AUDI TT ROADSTER 2011 Owners Manual

Manufacturer: AUDI, Model Year: 2011, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2011Pages: 260, PDF Size: 64.11 MB

Page 231 of 260

No.

25

Heater rear window Coupe/

heated rear window Roadster

26 Driver's side power window

27 Passenger's side power window

28 Not used

29 Washer pump

30 Cigarette lighter

31 Starter

32 Steering column module

33 Instrument cluster

34 Radio navigation system, radio

35 Audio amplifier

Engine (control unit)

37 CAN (Gateway)

38 Cigarette lighter

39 Not used

40 Not used

41 Not used

42 Not used

43 Not used

44 Not used

45 Not used

46 Not used

47 SOARS tuner, cell phone p ack-

age, TV tuner

48 VOA interface

49 N ot used

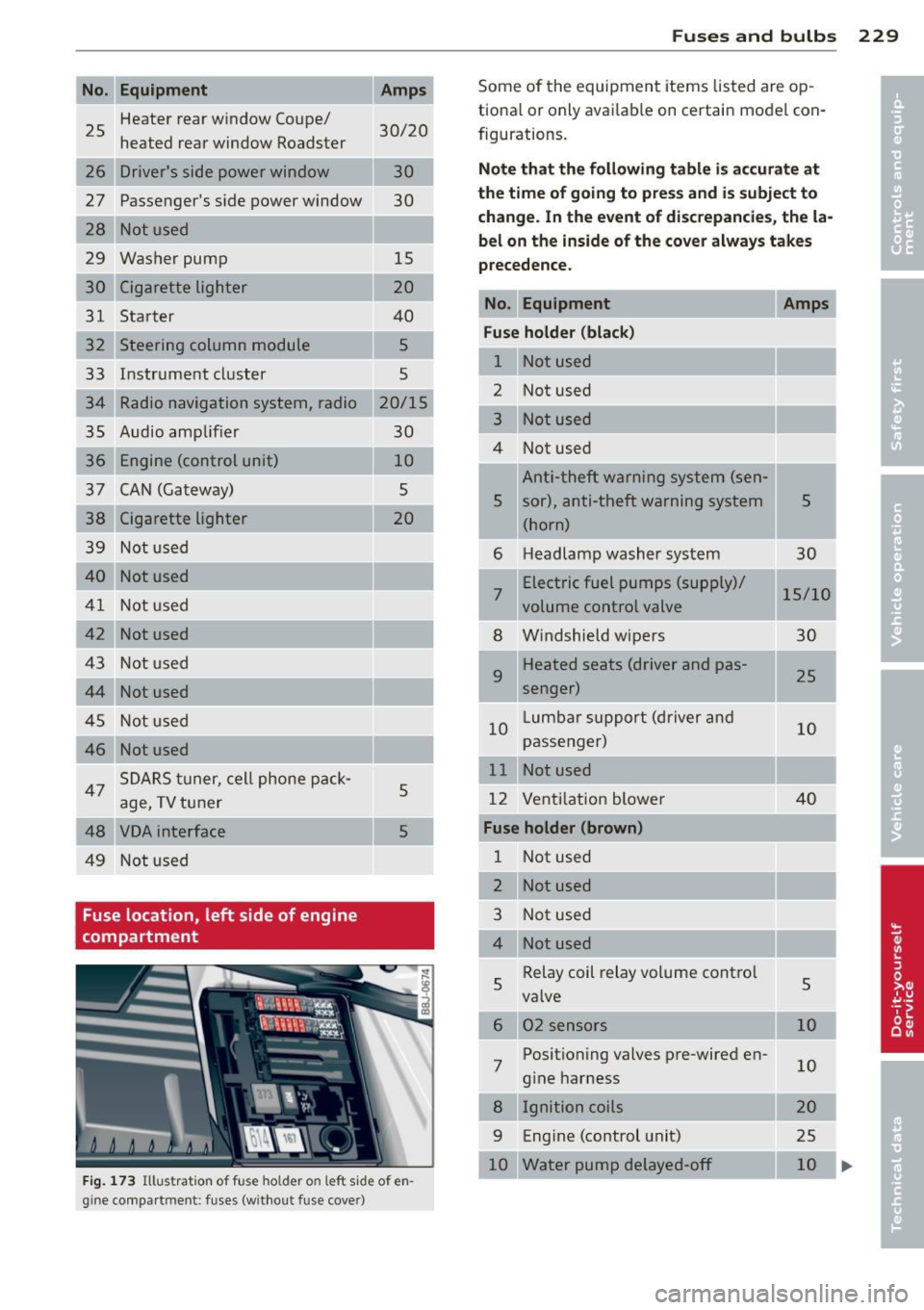

Fuse location, left side of engine

compartment Amps

30/20

30 15

40

30 10 5

20

-

5

5

F ig. 173 Illustrat ion of fuse holder on left side of en

g ine co mpa rtment : fuses (without fuse cover)

Fuse s and bulb s 229

Some of the equipment items listed are op

tiona l or only avai lab le on certain model con

figurations.

Note tha t the foll owing table i s ac cur ate at

the time of going t o press and is subject to

change . In the event of di screpancie s, the la·

bel on the inside of the cover always takes

precedence.

No . Equipment Amps

Fuse holder (black )

1 Notused -

----------'

2 Not used

3 Not used

4 Not used

Anti-theft warning system (sen-

5 sor), anti-theft wa rning system

(horn)

6 H eadlamp washer system

7

Electric fuel pumps (supply)/

volume control valve

8 W indshield wipers

9

Heated seats (driver and pas-

senger)

10

L umbar support (driver a nd

passenger)

11 Not used

12 Vent ilation blower

Fuse holder (brown )

1

2

3

4

5

6

7

9 N

ot used

Not used

Not used

Not used

Relay coil relay volume contro l

va lve

Position ing valves pre-wired en

g ine harness

I gnition coils

Eng ine (control unit)

10 Water pump delayed-off

5

30

15/10

30

25

10

40

-

5

10

10

20

25 10

1111-

Page 232 of 260

230 Fuses and bulbs

No. Equipment Amps

11 Feed (brake pedal) 5

-

12 Activated cha

rcoal filter/charge I pressure control valve 10

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace burned

out bulbs for you .

It is becoming increasingly more and more

difficult to replace vehicle light bulbs since in

many cases, other parts of the car must first

be removed before you are able to get to the

bulb . This applies especially to the light bulbs

in the front of your car which you can only

reach through the engine compartment.

Sheet metal and bulb holders can have sharp

edges that can cause ser ious cuts, and parts

must be correctly taken apart and then prop

e rly put back together to help prevent break

age of parts and long term damage from wa

ter that can enter housings that have not been

properly resealed.

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs

for you, since your dealer has the proper tools,

the correct bulbs and the expertise.

Gas discha rge lamps (Xenon lights}*:

Due to the high electrical voltage, have the

bulbs replaced by a qualified technician.

H eadlights with Xenon light can be identified

by the high voltage sticker.

A WARNING

Contact with high-voltage components of

the electrical system and improper re

placement of gas discharge (Xenon) head

light bulbs can cause serious personal in

jury and death.

- Xenon bulbs are pressurized and can ex

plode when being changed. -

Changing Xenon lamps requires the spe

cial tra ining, instructions and equip

ment.

- Only an authorized Audi dealer or other

qualified workshop should change the

bulbs in gas discharge lamps.

A WARNING

=

There are parts with sharp edges on the

openings and on the bulb holders that can

cause ser ious cuts.

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dealer or other qualified work

shop. Serious personal injury may result

from improperly performed work.

@ Tips

- If you must replace the light bulbs your

self, a lways remember that the engine

compartment of any vehicle is a hazard

ous area to work in. A lways read and

heed all WARNINGS

c:::> page 172, Engine

compartment

c::> &. .

-It is best to ask your authorized Audi

dealer whenever yo u need to change a

bulb .

-

Page 233 of 260

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who

have the necessary tools and equipment to

perform these operations.

Starting by pushing or

towing

(D Note

Vehicles with an automatic transmission

cannot be started by pushing or towing .

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

using a

pair of jumper cables to start the en

gine.

Jumper cables

Use only jumper cables of sufficiently

largec ross section to safely carry the starter

current. Refer to the manufacturer's specifica

tions.

Use only jumper cables which have

insulated

termina l clamps and are properly marked for

distinction :

plus(+) cable in most cases colored red

minus(-) cable

i n most cases colored black.

_& WARNING

Batteries contain electricity, ac id, and gas.

Any of these can cause very serious or fatal

injury. Follow the instructions below for

safe handling of your vehicle's battery.

- Always shield you r eyes and avoid lean

ing over the battery whenever possible.

Emergency situations 231

-A discharged battery can already freeze

at temperatures just below 32 °F (0 °C).

Before connecting a jumper cable, the

frozen battery must be thawed com

pletely, othe rwise it could explode .

- Do not allow battery acid to contact eyes

or skin . Flush any contacted area with

water immediately .

- Improper use of a booster battery to

start a vehicle may cause an explosion.

- Vehicle batter ies generate explosive gas

es. Keep sparks, flame and lighted ciga

rettes away from batteries.

- Do not try to jump start any veh icle w ith

a low ac id level in the battery.

- The voltage of the booster battery must

also have a 12-Volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery . Use of batteries of different voltage

or substantially different "Ah" rat ing

may cause an exp losion and personal in

jury.

- Never charge a frozen battery. Gas trap

ped in the ice may cause an explosion.

- Never charge o r use a battery that has

been frozen . The battery case may have

be weakened.

- Use of batter ies of different voltage or

substantially different capacity (Ah) rat

ing may cause an exp losion and injury .

The ca pa city (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS¢

page 172, Engine com

partment.

(D Note

- App lying a higher voltage booster bat

tery will cause expensive damage to sen

sit ive electronic components, such as

control units, relays, rad io, etc .

- There must be no electrical contact be

tween the vehicles as otherwise current

could already start to flow as soon as the

posit ive(+) terminals are connected. ..,. •

•

Page 234 of 260

232 Emergency situations

@ Tips

The discharged battery must be properly

connected to the vehicle's electrical sys

tem.

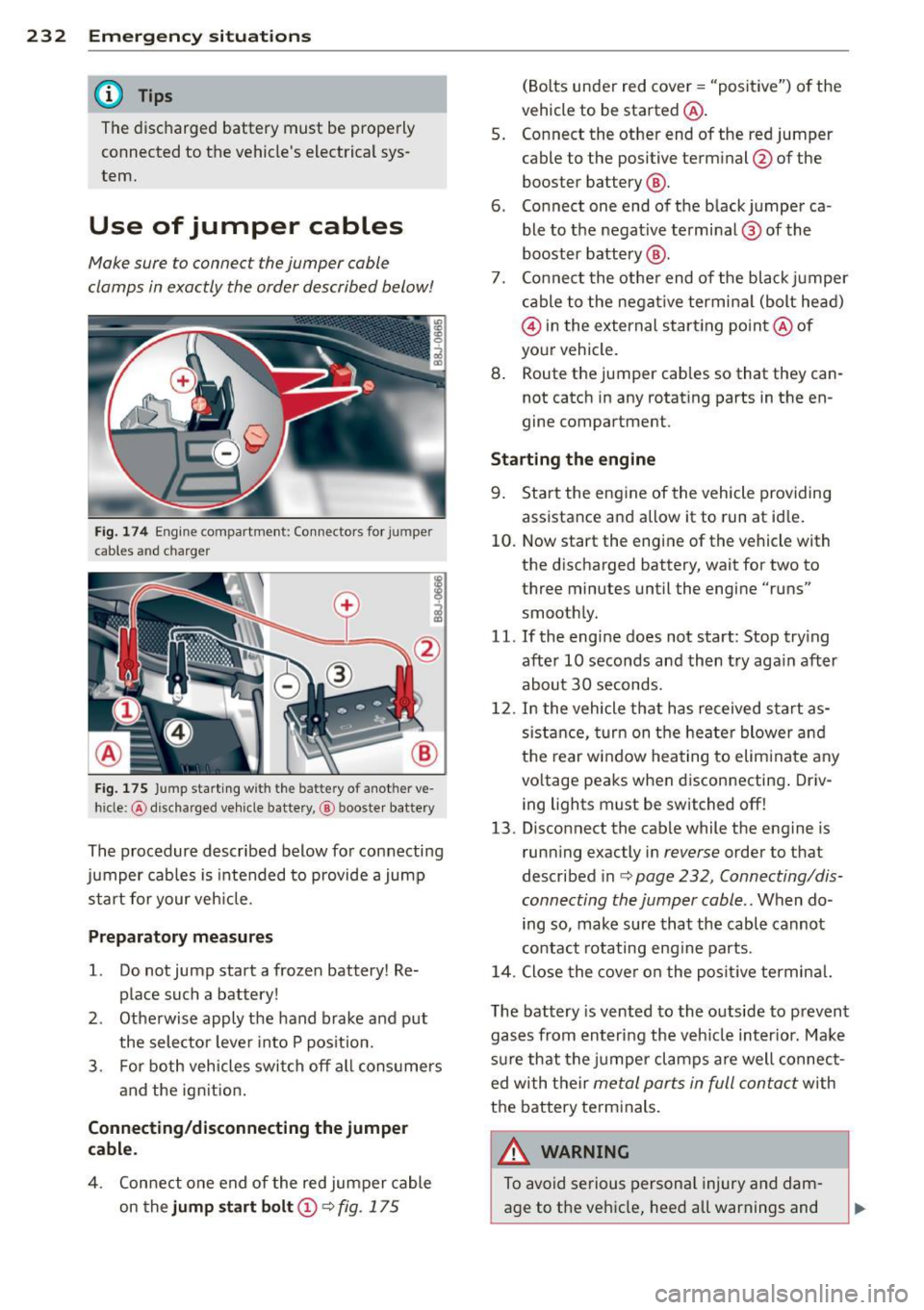

Use of jumper cables

Make sure to connect the jumper coble

clomps in exactly the order described below!

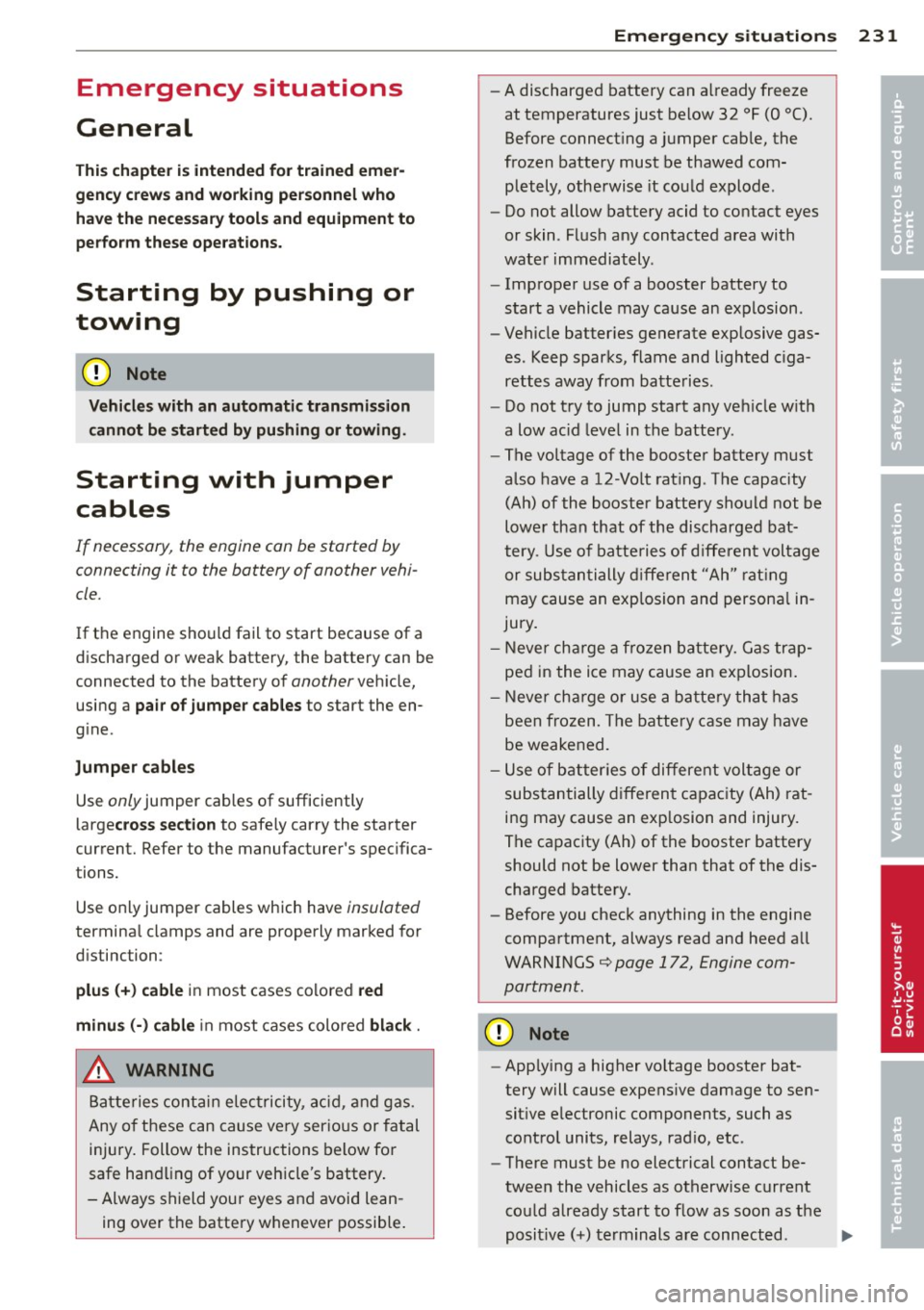

Fig. 174 Engine compart ment: Co nnectors for jumper

cables and charger

Fig. 175 Jump starting with the battery of another ve

hicle: @discharged veh icle battery, ® booste r battery

The procedure described below for connecting

jumper cables is intended to provide a jump

start for your veh icle.

Preparatory measures

1. Do not jump start a froze n battery! Re

place such a battery!

2 . Otherwise apply the hand brake and put

the selector lever into P position.

3. For both vehicles switch off all consumers

and the ign ition.

Connecting/disconnecting the jumper

cable .

4. Connect one end of the red jumper cable

on the

jump start bolt (D 9 fig. 175

(Bolts under red cover = "positive") of the

vehicle to be started @.

5. Connect the other end of the red jumper

cable to the positive terminal @of the

booster battery @.

6. Connect one end of the black jumper ca

ble to the negat ive terminal @of the

booster battery @.

7. Connect the other end of the black jumper

cable to the negative terminal (bolt head)

@ in the external start ing point @ of

your vehicle.

8. Route the jumper cables so that they can

not catch in any rotat ing parts in the en

gine compartment.

Starting the engine

9. Start the engine of the vehicle providing

assistance and allow it to run at id le .

10. Now start the engine of the vehicle with

the discharged battery, wait for two to

three minutes until the engine "runs"

smoothly.

11. If the eng ine does not start: Stop try ing

after 10 seconds and then try again after

about 30 seconds.

12. In the vehicle that has received start as

sistance, turn on the heater blower and

the rear window heating to elim inate any

vo ltage peaks when disconnecting . Driv

ing lights must be switched off!

13 . Disconnect the cable while the engine is

running exactly in

reverse order to that

described inc:>

page 232, Connecting/dis

connecting the jumper coble ..

When do

ing so, make sure that the cable cannot

contact rotating eng ine parts.

14. Close the cover on the posi tive terminal.

The battery is vented to the outside to prevent

gases from entering the vehicle inter ior. Make

sure that the jumper clamps are well connect

ed with their

metal parts in full contact with

the battery terminals.

A WARNING ~

To avoid serious personal injury and dam-

age to the vehicle, heed all warnings and

Page 235 of 260

instructions of the jumper cable

manufacturer. If in doubt, call for road

service.

- Jumper cables must be long enough so

that the vehicles do not touch.

- When connecting jumper cables, make

sure that they cannot get caught in any

moving parts in the engine compart

ment.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

<=> page 172, Engine com

partment .

@ Note

Improper hook-up of jumper cables can ru

in the generator.

-Always connect POSITIVE(+) to POSI

TIVE(+), and NEGATIVE(-) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw plugs on the battery

cells are screwed in firmly . If not, tighten

plugs prior to connecting clamp on nega

tive battery terminal.

- Please note that the procedure for con

necting a jumper cable as described

above applies spec ifically to the case of

your vehicle being jump started. When

you are giving a jump start to another ve

hicle, do

not connect the negative( -) ca

ble to the negative(- ) terminal on the

discharged battery@. Instead, securely

connect the negative (-) cable to either a

solid metal component that is firmly bolted to the engine block or to the en

gine block itself. If the battery that is be

in g charged does not vent to the outside,

escaping battery gas could ignite and ex

plode!

Emergency situations 233

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

ing.

T he following information is to be used by

commercial tow truck operators who know

how to operate their equipment safely.

- Never tow your Audi, towing will cause

damage to the engine and transmission.

- Never wrap the safety chains or winch ca

ble s around the brake lines .

- To prevent unnecessary damage, your Audi

must be transported with a car carrier

(flatbed truck).

- To load the vehicle on to the flat bed, use

the towing loop found in the vehicle tools

and attach to the front or rear anchorage

<=> page 234 and c:> page 235.

A WARNING

A vehicle being towed is not safe for pas

sengers. Never allow anyone to ride in a

vehicle be ing towed, for any reason.

-

•

•

Page 236 of 260

234 Emergency situations

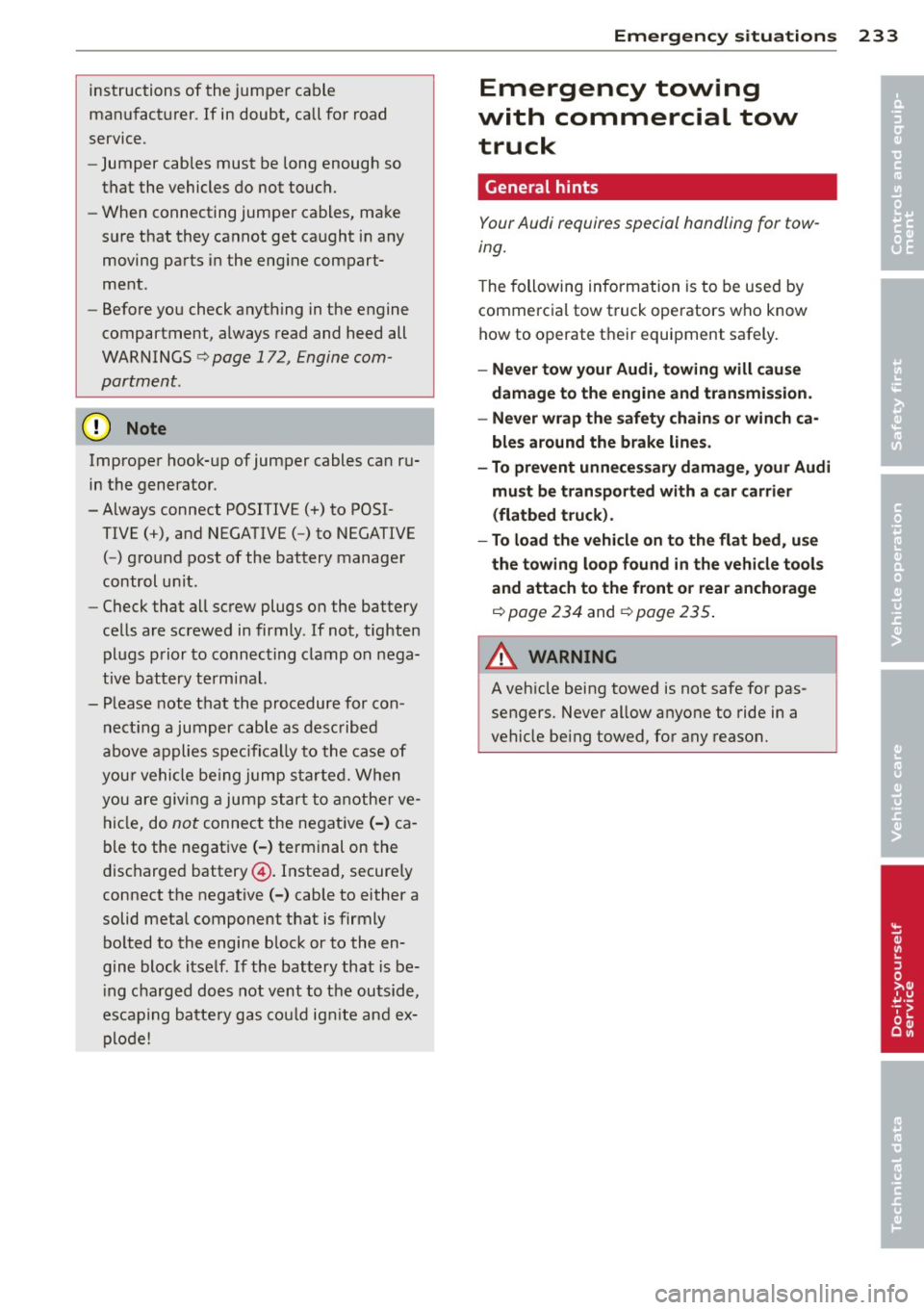

Front towing loop

Do not install the front towing loop until it is

needed.

Fig. 176 Front bumper: removing th e grill

Fig. 177 Front bumper: screwing in the tow ing loop

The towline eye fits into the threaded hole lo

cated on the r ight side of the front bumper

behind the grill .

... Remove the screwdriver and towing loop

from the vehicle toolkit

q page 218 .

... Insert the screwdriver into the slot as shown

and press toward the cente r of the vehicle

¢

fig. 176 . At the same time, pull the grill

forward and out .

.,. Screw the towing loop tight ly into the

threaded hole as far as it will go¢

fig. 177.

When it is no longer needed, unscrew the

towline eye and put it back into the on-board

too lkit. Make sure to have the towline eye

stored in the vehicle at all times.

When installing the grill for the air duct, be

sure that the tabs on the gr ill are first insert

ed into their guides on the vehicle. Then push

the grill into position .

A WARNING

-If the towing loop is not screwed in as far

as it will go, the thread can pull out when

the veh icle is towed -potent ial risk of an

accident.

Front towing loop

Applies to veh icles: w ith 265 hp engine

Only install the front towing loop when it is

needed .

Fig. 178 Right front sect ion: remov ing the air intake

grille

Fig. 179 Right front sect io n with plast ic cove r

A threaded opening with left-hand threads is

located at the front right of the bumper be·

hind the air intake grille. The towing loop is

installed in this opening .

.,. Remove the screwdriver and the towing loop

from the vehicle tool kit

q page 218.

... Reach through the air intake grille, grip the

hor izontal fins and pull it forward to re

move.

... Use the screwdriver to pry the plastic cover

off

q fig. 179.

... Install the towing loop in the threaded

opening and tighten it until it stops

q page 234, fig. 177.

Page 237 of 260

Remove the towing loop when you are done

using it and place it back in the vehicle tool

kit . A lways keep the tow ing loop in the vehi

cle.

When insta lling the air intake grille, insert the

tabs on the grille in the mounts on the vehicle

first . Then press the gri lle in to sec ure it.

A WARNING

If the towing loop is not tightened until it

stops when instal ling, the threads may be

pulled out when tow ing the ve hicle and

t hat could ca use an accident.

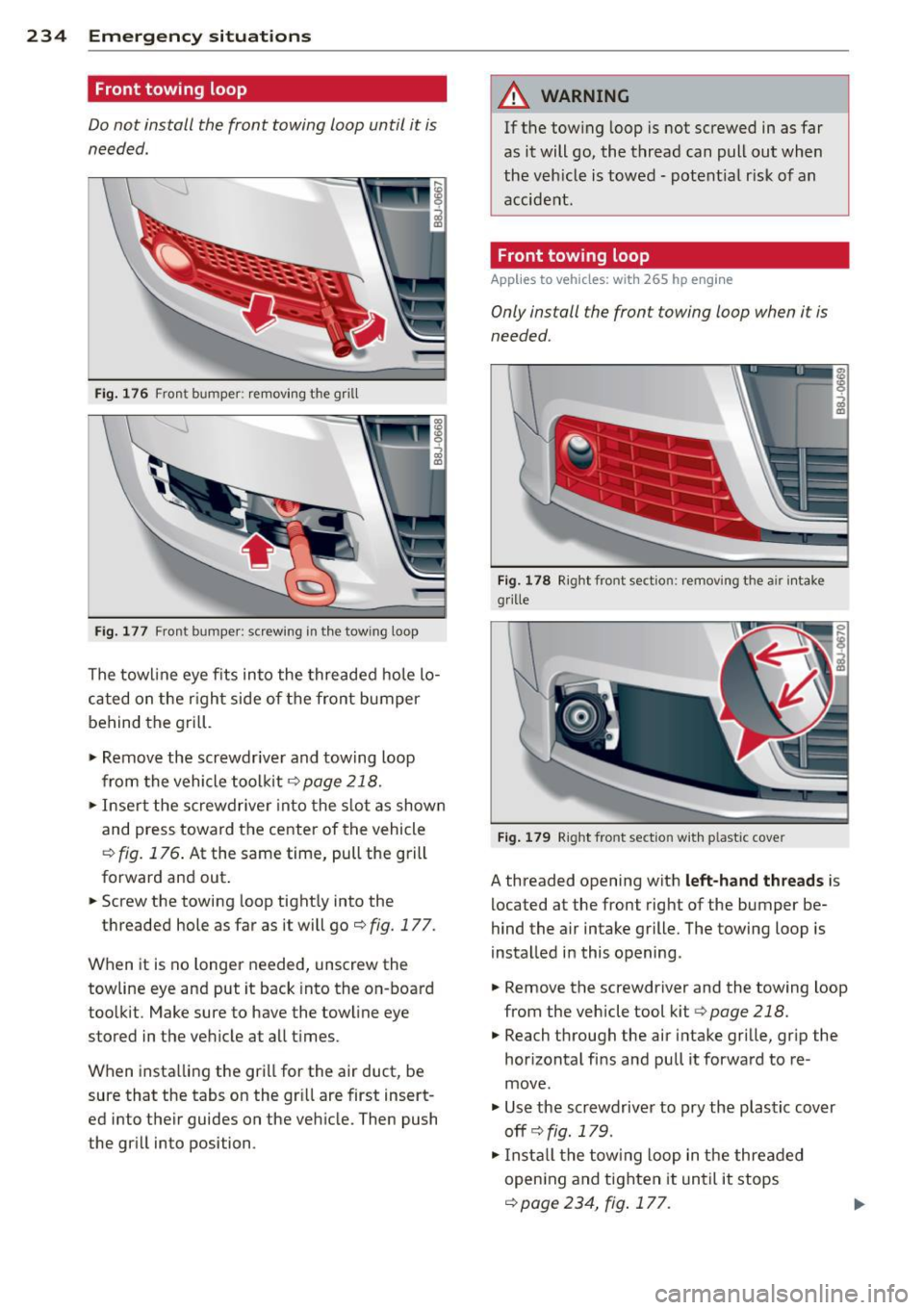

Rear towing loop

Do not install the rear towing loop until it is

needed.

Fi g. 180 Right rea r sect ion

Fi g. 18 1 Rea r bumper: screwing in t he tow in g loop

On the r ight side under the rear bumper there

i s a t hreaded hole for the tow ing loop. The

threaded hole is pro tected by a cove r.

"' Remove the towing loop from the ve hicle

toolkit

r:::;,page 218.

"'Press the right side of the cover inward

f orcefully to remove i t from the b umper.

¢fig. 180.

Emergency s itu ations 235

"' Sc rew the towing loop tightly into the

threaded ho le as far as it wi ll go.

When it is no longe r neede d, unscrew the

towing loop and put it back into the vehicle

toolk it . Be sure to have the towing loop sto red

in the vehicle at all times.

A WARNING

If t he tow ing loop is not screwed in as far

as it will go, the thread can pull out when

the vehicle is towed -potent ia l risk of an

accident.

loading the vehicle onto a flatbed truck

I

Fi g. 182 Ve hicle on flatbed truck

Front hook up

"'Align the vehicle wi th t he centerline of the

car carrier ramp.

"' Attach the winch hook to the front towline

eye prev iously insta lled.

Rear hook up

"' Alig n the vehicle wi th the center line of the

car car rier ramp .

"' Attach the winch hook to the rear tow line

eye previous ly insta lled.

(D Tips

Check caref ully to ma ke s ure the hook-up

i s secure before moving the car up the flat

bed truck ramp.

Page 238 of 260

236 Emergency situations

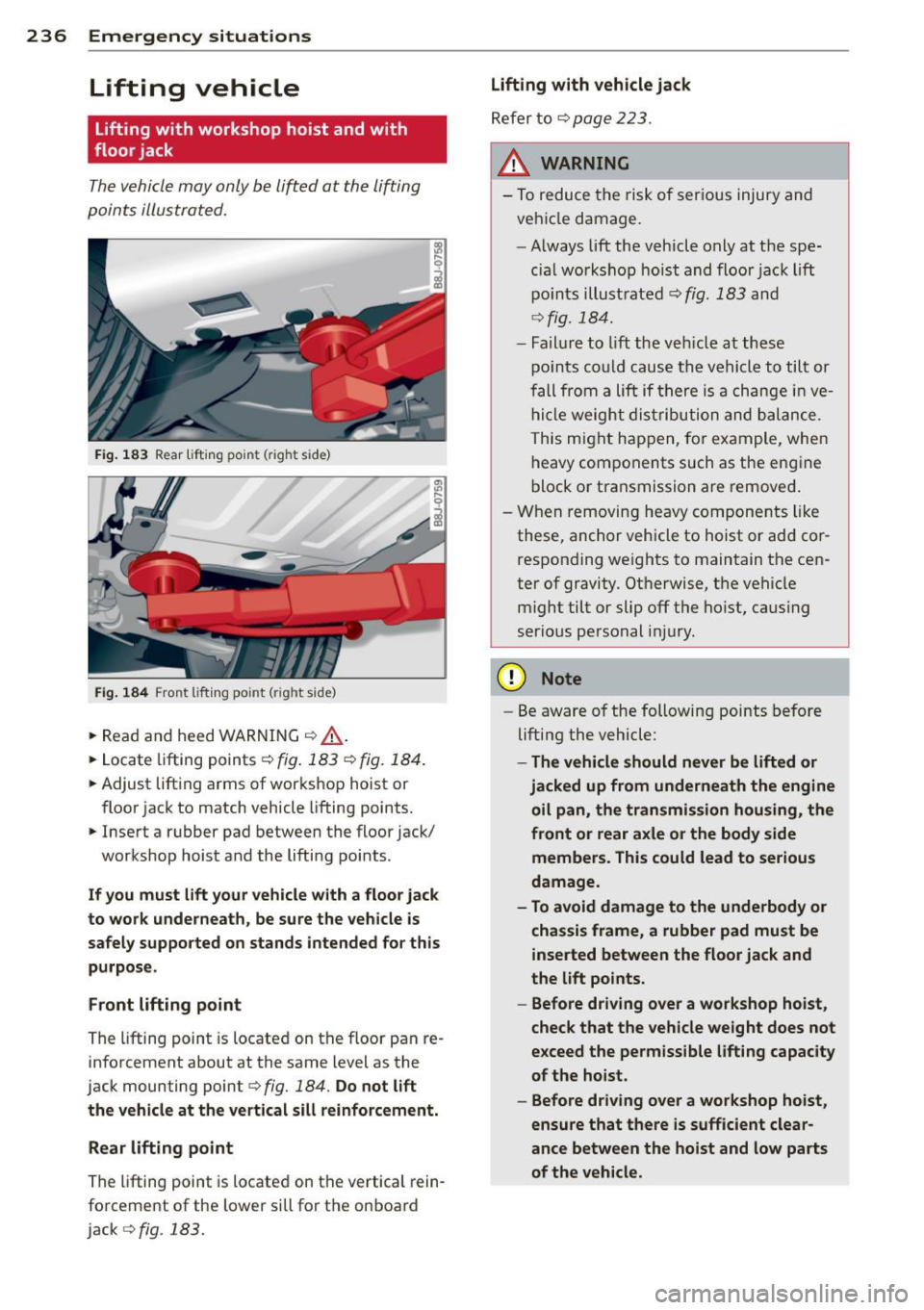

Lifting vehicle

Lifting with workshop hoist and with

floor jack

The vehicle may only be lif ted at the lifting

points illustra ted.

F ig. 18 3 Rear lift in g poin t (ri gh t side)

Fi g. 184 Front lift in g po int (r ig ht s ide)

• Read and heed WARNI NG ¢,& .

• Locate lifting points

q fig . 183 qfig . 184 .

• Adjust lift ing arms of workshop hoist or

floor jack to match vehicle lifting points.

• In se rt a rubber pad between the floor jack/

workshop hoist and the lifti ng po ints.

If you must lift your vehicle with a floor jack

to work underneath, be sure the vehicle is safely supported on stands intended for this

purpose.

Front lifting point

The lifting point is locate d on the floor pan re

info rcement about at the same level as the

jac k mounting point

q fig. 184. Do not lift

the vehicle at the vertical sill reinforcement.

Rear lifting point

The lifting point is locate d on t he vertical rein

forcement of the lower s ill for t he on boa rd

j ac k

¢fig . 183.

Lifting with vehicle jack

Refer to ¢page 223 .

/n.. WARNING

- To reduce the risk of ser io us injury and

veh icle d amage .

- Always lift th e vehicle onl y at t he spe

c ia l works ho p h oist and floor jac k lift

p o ints illust rated¢

fig . 183 and

¢fig. 184.

- Fa il u re t o lift th e veh icle at th ese

p oi nts co ul d cau se the vehicle to tilt or

f a ll from a li ft if th ere is a ch an ge i n ve

h icl e weig ht distr ibu tio n an d ba lan ce.

This mi ght happen, for ex amp le, when

h eavy com ponent s such as the engine

b lock o r transmission are remove d.

- W hen removin g heavy compone nts like

these , anch or vehicle to hoist or ad d co r

respon ding we ights to maintain t he cen

ter of gravity. Ot herwise , th e ve hicle

might tilt or slip off the ho ist, causing

serio us personal injury.

(D Note

-Be aware o f the following points before

lifting the vehicle:

- The vehicle should never be lifted or

jacked up from underneath the engine

oil pan, the transmission housing, the

front or rear axle or the body side members. This could lead to seriou s

damage .

- To avoid damage to the underbody or

chassis frame, a rubber pad must be inserted between the floor jack and

the lift points.

- Before driving over a workshop hoist ,

check that the vehicle weight does not

exceed the permissible lifting capacity

of the hoist .

- Before driving over a workshop hoist,

ensure that there is sufficient clear

ance between the hoist and low parts

of the vehicle.

-

Page 239 of 260

General information Explanation of

technical data

Some of the technical data listed in this man

ual require further explanation.

The tecical data for your vehicle are listed in

the charts starting on

c:> page 239 . This chap

ter p rovides general informa tion, notes and

restr ictions wh ich app ly to these data .

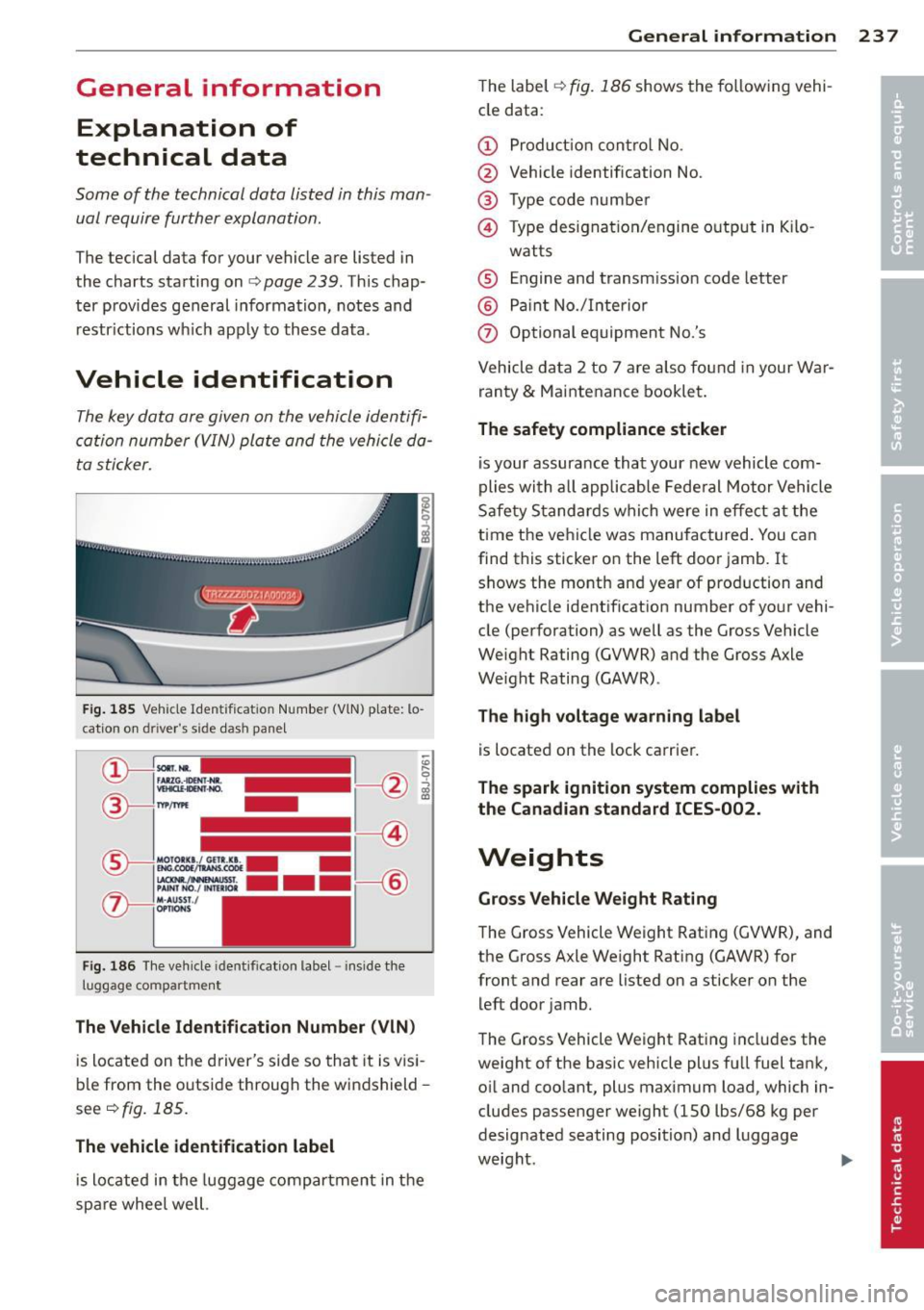

Vehicle identification

The key data are given on the vehicle identifi

ca tion number

(V IN) pla te and the vehicle da

ta sticker.

F ig. 1 85 Vehicle Ident ificat io n Num ber {V lN) p la te: lo

cation o n dr iver's s ide dash pa nel

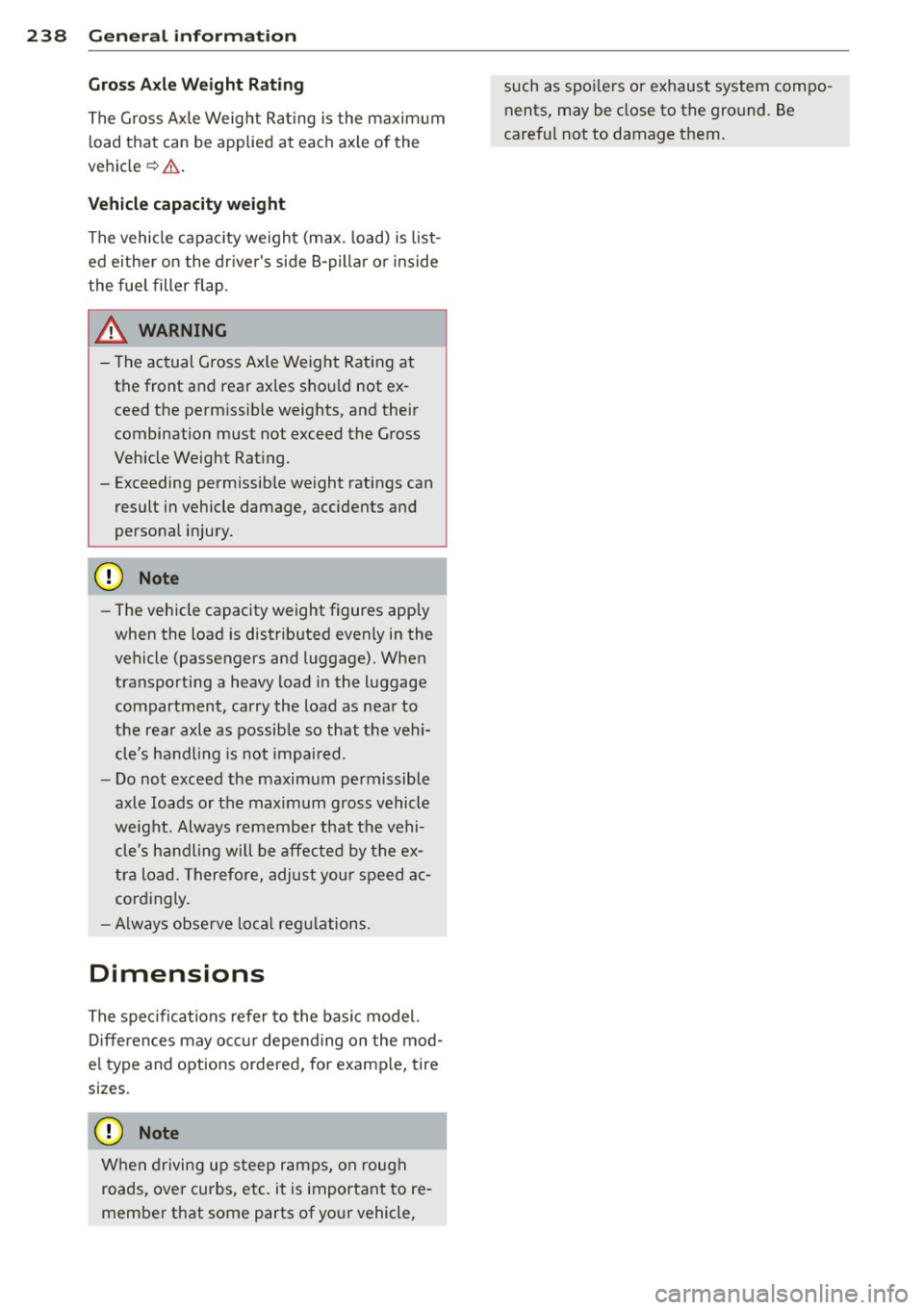

Fi g. 18 6 Th e ve hicle ident ificat ion label -inside the

l u ggage co mpartme nt

The Vehicle Identification Number (VlN)

is located on the d river's side so tha t it is v is i

b le from the outside through the windshield -

see

c!) fig. 185.

The vehicle identification label

i s located in the luggage compartment in t he

sp are wheel well.

General inform ation 23 7

The label c:> fig. 186 shows the fo llow ing vehi

cle data :

(D Productio n con trol No .

@ Vehicle identification No.

@ Type code numbe r

@ Type designat ion/en gine o utp ut in K ilo -

watts

® Engine and t ransmission code letter

® Pa in t No./Interior

(J) Optional equipment No.'s

Vehicle da ta 2 to 7 are a lso fo und in your W ar

ran ty

& Maintenance booklet .

The safety compliance sticker is your assurance that your new vehicle com

plies wi th a ll applicab le Fede ral Motor Vehicle

S afety S tandards which were in effect at the

time the ve hicl e was manufactured. You can

find this sticke r on the left door jamb. It

shows the month and yea r of prod uction and

the vehicle ident ificat ion number of yo ur vehi

cle (perforation) as well as the Gross Vehicle

Weight Rating (GVWR) and the Gross Axle

Weight Rating (GAWR) .

The high voltage warning label is located on the lock carrier.

The spark ignition system complies with

the Canadian standard ICES-002.

Weights

Gro ss Vehicle Weight Rating

The Gross Vehicle Weight Rat ing (GVWR), and

the Gross Axle Weight Rating (GAWR) for

front and rear are listed on a sticker on the left door jamb.

The Gross Vehicle Weight Rat ing includes the

weight of the bas ic vehicle plus fu ll fuel tank,

oi l and coo lant, plus maximum load, which in

cludes passenger we ight (150 lbs/68 kg per

designated seating position) and luggage

weight .

Page 240 of 260

238 Genera l inform ation

G ro ss Ax le Weight Rating

The Gross Axle Weight Rating is the maximum

l oad that can be applied at each axle of the

vehicle ~&. .

Vehicle capacity weight

The vehicle capac ity we ight (max. load) is list

ed eithe r on the dr iver's side B-pillar or inside

the fuel filler flap.

A WARNING

- The actual Gross Axle Weight Rat ing at

the front and rear axles should not ex

ceed the perm iss ible weights, and their

combination must not exceed the Gross

Vehicle Weight Rat ing .

- Exceeding permissib le we ight ratings can

result in vehicle damage, accidents and

personal injury.

@ Note

- The vehicle capacity weight figures apply

when the load is distributed evenly in the

vehicle (passengers and luggage) . When

transporting a heavy load in the luggage

compartment, carry the load as near to

the rear axle as possible so that the vehi

cle's handling is not impa ired.

- Do not exceed the maximum permissible

axle loads or the maximum gross vehicle

weight. Always remembe r that the vehi

cle's handling will be affected by the ex

tra load. Therefore, adjust your speed ac

cordingly.

- Always obse rve loca l regu lations.

Dimensions

-

The spec ifications refer to the basic model.

Differences may occ ur depending on the mod

e l type and options ordered, for examp le, tire

sizes.

(D Note

When driving up steep ramps, on rough

roads, ove r curbs, etc. it is important to re

member that some parts of your vehicle, such as spoi

le rs or exhaust system compo

nents, may be close to the ground. Be

careful not to damage them.