engine control system BMW 528i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 954 of 1002

Downloaded from www.Manualslib.com manuals search engine

721-6

I Airbag System (SRS)

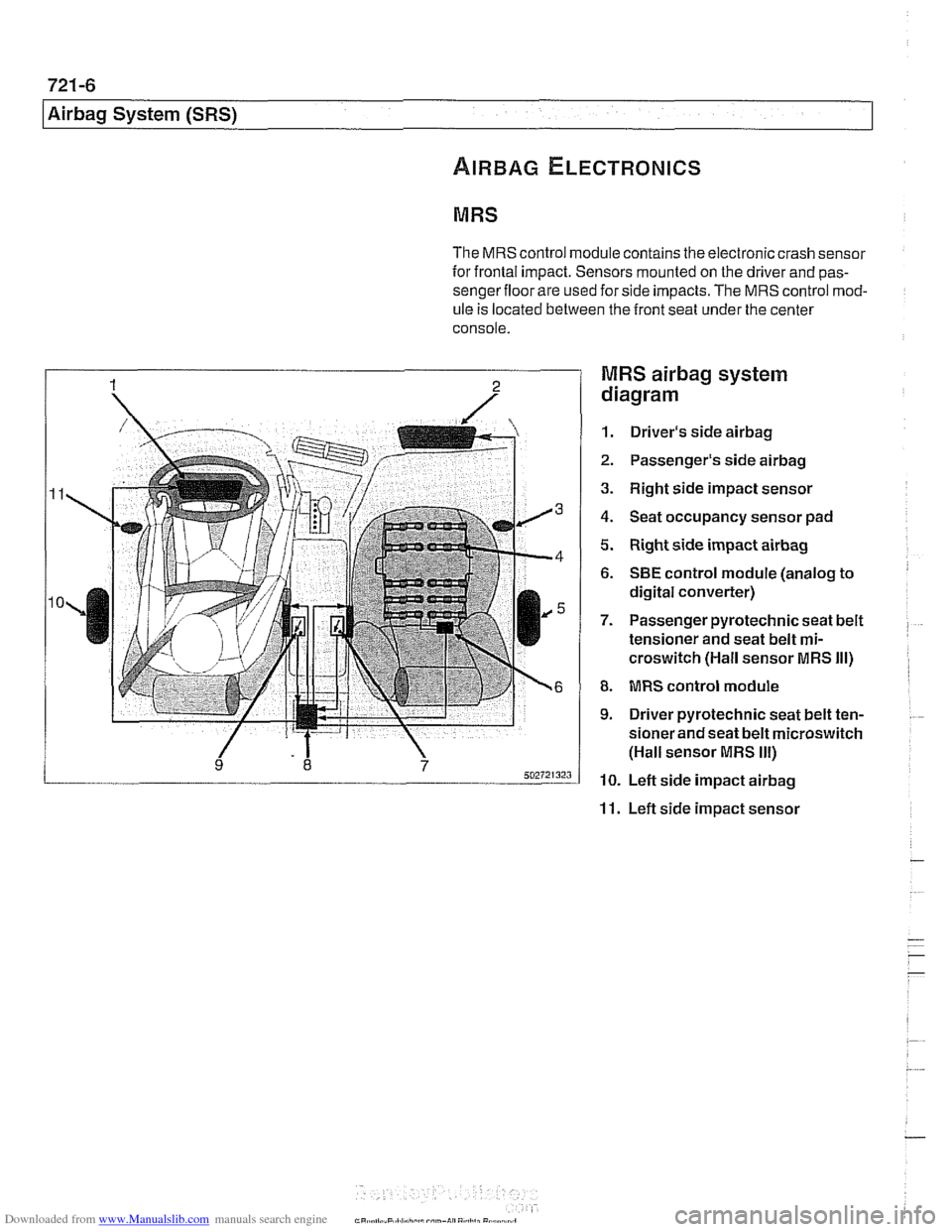

MRS

The MRS control module contains the electronic crash sensor

for frontal impact. Sensors mounted on the driver and

pas-

sengerfloor are used for side impacts. The MRS control mod-

ule

is located between the front seat under the center

console.

MRS airbag system

diagram

1. Driver's side airbag

2. Passenger's side airbag

3. Right side impact sensor

4. Seat occupancy sensor pad

5. Right side impact airbag

6. SBE control module (analog to

digital converter)

7. Passenger pyrotechnic seat belt

tensioner and seat belt

mi-

croswitch (Hall sensor MRS Ill)

8. MRS control module

9. Driver pyrotechnic seat belt ten-

sioner and seat belt microswitch

(Hall sensor MRS

Ill)

10. Left side impact airbag

11. Left side impact sensor

Page 955 of 1002

Downloaded from www.Manualslib.com manuals search engine

Airbag System (SRS)~

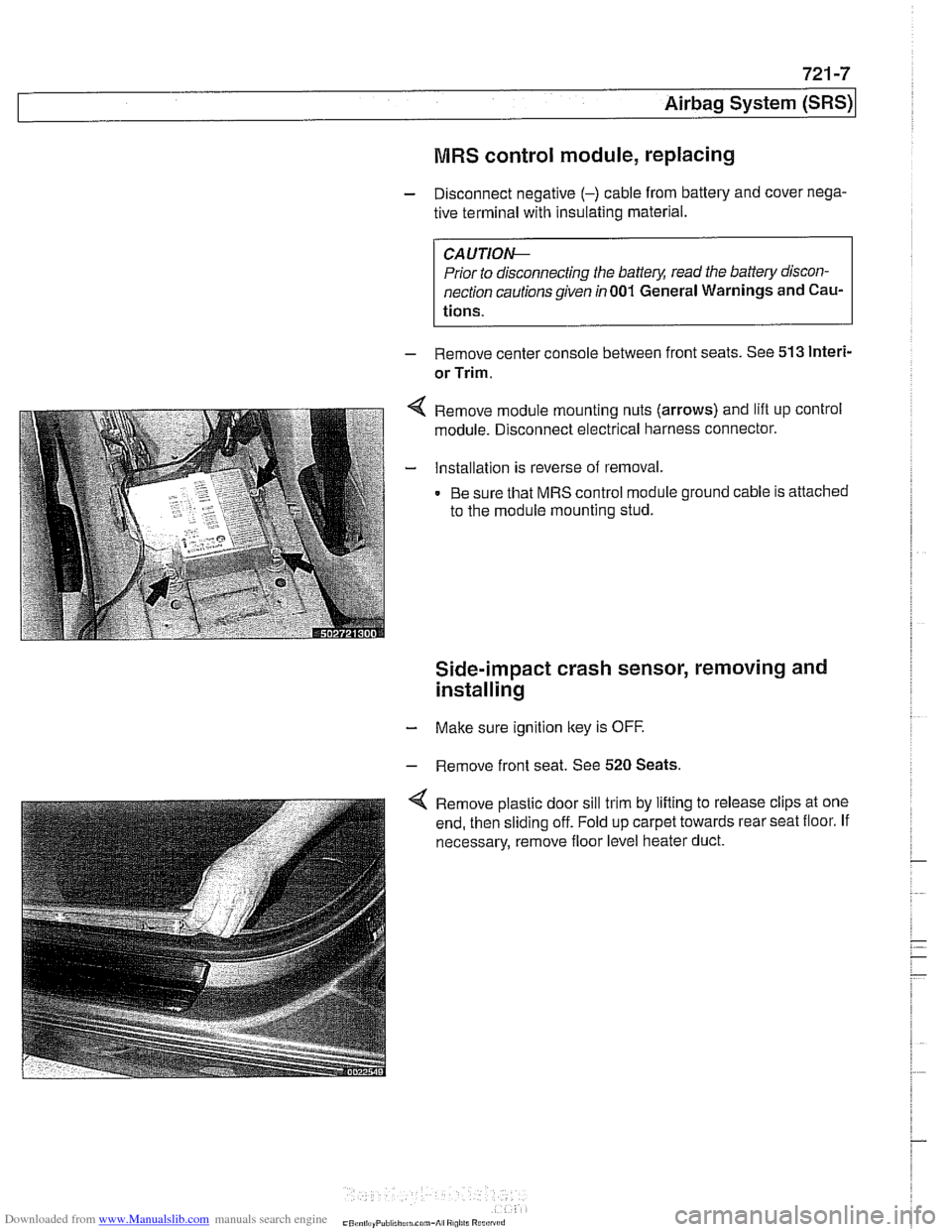

MRS control module, replacing

- Disconnect negative (-) cable from battery and cover nega-

tive terminal with insulating material.

CAUTIOI\C

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven in001 General Warnings and

Cau-

tions.

- Remove center console between front seats. See 513 lnteri-

or Trim.

Remove module mounting nuts (arrows) and lift up control

module. Disconnect electrical harness connector.

Installation is reverse of removal.

Be sure that MRS control module ground cable is attached

to the module mounting stud.

Side-impact crash sensor, removing and

installing

- Make sure ignition key is OFF.

- Remove front seat. See 520 Seats.

Remove plastic door sill trim by lifting to release clips at one

end, then sliding off. Fold up carpet towards rear seat floor. If

necessary, remove floor level heater duct.

Page 961 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD On-Board Diagnostics

I I

General ........................... OBD-1 Diaqnostic Trouble Codes (DTCs) . . OBD-9

On-Board Diagnostics (OBD I!) ..... OBD-I

Malfunction Indicator Light (MIL)

........ OBD-2

Scan tools and scan tool display.

........ OBD-3

Diagnostic monitors

.................. OED-4

Drive cycle

......................... OED-6

Readiness codes

.................... OBD-6

Diagnostic trouble codes

(DTCs) ........ OBD-7

-

Automatic transmission diagnostic

trouble codes

....................... OBD-9

Engine diagnostic trouble

codes: M52 engine.

................. OED-13

Engine diagnostic trouble

codes: M54 engine.

................. OBD-17

Engine diagnostic trouble

codes: M62 engine.

................. OBD-24

This chapter outlines the fundamentals and equipment

requirements of On-Board Diagnostics

I1 (OBD 11) standards

as they apply to BMW vehicles. Also covered here is a listing

of BMW and OBD

I1 diagnostic trouble codes (DTCs).

ON-BOARD DIAGNOSTICS (QBD !I)

OBD II standards were developed by the SAE (Society of

Automotive Engineers) and CARB (California Air Resources

Board).

OED I1 is the second generation of on-board self-

diagnostic equipment requirements. These standards were

originally mandated for California vehicles. Since

1996 they

have been applied

toall passengervehicles sold in the United

States.

On-board diagnostic capabilities are incorporated into the

hardware and soflwareof the enginecontrol module

(ECM) to

monitor virtually every component that can affect vehicle

emissions. The

OED I1 system works to ensure that

emissions remain as clean as possible over the life of the

vehicle.

Each emission-influencing component is checked by a

diagnostic routine (called a monitor) to verify that it is

functioning properly.

If a problem or malfunction is detected,

the

diagnostic executive built into the OBD I1 system

illuminates a malfunction indicator light (MIL) on the

instrument panel.

The OBD

I1 system also stores diagnostic trouble codes

(DTCs) about the detected malfunction in the ECM so that a

repair technician can accurately find and fix the problem.

Page 962 of 1002

Downloaded from www.Manualslib.com manuals search engine

OED-2

On-Board Diagnostics

Specialized OED II scan tool equipment is needed to access

the fault memory and

OED I1 data.

The extra hardware needed to operate the OED

I1 system

consists mainly of the following:

* Additional oxygen sensors downstream of the catalytic

converters.

Fuel tank pressure sensor and device to pressurize

fuel

storage system.

Several engine and performance monitoring devices

Standardized 16-pin

OED II connector under the

dashboard.

Upgraded components for the federally required reliability

mandate.

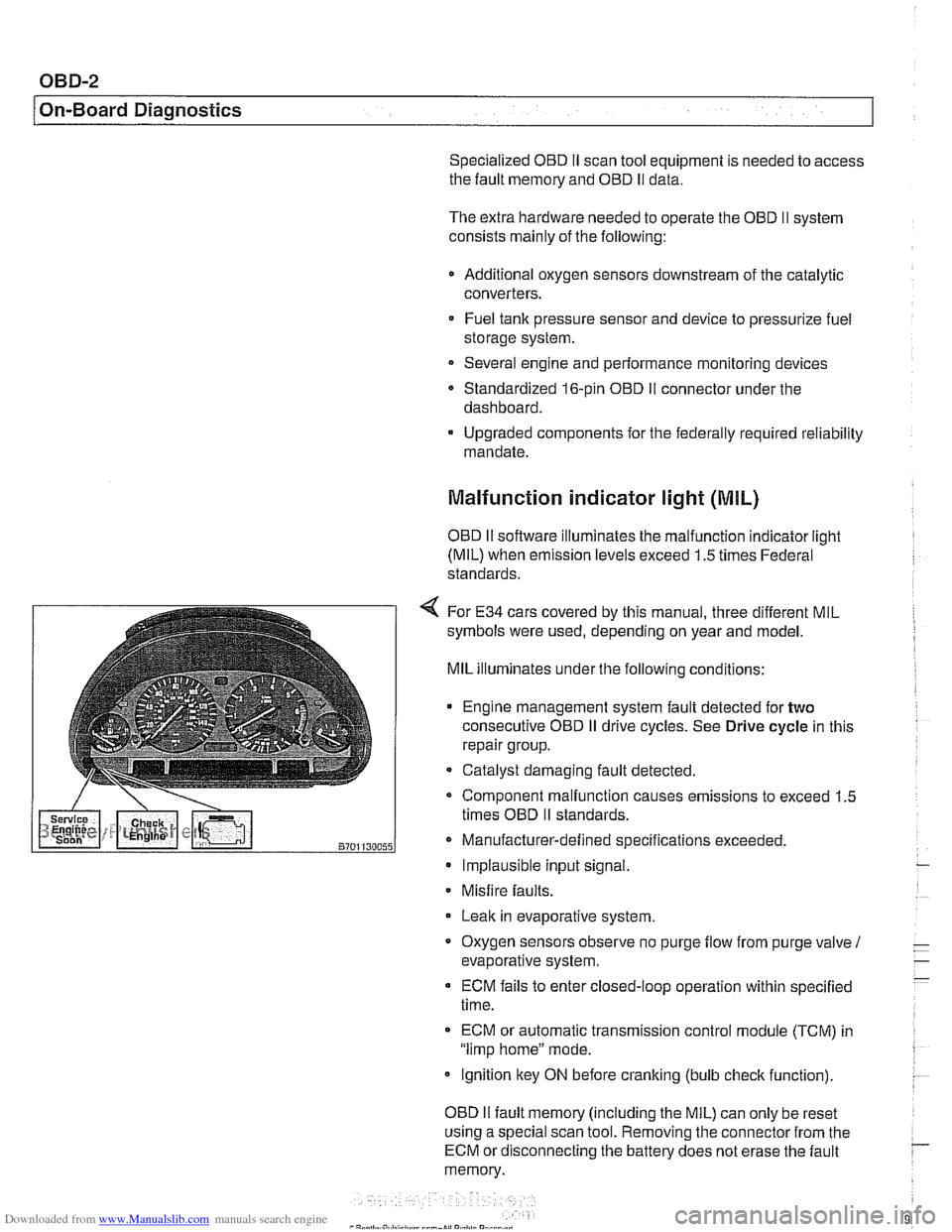

Malfunction indicator light (MIL)

OED II software illuminates the malfunction indicator light

(MIL) when emission levels exceed 1.5 times Federal

standards.

4 For E34 cars covered by this manual, three different MIL

symbols were used, depending on year and model.

MIL illuminates under the following conditions:

Engine management system fault detected for

two

consecutive OED iI drive cycles. See Drive cycle in this

repair group.

- Catalyst damaging fault detected.

Component malfunction causes emissions to exceed 1.5

times OED

II standards.

Manufacturer-defined specifications exceeded. Implausible input signal.

Misfire

faults.

Leak in evaporative system,

Oxygen sensors observe no purge

flow from purge valve 1

evaporative system.

ECM fails to enter closed-loop operation within specified

time.

ECM or automatic transmission control

module (TCM) in

"limp home" mode.

ignition key ON before cranking (bulb

check function).

OED

II fault memory (including the MIL) can only be reset

using a special scan tool. Removing the connector from the

ECM or disconnecting the battery does not erase the fault

memory.

Page 964 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

On-Board Diagnostics

Professional diagnostic scan tools available atthe time of this

printing include the BMW factory tools

(DISplus, GTI,

MoDiC) and a small number of aftermarket BMW-specific

tools. See

020 Maintenance.

In addition to the professional line of scan tools, inexpensive

generic OBD

II scan tool software programs and handheld

units are readily available. Though limited, they are

nonetheless powerful diagnostic tools. These tools read live

data streams and freeze frame data as well as a host of other

valuable diagnostic data.

Diagnostic monitors

Diagnostic monitors run tests and checks on specific

emission control systems, components, and functions.

A complete drive cycle is requiredforthe tests to bevalid. See

Drive cycle in this repair group. The diagnostic monitor

signals the

ECM of the loss or impairment of the signal or

component and determines if a signal or sensor is faulty

based on

3 conditions:

* Signal or component shorted to ground

Signal or component shorted to

B+

Signal or component missing (open circuit)

The OBD

II system monitors all emission control systems that

are installed. Emission control systems vary by vehicle model

and year. For example, a vehicle may not be equipped with

secondary air injection, so no secondary air readiness code

would be present.

OBD

II software monitors the following:

Oxygen sensors

Catalysts

Engine misfire

- Fuel tank evaporative control system

Secondary air injection Fuel system

Oxygen sensor monitoring. When driving conditions allow,

response rate and switching time of each oxygen sensor is

monitored. The oxygen sensor heater function is also

monitored. The OBD

II system differentiates between

precataylst and post-catalyst oxygen sensors and reads each

one individually. In order

forthe oxygen sensor to be

effectively monitored, the system must be in closed loop

operation.

Page 966 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-6

On-Board Diagnostics

Fuel system monitoring. This monitor looks at the fuel

delivery needed (long

/short term fuel trim) for proper engine

operation based on programmed data. If too much or not

enough fuel is delivered over a predetermined time, a DTC is

set and the MIL illuminates.

Fuel trim refers to adiustments to base fuel schedule.

Lono- ., term fuel trim refers to gradual adjustments to the fuel

calibration adjustment as compared to short term fuel trim.

Long term fuel trim adjustments compensate for gradual

changes that occur over time.

Fuel system monitoring monitors the calculated injection time

(ti) in relation to enginespeed, load and precatalyticconverter

oxygen

sensor(s) signals.

Using this data, the system optimizes fuel delivery for all

engine operating conditions.

Evaporative system monitoring. This monitor checks the

the fuel storage system and related fuel lines for leaks. It can

detect very small leaks anywhere in the system.

A leak detection unit (LDP or DMTL) is used to pressurize the

evaporative control system on a continuous basis (as the

drive cycle allows) and to

check system integrity.

Drive cycle

The OED II drive cycle is an important concept in

understanding OBD

II requirements. The purpose of the drive

cycle is to run ail of the emission-related on-board diagnostics

over a broad range of driving conditions.

A drive cycle is considered complete when all of the

diagnostic monitors have run their tests without interruption.

~ora drive cycle to be initiated, the vehicle must be started

cold and brought up to

1 60°F and at least 40°F above its

original starting temperature.

Readiness codes

Inspection/maintenance (I/M) readiness codes are mandated

as part of OBD

II. The readiness code is stored aftercomplete

diagnostic monitoring of specified components and systems

is carried out. The readiness code function was designed to

prevent manipulating an

I/M emission test procedure by

clearing faults codes or disconnecting the ECM or battery.

Page 967 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

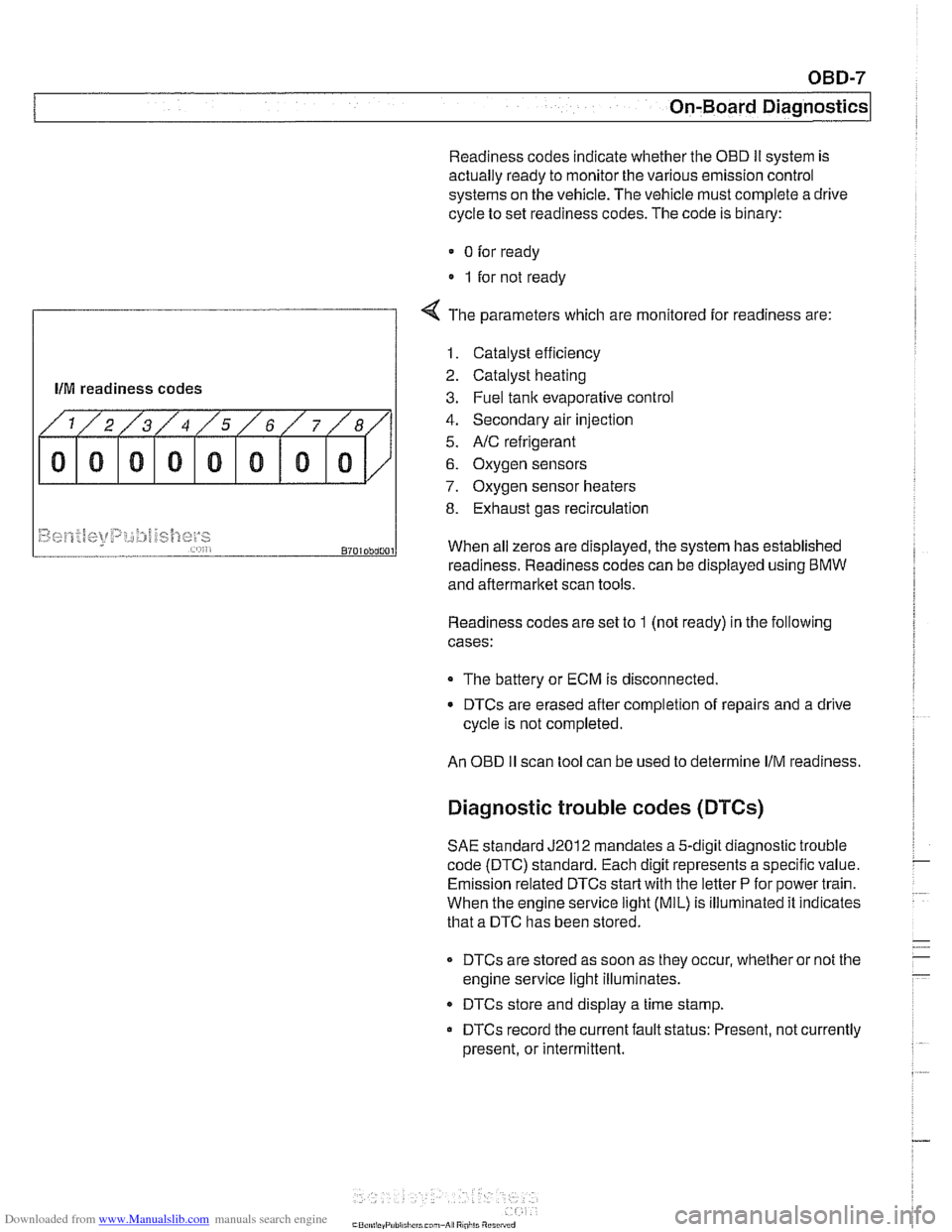

Readiness codes indicate whether the OED Ii system is

actually ready to monitor the various emission control

systems on the vehicle. The vehicle must complete a drive

cycle to set readiness codes. The code is binary:

0 for ready

1 for not ready

f

4 The parameters which are monitored for readiness are:

llM readiness codes

1. Catalyst efficiency

2. Catalyst heating

3. Fuel tank evaporative control

4. Secondary air injection

5.

NC refrigerant

6. Oxygen sensors

7. Oxygen sensor heaters

8. Exhaust gas recirculation

Readiness codes are set to 1 (not ready) in the following

cases:

~9~~.f~[<+t~t~p:,~;:#j~~{]~y~ ,,... , , 8701Dbd001

The battery or ECM is disconnected.

When

all zeros are displayed, the system has established

DTCs are erased after completion of repairs and a drive

cycle is not completed.

readiness. Readiness codes

can be displayed using BMW

and aftermarket scan tools.

An

OED II scan tool can be used to determine IIM readiness.

Diagnostic trouble codes (DTCs)

SAE standard J2012 mandates a 5-digit diagnostic trouble

code (DTC) standard. Each digit represents a specific value.

Emission related DTCs

start with the letter P for power train.

When the engine service

light (MIL) is illuminated it indicates

that a DTC has been stored.

DTCs are stored as soon as they occur, whether or not the

engine service light illuminates.

DTCs store and display a time stamp.

DTCs record the current fault status: Present, not currently

present, or intermittent.

Page 968 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-8

I On-Board Diagnostics

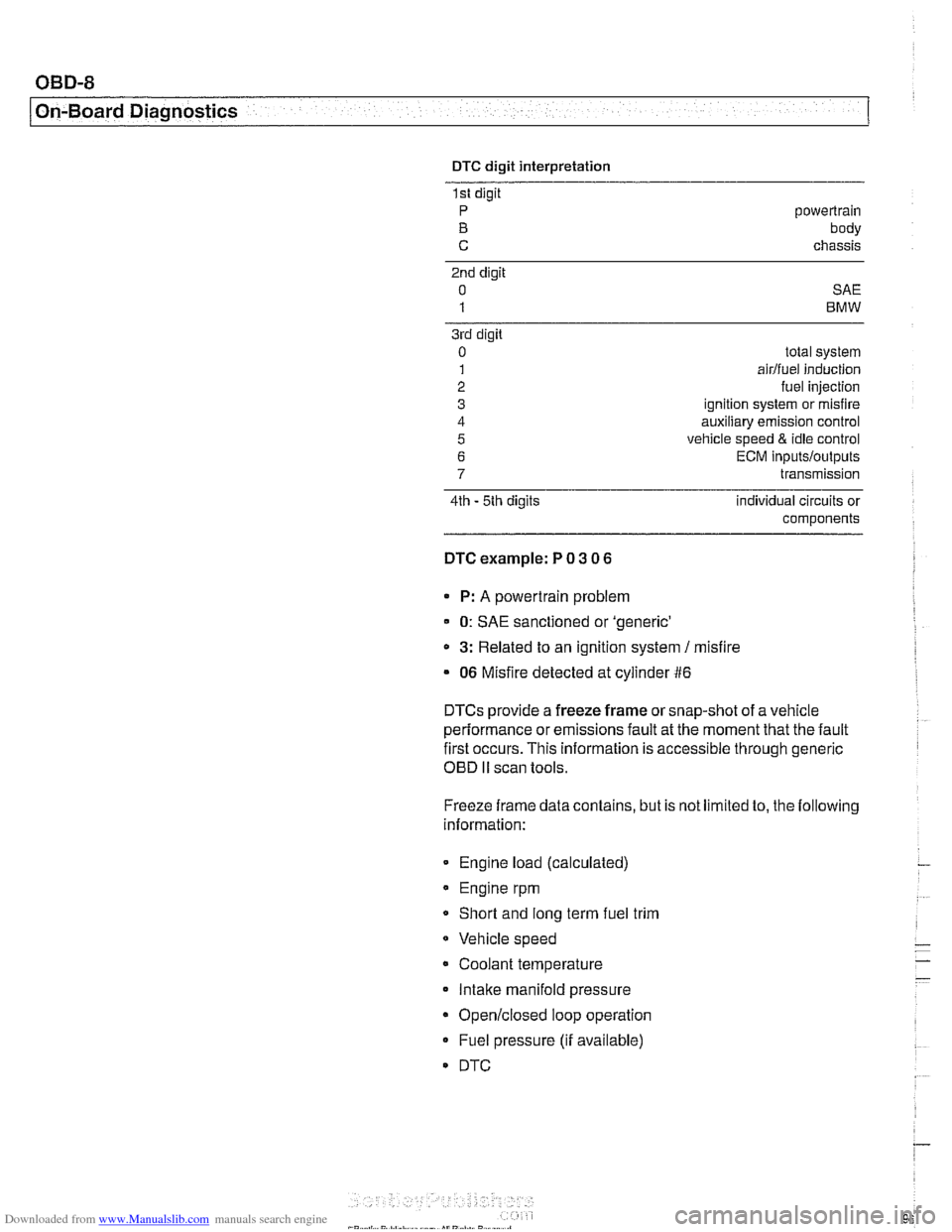

DTC digit interpretation

1st digit

P powertrain

B body

C chassis

2nd digit

0 SAE

1 BMW

3rd digit

0

1

2

3

4

5

6

7

4th - 5th digits total

system

airlfuei induction

fuel injection

ignition system or misfire

auxiliary emission control

vehicle speed

& idle control

ECM

inputs/outputs

transmission

individual circuits or

components

DTC example: P 0 3 0 6

P: A powertrain problem

0: SAE sanctioned or 'generic'

a 3: Related to an ignition system / misfire

06 Misfire detected at cylinder #6

DTCs provide a freeze frame or snap-shot of a vehicle

performance or emissions fault at the moment that the fault

first occurs. This information is accessible through generic

OED I1 scan tools.

Freeze frame data contains, but is not limited to, the following

information:

Engine load (calculated)

Engine rpm

Short and

long term fuel trim

Vehicle speed

Coolant temperature Intake manifold pressure

Open/closed loop operation

Fuel pressure (if available)

DTC

Page 969 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

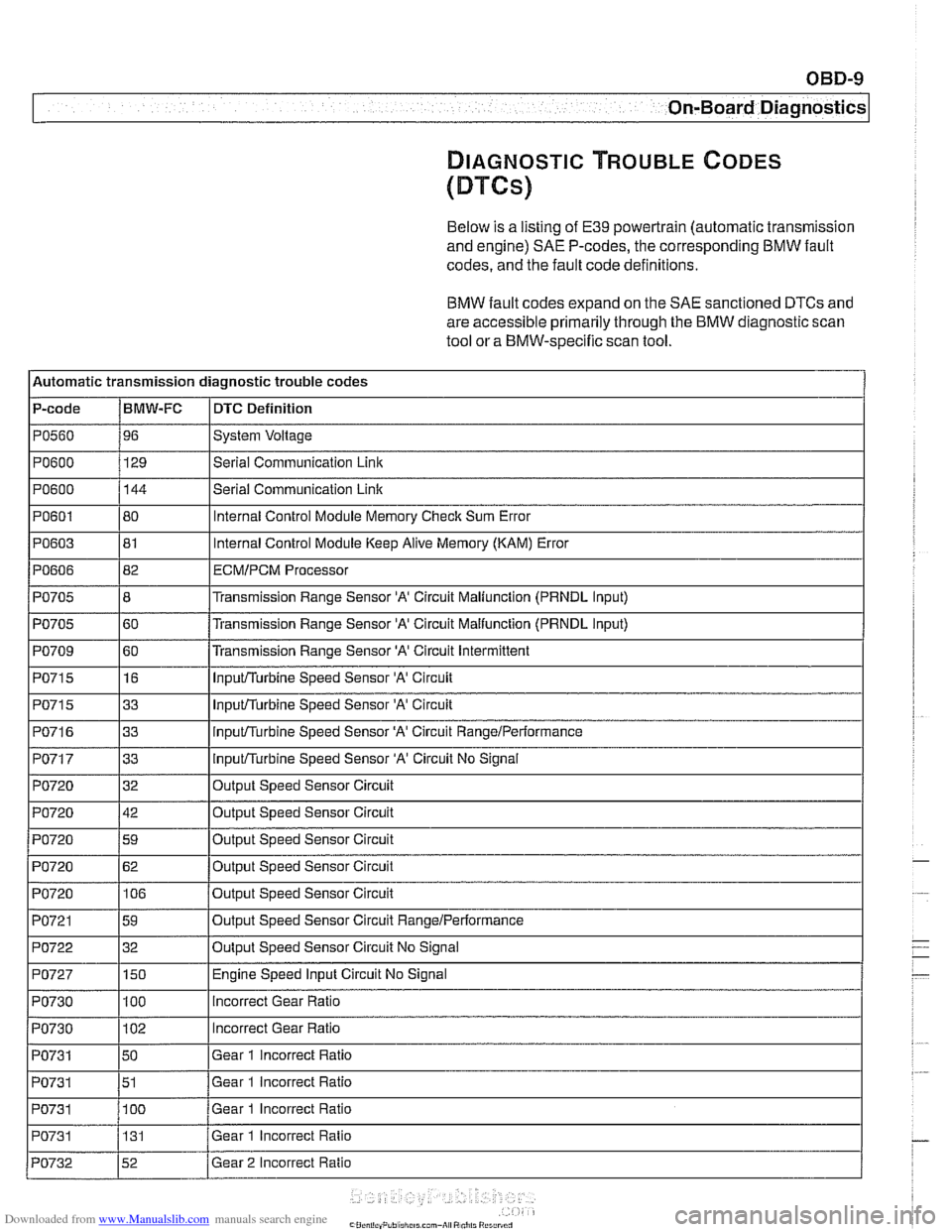

DIAGNOSTIC TROUBLE CODES

(DTCs)

Below is a listing of E39 powertrain (automatic transmission

and engine)

SAE P-codes, the corresponding BMW fault

codes, and the fault code definitions.

BMW fault codes expand on the SAE sanctioned DTCs and

are accessible primarily through the BMW diagnostic scan

tool or a BMW-specific scan tool.

l~utomatic transmission diagnostic trouble codes

P-code

IBMW-FC I DTC Definition

Ip0560 196 ISystem Voltage I

IPO~OO I129 l~eriai Communication Link I

1~0715 116 I InpuVTurbine Speed Sensor 'A' Circuit I

PO600

PO601

PO603

PO606

PO705

PO705

PO709

144

80

81

82

8

60

60

PO71 5

PO71 6

PO717

PO720

PO720

PO720

I I

PO721 159 loutput Speed Sensor Circuit RangeIPerformance I

Serial Communication Link

Internal Control Module Memory Check Sum Error

Internal Control Module Keep Alive Memory (KAM) Error

ECMIPCM Processor

Transmission Range Sensor 'A' Circuit Maliunction (PRNDL Input)

Transmission Range Sensor

'A' Circuit Malfunction (PRNDL input)

Transmission Range Sensor

'A' Circuit Intermittent

I I'

1~0722 132 IOutput Speed Sensor Circuit No Signal I

33

33

33

32

42

59

PO720

I I

PO727 1150 I Engine Speed Input Circuit No Signal

InpuVTurbine Speed Sensor 'A' Circuit

inpuVTurbine Speed Sensor 'A' Circuit RangeiPerformance

InpuVTurbine Speed Sensor 'A' Circuit No Signal

Output Speed Sensor Circuit

Output Speed Sensor Circuit

Out~ut Speed Sensor Circuit

PO720 1106 /output Speed Sensor Circuit

62

Output Speed Sensor Circuit

PO730

PO730

PO731

PO731

PO731 I I

100

102

50

51

100

PO731

incorrect Gear Ratio

Incorrect Gear Ratio

Gear 1 incorrect Ratio

Gear 1 incorrect Ratio

Gear 1 Incorrect Ratio

PO732 152 /Gear 2 Incorrect Ratio

131

Gear

1 Incorrect Ratio

Page 972 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-12

On-Board Diagnostics

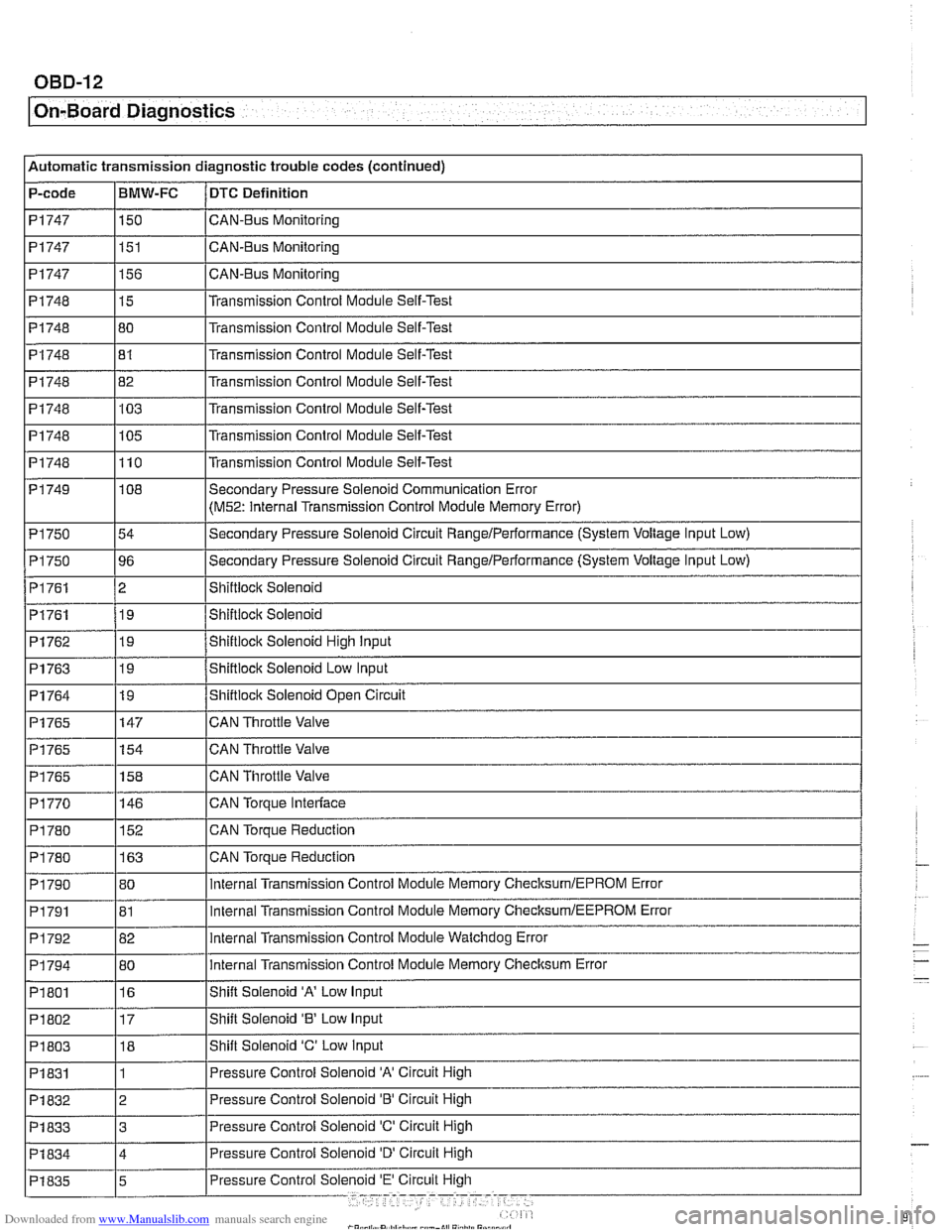

Automatic transmission diagnostic trouble codes (continued)

P-code

PI747

PI747

PI 747

PI748

PI748 I I

PI748

PI748

PI748

PI 748

PI 749

PI 750

P1750

PI761

PI761

BMW-FC

150

151

156

15

80

-- PI762

PI763

PI764

PI765

PI765

PI765

P1770

DTC Definition

CAN-BUS Monitoring

CAN-Bus Monitoring

CAN-Bus Monitoring

Transmission Control Module Self-Test

Transmission

Control Module Self-Test

PI748 182 l~ransmission Control Module Self-Test

81

103

105

110

I I

Transmission Control Module Self-Test

Transmission Control Module Self-Test

Transmission Control Module Self-Test

Transmission Control Module Self-Test

19

19

19

147

154

158

146

PI 790

PI791

P1792

PI 794

PI 801

P1802

PI 803

PI 831 Shiftiock Solenoid High input

Shiftlock Solenoid

Low Input

Shiftlock Solenoid Open Circuit

CAN Throttle Valve

CAN Throttle Valve

CAN Throttle Valve

CAN

Torpue Interlace

CAN Torque Reduction

PI 780

I I -

108

54

96

2 19

PI 780 1163 ICAN Torque Reduction

152

80

81

82

80

16

17 18

1 Secondary Pressure Solenoid Communication Error

(M52: Internal

Transmission Control Module Memory Error)

Secondary Pressure Solenoid Circuit

Rangelperformance (System Voltage Input Low)

Secondary Pressure Solenoid Circuit

RangeIPerformance (System Voltage Input Low)

Shiftioclc Solenoid

Shiftiocic Solenoid

internal Transmission Control Module Memory ChecksumlEPROM Error

internal Transmission Control Module Memory

ChecksumIEEPROM Error

internal Transmission Control Module Watchdog Error

internal Transmission Control Module Memory Checksum Error

Shift Solenoid

'A' Low Input

Shift Solenoid

'8' Low Input

Shift Solenoid

'C' Low input

Pressure Control Solenoid

'A' Circuit High

Pressure Control Solenoid 'B' Circuit High

PI832

PI833 13 IPressure Control Solenoid 'C' Circuit High

2