check engine BMW 528i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 60 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-28

1 Maintenance

- When replacing fuel filter:

Use appropriate hose clamping device to clamp off filter

inlet and outlet hoses to lessen fuel spillage.

Loosen center clamping bracket and hose clamps on

either end of filter.

Note arrow or markings indicating direction of flow on

new filter.

Install new filter using new hose clamps

- Drain fuel filter from inlet side into a container and inspect

drained fuel.

Checlc for rust, moisture and contamination.

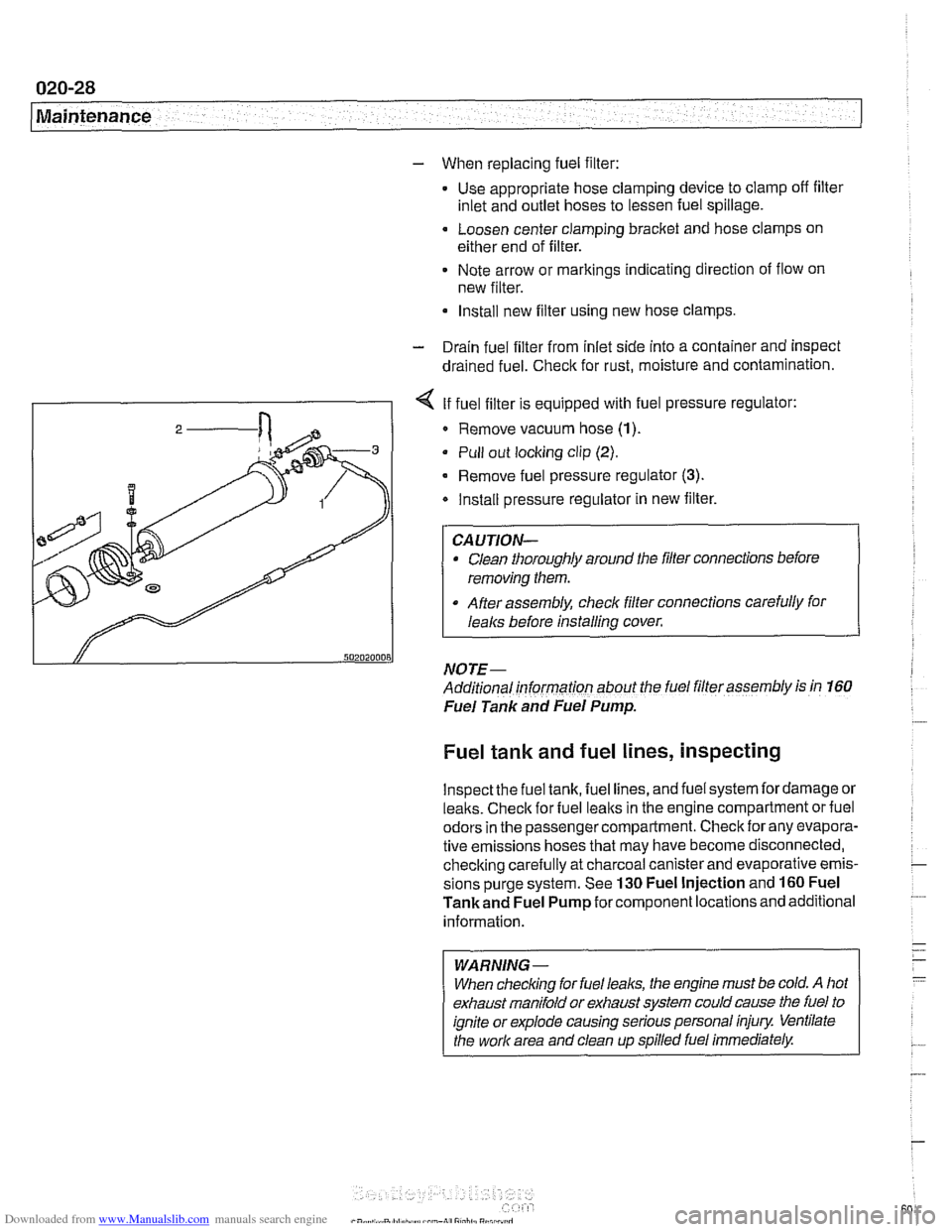

I - I < If fuel filter is equipped with fuel pressure regulator:

I 2 / Remove vacuum hose (1)

Pull out locking clip (2).

- Remove fuel pressure regulator (3).

Install pressure regulator in new filter.

Clean thoroughly around the filler connections before

removing them.

After assembly, check filter connections carefully for

I

I lealcs before installing cover.

NOTE- ~-

Additional informarion about the fuel filler assembly is in 160

Fuel Tank and Fuel Pump.

Fuel tank and fuel lines, inspecting

lnspectthe fuel tank, fuel lines, and fuel system fordamage or

lealts. Checlc for fuel lealts in the engine compartment or fuel

odors in the passenger compartment. Check for any evapora-

tive emissions hoses that may have become disconnected,

checking carefully at charcoal canister and evaporative emis-

sions purge system. See

130 Fuel Injection and 160 Fuel

Tankand Fuel Pump for component locations and additional

information.

WARNING-

When checlcing for fuel leal(s, the engine must be cold. A hot

exhaust manifold or exhaust system could cause the fuel to

ignite or explode causing serious personal injury Ventilate

the work area and clean up spilled fuel immediately.

Page 61 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Suspension, front, inspecting

Inspection of the front suspension and steering includes a

check of all moving parts

forwear and excessive play. Inspect

ball joint and tie-rod rubber seals and boots for cracks

ortears

that could allow the entry of dirt, water, and other

contaminants. See

310 Front Suspension.

Suspension, rear, inspecting

Differential and rear drive axle service consists of checking

and changing the gear oil, inspecting for leaks, and checking

the drive axle

CV joint boots for damage.

The areas where

lealts are most likely to occurare around the

drive shaft and drive axle mounting flanges. For more infor-

mation on identifying oil leaks and theircauses, see

330 Rear

Suspension and

331 Final Drive.

Tires, checking inflation pressure

Correct tire pressures are important to handling and stability,

fuel economy, and tire wear. Tire pressures change with tem-

perature. Pressures should be

checked oRen during season-

al temperature changes. Correct inflation pressures can be

found on the driver's door pillar and in the owner's manual.

Note that tire pressures should be higher when the car is

more heavily loaded.

WARNING-

Do not inflate any tire to a pressure higher than the tire's max-

imum inflation pressure listedon the sidewall. Use care when

adding air to warm tires. Warm tire pressures can increase as

much as

4 psi (0.3 bar) over their coldpressures.

Tires, rotating

BMW does not recommend tire rotation. Due to the car's sus-

pension design, the front tires begin to wear first at the outer

shoulder and the reartires begin to wearfirst at the middle of

the tread or inner shoulder. Rotating the tires may adversely

affect road handling and tire grip.

Transmission service, automatic

The automatic transmissions installed in E39 models are

filled with special automatic transmission fluid. The transmis-

sion lubricant type can be found on the "type-plate" on the

side of the transmission. The recommended lubricants are

listed earlier in this repair group. See Fluids and lubricants.

If in doubt, consult an authorized BMW dealer for alternate

Page 62 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-30

Maintenance

fluid use and the most-up-to-date information regarding

transmission operating fluids.

The automatic transmission is not equipped with a dipstick.

Therefore, checking the ATF level is an involved procedure

which includes measuring and maintaining a specified ATF

temperature during the checking procedure.

For more complete

ATF service information, including

checking

ATF level and ATF filter replacement procedures,

see

240 Automatic Transmission.

Transmission service, manual

Manual transmission service consists of inspecting for leaks

and checking the fluid. Evidence of transmission leaks is

like-

ly to be seen around the driveshaft mounting flange and at the

bottom of the bellhousing.

NOTE-

For more information on identifying oil

leaks and their

causes, see 230 Manual Transmission and210 Clutch.

Transmission fluid, checking and filling

(manual transmission)

Tne manual transmss'on inslalleo 'n rne E39 models s f;lled

with a special liierime iluid (ivlTF-LT-I). oi. ordinarily

does

not need to be changed.

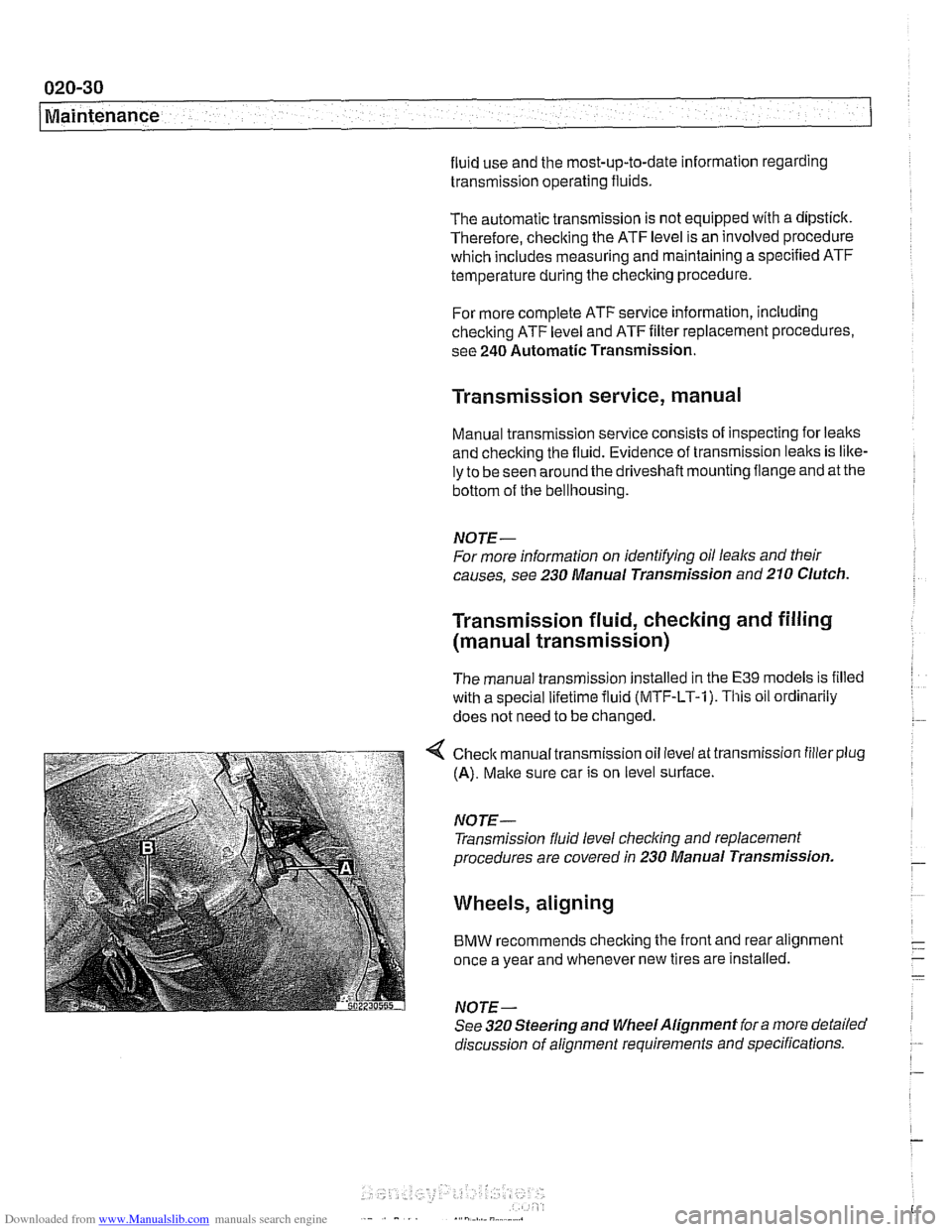

< Check manual transmission oil level at transmission filler plug

(A). Make sure car is on level surface.

NOTE- Transmission fluid level

checking and replacement

procedures are covered in 230 Manual Transmission.

Wheels, aligning

BMW recommends checking the front and rear alignment

once a year and whenever new tires are installed.

NOTE-

See 320 Steering and Wheel Alignment for a more detailed

discussion of alignment requirements and specifications.

Page 71 of 1002

Downloaded from www.Manualslib.com manuals search engine

Two common causes of driveability problems are incorrect

system voltage and bad grounds.

System voltage

Digital motor electronics (DME) requires that the system (bat-

tery) voltage be maintained within a narrow range of DC volt-

age.

DC voltage levels beyond or below the operating range,

or any

AIC voltage in the electrical system can cause havoc.

When troubleshooting an illuminated MIL, make sure the bat-

tery is fully charged and capable of delivering all its power to

the electrical system. An undercharged battery can amplify

AIC alternator output ripple.

To

make a quick check of the battery charge, measure the

voltage across the battery terminals with all cables attached

and the ignition off.

Afully charged battery will measure 12.6

volts or slightly more, compared to 12.1 5 volts for a battery

with a 25% charge.

The DME system operates at low voltage and current levels,

making it sensitive to small increases in resistance. The elec-

trical system is routinely subjected to corrosion, vibration and

wear, so faults or corrosion in the wiring harness and connec-

tors are not uncommon. Check the battery terminals

forcorro-

sion or loose cable connections. See 121 Battery, Starter,

Alternator for additional information.

If a battery cable connection has no

v~sible faults but is still

suspect, measure the voltage drop across the connection. A

large drop indicates excessive resistance, meaning that the

connection is corroded, dirty, or damaged. Clean or repairthe

connection and retest.

NOTE-

For instructions on conducting a voltage drop test and other

general electrical troubleshooting information, see

600 Elec-

trical System-General.

Visually inspect all wiring, connectors, switches and fuses in

the system. Loose or damaged connectors can cause inter-

mittent problems, especially the small terminals in the ECM

connectors. Disconnect the wiring harness connectors to

check for corrosion, and use electrical cleaning spray to re-

move contaminants.

Main grounds

Good grounds are critical to proper DME operation. If a

ground connection has no visible faults but is still suspect.

measure the voltage drop across the connection. A large volt-

age drop means high resistance. Clean or repair the connec-

tion and retest.

LBuntr.yP~sbhnllcn.can#-AII A,~iltl Rcsrwsd

Page 75 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-3

Engine Removal and lnstallationl

Q Fuel line plugs

(Tool No.

BMW 13 5 281 / 13 5 282)

4 Fuel line removal tool

(Tool No.

BMW 16 1 050)

CAUTION-

Disconnecting the battery may erase fault code@) storedin

memoiy Check for fault codes prior to disconnecting the

battery cables.

If the MIL (Malfunction Indicator Light, also may be

called "Check Engine" or "Service Engine Soon" light)

is illuminated, see

OBD On-Board Diagnostics for

DME fault code information.

It orhersysrem faults have been detected, as indicated I

by an ~llum~nated ABS, SRS orASC/DSC ~arning light,

see the appropriate repair group in this manual or an

authorized BMW dealer for more information on fault

codes.

NOTE- Engine removal procedures are similar for all 6-cylinder

models. When differences

exist, they are noted at the be-

ginning of each step. Engine are referred to by engine

code. See

100 Engine-General for engine code and appli-

cation information.

@ Be sure to cover all painted surfaces before beginning the

removal procedure. As an aid to installation, label all com-

ponents, wires and hoses before removing them. Do not

reuse

gaskets, O-rings or seals during reassembly.

The

intake manifold must be removed on &cylinder mod-

els before the engine can be removed.

WARNING-

Due to risk of personal injury, be sure the engine is cold be-

fore beginning the removal procedure.

Page 82 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

-6val and Installation -

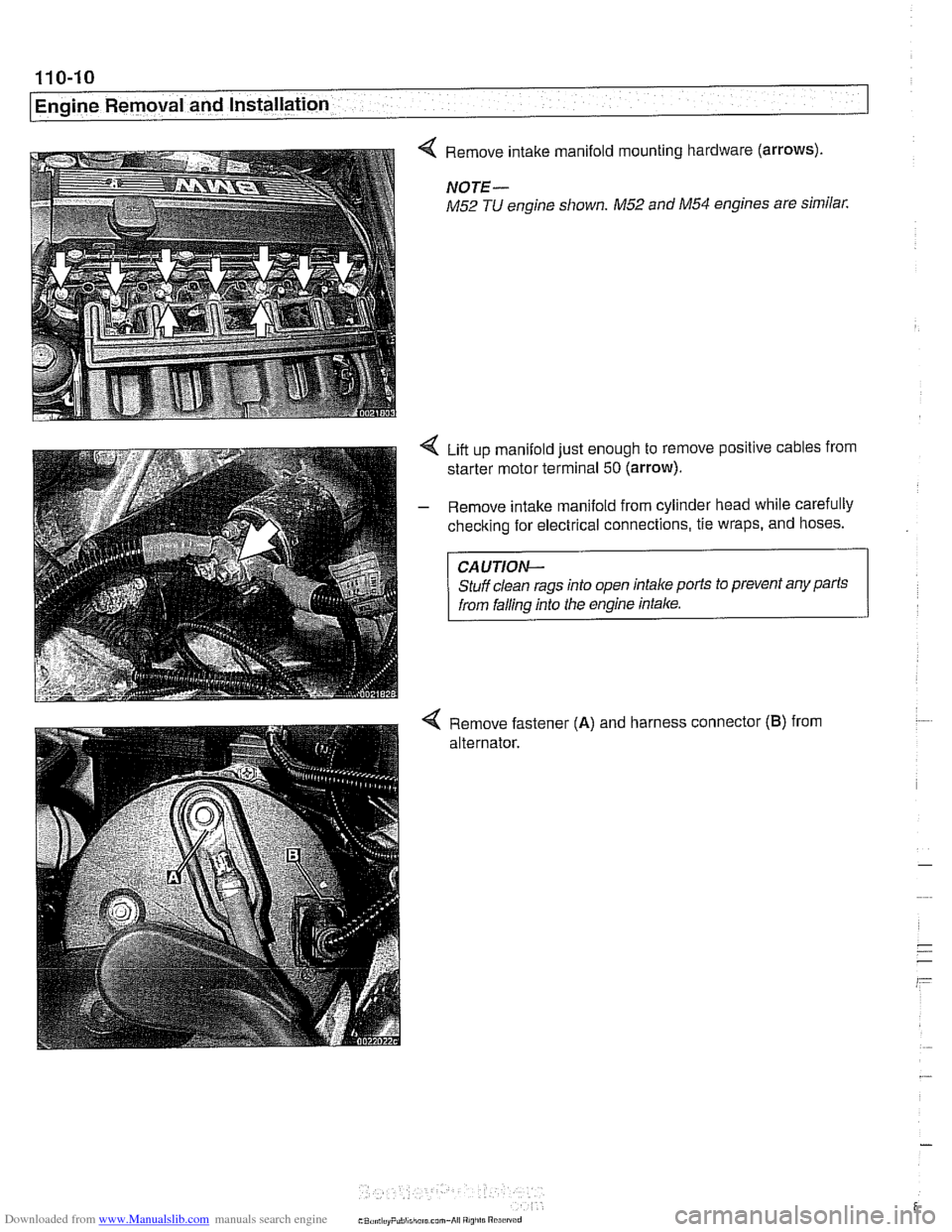

< Remove intake manifold mounting hardware (arrows).

NOTE-

M52 TU engine shown. M52 and M54 engines are similar.

Liit up manifold just enough to remove positive cables from

starter motor terminal

50 (arrow).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections, tie wraps, and hoses.

CAUTION-

Stuff clean rags into open intake ports to prevent any parts

from falling into the engine intake.

4 Remove fastener (A) and harness connector (B) from

alternator.

Page 86 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-14

I Engine Removal and Installation

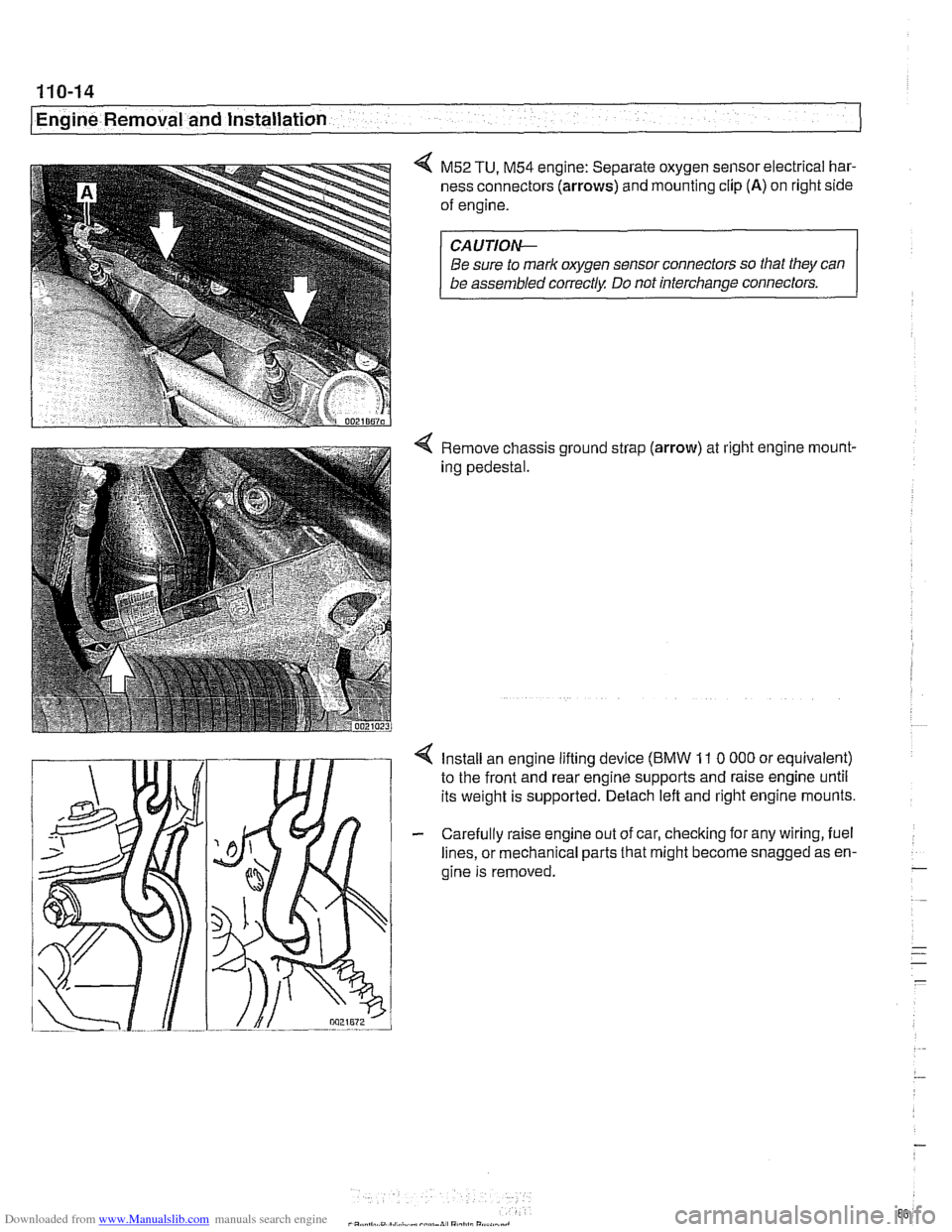

4 M52 TU, M54 engine: Separate oxygen sensor electrical har-

ness connectors

(arrows) and mounting clip (A) on right side

of engine.

CA UTIOW

Be sure to mark oxygen sensor connectors so that they can

be assembled correctly Do not interchange connectors.

4 Remove chassis ground strap (arrow) at right engine rnount-

ing pedestal.

4 Install an engine lifting device (BMW 11 0 000 or equivalent)

to the front and rear engine supports and raise engine until

its weight is supported. Detach left and right engine mounts.

- Carefully raise engine out of car, checking for any wiring, fuel

lines, or mechanical parts that might become snagged as en-

gine is removed.

-

. ..

- .- -

-

Page 87 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-15

Engine Removal and lnstallation

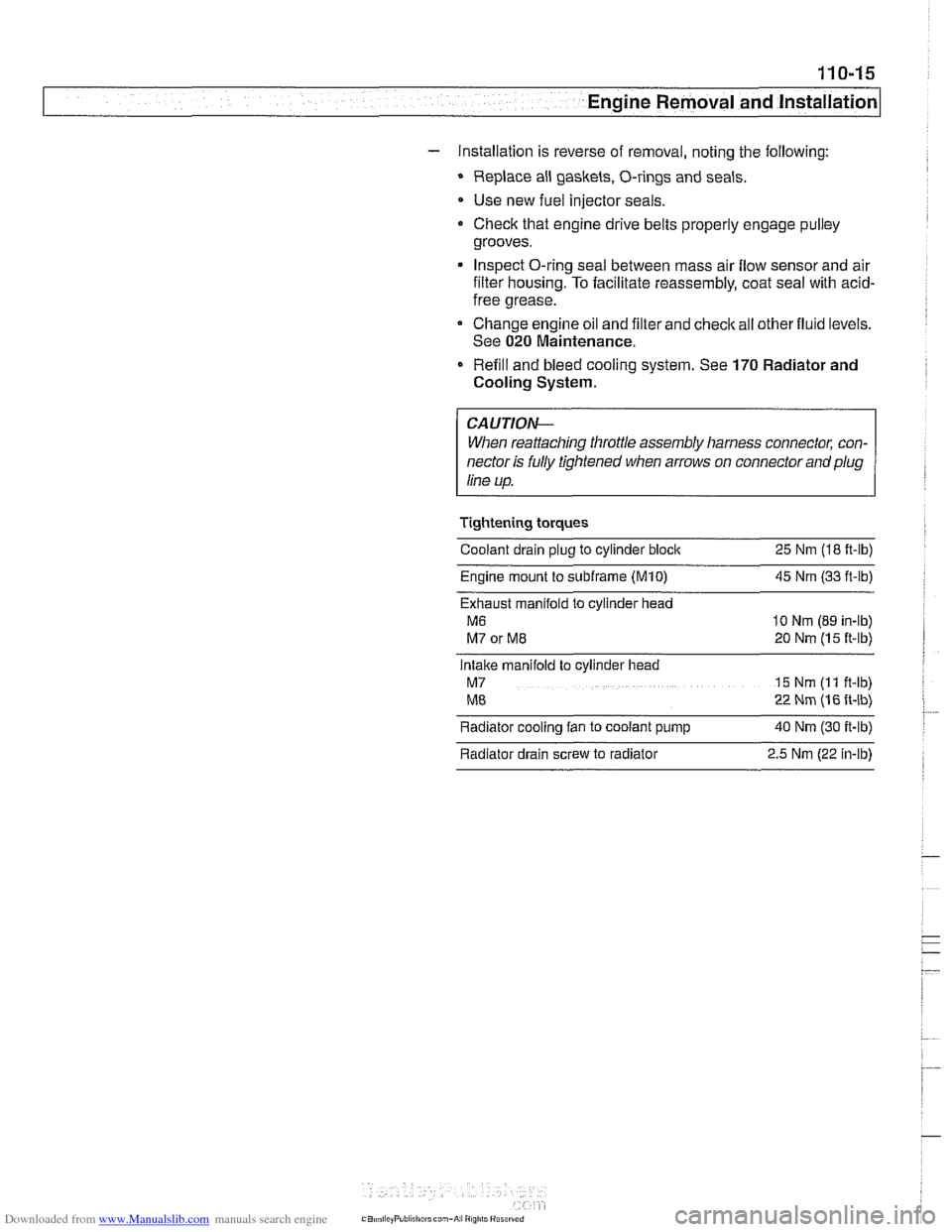

- Installation is reverse of removal, noting the following:

Replace all gaskets. O-rings and seals.

Use new fuel injector seals

Check that engine drive belts properly engage pulley

grooves.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with acid-

free grease.

Change engine oil and filter and

check all other fluid levels.

See

020 Maintenance.

Refill and bleed cooling system. See

170 Radiator and

Cooling System.

CAUTION--

When reattaching throttle assembly harness connectoc con-

nector is

fuNy tightened when arrows on connector and plug

line up.

Tightening torques

Coolant drain plug to cylinder block

25 Nm (18 ft-lb)

Engine mount to

subframe (M10) 45 Nm (33 ft-ib)

Exhaust manifold to cylinder head

M6 10 Nm (89 in-lb)

M7 or ME 20 Nm (15 ft-lb)

Intake manifold to cylinder head

M7 15 Nm (I 1 ft-lb)

ME 22 Nm (16 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb)

Radiator drain screw to radiator

2.5 Nm (22 in-lb)

Page 93 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

-- Engine Removal and installation' -

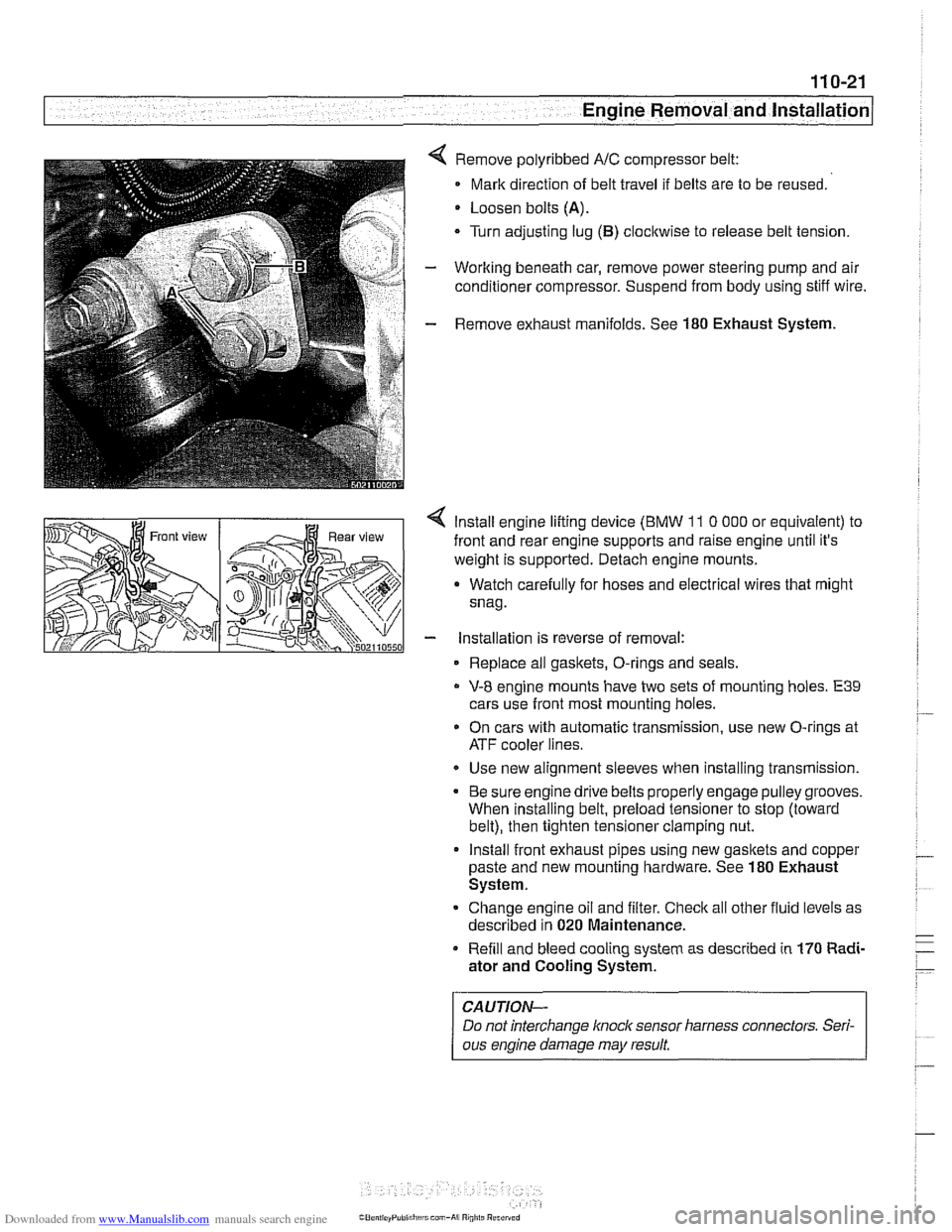

Remove polyribbed A/C compressor belt:

Mark direction of belt travel if belts are to be reused.

Loosen bolts

(A).

Turn adjusting lug (B) clocltwise to release belt tension.

Working beneath car, remove power steering pump and air

conditioner compressor. Suspend from body using stiff wire.

Remove exhaust manifolds. See

180 Exhaust System.

< lnstall engine lifting device (BMW 11 0 000 or equivalent) to

front and rear engine supports and raise engine until it's

weight is supported. Detach engine mounts.

a Watch carefully for hoses and electrical wires that might

snag.

- installation is reverse of removal:

Replace all gaskets, O-rings and seals.

V-8 engine mounts have two sets of mounting holes. E39

cars use front most mounting holes.

* On cars with automatic transmission, use new O-rings at

ATF cooler lines.

Use new alignment sleeves when installing transmission.

Be sure engine drive belts properly engage pulley grooves.

When installing belt, preload tensioner to stop (toward

belt), then tighten tensioner clamping nut.

lnstall front exhaust pipes using new gasltets and copper

paste and new mounting hardware. See

180 Exhaust

System.

Change engine oil and filter. Check all other fluid levels as

described in

020 Maintenance.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

CAUTION-

Do not interchange knoclc sensor harness connectors. Seri-

ous engine damage may result

Page 95 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-1

11 3 Cylinder Head

Removal and Installation

General ........................... .I 13-2

Special tools ........................ .I 13-2

Diagnostic Testing. ................ .I1 3-5

Cylinder compression, checking ......... ,113-5

Wet compression test ................. .I1 3-7

Cylinder leak-down test. ................ 11 3-8

Cylinder Head Removal and Installation

(M52 Engine) ...................... .I1 3-8

Cylinder head, removing, M52 engine .... ,113-8

Cylinder head, installing, M52 engine ... ,113-17

Cylinder Head Removal and Installation

(M52 TU and M54 Engines). ........ ,113-22

Cylinder head, removing, M52 TU

and

M54 engines. ................... .I1 3-22

Cylinder head, installing, M52 TU

and

M54 engine. .................... .I1 3-39

Double VANOS Timing

Chain Components

................ 11 3-46

Double VANOS timing chain components,

installing,

M52 TU and M54 engines ..... 113-46

Cylinder Head Removal and Installation

(M62 Engine). ..................... 11 3-56

Intake manifold, removal and installation,

M62 engine. ........................ 11 3-66

Left cylinder head, removing,

M62 engine. ........................ 11 3-61

Left cylinder head, installing,

M62 engine. ........................ 11 3-66

Right cylinder head, removing,

M62 engine ........................ 11 3-72

Right cylinder head, installing,

M62 engine ........................ 11 3-77