 226.

- The wheel bolts should be clea n and easy

to tu rn . Check for d irt and corrosion on

the mat ing s urfaces of both the wheel

and the hub. Rem ove a ll dirt from these

su rfaces before rem ounting the wheel.

Notes on wheel change

Please read the information <=> page 205 , New

tires and replacing tires and wheels ,

if you are

going to use a spare t ire which is different

from the tires on your ve hicle.

Afte r you change a tire :

What do I do now? 225

-Check the tire pre ssure on the spare imme

diately after mounting.

- Have the whe el bolt tightening torque

checked with a torque wrench as soon a s

possible by your authorized Audi dealer or

a qualified service station.

- With steel and alloy wheel rim s, the wheel

bolt s are cor rectly tightened at a torque of

90 ft lb (120 Nm ).

- If you noti ce while changing a tire that the

wheel bolts are corroded and difficult to

turn , then they should be replaced before

you check the tightening to rque.

- Replace the flat tire w ith a new one and

have it installed on your vehicle as soon as

possible. Remount the whee l co ver.

Until then , dr ive with extra care and at re

duced speeds.

A WARNING

- If you are going to equ ip your vehicle

w it h tires o r rims which differ from those

which were factory installed, then be

sure to rea d the information

¢ page 205,

New tire s and replacing tires and

wheels.

- Always sto re the too ls secu rely in lug

gage com partmen t. Othe rwise , in a n ac

cident or s udden m aneuver they cou ld fly

forwa rd, causing inj ury to passengers in

the vehicle.

(D Note

D o not use comme rcially ava ilab le tire

se alants . Ot herwise, t he e lectr ic al c ompo

nen ts of the tire pressu re monitoring sys

tem will no lo nger work p roperly and the

sensor fo r the tire pressure mon itor ing

system will have to be rep laced by a quali

fied workshop. •

•