Fuel system BMW 528i 1998 E39 Owners Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 901 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

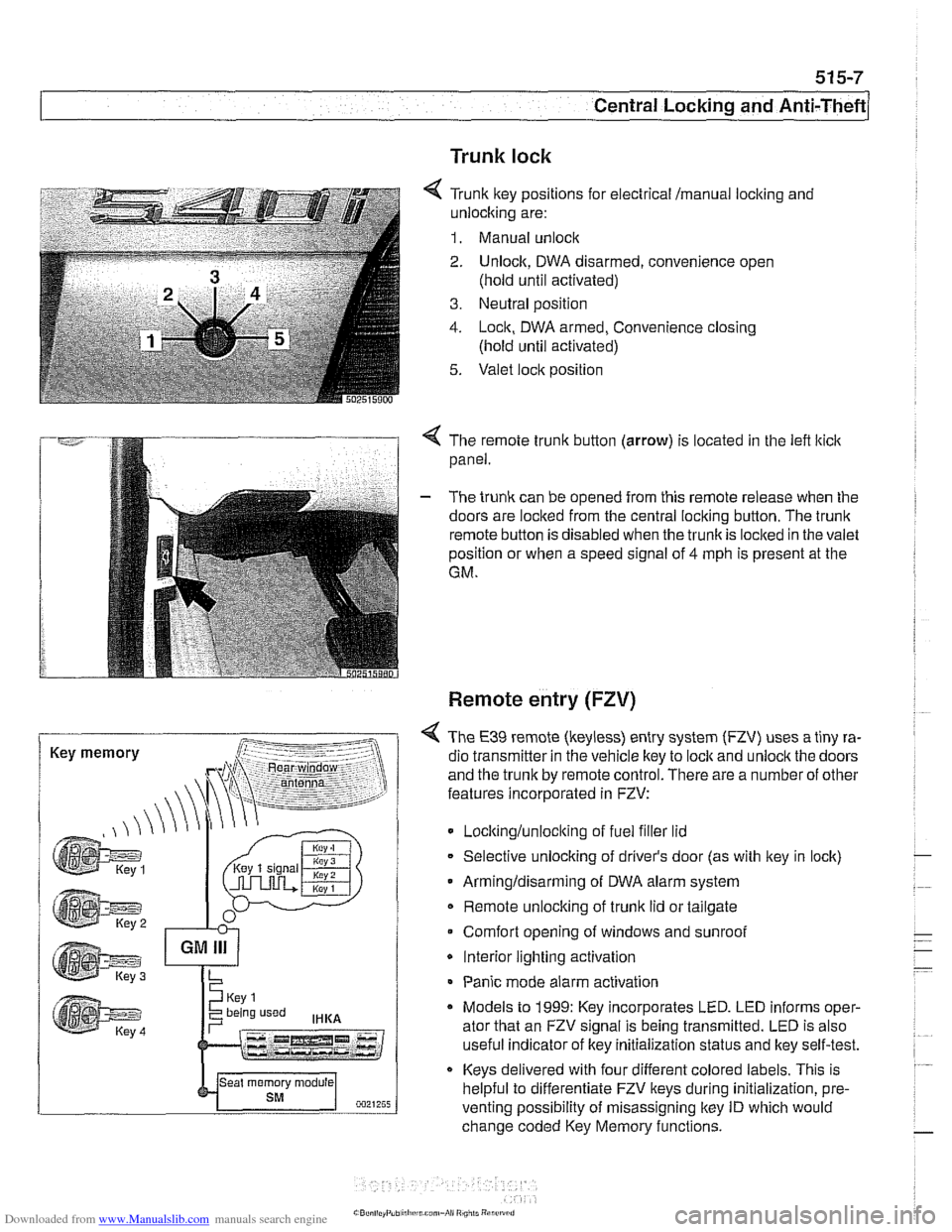

Trunk lock

6 Tr~nk ftey pos~rions for eecir'cal mama, locking and

-nlock~ng are:

1. Manual unock .. - - - ........ - ..- .- ................. s.=.=-- 2. Unlock. DWA oisarmed, conven:ence open

(nold

un1:l aclivaledj

3. Ne~tral posit'on

1. -ocn. DWA armeo, Convenience closng

(hold ~nti activated)

5. Valet .oc,t position

. -- .............-... .- . - -.....

Key memory

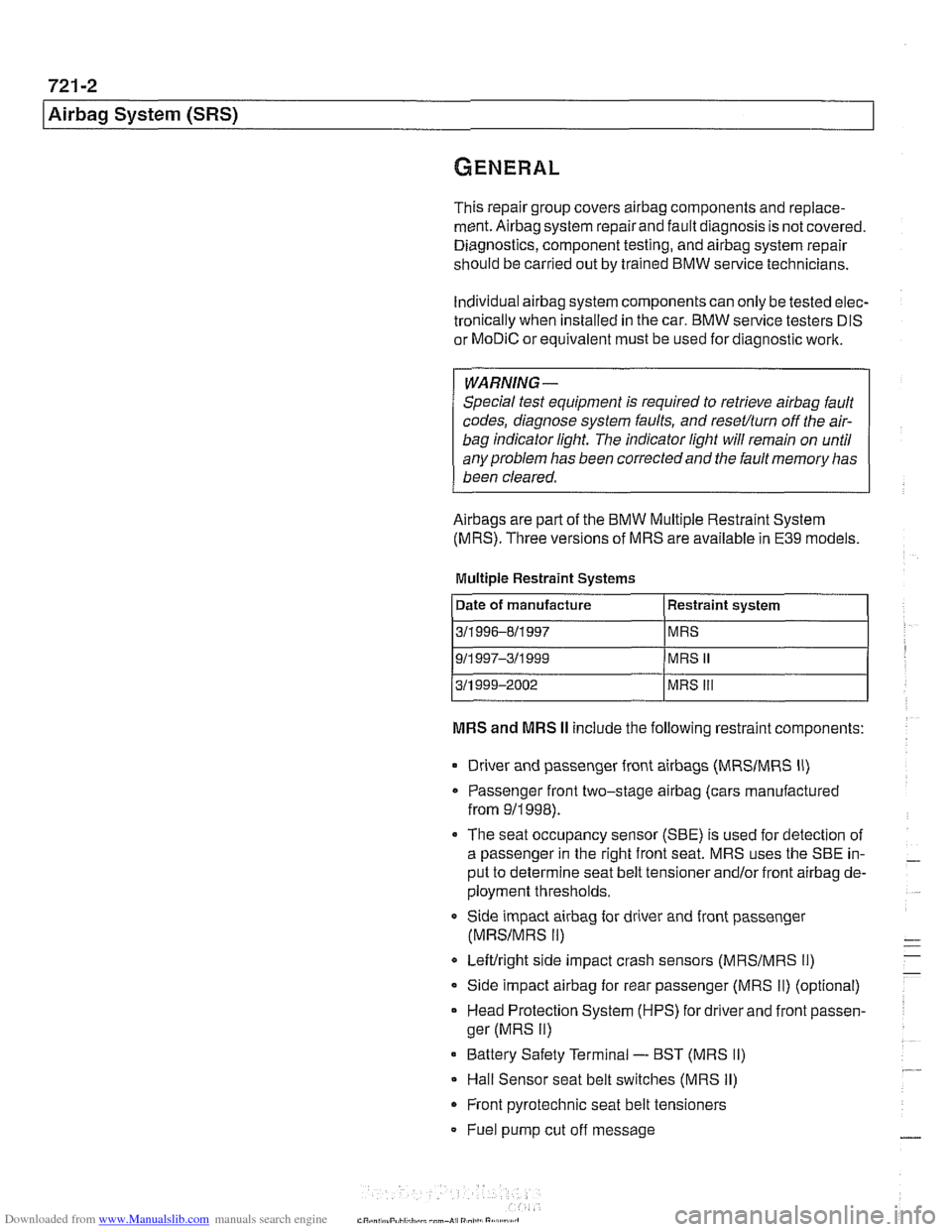

< The remote trunk button (arrow) is located in the lefl lticlc

panel.

- The trunk can be opened from this remote release when the

doors are locked from the central locking button. The

trunk

remote button is disabled when the trunkis loclted in the valet

position or when a speed signal of

4 mph is present at the

GM.

Remote entry (FZV)

< The €39 remote (keyless) entry system (FZV) uses a tiny ra-

dio transmitter in the vehicle key to

lock and unlock the doors

and the trunk by remote control. There are a number of other

features incorporated in FZV:

Locltinglunloclting of fuel filler lid

Selective unlocking of driver's door (as with key in lock)

Armingldisarming of DWA alarm system

Remote unlocking of

trunk lid or tailgate

Comfort opening of windows and sunroof

* Interior lighting activation

Panic mode alarm activation

* Models to 1999: Key incorporates LED. LED informs oper-

ator that an FZV signal is being transmitted. LED is also

useful indicator of key initialization status and lkey self-test.

Keys delivered with four different colored labels. This is

helpful to differentiate FZV keys during initialization,

pre.

venting possibility of misassigning key ID which would

change coded Key Memory functions.

Page 950 of 1002

Downloaded from www.Manualslib.com manuals search engine

721 -2

l~irba~ System (SRS)

This repair group covers airbag components and replace-

ment.

Airbag system repairand fault diagnosis is not covered.

Diagnostics, component testing, and

airbag system repair

should be carried out by trained BMW service technicians.

Individual

airbag system components can only be tested elec-

tronically when installed in the car. BMW service testers

DIS

or MoDiC or equivalent must be used for diagnostic work.

WARNING-

Special test equipment is required to retrieve airbag fault

codes, diagnose system faults, and

reseffturn off the air-

bag indicator light. The indicator light will remain on until

any problem has been corrected and the fault memory has

been cleared.

Airbags are part of the BMW Multiple Restraint System

(MRS). Three versions of MRS are available in E39 models.

Multiple Restraint Systems

MRS and MRS II include the following restraint components:

311 996-811 997

911

997-311 999

311 999-2002

Driver and passenger front

airbags (MRSIMRS II)

MRS

MRS

II

MRS Ill

Passenger front two-stage airbag (cars manufactured

from

911998).

The seat occupancy sensor (SBE) is used for detection of

a passenger in the right front seat. MRS uses the SBE in-

put to determine seat belt tensioner

and/or front airbag de-

ployment thresholds.

Side impact

airbag for driver and front passenger

(MRSIMRS II)

Leftlright side impact crash sensors (MRSIMRS 11)

Side impact airbag for rear passenger (MRS II) (optional)

Head Protection System (HPS) for driver and front passen-

ger (MRS

II)

Battery Safety Terminal - BST (MRS II)

Hall Sensor seat belt switches (MRS II)

Front pyrotechnic seat belt tensioners

Fuel pump cut off message

Page 962 of 1002

Downloaded from www.Manualslib.com manuals search engine

OED-2

On-Board Diagnostics

Specialized OED II scan tool equipment is needed to access

the fault memory and

OED I1 data.

The extra hardware needed to operate the OED

I1 system

consists mainly of the following:

* Additional oxygen sensors downstream of the catalytic

converters.

Fuel tank pressure sensor and device to pressurize

fuel

storage system.

Several engine and performance monitoring devices

Standardized 16-pin

OED II connector under the

dashboard.

Upgraded components for the federally required reliability

mandate.

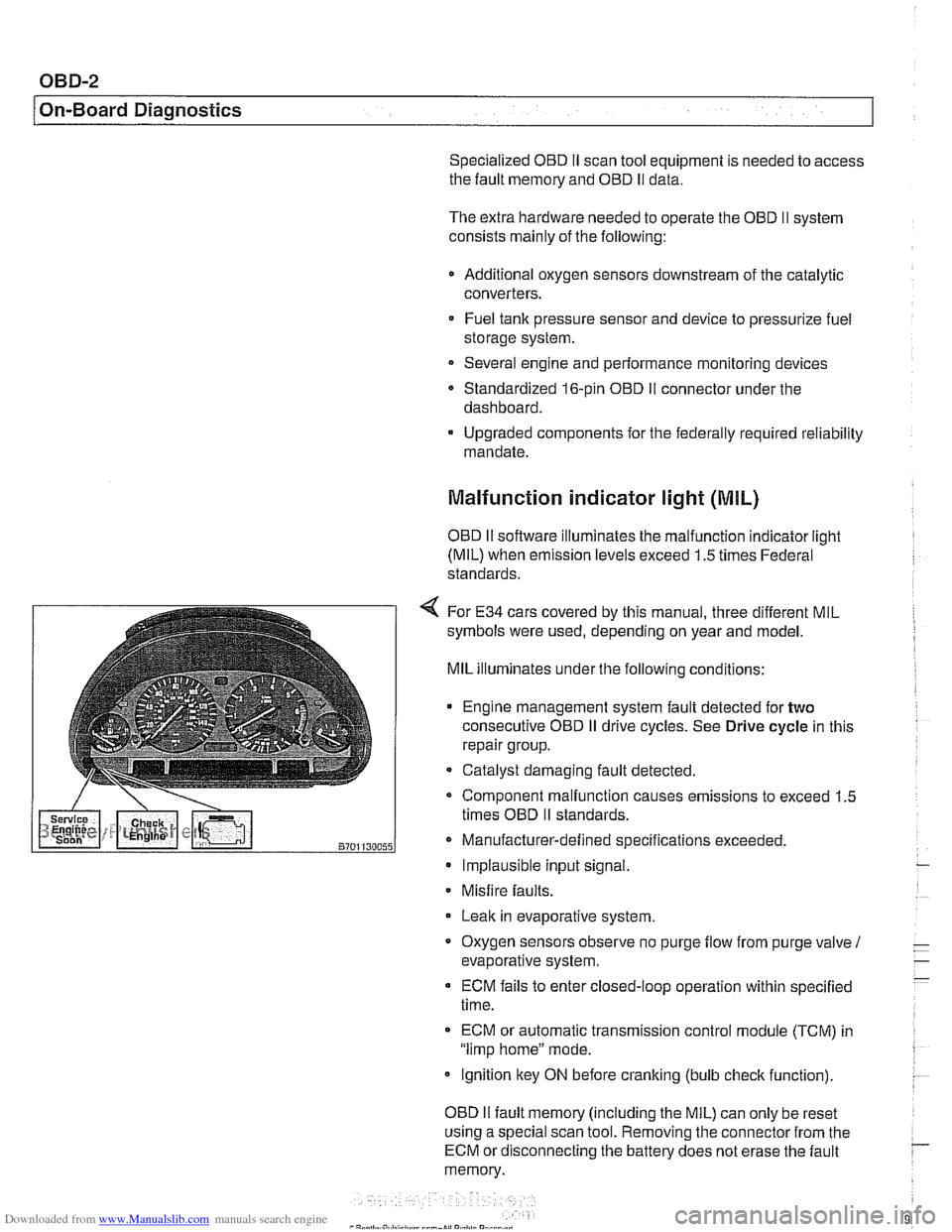

Malfunction indicator light (MIL)

OED II software illuminates the malfunction indicator light

(MIL) when emission levels exceed 1.5 times Federal

standards.

4 For E34 cars covered by this manual, three different MIL

symbols were used, depending on year and model.

MIL illuminates under the following conditions:

Engine management system fault detected for

two

consecutive OED iI drive cycles. See Drive cycle in this

repair group.

- Catalyst damaging fault detected.

Component malfunction causes emissions to exceed 1.5

times OED

II standards.

Manufacturer-defined specifications exceeded. Implausible input signal.

Misfire

faults.

Leak in evaporative system,

Oxygen sensors observe no purge

flow from purge valve 1

evaporative system.

ECM fails to enter closed-loop operation within specified

time.

ECM or automatic transmission control

module (TCM) in

"limp home" mode.

ignition key ON before cranking (bulb

check function).

OED

II fault memory (including the MIL) can only be reset

using a special scan tool. Removing the connector from the

ECM or disconnecting the battery does not erase the fault

memory.

Page 964 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

On-Board Diagnostics

Professional diagnostic scan tools available atthe time of this

printing include the BMW factory tools

(DISplus, GTI,

MoDiC) and a small number of aftermarket BMW-specific

tools. See

020 Maintenance.

In addition to the professional line of scan tools, inexpensive

generic OBD

II scan tool software programs and handheld

units are readily available. Though limited, they are

nonetheless powerful diagnostic tools. These tools read live

data streams and freeze frame data as well as a host of other

valuable diagnostic data.

Diagnostic monitors

Diagnostic monitors run tests and checks on specific

emission control systems, components, and functions.

A complete drive cycle is requiredforthe tests to bevalid. See

Drive cycle in this repair group. The diagnostic monitor

signals the

ECM of the loss or impairment of the signal or

component and determines if a signal or sensor is faulty

based on

3 conditions:

* Signal or component shorted to ground

Signal or component shorted to

B+

Signal or component missing (open circuit)

The OBD

II system monitors all emission control systems that

are installed. Emission control systems vary by vehicle model

and year. For example, a vehicle may not be equipped with

secondary air injection, so no secondary air readiness code

would be present.

OBD

II software monitors the following:

Oxygen sensors

Catalysts

Engine misfire

- Fuel tank evaporative control system

Secondary air injection Fuel system

Oxygen sensor monitoring. When driving conditions allow,

response rate and switching time of each oxygen sensor is

monitored. The oxygen sensor heater function is also

monitored. The OBD

II system differentiates between

precataylst and post-catalyst oxygen sensors and reads each

one individually. In order

forthe oxygen sensor to be

effectively monitored, the system must be in closed loop

operation.

Page 966 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-6

On-Board Diagnostics

Fuel system monitoring. This monitor looks at the fuel

delivery needed (long

/short term fuel trim) for proper engine

operation based on programmed data. If too much or not

enough fuel is delivered over a predetermined time, a DTC is

set and the MIL illuminates.

Fuel trim refers to adiustments to base fuel schedule.

Lono- ., term fuel trim refers to gradual adjustments to the fuel

calibration adjustment as compared to short term fuel trim.

Long term fuel trim adjustments compensate for gradual

changes that occur over time.

Fuel system monitoring monitors the calculated injection time

(ti) in relation to enginespeed, load and precatalyticconverter

oxygen

sensor(s) signals.

Using this data, the system optimizes fuel delivery for all

engine operating conditions.

Evaporative system monitoring. This monitor checks the

the fuel storage system and related fuel lines for leaks. It can

detect very small leaks anywhere in the system.

A leak detection unit (LDP or DMTL) is used to pressurize the

evaporative control system on a continuous basis (as the

drive cycle allows) and to

check system integrity.

Drive cycle

The OED II drive cycle is an important concept in

understanding OBD

II requirements. The purpose of the drive

cycle is to run ail of the emission-related on-board diagnostics

over a broad range of driving conditions.

A drive cycle is considered complete when all of the

diagnostic monitors have run their tests without interruption.

~ora drive cycle to be initiated, the vehicle must be started

cold and brought up to

1 60°F and at least 40°F above its

original starting temperature.

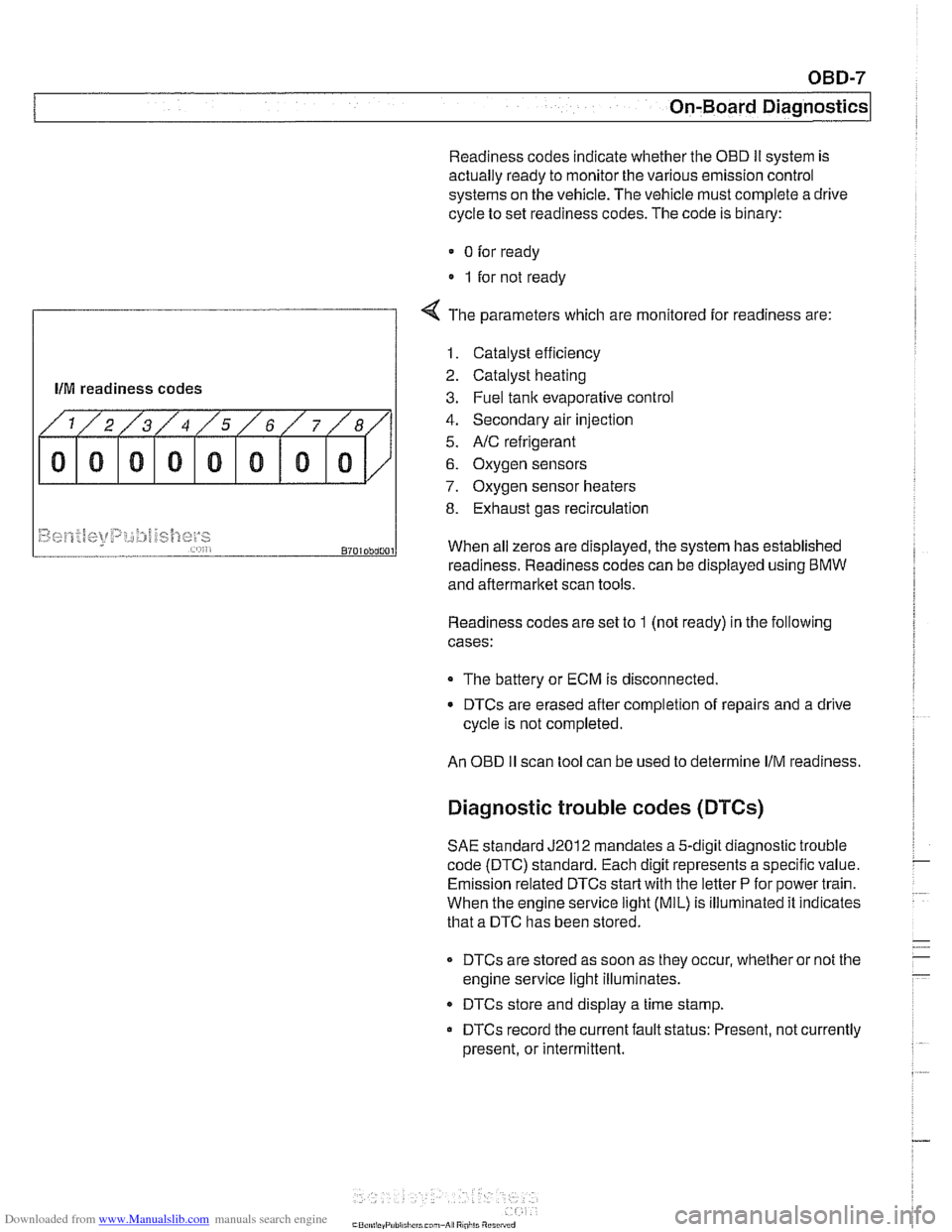

Readiness codes

Inspection/maintenance (I/M) readiness codes are mandated

as part of OBD

II. The readiness code is stored aftercomplete

diagnostic monitoring of specified components and systems

is carried out. The readiness code function was designed to

prevent manipulating an

I/M emission test procedure by

clearing faults codes or disconnecting the ECM or battery.

Page 967 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

Readiness codes indicate whether the OED Ii system is

actually ready to monitor the various emission control

systems on the vehicle. The vehicle must complete a drive

cycle to set readiness codes. The code is binary:

0 for ready

1 for not ready

f

4 The parameters which are monitored for readiness are:

llM readiness codes

1. Catalyst efficiency

2. Catalyst heating

3. Fuel tank evaporative control

4. Secondary air injection

5.

NC refrigerant

6. Oxygen sensors

7. Oxygen sensor heaters

8. Exhaust gas recirculation

Readiness codes are set to 1 (not ready) in the following

cases:

~9~~.f~[<+t~t~p:,~;:#j~~{]~y~ ,,... , , 8701Dbd001

The battery or ECM is disconnected.

When

all zeros are displayed, the system has established

DTCs are erased after completion of repairs and a drive

cycle is not completed.

readiness. Readiness codes

can be displayed using BMW

and aftermarket scan tools.

An

OED II scan tool can be used to determine IIM readiness.

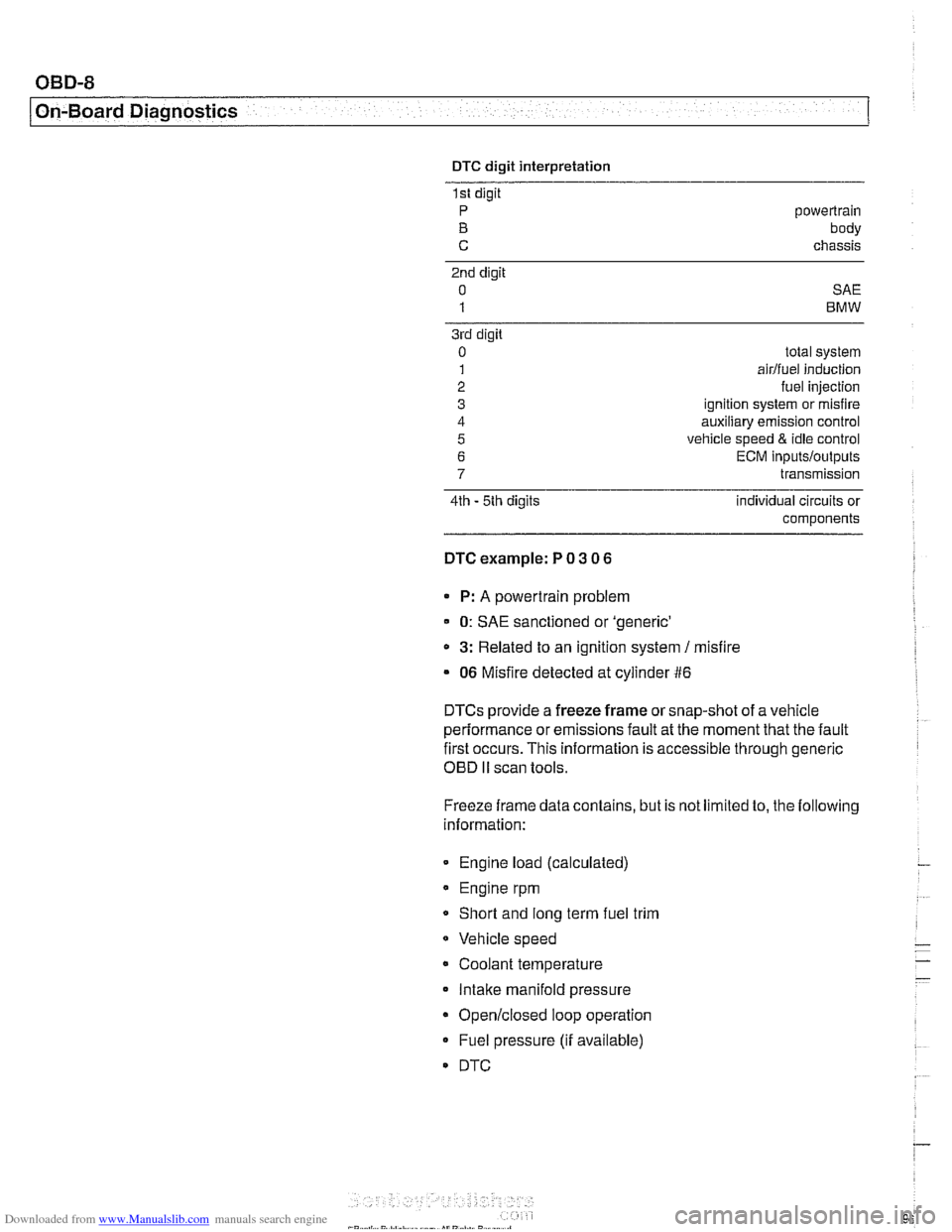

Diagnostic trouble codes (DTCs)

SAE standard J2012 mandates a 5-digit diagnostic trouble

code (DTC) standard. Each digit represents a specific value.

Emission related DTCs

start with the letter P for power train.

When the engine service

light (MIL) is illuminated it indicates

that a DTC has been stored.

DTCs are stored as soon as they occur, whether or not the

engine service light illuminates.

DTCs store and display a time stamp.

DTCs record the current fault status: Present, not currently

present, or intermittent.

Page 968 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-8

I On-Board Diagnostics

DTC digit interpretation

1st digit

P powertrain

B body

C chassis

2nd digit

0 SAE

1 BMW

3rd digit

0

1

2

3

4

5

6

7

4th - 5th digits total

system

airlfuei induction

fuel injection

ignition system or misfire

auxiliary emission control

vehicle speed

& idle control

ECM

inputs/outputs

transmission

individual circuits or

components

DTC example: P 0 3 0 6

P: A powertrain problem

0: SAE sanctioned or 'generic'

a 3: Related to an ignition system / misfire

06 Misfire detected at cylinder #6

DTCs provide a freeze frame or snap-shot of a vehicle

performance or emissions fault at the moment that the fault

first occurs. This information is accessible through generic

OED I1 scan tools.

Freeze frame data contains, but is not limited to, the following

information:

Engine load (calculated)

Engine rpm

Short and

long term fuel trim

Vehicle speed

Coolant temperature Intake manifold pressure

Open/closed loop operation

Fuel pressure (if available)

DTC

Page 975 of 1002

Downloaded from www.Manualslib.com manuals search engine

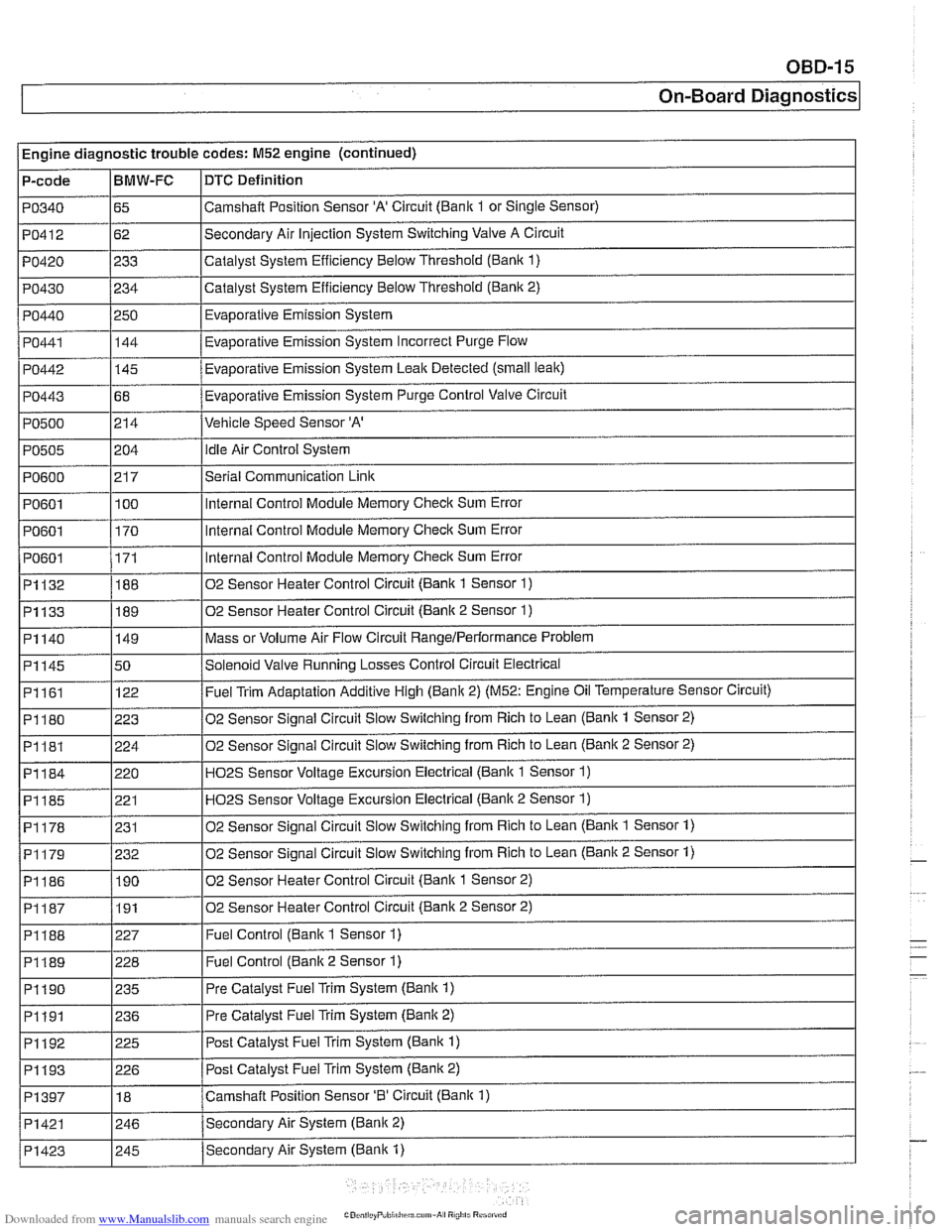

OBD-15

On-Board ~iagnosticsl

Engine diagnostic trouble codes: M52 engine (continued)

P-code

PO340

PO412

PO420

PO430

PO440

PO441

PO442

PO443

PO500

PO505

PO600

PO601

PO601

I PO601

~1132

~1133

BMW-FC

65

62

233

234

250 144

-

145

68

214

i I

DTC Definition

Camshalt Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

Secondary Air Injection System Switching Valve A Circuit

Catalyst System Efficiency Below Threshold

(Bank 1)

Catalyst System Efficiency Below Threshold (Bank 2)

Evaporative Emission System

Eva~orative Emission Svstem Incorrect Purge Flow .

Evaporative Emission System Leak Detected (small leak)

Evaporative Emission System Purge Control Valve Circuit

Vehicle Speed Sensor 'A'

204

21 7

100

170

171

188

189

PI161

PI180

PI181

PI184

PI185

PI178

02 Sensor Heater Control Circuit (Bank 2 Sensor 2) I

idle Air Control System

Serial Communication

Link

Internal Control Module Memory Check Sum Error

Internal Control Module Memory

Check Sum Error

Internal Control Module Memory

Check Sum Error

02 Sensor Heater Control Circuit (Bank 1 Sensor

1)

02 Sensor Heater Control Circuit (Bank 2 Sensor 1)

Mass or Volume Air Flow Circuit RangeIPerlormance Problem PI140

I

I I

P1188 1227 I Fuel Control (Bank 1 Sensor 1)

PI145 150 /Solenoid Valve Running Losses Control Circuit Electrical

149

122

223

224

220 221

231

I I

P1189 1228 I Fuel Control (Banlc 2 Sensor 1)

Fuel Trim Adaptation Additive High (Bank 2) (M52: Engine Oil Temperature Sensor Circuit)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 1 Sensor 2)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 2 Sensor 2)

H02S Sensor Voltage Excursion Electrical (Banlc 1 Sensor 1)

HO2S Sensor Voltage Excursion Electrical (Banlc 2 Sensor 1)

02 Sensor Sianai Circuit Slow Switchina from Rich to Lean (Bank 1 Sensor 1)

02 Sensor Signal Circuit Slow Switching from Rich to Lean (Bank 2 Sensor 1) PI179

I I

PI190 1235 I Pre Catalyst Fuel Trim System (Banlc 1)

PI186 1190 102 Sensor Heater Control Circuit (Banlc 1 Sensor 2)

232

I I

PI191 1236 I Pre

Catalyst Fuel Trim System (Banlc 2)

PI192

. . -- - i Pi193 1226 I Post Catalvst Fuel Trim Svstem (Bank 2)

225

PI397

I I

Post Catalyst Fuel Trim System (Bank 1)

PI421 1246 /Secondarv Air System (Bank 2)

18

Secondary Air System (Bank

1) PI423

Camshaft Position Sensor '0' Circuit (Bank 1)

I 245

Page 979 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~ia~nosticsl

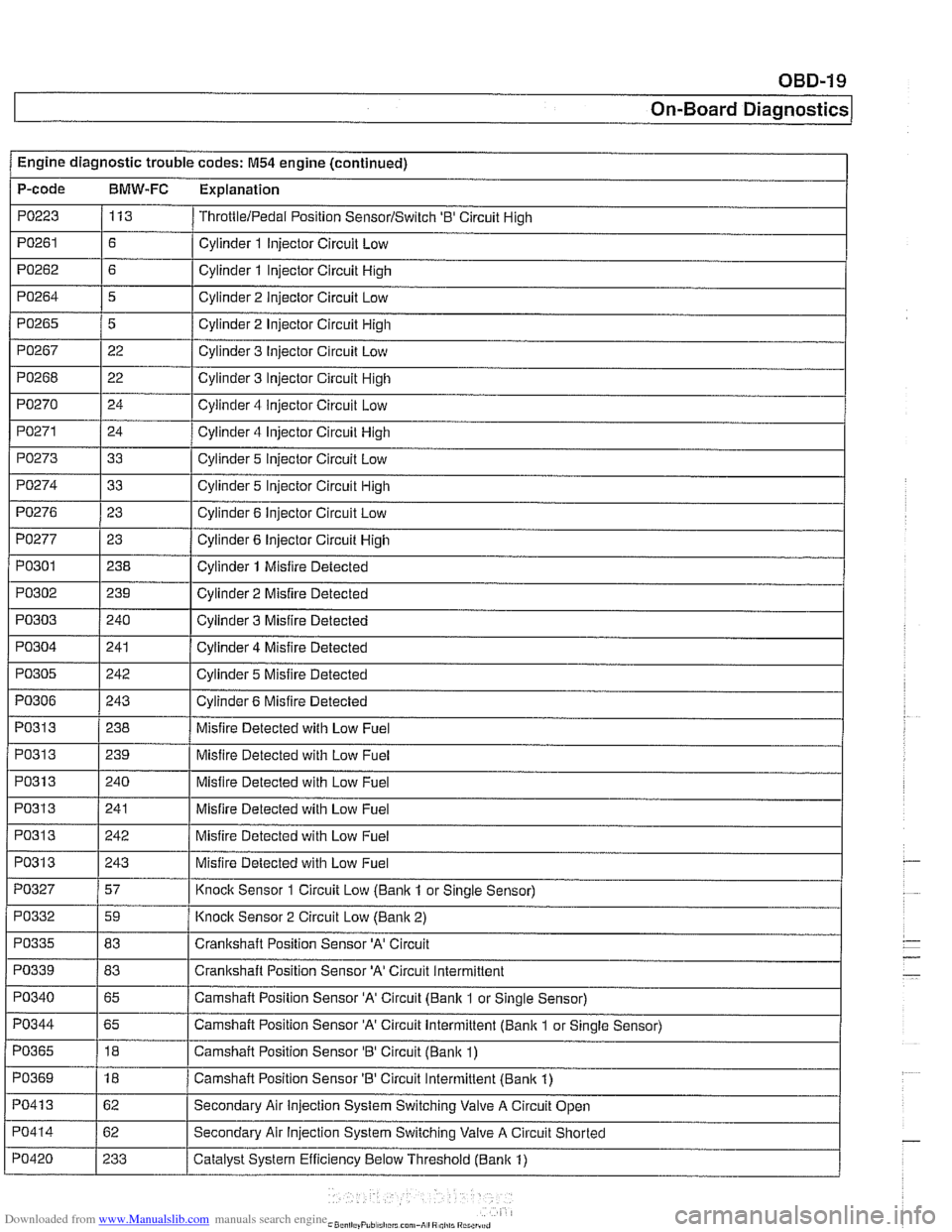

Engine diagnostic trouble codes: M54 engine (continued) I -.

P-code BMW-FC Explanation

PO223 113 ThrottlelPedal Position SensorlSwitch '0' Circuit High

PO261 / Cylinder 1 Injector Circuit Low

PO271 Cylinder 4 Injector Circuit High

PO273 Cylinder 5 Injector Circuit Low

Cylinder 2 Injector Circuit High

Cylinder 3 Injector Circuit

Low

Cylinder 3 Injector Circuit High

Cylinder 4

iniector Circuit Low

PO265

PO267

PO268

PO270

, I

PO277 1 23 1 Cylinder 6 Injector Circuit High

5

22

22

24

I I

PO274

PO301

PO302

PO303

PO304

PO276 1 23 I Cylinder 6 Injector Circuit Low

33

I

I -

I I

PO31 3 1 240 I Misfire Detected with Low Fuel Cylinder 5 Injector Circuit High

238

239

240

241

PO305

I I

Cylinder 1 Misfire Detected

Cylinder 2 Misfire Detected

Cylinder 3 Misfire Detected

Cylinder 4 Misfire Detected

PO313

PO306 1 243 I Cylinder 6 Misfire Detected

242

PO313

PO313

PO31 3

PO327

Cylinder 5 Misfire

Detected

PO31 3 1239 I Misfire Detected with Low Fuel

238

PO332

PO335

PO339 - PO340

Misfire Detected with Low Fuel

241

242

243

57

PO344

PO365

PO369

PO41 3

PO414

PO420

Misfire Detected with Low Fuel

Misfire Detected with Low Fuel

Misfire Detected with Low Fuel

Knock Sensor 1 Circuit Low

(Banlc 1 or Sinale Sensor)

59

83

83

65

-

Knoclc Sensor 2 Circuit Low (Banlc 2)

Crankshaft Position Sensor

'A' Circuit

Crankshaft Position Sensor

'A' Circuit Intermittent

Camshaft Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

65

18

18

62

62

233 Camshaft Position Sensor

'A' Circuit Intermittent (Bank 1

or Single Sensor)

Camshaft Position Sensor

'B' Circuit (Banlc 1)

Camshaft Position Sensor 'B' Circuit Intermittent (Bank 1)

Secondary Air Injection System Switching Valve A Circuit Open

Secondary Air

Injection System Switching Valve A Circuit Shorted

Catalyst System Efficiency Below Threshold (Bank 1)

Page 980 of 1002

Downloaded from www.Manualslib.com manuals search engine

I On-Board Diagnostics

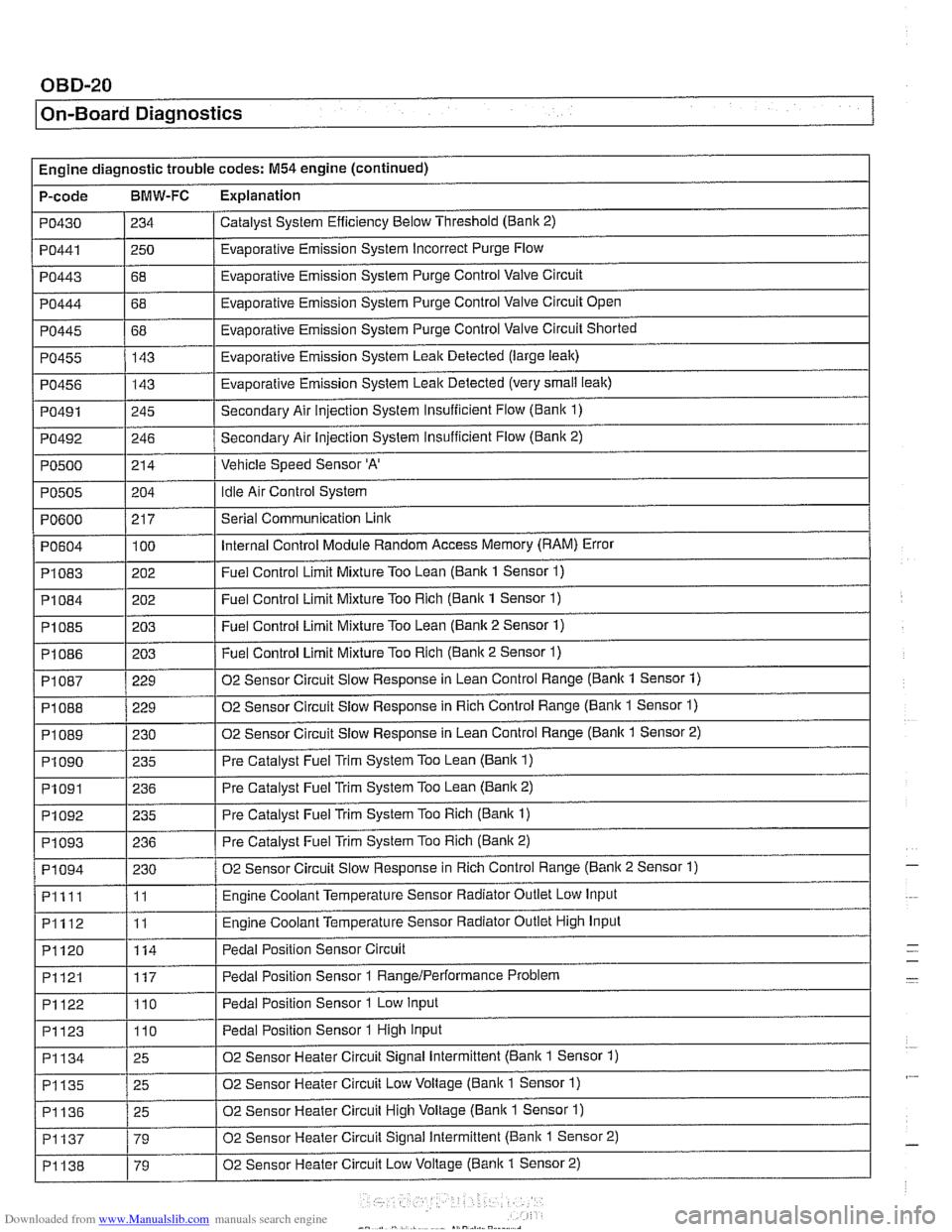

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

Catalyst System Efficiency Below Threshold (Bank 2)

PO430

PO443

PO444

PO445

PO455

PO456

PO491

PO492

PO500

PO441 1250 / Evaporative Emission System Incorrect Purge Flow

234

I I

68

68

68 143

143

245

246

214

PO604

PI083

PI084

PI085

PI086

Evaporative Emission System Purge Control Valve Circuit

Evaporative Emission System Purge Control Valve Circuit Open

Evaporative Emission System Purge Control Valve Circuit Shorted

Evaporative Emission System Leak Detected (large leak)

Evaporative Emission System Leak Detected (very

small leak)

Secondary Air injection System Insufficient Flow (Bani( 1)

Secondary Air Injection System insufficient Flow

(Banic 2)

Vehicle Speed Sensor

'A'

Idle Air Control System PO505

.

PI 087

PI 088

PI089

PI090

PO600 / 217 I Serial Communication Link

204

100

202

202

203

203

PI091

PI092

PI093

PI094

Pllll

PI112

PI120

Internal Control Module Random Access Memory (RAM) Error

Fuel Control Limit Mixture Too Lean (Bank 1 Sensor

1)

Fuel Control Limit Mixture Too Rich (Bank 1 Sensor 1)

Fuel Control Limit Mixture Too Lean (Bank 2 Sensor 1)

Fuel Control Limit Mixture Too Rich (Banic 2 Sensor 1) ~ ~

229

229

230 235

PI121

PI122

PI123

02 Sensor Circuit Slow Response in Lean Control Range (Bank 1 Sensor 1)

02 Sensor Circuit Slow Response in Rich Control Range (Bank 1 Sensor

1)

02 Sensor Circuit Slow Response in Lean Control Range (Banlc 1 Sensor 2)

Pre Catalyst Fuel Trim System Too Lean

(Bank 1)

236

235

236

230

11

11

114

PI134

PI135

PI136

PI137

PI138

Pre Catalyst Fuel Trim System Too Lean (Banic 2)

Pre Catalyst Fuel Trim System Too Rich

(Bank 1)

Pre Catalyst Fuel Trim System Too Rich (Bank 2)

02 Sensor Circuit Slow Response in Rich Control Range (Banic 2 Sensor 1)

Engine Coolant Temperature Sensor Radiator Outlet Low Input

Engine Coolant Temperature Sensor Radiator Outlet High Input

Pedal Position Sensor Circuit

117

110

110

25

25

25

79

79 Pedal Position Sensor 1

RangeIPerformance Problem

Pedal Position Sensor 1 Low Input

Pedal Position Sensor 1 High Input

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 1)

02 Sensor Heater Circuit Low Voltage (Bank 1 Sensor

1)

02 Sensor Heater Circuit High Voltage (Bank 1 Sensor 1)

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 2)

02 Sensor Heater Circuit Low Voltage

(Banic 1 Sensor 2)

-

-