fault code BMW 530i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 530i, Model: BMW 530i 2001 E39Pages: 1002

Page 8 of 1002

Downloaded from www.Manualslib.com manuals search engine

I General Warnings and Cautions

WARNINGS (continued)

. The air conditioning system is filled with chemical refrigerant,

which is hazardous. The AIC system should be serviced only by

trained technicians using approved refrigerant recoverylrecycling

equipment, trained in related safety precautions, and familiar with

regulations governing the discharging and disposal of automotive

chemical refrigerants.

. Do not expose any part of the AIC system to high temperatures

such as open flame. Excessive heat will increase system pres-

sure and may cause the system to burst.

Some aerosol tire inflators are highly flammable. Be extremely

cautious when repairing a tire that may have been inflated using

an aerosol tire inflator. Keep sparks, open flame or other sources

of ignition away

from the tire repair area. Inflate and deflate the

tire at least four

times before breaking the bead from the rim.

Completely remove the tire from the rim before attempting any re-

pair.

Cars covered by this manual are equipped with a supplemental

restraint system (SRS), that automatically deploys

airbags and

pyrotechnic seat belt tensioners

In the event oi a frontal or side

impact. These are explosive devices. Handled improperly or with-

out adequate safeguards, they can be accidently activated and

cause serious injury.

- The ignition system produces high voltages that can be fatal.

Avoid contact with exposed terminals and use extreme care when

working on a car with the engine running or the ignition switched

on.

. Place jack stands only at locations specified by the manufacturer.

The vehicle

illtino iack su~olied with the vehicle is intended fortire -. , . changes only. A heavy duty floor jack should be used lo lift vehicle

before installing

jacl( stands. See 010 General.

- Battery acid (electrolyte) can cause severe burns. Flush contact

area

with water, seek medical attention.

Aerosol cleaners and solvents may contain hazardous or deadly

vapors and are highly flammable. Use only in a well ventilated ar-

ea. Do not use on hot surfaces (engines, brakes, etc.).

Do not remove

coolant reservoir or radiator cap with the engine

hot. Danger of burns and engine damage.

CAUTIONS-

See also WARNINGS

- if you lack the slqills, tools and equipment, or a suitable worl(shop

for any procedure described in this manual, leave such repairs to

an authorized BMW dealer or other qualified shop.

BMW is constantly improving its cars and sometimes these

changes, both in parts and specifications, are made applicable to

earlier models. Therefore, part numbers listed in this manual are

for reference only. Always check with your authorized BMW deal-

er parts department for the latest information.

Before starting a job, make certain that you have all the neces-

sary tools and parts on hand. Read ail the instructions thorough-

ly, and do not attempt shortcuts. Use tools appropriate to the

work and use only replacement parts meeting BMW specifica-

tions.

Use pneumatic and electric tools only to loosen threaded parts

and fasteners. Never use these tools to tighten fasteners, espe-

cially on light alloy parts. Always use a torque wrench to tighten

fasteners to the tightening torque specification listed.

Be mindful of the environment and ecology. Before you drain the

crankcase, find out the proper way to dispose of the

oil. Do not

pour

oil onto the ground, down a drain, or into a stream, pond or

lake. Dispose of waste in accordance with Federal, State and

Local laws.

The control module for the anti-lock brake system

(ABS) cannot

withstand temperatures from a paint-drying booth or a heat

lamp

in excess of 203" F (95°C) and should not be subjected to tem-

peratures in excess of 185°F

(8S°C) for more than two hours.

- Before doing any electrical welding on cars equipped with ABS,

disconnect the battery negative

(-) terminal (ground strap) and

the ABS control module connector.

- Always make sure ignition is off before disconnecting battery.

Label battery cables before disconnecting. On some models, bat-

tery cables are not color coded.

Disconnecting the battery may erase fault code@) stored in control

module memory. Using special BMW diagnoslic equipment, check

lor

iauit codes prior to disconnecting the battery cables. If the mal-

I.mct on ndicator Ignt (MIL) s I. ..minaled. see OBD On-Board

Diaanostics

Tl11s iant is iuenlfted as lne Check Ena~ne oht

(1997-2000 models jor~ervlce Engine Soon light (2061 andlater

models). If any other system iaults have been detected (indicated

by an illuminated warning light), see an authorized BMW dealer.

If a normal

or rapid charger is used to charge battery, the battery

must be disconnected and removed from the vehicle in order to

avoid damaging the vehicle.

- Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

* Connect and disconnect a battery charger only with the battery

charger switched off.

- Sealed or "maintenance free" batteries should be slow-charged

only, at an amperage rate that is approximately 10% of the bat-

tery's ampere-hour (Ah)

rating.

. Do not allow battery charging voltage to exceed 16.5 volts. If the

battery begins producing gas or boiling violently, reduce the

charging rate.

Boosting a sulfated battery at a high charging rate

can cause an explosion.

Page 39 of 1002

Downloaded from www.Manualslib.com manuals search engine

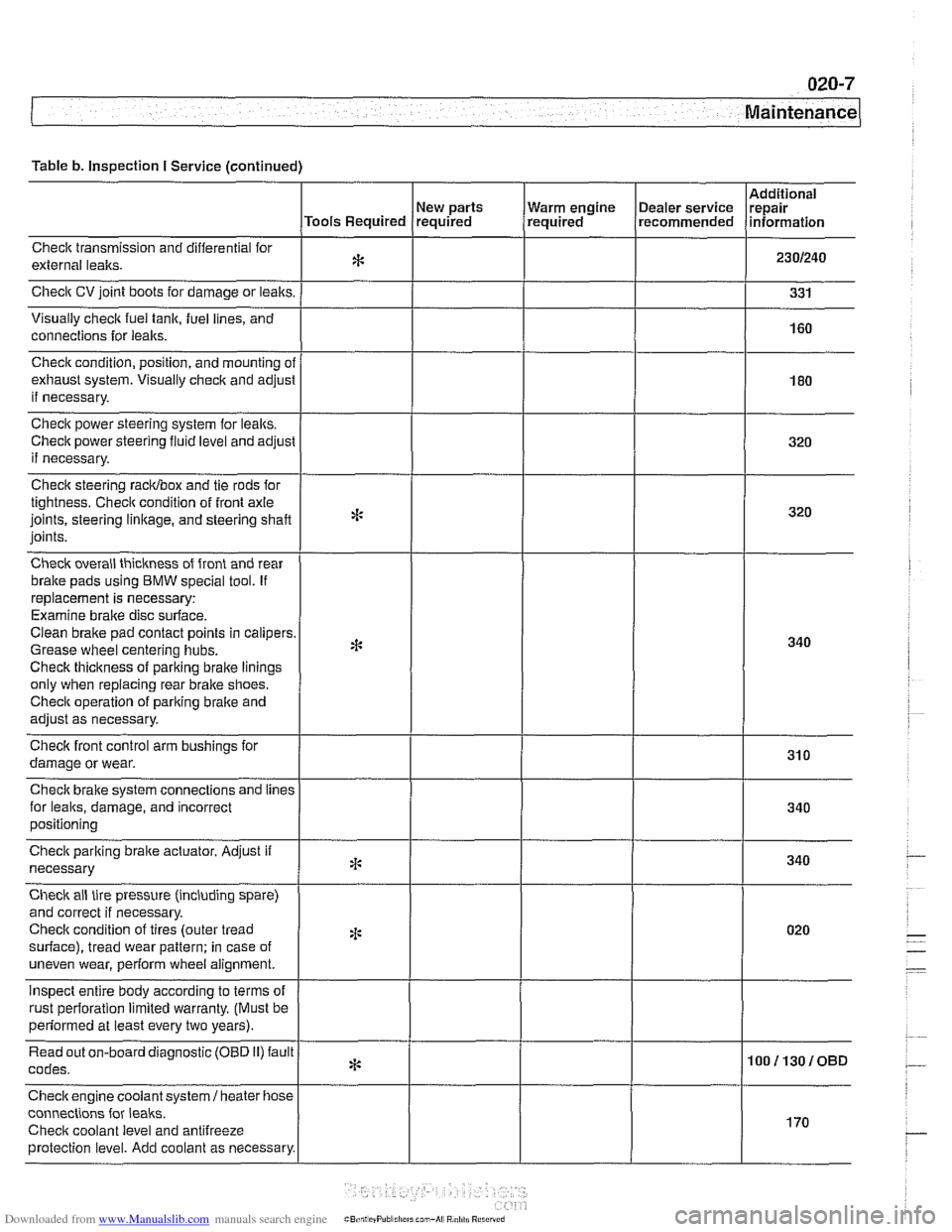

Table b. Inspection I Service (continued)

Checlt transmission and differential for

external lealts.

Check CV joint boots for damage or leaks.

Visually

check fuel tank, fuel lines, and

connections for

leaks.

New parts

Tools Required required

Check condition, position, and mounting

ol

exhaust system. Visually check and adjusl

if necessary.

Check power steering system for lealts.

Check power steering

fluid level and adjust

if necessary.

Check steering racidbox and tie rods for

tightness. Checit condition of front axle

joints, steering

linkage, and steering shaft

joints.

Check overall thickness of front and rear

bralte pads using

BMW special tool. If

replacement is necessary:

Examine brake disc surface.

Clean brake pad contact points in calipers

Grease wheel centering hubs.

Checlt thickness of parking brake linings

only when replacing rear brake shoes.

Checit operation of pariting brake and

adjust as necessary.

Checlt front control arm bushings for

damage or wear.

Check brake system connections and

lines

for leaks, damage, and incorrect

positioning Warm

engine

(~ealer service Irepair , required recommended lnformat~on

Check parking braite actuator. Adjust if

necessary

Check ail tire pressure (including spare)

and correct if necessary.

Checlt condition of tires (outer tread

surface), tread wear pattern: in case of

uneven wear, perform wheel alignment.

inspect entire body according to terms of

rust oerforation limited warrantv. (Must be

*:

4:

2 ~ perfdrmed at least every two years). I

Read out on-board diagnostic (OBD 11) fault

codes.

Checkengine coolant

system1 heater hose

connections for

leaks.

Checit coolant level and antifreeze

protection level. Add coolant as necessary.

* 100113010BD

I

170

Page 59 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-. -

Maintenance

Drive axle joint

(CV joint) boots, inspecting

CVjoint protective boots must be closely inspected forcracks

and any other damage that will allow contaminants to get into

the joint.

If the rubber boots fail, the water and dirt that enter

the joint will quickly damage it.

NOTE-

Replacement of the CVjoint boots and inspection of the

joints are described

in 331 Final Drive.

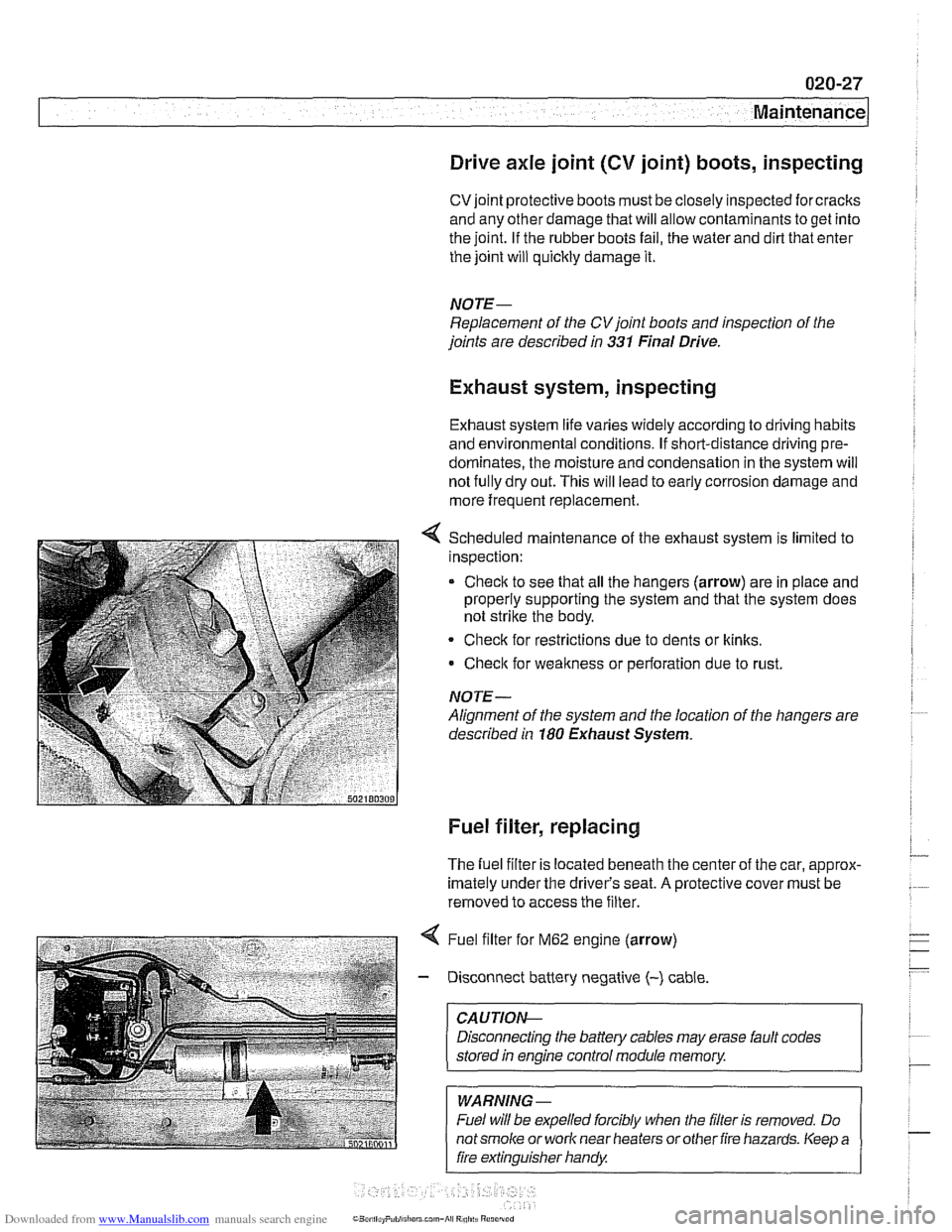

Exhaust system, inspecting

Exhaust system life varies widely according to driving habits

and environmental conditions. If short-distance driving pre-

dominates, the moisture and condensation in the system will

not fully dry out. This will lead to early corrosion damage and

more frequent replacement.

Scheduled maintenance of the exhaust system is limited to

inspection:

* Check to see that all the hangers (arrow) are in place and

properly supporting the system and that the system does

not strike the body.

Check for restrictions due to dents or

kinlts,

Check for weakness or perforation due to rust.

NOTE-

Alignment of the system and the location of the hangers are

described in

180 Exhaust System.

Fuel filter, replacing

The fuel filter is located beneath the center of the car, approx-

imately under the driver's seat.

A protective cover must be

removed to access the filter.

4 Fuel filter for M62 engine (arrow)

- Disconnect battery negative (-) cable

CAUTIOI\C

Disconnecting the battery cables may erase fault codes

stored

in engine control module memory.

WARNING -

Fuel will be expelled forcibly when the filter is removed. Do

notsmoke or work near heaters orother fire hazards. Keep a

fire extinguisher handy

Page 75 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-3

Engine Removal and lnstallationl

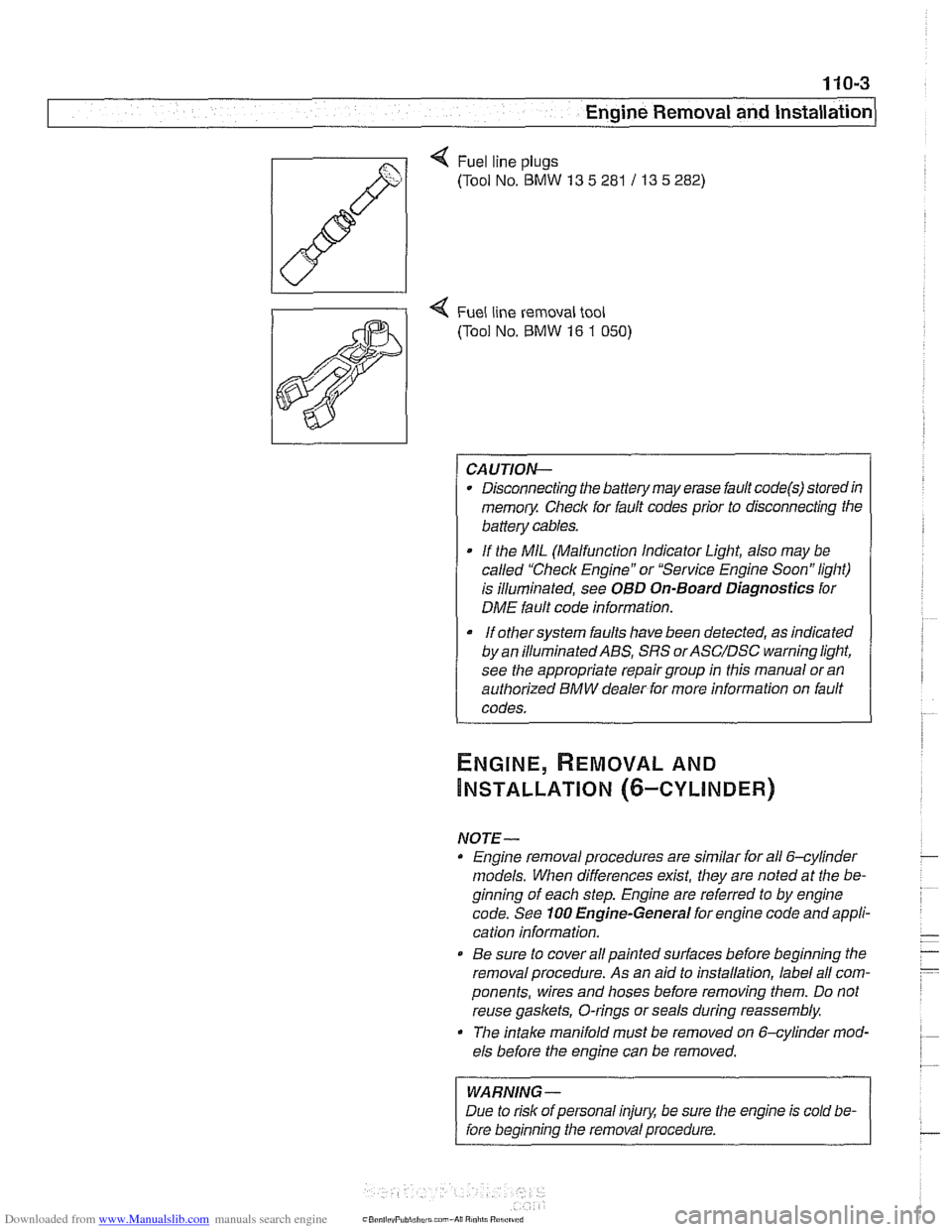

Q Fuel line plugs

(Tool No.

BMW 13 5 281 / 13 5 282)

4 Fuel line removal tool

(Tool No.

BMW 16 1 050)

CAUTION-

Disconnecting the battery may erase fault code@) storedin

memoiy Check for fault codes prior to disconnecting the

battery cables.

If the MIL (Malfunction Indicator Light, also may be

called "Check Engine" or "Service Engine Soon" light)

is illuminated, see

OBD On-Board Diagnostics for

DME fault code information.

It orhersysrem faults have been detected, as indicated I

by an ~llum~nated ABS, SRS orASC/DSC ~arning light,

see the appropriate repair group in this manual or an

authorized BMW dealer for more information on fault

codes.

NOTE- Engine removal procedures are similar for all 6-cylinder

models. When differences

exist, they are noted at the be-

ginning of each step. Engine are referred to by engine

code. See

100 Engine-General for engine code and appli-

cation information.

@ Be sure to cover all painted surfaces before beginning the

removal procedure. As an aid to installation, label all com-

ponents, wires and hoses before removing them. Do not

reuse

gaskets, O-rings or seals during reassembly.

The

intake manifold must be removed on &cylinder mod-

els before the engine can be removed.

WARNING-

Due to risk of personal injury, be sure the engine is cold be-

fore beginning the removal procedure.

Page 96 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-2

Cylinder Head Removal and Installation

This group covers cylinder head removal and installation as

well as cylinder

headlvalve diagnostic procedures.

In the procedures in this repair group, engines are referred to

by engine code. If necessary, see

100 Engine-General for

engine code and application information.

The information given in this repair group assumes that the

engine is installed in the engine bay. On the

6-cylinder en-

gines, the VANOS control unit must be removed in orderto re-

move the cylinder head from the engine block. On

M52TU

and M54 engines, camshafts must be removed from the cylin-

der head before the head is removed.

The cylinder head removal and installation procedures for the

M62 V-8 are also included, butthe proceduresforthe M62TU

V-8 with VANOS are not provided.

For cylinder head and valvetrain reconditioning information,

see

116 Cylinder Head and Valvetrain.

For specific repair procedures, refer to the appropriate repair

group:

020 Maintenance

116 Cylinder Head and Valvetrain

117 Camshaft Timing Chain

170 Radiator and Cooling System

610 Component locations

NOTE-

If a head gasket problem is suspected, a compression test or

leak-down test will usually detect the fault See Diagnostic

Testing later

in this group.

Special tools

Special BMW service tools are required to properly remove

and install the cylinder head on engines covered by this man-

ual. The special tools are used to time the valvetrain to the

crankshaft, and to remove the VANOS control unit, the cam-

shafts and the

Tom (El2) head bolts. Read the entire proce-

dure through before beginning the job.

Page 183 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and valvetrain1

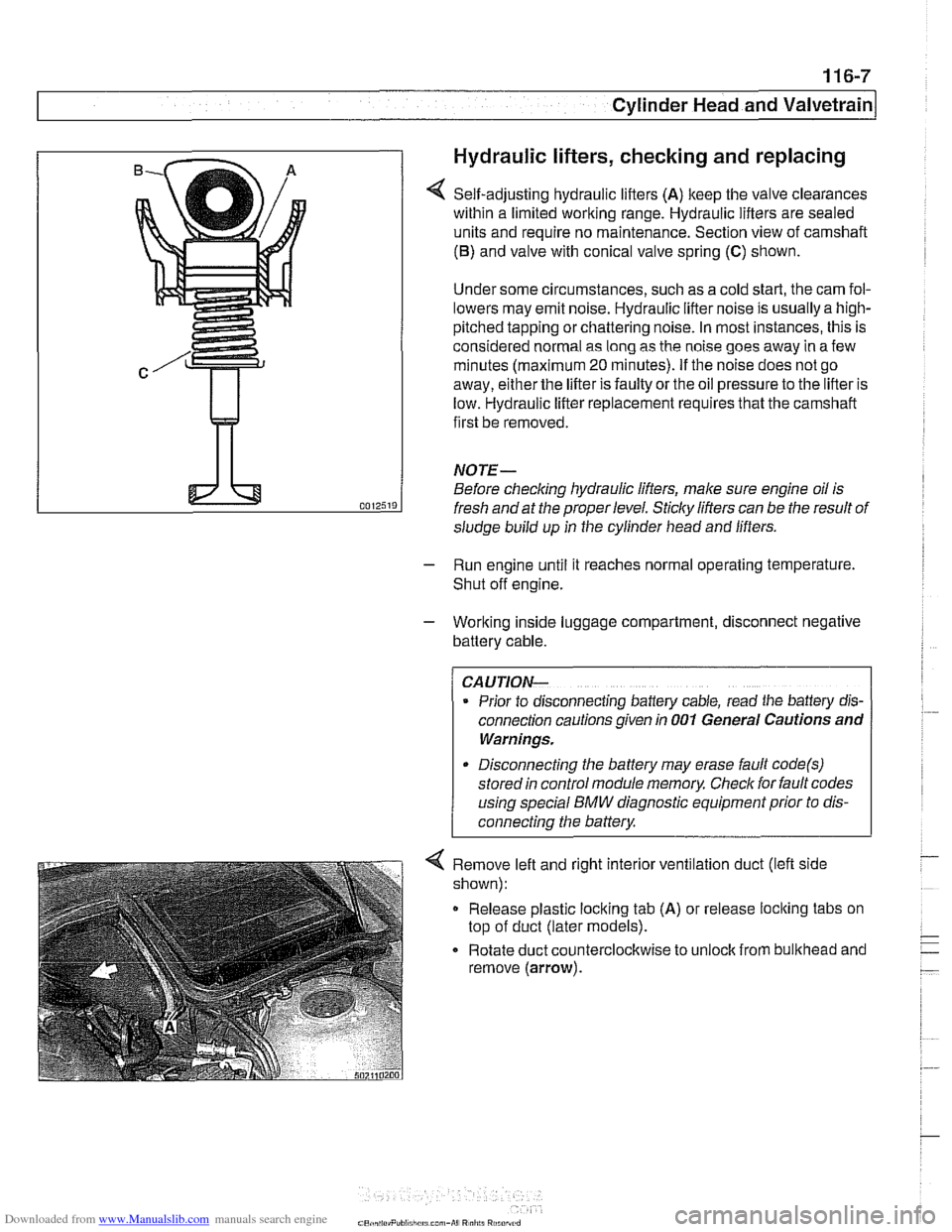

Hydraulic lifters, checking and replacing

Self-adjusting hydraulic lifters (A) keep the valve clearances

within a limited working range. Hydraulic lifters are sealed

units and require no maintenance. Section view of camshaft

(6) and valve with conical valve spring (C) shown.

Under some circumstances, such as a cold start, the cam fol-

lowers may emit noise. Hydraulic lifter noise is usually a

high-

pitched tapping or chattering noise. In most instances, this is

considered normal as long as the noise goes away in a few

minutes (maximum

20 minutes). If the noise does not go

away, either the lifter is faulty or the oil pressure to the lifter is

low. Hydraulic lifter replacement requires that the camshaft

first be removed.

NOTE-

Before checking hydraulic lifters, male sure engine oil is

fresh and at the proper level.

Sticky lifters can be the result of

sludge build up in the cylinder head and lifters.

- Run engine until it reaches normal operating temperature.

Shut off engine.

- Working inside luggage compartment, disconnect negative

battery cable.

CAUTION-

Prior to disconnecting battery cable, read the baltery dls-

connection cautions given In 001 General Cautions and

Warnings.

Disconnecting the battery may erase fault

code(s)

stored in control module memory Check for fault codes

4 Remove left and right interior ventilation duct (left side

shown):

Release plastic locking tab

(A) or release loclting tabs on

top of duct (later models).

Rotate duct counterclockwise to

unloclt from bulithead and

remove (arrow).

Page 238 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-2

Camshaft Timing Chain

This repair group covers timing chain and VANOS repair

information for the following engines:

M52 (Single VANOS 6-cylinder engine)

M52

TU and M54 (Double VANOS engines)

M62 (Non VANOS

V-8 engine)

NOTE-

The M62 TU V-8 engine with VANOS Variable Camshaft

Timing repair information is not included.

NOTE-

See 100 Engine General for engine code and application

information.

Worn timing chains and sprocltets can lead to noisy operation

and erratic valve timing. Afaulty tensionercan also cause tim-

ing chain noises.

For specific repair procedures, refer to the appropriate repair

group:

020 Maintenance

113 Cylinder Head Removal and Installation

119 Lubrication System

121 Ignition System

170 Radiator and Cooling System

Special tools

Special BMW service tools are needed to perform the service

and repairs procedures covered in this repair group. Many of

these tools are expensive and only available through an au-

thorized BMW dealer. Be sure to read each procedure thor-

oughly before starting a job to determine which special tools

will be necessary.

In addition, Double VANOS system diagnosis can only be

carried out by using BMW specific electronic scan tools, such

as BMW

DISplus, MoDiC or equivalent.

4 Torque wrench wl flex extension

(Tool No. BMW 00

9 250)

Page 242 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

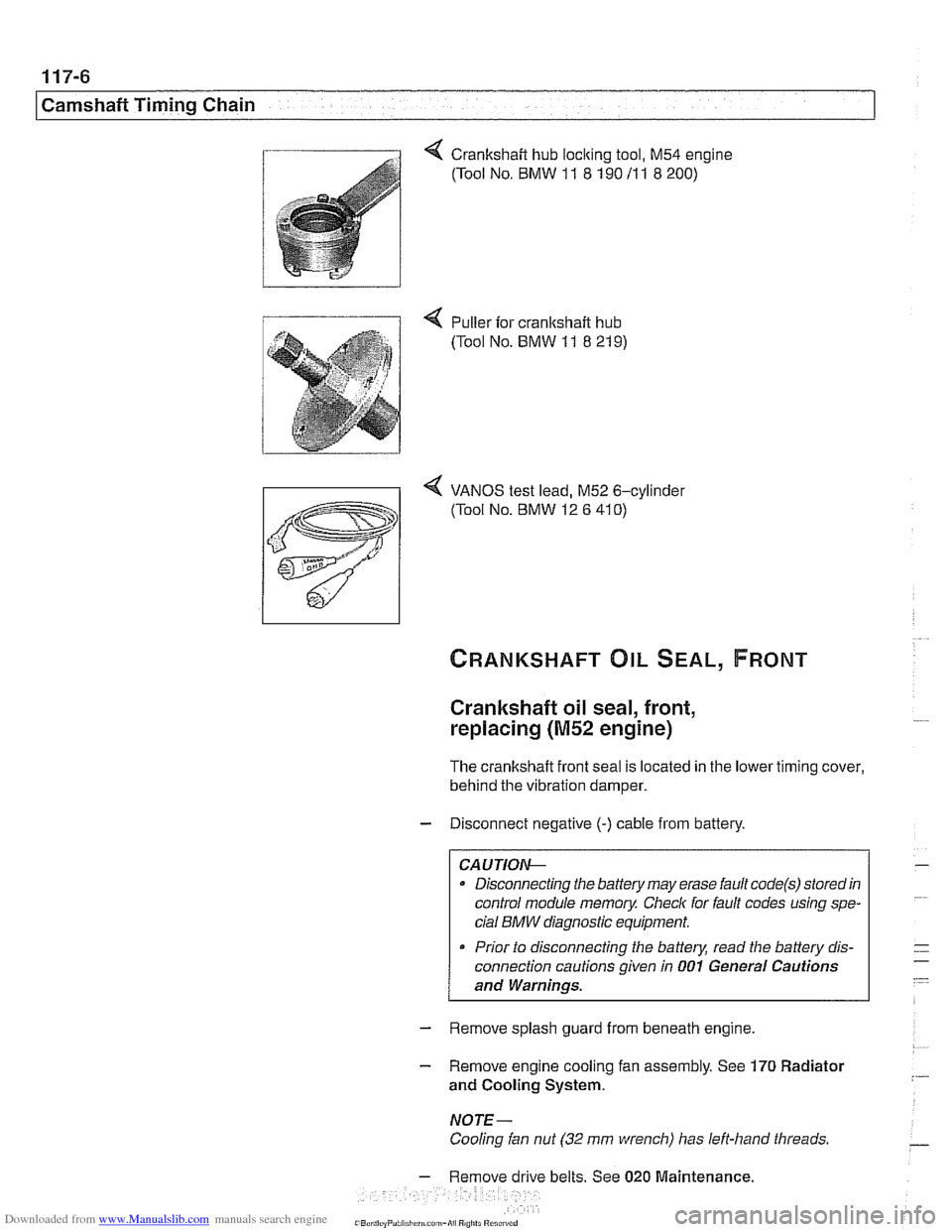

4 Crankshaft hub loclting tool. M54 engine

(Tool No.

BMW 11 8 190 11 1 8 200)

4 VANOS test lead, M52 6-cylinder

(Tool No.

BMW 12 6 410)

Crankshaft oil seal, front,

replacing

(M52 engine)

The crankshaft front seal is located in the lower timing cover,

behind the vibration damper.

- Disconnect negative (-) cable from battery.

CAUTIOIG

a Disconnecting the battery may erase fault code(s) stored in

control module memory Check

for fault codes using spe-

cial

BMW diagnostic equipment.

Prior to disconnecting the battery, read

the battery dis-

connection cautions given in

001 General Cautions

and

Warninqs.

- Remove splash guard from beneath engine.

- Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

NOTE-

Cooling ian nut (32 mm wrench) has left-hand threads.

- Remove drive belts. See 020 Maintenance.

,~R,~",,,~"P,,,,!,.,,,.,"?,,m-A,, P,",,,s

Page 245 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

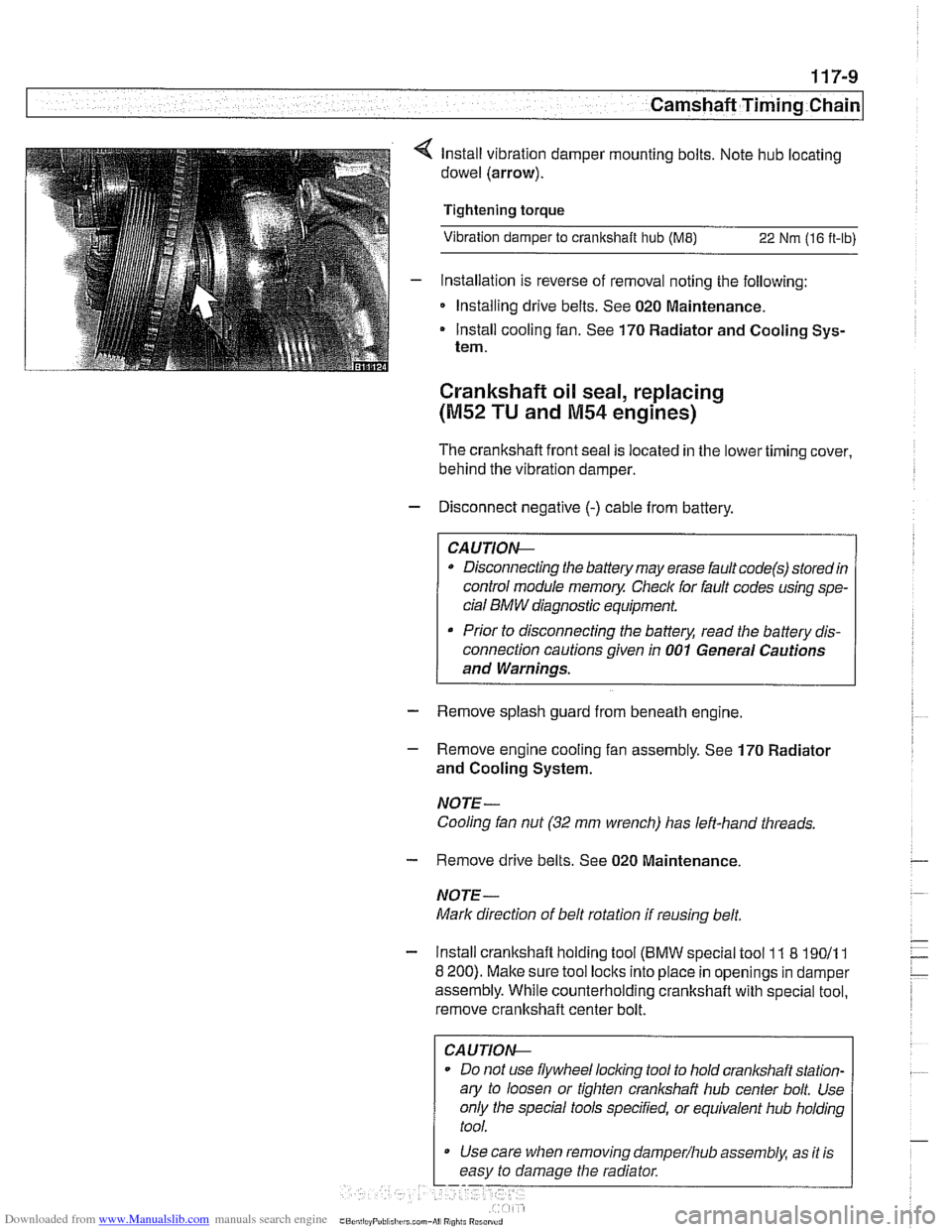

lnstall vibration damper mounting bolts. Note hub locating

dowel (arrow).

Tightening torque

Vibration damper to crankshaft hub

(ME) 22 Nm (16 ft-lb)

- Installation is reverse of removal noting the following:

Installing drive belts. See 020 Maintenance.

Install cooling fan. See 170 Radiator and Cooling Sys-

tem.

Crankshaft oil seal, replacing

(M52 TU and M54 engines)

The crankshafl front seal IS located in the lower timing cover,

behind the

vibrat~on damper.

- Disconnect negative (-) cable from battery.

Disconnecting the battery may erase fault

code(s) storedin

control module memoy Checlc for fault codes using spe-

cial

BMW diagnostic equipment.

Prior to disconnecting the battery, read the battery dis-

connection cautions given in

001 General Cautions

and Warnings.

- Remove splash guard from beneath engine

- Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

NOTE- Cooling fan nut

(32 mm wrench) has left-hand threads.

- Remove drive belts. See 020 Maintenance

NOTE-

Mark direction of belt rotation if reusing belt.

- Install crankshaft holding tool (BMW special tool 11 8 19011 1

8 200). Make sure tool locks into place in openings in damper

assembly. While counterholding crankshafl with special tool,

remove crankshaft center bolt.

CAUTIOI\C

Do not use flywheel locling tool to hold crankshaft station-

ary to loosen or tighten

cranl(shaft hub center bolt. Use

only the special tools specified, or equivalent hub holding

tool.

Use care when removing

damper/hub assembly, as ~t is

easy to damage the radiator

Page 247 of 1002

![BMW 530i 2001 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center BMW 530i 2001 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center](/img/1/2822/w960_2822-246.png)

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Coat new seal with oil and position in timing chain cover. Use

BMW special tool 11

3 280 and crankshaft center bolt to draw

seal in flush with timing case cover.

- Align vibration damper assembly with keyway and tap into

place. Insert new center bolt with washer.

CA

UTIOG

Inspect woodruff key for damage before installing hub

assembly.

- Install crankshaft holding tool malting sure tool locks into

place in openings in damper assembly. While counterholding

cranltshaft, tighten crankshaft center bolt.

- Attach special tools 11 8 20011 1 8 190 to damper assembly.

Counterhold damper with 11 8 190 while tightening center

bolt.

Tightening

torque

Vibration damper hub to crankshaft 410 Nm (302 it-ib)

- Installation is reverse of removal noting the following:

Install drive belts. See 020 Maintenance.

Install cooling fan. See 170 Radiator and Cooling Sys-

tem.

Crankshaft oil seal, replacing

(M62 and M62 TU engines)

- Disconnect negative (-) cable from battery

CAUTIOG

Disconnecting the battery may erase fault code(s) storedin

control module memory. Check for fault codes using spe-

cial BMW diagnostic equipment.

* Prior to disconnecting the battery, read the battery dis-

connection cautions in

001 General cautions and

warnings.

- Remove splash guard from beneath engine

- Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

NOTE

-

Cooling fan nut (32 mm wrench) has left-hand threads.

- Remove drive belts. See 020 Maintenance.

NOTE-

Marlc direction of belt rotation if reusing belt.