Temperature sensor BMW 528i 1997 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 727 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear Suspension

- Remainder of installation is reverse of removal, noting the fol-

lowing.

Tighten suspension arm and shock absorber fasteners to

final torque only afler vehicle has been lowered and sus-

pension has settled.

Tightening torques

ABS pulse sensor to wheel bearing carrier 8

Nrn (6 ft-lb)

Air line connection 2 Nrn (18 in-lb)

Brake rotor to hub 16

Nrn (12 ft-lb)

Driveshaft

CV joint to final drive flange

- MI0 (Torx bolts) 70

Nrn (51 ft-lb)

- MB (compression nut) 32 Nrn (24 ft-lb)

Rear

brake pad carrier (caliper) to wheel 65

Nrn (48 ft-lb)

bearing carrier

Road wheel to hub

120ilO Nrn

(89 i-7 ft-lb)

Rear subframe mounting bushings,

removing and installing

- Remove rear subframe mounting bolts as described earlier.

Lower

subframe approximately 40 - 45 mm (1 -2 in).

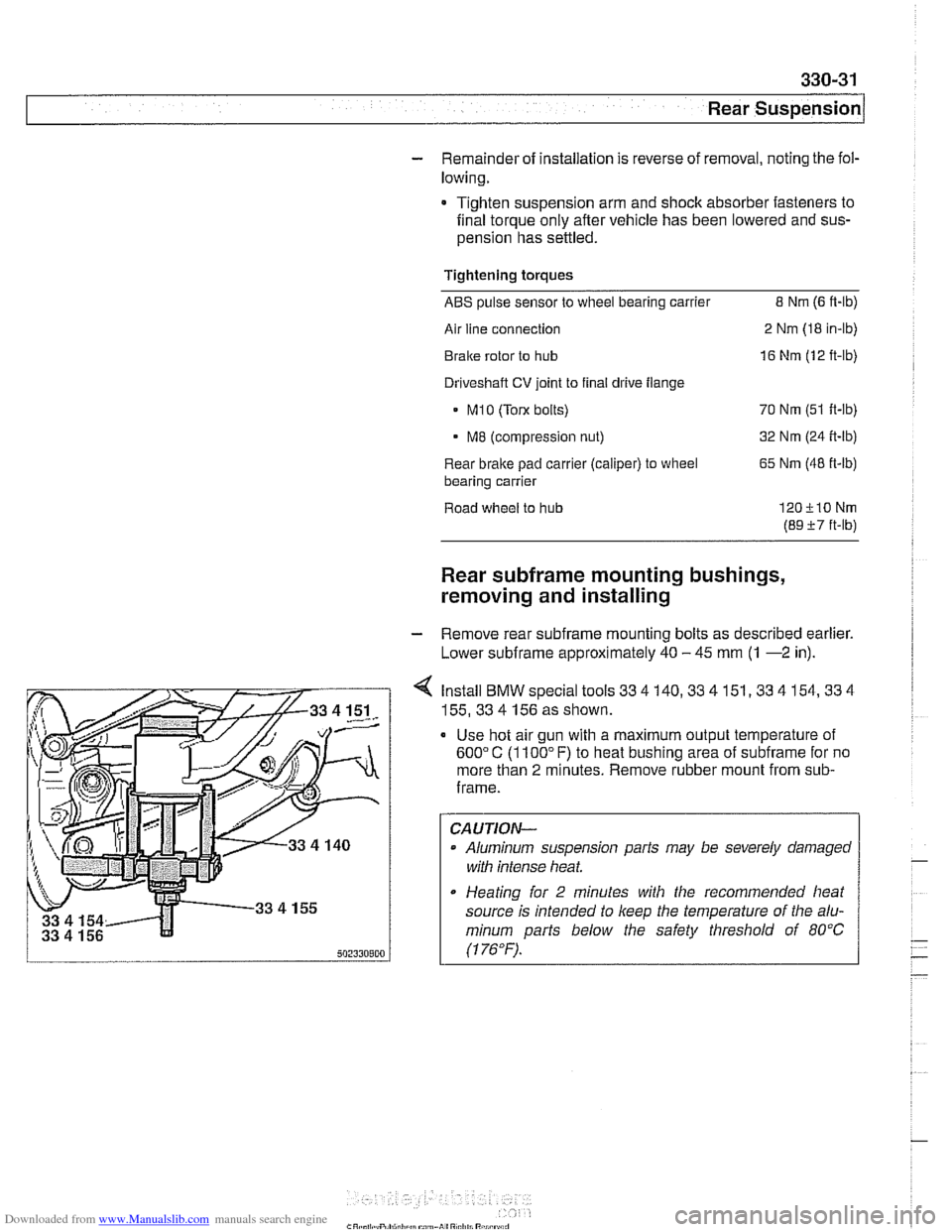

4 Install BMW special tools 33 4 140,33 4 151,33 4 154,33 4

155,33 4 156 as shown.

Use hot air gun with a maximum output temperature of

600°C (1100" F) to heat bushing area of subframe for no

more than

2 minutes. Remove rubber mount from sub-

frame.

CAUTION-

Aluminum suspension parts may be severely damaged

witli intense heat

* Heating for 2 minutes with the recommended heat

source is intended to

keep the temperature of the alu-

minum

parts below the safety threshold of 80°C

(1 76°F). .

Page 966 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-6

On-Board Diagnostics

Fuel system monitoring. This monitor looks at the fuel

delivery needed (long

/short term fuel trim) for proper engine

operation based on programmed data. If too much or not

enough fuel is delivered over a predetermined time, a DTC is

set and the MIL illuminates.

Fuel trim refers to adiustments to base fuel schedule.

Lono- ., term fuel trim refers to gradual adjustments to the fuel

calibration adjustment as compared to short term fuel trim.

Long term fuel trim adjustments compensate for gradual

changes that occur over time.

Fuel system monitoring monitors the calculated injection time

(ti) in relation to enginespeed, load and precatalyticconverter

oxygen

sensor(s) signals.

Using this data, the system optimizes fuel delivery for all

engine operating conditions.

Evaporative system monitoring. This monitor checks the

the fuel storage system and related fuel lines for leaks. It can

detect very small leaks anywhere in the system.

A leak detection unit (LDP or DMTL) is used to pressurize the

evaporative control system on a continuous basis (as the

drive cycle allows) and to

check system integrity.

Drive cycle

The OED II drive cycle is an important concept in

understanding OBD

II requirements. The purpose of the drive

cycle is to run ail of the emission-related on-board diagnostics

over a broad range of driving conditions.

A drive cycle is considered complete when all of the

diagnostic monitors have run their tests without interruption.

~ora drive cycle to be initiated, the vehicle must be started

cold and brought up to

1 60°F and at least 40°F above its

original starting temperature.

Readiness codes

Inspection/maintenance (I/M) readiness codes are mandated

as part of OBD

II. The readiness code is stored aftercomplete

diagnostic monitoring of specified components and systems

is carried out. The readiness code function was designed to

prevent manipulating an

I/M emission test procedure by

clearing faults codes or disconnecting the ECM or battery.

Page 973 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

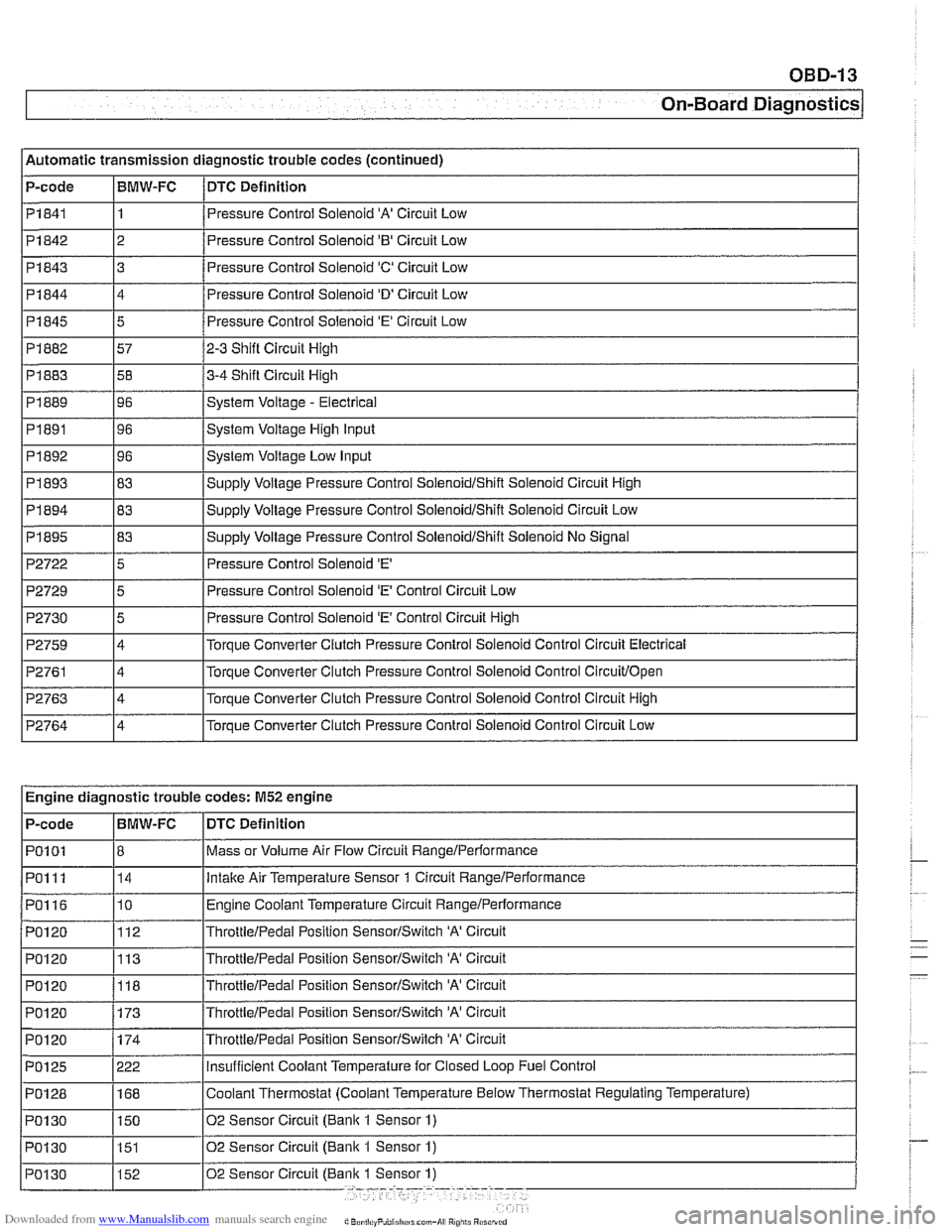

l~utomatic transmission diagnostic trouble codes (continued)

P-code

1 Pi844

I I

14 /Pressure Control Solenoid 'D' Circuit Low

I I PI841 11 /Pressure Control Solenoid 'A' Circuit Low

BMW-FC

Pi842

I

P2722 15 I Pressure Control Solenoid 'E' I

DTC

Definition

Pi 845

Pi 882

Pi 883

PI 889

PI891

PI 892

PI 893

Pi 843 3 8

2 Pressure Control Solenoid '0' Circuit Low

5

57

58

96

96

96

83

P2729

P2730

P2759

P2761

P2763

P2764

Pressure Control Solenoid 'E' Circuit Low

2-3 Shift Circuit High

3-4 Shift Circuit High

System Voltage

- Electrical

System Voltage High Input

System Voltage Low Input

SUDP~V Voltaqe Pressure Control SoienoidIShift Solenoid Circuit High

~~ ~~ ~ Engine diagnostic trouble codes: M52 engine

5

5

4

4

4

4

I I

Pressure Control Solenoid 'E' Control Circuit Low

Pressure Control Solenoid

'E' Control Circuit High

Torque Converter Clutch Pressure Control

Solenoid Control Circuit Electrical

Torque Converter Clutch Pressure Control Solenoid Control

Circuitlopen

Torque Converter Clutch Pressure Control Solenoid Control Circuit High

Torque Converter Clutch Pressure Control Solenoid Control Circuit Low

DTC Definition

Mass or Volume Air

Flow Circuit RangeIPerformance

lntalte Air Temperature Sensor 1 Circuit Rangelperformance

Engine Coolant Temperature Circuit RangeIPerformance

ThrottieIPedai Position SensorISwitch 'A' Circuit

ThrottleIPedai Position SensorISwitch 'A' Circuit

P-code

PO1

01

PO1 11

PO116

PO120

PO120

PO1 20 BMW-FC

8 14

10

112

113

POI 20 1173 /~hrottie/~edal Position SensorISwitch 'A' Circuit

118

ThrottieIPedai Position SensorISwitch 'A' Circuit

Page 975 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-15

On-Board ~iagnosticsl

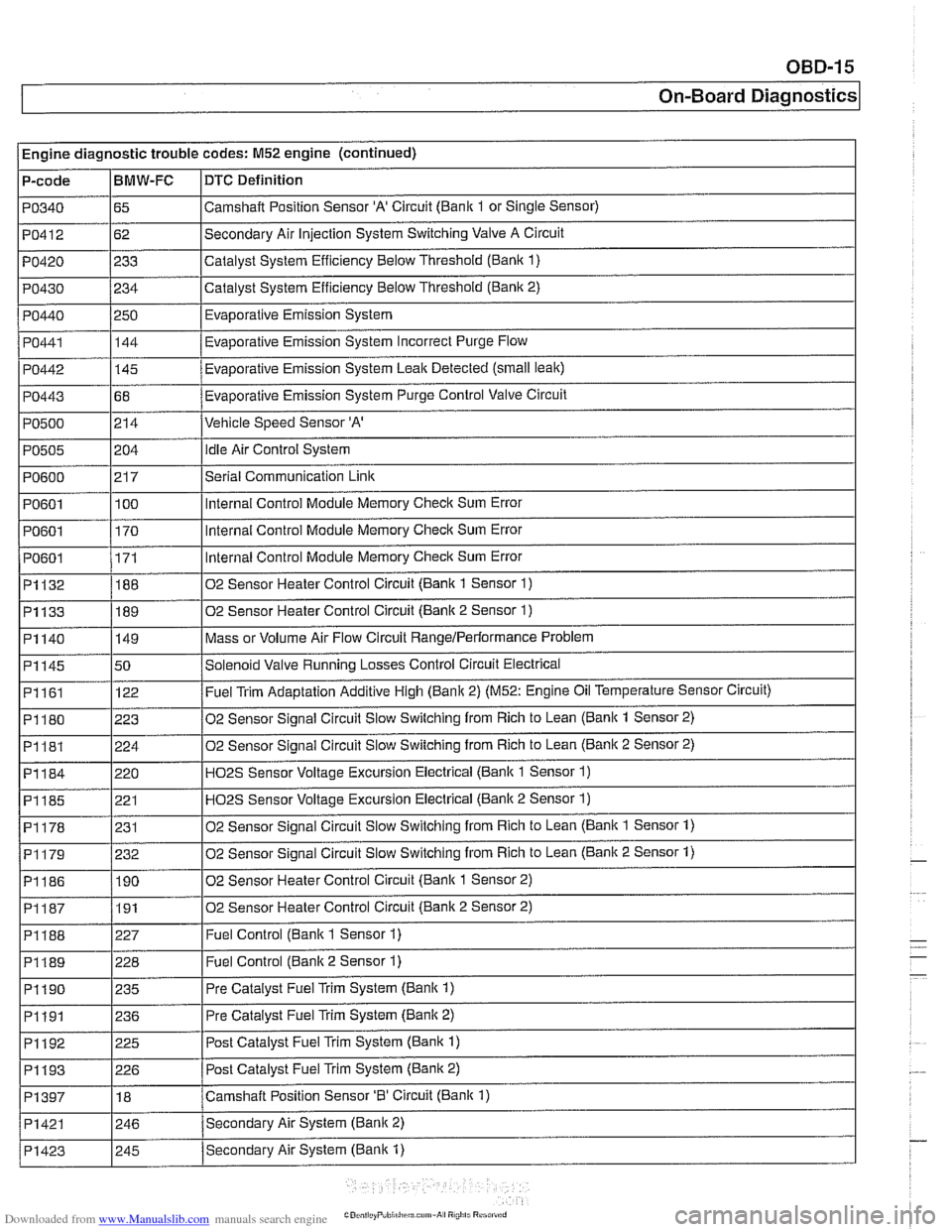

Engine diagnostic trouble codes: M52 engine (continued)

P-code

PO340

PO412

PO420

PO430

PO440

PO441

PO442

PO443

PO500

PO505

PO600

PO601

PO601

I PO601

~1132

~1133

BMW-FC

65

62

233

234

250 144

-

145

68

214

i I

DTC Definition

Camshalt Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

Secondary Air Injection System Switching Valve A Circuit

Catalyst System Efficiency Below Threshold

(Bank 1)

Catalyst System Efficiency Below Threshold (Bank 2)

Evaporative Emission System

Eva~orative Emission Svstem Incorrect Purge Flow .

Evaporative Emission System Leak Detected (small leak)

Evaporative Emission System Purge Control Valve Circuit

Vehicle Speed Sensor 'A'

204

21 7

100

170

171

188

189

PI161

PI180

PI181

PI184

PI185

PI178

02 Sensor Heater Control Circuit (Bank 2 Sensor 2) I

idle Air Control System

Serial Communication

Link

Internal Control Module Memory Check Sum Error

Internal Control Module Memory

Check Sum Error

Internal Control Module Memory

Check Sum Error

02 Sensor Heater Control Circuit (Bank 1 Sensor

1)

02 Sensor Heater Control Circuit (Bank 2 Sensor 1)

Mass or Volume Air Flow Circuit RangeIPerlormance Problem PI140

I

I I

P1188 1227 I Fuel Control (Bank 1 Sensor 1)

PI145 150 /Solenoid Valve Running Losses Control Circuit Electrical

149

122

223

224

220 221

231

I I

P1189 1228 I Fuel Control (Banlc 2 Sensor 1)

Fuel Trim Adaptation Additive High (Bank 2) (M52: Engine Oil Temperature Sensor Circuit)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 1 Sensor 2)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 2 Sensor 2)

H02S Sensor Voltage Excursion Electrical (Banlc 1 Sensor 1)

HO2S Sensor Voltage Excursion Electrical (Banlc 2 Sensor 1)

02 Sensor Sianai Circuit Slow Switchina from Rich to Lean (Bank 1 Sensor 1)

02 Sensor Signal Circuit Slow Switching from Rich to Lean (Bank 2 Sensor 1) PI179

I I

PI190 1235 I Pre Catalyst Fuel Trim System (Banlc 1)

PI186 1190 102 Sensor Heater Control Circuit (Banlc 1 Sensor 2)

232

I I

PI191 1236 I Pre

Catalyst Fuel Trim System (Banlc 2)

PI192

. . -- - i Pi193 1226 I Post Catalvst Fuel Trim Svstem (Bank 2)

225

PI397

I I

Post Catalyst Fuel Trim System (Bank 1)

PI421 1246 /Secondarv Air System (Bank 2)

18

Secondary Air System (Bank

1) PI423

Camshaft Position Sensor '0' Circuit (Bank 1)

I 245

Page 976 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

On-Board Diagnostics - - --- - -- - -

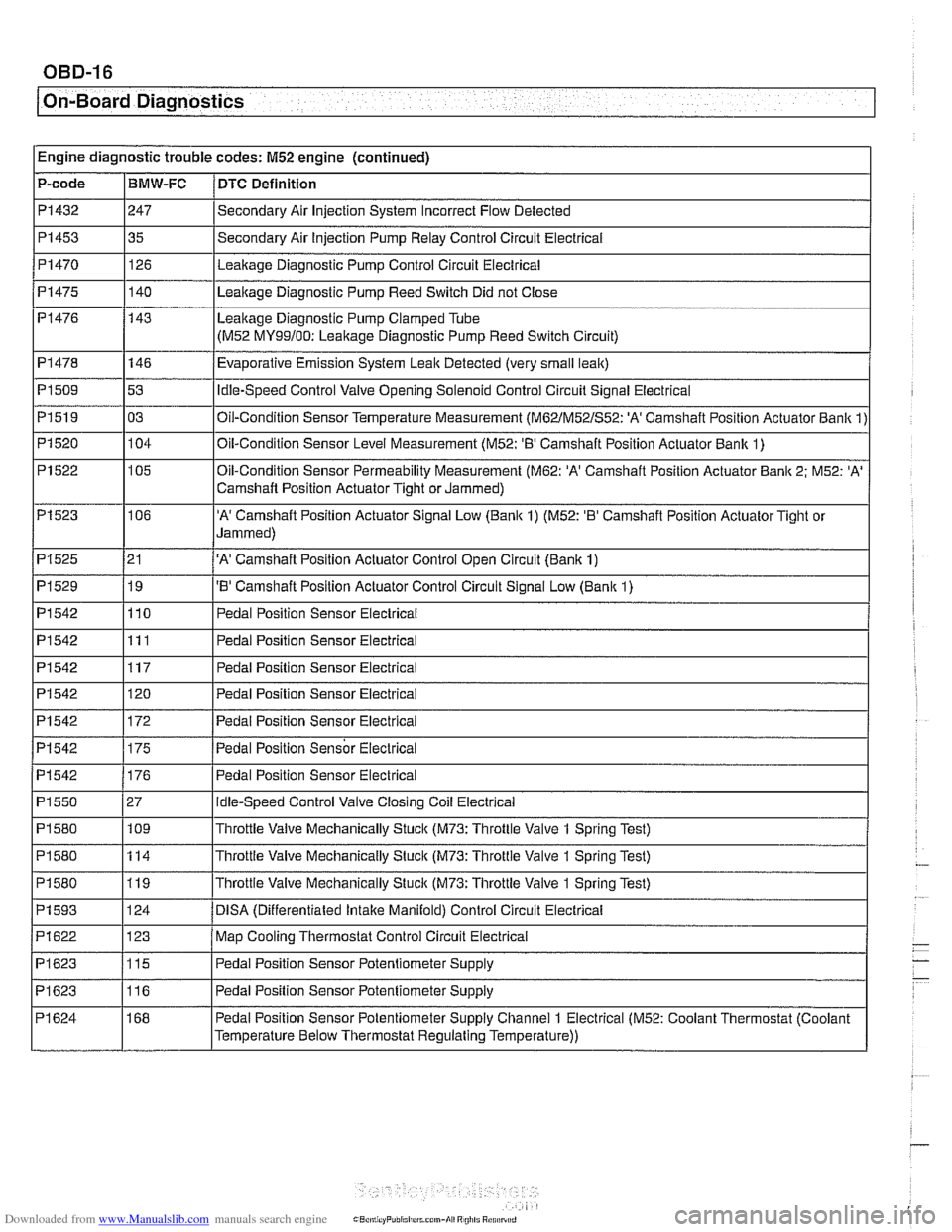

PI542

PI550

PI580

PI 580

PI 580

PI 593

PI622

PI623

PI623

PI 624 176

27 109

114

119

124

123

115

116

168 Pedal Position Sensor Electrical

Idle-Speed

Control Valve Closing Coil Electrical

Throttle Valve Mechanically Stuck

(M73: Throttle Valve 1 Spring Test)

Throttle Valve Mechanically Stuck

(M73: Throttle Valve 1 Spring Test)

Throttle Valve Mechanically Stuck

(M73: Throttle Valve 1 Spring Test)

DlSA (Differentiated lntalte Manifold) Control Circuit Electrical

Map Cooling Thermostat Control Circuit Electrical

Pedal Position Sensor Potentiometer Supply

Pedal Position Sensor Potentiometer Supply

Pedal Position Sensor Potentiometer Supply Channel

1 Electrical (M52: Coolant Thermostat (Coolant

Temperature Below Thermostat Regulating Temperature))

Page 977 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~iaanosticsl

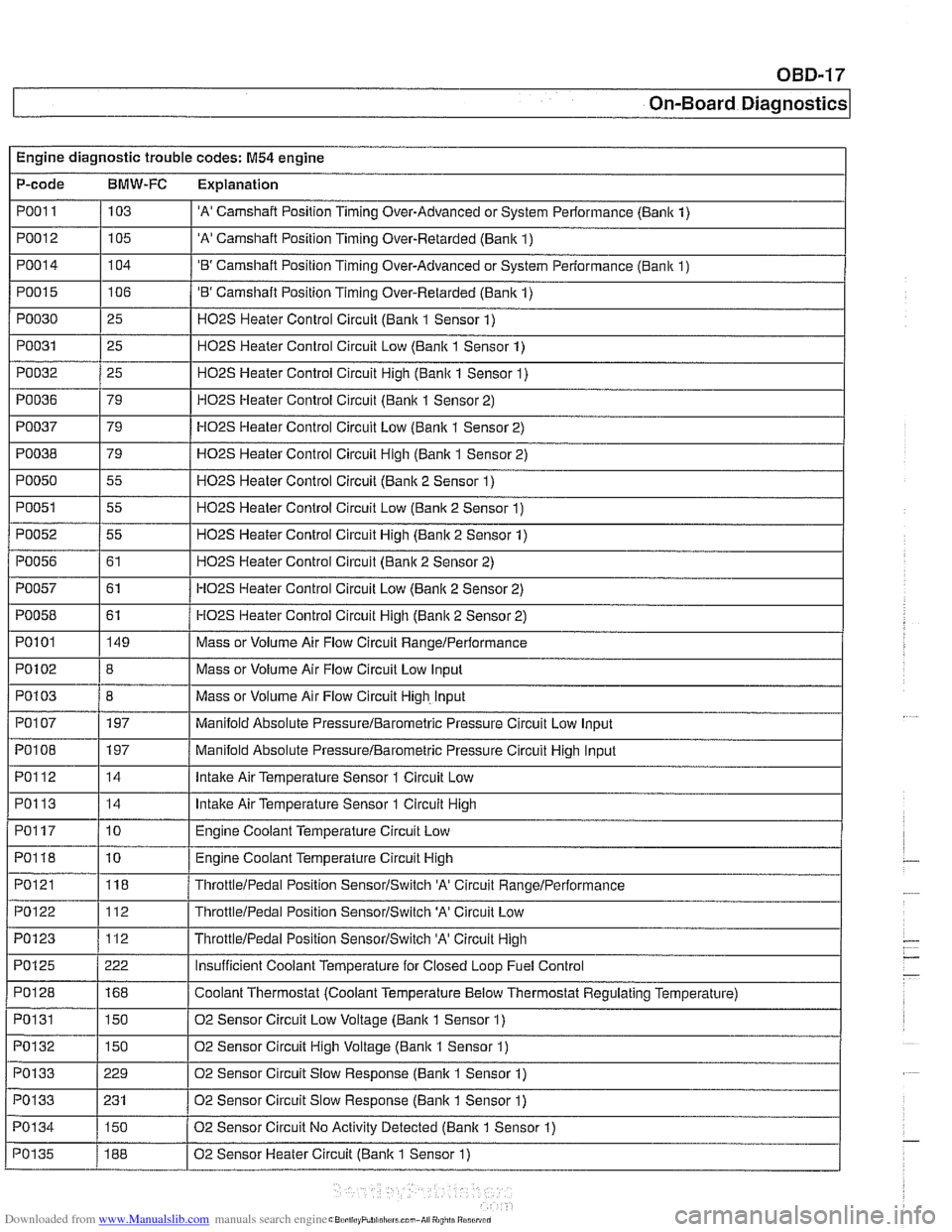

Engine diagnostic trouble codes: M54 engine

P-code

BMW-FC Explanation

PO01 I / 103 I 'A' Camshaft Position Timing Over-Advanced or System Performance (Banlc 1) I I

PO012 1105 I 'A' Camshaft Position Timing Over-Retarded (Bank 1) I I

PO01 4 1104 I 'B' Camshaft Position Timing Over-Advanced or System Performance (Bank 1)

PO01 5

PO030

PO031

PO032

I 1

PO038 179 / HO2S Heater Control Circuit High (Bank 1 Sensor 2)

I I -.

I I

PO050 1 55 I H02S Heater Control Circuit (Bank 2 Sensor 1)

106

25

25

25

PO036

I I

PO051 1 55 I H02S Heater Control Circuit Low (Bank 2 Sensor 1)

'B' Camshaft Position Timing Over-Retarded (Bank 1)

H02S Heater Control Circuit (Bank 1 Sensor 1)

H02S Heater Control Circuit Low (Bank 1 Sensor 1)

H02S Heater Control Circuit Hiqh (Bank 1 Sensor 1)

PO037 1 79 I HO2S Heater Control Circuit Low (Bank 1 Sensor 2)

79

HOPS Heater

Control Circuit (Banlc 1 Sensor 2)

PO052

PO056

PO057

PO058

I I

PO1 03 / 8 I Mass or Volume Air Flow Circuit High. Input

I I -.

I I

PO1 07 1 197 I Manifold Absolute PressureIBarometric Pressure Circuit Low Input

55

61

61

61

PO101

I I

POI08 1197 / Manifold Absolute PressureIBarometric Pressure Circuit High Input

H02S Heater Control Circuit High (Bank 2 Sensor 1)

H02S Heater Control Circuit (Bank 2 Sensor 2)

HO2S Heater Control Circuit Low (Bank 2 Sensor 2)

HO2S Heater Control Circuit Hiqh (Banlc 2 Sensor 2)

PO102 18 I Mass or Volume Air Flow Circuit Low Input

149

I I -

PO122 112 ThrottleIPedai Position SensorISwitch 'A' Circuit Low

PO123 1112 I ThrottleIPedal Position SensorISwitch 'A' Circuit High

Mass

or Volume Air Flow Circuit

RangeIPerformance

PO112

PO113

PO1 17

PO118

PO121

14

14

10

10

118

PO128

PO1 31

PO132

PO133

PO133

PO1 34 Intake

Air Temperature Sensor 1 Circuit Low

Intake Air Temperature Sensor 1 Circuit High

Engine Coolant Temperature Circuit Low

Engine Coolant Temperature Circuit High

ThrottleIPedal Position SensorISwitch 'A' Circuit RanqeIPerformance

I I

168

150

150

229

231

150

PO135

Coolant Thermostat (Coolant Temperature Below Thermostat Regulating Temperature)

02 Sensor Circuit Low Voltage (Bank 1 Sensor 1)

02 Sensor Circuit High Voltage (Bank 1 Sensor 1)

02 Sensor Circuit Slow Response (Bank

1 Sensor 1)

02 Sensor Circuit Slow Response

(Banlc 1 Sensor 1)

02 Sensor Circuit No Activitv Detected

(Banlc 1 Sensor 1)

188 02 Sensor Heater Circuit (Bank 1 Sensor 1)

Page 980 of 1002

Downloaded from www.Manualslib.com manuals search engine

I On-Board Diagnostics

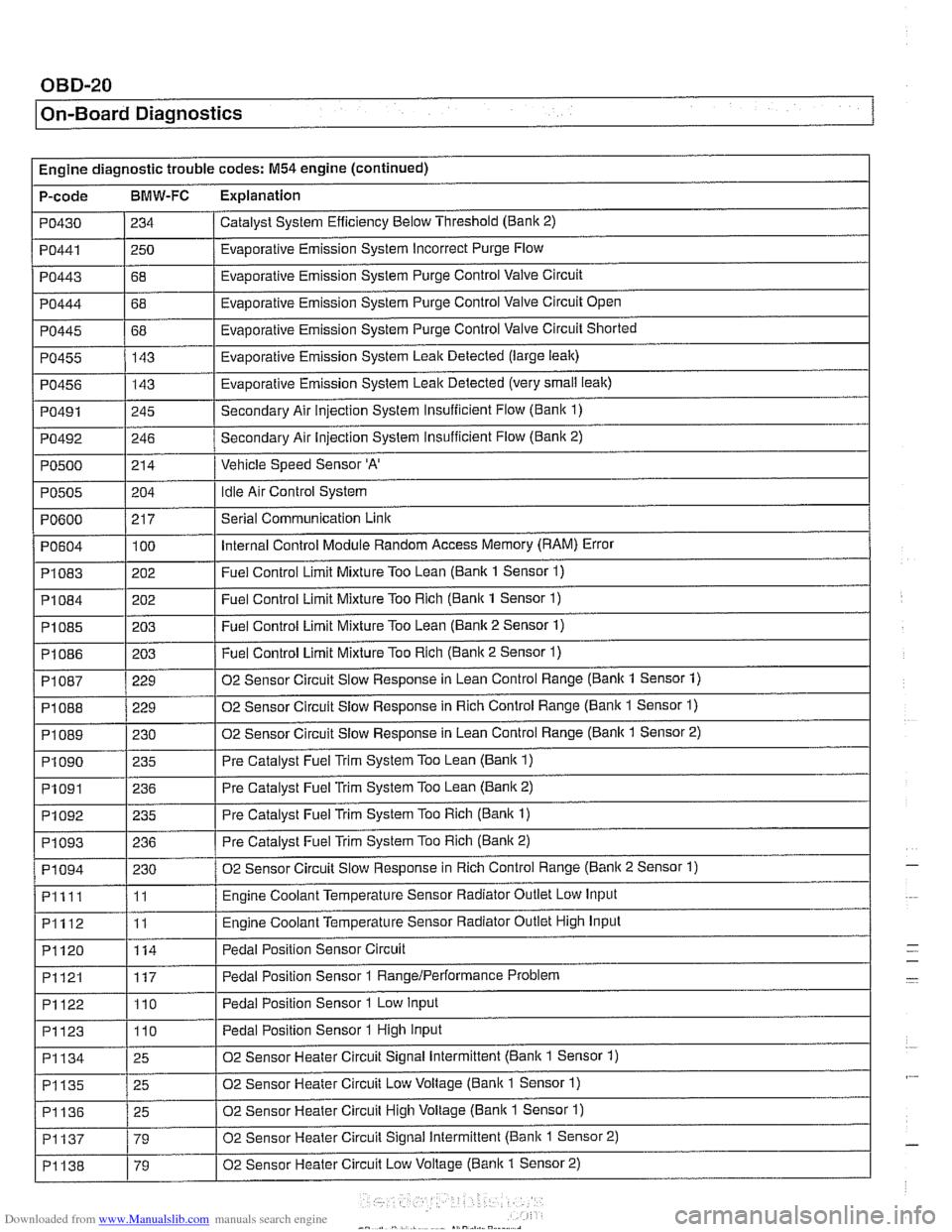

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

Catalyst System Efficiency Below Threshold (Bank 2)

PO430

PO443

PO444

PO445

PO455

PO456

PO491

PO492

PO500

PO441 1250 / Evaporative Emission System Incorrect Purge Flow

234

I I

68

68

68 143

143

245

246

214

PO604

PI083

PI084

PI085

PI086

Evaporative Emission System Purge Control Valve Circuit

Evaporative Emission System Purge Control Valve Circuit Open

Evaporative Emission System Purge Control Valve Circuit Shorted

Evaporative Emission System Leak Detected (large leak)

Evaporative Emission System Leak Detected (very

small leak)

Secondary Air injection System Insufficient Flow (Bani( 1)

Secondary Air Injection System insufficient Flow

(Banic 2)

Vehicle Speed Sensor

'A'

Idle Air Control System PO505

.

PI 087

PI 088

PI089

PI090

PO600 / 217 I Serial Communication Link

204

100

202

202

203

203

PI091

PI092

PI093

PI094

Pllll

PI112

PI120

Internal Control Module Random Access Memory (RAM) Error

Fuel Control Limit Mixture Too Lean (Bank 1 Sensor

1)

Fuel Control Limit Mixture Too Rich (Bank 1 Sensor 1)

Fuel Control Limit Mixture Too Lean (Bank 2 Sensor 1)

Fuel Control Limit Mixture Too Rich (Banic 2 Sensor 1) ~ ~

229

229

230 235

PI121

PI122

PI123

02 Sensor Circuit Slow Response in Lean Control Range (Bank 1 Sensor 1)

02 Sensor Circuit Slow Response in Rich Control Range (Bank 1 Sensor

1)

02 Sensor Circuit Slow Response in Lean Control Range (Banlc 1 Sensor 2)

Pre Catalyst Fuel Trim System Too Lean

(Bank 1)

236

235

236

230

11

11

114

PI134

PI135

PI136

PI137

PI138

Pre Catalyst Fuel Trim System Too Lean (Banic 2)

Pre Catalyst Fuel Trim System Too Rich

(Bank 1)

Pre Catalyst Fuel Trim System Too Rich (Bank 2)

02 Sensor Circuit Slow Response in Rich Control Range (Banic 2 Sensor 1)

Engine Coolant Temperature Sensor Radiator Outlet Low Input

Engine Coolant Temperature Sensor Radiator Outlet High Input

Pedal Position Sensor Circuit

117

110

110

25

25

25

79

79 Pedal Position Sensor 1

RangeIPerformance Problem

Pedal Position Sensor 1 Low Input

Pedal Position Sensor 1 High Input

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 1)

02 Sensor Heater Circuit Low Voltage (Bank 1 Sensor

1)

02 Sensor Heater Circuit High Voltage (Bank 1 Sensor 1)

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 2)

02 Sensor Heater Circuit Low Voltage

(Banic 1 Sensor 2)

-

-

Page 983 of 1002

![BMW 528i 1997 E39 Service Manual Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic troubl BMW 528i 1997 E39 Service Manual Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic troubl](/img/1/2822/w960_2822-982.png)

Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

PI 604

PI604

PI619

PI620

PI624

PI632

PI633

PI634

P1 634

PI 634

PI 635

PI 636 50

51 123

123

146 i I

I

I Barometric Pressure Circuit Low

Control

Module Self-Test,

Speed Monitoring

Control Module Self-Test, Speed Monitoring

Map Cooling Thermostat Control Circuit Signal Low

Map Cooling Thermostat Control Circuit Signal High Pedal Position Sensor Potentiometer Supply Channel

1 Electrical (M52: Coolant Thermostat (Coolant

Temperature Below Thermostat Regulating Temperature))

115

115

115

135

136

115

109

PI639

PI675

PI694

P2088

P2089

P2090

P2091

I I

P2229 1197 I Barometric Pressure Circuit High

Throttle

Valve Adaptation Conditions Not Met

Throttle

Valve Adaptation Limp-Home Position Unknown

Throttle Valve Adaptation Spring Test Failed

Throttle

Valve Adaptation Spring Test Failed

Throttle

Valve Adaptation Spring Test Failed

Throttle Valve Adaptation Lower Mechanical Stop not Adapted

Throttle Valve Control Circuit

Throttle Valve Position Control, Control Deviation

PI 637

I I

P2270 1215 1 02 Sensor Signal Stuck Lean (Banic 1 Sensor 2)

PI 638 1160 I Throttle Valve Position Control Throttle Stucic Temporarily

162

161

135

136

21

21 19

19 Throttle

Valve Position Control Throttle

Stucic Permanently

Throttle Valve Actuator Start Test Re-Adaptation Required

Throttle Valve Actuator Start Test Spring Test and Limp-Home Position Failed

'A' Camshaft Position Actuator Control Circuit Low (Banlc 1)

'A' Camshaft Position Actuator Control Circuit High (Banlc 1)

'B' Camshaft Position Actuator Control Circuit Low (Bank 1)

'B' Camshaft Position Actuator Control Circuit High (Bank 1)

P2271

P2272

P2273

P3041

P3198 I I -

215

216

21 6

10481

10205 02

Sensor Signal Stucic Lean (Bank 1 Sensor 2)

02 Sensor Signal

Stuclc Lean (Bank 2 Sensor 2)

02 Sensor Signal Stuclc Lean (Bank 2 Sensor 2)

02 Sensor Lean and Rich Voltage Thresholds not Reached (Bank 2 Sensor 2)

Engine Coolant Temperature Gradient Too High

Engine Coolant Temperature Signal Stuck

P3199

P3238 1 10289 I Control Module Monitoring TPU Chip Defective

10207

Page 984 of 1002

Downloaded from www.Manualslib.com manuals search engine

/ On-Board Diaanostics I

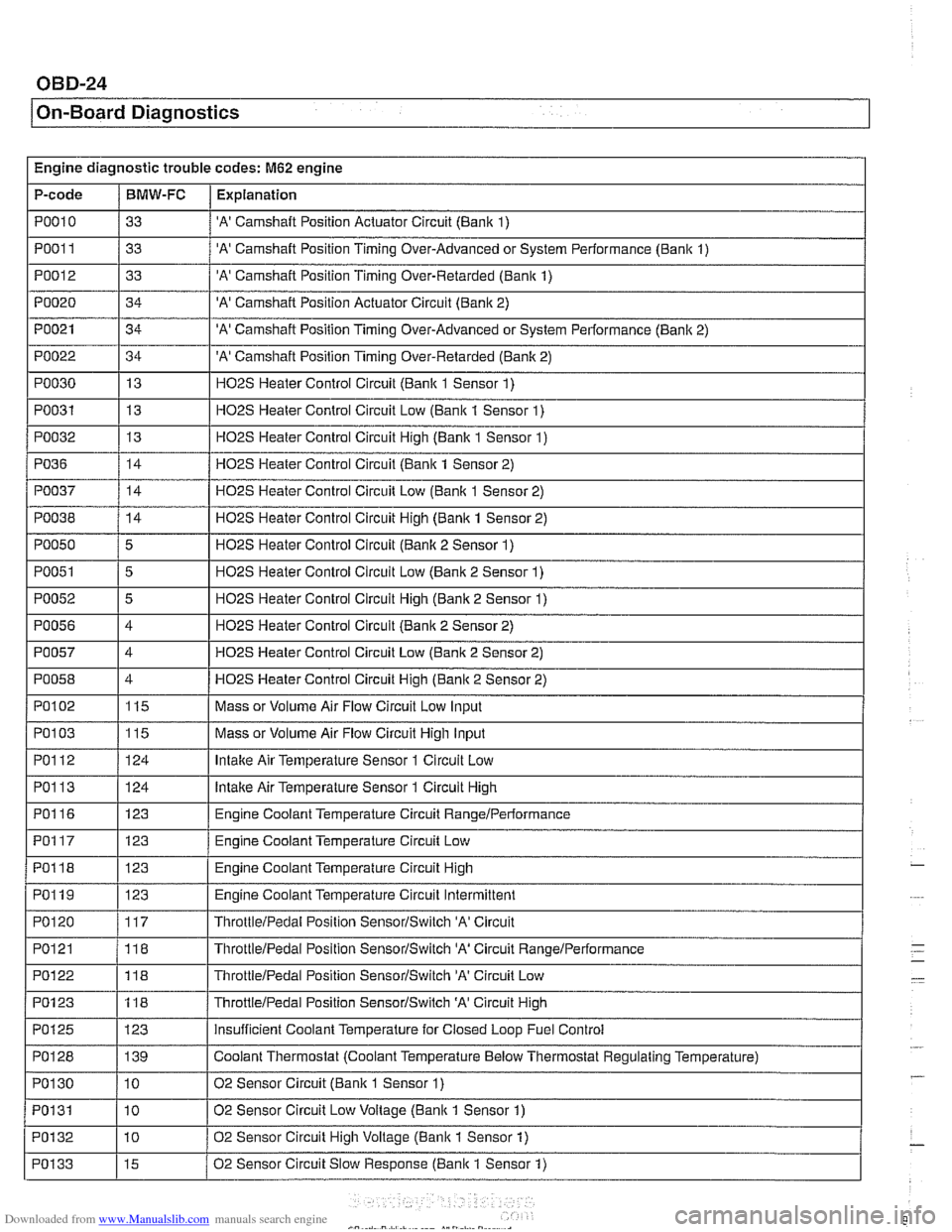

Engine diagnostic trouble codes: M62 engine

P-code

PO01 1

PO012

PO020

PO021

PO022

PO030

PO031

PO032

I I

PO038 / 14 I H02S Heater Control Circuit High (Bank 1 Sensor 2)

PO010 / 33 / 'A' Camshaft Position Actuator Circuit (Bank 1)

BMW-FC

I I -.

Explanation

33

33

34

34

34 13

13

13

PO36

'A' Camshaft Position Timing Over-Advanced or System Performance (Bank 1)

'A' Camshaft Position Timing Over-Retarded (Bank 1)

'A' Camshaft Position Actuator Circuit (Bank 2)

'A' Camshaft Position Timing Over-Advanced or System Performance (Banlc 2)

'A' Camshaft Position Timing Over-Retarded (Banlc 2)

H02S Heater Control Circuit (Bank 1 Sensor 1)

H02S Heater Control Circuit Low (Bank 1 Sensor 1)

HOPS Heater Control Circuit Hiqh (Banlc 1 Sensor 1)

PO050

PO051

PO052

PO056

PO057

PO058

PO037 / 14 / H02S Heater Control Circuit Low (Bank 1 Sensor 2)

14

I I -.

Ir-1 ThrottleIPedal Position SensorISwitch 'A' Circuit

Low-

HO2S Heater Control Circuit (Bank 1 Sensor 2)

5

5

5

4

4

4

PO102

PO1 13

PO116

PO117

PO118

PO119

PO120

PO121

H02S Heater Control Circuit (Banlc 2 Sensor 1)

H02S Heater Control Circuit Low (Bank 2 Sensor 1)

H02S Heater Control Circuit High (Bank 2 Sensor 1)

H02S Heater Control Circuit (Bank 2 Sensor 2)

HO2S Heater Control Circuit Low (Bank 2 Sensor 2)

HO2S Heater Control Circuit Hiqh (Bank 2 Sensor 2)

PO103 1115 I Mass or Volume Air Flow Circuit High Input

115

124

123

123

123

123

117

118

PO1 23

PO125

PO128

PO1 30

PO131

POI 32

PO133

Mass or Volume Air Flow Circuit Low Input

lntalte Air Temperature Sensor 1 Circuit High

Engine Coolant Temperature Circuit

RangeIPerlormance

Engine Coolant Temperature Circuit Low

Engine Coolant Temperature Circuit High

Engine Coolant Temperature Circuit Intermittent

ThrottleIPedal Position SensorISwitch 'A' Circuit

ThrottieIPedal Position SensorISwitch 'A' Circuit RanqeIPerformance

118

123 139

10

10

10

15

ThrottleIPedai Position SensorlSwitch 'A' Circuit High

insufficient Coolant Temperature for Closed Loop Fuel Control

Coolant Thermostat (Coolant Temperature Below Thermostat Regulating Temperature)

02 Sensor Circuit (Bank

1 Sensor 1)

02 Sensor Circuit Low Voltage (Bank 1 Sensor 1)

02 Sensor Circuit High Voltage (Bank

1 Sensor 1)

02 Sensor Circuit Slow Response (Bank 1 Sensor

1)

Page 991 of 1002

Downloaded from www.Manualslib.com manuals search engine

INDEX 'tl

WARNING

Your common sense, good

judgemenl, and general alertness are

crucial to sale and successiul service

worlr. Belore attempting any work on

your

BMM be sure lo read 001

General Warnings and Cautions

and the

copyriglll page at the front 01

the manual. Review these warnings

and

caulions each lime you prepare

lo work on your BMW. Please also

read any warnings and cautions that

accompany

tile procedures in the

manual.

312-way valve (running losses)

see Fuel tank

Abbreviations, commonly used 600-14

ABS (antilock brake system)

see

Bral(es

A/C air distribution motors

see stepper motors (below)

blower final stage (resistor pack),

replacing

640-16

blower, removinglinslalling

640-1 5

compressor, replacing

640-24 condenser, replacing 64045

control panellmodule, removing1

installing

640-1 1

evaporakr, removinglinstalling 640-29

evaporator temperature sensor

640-12 expansion valve, removinglinstailing

640-27

IHKA/ IHKR system description 640-5

receiveridrier, replacing 640-26

stepper motors 640-1 3 ventilation microiilter, replacing

020-22. 640-17

see also Heating

Accelerator

iinlcage

see Maintenance

Activated carbon canister

see Fuel tank

ADS (auxiliary throttle valve)

130-57

Air compressor

330-44

Air conditioning

see

AIC

Air distribution (flap) motors

seeNC, stepper motors

Air filter see Maintenance

Air spring

300-6, 330-12

Airbag system (SRS)

2-stage

airbag 721-4

control module, replacing 721-7 driver airbag, removinglinstalling

721-8

iiead protection airbag 721-12 components 721-1 1

indicator

lighl721-4

passenger airbag, removinglinstalling

721-9 side-impact airbags crash sensor,

replacing

721-7

Airflow sensor see 130 under appropriate

fuel

injection system

Air pump

see 130 under appropriate fuel

injection system, secondary air

injection system

Air suspension

see Electronic height control

(EHC)

Alarm

see Anti-theft alarm

Alignment see

Wheei alignment

Aluminum suspension components

300-2

Antenna 650-6

Alternator see Battery, starter, alte rnator

Amplifier

650-4

Anti-theft alarm (DWA)

515-24 emergency disarming 515-31

Antifreeze (engine coolant)

see Maintenance

see also Cooling system

Antilock brake system (ABS) see Brakes

ASC see Brakes

ATF (automatic transmission fluid)

see Automatic transmission

see also Cooling systern

Automatic headlight adjustmenl

(LWR) see Lights

Automatic seat belt tensioner

720-4

Automatic shiftloclc

see

Gearshift

Automatic transmission

applications

200-3, 240-4

ATF 020-10, 200-4

capacity 240-8 checking 240-6

drainingifilling 240-7

heat exchanger 170-5

fluid pan and strainer 240-9 gearshift

see Gearshift

ID tag

200-3 range switch 610-6

removaliinstallation 240-10

steptronic see Gearshift

Auxiliary cooling fan

see

Coollng system, electric Ian

Auxiliary throttle valve (ADS)

130-57

Axle joint

see Drive axle

Back-up light switch

automatic transmission see Automatic transmission. range switch

- .~.~~~

manual transmission 230-8 -

- I