replace timing chain BMW 525i 1999 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 525i, Model: BMW 525i 1999 E39Pages: 1002

Page 279 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

- Connect electrical harness connectors to camshaft position

sensors and VANOS solenoid valves.

- Remove BMW special locking tools from rear of cylinder

head.

- Remove cranltshaft locking tool and replace sealing plug.

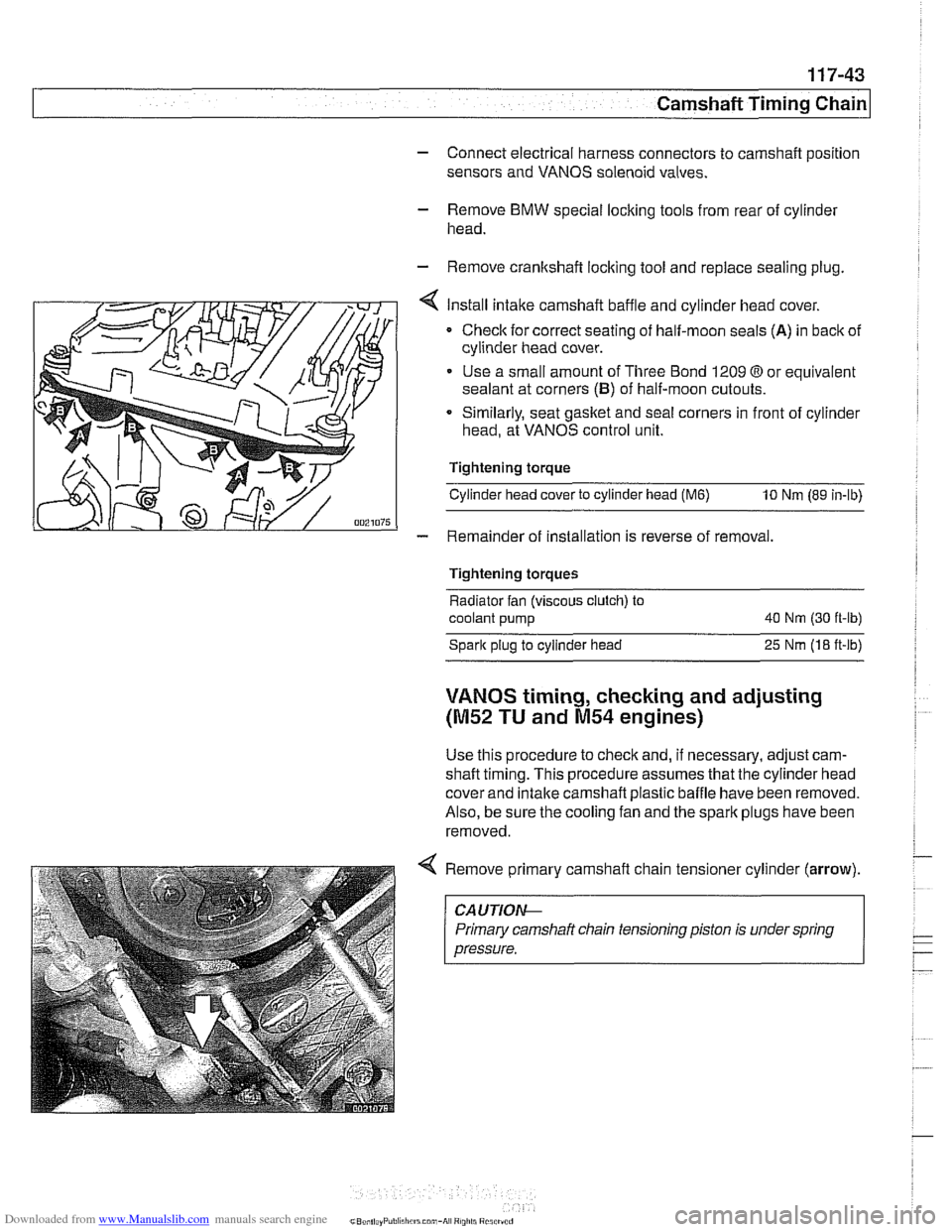

Install intake camshaft baffle and cylinder head cover.

Checlc for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(B) of half-moon cutouts.

Similarly, seat gasket and

seal corners in front of cylinder

head, at VANOS control unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

- Remainder of installation is reverse of removal.

Tightening torques

Radiator fan (viscous clutch) to

coolant pump 40

Nm (30 ft-lb)

Spark plug to cylinder head

25 Nrn (18 ft-lb)

VANOS timing, checking and adjusting

(M52 TU and M54 engines)

Use this procedure to check and, if necessary, adjust cam-

shaft timing. This procedure assumes that the cylinder head

cover and intake

camshaft plastic baffle have been removed.

Also, be sure the cooling fan and the spark plugs have been

removed.

Remove primary camshaft chain tensioner cylinder

(arrow).

~~ ~ ~~ ~--~

CA UTlOAC

Primary camshaft chain tensioning piston is under spring

pressure.

Page 292 of 1002

Downloaded from www.Manualslib.com manuals search engine

~ ~~ ~

I Camshaft Timing Chain I --

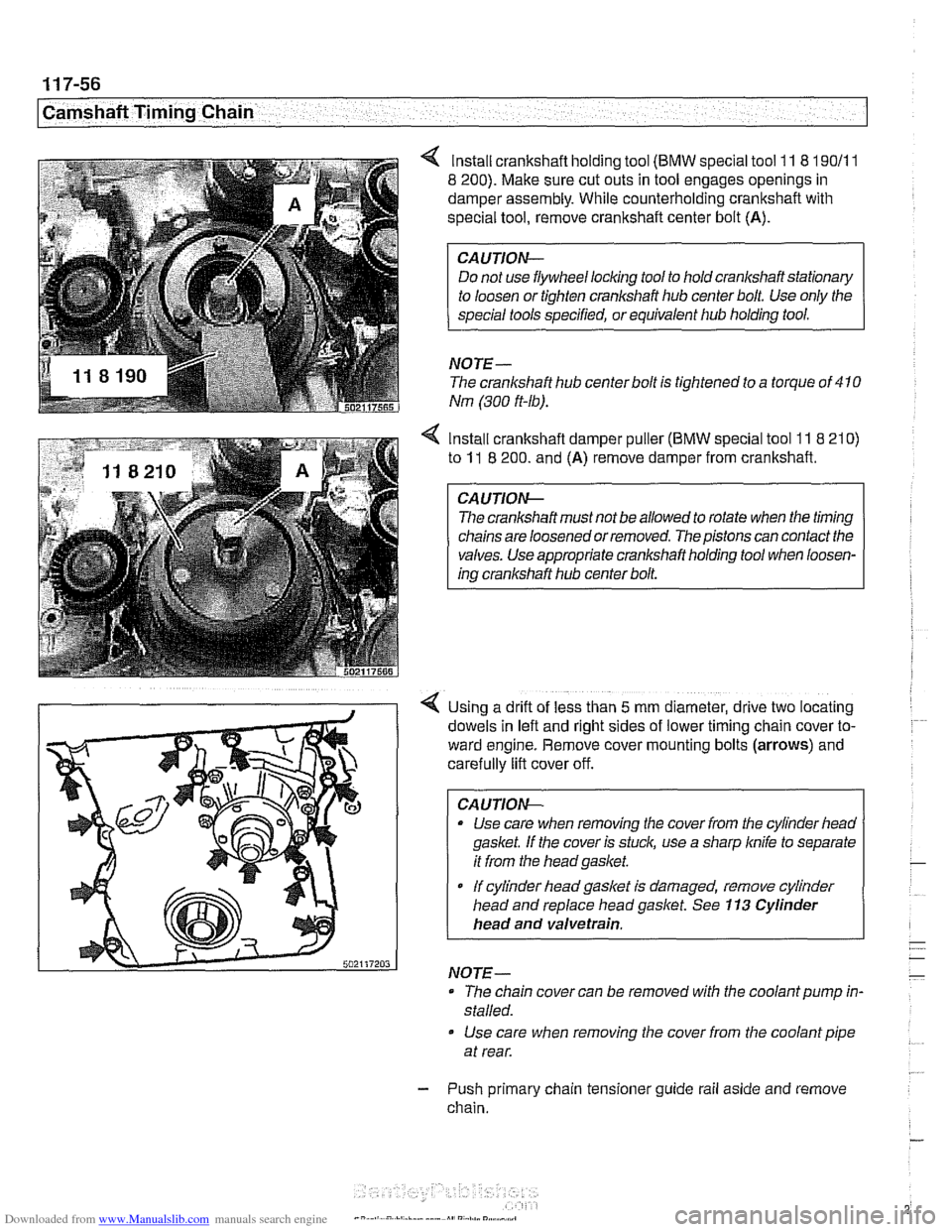

lnstall crankshaft holding tool (BMW special tool 11 8 190/11

8 200). Make sure cut outs in tool engages openings in

damper assembly. While counterholding crankshaft with

special tool, remove crankshaft center bolt (A).

CAUTION-

Do not use flywheel locking tool to hold crankshaft stationary

NOTE-

The crankshaft hub centerbolt is tightened to a torque of 410

Nm (300 ft-lb).

4 Install crankshaft damper puller (BMW special tool 11 8 210)

to 11 8 200. and (A) remove damper from crankshaft.

The crankshaft must not be allowed to rotate when the timing

chains are loosened or removed. The pistons can contact the

valves. Use appropriate crankshaft holding tool when loosen-

ing crankshaft hub center bolt.

Using a drift of less than

5 mm diameter, drive two locating

dowels in left and right sides of lower timing

cham cover to-

ward engine. Remove cover mounting bolts

(arrows) and

carefully lift cover off.

CA

UTION-

* Use care when removing the cover from the cylinder heao

gasket. If the cover is stuck, use a sharp

knife to separate

it from the headgasket.

If cylinder liead gasket Is damaged, remove cylinder

head and replace head gasket. See

113 Cylinder

head and valvetrain.

NOTE-

- The chain cover can be removed with the coolant pump in-

stalled.

Use care when removing the cover from the coolant pipe

at rear.

- Push primary chain tensioner guide rail aside and remove

chain.

Page 293 of 1002

Downloaded from www.Manualslib.com manuals search engine

... -.

rpp- --- Camshaft Timing Chain1

Timing chains, installing

(M52 TU and M54 engines)

CAUTIOI\C

The procedure outlined below assumes that the camshaits

are lockedin the

TDC installation position with speciallocling

tools as shown earliel:

- inspect timing chain sprockets. Inspect guide rail and ten-

sioner rail for damage. Replace any part that is worn

or dam-

aged.

NOTE-

If any sprockets are being replaced due to wear, the chain

should also be replaced.

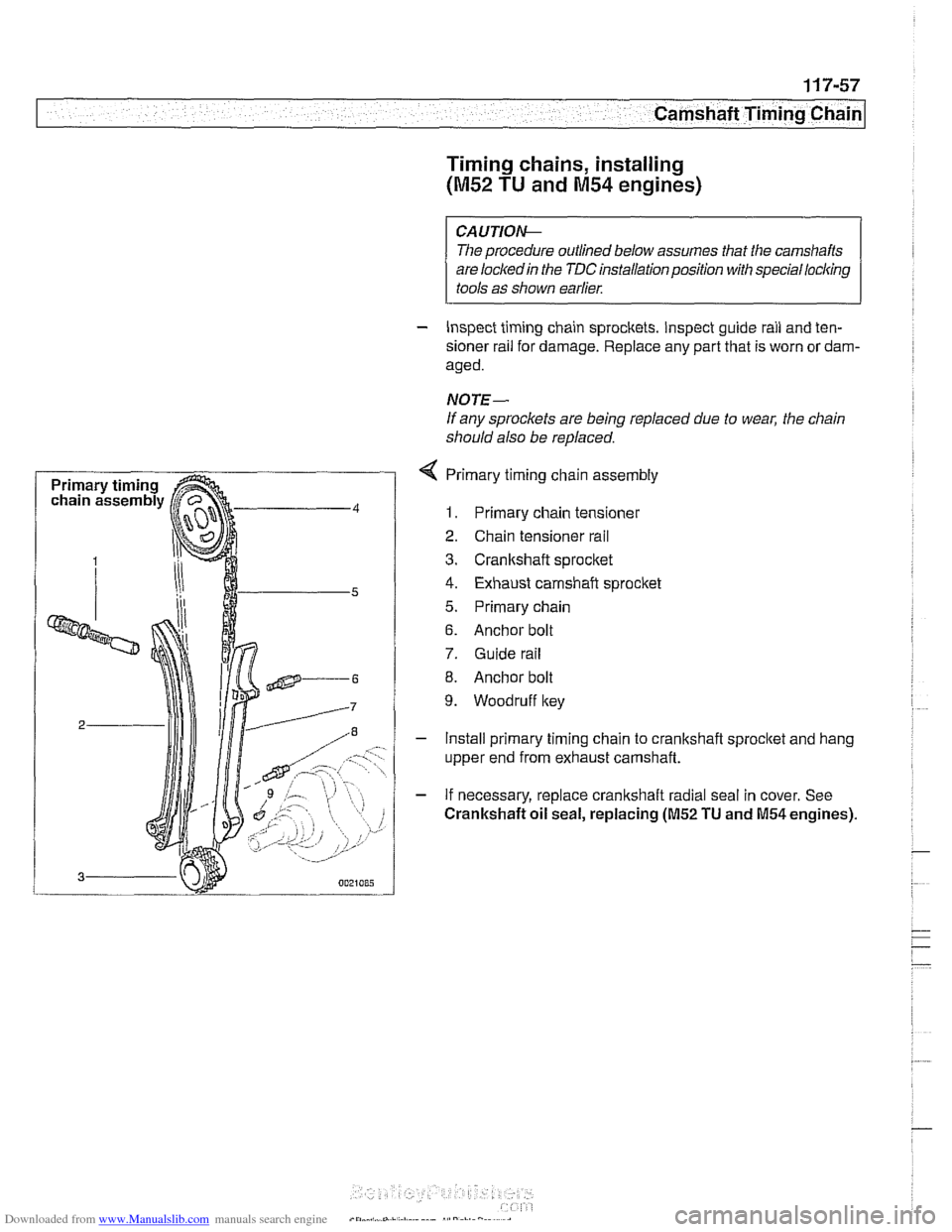

4 Primary timing chain assembly

1. Primary chain tensioner

2. Chain tensioner rail

3. Cranltshaft sprocket

4. Exhaust camshaft sprocket

5. Primary chain

6. Anchor bolt

7. Guide rail

8. Anchor bolt

9. Woodruff key

- Install primary timing chain to crankshaft sprocltet and hang

upper end from exhaust camshaft.

- If necessary, replace crankshaft radial seal in cover. See

Crankshaft oil seal, replacing (M52 TU and M54 engines).

Page 310 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Camshaft Timina Chain

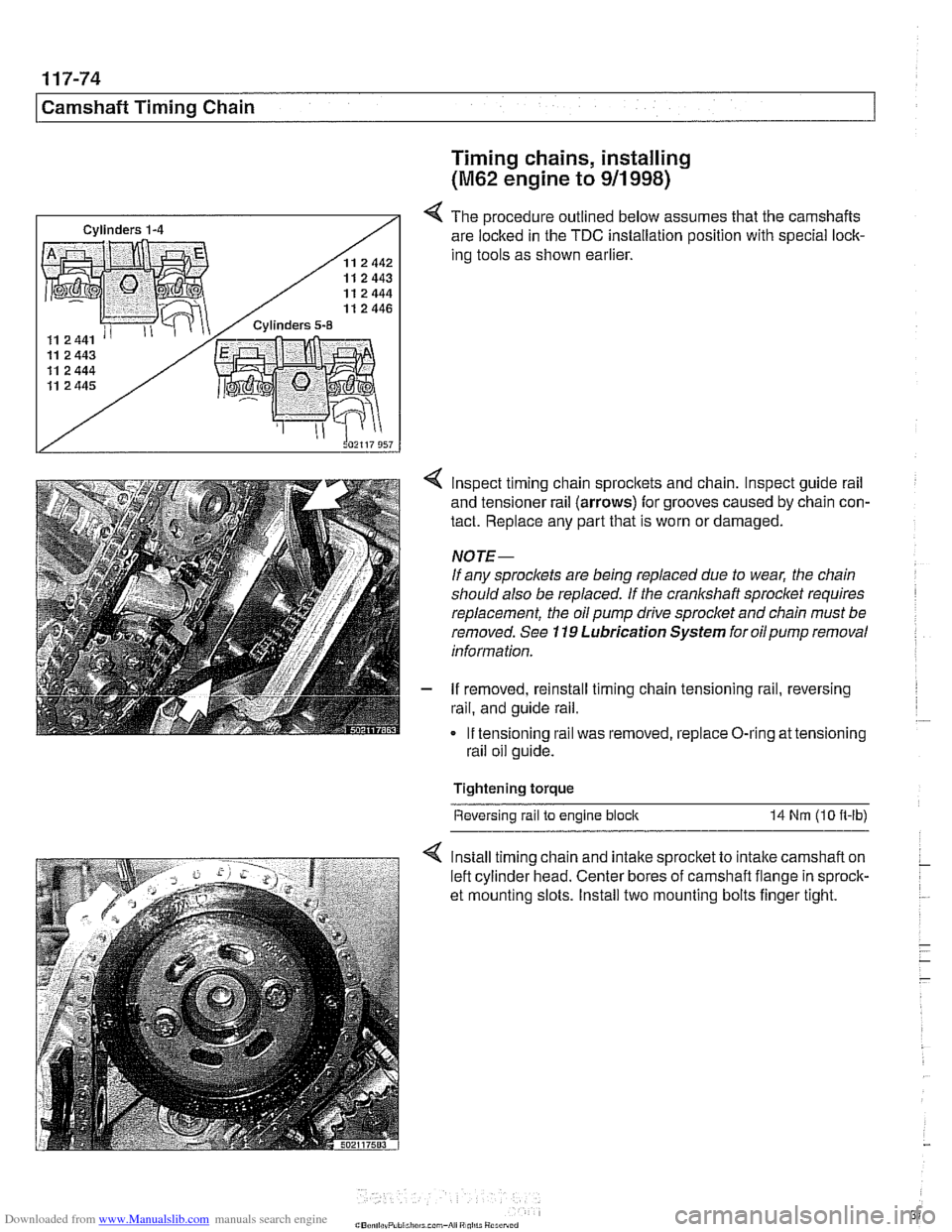

/ Cylinders 5-8

Timing chains, installing

(M62 engine to 911 998)

4 The procedure outlined below assumes that the camshafts

are locked in the TDC installation position with special lock-

ing tools as shown earlier.

4 lnspect timing chain sprocltets and chain. Inspect guide rail

and tensioner rail

(arrows) for grooves caused by chain con-

tact. Replace any part that is worn or damaged.

NOTE-

If any sprocl(ets are being replaced due to wear, the chain

should also be replaced.

If the crankshaft sprocket requires

replacement, the oil pump

drive sprocket and chain must be

removed. See

119 Lubrication System for oilpump removal

information.

- If removed, reinstall timing chain tensioning rail, reversing

rail, and guide rail.

If tensioning rail was removed, replace O-ring at tensioning

rail oil guide.

Tightening torque Reversing rail

to engine block 14 Nrn (10 n-lb)

4 lnstall timing chain and intalte sprocket to intake camshaft on

left cylinder head. Center bores of camshaft flange in sprock-

et mounting slots. Install two mounting bolts finger tight.

Page 311 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain1

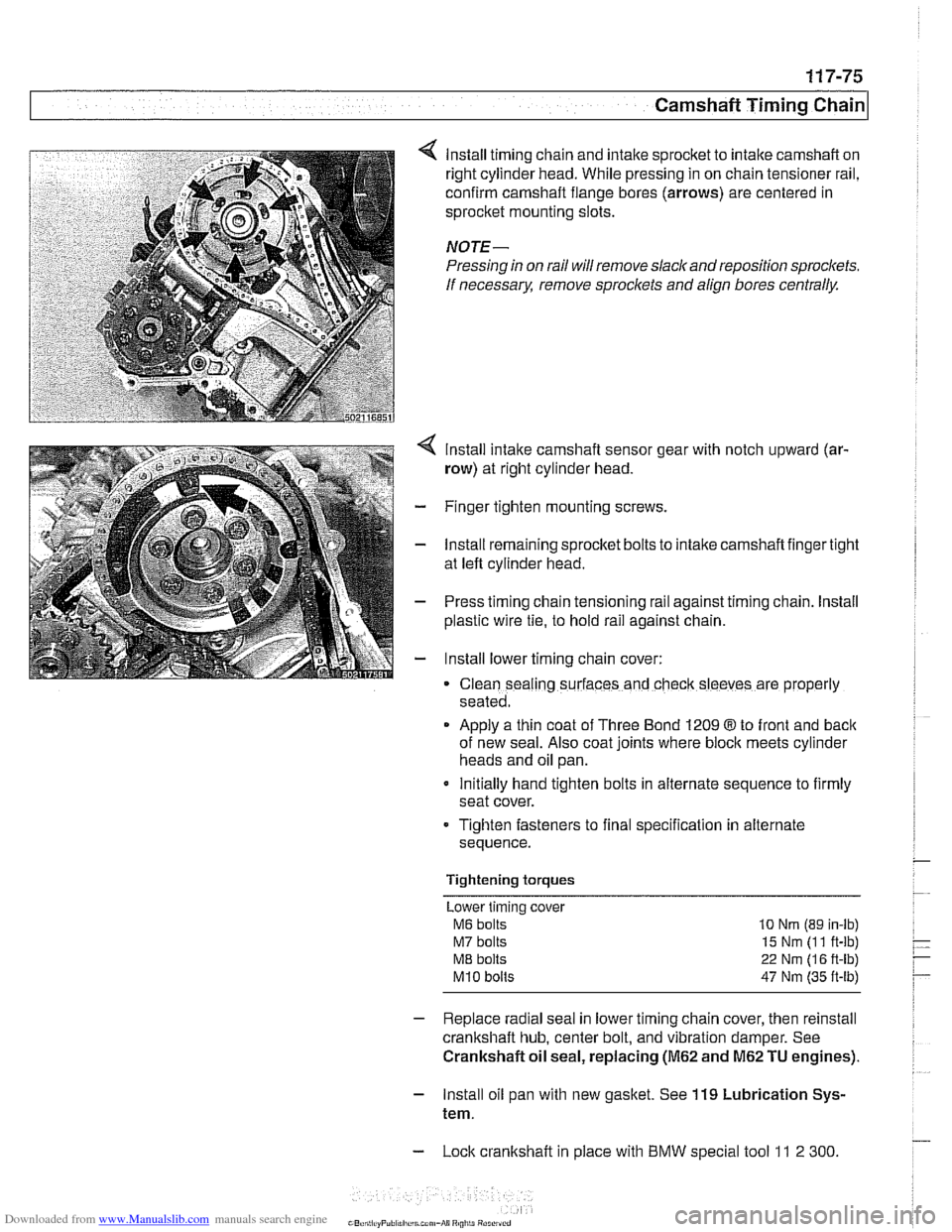

lnstall timing chain and intake sprocket to intake camshaft on

right cylinder head. While pressing in on chain tensioner rail,

confirm camshaft flange bores (arrows) are centered in

sprocket mounting slots.

NOTE-

Pressing in on rail will remove slack and reposition sprockets.

If

necessarx remove sproclets and align bores centrally.

lnstall intake camshaft sensor gear with notch upward (ar-

row) at right cylinder head.

- Finger tighten mounting screws.

- lnstall remaining sprocket bolts to intake camshaft finger tight

at left cylinder head.

- Press timing chain tensioning rail against timing chain. lnstall

plastic wire

tie, to hold rail against chain.

- lnstall lower timing chain cover:

Clean sealing surfaces and check sleeves are properly

seated.

Apply a thin coat of Three Bond 1209

8 to front and back

of new seal. Also coat joints where block meets cylinder

heads and oil pan.

Initially hand tighten bolts in alternate sequence to firmly

seat cover.

Tighten fasteners to final specification in alternate

sequence.

Tightening torques Lower timing cover

M6 bolts 10 Nrn (89 in-lb)

M7 bolts 15 Nm (1 1 ft-lb)

ME bolts 22 Nm (1 6 ft-lb)

M10 bolts 47 Nm (35 ft-lb)

- Replace radial seal in lower timing chain cover, then reinstall

crankshaft hub, center bolt, and vibration damper. See

Crankshaft oil seal, replacing

(M62 and M62 TU engines).

- lnstall oil pan with new gasket. See 119 Lubrication Sys-

tem.

- Lock crankshaft in place with BMW special tool 11 2 300

Page 313 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

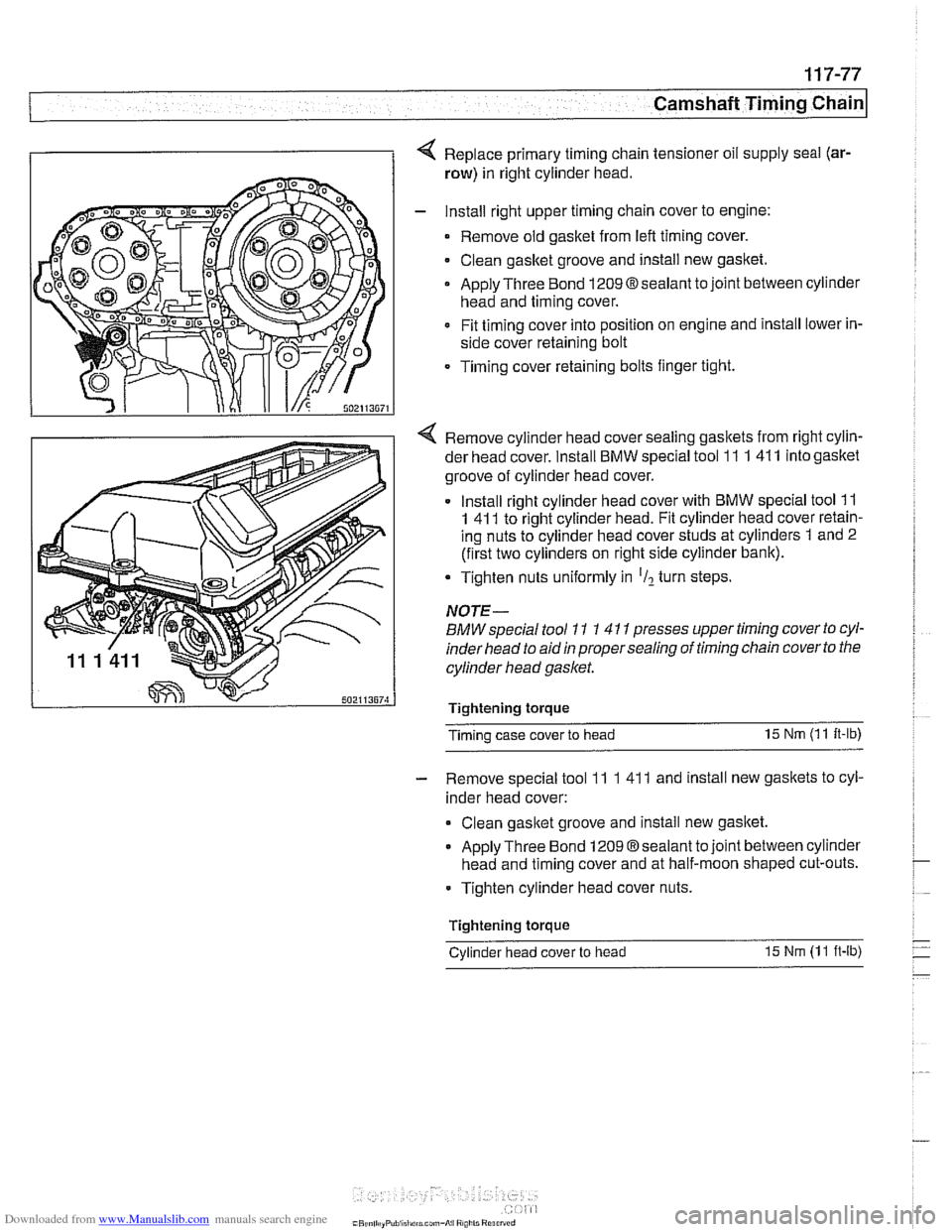

4 Replace primary timing chain tensioner oil supply seal (ar-

row) in right cylinder head.

- Install right upper timing chain cover to engine:

Remove old gasket from

left timing cover.

Clean gasket groove and install new gasket.

Apply Three Bond

1209Osealant to joint between cylinder

head and timing cover.

Fit timing cover into position on engine and install lower in-

side cover retaining bolt

Timing cover retaining bolts finger tight.

4 Remove cylinder head cover sealing gaskets from right cylin-

der head cover. Install

BMW special tool 11 1 41 1 into gasltet

groove of cylinder head cover.

Install right cylinder head cover with

BMW special tool 11

1 41 1 to right cylinder head. Fit cylinder head cover retain-

ing nuts to cylinder head cover studs at cylinders 1 and 2

(first two cylinders on right side cylinder bank).

Tighten nuts uniformly in

'Il turn steps.

NOTE-

BMW special tool 11 1 4 11 presses upper timing cover to cyl-

inder head to aid

in proper sealing of timing chain cover to the

cylinder head gasket.

Tightenlng torque

Timing case cover to head 15

Nm (1 1

It-lb)

- Remove special tool 11 1 41 1 and install new gaskets to cyl-

inder head cover:

Clean gasltet groove and install new gasltet.

Apply Three Bond 1209 Osealant to joint between cylinder

head and timing cover and at half-moon shaped cut-outs.

Tighten cylinder head cover nuts.

Tightenlng torque

-

Cylinder head cover to head 15 Nm (1 1 ft-lb)

Page 319 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain/

- Tighten accessible sprocket retaining bolts in the following

order:

Leit exhaust camshaft

Right exhaust

camshait

Leit intake camshaft

Right

intalte camshait

Tightening torque

Sprocket bolts to camshaft flange

15 Nm (1 1 ft-lb)

- Remove BMW special tool 11 2 300 from tool bore at bell-

housing and remove

camshaft loclting tools from cylinder

heads.

Using crankshaft center bolt, turn engine over clockwise at

least one

comolete rotation so that remainino camshaft

sprocltet

retaking bolts are accessible. -

- Tighten remaining camshait sprocket retaining bolts

Tightening torque Sprocket bolts to camshaft

flange 15 Nm (I 1 It-lb)

- Remove BMW special tool 11 3 390 from primary timing

chain tensioner bore and reinstall primary chain tensioner

- Remainder of installation is reverse or removal, noting the fol-

lowing:

Remove gasket residue from cylinder head sealing sur-

face.

Apply a thin bead of Three Bond 1209

O sealing com-

pound to joints at cylinder head cover and timing case cov-

er and at half-moon sections at rear of cylinder heads.

Replace cylinder head cover

gaskets if necessary.

Page 516 of 1002

Downloaded from www.Manualslib.com manuals search engine

.," --

Radiator and Cooling System --- 1

insert two M6 screws (arrows) in tapped bores and tighten

uniformly until pump is free from timing chain cover (thermo-

stat and hoses have been removed for purposes of visual

clarity).

Installation is reverse of removal, noting the following:

Be sure to replace sealing O-ring and gaskets.

Coat O-ring with water-based lubricant during installation.

Refill with coolant. See Coolant, draining and filling

(6-

cylinder models).

Tightening torques

-

Coolant pump to timing chain 10 Nm (89 in-lb)

cover

Coolant pump pulley to coolant

10 Nm (89 in-lb

pump

Engine block drain plug to block 25 Nm (1 8 It-lb)

Radiator drain plug to radiator 2 - 3 Nm (I8 - 27 in-lb)

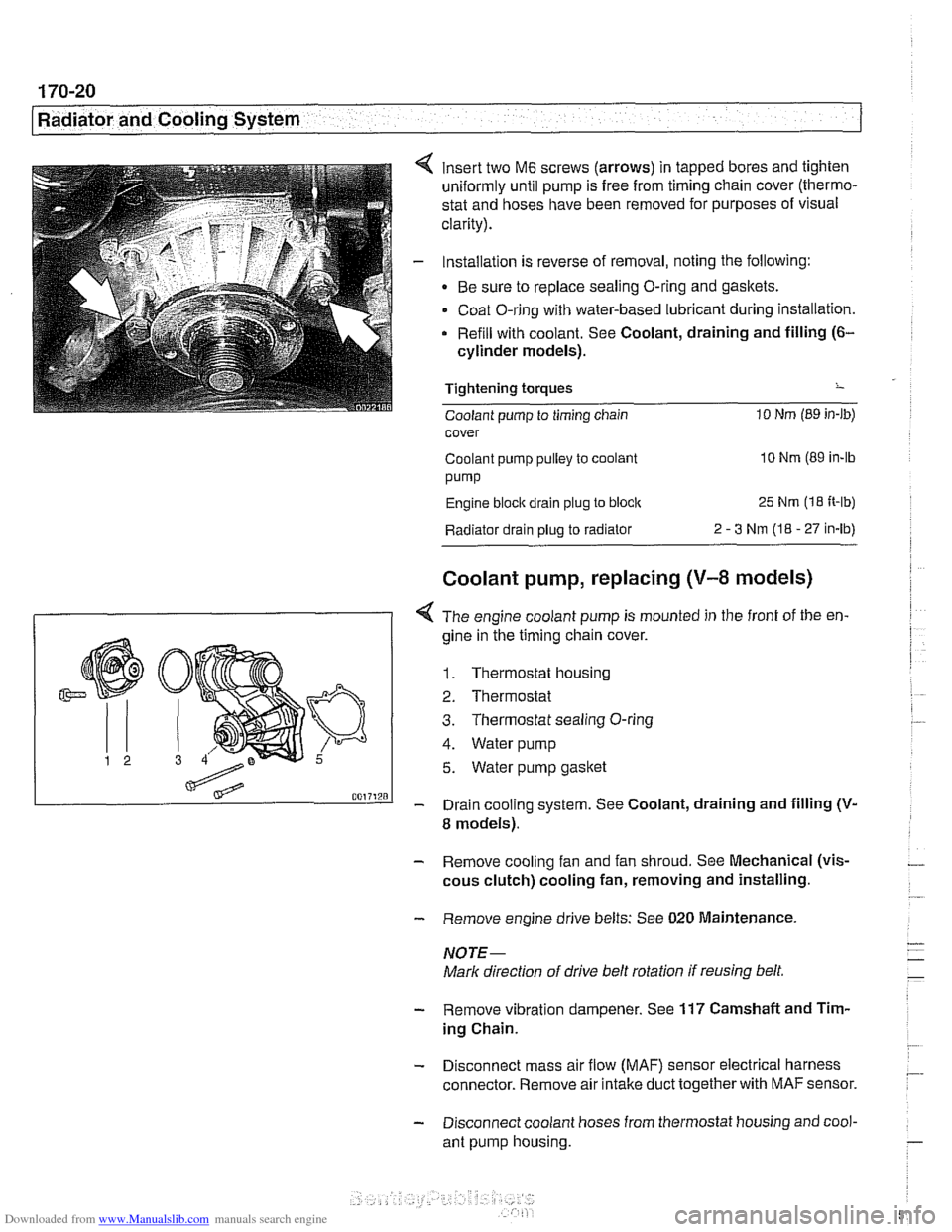

Coolant pump, replacing (V-8 models)

I 1 < The engine coolant pump is mounted in the front of the en-

gine in ;he timing chain cover.

1. Thermostat housing

2. Thermostat

3. Thermostat sealing O-ring

4. Water pump

5. Water pump gasket

- Drain cooling system. See Coolant, draining and filling (V-

8 models).

- Remove cooling fan and fan shroud. See Mechanical (vis-

cous clutch) cooling fan, removing and installing.

- Remove engine drive belts: See 020 Maintenance.

NOTE-

Mark direction of drive belt rotation if reusing belt,

- Remove vibration dampener. See 117 Camshaft and Tim-

ing Chain.

- Disconnect mass air flow (MAF) sensor electrical harness

connector. Remove air intake duct together with

MAF sensor.

- Disconnect coolant hoses from thermostat housing and cool-

ant pump housing.

Page 992 of 1002

Downloaded from www.Manualslib.com manuals search engine

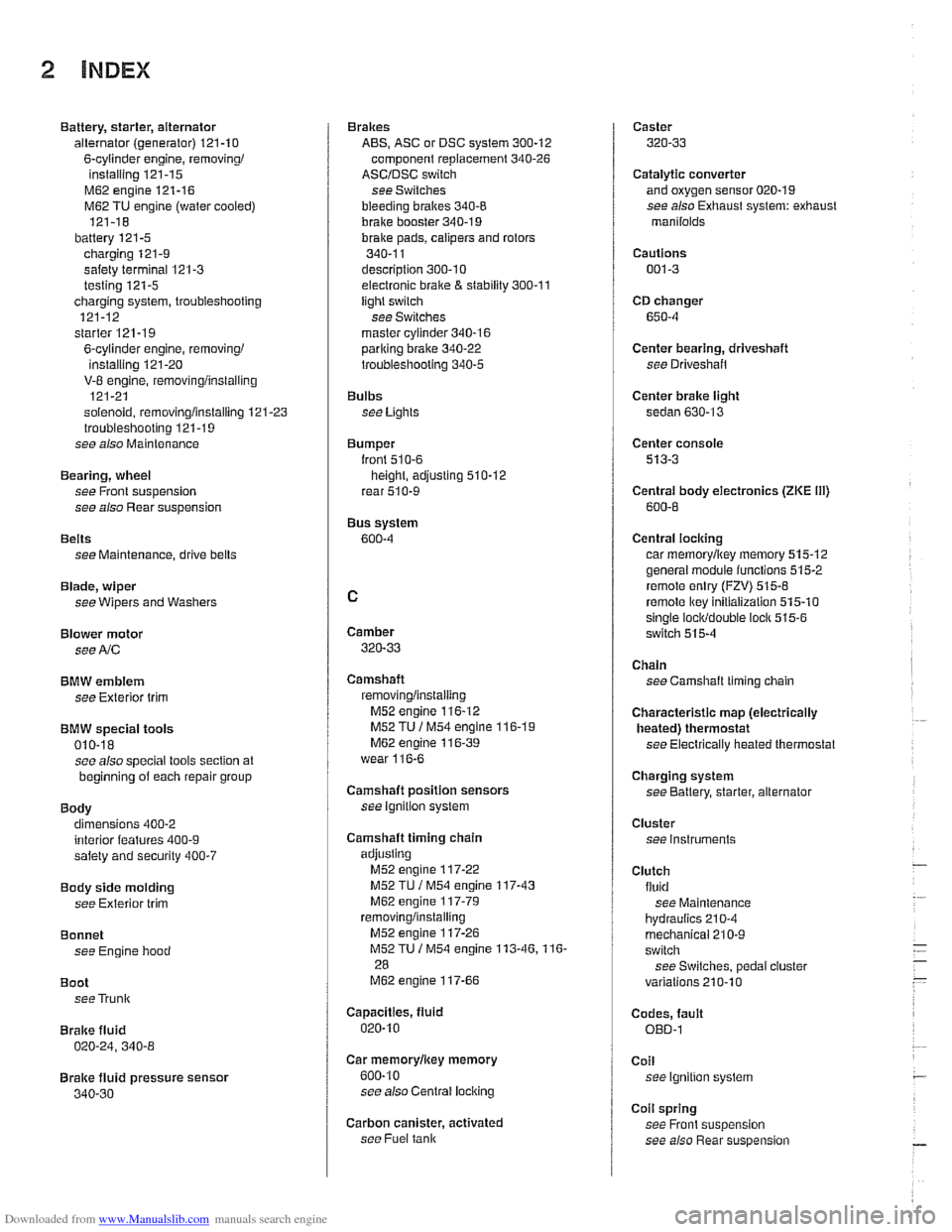

2 INDEX

Battery, starter, alternator

alternator (generator)

121-10

6-cylinder engine, removingi

installing 121-15

M62 engine 121-16

M62 TU engine (water cooled)

121-18

battery

121-5 charging 121-9

safety terminal 121-3

testing 121-5 charging system, troubleshooting

121-12

starter

121-1 9

6-cylinder engine, removingi instaliinq 121-20 . V-8 engine, rernovinglinsialiing

121-21

solenoid, removinglinstalling

121-23 troubleshooting 121-19

see also Maintenance

Bearing, wheel

see Front suspension

see also Rear suspension

Belts see Maintenance, drive belts

Blade, wiper

see Wipers and Washers

Blower motor see

A/C

BMW emblem

see Exterior trim

BMW special tools 010-18 see also special tools section at

beginning

of each repair group

Body dimensions 400-2

interior features

400-9 salety and security 400-7

Body side molding

see Exterior trim

Bonnet see Engine hood

Boot see Trunk

Brake fluid

020-24, 340-8

Brake fluid pressure sensor

340-30

Brakes

ABS, ASC or DSC system

300-12

component replacement 340-26

ASCIDSC switch

see Switches

bleeding

bralces 340-8

brake booster 340-1 9 bralce Dads. caiioers and rotors ,., 340-1 1

descriotion 300-10

e~ectrdnic brake & stability 300-11

light switch

see Switches

master cylinder

340-16 pariking brake 340-22

troubleshooting 340-5

Bulbs see Lights

Bumper

lront 510-6 height, adjusting 510-12

rear 510-9

Bus system

600-4

Camber

320-33

Camshaft

removingiinslaiiing

M52 engine 116-12

M52 TU

/ M54 engine 116-1 9 M62 engine 11 6-39

wear

116-6

Camshaft position sensors

see ignition system

Camshaft timing chain

adjusting M52 engine

117-22

M52 TU I M54 engine 117-43

M62 engine 117-79 removinglinstalling

M52 engine 117-26

M52TU 1 M54 engine 113-46.116-

28

M62 engine 117-66

Capacities, fluid

020.10

Car rnemorvlicev memorv . . 600-10

see also Centrai

lociking

Carbon canister, activated

see Fuel

tank

Caster

320-33

Catalytic converter and oxygen sensor 020-19

see also Exhaust system: exhaust

manilolds

Cautions

001-3

CD changer

650-4

Center bearing, driveshaft

see Driveshait

Center brake light

sedan

630-13

Center console

513-3

Centrai body electronics (ZKE 111)

600-6

Central locking

car memoryiey memory 515.12 general module iunctions 515-2

remote entry (FZV) 515-8

remote lkey initialization 515-10 single lociddouble ioclk 515-6

switch 515-4

Chain

see Camshaft liming chain

Characteristic map (electrically heated) thermostat

see Electrically heated thermostat

Charging system

see Battery, starter, alternator

Cluster see instruments

Clutch fluid see Maintenance

hydraulics

210-4

mechanical 210-9

switch

see Switches, pedal ciuster

variations

210.10

Codes, fault OED-1

Coil

see Ignition system

Coil spring

see Front suspension

see also Rear

suspe nsion