Fuel system BMW 528i 1998 E39 Manual Online

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

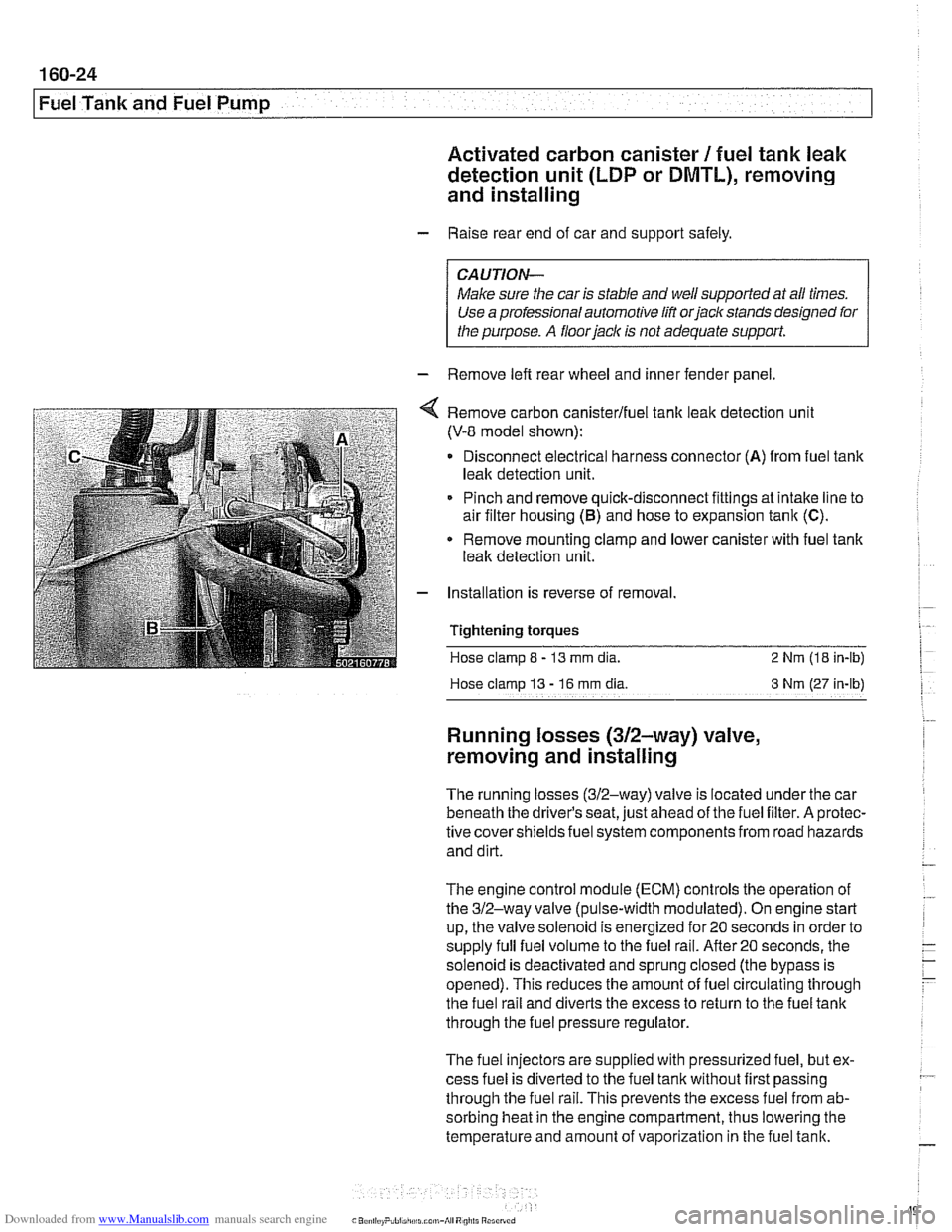

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 495 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-25

Fuel Tank and Fuel pump1

The 312-way valve is also activated briefly if an engine misfire

is detected. This provides full fuel flow through the fuel rail to

determine if the misfire was caused by a lean fuel condition.

The valve is monitored by the ECM forfaults.

- Using BMW or compatible scan tool, read out fault memory.

See

OBD On-Board Diagnostics.

- Turn off ignition.

- Raise car and support safely.

CA UTIOW

Male sure the car is stable and well suppodedat all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Worlting under car beneath driver's seat, remove protective

panel from fuel filter and 312-way valve.

- Clamp off fuel lines at 312-way valve.

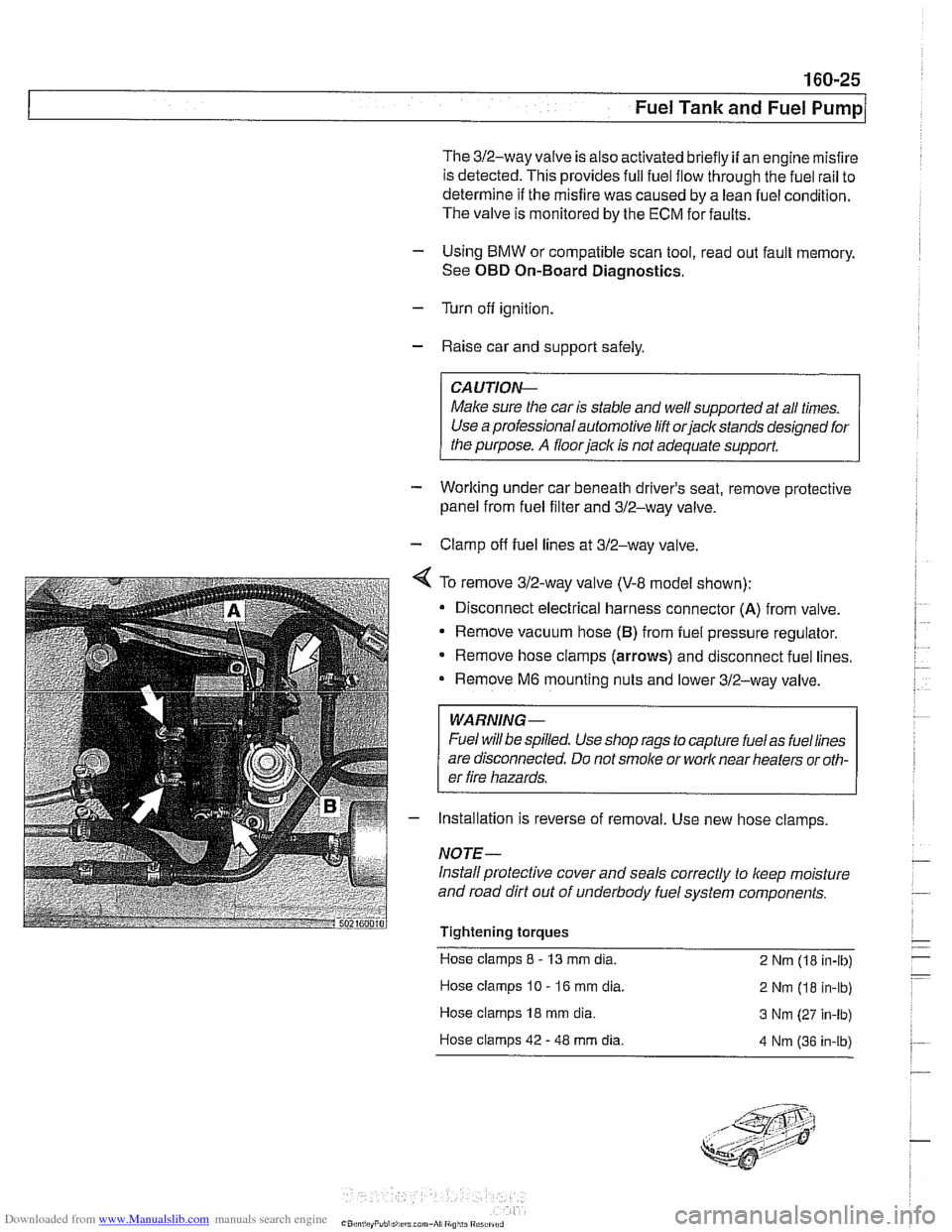

4 To remove 312-way valve (V-8 model shown):

Disconnect electrical harness connector

(A) from valve.

Remove vacuum hose

(B) from fuel pressure regulator.

* Remove hose clamps (arrows) and disconnect fuel lines.

Remove

M6 mounting nuts and lower 312-way valve.

WARNING-

Fuel will be spilled. Use shop rags to capture fuelas fuellines

are disconnected. Do not

smoke or work near heaters or oth-

er fire hazards.

- Installation is reverse of removal. Use new hose clamps

NOTE-

Install protective cover and seals correctly to keep moisture

and road dirt out of underbody fuel system components.

Tightening torques Hose clamps

8 - 13 mm dia.

2 Nm (18 in-lb)

Hose clamps

10 - 16 mm dia.

2 Nm (18 in-lb)

Hose clamps

18 mm dia. 3 Nm (27 in-lb)

Hose clamps 42

- 48 mm dia. 4 Nm 136 in-ib)

Page 502 of 1002

Downloaded from www.Manualslib.com manuals search engine

.. - -

I Radiator and Cooling System

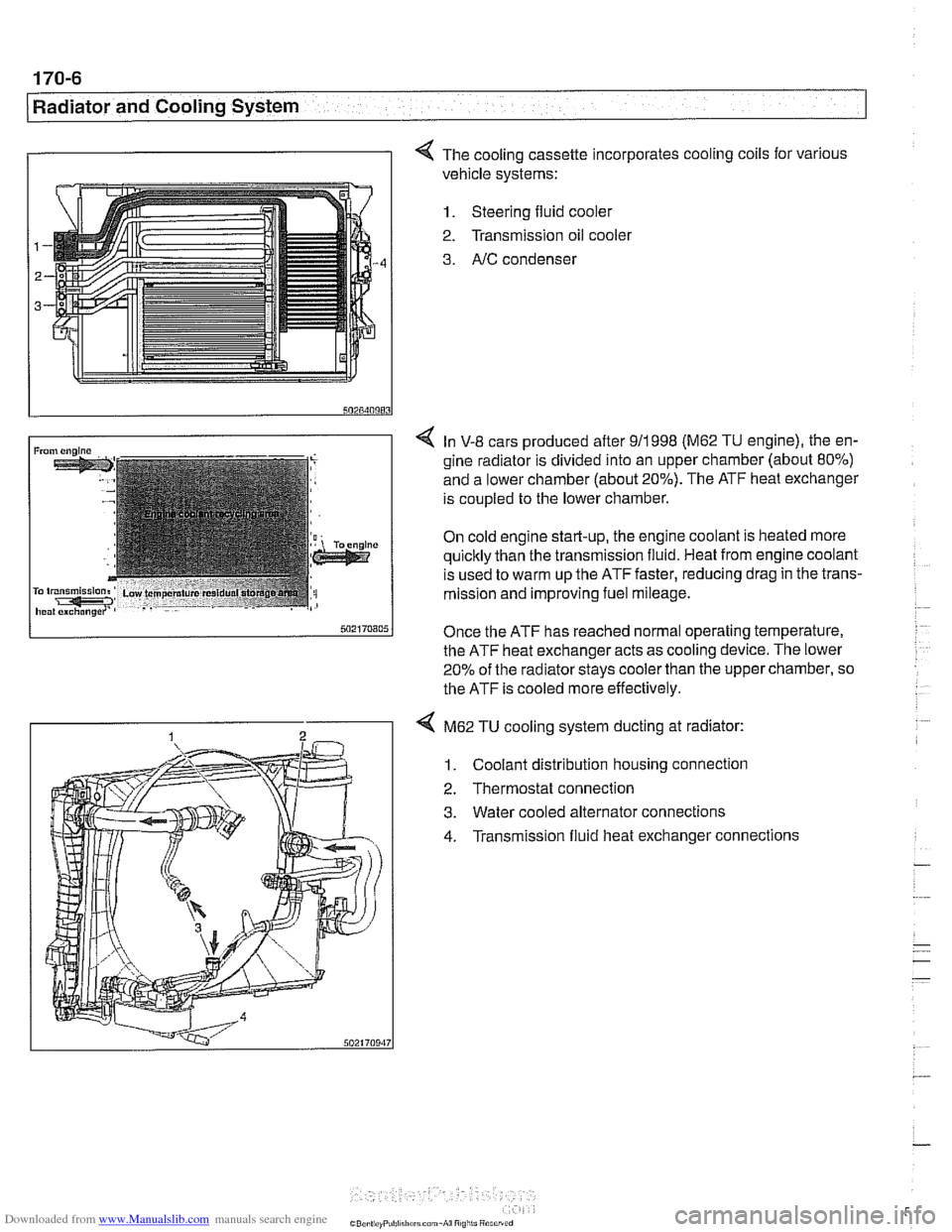

I I 4 The cooling cassette incorporates cooling coils for various

vehicle systems:

1. Steering fluid cooler

2. Transmission oil

coolel

3. AIC condenser

4 In V-8 cars produced after 911998 (M62 TU engine), the en-

gine radiator is divided into an upper chamber (about 80%)

and a lower chamber (about 20%). The ATF heat exchanger

is coupled to the lower chamber.

On cold engine start-up, the engine coolant is heated more

quicltly than the transmission fluid. Heat from engine coolant

is used to warm up the ATF faster, reducing drag in the trans-

mission and improving fuel mileage.

Once the ATF has reached normal operating temperature,

the ATF heat exchanger acts as cooling device. The lower

20% of the radiator

stays cooler than the upper chamber, so

the ATF is cooled more effectively.

4 M62 TU cooling system ducting at radiator:

1. Coolant distribution housing connection

2. Thermostat connection

3. Water cooled alternator connections

4. Transmission fluid heat exchanger connections

Page 531 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Exhaust System

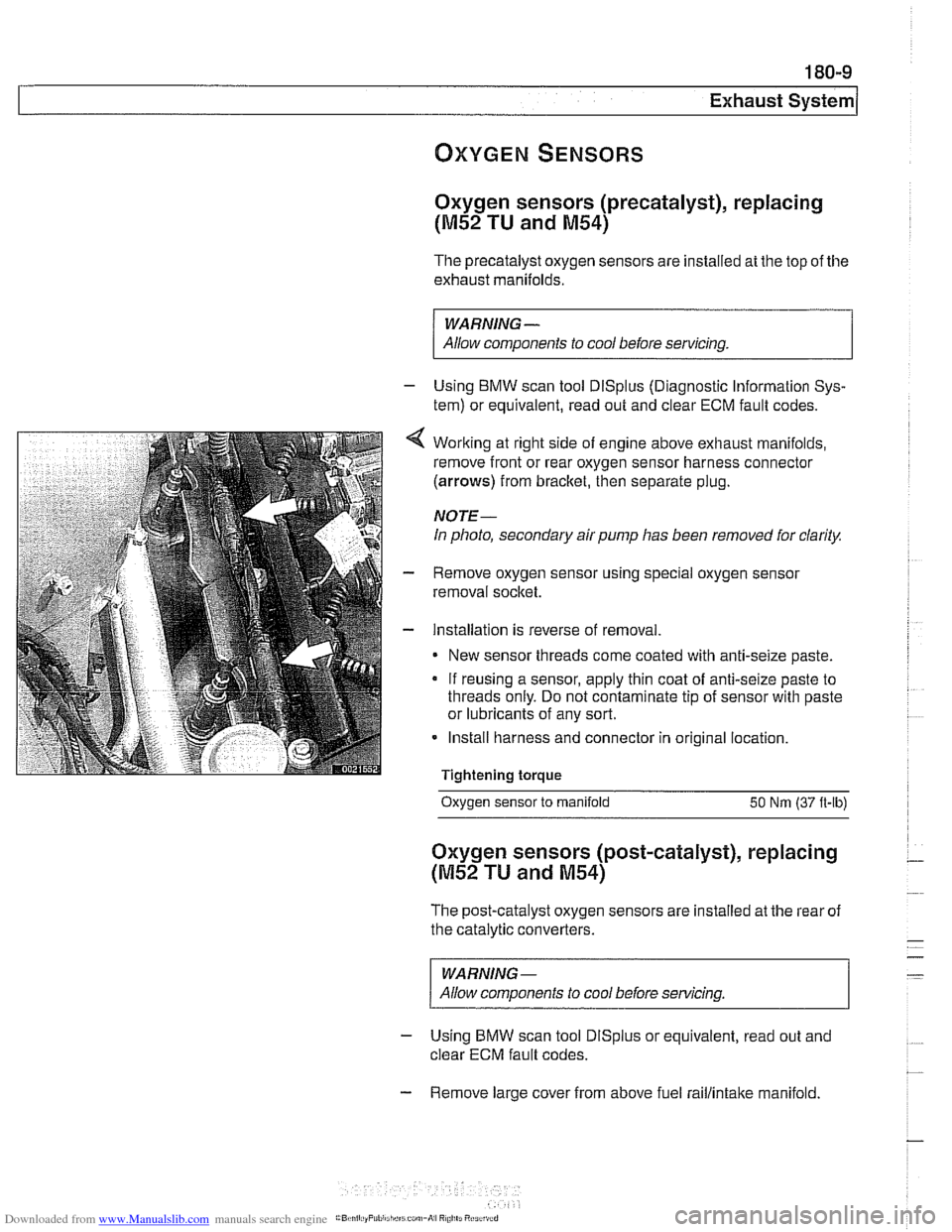

Oxygen sensors (precatalyst), replacing

(M52 TU and M54)

The precatalyst oxygen sensors are installed at the top of the

exhaust manifolds.

WARNING-

Allow components to cool before servicing.

- Using BMW scan tool DlSplus (Diagnostic Information Sys-

tem) or equivalent, read out and clear ECM fault codes.

Working at right side of engine above exhaust manifolds,

remove front or rear oxygen sensor harness connector

(arrows) from bracket, then separate plug.

NOTE-

In photo, secondary air pump has been removed for clarity.

Remove oxygen sensor using special oxygen sensor

removal socket.

Installation is reverse of removal

New sensor threads come coated with anti-seize paste.

If reusing a sensor, apply thin coat of anti-seize paste to

threads only. Do not contaminate tip of sensor with paste

or lubricants of any sort.

Install harness and connector in original location.

Tightening torque

- -.

Oxygen sensor to manifold 50 Nm (37 ft-lb)

Oxygen sensors (post-catalyst), replacing

(M52 TU and M54)

The post-catalyst oxygen sensors are installed at the rear of

the catalytic converters.

WARNING-

Allow components to cool before servicing

- Using BMW scan tool DlSplus or equivalent, read out and

clear ECM fault codes.

- Remove large cover from above fuel raillintake manifold.

Page 633 of 1002

Downloaded from www.Manualslib.com manuals search engine

Suspension, Steering and Brakes - ~enerail

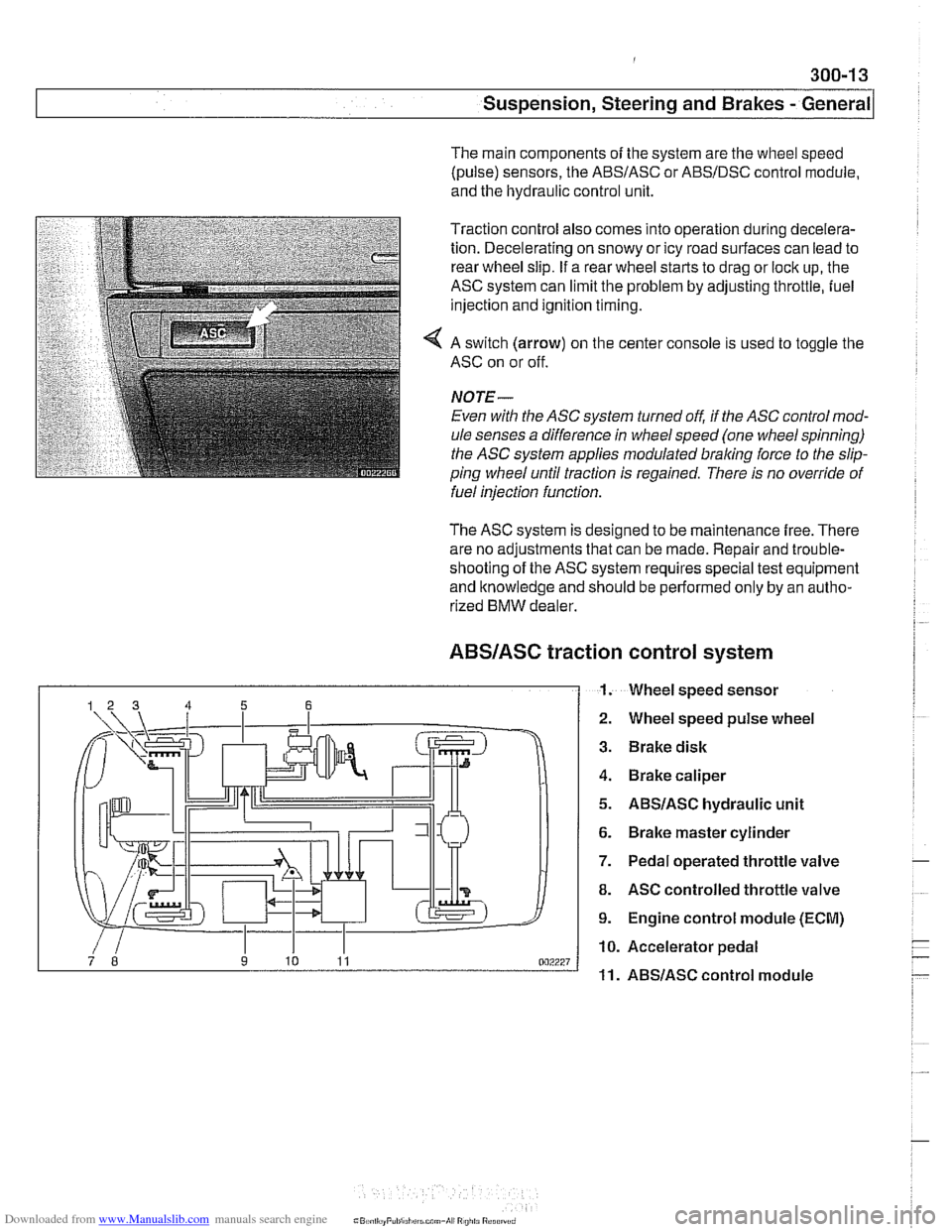

The main components of the system are the wheel speed

(pulse) sensors, the

ABSIASC or ABSIDSC control module,

and the hydraulic control unit.

Traction control also comes into operation during decelera-

tion. Decelerating on snowy or icy road surfaces can lead to

rear wheel slip. If a rear wheel starts to drag or lock up, the

ASC system can limit the problem by adjusting throttle, fuel

injection and ignition timing.

4 A switch (arrow) on the center console is used to toggle the

ASC on or off.

NOJE-

Even with the ASC system turned off, if the ASC control mod-

ule senses a difference in wheel speed (one wheel spinning)

the

ASC system applies modulated braling force to the slip-

ping wheel until traction is regained. There is no override of

fuelinjection function.

The ASC system is designed to be maintenance free. There

are no adjustments that can be made. Repair and trouble-

shooting of the ASC system requires special test equipment

and knowledge and should be performed only by an autho-

rized

BMW dealer.

ABSIASC traction

I 1.

control system

Wheel speed sensor

Wheel speed pulse wheel

Brake disk

Brake caliper

ABSIASC hydraulic unit

Brake master cylinder

Pedal operated throttle valve

ASC controlled throttle valve

Engine control module (ECM)

Accelerator pedal

ABSlASC control module

Page 634 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 4

I Susoension. Steerina and Brakes - General

DSC system I

Dynamic Stability Control (DSC)

Dynamic Stability Control (DSC) utilizes many principles and

components of the ASC traction control system. DSC is ac-

tive throughoutthe driving range, unlike ASC which is only ac-

tive during acceleration and braking. DSC helps stabilize the

vehicle in cornering and avoidance maneuvers by adjusting

engine controls such as throttle, ignition, fuel injection and the

application of

brake pressure individually to the wheels.

Inputs

fi- 0

2 4-* .. o

[11-' IJ

411m4

3?-

G

4 The DSC control module uses various inputs to determine

vehicle instability during braking, cornering, or reduced trac-

tion situations. Based upon these inputs the ABSIDSC con-

trol module sends outputs to the engine control module and

the ABSIDSC hydraulic unit to activate torque reduction pro-

tocols and braking intervention.

-

ABSIDSC control module

OUI~YIS

4

The DSC system can be toggled on and off by a switch

mounted on the center console. Turning off the DSC system

does not disable ABS or ASC functions.

+

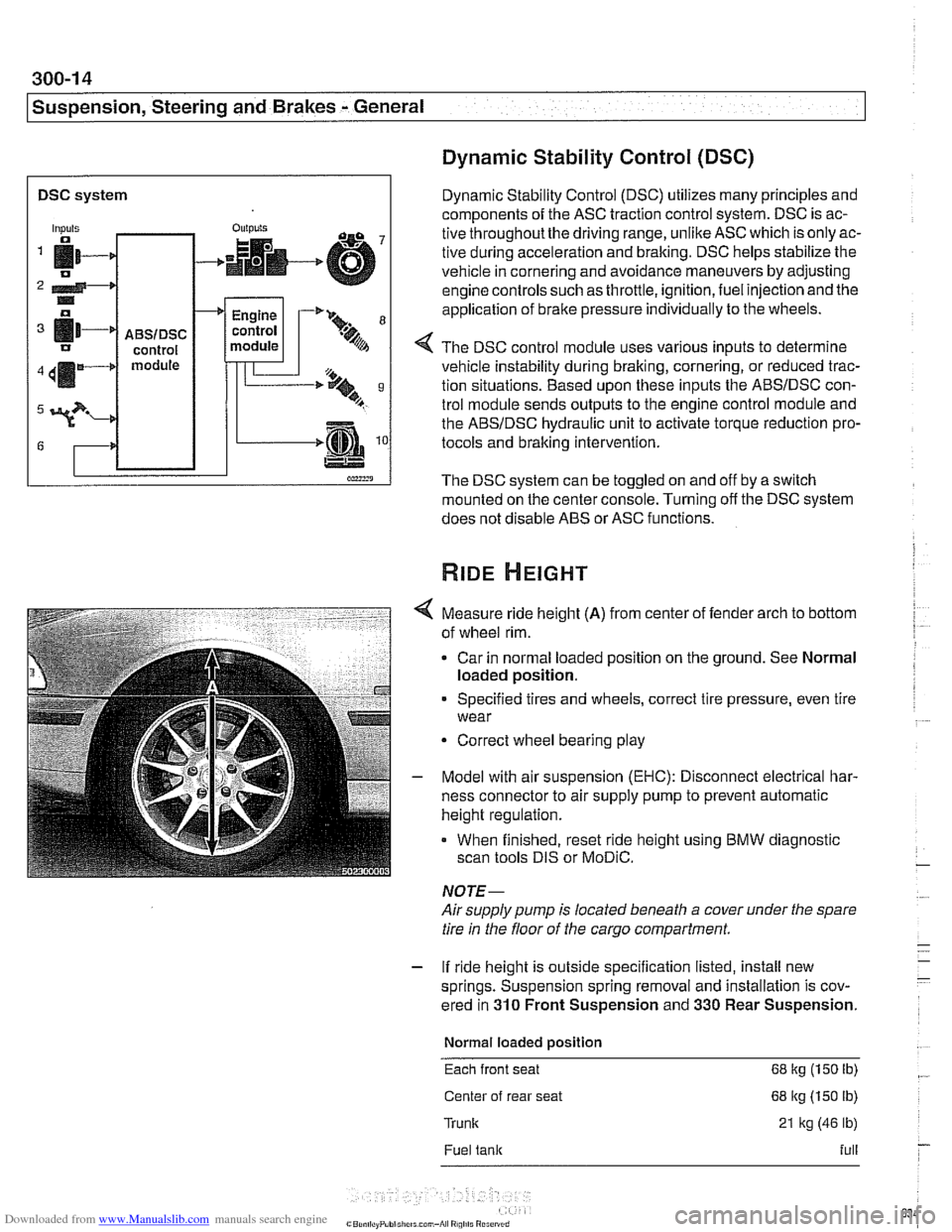

Measure ride height (A) from center of fender arch to bottom

of wheel rim.

Car in normal loaded position on the ground. See Normal

loaded position.

Engine

control

module

Specified tires and wheels, correct tire pressure, even tire

wear

-'* 9-

.%A

Correct wheel bearing play

T'== ..t, 9 B

-.m

Model with air suspension (EHC): Disconnect electrical har-

ness connector to air supply pump to prevent automatic

height regulation.

When finished, reset ride height using BMW diagnostic

scan tools DIS or

MoDiC.

NOTE-

Airsupply pump is located beneath a cover under the spare

tire in the floor of the cargo compartment.

- If ride height is outside specification listed, install new

springs. Suspension spring removal and installation is cov-

ered in

310 Front Suspension and 330 Rear Suspension.

Normal loaded position

Each front seat 68 kg (150 Ib)

Center of rear seat 68 kg (150 lb)

Trunk 21 kg (46 lb)

Fuel tank full

Page 802 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-8

Body-General

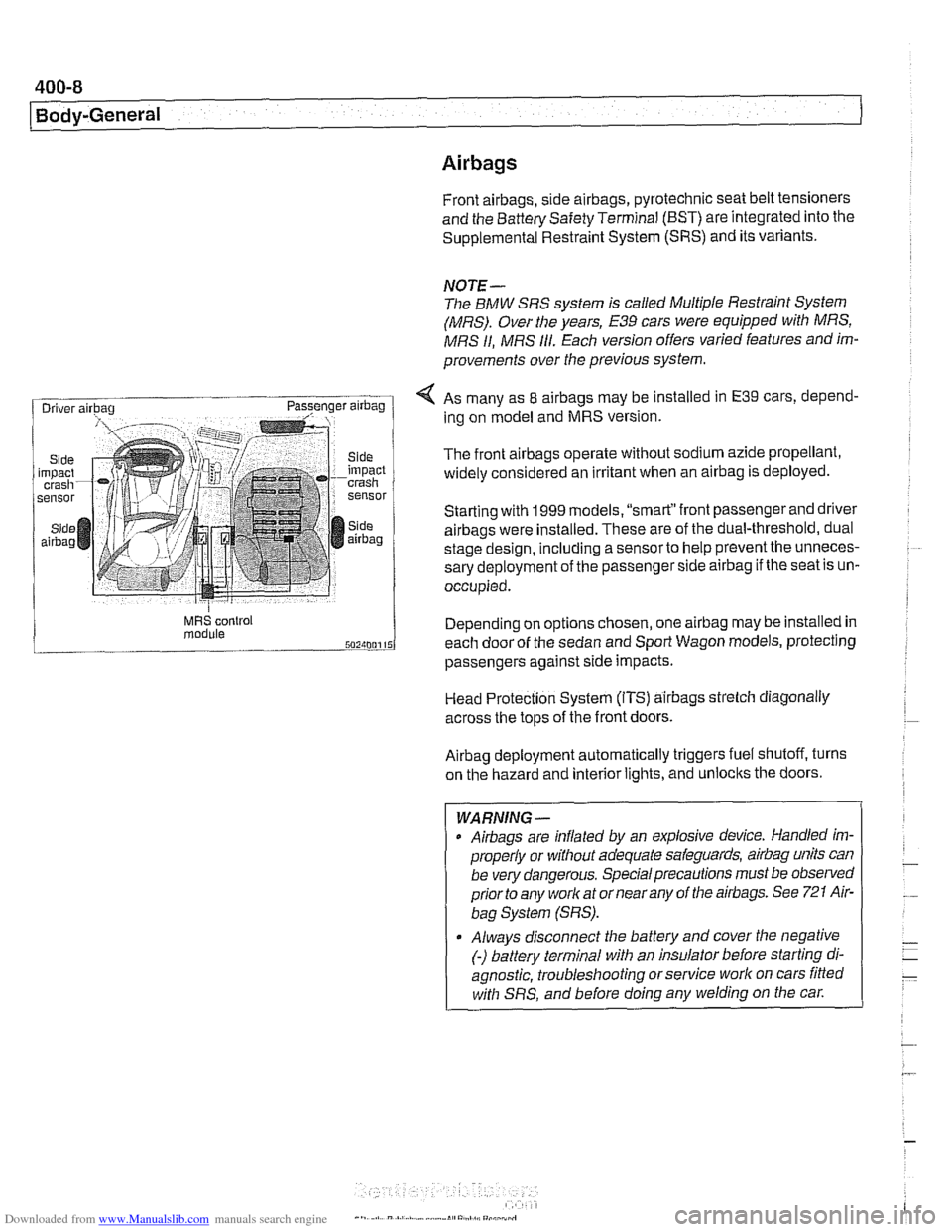

Airbags

Front airbags, s~de a~rbags, pyrotechnic seat belt tensioners

and the Battery Safety Terminal (BST) are integrated into the

Supplemental Restraint System (SRS) and its variants.

NOTE-

The BMW SRS system is called Multiple Restra~nt System

(MRS). Over the years,

E39 cars were equipped with MRS,

MRS

11, MRS 111. Each version offers varied features and im-

provements over the previous system.

< As many as 8 airbags may be installed in E39 cars, depend-

ing on model and MRS version.

The front

airbags operate without sodium azide propellant,

widely considered an irritant when an

airbag is deployed.

Starting with

1999 models. "smart"front passenger and driver

airbags were installed. These are of the dual-threshold, dual

stage design, including a

sensorto help prevent the unneces-

sary deployment of the passenger side

airbag if the seat is un-

occupied.

MRS control Depend~ng on options chosen, one airbag may be installed in module each door of the sedan and Sport Wagon models, protecting

passengers against

s~de impacts.

Head Protection System (ITS)

airbags strelch diagonally

across the tops of the front doors.

Airbag deployment automatically triggers fuel shutoff, turns

on the hazard and interior lights, and unlocks the doors.

- -

WARNING -

Airbags are inflated by an explosive device. Handled im-

properly or without adequate safeguards,

airbag units can

be very dangerous. Special precautions must be observed

prior to any worlc at or near any of the airbags. See

721 Air-

bag System (SRS).

Always disconnect the battery and cover the negative

(-) battery terminal with an insulator before starting di-

agnostic, troubleshooting or service work on cars fitted

with SRS, and before doing any welding on the

car.

Page 896 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-2

/Central Locking and Anti-Theft

This section covers repair information for door, trunk and car-

go compartment locks, central locking, electronic

immob~liza-

tion (EWS) and anti-theft alarm (DWA).

€39 cars are equipped with sophisticated self-diagnostic elec-

trical systems. When experiencing malfunctions relating to

central locking. EWS or anti-theft systems, start the diagnosis

process using the

BMW service tester DIS, GT 1, MoDiC or

equivalent scan tool. An advanced diagnostic scan tool can

usually pinpoint electrical faults quickly and safely.

Additional electrical information can be found in:

610 Electrical Component Locations

ELE Electrical Wiring Diagrams

Central locking in E39 vehicles controls the door

locks, trunk

or tailgate lock and fuel filler flap lock. The control module for

the Central Body Electronics system (ZKE

Ill), lknown as the

General Module (GM

Ill), controls central locking.

ZKE

Ill manages the following central locking related func-

tions:

Central locking

* Keyless entry

Key memory

Power trunk release

Electric opening of tailgate

DWA alarm system

Diagnosis

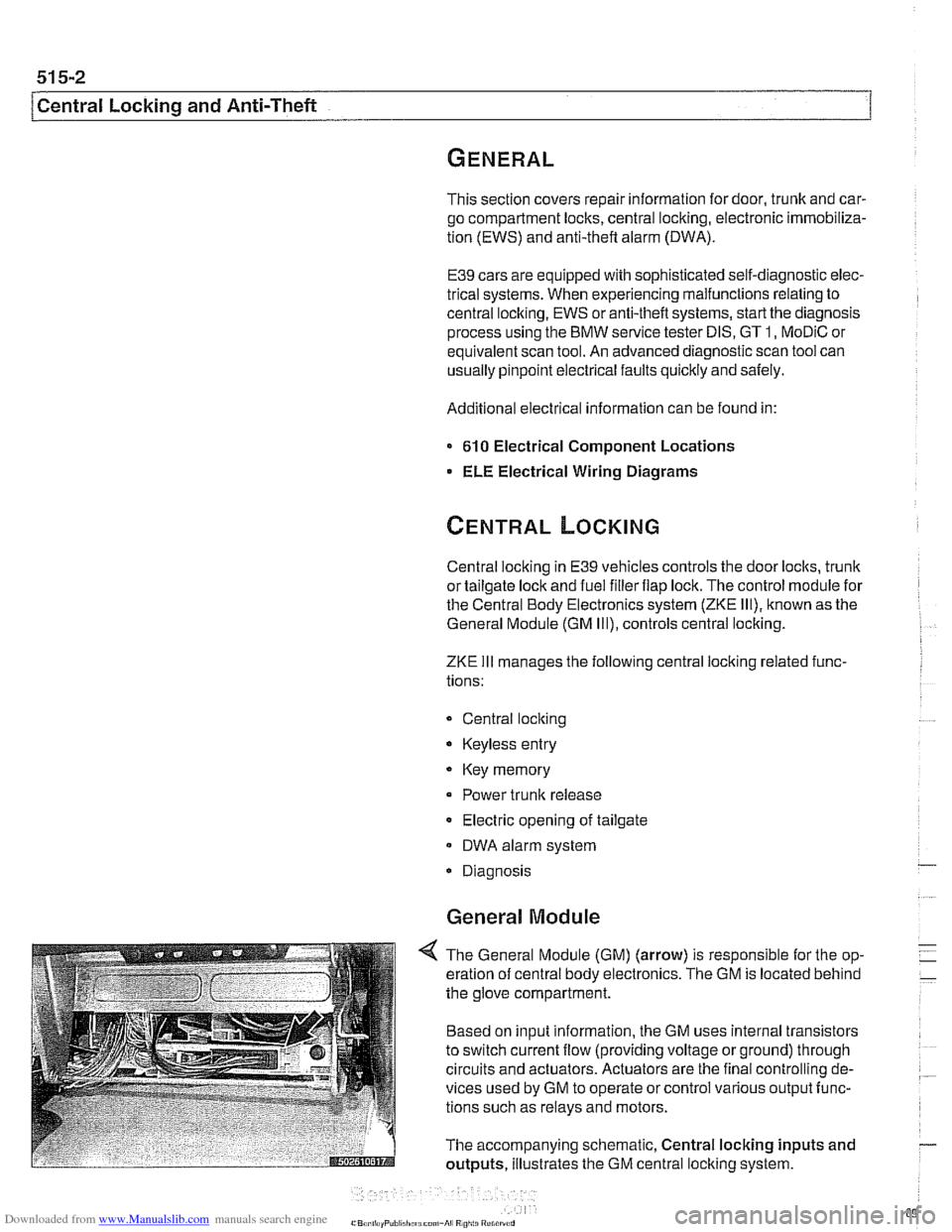

General Module

4 The General Module (GM) (arrow) is responsible for the op-

eration of central body electronics. The GM is located behind

the glove compartment.

Based on input information, the GM uses internal transistors

to switch current flow (providing voltage or ground) through

circuits and actuators. Actuators are the final controlling de-

vices used by GM to operate or control various output func-

tions such as relays and motors.

The accompanying schematic, Central locking inputs and

outputs, illustrates the GM central locking system.

Page 898 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-4

I Central Locking and Anti-Theft

Driver's door lock

The

lock/unlock signals are sent as input to the door module

from two microswitches on the lockcylinder. The driver's door

module carries out the locking

/ unlocking functions of the

driver's door through its final stage control.

The signal to lock the remaining doors, trunk or tailgate and

fuel flap is sent over the P-Bus to the GM and the passenger

door module. Activation of the passengers door

loclt is carried

out by the passenger door module. The rear doors, trunlt or

tailgate and fuel flap are

locked by the f~nal stage in the GM.

When

locked from the outside, all doors are set to the double

lock position and the GM will not carry out any unlock com-

mands from the central

loclc button or remote trunk release

button.

Selective unlocking

When unlocking with the key or the remote transmitter, the

first unloclcrequestwill only unlock the driver'sdoor. A second

unlock request will unlock the remaining doors, trunk or tail-

gate and fuel flap.

Trunk locking

I

The vehicle can be locked/unlocked from the trunlc loclc cylin-

der. The GM locks the trunk or tailgate, rear doors and fuel fill-

er. The locking command is passed over the P-Bus to the

respective door modules to lock the driver's and passengers

doors.

Locking the trunk and removing the key in the

hor~zontal posi-

tion will set the valet lock and prevent opening of the trunlt

with the central locking system.

Central locking switch

-

< The central locking master control switch (arrow) is located

in the center console behind the shifter.

The central locking button will only single

loclt the doors

and trunk. The filler flap remains unloclted for refueling pur-

poses.

If a door is opened from inside while centrally locked, the

remaining doors remain locked.

The open door can be relocked, when closed, by manually

locking or pressing the central locking button twice. This

synchronizes the door

locks.

Page 900 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-6

(Central Locking and Anti-Theft

Each rear door is equipped with the child lock-out lever, pre-

venting the door from being opened from the inside regard-

less of loclc button position.

Starting with models produced afler

911997, the General

Module and electronic immobilizer (EWS) interface via the

K-

Bus to monitor double lock status and to initiate double loclc

override. This feature allows the doors to be opened from the

inside if a key accepted by EWS is switched on in the ignition.

See Single lock and double lock function.

The door loclc buttons are mechanically uncoupled from the

actuators when locked. The remote keyless entry system

(FZV) is standard equipment. This allows for elimination of

the passengers side door

loclt cylinder.

Another function of the locking system is the

sofl close trunk

(SCA) system, where applicable.

Single lock and double lock function

(2000 and later models)

On models produced after

911999, each door lock actuator in-

corporates two motors:

Single lock motor controls the mechanical loclc mechanism

when the central lock switch is pressed to single loclc the

vehicle. The loclc mechanism is fully locked at this point but

can stil. be openeo from

the interor by pulng the appropri-

are interior door nandle lwce or by pressing rhe central

lock switch again. When single

lock'function is activated,

the fuel filler flap actuator is not locked.

Double lock motor, also known as central arrest, is activat-

ed only when the vehicle is locked from the outside at the

driver's door lock with a key or when the GM receives a

lock request from the remote entry (FZV) system. In this

case the double lock motor is activated simultaneously

with the single lock motor. The function of the double loclc

motor is to mechanically offset an internal rod in the loclc

actuator, disabling it from unlocking the vehicle from the in-

terior. This prevents the doors from being unloclted by any

means except from an unlock request at the driver's door

or via the FZV remote key.

Lock cylinder safety

4 The driver's door loclc and the trunk loclc incorporate an over-

running loclc cylinder similar to the ignition lock. If any key

other than the vehicle key, or a tool such as a screwdriver or

dent-puller, is inserted into the cylinder, it will cause the cyl-

inder to freewheel or spin.