Iat BMW 325i 1993 E36 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1993, Model line: 325i, Model: BMW 325i 1993 E36Pages: 759

Page 214 of 759

200-2

TRANSMISSION-GENERAL

Transmission

ID

Codes

On

both

manual

and

automatic

transmissions,

the

code

let-

ter

and

transmission

type

numbers

should

be

located

onan

ID

plate

attached

to

the

síde

of

thetransmission

.

Do

not

rely

on

numbers

cast

on

the

transmission

case

for

identification

.

In

addition,

thetransmission

lubricant

varies

between

trans-

missions

and

model

years

.

Fluid

application

information

should

be

clearly

marked

on

a

label

on

thetransmission

.

On

manual

transmissions,

either

ATF

(orange

label

reads

ATF-Oil!)

or

a

special

BMW

lubricant

(yellow

label

reads

MTF-

LT

1)

are

used

.

See

230Manual

Transmission

.

Automatic

transmissions

are

filled

with

either

Dexron

III

ATF

(black

trans

.

type

plate

reads

ATF-Oil!),

a

special

ffe-

time

oil

(green

trans

.

type

plate

reading

Life-Time

ó1)

.

See

240AutomaticTransmission

.

GENERAL

CAUTION-

lf

in

doubtas

to

the

typeof

fluid

installed

in

a

par-

ticular

transmission,

consult

and

authorized

BMW

dealer

service

department

for

the

latest

in

operat-

ing

fluids

.

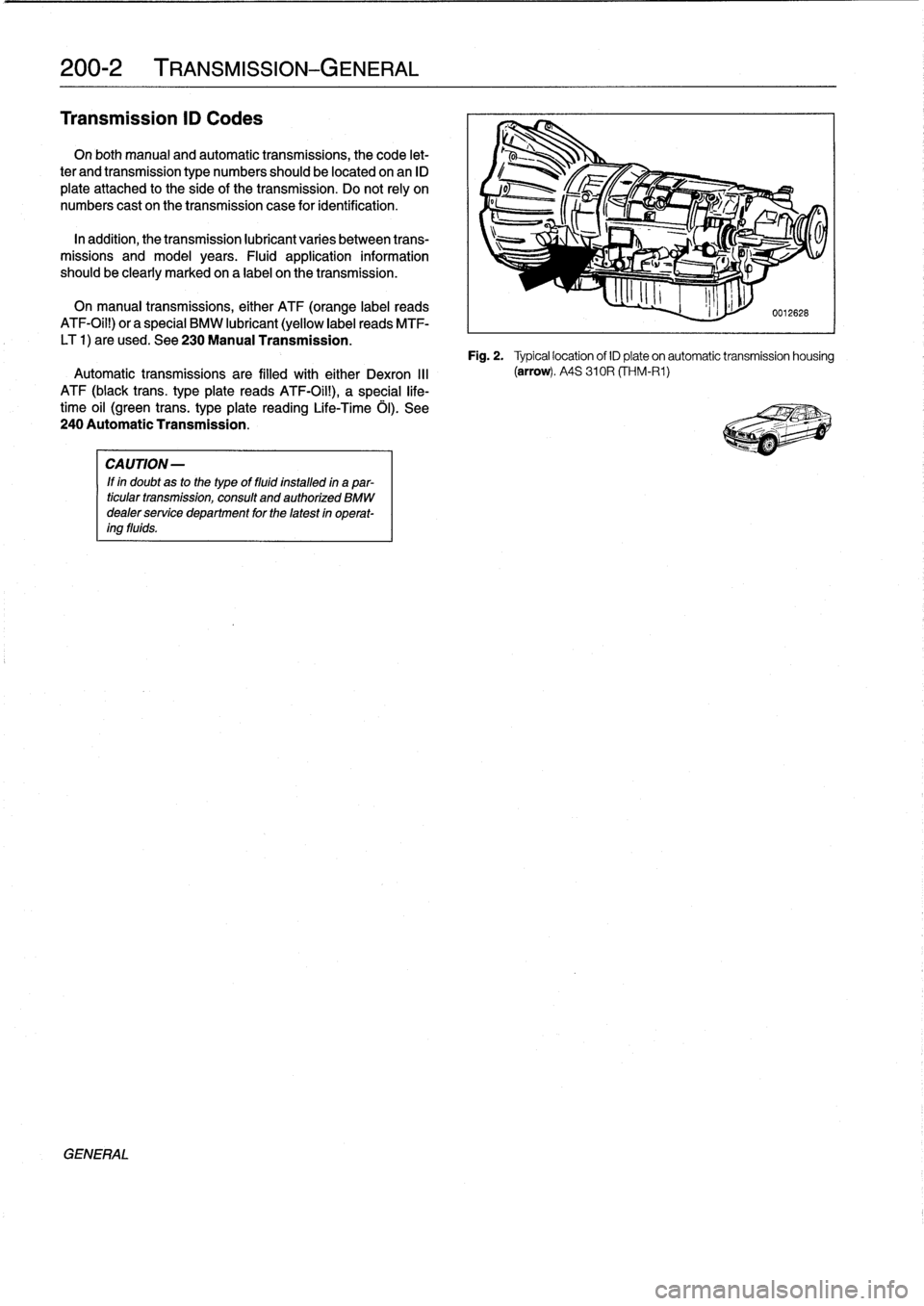

Fig

.

2

.

Typical

location

of

IDpíate

on

automatic

transmission

housing

(arrow)

.

A4S

310R

(THM-R1)

Page 216 of 759

210-2

CLUTCH

Clutch

hydraulic

system,

bleeding

and

flushing

If

the

clutch/brake

fluid

is

murky

or

muddy,

or

has

not

been

changed

within

the

last

two

years,

the

system

should

be

flushed

.

Flushing

the

old

fluid

from

the

clutch

lines

is

done

us-

ing

a

brake

system

pressure

bleeder

.

1

.

Remove

brake

fluíd

reservoir

cap

.

Usinga

clean

sy-

ringe,

remove

brake

fluid

from

reservoir

.

Refill

reservoir

with

clean

fluid

.

2

.

Attach

pressure

brake

bleeder

to

fluid

reservoír

.

CA

UTION-

Do

not

exceed

2

bar

(29

psi)

pressure

at

the

fluid

reservoir

when

bleeding

or

flushing

the

hydraulic

system

.

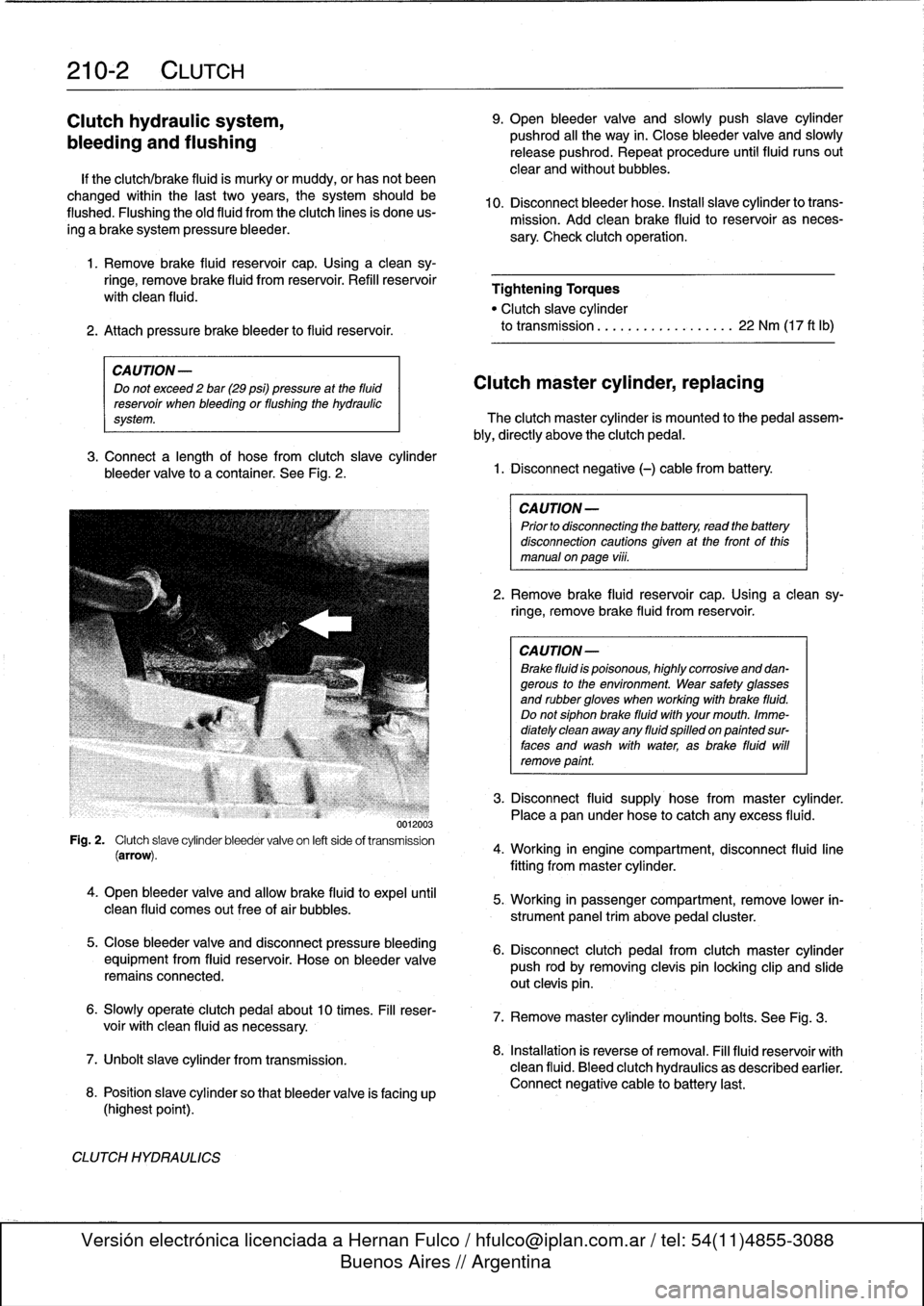

3

.

Connect

a

length

of

hose

from

clutch

slave

cylinder

bleeder

valve

lo

a

container

.

See

Fig

.

2

.

0012003

Fig

.

2

.

Clutch

slave

cylinder

bleeder

valve

on

left

side

of

transmission

(arrow)

.

4

.

Open

bleeder

valve

and

allow

brake

fluid

to

expel

until

clean

fluid

comes

out

free

of

air

bubbles

.

5

.

Close

bleeder

valve

and

disconnect

pressure

bleeding

equipment

from

fluid

reservoir

.

Hose

on

bleeder

valve

remainsconnected

.

6

.

Slowly

operate

clutch

pedal

about10

times

.

Fill

reser-

voir

with

clean

fluid

asnecessary

.

7

.

Unbolt

slavecylinder

from

transmission

.

8

.

Position

slave

cylinder

so

that

bleeder

valve

is

facing

up

(highest

point)

.

CLUTCH

HYDRAULICS

9

.

Open

bleeder

valve

and

slowly

push

slave

cylinder

pushrod

al¡

the

way

in

.

Close

bleeder

valve

and

slowly

release

pushrod

.

Repeat

procedure

until

fluid

runs

out

clear

and

without

bubbles

.

10

.

Disconnect

bleeder

hose

.

Instan

slavecylinder

lo

trans-

mission

.

Add

cleanbrake

fluid

to

reservoir

as

neces-

sary

.

Check

clutch

operation

.

Tightening

Torques

"

Clutch

slave

cylinder

to

transmission

................

..

22

Nm

(17

ft

lb)

Clutch

master

cylinder,

replacing

The

clutch

master

cylinder

is

mounted

to

the

pedal

assem-

bly,

directly

above

the

clutch

pedal

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

on

page

viii

.

2

.

Remove

brake

fluid

reservoir

cap

.

Usinga

clean

sy-

ringe,

remove

brake

fluid

from

reservoir

.

CA

UTION-

Brake

fluid

is

poisonous,

highly

corrosive

and

dan-gerous

to

the

environment

.

Wear

safety

glasses

and

rubbergloves

when

working

with

brake

fluid

.

Do

notsiphonbrake

fluid

with

your

mouth

.

Imme-

diately

clean

away

any

fluid

spilled

on

painted

sur-

faces

and

wash

with

water,

asbrake

fluid

will

remove

point

.

3

.

Disconnect

fluid

supply

hose

from

master

cylinder

.

Placea

pan

under

hose

to

catch

any

excess

fluid

.

4

.

Working

in

engine

compartment,

disconnect

fluid

line

fitting

frommaster

cylinder

.

5

.

Working

in

passenger

compartment,

remove

lower

in-

strument

panel

trim

above

pedal

cluster

.

6

.

Disconnect

clutch

pedal

from

clutch

master

cylinder

push

rod

by

removing

clevis

pin

locking

clip

and

slide

out

clevis

pin

.

7

.

Remove

master

cylinder

mounting

bolts

.

See

Fig

.

3

.

8

.

Installation

is

reverse

of

removal

.

Fill

fluid

reservoir

with

clean

fluid

.

Bleed

clutch

hydraulics

as

described

earlier

.

Connect

negative

cable

to

battery

last

.

Page 220 of 759

210-

6

CLUTCH

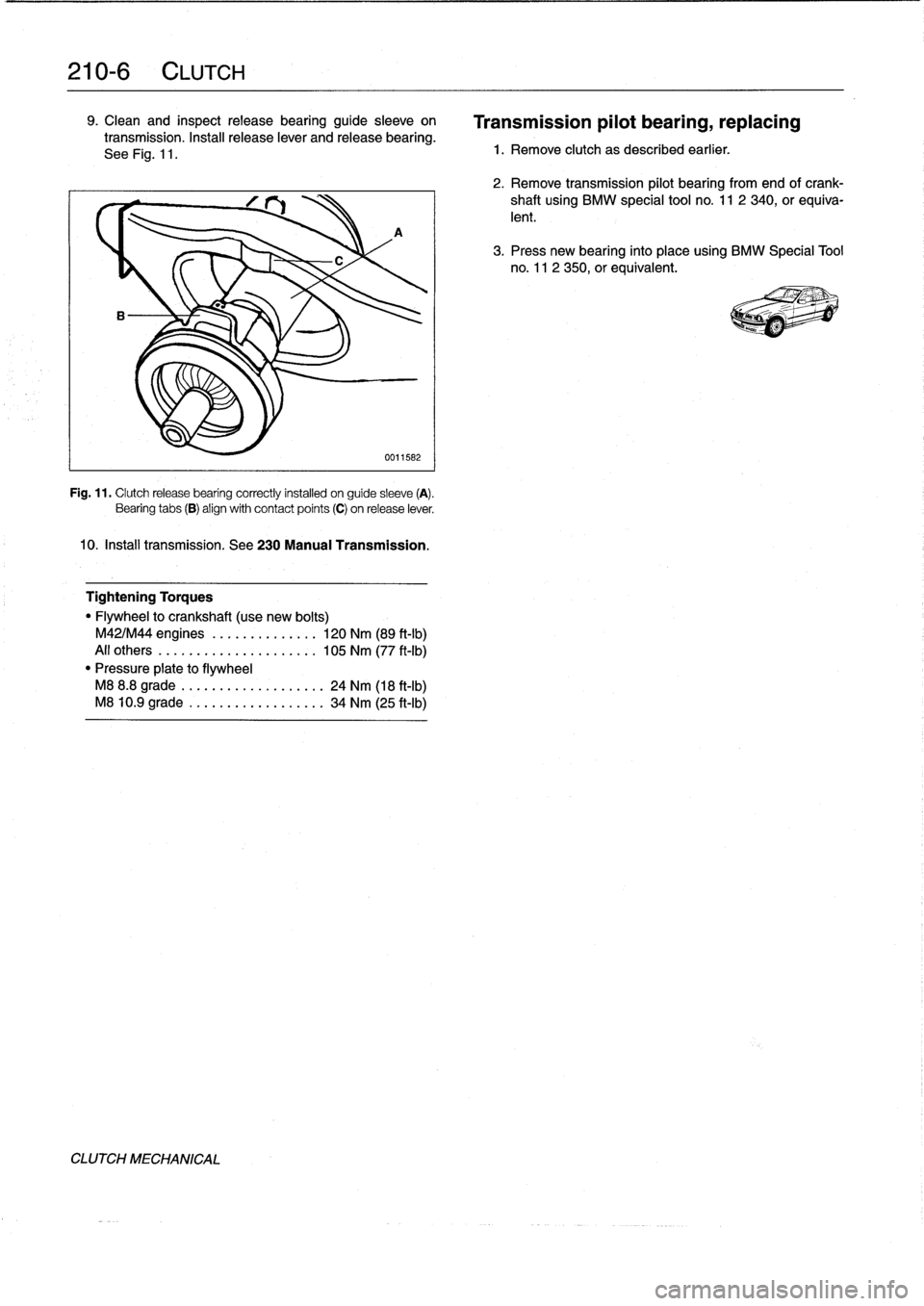

9

.

Clean

and

inspectrelease

bearing

guide

sleeve

on

transmission

.

Install

release

lever

and

release

bearing

.

See

Fig

.

11

.

A

0011582

Fig

.

11

.

Clutchrelease

bearing

correctly

installed

on

guide

sleeve

(A)

.

Bearing

tabs

(B)

align

with

contact

points

(C)

on

release

lever

.

10

.

Insta¡¡

transmission

.

See230

Manual

Transmission

.

Tightening

Torques

"

Flywheel

to

crankshaft

(use

new

bolts)

M42/M44

engines

....

.

..

...

....

120

Nm

(89

ft-Ib)

All

others

..........

..

.

..

......

105

Nm

(77

ft-Ib)

"

Pressure

píate

to

flywheel

M8

8

.8

grade

......

...

.

.

........

24

Nm

(18

ft-Ib)

M8

10

.9

grade

.....

..

..

..

.......

34

Nm

(25

ft-Ib)

CLUTCH

MECHANICAL

Transmission

pilot

bearing,

replacing

1

.

Remove

clutch

as

described

earlier

.

2

.

Remove

transmission

pilot

bearing

from

end

ofcrank-

shaft

using

BMW

special

tool

no

.

11

2

340,

or

equiva-

lent

.

3

.

Press

new

bearing

finto

placeusing

BMW

Specíal

Tool

no

.

11

2

350,or

equivalent

.

Page 225 of 759

11

.

Raise

transmission

and

reinstall

transmission

cross-

member

.

12

.

Install

driveshaft

using

new

nuts

.

See

260

Driveshaft

.

13

.

Check

transmission

oil

leve¡,

topping

up

asnecessary

.

Tightening

Torques

"

Transmission

crossmember

to

chassis

M8

...............

.

...

.

..

22-24

Nm

(16-17

ft-Ib)

M10

..............

.

..

...

..

.

...

42

Nm

(31

ft-Ib)

"

Transmission

outputflange

to

output

shaft

O

001202

2

Z

:Z

ZZZ~

%

_

j

Stage

I.................

..

.

..

190

Nm

(140

ft-Ib)

Stage

II

(after

loosening)

....

.

.

.

..

120

Nm

(89

ft-Ib)

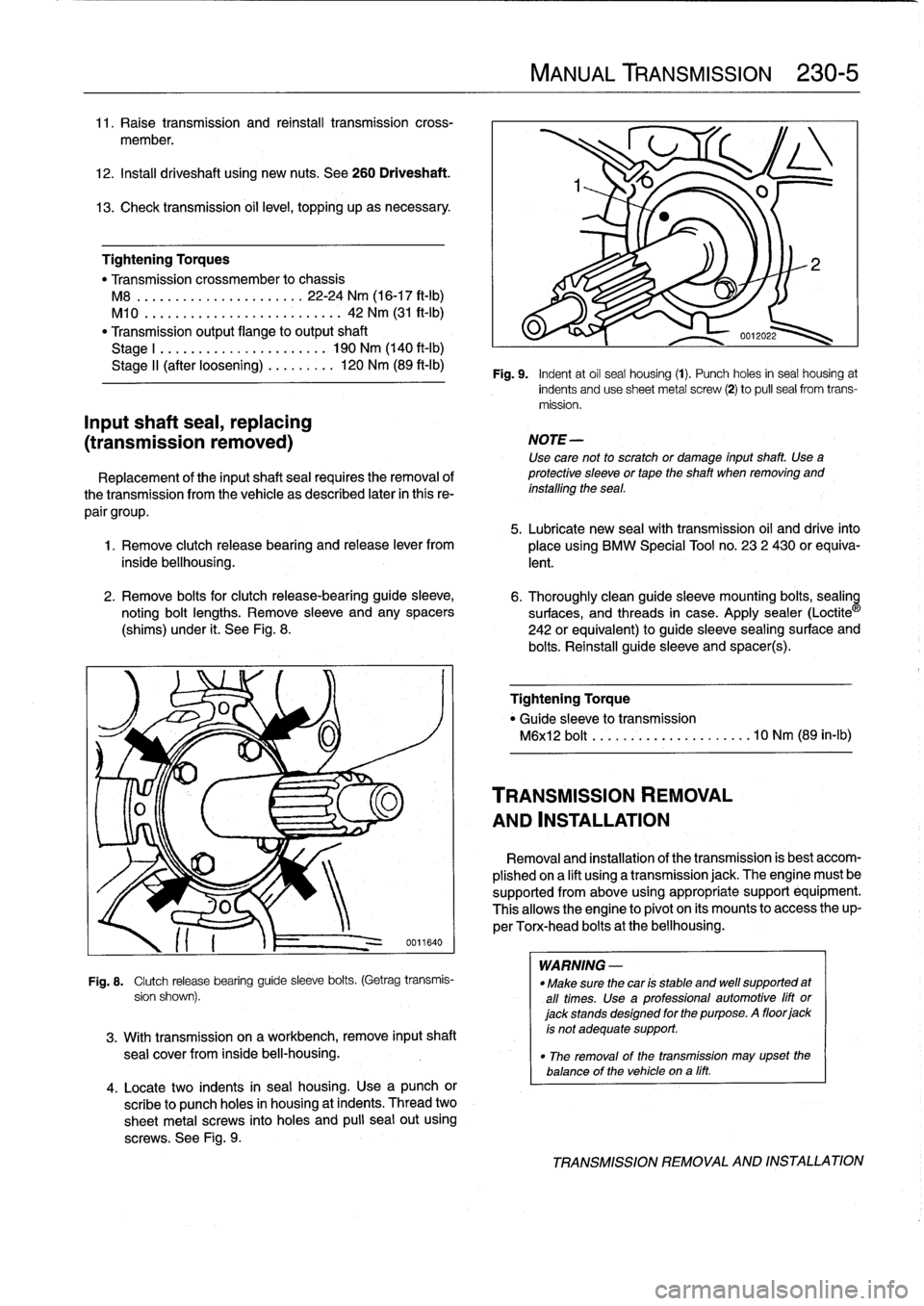

Fi

g

.

9

.

Indent

at

oil

seal

housing

(1)

.

Punch

holes

in

seal

housing

at

Inputshaft

sea¡,

replacing

(transmission

removed)

Replacement

of

the

inputshaft

sea¡

requires

the

removal

of

thetransmission

from

the

vehicle

as

described

later

in

this

re-

pair

group

.

5

.

Lubricate

new

sea¡with

transmission

oil

and

drive

into

1

.

Remove

clutch

release

bearing

and

release

lever

from

placeusing

BMW

Special

Tool

no

.

23

2

430

or

equiva-

inside

bellhousing

.

lent

.

2

.

Remove

bolts

for

clutch

release-bearing

guide

sleeve,

6

.

Thoroughly

cleanguide

sleeve

mounting

bolts,

sealin

noting

bolt

lengths

.

Remove

sleeve

and

any

spacers

surfaces,

and

threads

in

case

.

Apply

sealer

(Loctite

(shims)

under

¡t

.

See

Fig

.

8

.

242

or

equivalent)

to

guide

sleeve

sealingsurface

and

bolts

.

Reinstall

guide

sleeve

and

spacer(s)

.

0011640

Fig

.

8

.

Clutch

release

bearing

guide

sleeve

bolts

.

(Getrag

transmis-

sion

shown)

.

3

.

With

transmission

on

aworkbench,

remove

input

shaft

sea¡

cover

from

inside

bel¡-housing

.

4

.

Locate

two

indents

in

seal

housing

.

Use

a

punch

or

scribe

to

punch

holes

in

housing

at

indents

.

Thread

two

sheetmetal

screws

into

holes

and

pulí

seal

out

using

screws

.

See

Fig

.

9

.

MANUAL

TRANSMISSION

230-

5

indents

anduse

sheetmetal

screw

(2)

to

pul¡

sea¡

from

trans-

mission

.

NOTE-

Use

care

not

to

scratch

or

damage

input

shaft

.

Use

a

protective

sleeve

or

tape

the

shaft

when

removing

and

installing

the

sea¡

.

Tightening

Torque

"

Guide

sleeveto

transmission

M6xl2

bolt

.......

...

.

.

.........

10

Nm

(89

in-lb)

TRANSMISSION

REMOVAL

AND

INSTALLATION

Removal

and

installation

of

the

transmission

is

best

accom-

plished

ona

lift

using

a

transmission

jack

.

The

engine

must

be

supported

from

above

using

appropriate

support

equipment

.

Thisallows

the

engine

to

pivot

on

its

mounts

to

access

theup-

perTorx-head

bolts

at

the

bellhousing

.

WARNING

-

"

Make

sure

thecar

is

stable

and

well

supported

at

all

times

.

Use

a

professional

automotive

lift

or

jack

stands

designed

for

the

purpose

.

A

floor

jack

is

not

adequate

support

.

"

The

removal

of

the

transmission

may

upset

the

balance

of

the

vehicle

ona

líft

.

TRANSMISSION

REMOVAL

AND

INSTALLATION

Page 227 of 759

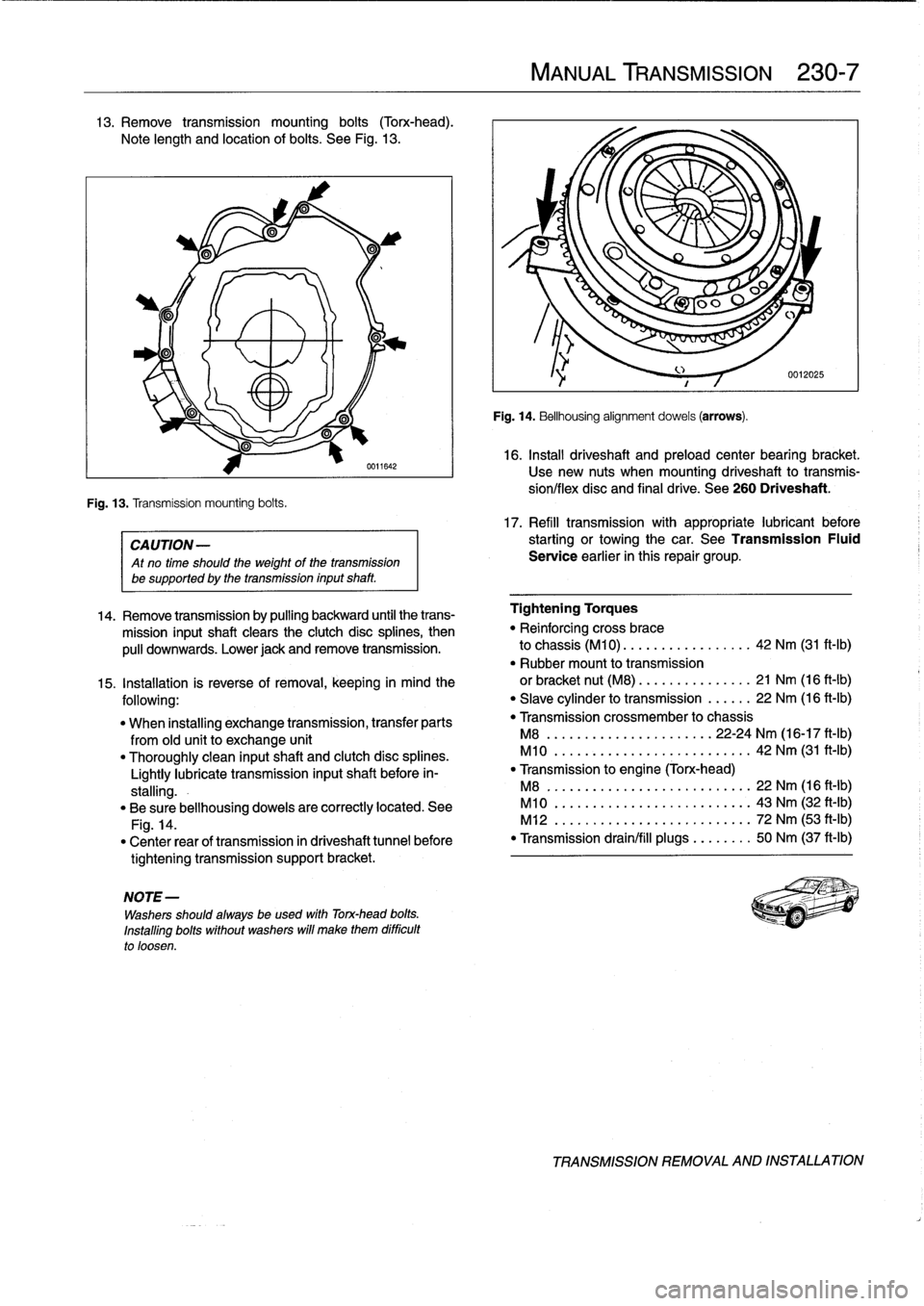

13

.

Remove

transmission

mounting

bolts

(Torx-head)

.

Note

length

and

location

of

bolts

.

See

Fig

.

13

.

Fig

.

13

.

Transmission

mounting

bolts

.

0611642

CA

UTION-

Atno

time

should

the

weight

of

thetransmission

be

supported

by

the

transmission

inputshaft

.

NOTE

-

Washers

should

always

be

used

with

Torx-head

bolts

.

Installing

bolts

without

washers

will

make

them

difficult

to

loosen

.

MANUAL

TRANSMISSION

230-

7

Fig

.

14

.

Bellhousing

alignment

dowels

(arrows)

.

16

.

Install

driveshaft

and

preload

center

bearing

bracket

.

Usenew

nuts

when

mounting

driveshaft

to

transmis-

síon/flex

disc

and

final

drive

.

See

260

Driveshaft

.

17

.

Refill

transmission

with

appropriate

lubricant

before

starting

or

towingthe

car

.

See

Transmission

Fluid

Service

earlier

in

this

repair

group

.

14

.

Remove

transmission

by

pulling

backward

until

the

trans-

Tightening

Torques

mission

inputshaft

clears

the

clutch

disc

splines,

then

"

Reinforcing

cross

brace

pulí

downwards

.

Lower

jack

andremove

transmission

.

to

chassis

(M10)

.

...

.............

42

Nm

(31

ft-Ib)

"

Rubber

mount

to

transmission

15

.

Installation

is

reverse

of

removal,

keeping

in

mind

the

or

bracket

nut

(M8)

.

...

.

...

.......

21

Nm

(16

ft-Ib)

following

:

"

Slave

cylinder

to

transmission

......

22

Nm

(16

ft-Ib)

"

When

installing

exchange

transmission,

transfer

parts

"

Transmission

crossmember

to

chassis

from

old

unit

to

exchange

unit

M8

...............

.

.

...

..

22-24

Nm

(16-17

ft-Ib)

"

Thoroughly

clean

inputshaft

and

clutch

disc

splines

.

M10

..............

.

..

..

.......

42

Nm

(31

ft-Ib)

Lightly

lubrícate

transmission

inputshaft

before

in-

"

Transmission

to

engine

(Torx-head)

stalling

.-

M8

..

..................

..

.

..

..

22

Nm

(16

ft-Ib)

"

Be

sure

bellhousing

dowels

are

correctly

located

.

See

M10

.

.................

...

.

..

..

43

Nm

(32

ft-Ib)

Fig

.

14

.

M12

.

..................

..

.

..

..

72

Nm

(53

ft-Ib)

"

Center

rear

of

transmission

in

driveshaft

tunnel

before

"

Transmission

drain/fill

plugs

.

..

.

..

..

50

Nm

(37

ft-Ib)

tightening

transmission

support

bracket

.

TRANSMISSION

REMOVAL

AND

INSTALLATION

Page 230 of 759

240-2

AUTOMATIC

TRANSMISSION

WARNING

-

If

the

appropriate

temperature

measuring

equip-

ment

is

not

available,

ATF

leve¡

checking

shouldbe

left

to

an

authorized

BMW

dealer

The

checking

pro-

cedure

should

be

done

on

a

lift

with

the

engine

run-

ning

in

neutral

.

In

addition,

the

transmission

fluid

temperature

must

be

maintained

within

a

narrow

range

duringthe

checking

procedure

.

1

.

Place

vehicle

on

a

lift

.

WARNING

-

To

lift

the

vehicle

safely,

see

010

Fundamentals

for

the

Do-it-Yourself

Owner

.

2

.

Warm

up

drivetrain

by

running

engine

until

ATF

reach-

es

specified

temperature

.

Apply

brake

and,

while

idling

engine,

shift

through

all

gears

severa¡

times

.

Turn

en-

gine

off

.

ATF

Level

Checking

"

Fluid

temperature

..

...........

30-55°C

(86-131°F)

3

.

Remove

ATF

fill

plug

.

Place

transmission

in

neutral

and

ATF,draining

and

filling

restart

engine

.

See

Fig

.

1

or

Fig

.

2

.

Fig

.

1

.

ATF

fill

plug

(A)

on

MS

270R/A4S310R

transmissions

.

4

.

With

ATF

at

specified

temperature,

add

(luid

until

it

spilis

from

fill

hole

.

WARNING

-

HotATFcan

scald

.

Weareye

protection

and

protec-

tive

clothing

and

gloves

duringthe

check

.

If

thetransmission

was

overfilled,

hot

ATF

will

spill

from

the

filler

hole

when

the

fill

plug

is

removed

.

5

.

Reinstall

fill

plug

using

new

sealing

ring

.

TRANSMISSION

SERVICE

011743

0011742

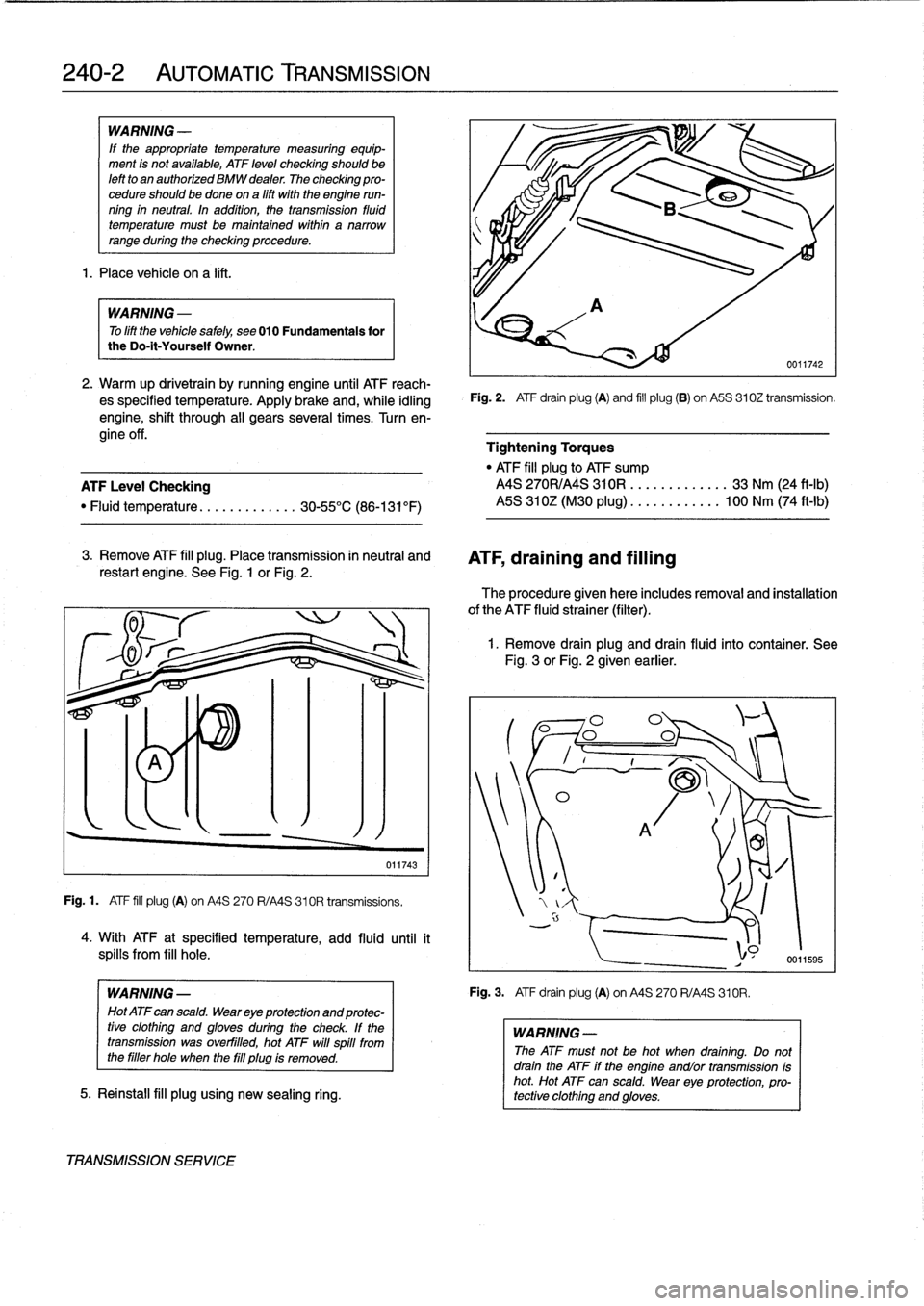

Fig

.

2

.

ATF

drain

plug

(A)

and

fill

plug

(B)

on

A5S

310Z

transmission

.

Tightening

Torques

"

ATF

fill

plug

to

ATF

sump

MS

270R/A4S

31

OR

.............

33

Nm

(24

ft-Ib)

MS

310Z

(M30

plug)

............

100

Nm

(74

ft-Ib)

The

procedure

given

here

includes

removal

and

installation

of

the

ATF

(luid

strainer

(filter)

.

1

.

Remove

drain

plug

and

drain

fluidinto

container

.

See

Fig

.

3

or

Fig

.

2

given

earlier

.

0~

0

/\1--Z

.IZ

~

~

A

~

"o

15/

Fig

.

3

.

ATF

drain

plug

(A)

on

A4S

270R/A4S

310R

.

WARNING

-

The

ATF

must

not

be

hot

when

draining

.

Do

not

drain

the

ATF

if

the

engineandlor

transmission

Is

hot

.

Hot

ATF

can

scald

.

Wear

eye

protection,

pro-

tective

clothing

and

gloves

.

0011595

Page 232 of 759

240-

4

AUTOMATIC

TRANSMISSION

TRANSMISSION

REMOVALAND

INSTALLATION

Removal

and

installation

of

thetransmission

is

best

accom-

plished

on

a

lift

using

a

transmission

jack

.

Use

caution

and

safe

workshop

practices

when

working

beneath

car

and

low-

ering

transmission

.

WARNING

-

To

lift

the

vehicle

safely,

see010

Fundamentals

for

the

Do-it-Yourself

Owner

.

CAUTION-

"

Be

sure

the

vehicle

is

properly

supported

.

The

removal

of

the

transmission

may

upset

the

bal-

ance

of

the

vehicle

on

a

lift

.

"

Tilting

the

engine

to

remove

the

transmission

can

lead

to

damage

to

various

components

due

to

lack

of

clearance

.

-On

carswith

AST

remove

throttle

body

.

-Remove

brake

fluid

reservoir

if

necessary

.

Torx-head

bolts

are

used

to

mount

thetransmission

to

the

bellhousing

.

Be

sure

to

have

appropriate

tools

on

hand

before

starting

thejob

.

2

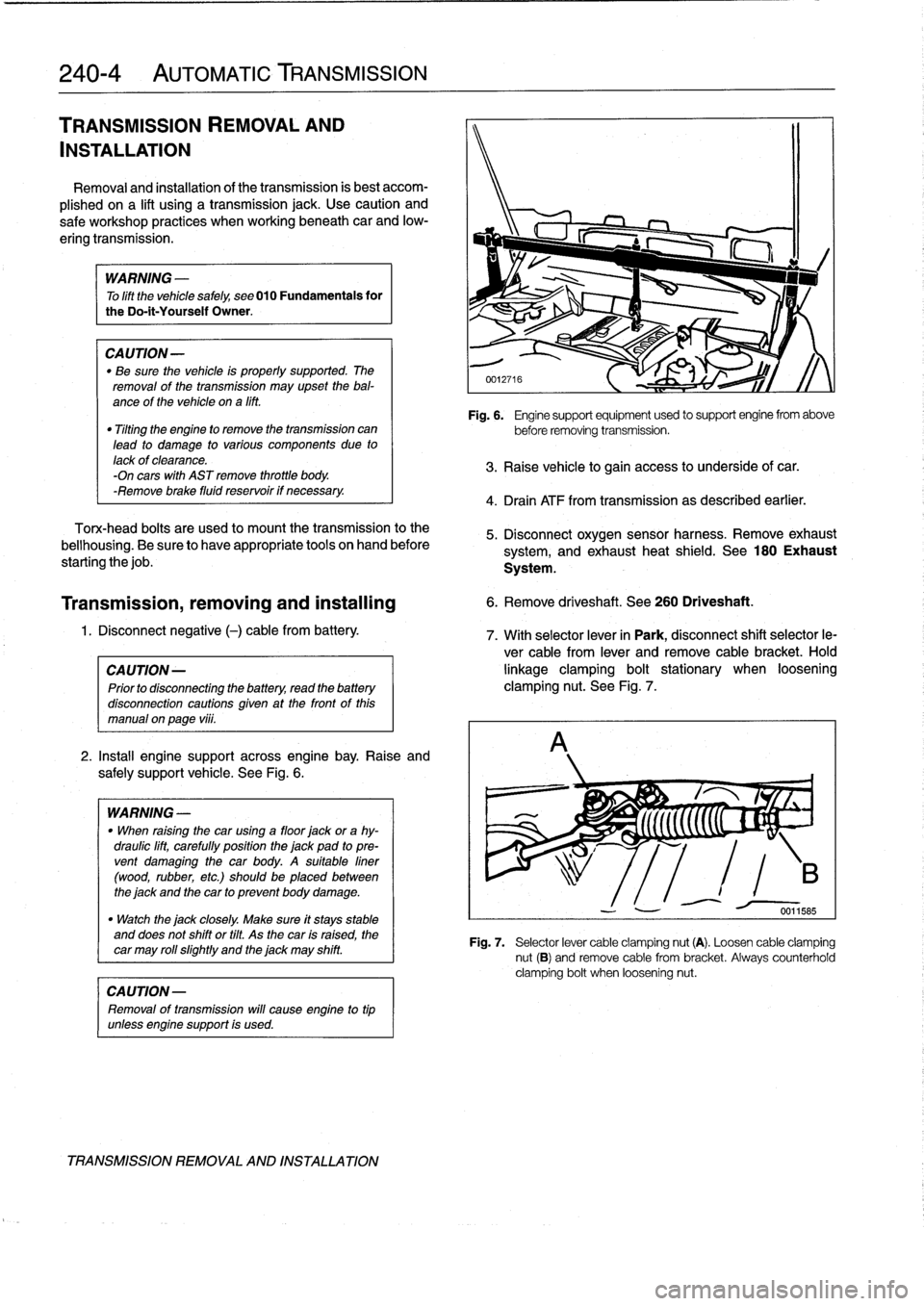

.

Install

engine

support

across

engine

bay

.

Raise

and

safely

support

vehicle

.

See

Fig

.

6

.

WARNING

-

"

When

raising

thecar

using

a

floor

jack

or

a

hy-

draulic

lift,

carefully

position

the

jack

pad

to

pre-

vent

damaging

the

car

body

.

A

suitable

liner

(wood,

rubber,

etc

.)

should

be

placed

between

the

jack

and

the

car

to

prevent

body

damage

.

"

Watch

the

jack

closely

.

Make

sure

it

stays

stable

and

does

not

shift

or

tilt

.

As

the

car

is

raised,

the

car

may

roll

slightty

and

the

jack

may

shift

.

CAUTION-

Removal

of

transmission

will

cause

engine

to

tip

unlessengine

support

is

used

.

TRANSMISSION

REMOVAL

AND

INSTALLATION

Fig

.

6

.

Engine

support

equipment

used

to

support

engine

from

above

before

removing

transmission

.

3

.

Raise

vehicle

to

gain

access

to

underside

of

car

.

4

.

Drain

ATF

from

transmission

as

described

earlier

.

5

.

Disconnect

oxygen

sensor

harness

.

Remove

exhaust

system,

and

exhaust

heat

shield

.

See

180

Exhaust

System

.

Transmission,

removing

and

installing

6

.

Remove

driveshaft

.

See

260

Driveshaft

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

7

.

With

selector

lever

in

Park,

disconnect

shift

selector

le-

ver

cable

from

lever

and

remove

cable

bracket

.

Hold

CA

UTION-

linkage

clamping

bolt

stationary

when

loosening

Prior

to

disconnectiog

the

battery,

read

the

battery

clamping

nut

.

See

Fig

.

7

.

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vi¡¡

.

Fig

.

7

.

Selector

lever

cable

clamping

nut

(A)

.

Loosen

cable

clamping

nut

(B)

and

remove

cable

from

bracket

.

Always

counterholdclamping

bolt

when

loosening

nut

.

Page 239 of 759

Fig

.

10

.

Align

contact

slide

(1)

with

slot

in

switch

housing

(2)

before

in-

stalling

gear

position/neutral

safety

switch

.

Fig

.

11

.

Engage

release

button

pin

to

hole

in

pull

rod

before

installing

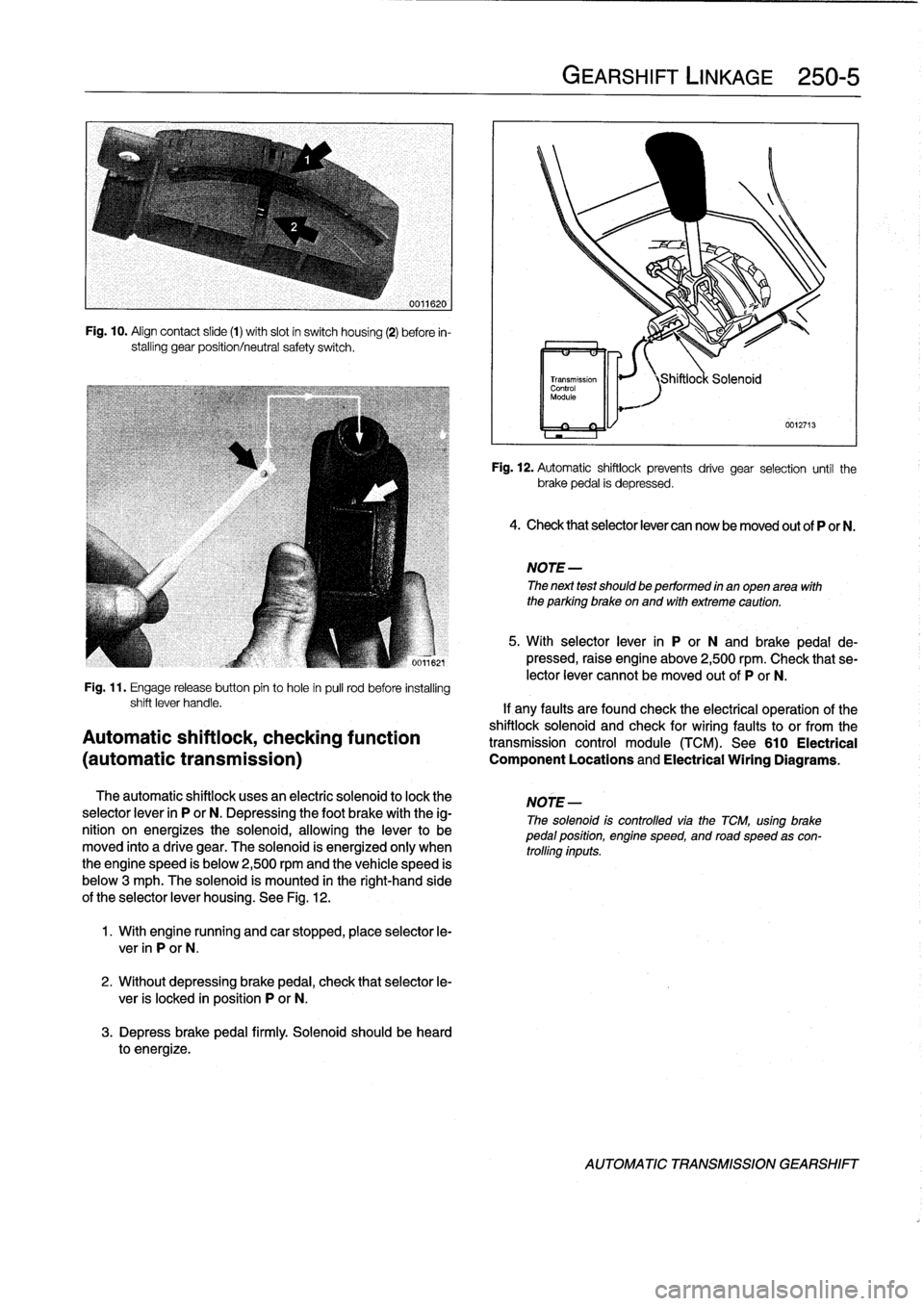

The

automatic

shiftlock

uses

an

electríc

solenoid

to

lock

the

selector

lever

in

P

or

N

.

Depressing

the

foot

brake

withthe

ig-

nition

on

energizes

the

solenoid,

allowingthe

lever

to

be

moved

into

a

drive

gear

.

The

solenoid

is

energized

only

when

the

engine

speed

is

below

2,500

rpmand

thevehicle

speed

is

below

3

mph

.

The

solenoid

ís

mounted

in

the

right-hand

side

of

theselector

lever

housing

.

See

Fig

.

12

.

1

.

With

engine

running

and

car

stopped,

place

selector

le-

ver

in

P

or

N

.

2

.

Without

depressing

brake

pedal,

check

that

selector

le-

ver

is

locked

in

position

P

or

N

.

3

.

Depress

brakepedal

firmly

.

Solenoid

should

be

heard

to

energize

.

GEARSHIFT

LINKAGE

250-

5

Fig

.

12

.

Automatic

shiftlock

prevents

drive

gear

selection

until

the

brakepedal

is

depressed

.

4

.

Check

thatselector

lever

can

now

be

moved

out

of

P

or

N

.

NOTE

-

The

next

test

should

be

performed

in

anopen

area

with

the

parking

brake

on

and

with

extreme

caution

.

5

.

With

selector

lever

in

P

or

N

and

brake

pedal

de-

pressed,

raise

engine

above

2,500

rpm

.

Check

that

se-

lector

lever

cannotbe

moved

outof

P

or

N

.

shift

lever

handle

.

If

any

faults

are

found

check

the

electrical

operation

of

the

shiftlock

solenoid

and

check

for

wiring

faultsto

or

from

the

Automatic

shiftiock,

checking

function

transmission

control

module(TCM)

.

See610

Electrical

(automatic

transmission)

Component

Locations

and

Electrical

Wiring

Diagrams

.

NOTE

-

The

solenoid

is

controlled

viathe

TCM,

using

brakepedal

position,

engine

speed,

and

road

speed

as

con-

trolling

inputs

.

AUTOMATIC

TRANSMISSION

GEARSHIFT

Page 243 of 759

Symptom

1

Probable

cause

4

.

Vibration,

audible

a

.

Front

centering

guide

worn,

or

a

.

Check

front

centering

guide

and

replace

if

necessary

.

Check

rumble

over35

mph

driveshaft

mounting

flanges

out

of

runout

of

driveshaft

mounting

flanges

.

(60

km/h)

.

round

or

damaged

.

b

.

Mounting

flange

bolts

loose

or

holes

b

.

Remove

driveshaft

and

check

transmissionoutput

flange

and

worn

.

final

drive

input

flange

.

Replace

if

necessary

.

c

.

Driveshaft

unbalanced

.

c

.

Check

driveshaft

for

loose

or

missing

balance

weights

.

Have

driveshaft

rebalanced

or

replace

if

necessary

.

DRIVESHAFT

SERVICE

Driveshaft,

aligning

d

.

Universal

joints

worn

or

seized

.

d

.

Check

universal

joint

play

and

movement

.

Replace

driveshaft

if

necessary

.

e

.

Sliding

coupling

seized

.

e

.

Remove

driveshaft

and

check

movement

of

sliding

coupling

.

1

Clean

coupling

splines

or

replace

parts

asnecessary

.

f

.

Incorrect

preload

of

center

bearing

.

f

.

Check

preload

of

center

bearing

.

Readjust

if

necessary

.

g

.

Center

bearing

faulty

.

g

.

Replace

center

bearing

.

h

.

Final

drive

rubber

mount

faulty

h

.

Inspect

final

drive

rubber

mount

and

replace

if

necessary

.i.

Driveshaft

misaligned

.

i.

Check

driveshaft

alignment

.

Repair

kits

for

the

universal

joints

are

not

available,

and

it

is

not

common

practice

to

repair

the

universal

joints

on

BMW

driveshafts

.

Worn

or

damaged

universal

joints

usually

require

replacement

of

that

section

of

the

driveshaft

.

The

driveshaft

is

balanced

to

cose

tolerances

.

Whenever

it

is

to

be

removed

or

disassembied,

the

mounting

flanges

and

driveshaft

sections

should

bemarked

with

paint

or

a

punch

before

proceeding

with

work

.

This

will

ensure

that

the

drive-

shaft

can

be

reassembled

or

installed

in

exactlythe

same

ori-

entation

.

Universal

joint

play

"

Maximum

allowable

...........

0.15

mm

(0.006

in

.)

The

alignment

of

the

driveshaft

does

not

normally

need

to

be

checked

unless

the

engine/transmission

orthe

final

drive

havebeen

removed

and

installed

.

If,

however,

all

other

parts

of

the

driveshaft

havebeen

inspected

and

found

to

be

okay,

butthere

is

still

noise

or

vibration,

driveshaft

alignment

should

be

checked

.

There

aretwo

important

driveshaft

alignment

checks

.

The

first

is

to

make

sure

that

the

driveshaft

runs

straight

from

the

transmission

to

the

final

drive

;

without

any

variation

from

side-

to-side

caused

by

misalignment

ofthe

engine/transmission

in

its

mounts

.

Make

a

basic

check

by

sighting

along

the

drive-

shaft

from

back

lo

front

.

Any

misalignmentshould

be

apparent

from

the

center

bearingforward

.

To

adjustthe

side-to-side

alignment,

loosen

the

transmission

or

engine

mounts

to

repo-

sition

them,

then

retighten

the

mounts

:

The

driveshaft

should

be

exactly

centered

in

the

driveshaft

tunnel

.

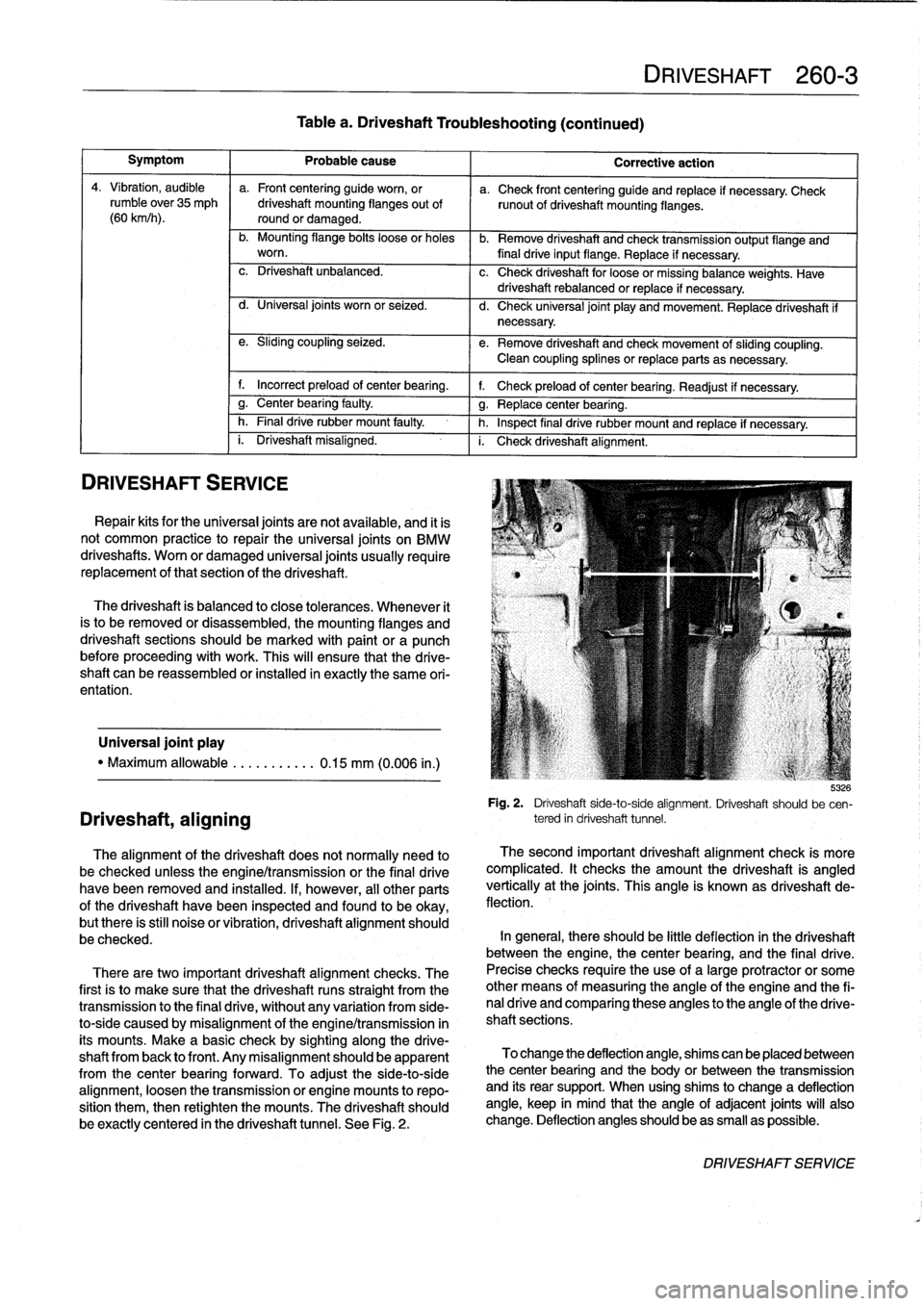

See

Fig

.

2

.

Table

a

.

Driveshaft

Troubleshooting

(continued)

DRIVESHAFT

260-3

Corrective

action

b

:izó

Fig

.

2

.

Driveshaft

side-to-side

alignment

.

Driveshaft

should

be

cen-

tered

in

driveshaft

tunnel

.

The

second

important

driveshaft

alignment

check

is

more

complicated

.

It

checks

the

amount

the

driveshaft

is

angled

vertically

at

the

joints

.

This

angle

is

known

as

driveshaft

de-

flection

.

In

general,

there

should

be

little

deflection

in

the

driveshaft

between

the

engine,

thecenter

bearing,

and

the

final

drive

.

Precise

checks

require

theuse

of

a

large

protractor

or

some

other

means

of

measuring

the

angle

of

the

engine

and

the

fi-

nal

drive

and

comparing

these

angles

to

the

angle

of

the

drive-

shaft

sections

.

To

change

the

deflection

angle,

shims

can

be

placed

between

the

center

bearing

and

the

body

or

between

the

transmission

and

íts

rear

support

.

When

using

shims

to

change

a

deflection

angle,

keep

in

mind

that

the

angle

of

adjacent

joints

will

also

change

.

Deflection

anglesshould

beas

small

as

possible

.

DRIVESHAFTSERVICE

Page 251 of 759

Wheel

brake

caliper

Electronic

control

module

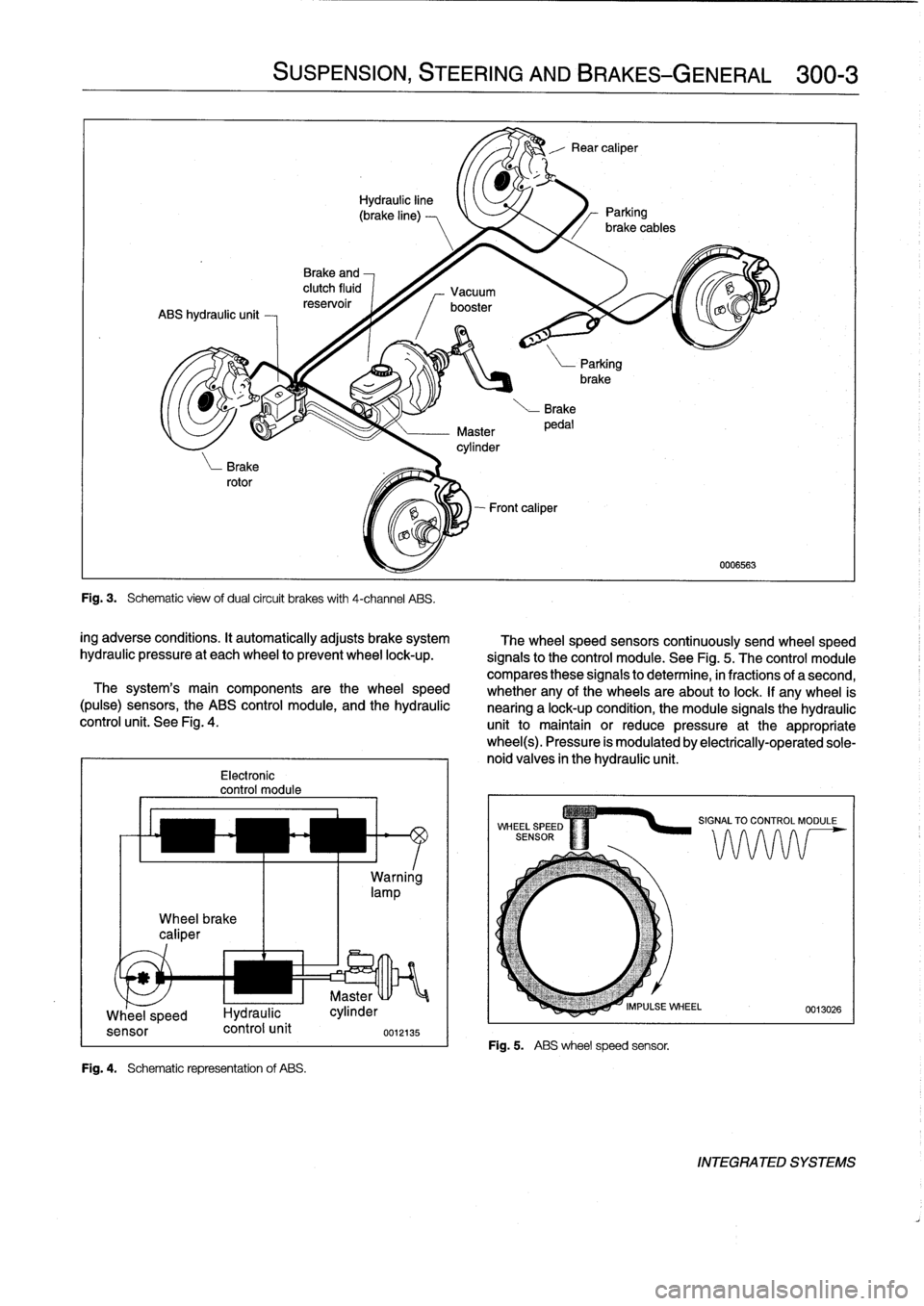

Fig

.

4

.

Schematic

representation

of

ABS

.

SUSPENSION,

STEERING

ANDBRAKES-GENERAL

300-3

Fig

.

3

.

Schematic

view

ofdual

circuit

brakes

with

4-channel

ABS

.

ing

adverse

conditions

.

It

automatically

adjusts

brake

system

hydraulic

pressure

at

each

wheel

to

prevent

wheel

lock-up

.

The

system's

main

components

arethe

wheel

speed

(pulse)

sensors,

the

ABS

control

module,

and

the

hydraulic

control

unit

.

See

Fig

.

4

.

Warning

lamp

u

Master

Whee

_

l

speed

I-lydraulic

cylinder

sensor

control

unit

0012135

UNI

The

wheel

speed

sensors

continuously

send

wheel

speed

signals

to

the

control

module

.

See

Fig

.

5

.

The

control

module

compares

these

signals

to

determine,

in

fractions

of

a

second,

whether

any

of

the

wheels

areabout

to

lock

.

If

any

wheel

is

nearing

a

lock-up

condition,

the

module

signals

the

hydraulic

unit

to

maintain

or

reduce

pressure

at

the

appropriatewheel(s)

.

Pressure

is

modulated

by

electrically-operated

sole-

noid

valves

in

the

hydraulic

unit

.

Fig

.

5

.

ABS

wheelspeed

sensor

.

0006563

INTEGRATED

SYSTEMS