Fuel system BMW 528i 1998 E39 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 472 of 1002

Downloaded from www.Manualslib.com manuals search engine

This repair group covers service information specifically for the fuel supply system. Information on the fuel injection sys-

tem is covered in

130 Fuel Injection.

In the descriptions and procedures given below, engine and

engine management (DME) systems are referred to by man-

ufacturer code. If necessary, see

100 Engine-General for

model year, engine code, and DME applications.

NOTE-

Fuel filter replacement is covered in 020 Maintenance,

Special tools

Some of the procedures in this group require the use of

special tools.

I( Fuel line clamp 13 3 010 (Tool No. BMW 13 3 01 0)

4 Fuel pressure gauge T-fitting with shut-off valve

(Tool No. BMW 13

5 220)

Page 473 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

Fuel pump

The electric fuel pump is mounted in the fuel tank in tandem

with the right side fuel level sender. The fuel pump delivers

pressurized fuel to the fuel injection system.

A pressure regu-

lator maintains system pressure. The quantity of fuel supplied

exceeds demand, so excess fuel returns to the fuel tank via a

return line. See

130 Fuel Injection for more information.

NOTE-

Fuel pump removal procedures are given under Fuel level

sender (right side) and fuel pump, removing and install-

ing.

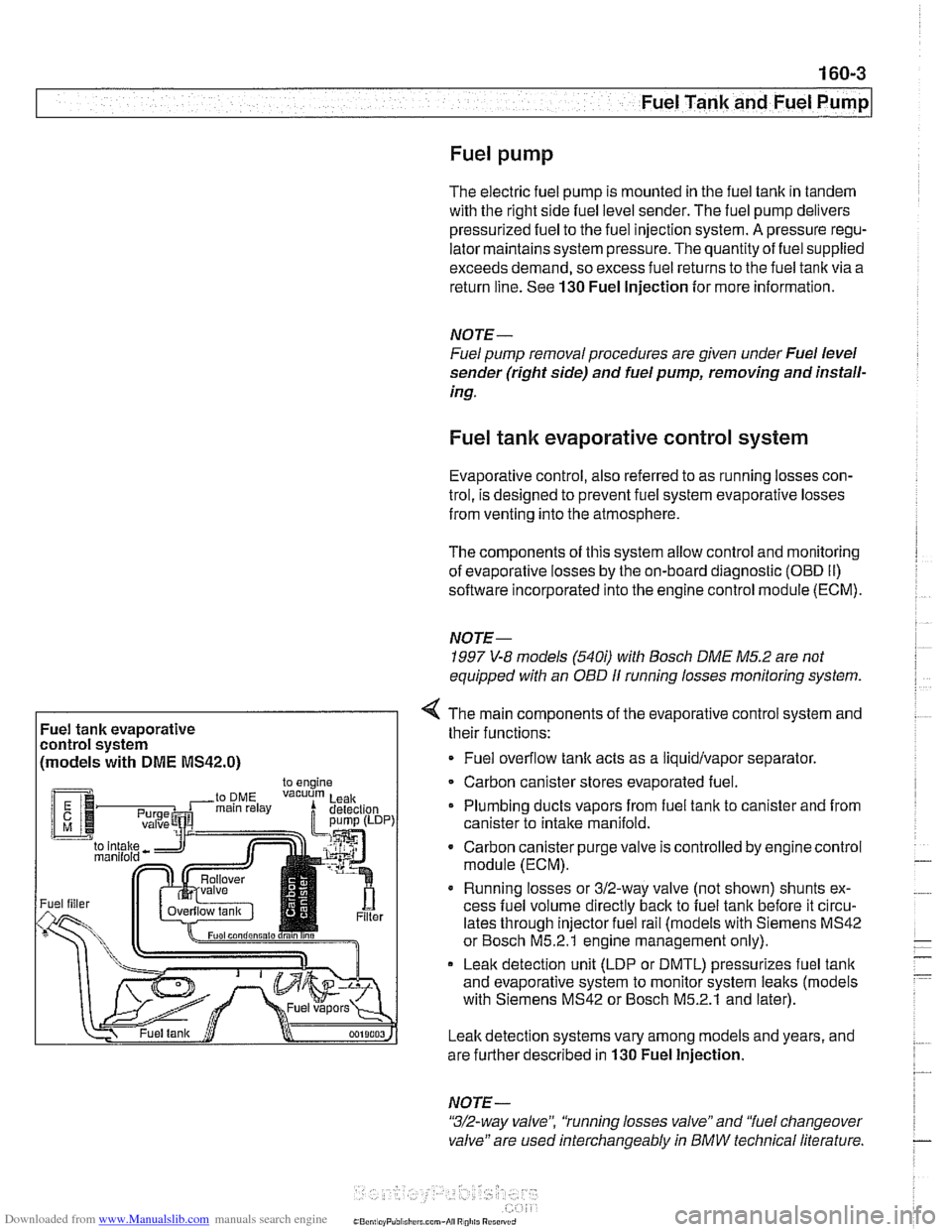

Fuel tank evaporative control system

Evaporative control, also referred to as running losses con-

trol, is designed to prevent fuel system evaporative losses

from venting into the atmosphere.

The components of this system allow control and monitoring

of evaporative losses by the on-board diagnostic

(OED II)

software incorporated into the engine control module (ECM).

NOTE-

1997 V-8 models (540i) with Bosch DME M5.2 are not

equipped with an

OBD I1 running losses monitoring system.

Fuel tank evaporative

control system

(models with

DME MS42.0)

4 The main components of the evaporative control system and

their functions:

Fuel overflow

tank acts as a liquidlvapor separator

Carbon canister stores evaporated fuel.

Plumbing ducts vapors from fuel tank to canister and from

canister to intake

manifold.

- Carbon canister purge valve is controlled by enginecontrol

module (ECM).

Running losses or 312-way valve (not shown) shunts ex-

cess fuel volume directly

back to fuel tank before it circu-

lates through injector fuel rail (models with Siemens MS42

or Bosch M5.2.1 engine management only).

Leak detection unit (LDP or DMTL) pressurizes fuel

tank

and evaporative system to monitor system leaks (models

with Siemens MS42 or Bosch M5.2.1 and later).

Leak detection systems vary among models and years, and

are further described in

130 Fuel Injection.

NOTE -

"3/2-way valve", 'tunning losses valve" and "fuel changeover

valve" are used interchangeably

in BMW technical literature.

Page 474 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

Evaporative system troubleshooting

- Start by accessing diagnostic trouble codes (DTCs) using a

BMW or BMW compatible aftermarket scan tool.

For purposes of OBD

II emissions compliance, the DME

system sets a diagnostic trouble code (DTC) when it de-

tects a leak that is equal or larger than minimum

lealc

sensed by system.

Malfunction Indicator Light (MIL) is illuminated upon sec-

ond recurrence of fault. See OBD On-Board Diagnostics.

- When leak testing, observe following conditions to obtain

plausible results:

Fuel tank

'1, to 'I., full.

0 Vehicle parked for at least 2 hours to allow fuel to reach

room temperature.

Ideal fuel temperature is 10"- 20°C

(50"

- 68" F).

Do not refuel immediately before

lealc test.

- If a leak is detected, check the following areas:

* Fuel filter cap (leaking or off).

Fuel tank ventilation lines leaking at fuel

tank or activated

carbon canister.

i

Tank ventilation valve leaking (in engine compartment).

Fuel level

sensorlfuel pump cap leaking.

Evaporative system component replacement is covered later

in

th~s group in Fuel Tank and Fuel Lines.

Page 475 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

Warnings and cautions

Observe the following warnings and cautions when servicing

the fuel system.

WARNING-

* The fuel system is designed to retain pressure even when

the ignition is off. When working with the fuelsystem, loos-

en the fuel lines slowly to allow residual

fuel pressure to

dissipate. Avoid spraying fuel. Use shop rags to capture

leaking fuel.

Before beginning any work on the fuel system, place a

fire extinguisher in the vicinity of the work area.

Fuel is highly flammable. When working around fuel, do

not disconnect any wires that could cause electrical

sparks. Do not smoke or worknearheaters or other fire

hazards.

* Always unscrew the fuel tank cap to release pressure

in the

tanlc before working on the tank or lines.

When disconnecting a fuel hose, wrap shop rag around

end of hose to prevent spray of fuel under pressure.

Do not use a work light with an incandescent bulb near

any fuel. Fuel may spray on the hot bulb causing a fire.

0 Make sure the worlc area is properly ventilated.

CAUTION-

- Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions an4

Warnings.

Before

making any electrical tests with the ignition

turned on, disable the ignition system as described in

120 Ignition System. Be sure the battery is discon-

nected when replacing components.

To prevent damage to the ignition system or other DME

components, including the engine control module

(ECM), always connect and disconnect wires and test

equipment with the ignition off.

Cleanliness is essential when

worl~ing with the fuel sys-

tem. Thoroughly clean the fuel line unions before dis-

connecting any of the lines.

Use only clean tools. Keep removed parts clean and

sealed or covered with a clean, lint-free cloth, especial-

ly if completion of the repair is delayed.

Do not move the car while the fuel system is open.

Avoid using high pressure compressed air to blow out

lines and components. High pressure can rupture inter-

nal seals and gaskets.

Always replace seals, O-rings and hose clamps.

Page 476 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-- -

/ Fuel Tank and Fuel Pump - .. -. -- 1

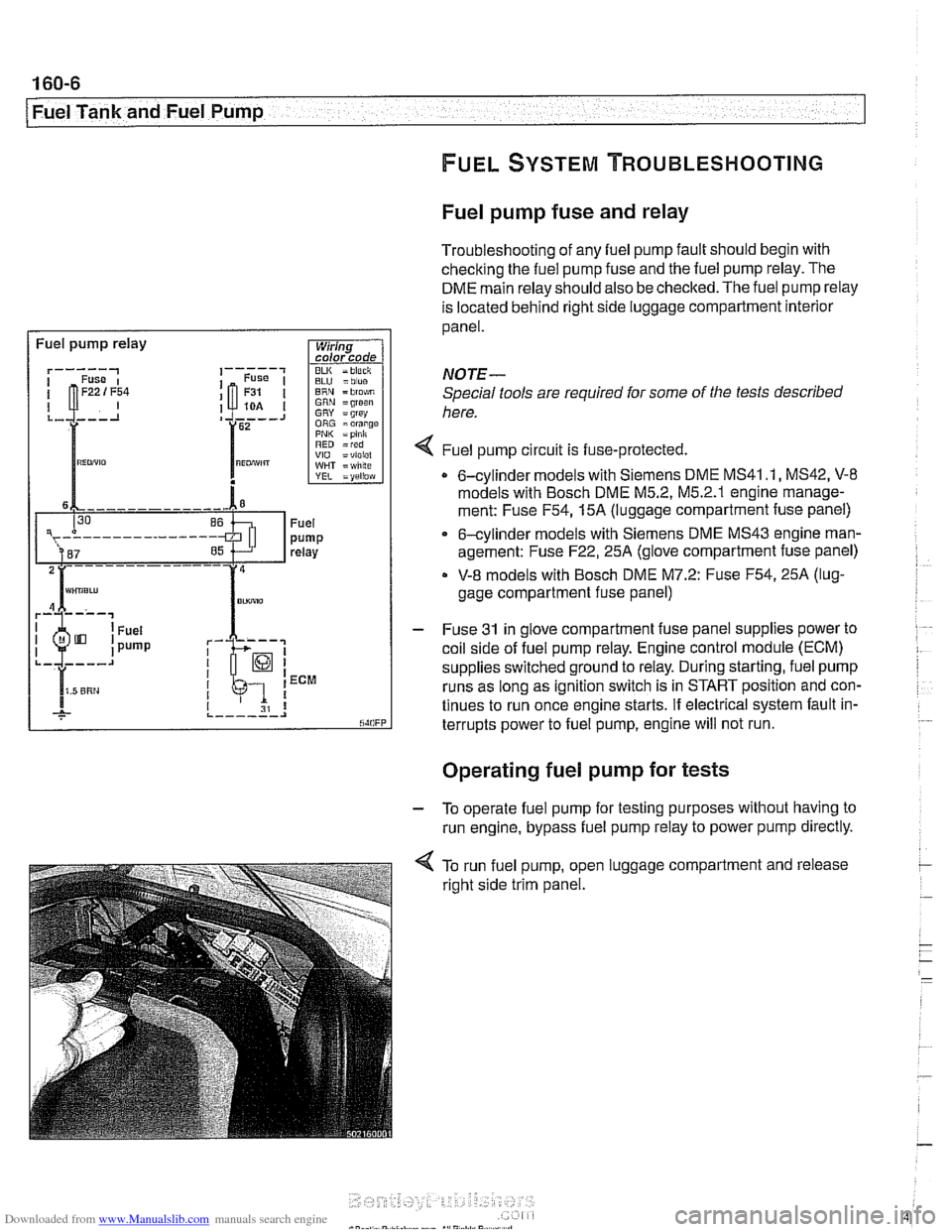

Fuel pump fuse and relay

Troubleshooting of any fuel pump fault should begin with

checking the fuel pump fuse and the fuel pump relay. The

DME main relay should also be checked. The fuel pump relay

is located behind right side luggage compartment interior

panel.

I Fuel pump relay

BLU =blue ERN = blo$,m GRN =groan GRY = grsy ORG =orange PNI< =pink RED =red VIO =violel WHT = wlilte

rk-; I I 1 ECM

I I I 31 8 ,._--___.I

NOTE-

Special tools are required for some of the tests described

here.

4 Fuel pump circu~t is fuse-protected.

0 6-cylinder models with Siemens DME MS41 .I, MS42, V-8

models with Bosch DME M5.2, M5.2.1 englne manage-

ment: Fuse

F54,15A (luggage compartment fuse panel)

6-cylinder models with Siemens DME MS43 engine man-

agement: Fuse

F22,25A (glove compartment fuse panel)

V-8 models with Bosch DME M7.2: Fuse F54,25A (lug-

gage compartment fuse panel)

- Fuse 31 in glove compartment fuse panel supplies power to

coil side of fuel pump relay. Engine control module (ECM)

supplies switched ground to relay. During starting, fuel pump

runs as long as ignition switch is in START position and con-

tinues to run once engine starts. If electrical system fault in-

terrupts power to fuel pump, engine will not run.

. .

Operating fuel pump for tests

- To operate fuel pump for testing purposes without having to

run engine, bypass fuel pump relay to power pump directly.

< To run fuel pump, open luggage compartment and release

right side trim panel.

Page 482 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

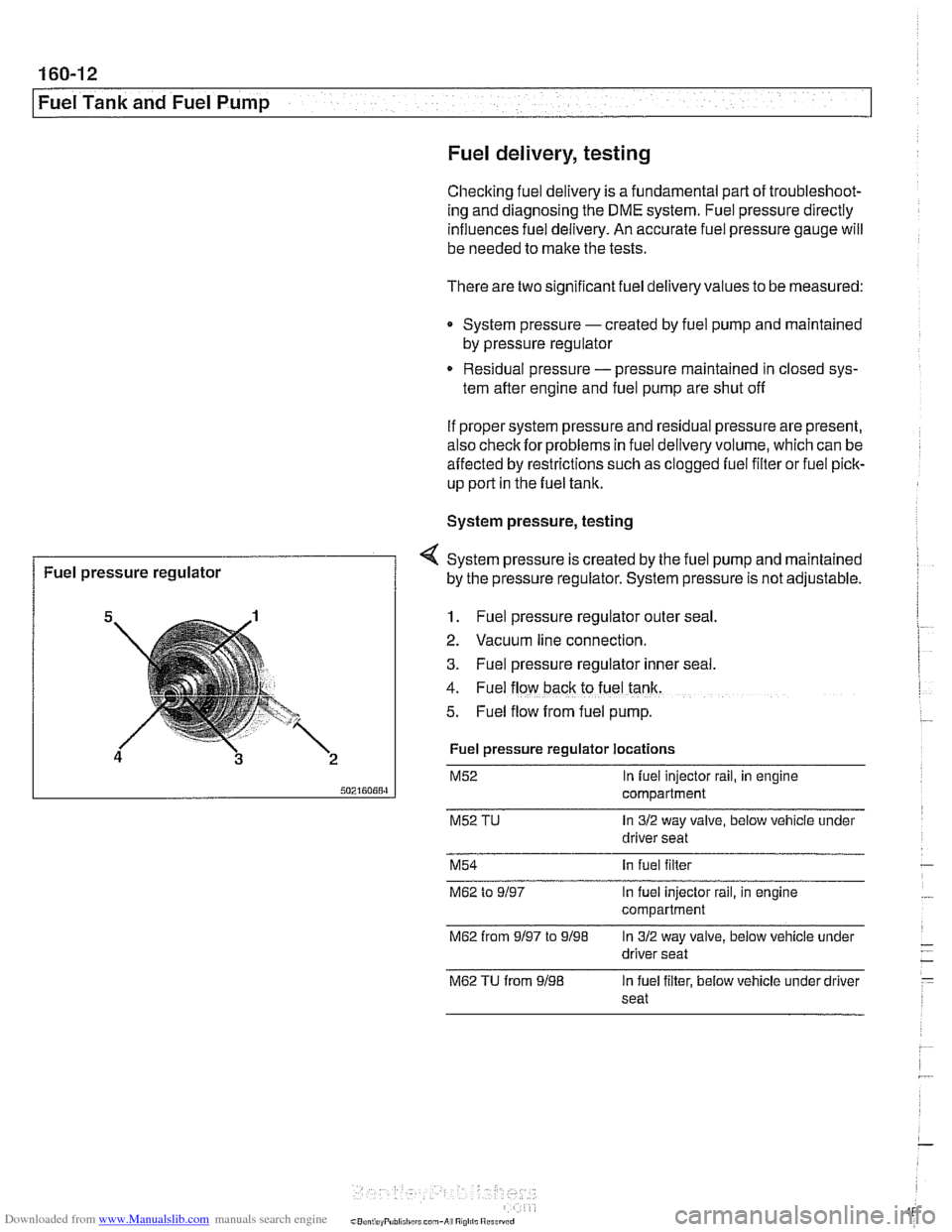

Fuel delivery,

testing

Checitino fuel delive~ is a fundamental oart of troubleshoot- .. ing and diagnosing thk DME system. ~ukl pressure directly

influences

fuel delivery. An accurate fuel pressure gauge will

be needed to make the tests.

There are two significant fuel deliveryvalues to be measured:

* System pressure - created by fuel pump and maintained

by pressure regulator

Residual pressure

- pressure maintained in closed sys-

tem after engine and fuel pump are shut off

if proper system pressure and residual pressure are present,

also check for problems in fuel delivery volume, which can be

affected by restrictions such as clogged fuel filter or fuel pick-

up port in the fuel tank.

System pressure, testing

1. Fuel pressure regulator outer seal

4 System pressure is created by the fuel pump and maintained

2. Vacuum line connection.

3. Fuel pressure regulator Inner seal.

4. Fuel flow back to fuel tank.

5. Fuel flow from fuel pump.

Fuel pressure

regulator

Fuel pressure regulator locations

M52 In fuel injector rail, in engine

compartment

M52 TU In 312 way valve, below vehicle under

driver seat

by the pressure

regulator. System pressure is not adjustable.

M54 In fuel filter

M62 to 9/97 In fuel injector rail, in engine

compartment

M62 from 9/97 to 9/98 In 312 way valve, below vehicle under

driver seat

M62 TU from 9/98 In fuel filter, below vehicle under driver

seat

Page 483 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

4 Relieve system pressure and attach a fuel pressure gauge as

described in Fuel pressure gauge, installing (6-cylinder

models) or Fuel pressure gauge, installing

(V-8 models).

WARNING-

Fuel in fuel line is under pressure (approx. 3 - 5 bar or 45 -

75psi) and may be expelled underpressure. Do not smoke

or

worlc near heaters or other fire hazards. Keep a fire ex-

tinguisher handy Before disconnecting fuel hoses, wrap a

cloth around fuel hoses to absorb any

leaking fuel. Catch

and dispose of escaped fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

in the tank before

working on the tank or lines.

- Operate fuel pump as described in Operating fuel pump for

tests. Compare fuel pressure to specifications in accompa-

nying table.

Fuel pressure specification

All E39 vehicles 3.5 +0.2 bar (50.76 i2.9 psi)

- If pressure is low, repeat test while gradually pinching off re-

turn hose to fuel tank. Pressure should rise rapidly. If not, fuel

pump is most likely faulty. If pressure rises, the fuel pressure

regulator is most

likely faulty.

- If pressure is too high, checlc return line from pressure regu-

lator to tank. Check for

ltinks in hose. If no faults can be

found, pressure regulator is most likely faulty.

CAUTION-

The fuel pump is capable of developing a higher pressure

than that regulated by the pressure regulator. In the event the

fuel pump checlc valve is faulty (stuck closed), male sure the

I fuel pressure does not rise above 6.0 bar (87psi). Damage

to the fuel lines or fuel system components could result.

- Reassemble engine, noting the following:

Remove fuel pressure gauge and fittings.

Replace schraeder valve, if removed

Replace fuel pump relay.

Replace fuel filler cap.

Residual pressure, testing

For quick restarts and to avoid vapor lock when the engine is

hot, the fuel injection system retains fuel pressure after the

engine is shut off. This residual pressure is primarily

rnain-

tained by the fuel pressure regulator and a checlc valve at the

fuel pump

outlet.

Page 484 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .

I Fuel Tank and Fuel Pump I

4 Relieve system pressure and attach afuel pressure gauge as

described in Fuel pressure gauge, installing (6-cylinder

models) or Fuel pressure gauge, installing

(V-8 models).

WARNING -

Fuel in fuel line is underpressure (approx. 3 - 5 bar or45 -

75psi) and may be expelled underpressure. Do not smoke

or work near heaters or other fire hazards. Keep a fire ex-

tinguisher handy. Before disconnecting fuel hoses, wrap a

cloth around fuel hoses to absorb any leaking fuel. Catch

and dispose of escaped fuel. Plug all open fuel lines.

. Always unscrew the fuel tank cap to release pressure

in the tank before working on the tank or lines

- Start engine allow it to run for approximately one minute.

Note fuel pressure reading.

- Observe fuel pressure reading after approximately 20 mln-

utes. The pressure should not drop more than 0.5 bar from

system pressure listed in fuel pressure specifications in ac-

companying table.

Fuel pressure specification

Ail

E39 vehicles 3.5 i-0.2 bar (50.76 i2.9 psi)

- When finished, disconnect pressure gauge and fitting, and

replace schraeder valve, if removed.

- If fuel system does not maintain pressure:

Visually check for leaks in fuel lines and unions,

Check for leaking

injector(s).

Check for faulty fuel pump check valve.

- To test fuel pump check valve:

Repeat residual pressure test.

Immediately aftershutting off engine, pinch off fuel delivery

line using a fuel hose pinch clamp (BMW

13 3 010 or

equivalent).

If pressure is now maintained, fault is most likely at fuel

pump check valve.

If pressure again drops below specifications, fault is most

likely in fuel pressure regulator.

Page 490 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

I Fuel Tank and Fuel Pump

The plastic fuel tank is mounted underneath the center of the

car (underneath the rear seat). Mounted in the fuel tank are

the fuel pump and fuel level sending units. Connecting lines

for the evaporative emission control system and expansion

tank are also attached to the tank.

Fuel

tank capacity for E39 models

Tank capacity

70 liters (18.5 gal)

Reserve capacity

8 liters (2.1 gal)

Fuel tank, draining

Drain fuel tank into a safe storage unit using an approved fuel

pumping device.

WARNING-

# Before removing tank, be sure that all hot components,

such as the exhaust system, are completely cooled down.

Fuel may be spilled. Do not smoke or

work near heat-

ers or other fire hazards.

- Start engine and allow to run 10 - 15 seconds to fill fuel com-

pensating siphon assembly. This will allow both lobes of fuel

tank to he drawn off through fuel filler pipe,

- Disconnect negative cable from battery.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions given

in 001 General Warnings and Cau-

tions.

- Remove fuel tank filler cap

- Slide suction hose into filler neck about 130 cm (51 in.), twist-

ing as necessary. Withdraw fuel into storage unit.

- Monitor fuel level reduction in both lobes:

- Remove rear seat cushion and access both fuel tank send-

er harness connectors.

Use multimeter to measure resistance at both senders,

Resistance should drop as fuel level drops.

- If siphoning mechanism is faulty, drain left tank lobe sepa-

rately by removing sender cover and pumping fuel directly

out of left lobe.

Page 491 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel pump/

- Remove suction hose from tank filler neck carefully to avoid

damaging filler neck baffle plate.

CAUTION-

After finishing repairs but before starling engine, be sure

there is at least

5 liters (1.5 gallons) of fuel in tanlc. The fuel

pump will be damaged if run without fuel.

Fuel tank, removing and installing

- Remove fuel tank filler cap and drain tank as described

earlier.

- Disconnect negative cable from battery.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

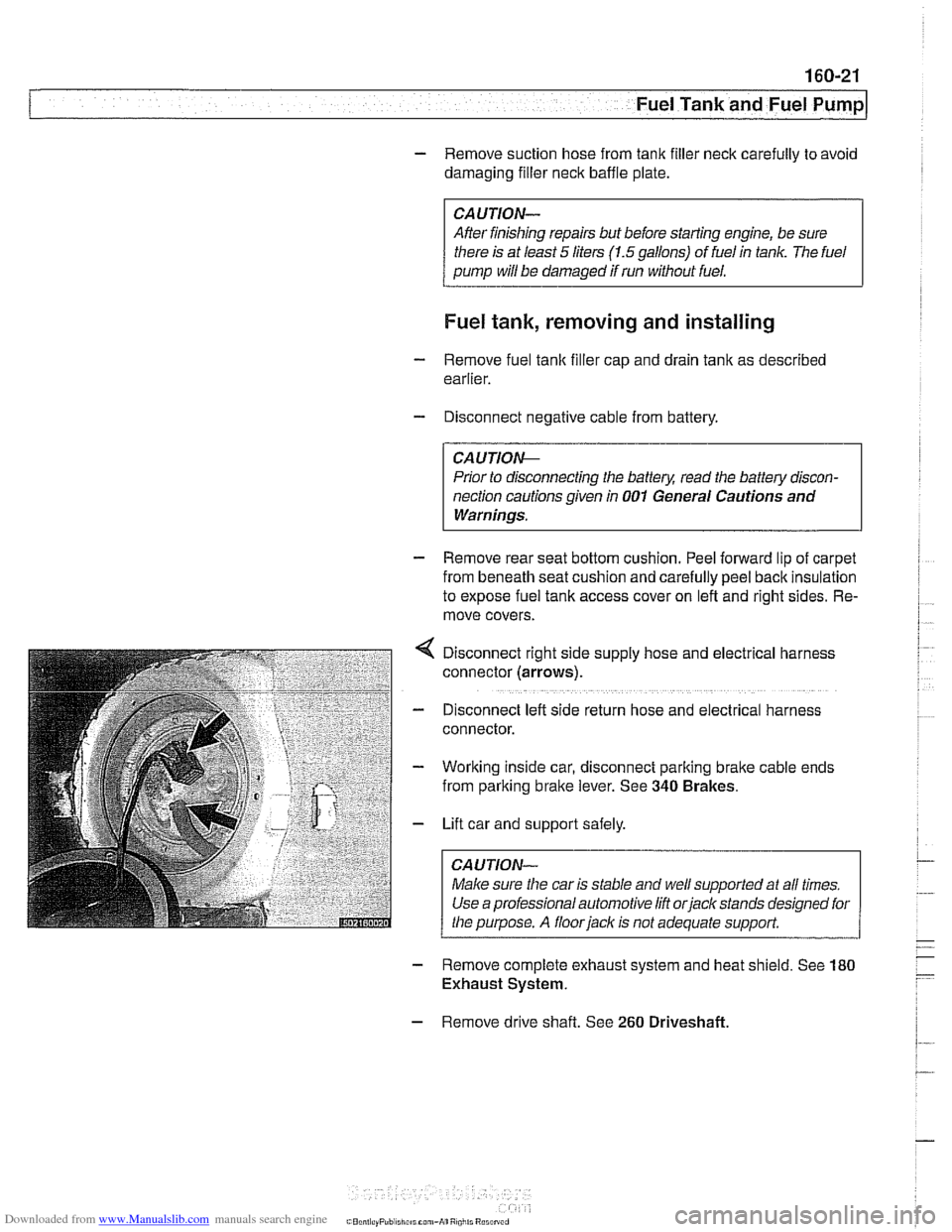

- Remove rear seat bottom cushion. Peel forward lip of carpet

from beneath seat cushion and carefully peel back insulation

to expose fuel tank access cover on left and right sides. Re-

move covers.

Disconnect right side supply hose and

electr~cal harness

connector (arrows).

D~sconnect left side return hose and electrical harness

connector.

Working inside car, disconnect parking

bralte cable ends

from parking brake lever. See

340 Brakes.

Lift car and support safely.

Make sure the car is stable and

we/ supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floorjaclc is not adequate support.

- Remove complete exhaust system and heat shield. See 180

Exhaust System.

- Remove drive shaft. See 260 Driveshaft