fault code BMW 530i 2001 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 530i, Model: BMW 530i 2001 E39Pages: 1002

Page 777 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 5

Brakes

- Remainder of installation is reverse of removal.

- Clean brake caliper mounting bolts (7 mm Allen). Replace

ones which are not in perfect condition. Do not grease.

Top up brake fluid to MAX marking.

- Before driving car, pump bralte pedal several times so that

brake pads contact brake rotors.

Check that brake fluid level is correct. Top up if necessary.

Hold ignition key for at least

30 seconds in accessory po-

sition without starting engine. This clears any fault codes in

memory and turns off brake pad warning light.

Tightening torques Brake caliper to pad carrier

(7 mm Allen)

Front caliper

30 Nm (22 It-lb)

- Rear caliper 28 Nm (21 It-lb)

Road wheel to hub

120i 10 Nm (89i7 ft-lb)

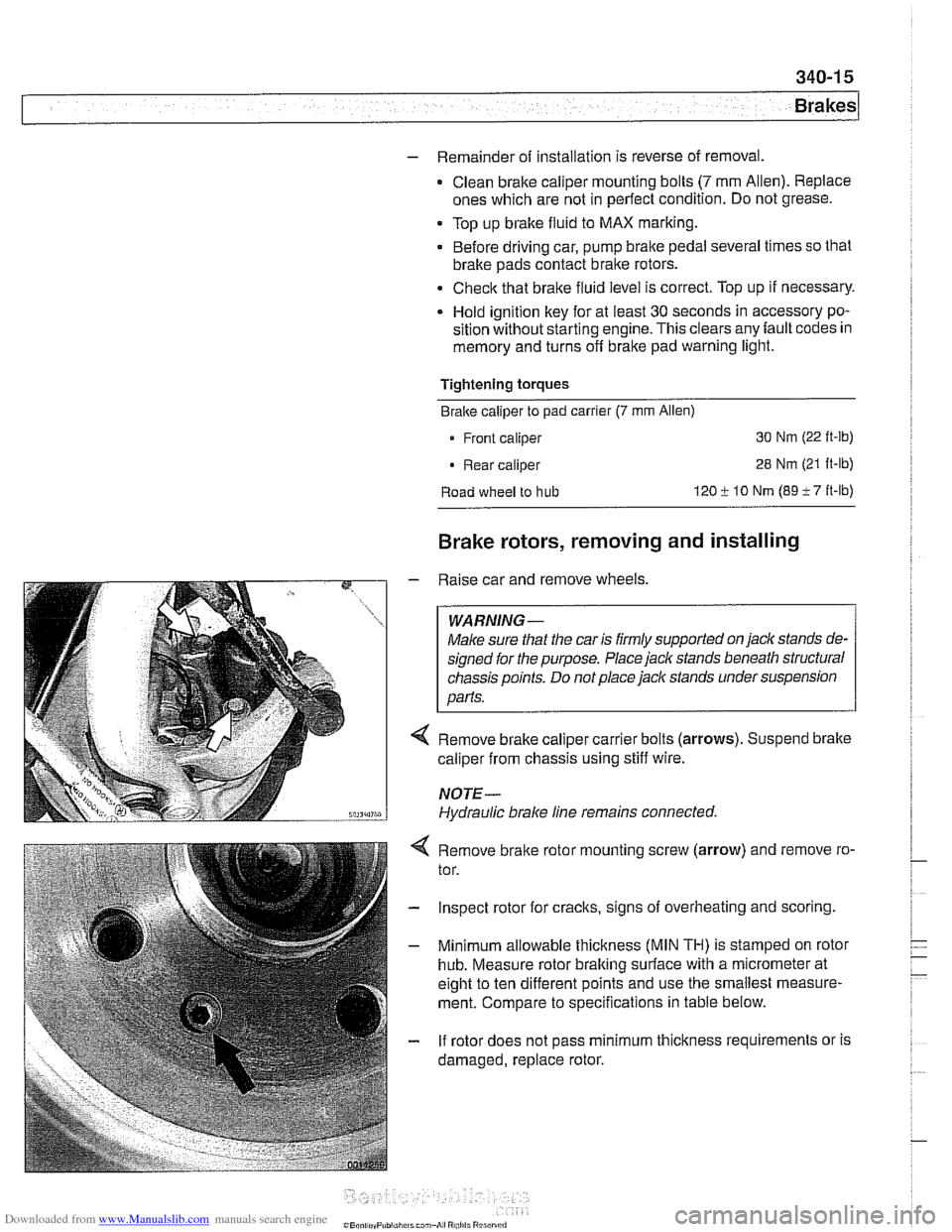

Brake rotors, removing and installing

- Raise car and remove wheels

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

Remove brake caliper carrier bolts (arrows). Suspend brake

caliper from chassis using stiff wire.

NOTE-

Hydraulic brake line remains connected.

4 Remove bralte rotor mounting screw (arrow) and remove ro-

tor.

- Inspect rotor for cracks, signs of overheating and scoring.

- Minimum allowable thickness (MIN TH) is stamped on rotor

hub. Measure rotor braking surface with a micrometer at

eight to ten different points and use the smallest measure-

ment. Compare to specifications in table below.

- If rotor does not pass minimum thickness requirements or is

damaged, replace rotor.

Page 793 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-31

Brakes

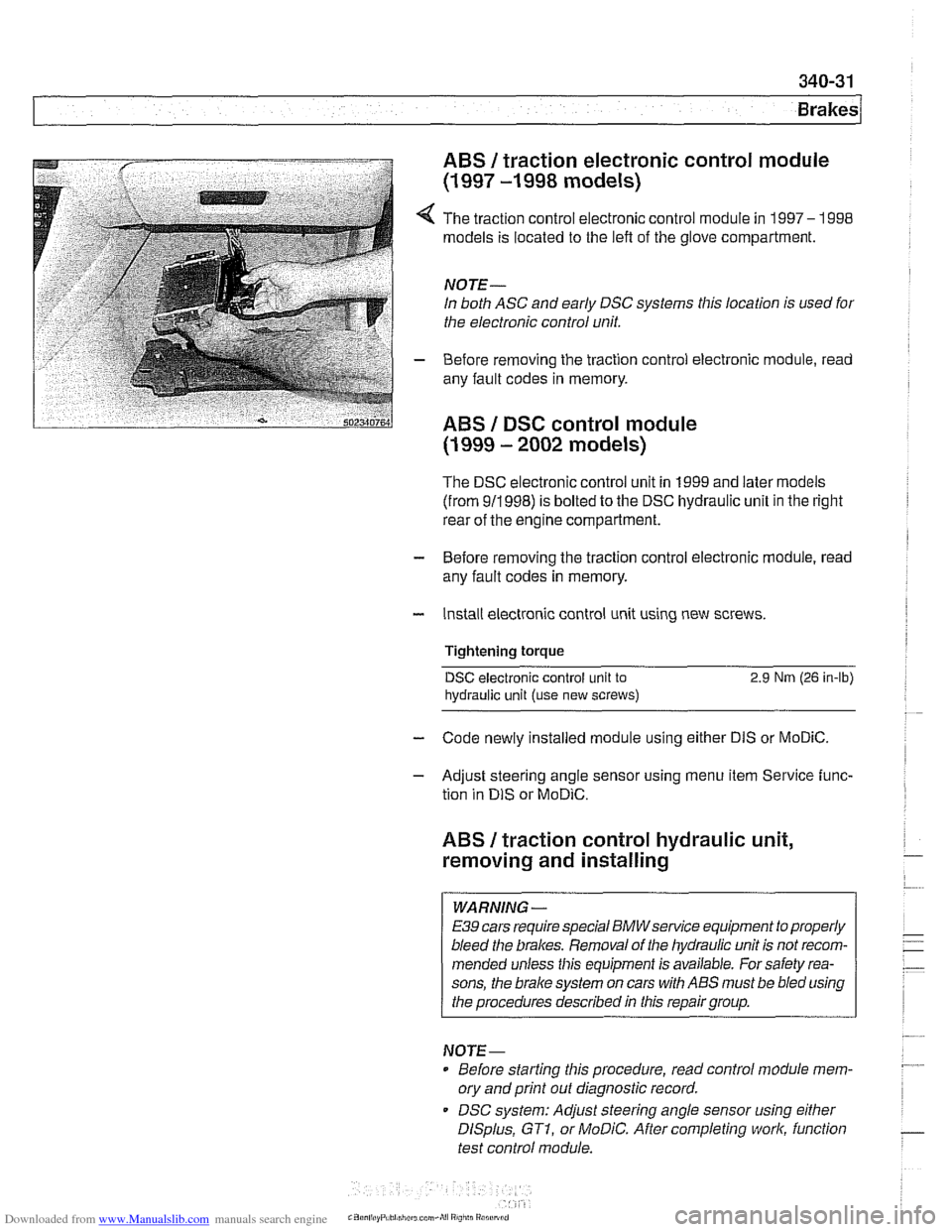

ABS 1 traction electronic control module

(1 997 -1 998 models)

4 The traction control electronic control module in 1997- 1998

models is located to the left of the glove compartment.

NOTE-

In both ASC and early DSC systems this location is used for

the electronic control unit.

- Before removing the traction control electronic module, read

any fault codes in memory.

ABS I DSC control module

(1 999 - 2002 models)

The DSC electronic control unit in 1999 and later models

(from 911998) is bolted to the DSC hydraulic unit in the right

rear of the engine compartment.

- Before removing the traction control electronic module, read

any fault codes in memory.

- Install electronic control unit using new screws.

Tightening torque

DSC electronic control unit to 2.9 Nrn (26 in-lb)

hydraulic

unit (use new screws)

- Code newly installed module using either DIS or MoDiC.

- Adjust steering angle sensor using menu item Service func-

tion in

DIS or MoDiC.

ABS I traction control hydraulic unit,

removing and installing

WARNING -

E39 cars require special BMWsewice equipment to properly

bleed the brakes. Removal of the hydraulic unit is not recom-

mended unless this equipment is available. For safety rea-

sons, the

brake system on cars with ABS must be bled using

the procedures described in this repair group.

NOTE-

Before starting this procedure, read control module mem-

ory and print

out diagnostic record.

DSC system: Adjust steering angle sensor using

either

DISplus, GTI, or MoDiC. After completing work, function

test control module.

Page 868 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 2-4

I Door Windows

/ Anti-trap strip

Power window motors

The window motors are mounted on cable regulators. The

window motor control circuit consists of two wires for operat-

ing the motor in both directions.

The motors are activated by relays in the GM

Ill. The relays

provide either power or ground depending on the direction of

window travel. The GM

Ill controls the polarity based on a re-

quest to run the window from a window switch or a conve-

nience

openinglclosing signal.

Convenience openinglclosing

The GM Iii provides the convenience openlclose feature, pro-

viding control of the power windows (and sunroof) from out-

side the vehicle with the key in the driver's door lock. The FZV

(remote key) provides the same function for window opening

only.

Anti-trap protection is active during convenience closing from

the driver's door lock.

If the GM receives a request to operate convenience closing

or opening for more than

110 seconds, the function is deacti-

vated and a

fault code is stored.

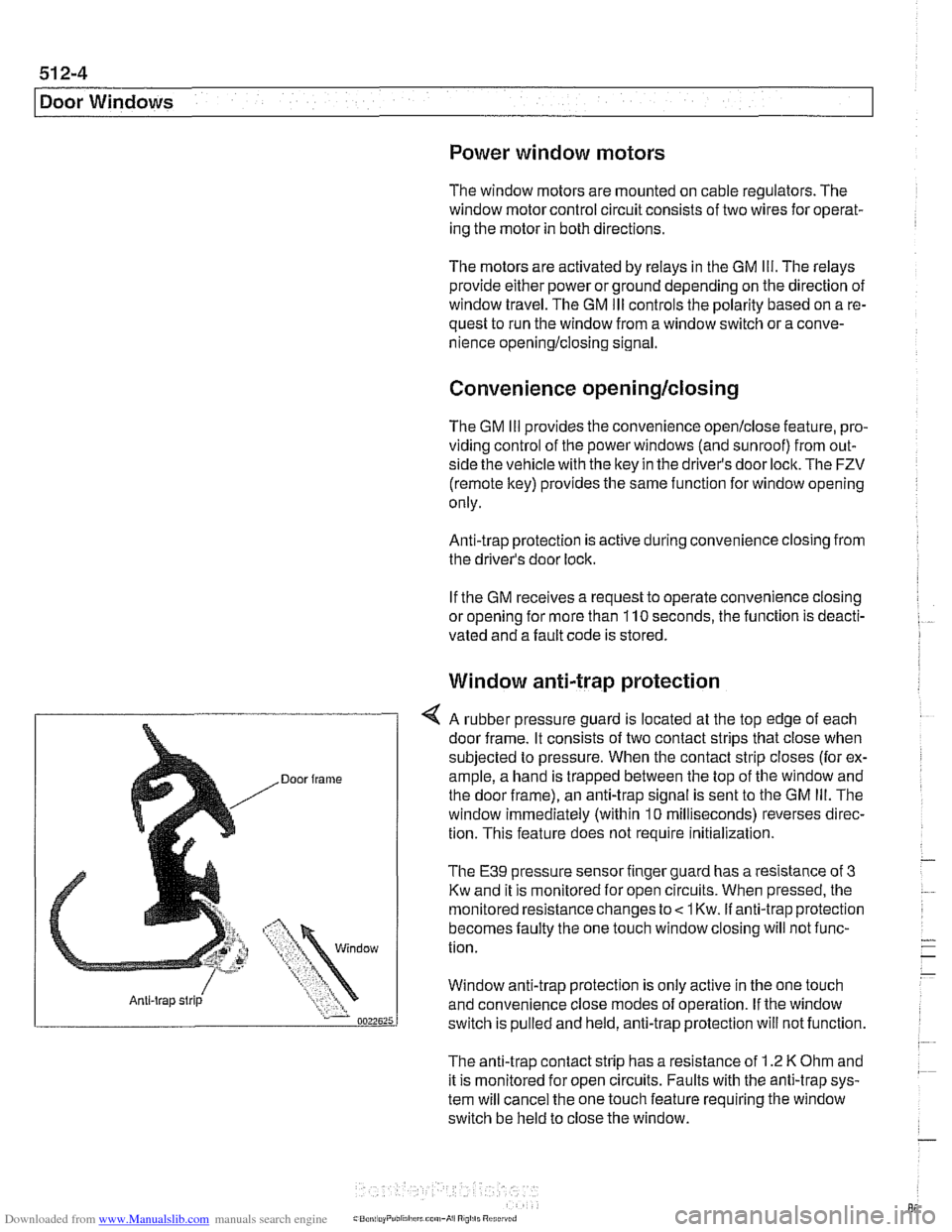

Window anti-trap protection

4 A rubber pressure guard is located at the top edge of each

door frame. It consists of two contact strips that close when

subjected to pressure. When the contact strip closes (for ex-

ample, a hand is trapped between the top of the window and

the door frame), an anti-trap signal is sent to the GM

Ill. The

window immediately (within

10 milliseconds) reverses direc-

tion. This feature does not require

initialization.

The E39 pressure sensor finger guard has a resistance of 3

Kw and it is monitored for open circuits. When pressed, the

monitored resistance changes to

< 1 Kw. if anti-trap protection

becomes faulty the one touch window closing will not func-

tion.

Window anti-trap protection is

only active in the one touch

and convenience close modes of operation. If the window

switch is pulled and held, anti-trap protection will not function.

The anti-trap contact strip has a resistance of

1.2 K Ohm and

it is monitored for open circuits. Faults with the anti-trap sys-

tem will cancel the one touch feature requiring the window

switch be held to close the window.

Page 899 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

DWA alarm

The DWA alarm system is

armedldisarmed when thevehicle

is locked / unlocked from either the door or trunk.

Convenience closing

I opening

The windows and sun roof can be closed or opened by hold-

ing the key in the

loclc I unlock position.

Crash sensor

The crash sensor is located in the left front

kick panel. It func-

tions by unlocking all doors in the event of an accident.

NOTE-

Continuous and repeated locliing / unlocking may cause

timedarrest of

the locliing system. When activated, the timed

arrest lasts for two minutes. The timed arrest does not affect

the crash sensor

unlocliing the doors in case of an accident.

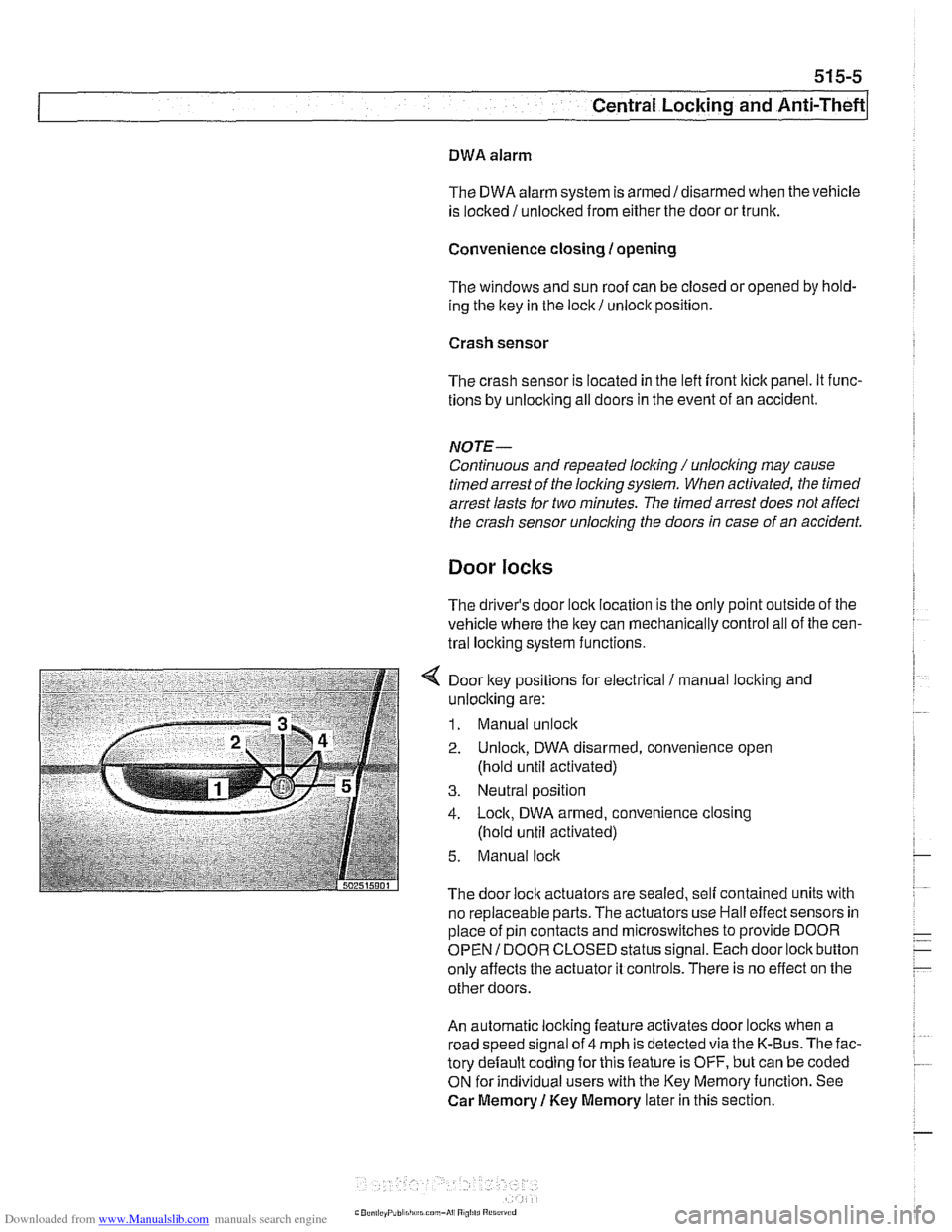

Door locks

The driver's door lock location is the only point outside of the

vehicle where the ltey can mechanically control all of the cen-

tral locking system functions.

4 Door key positions for electrical / manual loclting and

unlocking are:

1. Manual unlock

2. Unlock, DWA disarmed, convenience open

(hold until activated)

3. Neutral position

4. Lock, DWA armed, convenience closing

(hold until activated)

5. Manual lock

The door lock actuators are sealed. self contained units with

no replaceable parts. The

actuators use Hall effect sensors in

place of pin contacts and microswitches to provide DOOR

OPEN

I DOOR CLOSED status signal. Each door lock button

only affects the actuator it controls. There is no effect on the

other doors.

An automatic locking feature activates door locks when a

road speed signal of 4 mph is detected via the K-Bus. The fac-

tory default coding for this feature is OFF, but can be coded

ON for individual users with the Key Memoryfunction. See

Car Memory

1 Key Memory later in this section.

Page 904 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Central Locking and Anti-Theft

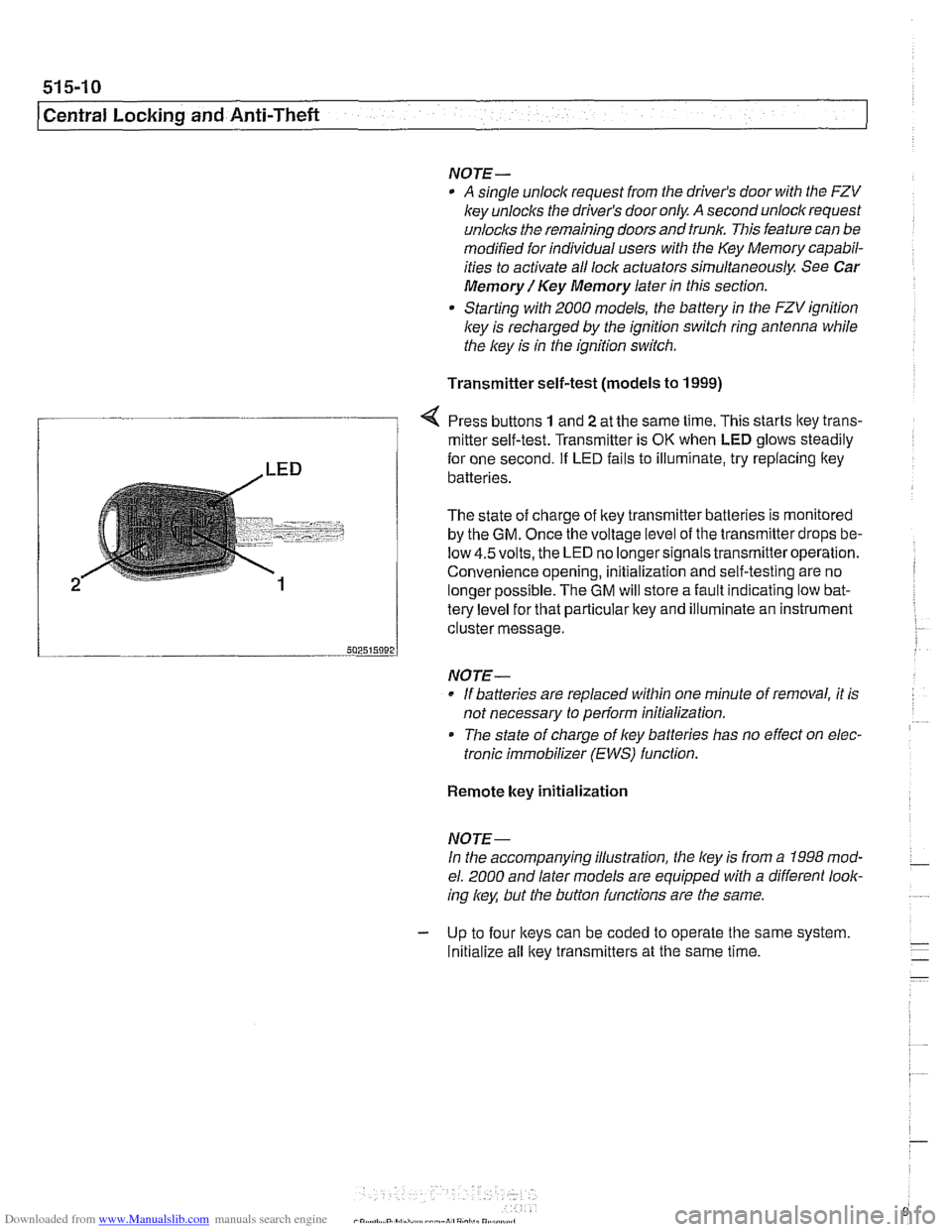

NOJE-

A single unlock request from the driver's door with the FZV

key unlocks the driver's door only.

A second unlock request

unlocls the remaining doors and trunk. This feature can be

modified for individual users with the Key Memory capabil-

ities to activate all lock actuators simultaneously See Car

Memory

/ Key Memory later in this section.

Starting with 2000 models, the battery in the FZV ignition

Icey is recharged by the ignition switch ring antenna while

the ley is in the ignition switch.

Transmitter self-test (models to

1999)

Press buttons 1 and 2 at the same time. This starts ltey trans-

/ mitter self-test. Transmitter is OK when LED glows steadily

te{le"el for that particular key and illuminate an instrument

cluster message.

-- 502515092 J

NO JE-

If batteries are replaced within one minute of removal, it is

not necessary to

periorm initialization.

Tlie state of charge of key batteries has no effect on elec-

tronic immobilizer (EWS) function.

2

Remote key initialization

for one second. If LED fails to illuminate, try replacing ltey~

batteries.

The state of charge of key transmitter batteries is monitored

by the

GM. Once the voltage level of the transmitter drops be-

low

4.5volts, the LED no longersignals transmitteroperation.

Convenience opening, initialization and self-testing are no

lonaer ~ossible. The GM will store a fault indicatina low bat-

NOJE-

In the accompanying illustration, the key is from a 1998 mod-

el. 2000 and later models are equipped with a different look-

ing

/

Initialize all key transmitters at the same time.

Page 950 of 1002

Downloaded from www.Manualslib.com manuals search engine

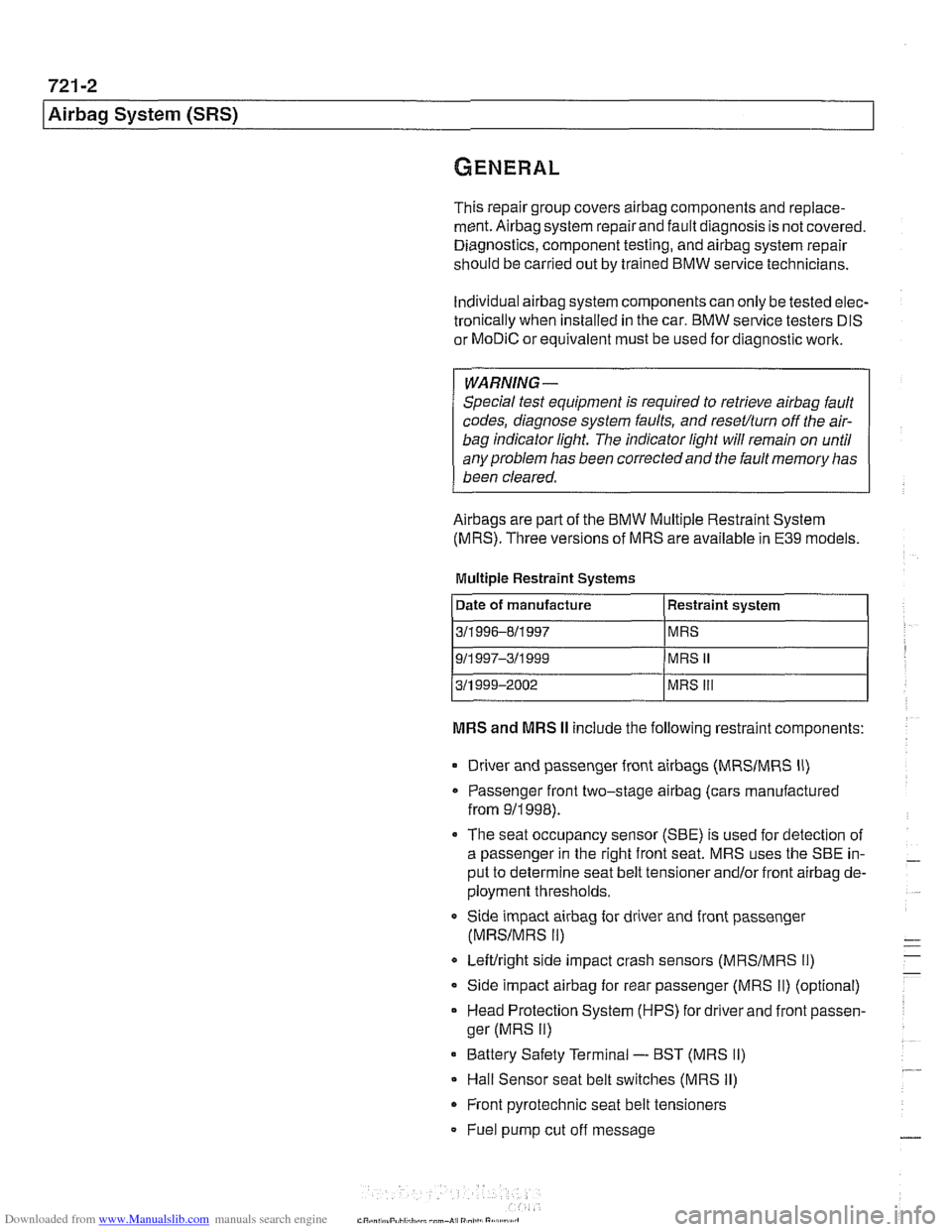

721 -2

l~irba~ System (SRS)

This repair group covers airbag components and replace-

ment.

Airbag system repairand fault diagnosis is not covered.

Diagnostics, component testing, and

airbag system repair

should be carried out by trained BMW service technicians.

Individual

airbag system components can only be tested elec-

tronically when installed in the car. BMW service testers

DIS

or MoDiC or equivalent must be used for diagnostic work.

WARNING-

Special test equipment is required to retrieve airbag fault

codes, diagnose system faults, and

reseffturn off the air-

bag indicator light. The indicator light will remain on until

any problem has been corrected and the fault memory has

been cleared.

Airbags are part of the BMW Multiple Restraint System

(MRS). Three versions of MRS are available in E39 models.

Multiple Restraint Systems

MRS and MRS II include the following restraint components:

311 996-811 997

911

997-311 999

311 999-2002

Driver and passenger front

airbags (MRSIMRS II)

MRS

MRS

II

MRS Ill

Passenger front two-stage airbag (cars manufactured

from

911998).

The seat occupancy sensor (SBE) is used for detection of

a passenger in the right front seat. MRS uses the SBE in-

put to determine seat belt tensioner

and/or front airbag de-

ployment thresholds.

Side impact

airbag for driver and front passenger

(MRSIMRS II)

Leftlright side impact crash sensors (MRSIMRS 11)

Side impact airbag for rear passenger (MRS II) (optional)

Head Protection System (HPS) for driver and front passen-

ger (MRS

II)

Battery Safety Terminal - BST (MRS II)

Hall Sensor seat belt switches (MRS II)

Front pyrotechnic seat belt tensioners

Fuel pump cut off message

Page 957 of 1002

Downloaded from www.Manualslib.com manuals search engine

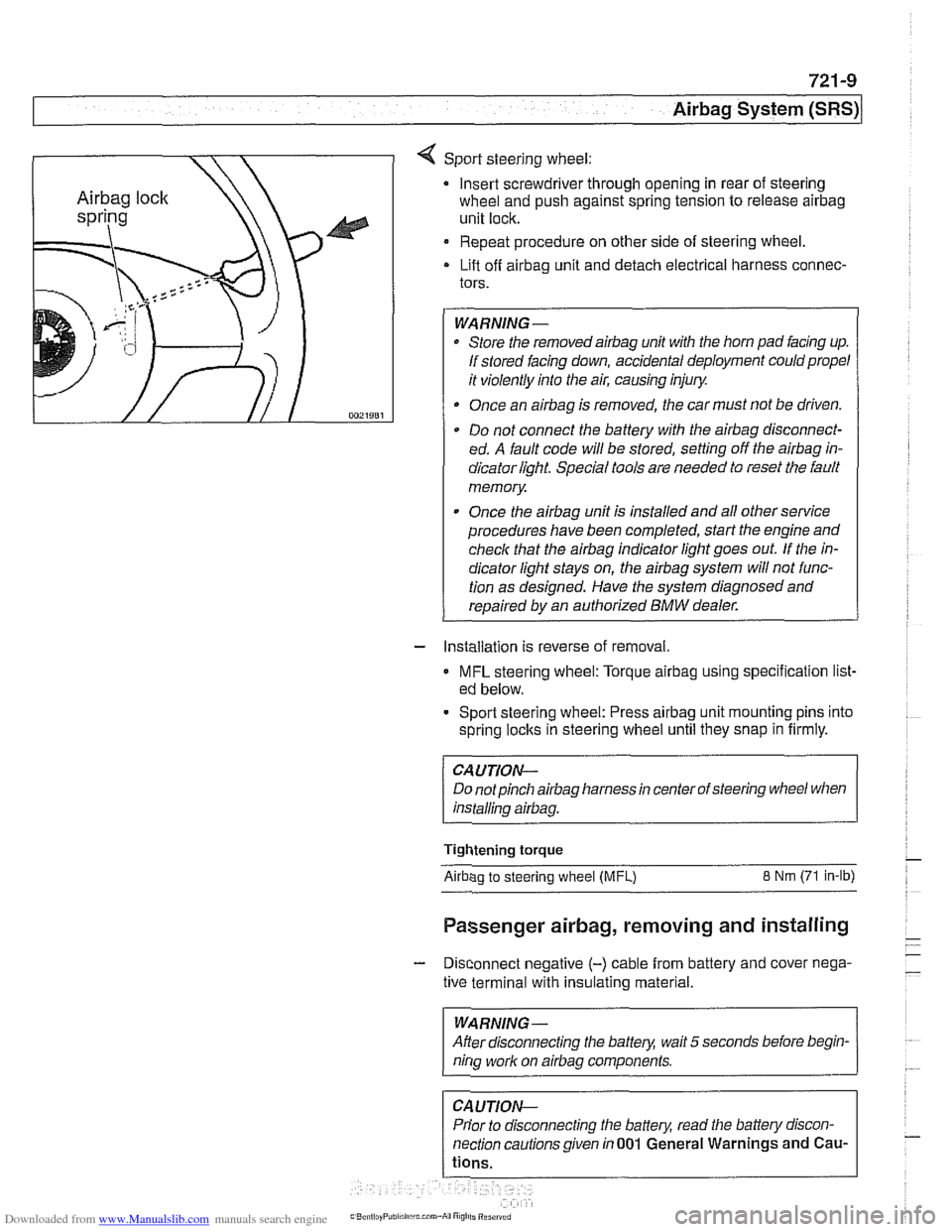

721 -9

Airbaq System ~SRS)~

4 Sport steering wheel:

Insert screwdriver through opening in rear of steering

wheel and push against spring tension to release

airbag

unit lock.

Repeat procedure on other side of steering wheel.

Lift off

airbag unit and detach electrical harness connec-

tors.

WARNING-

Store the removedairbag unit with the horn pad facing up.

If stored facing down, accidental deployment could propel

it violently into the air, causing injury.

Once an

airbag is removed, the car must not be driven.

Do not connect the battery with the

airbag disconnect-

ed. A fault code will be stored, setting off the

airbag in-

dicator light Special tools are needed to reset the fault

memory

Once the

airbag unit is installed and all other service

procedures have been completed, start the engine and

check that the

airbag indicator light goes out. If the in-

dicator light stays on, the

airbag system will not func-

tion as designed. Have the system diagnosed and

repaired by an authorized

BMW dealer.

- Installation is reverse of removal.

MFL steering wheel: Torque airbag using specification list-

ed below.

- Sport steering wheel: Press airbag unit mounting pins into

spring

loclts in steering wheel until they snap in firmly.

CAUTION--

Do notpinch airbag harness in center of steering wheel when

installino

airbaa.

Tightening torque

Airbao to steerino wheel IMFL) 8 Nm (71 in-lb)

Passenger airbag, removing and installing

- Disconnect negative (-) cable from battery and cover nega-

tive terminal with insulating material.

--

WARNING -

After disconnecting the batteg wait 5 seconds before begin-

nina work on airbaa components.

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven in001 General Warnings and

Cau-

Page 963 of 1002

Downloaded from www.Manualslib.com manuals search engine

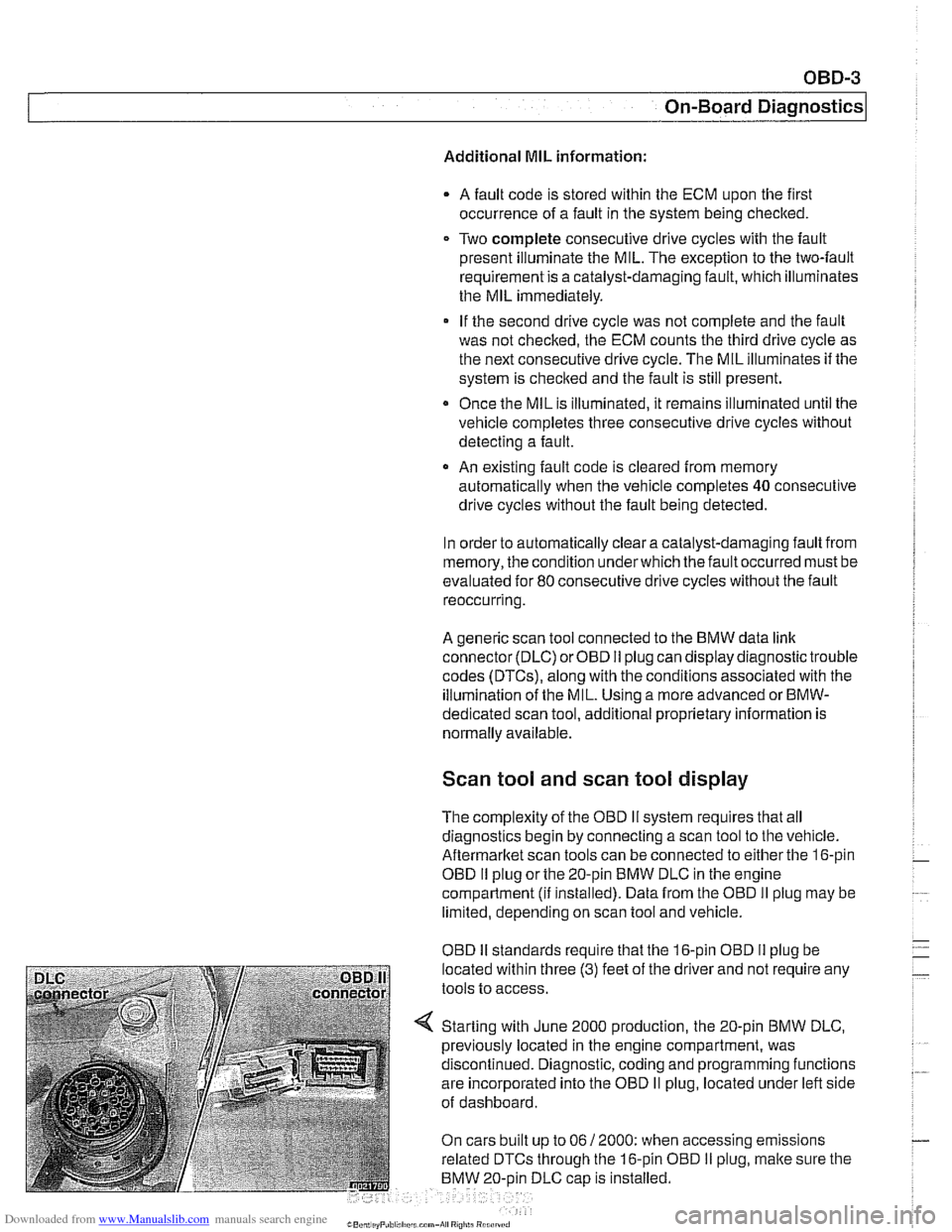

OBD-3

On-Board

~iactnosticsl

Additional MIL information:

A fault code is stored within the ECM upon the first

occurrence of a fault in the system being checlted.

Two complete consecutive drive cycles with the iault

present illuminate the MIL. The exception to the two-fault

requirement is a catalyst-damaging fault, which illuminates

the MIL immediately.

If the second drive cycle was not complete and the fault

was not checked, the ECM counts the third drive cycle as

the next consecutive drive cycle. The MIL illuminates

if the

system is checked and the fault is still present.

Once the MIL is illuminated, it remains illuminated until the

vehicle completes three consecutive drive cycles without

detecting a fault.

0 An existing fault code is cleared from memory

automatically when the vehicle completes

40 consecutive

drive cycles without the fault being detected.

In order to automatically clear a catalyst-damaging fault from

memory, the condition underwhich the fault occurred must be

evaluated for 80 consecutive drive cycles without the fault

reoccurring.

A generic scan tool connected to the BMW data link

connector (DLC) or OBD

I1 plug can display diagnostic trouble

codes (DTCs), along with the conditions associated with the

illumination of the MIL. Using a more advanced or

BMW-

dedicated scan tool, additional proprietary information is

normally available.

Scan tool and scan tool display

The complexity of the OBD I1 system requires that all

diagnostics begin by connecting a scan tool to the vehicle.

Aftermarltet scan tools can be connected to either the 16-pin

OBD

I1 plug or the 20-pin BMW DLC in the engine

compartment

(ii installed). Data from the OBD II plug may be

limited, depending on scan tool and vehicle.

OBD

I1 standards reouire that the 16-oin OBD I1 oluo be

located within three

(3) feet of the driier and not're&ire any

tools to access.

Starting with June 2000 production, the 20-pin BMW DLC,

previously located in the engine compartment, was

discontinued. Diagnostic, coding and programming functions

are incorporated into the OBD

II plug, located under left side

of dashboard.

On cars built up to 06

/ 2000: when accessing emissions

related DTCs through the 16-pin OBD

I1 plug, malte sure the

BMW 20-oin DLC

caD is installed.

Page 964 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

On-Board Diagnostics

Professional diagnostic scan tools available atthe time of this

printing include the BMW factory tools

(DISplus, GTI,

MoDiC) and a small number of aftermarket BMW-specific

tools. See

020 Maintenance.

In addition to the professional line of scan tools, inexpensive

generic OBD

II scan tool software programs and handheld

units are readily available. Though limited, they are

nonetheless powerful diagnostic tools. These tools read live

data streams and freeze frame data as well as a host of other

valuable diagnostic data.

Diagnostic monitors

Diagnostic monitors run tests and checks on specific

emission control systems, components, and functions.

A complete drive cycle is requiredforthe tests to bevalid. See

Drive cycle in this repair group. The diagnostic monitor

signals the

ECM of the loss or impairment of the signal or

component and determines if a signal or sensor is faulty

based on

3 conditions:

* Signal or component shorted to ground

Signal or component shorted to

B+

Signal or component missing (open circuit)

The OBD

II system monitors all emission control systems that

are installed. Emission control systems vary by vehicle model

and year. For example, a vehicle may not be equipped with

secondary air injection, so no secondary air readiness code

would be present.

OBD

II software monitors the following:

Oxygen sensors

Catalysts

Engine misfire

- Fuel tank evaporative control system

Secondary air injection Fuel system

Oxygen sensor monitoring. When driving conditions allow,

response rate and switching time of each oxygen sensor is

monitored. The oxygen sensor heater function is also

monitored. The OBD

II system differentiates between

precataylst and post-catalyst oxygen sensors and reads each

one individually. In order

forthe oxygen sensor to be

effectively monitored, the system must be in closed loop

operation.

Page 966 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-6

On-Board Diagnostics

Fuel system monitoring. This monitor looks at the fuel

delivery needed (long

/short term fuel trim) for proper engine

operation based on programmed data. If too much or not

enough fuel is delivered over a predetermined time, a DTC is

set and the MIL illuminates.

Fuel trim refers to adiustments to base fuel schedule.

Lono- ., term fuel trim refers to gradual adjustments to the fuel

calibration adjustment as compared to short term fuel trim.

Long term fuel trim adjustments compensate for gradual

changes that occur over time.

Fuel system monitoring monitors the calculated injection time

(ti) in relation to enginespeed, load and precatalyticconverter

oxygen

sensor(s) signals.

Using this data, the system optimizes fuel delivery for all

engine operating conditions.

Evaporative system monitoring. This monitor checks the

the fuel storage system and related fuel lines for leaks. It can

detect very small leaks anywhere in the system.

A leak detection unit (LDP or DMTL) is used to pressurize the

evaporative control system on a continuous basis (as the

drive cycle allows) and to

check system integrity.

Drive cycle

The OED II drive cycle is an important concept in

understanding OBD

II requirements. The purpose of the drive

cycle is to run ail of the emission-related on-board diagnostics

over a broad range of driving conditions.

A drive cycle is considered complete when all of the

diagnostic monitors have run their tests without interruption.

~ora drive cycle to be initiated, the vehicle must be started

cold and brought up to

1 60°F and at least 40°F above its

original starting temperature.

Readiness codes

Inspection/maintenance (I/M) readiness codes are mandated

as part of OBD

II. The readiness code is stored aftercomplete

diagnostic monitoring of specified components and systems

is carried out. The readiness code function was designed to

prevent manipulating an

I/M emission test procedure by

clearing faults codes or disconnecting the ECM or battery.