BMW 3 SERIES 1987 E30 Workshop Manual

Manufacturer: BMW, Model Year: 1987, Model line: 3 SERIES, Model: BMW 3 SERIES 1987 E30Pages: 228, PDF Size: 7.04 MB

Page 121 of 228

Refer to the information on page 0-7 at the

front of this manual before detaching the

cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

Bosch alternator

2Remove the voltage regulator from the back

of the alternator (see Section 16).

3Measure the length of the brushes (see

illustration). They should not be less than

6.0 mm. If any are worn past this point, renew

them all as a set. 4Also check for excessively worn slip rings

(see illustration 16.5).

5The brushes are retained either by set

screws or by solder. If you are not skilled at

soldering, it may be best to have an auto

electrician fit the new brushes. Note: Be

careful not to apply heat to the solder joint for

more than 5 seconds. If necessary, use a heat

sink to capture the excess heat. This can be

accomplished by clamping a pair of needle-

nose pliers next to the solder joint.

6On the screw type, hold the assembly in

place and refit the screws. Tighten them

evenly, a little at a time, so the holder isn’t

distorted.

7Refit the regulator assembly to the

alternator.8Reconnect the battery negative cable.

Motorola alternator

9Remove the alternator.

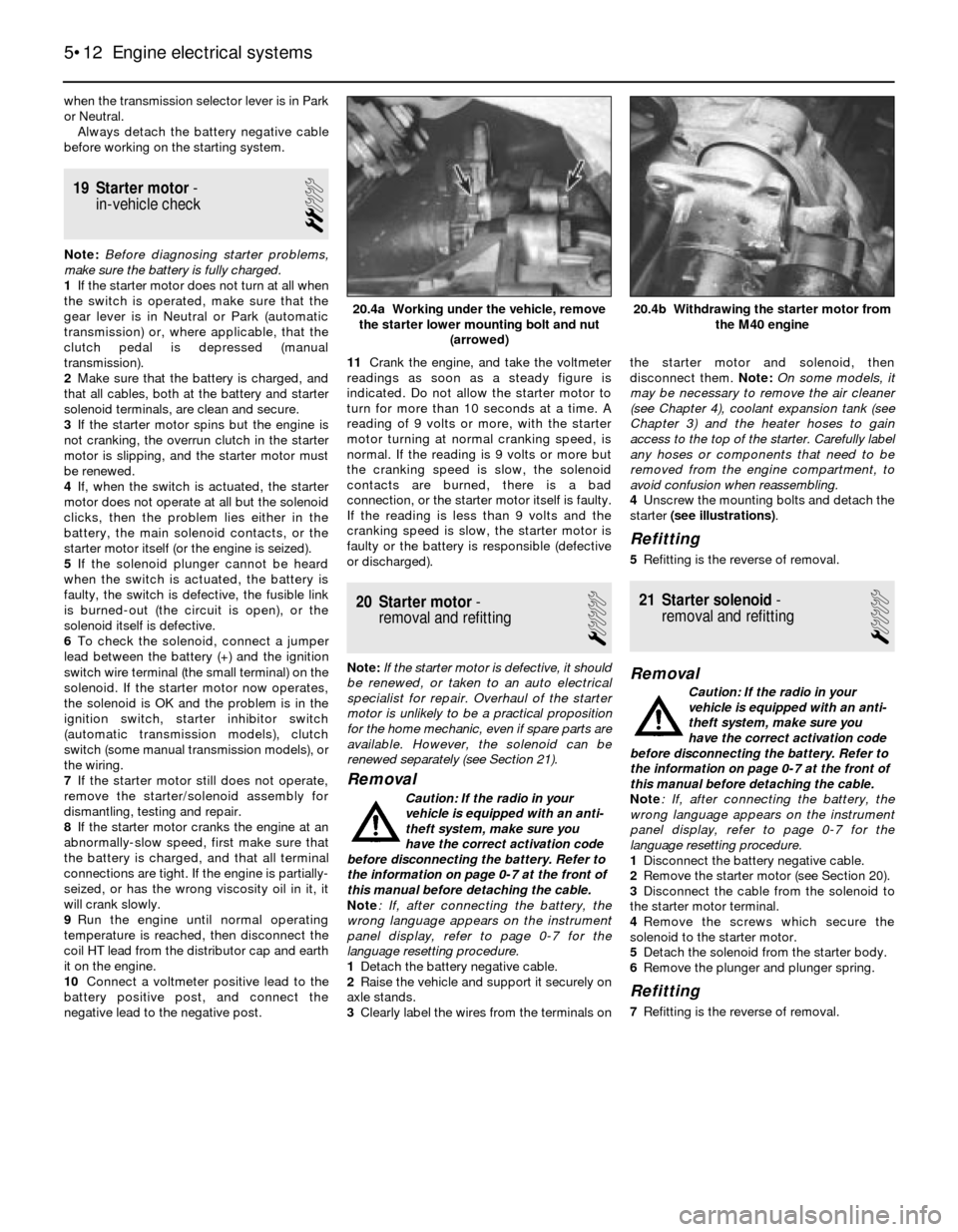

10The brushes are mounted under the

regulator on the rear of the alternator (see

illustration 16.7).

11Remove the mounting screws and

insulating washers, and separate the voltage

regulator and brush holder from the brush end

housing.

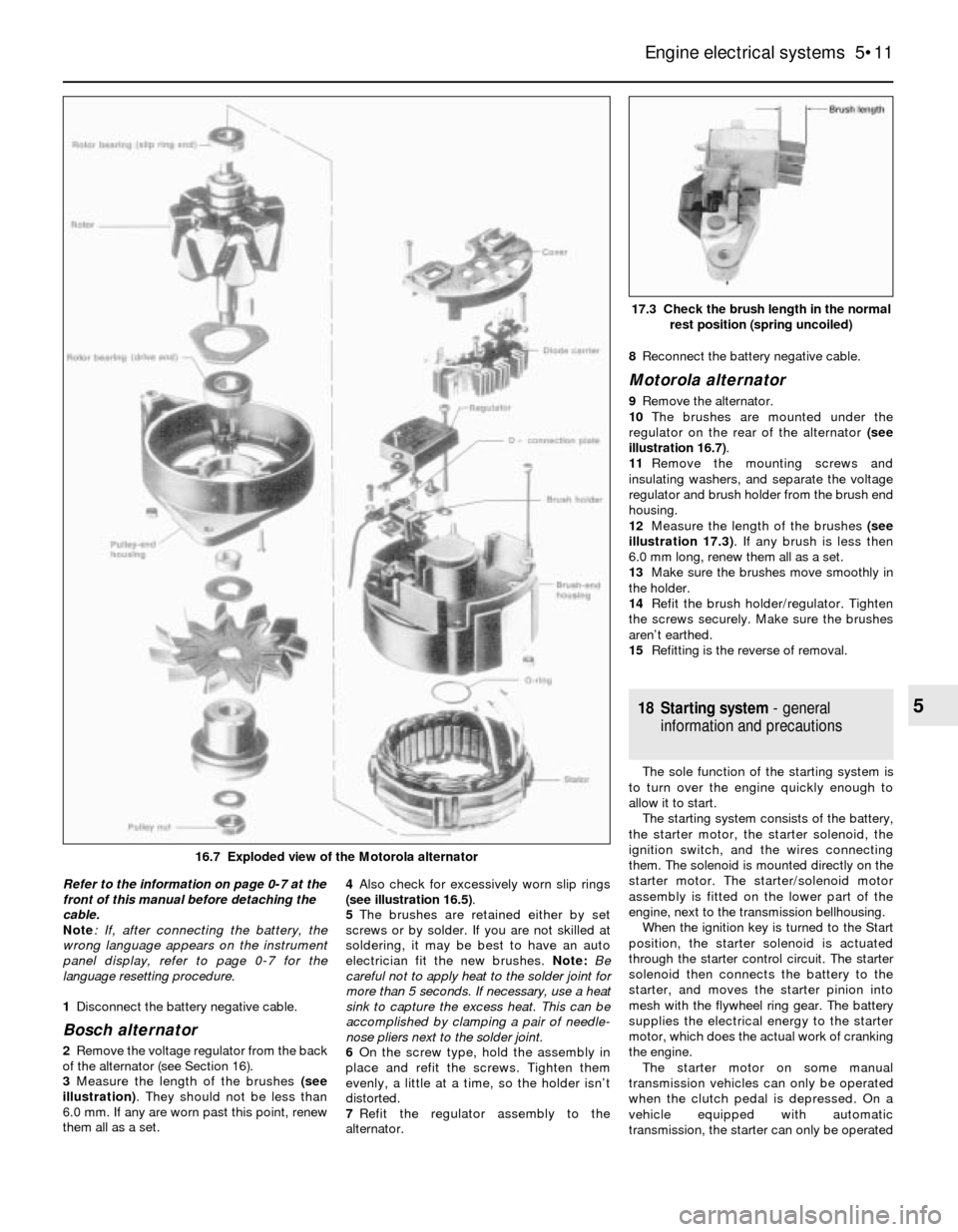

12Measure the length of the brushes (see

illustration 17.3). If any brush is less then

6.0 mm long, renew them all as a set.

13Make sure the brushes move smoothly in

the holder.

14Refit the brush holder/regulator. Tighten

the screws securely. Make sure the brushes

aren’t earthed.

15Refitting is the reverse of removal.

18 Starting system- general

information and precautions

The sole function of the starting system is

to turn over the engine quickly enough to

allow it to start.

The starting system consists of the battery,

the starter motor, the starter solenoid, the

ignition switch, and the wires connecting

them. The solenoid is mounted directly on the

starter motor. The starter/solenoid motor

assembly is fitted on the lower part of the

engine, next to the transmission bellhousing.

When the ignition key is turned to the Start

position, the starter solenoid is actuated

through the starter control circuit. The starter

solenoid then connects the battery to the

starter, and moves the starter pinion into

mesh with the flywheel ring gear. The battery

supplies the electrical energy to the starter

motor, which does the actual work of cranking

the engine.

The starter motor on some manual

transmission vehicles can only be operated

when the clutch pedal is depressed. On a

vehicle equipped with automatic

transmission, the starter can only be operated

Engine electrical systems 5•11

17.3 Check the brush length in the normal

rest position (spring uncoiled)

5

16.7 Exploded view of the Motorola alternator

Page 122 of 228

when the transmission selector lever is in Park

or Neutral.

Always detach the battery negative cable

before working on the starting system.

19 Starter motor-

in-vehicle check

2

Note:Before diagnosing starter problems,

make sure the battery is fully charged.

1If the starter motor does not turn at all when

the switch is operated, make sure that the

gear lever is in Neutral or Park (automatic

transmission) or, where applicable, that the

clutch pedal is depressed (manual

transmission).

2Make sure that the battery is charged, and

that all cables, both at the battery and starter

solenoid terminals, are clean and secure.

3If the starter motor spins but the engine is

not cranking, the overrun clutch in the starter

motor is slipping, and the starter motor must

be renewed.

4If, when the switch is actuated, the starter

motor does not operate at all but the solenoid

clicks, then the problem lies either in the

battery, the main solenoid contacts, or the

starter motor itself (or the engine is seized).

5If the solenoid plunger cannot be heard

when the switch is actuated, the battery is

faulty, the switch is defective, the fusible link

is burned-out (the circuit is open), or the

solenoid itself is defective.

6To check the solenoid, connect a jumper

lead between the battery (+) and the ignition

switch wire terminal (the small terminal) on the

solenoid. If the starter motor now operates,

the solenoid is OK and the problem is in the

ignition switch, starter inhibitor switch

(automatic transmission models), clutch

switch (some manual transmission models), or

the wiring.

7If the starter motor still does not operate,

remove the starter/solenoid assembly for

dismantling, testing and repair.

8If the starter motor cranks the engine at an

abnormally-slow speed, first make sure that

the battery is charged, and that all terminal

connections are tight. If the engine is partially-

seized, or has the wrong viscosity oil in it, it

will crank slowly.

9Run the engine until normal operating

temperature is reached, then disconnect the

coil HT lead from the distributor cap and earth

it on the engine.

10Connect a voltmeter positive lead to the

battery positive post, and connect the

negative lead to the negative post.11Crank the engine, and take the voltmeter

readings as soon as a steady figure is

indicated. Do not allow the starter motor to

turn for more than 10 seconds at a time. A

reading of 9 volts or more, with the starter

motor turning at normal cranking speed, is

normal. If the reading is 9 volts or more but

the cranking speed is slow, the solenoid

contacts are burned, there is a bad

connection, or the starter motor itself is faulty.

If the reading is less than 9 volts and the

cranking speed is slow, the starter motor is

faulty or the battery is responsible (defective

or discharged).

20 Starter motor-

removal and refitting

1

Note:If the starter motor is defective, it should

be renewed, or taken to an auto electrical

specialist for repair. Overhaul of the starter

motor is unlikely to be a practical proposition

for the home mechanic, even if spare parts are

available. However, the solenoid can be

renewed separately (see Section 21).

Removal

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Detach the battery negative cable.

2Raise the vehicle and support it securely on

axle stands.

3Clearly label the wires from the terminals onthe starter motor and solenoid, then

disconnect them. Note: On some models, it

may be necessary to remove the air cleaner

(see Chapter 4), coolant expansion tank (see

Chapter 3) and the heater hoses to gain

access to the top of the starter. Carefully label

any hoses or components that need to be

removed from the engine compartment, to

avoid confusion when reassembling.

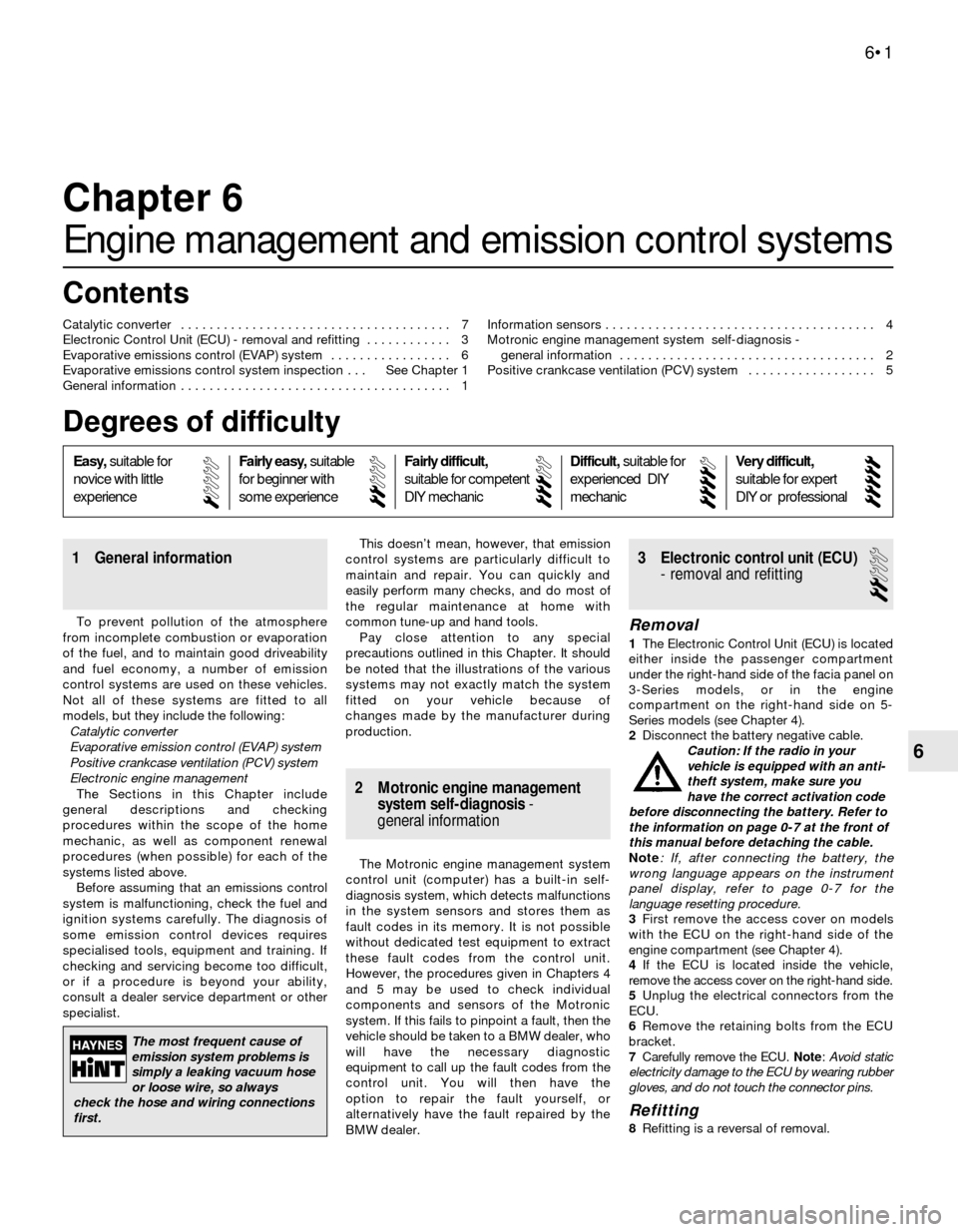

4Unscrew the mounting bolts and detach the

starter (see illustrations).

Refitting

5Refitting is the reverse of removal.

21 Starter solenoid-

removal and refitting

1

Removal

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2Remove the starter motor (see Section 20).

3Disconnect the cable from the solenoid to

the starter motor terminal.

4Remove the screws which secure the

solenoid to the starter motor.

5Detach the solenoid from the starter body.

6Remove the plunger and plunger spring.

Refitting

7Refitting is the reverse of removal.

5•12 Engine electrical systems

20.4b Withdrawing the starter motor from

the M40 engine20.4a Working under the vehicle, remove

the starter lower mounting bolt and nut

(arrowed)

Page 123 of 228

6

Chapter 6

Engine management and emission control systems

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electronic Control Unit (ECU) - removal and refitting . . . . . . . . . . . . 3

Evaporative emissions control (EVAP) system . . . . . . . . . . . . . . . . . 6

Evaporative emissions control system inspection . . . See Chapter 1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Information sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Motronic engine management system self-diagnosis -

general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Positive crankcase ventilation (PCV) system . . . . . . . . . . . . . . . . . . 5

6•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty Contents

1 General information

To prevent pollution of the atmosphere

from incomplete combustion or evaporation

of the fuel, and to maintain good driveability

and fuel economy, a number of emission

control systems are used on these vehicles.

Not all of these systems are fitted to all

models, but they include the following:

Catalytic converter

Evaporative emission control (EVAP) system

Positive crankcase ventilation (PCV) system

Electronic engine management

The Sections in this Chapter include

general descriptions and checking

procedures within the scope of the home

mechanic, as well as component renewal

procedures (when possible) for each of the

systems listed above.

Before assuming that an emissions control

system is malfunctioning, check the fuel and

ignition systems carefully. The diagnosis of

some emission control devices requires

specialised tools, equipment and training. If

checking and servicing become too difficult,

or if a procedure is beyond your ability,

consult a dealer service department or other

specialist.This doesn’t mean, however, that emission

control systems are particularly difficult to

maintain and repair. You can quickly and

easily perform many checks, and do most of

the regular maintenance at home with

common tune-up and hand tools.

Pay close attention to any special

precautions outlined in this Chapter. It should

be noted that the illustrations of the various

systems may not exactly match the system

fitted on your vehicle because of

changes made by the manufacturer during

production.

2 Motronic engine management

system self-diagnosis-

general information

The Motronic engine management system

control unit (computer) has a built-in self-

diagnosis system, which detects malfunctions

in the system sensors and stores them as

fault codes in its memory. It is not possible

without dedicated test equipment to extract

these fault codes from the control unit.

However, the procedures given in Chapters 4

and 5 may be used to check individual

components and sensors of the Motronic

system. If this fails to pinpoint a fault, then the

vehicle should be taken to a BMW dealer, who

will have the necessary diagnostic

equipment to call up the fault codes from the

control unit. You will then have the

option to repair the fault yourself, or

alternatively have the fault repaired by the

BMW dealer.

3 Electronic control unit (ECU)

- removal and refitting

2

Removal

1The Electronic Control Unit (ECU) is located

either inside the passenger compartment

under the right-hand side of the facia panel on

3-Series models, or in the engine

compartment on the right-hand side on 5-

Series models (see Chapter 4).

2Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3First remove the access cover on models

with the ECU on the right-hand side of the

engine compartment (see Chapter 4).

4If the ECU is located inside the vehicle,

remove the access cover on the right-hand side.

5Unplug the electrical connectors from the

ECU.

6Remove the retaining bolts from the ECU

bracket.

7Carefully remove the ECU. Note: Avoid static

electricity damage to the ECU by wearing rubber

gloves, and do not touch the connector pins.

Refitting

8Refitting is a reversal of removal.

The most frequent cause of

emission system problems is

simply a leaking vacuum hose

or loose wire, so always

check the hose and wiring connections

first.

Page 124 of 228

4 Information sensors

2

Note:Refer to Chapters 4 and 5 for additional

information on the location and diagnosis of

the information sensors that are not covered in

this Section.

Coolant temperature sensor

General description

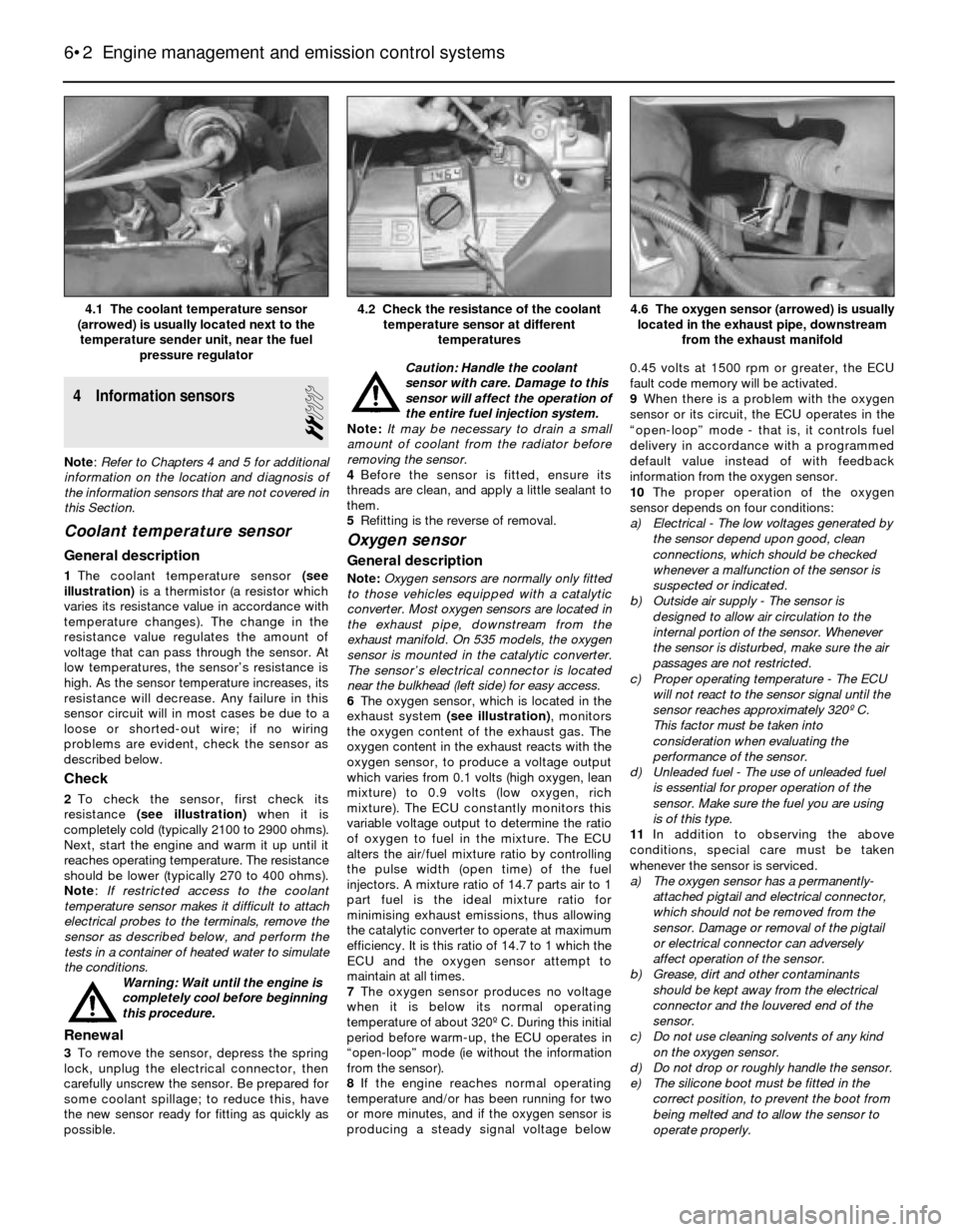

1The coolant temperature sensor (see

illustration)is a thermistor (a resistor which

varies its resistance value in accordance with

temperature changes). The change in the

resistance value regulates the amount of

voltage that can pass through the sensor. At

low temperatures, the sensor’s resistance is

high. As the sensor temperature increases, its

resistance will decrease. Any failure in this

sensor circuit will in most cases be due to a

loose or shorted-out wire; if no wiring

problems are evident, check the sensor as

described below.

Check

2To check the sensor, first check its

resistance (see illustration)when it is

completely cold (typically 2100 to 2900 ohms).

Next, start the engine and warm it up until it

reaches operating temperature. The resistance

should be lower (typically 270 to 400 ohms).

Note: If restricted access to the coolant

temperature sensor makes it difficult to attach

electrical probes to the terminals, remove the

sensor as described below, and perform the

tests in a container of heated water to simulate

the conditions.

Warning: Wait until the engine is

completely cool before beginning

this procedure.

Renewal

3To remove the sensor, depress the spring

lock, unplug the electrical connector, then

carefully unscrew the sensor. Be prepared for

some coolant spillage; to reduce this, have

the new sensor ready for fitting as quickly as

possible.Caution: Handle the coolant

sensor with care. Damage to this

sensor will affect the operation of

the entire fuel injection system.

Note: It may be necessary to drain a small

amount of coolant from the radiator before

removing the sensor.

4Before the sensor is fitted, ensure its

threads are clean, and apply a little sealant to

them.

5Refitting is the reverse of removal.

Oxygen sensor

General description

Note:Oxygen sensors are normally only fitted

to those vehicles equipped with a catalytic

converter. Most oxygen sensors are located in

the exhaust pipe, downstream from the

exhaust manifold. On 535 models, the oxygen

sensor is mounted in the catalytic converter.

The sensor’s electrical connector is located

near the bulkhead (left side) for easy access.

6The oxygen sensor, which is located in the

exhaust system (see illustration), monitors

the oxygen content of the exhaust gas. The

oxygen content in the exhaust reacts with the

oxygen sensor, to produce a voltage output

which varies from 0.1 volts (high oxygen, lean

mixture) to 0.9 volts (low oxygen, rich

mixture). The ECU constantly monitors this

variable voltage output to determine the ratio

of oxygen to fuel in the mixture. The ECU

alters the air/fuel mixture ratio by controlling

the pulse width (open time) of the fuel

injectors. A mixture ratio of 14.7 parts air to 1

part fuel is the ideal mixture ratio for

minimising exhaust emissions, thus allowing

the catalytic converter to operate at maximum

efficiency. It is this ratio of 14.7 to 1 which the

ECU and the oxygen sensor attempt to

maintain at all times.

7The oxygen sensor produces no voltage

when it is below its normal operating

temperature of about 320º C. During this initial

period before warm-up, the ECU operates in

“open-loop” mode (ie without the information

from the sensor).

8If the engine reaches normal operating

temperature and/or has been running for two

or more minutes, and if the oxygen sensor is

producing a steady signal voltage below 0.45 volts at 1500 rpm or greater, the ECU

fault code memory will be activated.

9When there is a problem with the oxygen

sensor or its circuit, the ECU operates in the

“open-loop” mode - that is, it controls fuel

delivery in accordance with a programmed

default value instead of with feedback

information from the oxygen sensor.

10The proper operation of the oxygen

sensor depends on four conditions:

a) Electrical - The low voltages generated by

the sensor depend upon good, clean

connections, which should be checked

whenever a malfunction of the sensor is

suspected or indicated.

b) Outside air supply - The sensor is

designed to allow air circulation to the

internal portion of the sensor. Whenever

the sensor is disturbed, make sure the air

passages are not restricted.

c) Proper operating temperature - The ECU

will not react to the sensor signal until the

sensor reaches approximately 320º C.

This factor must be taken into

consideration when evaluating the

performance of the sensor.

d) Unleaded fuel - The use of unleaded fuel

is essential for proper operation of the

sensor. Make sure the fuel you are using

is of this type.

11In addition to observing the above

conditions, special care must be taken

whenever the sensor is serviced.

a) The oxygen sensor has a permanently-

attached pigtail and electrical connector,

which should not be removed from the

sensor. Damage or removal of the pigtail

or electrical connector can adversely

affect operation of the sensor.

b) Grease, dirt and other contaminants

should be kept away from the electrical

connector and the louvered end of the

sensor.

c) Do not use cleaning solvents of any kind

on the oxygen sensor.

d) Do not drop or roughly handle the sensor.

e) The silicone boot must be fitted in the

correct position, to prevent the boot from

being melted and to allow the sensor to

operate properly.

6•2 Engine management and emission control systems

4.6 The oxygen sensor (arrowed) is usually

located in the exhaust pipe, downstream

from the exhaust manifold4.2 Check the resistance of the coolant

temperature sensor at different

temperatures4.1 The coolant temperature sensor

(arrowed) is usually located next to the

temperature sender unit, near the fuel

pressure regulator

Page 125 of 228

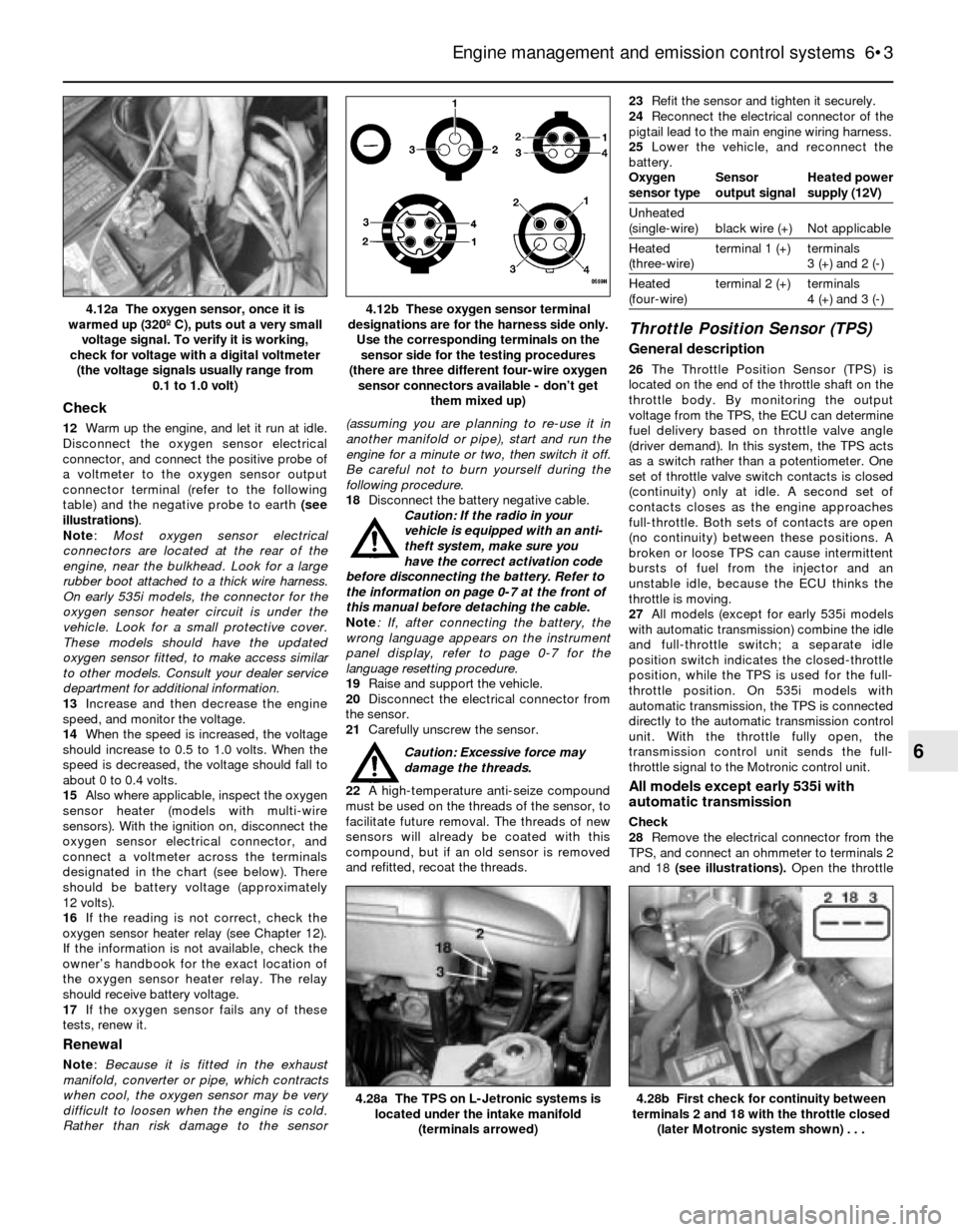

Check

12Warm up the engine, and let it run at idle.

Disconnect the oxygen sensor electrical

connector, and connect the positive probe of

a voltmeter to the oxygen sensor output

connector terminal (refer to the following

table) and the negative probe to earth (see

illustrations).

Note:Most oxygen sensor electrical

connectors are located at the rear of the

engine, near the bulkhead. Look for a large

rubber boot attached to a thick wire harness.

On early 535i models, the connector for the

oxygen sensor heater circuit is under the

vehicle. Look for a small protective cover.

These models should have the updated

oxygen sensor fitted, to make access similar

to other models. Consult your dealer service

department for additional information.

13Increase and then decrease the engine

speed, and monitor the voltage.

14When the speed is increased, the voltage

should increase to 0.5 to 1.0 volts. When the

speed is decreased, the voltage should fall to

about 0 to 0.4 volts.

15Also where applicable, inspect the oxygen

sensor heater (models with multi-wire

sensors). With the ignition on, disconnect the

oxygen sensor electrical connector, and

connect a voltmeter across the terminals

designated in the chart (see below). There

should be battery voltage (approximately

12 volts).

16If the reading is not correct, check the

oxygen sensor heater relay (see Chapter 12).

If the information is not available, check the

owner’s handbook for the exact location of

the oxygen sensor heater relay. The relay

should receive battery voltage.

17If the oxygen sensor fails any of these

tests, renew it.

Renewal

Note: Because it is fitted in the exhaust

manifold, converter or pipe, which contracts

when cool, the oxygen sensor may be very

difficult to loosen when the engine is cold.

Rather than risk damage to the sensor(assuming you are planning to re-use it in

another manifold or pipe), start and run the

engine for a minute or two, then switch it off.

Be careful not to burn yourself during the

following procedure.

18Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

19Raise and support the vehicle.

20Disconnect the electrical connector from

the sensor.

21Carefully unscrew the sensor.

Caution: Excessive force may

damage the threads.

22A high-temperature anti-seize compound

must be used on the threads of the sensor, to

facilitate future removal. The threads of new

sensors will already be coated with this

compound, but if an old sensor is removed

and refitted, recoat the threads.23Refit the sensor and tighten it securely.

24Reconnect the electrical connector of the

pigtail lead to the main engine wiring harness.

25Lower the vehicle, and reconnect the

battery.

Oxygen Sensor Heated power

sensor type output signal supply (12V)

Unheated

(single-wire) black wire (+) Not applicable

Heated terminal 1 (+) terminals

(three-wire) 3 (+) and 2 (-)

Heated terminal 2 (+) terminals

(four-wire) 4 (+) and 3 (-)

Throttle Position Sensor (TPS)

General description

26The Throttle Position Sensor (TPS) is

located on the end of the throttle shaft on the

throttle body. By monitoring the output

voltage from the TPS, the ECU can determine

fuel delivery based on throttle valve angle

(driver demand). In this system, the TPS acts

as a switch rather than a potentiometer. One

set of throttle valve switch contacts is closed

(continuity) only at idle. A second set of

contacts closes as the engine approaches

full-throttle. Both sets of contacts are open

(no continuity) between these positions. A

broken or loose TPS can cause intermittent

bursts of fuel from the injector and an

unstable idle, because the ECU thinks the

throttle is moving.

27All models (except for early 535i models

with automatic transmission) combine the idle

and full-throttle switch; a separate idle

position switch indicates the closed-throttle

position, while the TPS is used for the full-

throttle position. On 535i models with

automatic transmission, the TPS is connected

directly to the automatic transmission control

unit. With the throttle fully open, the

transmission control unit sends the full-

throttle signal to the Motronic control unit.

All models except early 535i with

automatic transmission

Check

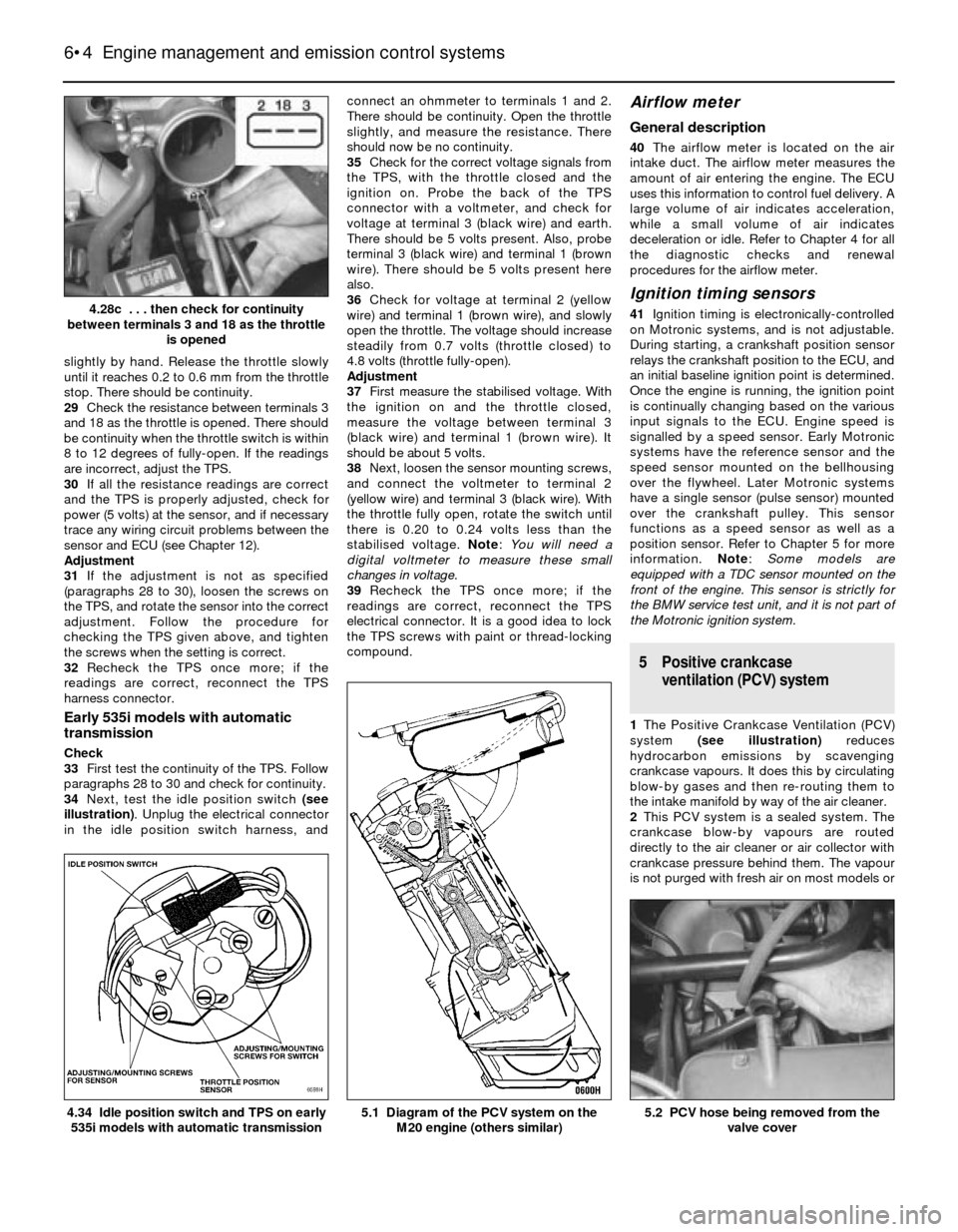

28Remove the electrical connector from the

TPS, and connect an ohmmeter to terminals 2

and 18 (see illustrations). Open the throttle

Engine management and emission control systems 6•3

4.12b These oxygen sensor terminal

designations are for the harness side only.

Use the corresponding terminals on the

sensor side for the testing procedures

(there are three different four-wire oxygen

sensor connectors available - don’t get

them mixed up)4.12a The oxygen sensor, once it is

warmed up (320º C), puts out a very small

voltage signal. To verify it is working,

check for voltage with a digital voltmeter

(the voltage signals usually range from

0.1 to 1.0 volt)

4.28b First check for continuity between

terminals 2 and 18 with the throttle closed

(later Motronic system shown) . . .4.28a The TPS on L-Jetronic systems is

located under the intake manifold

(terminals arrowed)

6

Page 126 of 228

slightly by hand. Release the throttle slowly

until it reaches 0.2 to 0.6 mm from the throttle

stop. There should be continuity.

29Check the resistance between terminals 3

and 18 as the throttle is opened. There should

be continuity when the throttle switch is within

8 to 12 degrees of fully-open. If the readings

are incorrect, adjust the TPS.

30If all the resistance readings are correct

and the TPS is properly adjusted, check for

power (5 volts) at the sensor, and if necessary

trace any wiring circuit problems between the

sensor and ECU (see Chapter 12).

Adjustment

31If the adjustment is not as specified

(paragraphs 28 to 30), loosen the screws on

the TPS, and rotate the sensor into the correct

adjustment. Follow the procedure for

checking the TPS given above, and tighten

the screws when the setting is correct.

32Recheck the TPS once more; if the

readings are correct, reconnect the TPS

harness connector.

Early 535i models with automatic

transmission

Check

33First test the continuity of the TPS. Follow

paragraphs 28 to 30 and check for continuity.

34Next, test the idle position switch (see

illustration). Unplug the electrical connector

in the idle position switch harness, andconnect an ohmmeter to terminals 1 and 2.

There should be continuity. Open the throttle

slightly, and measure the resistance. There

should now be no continuity.

35Check for the correct voltage signals from

the TPS, with the throttle closed and the

ignition on. Probe the back of the TPS

connector with a voltmeter, and check for

voltage at terminal 3 (black wire) and earth.

There should be 5 volts present. Also, probe

terminal 3 (black wire) and terminal 1 (brown

wire). There should be 5 volts present here

also.

36Check for voltage at terminal 2 (yellow

wire) and terminal 1 (brown wire), and slowly

open the throttle. The voltage should increase

steadily from 0.7 volts (throttle closed) to

4.8 volts (throttle fully-open).

Adjustment

37First measure the stabilised voltage. With

the ignition on and the throttle closed,

measure the voltage between terminal 3

(black wire) and terminal 1 (brown wire). It

should be about 5 volts.

38Next, loosen the sensor mounting screws,

and connect the voltmeter to terminal 2

(yellow wire) and terminal 3 (black wire). With

the throttle fully open, rotate the switch until

there is 0.20 to 0.24 volts less than the

stabilised voltage. Note: You will need a

digital voltmeter to measure these small

changes in voltage.

39Recheck the TPS once more; if the

readings are correct, reconnect the TPS

electrical connector. It is a good idea to lock

the TPS screws with paint or thread-locking

compound.

Airflow meter

General description

40The airflow meter is located on the air

intake duct. The airflow meter measures the

amount of air entering the engine. The ECU

uses this information to control fuel delivery. A

large volume of air indicates acceleration,

while a small volume of air indicates

deceleration or idle. Refer to Chapter 4 for all

the diagnostic checks and renewal

procedures for the airflow meter.

Ignition timing sensors

41Ignition timing is electronically-controlled

on Motronic systems, and is not adjustable.

During starting, a crankshaft position sensor

relays the crankshaft position to the ECU, and

an initial baseline ignition point is determined.

Once the engine is running, the ignition point

is continually changing based on the various

input signals to the ECU. Engine speed is

signalled by a speed sensor. Early Motronic

systems have the reference sensor and the

speed sensor mounted on the bellhousing

over the flywheel. Later Motronic systems

have a single sensor (pulse sensor) mounted

over the crankshaft pulley. This sensor

functions as a speed sensor as well as a

position sensor. Refer to Chapter 5 for more

information. Note: Some models are

equipped with a TDC sensor mounted on the

front of the engine. This sensor is strictly for

the BMW service test unit, and it is not part of

the Motronic ignition system.

5 Positive crankcase

ventilation (PCV) system

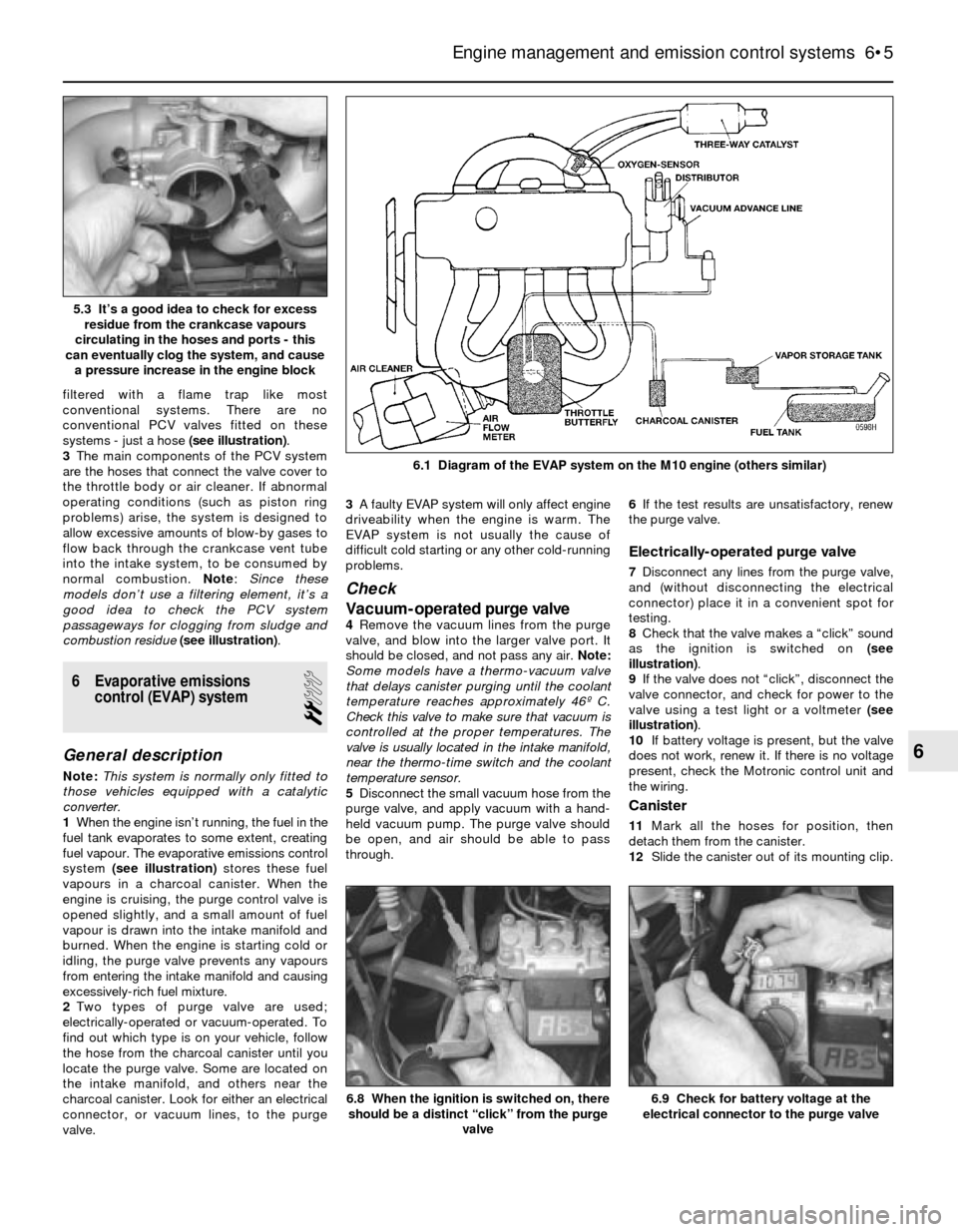

1The Positive Crankcase Ventilation (PCV)

system (see illustration)reduces

hydrocarbon emissions by scavenging

crankcase vapours. It does this by circulating

blow-by gases and then re-routing them to

the intake manifold by way of the air cleaner.

2This PCV system is a sealed system. The

crankcase blow-by vapours are routed

directly to the air cleaner or air collector with

crankcase pressure behind them. The vapour

is not purged with fresh air on most models or

6•4 Engine management and emission control systems

5.2 PCV hose being removed from the

valve cover5.1 Diagram of the PCV system on the

M20 engine (others similar)4.34 Idle position switch and TPS on early

535i models with automatic transmission

4.28c . . . then check for continuity

between terminals 3 and 18 as the throttle

is opened

Page 127 of 228

filtered with a flame trap like most

conventional systems. There are no

conventional PCV valves fitted on these

systems - just a hose (see illustration).

3The main components of the PCV system

are the hoses that connect the valve cover to

the throttle body or air cleaner. If abnormal

operating conditions (such as piston ring

problems) arise, the system is designed to

allow excessive amounts of blow-by gases to

flow back through the crankcase vent tube

into the intake system, to be consumed by

normal combustion. Note: Since these

models don’t use a filtering element, it’s a

good idea to check the PCV system

passageways for clogging from sludge and

combustion residue(see illustration).

6 Evaporative emissions

control (EVAP) system

2

General description

Note:This system is normally only fitted to

those vehicles equipped with a catalytic

converter.

1When the engine isn’t running, the fuel in the

fuel tank evaporates to some extent, creating

fuel vapour. The evaporative emissions control

system (see illustration)stores these fuel

vapours in a charcoal canister. When the

engine is cruising, the purge control valve is

opened slightly, and a small amount of fuel

vapour is drawn into the intake manifold and

burned. When the engine is starting cold or

idling, the purge valve prevents any vapours

from entering the intake manifold and causing

excessively-rich fuel mixture.

2Two types of purge valve are used;

electrically-operated or vacuum-operated. To

find out which type is on your vehicle, follow

the hose from the charcoal canister until you

locate the purge valve. Some are located on

the intake manifold, and others near the

charcoal canister. Look for either an electrical

connector, or vacuum lines, to the purge

valve.3A faulty EVAP system will only affect engine

driveability when the engine is warm. The

EVAP system is not usually the cause of

difficult cold starting or any other cold-running

problems.

Check

Vacuum-operated purge valve

4Remove the vacuum lines from the purge

valve, and blow into the larger valve port. It

should be closed, and not pass any air. Note:

Some models have a thermo-vacuum valve

that delays canister purging until the coolant

temperature reaches approximately 46º C.

Check this valve to make sure that vacuum is

controlled at the proper temperatures. The

valve is usually located in the intake manifold,

near the thermo-time switch and the coolant

temperature sensor.

5Disconnect the small vacuum hose from the

purge valve, and apply vacuum with a hand-

held vacuum pump. The purge valve should

be open, and air should be able to pass

through.6If the test results are unsatisfactory, renew

the purge valve.

Electrically-operated purge valve

7Disconnect any lines from the purge valve,

and (without disconnecting the electrical

connector) place it in a convenient spot for

testing.

8Check that the valve makes a “click” sound

as the ignition is switched on (see

illustration).

9If the valve does not “click”, disconnect the

valve connector, and check for power to the

valve using a test light or a voltmeter (see

illustration).

10If battery voltage is present, but the valve

does not work, renew it. If there is no voltage

present, check the Motronic control unit and

the wiring.

Canister

11Mark all the hoses for position, then

detach them from the canister.

12Slide the canister out of its mounting clip.

Engine management and emission control systems 6•5

6.1 Diagram of the EVAP system on the M10 engine (others similar)

6.9 Check for battery voltage at the

electrical connector to the purge valve6.8 When the ignition is switched on, there

should be a distinct “click” from the purge

valve

6

5.3 It’s a good idea to check for excess

residue from the crankcase vapours

circulating in the hoses and ports - this

can eventually clog the system, and cause

a pressure increase in the engine block

Page 128 of 228

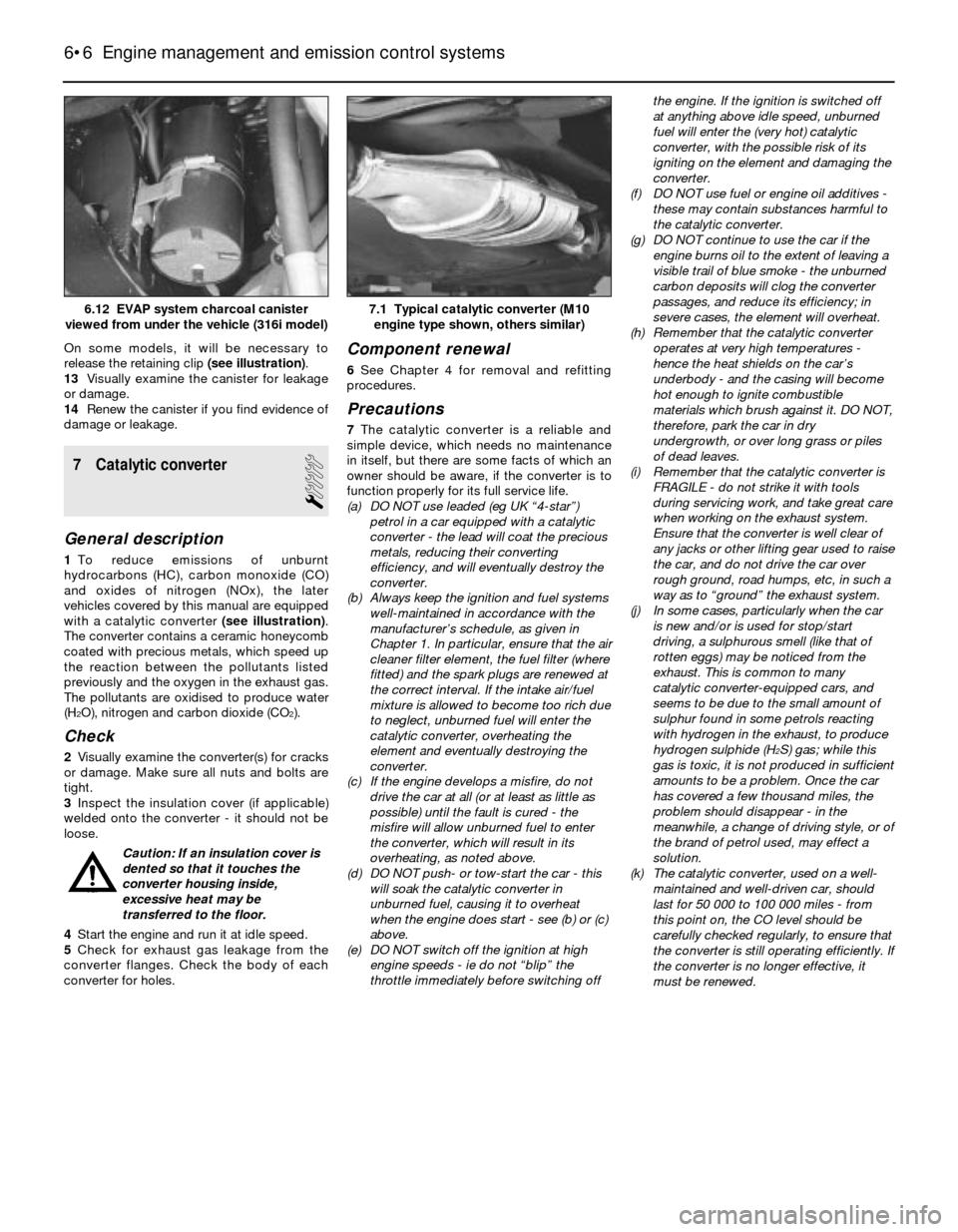

On some models, it will be necessary to

release the retaining clip (see illustration).

13Visually examine the canister for leakage

or damage.

14Renew the canister if you find evidence of

damage or leakage.

7 Catalytic converter

1

General description

1To reduce emissions of unburnt

hydrocarbons (HC), carbon monoxide (CO)

and oxides of nitrogen (NOx), the later

vehicles covered by this manual are equipped

with a catalytic converter (see illustration).

The converter contains a ceramic honeycomb

coated with precious metals, which speed up

the reaction between the pollutants listed

previously and the oxygen in the exhaust gas.

The pollutants are oxidised to produce water

(H

2O), nitrogen and carbon dioxide (CO2).

Check

2Visually examine the converter(s) for cracks

or damage. Make sure all nuts and bolts are

tight.

3Inspect the insulation cover (if applicable)

welded onto the converter - it should not be

loose.

Caution: If an insulation cover is

dented so that it touches the

converter housing inside,

excessive heat may be

transferred to the floor.

4Start the engine and run it at idle speed.

5Check for exhaust gas leakage from the

converter flanges. Check the body of each

converter for holes.

Component renewal

6See Chapter 4 for removal and refitting

procedures.

Precautions

7The catalytic converter is a reliable and

simple device, which needs no maintenance

in itself, but there are some facts of which an

owner should be aware, if the converter is to

function properly for its full service life.

(a) DO NOT use leaded (eg UK “4-star”)

petrol in a car equipped with a catalytic

converter - the lead will coat the precious

metals, reducing their converting

efficiency, and will eventually destroy the

converter.

(b) Always keep the ignition and fuel systems

well-maintained in accordance with the

manufacturer’s schedule, as given in

Chapter 1. In particular, ensure that the air

cleaner filter element, the fuel filter (where

fitted) and the spark plugs are renewed at

the correct interval. If the intake air/fuel

mixture is allowed to become too rich due

to neglect, unburned fuel will enter the

catalytic converter, overheating the

element and eventually destroying the

converter.

(c) If the engine develops a misfire, do not

drive the car at all (or at least as little as

possible) until the fault is cured - the

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above.

(d) DO NOT push- or tow-start the car - this

will soak the catalytic converter in

unburned fuel, causing it to overheat

when the engine does start - see (b) or (c)

above.

(e) DO NOT switch off the ignition at high

engine speeds - ie do not “blip” the

throttle immediately before switching offthe engine. If the ignition is switched off

at anything above idle speed, unburned

fuel will enter the (very hot) catalytic

converter, with the possible risk of its

igniting on the element and damaging the

converter.

(f) DO NOT use fuel or engine oil additives -

these may contain substances harmful to

the catalytic converter.

(g) DO NOT continue to use the car if the

engine burns oil to the extent of leaving a

visible trail of blue smoke - the unburned

carbon deposits will clog the converter

passages, and reduce its efficiency; in

severe cases, the element will overheat.

(h) Remember that the catalytic converter

operates at very high temperatures -

hence the heat shields on the car’s

underbody - and the casing will become

hot enough to ignite combustible

materials which brush against it. DO NOT,

therefore, park the car in dry

undergrowth, or over long grass or piles

of dead leaves.

(i) Remember that the catalytic converter is

FRAGILE - do not strike it with tools

during servicing work, and take great care

when working on the exhaust system.

Ensure that the converter is well clear of

any jacks or other lifting gear used to raise

the car, and do not drive the car over

rough ground, road humps, etc, in such a

way as to “ground” the exhaust system.

(j) In some cases, particularly when the car

is new and/or is used for stop/start

driving, a sulphurous smell (like that of

rotten eggs) may be noticed from the

exhaust. This is common to many

catalytic converter-equipped cars, and

seems to be due to the small amount of

sulphur found in some petrols reacting

with hydrogen in the exhaust, to produce

hydrogen sulphide (H

2S) gas; while this

gas is toxic, it is not produced in sufficient

amounts to be a problem. Once the car

has covered a few thousand miles, the

problem should disappear - in the

meanwhile, a change of driving style, or of

the brand of petrol used, may effect a

solution.

(k) The catalytic converter, used on a well-

maintained and well-driven car, should

last for 50 000 to 100 000 miles - from

this point on, the CO level should be

carefully checked regularly, to ensure that

the converter is still operating efficiently. If

the converter is no longer effective, it

must be renewed.

6•6 Engine management and emission control systems

7.1 Typical catalytic converter (M10

engine type shown, others similar)6.12 EVAP system charcoal canister

viewed from under the vehicle (316i model)

Page 129 of 228

9

General

Brake fluid type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Disc brakes

Minimum brake pad thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake disc minimum permissible thickness (wear limit)*

Front

3-Series

Solid discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.7 mm

Ventilated discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.0 mm

5-Series

Solid discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 mm

Ventilated discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.0 mm

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 mm

Brake disc minimum thickness after machining

Front

3-Series

Solid discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.1 mm

Ventilated discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.4 mm

5-Series

Solid discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.4 mm

Ventilated discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.4 mm

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.4 mm

Parallelism (difference between any two measurements) . . . . . . . . . . . 0.02 mm

Maximum disc run-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 mm

*Refer to marks cast into the disc (they supersede information printed here)

Brake pedal adjustments

Brake pedal/servo pushrod adjustment (A) (3-Series) . . . . . . . . . . . . . . 125 mm

Brake pedal height (pedal-to-bulkhead distance)

3-Series

Left-hand-drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235 mm

Right-hand-drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273 mm

5-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245 mm

Stop-light switch adjustment (dimension A - see text) . . . . . . . . . . . . . . 5.0 mm to 6.0 mm

Handbrake

Handbrake shoe lining minimum thickness . . . . . . . . . . . . . . . . . . . . . . 1.5 mm

Handbrake lever travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 to 8 clicks

Chapter 9 Braking system

Anti-lock brake system (ABS) - general information . . . . . . . . . . . . . 2

Brake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake disc - inspection, removal and refitting . . . . . . . . . . . . . . . . . 5

Brake fluid level check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake hoses and lines - inspection and renewal . . . . . . . . . . . . . . . . 15

Brake hydraulic system - bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Brake pedal - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Brake vacuum servo - check, removal and refitting . . . . . . . . . . . . . 8

Disc brake caliper - removal, overhaul and refitting . . . . . . . . . . . . . 4Disc brake pads - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drum brake shoes - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Handbrake assembly - check, removal and refitting . . . . . . . . . . . . 12

Handbrake - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Handbrake cable(s) - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hydraulic brake servo - description, removal and refitting . . . . . . . . 9

Master cylinder - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 7

Stop-light switch - check and adjustment . . . . . . . . . . . . . . . . . . . . 14

9•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 130 of 228

Torque wrench settingsNm

Front disc brake caliper

Caliper guide (mounting) bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 35

Caliper bracket-to-strut housing bolts

3-Series, E30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5-Series, E34 (“new-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Rear disc brake caliper

Caliper guide (mounting) bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 35

Carrier-to-trailing arm bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Brake hose-to-caliper fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 to 17

Master cylinder-to-brake servo nuts

3-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 29

Brake servo mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 24

Hydraulic line-to-hydraulic brake servo threaded

fittings - 5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

9•2 Braking system

1 General information

All 3-Series models, and 5-Series E28 (“old-

shape”) models, are equipped with front disc

brakes and either rear drum or rear disc

brakes. 5-Series E34 (“new-shape”) models

have disc brakes front and rear. Front and

rear brakes are self-adjusting on all models.

Some later models are equipped with an Anti-

lock Braking System (ABS); this is described

in Section 2.

Hydraulic system

The hydraulic system consists of two

separate circuits. The master cylinder has

separate reservoirs for the two circuits; in the

event of a leak or failure in one hydraulic

circuit, the other circuit will remain operative.

Brake servo

The vacuum brake servo, utilising engine

manifold vacuum and atmospheric pressure

to provide assistance to the hydraulically

operated brakes, is mounted on the bulkhead

in the engine compartment.

A hydraulic brake servo system is used on

5-Series E28 models. This system uses

hydraulic pressure from the power steering

pump to assist braking.

Handbrake

The handbrake operates the rear brakes,

and is cable-operated via a lever mounted in

the centre console. The handbrake assembly

on rear drum brake models is part of the rear

drum brake assembly, and is self-adjusting.

On rear disc brake models, the handbrake

uses a pair of brake shoes located inside the

centre portion of the rear brake disc, and is

manually-adjusted.

Brake pad wear warning system

The brake pad wear warning system is

linked to a red warning light in the instrumentcluster, which comes on when the brake pads

have worn down to the point at which they

require renewal. DO NOT ignore this reminder.

If you don’t renew the pads shortly after the

brake pad wear warning light comes on, the

brake discs will be damaged.

On some models, the brake pad wear

warning system also includes an early

warning light that comes on only when the

brake pedal is depressed, letting you know in

advance that the pads need to be renewed.

The wear sensor is attached to the brake

pads. The sensor is located at the left front

wheel; on some models, there is another

sensor at the right rear wheel. The wear

sensor is part of a closed circuit. Once the

pads wear down to the point at which they’re

flush with the sensor, the disc grinds away the

side of the sensor facing the disc. Thus, the

wire inside the sensor is broken, and the red

light on the instrument panel comes on.

Always check the sensor(s) when renewing

the pads. If you change the pads before the

warning light comes on, the sensor(s) may still

be good; once the light has come on, renew

the sensor.

Service

After completing any operation involving

dismantling of any part of the brake system,

always test drive the vehicle to check for

proper braking performance before resuming

normal driving. When testing the brakes, try to

select a clean, dry, road with no camber (ie as

flat as possible) and with no other traffic.

Conditions other than these can lead to

inaccurate test results.

Test the brakes at various speeds with both

light and heavy pedal pressure. The vehicle

should stop evenly, without pulling to one side

or the other. Avoid locking the brakes,

because this slides the tyres and diminishes

braking efficiency and control of the vehicle.

Tyres, vehicle load and wheel alignment are

factors which also affect braking

performance.

2 Anti-lock Braking system

(ABS)- general information

The Anti-lock Braking System is designed

to maintain vehicle control, directional stability

and optimum deceleration under severe

braking conditions on most road surfaces. It

does so by monitoring the rotational speed of

each wheel and controlling the brake line

pressure to each wheel during braking. This

prevents the wheels from locking up.

The ABS system has three main

components - the wheel speed sensors, the

electronic control unit, and the hydraulic

control unit. The sensors - one at each wheel

since 1985, but at both front wheels and one

at the rear differential on earlier models - send

a variable voltage signal to the control unit,

which monitors these signals, compares them

to its program information, and determines

whether a wheel is about to lock up. When a

wheel is about to lock up, the control unit

signals the hydraulic unit to reduce hydraulic

pressure (or not increase it further) at that

wheel’s brake caliper. Pressure modulation is

handled by electrically-operated solenoid

valves.

If a problem develops within the system, an

“ABS” warning light will glow on the

dashboard. Sometimes, a visual inspection of

the ABS system can help you locate the

problem. Carefully inspect the ABS wiring

harness. Pay particularly close attention to the

harness and connections near each wheel.

Look for signs of chafing and other damage

caused by incorrectly-routed wires. If a wheel

sensor harness is damaged, the sensor

should be renewed (the harness and sensor

are integral).

Warning: DO NOT try to repair an

ABS wiring harness. The ABS

system is sensitive to even the

smallest changes in resistance. Repairing

the harness could alter resistance values