engine removal BMW 540i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 462 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-72

Fuel Injection

I Oxygen sensors, replacing

4 Four Bosch oxygen sensors (2 precatalytic converter sen-

sors and

2 post-catalytic converter sensors) provide a vary-

ing voltage signal

[0.2 vdc (max. lean) to 0.8 vdc (max. rich)]

to the ME

7.2 ECM representing oxygen content in the ex-

haust gas.

WARNING-

Exhaust manifolds and pipes can be hot enough to cause se-

rious burns. Wear suitable heavy gloves and other appropri-

ate protection.

- Using a special oxygen sensor socltet, remove the threaded

sensors from the exhaust system.

- If not already applied, coat the new oxygen sensor threads

with an anti-seize compound before installation. Do not get

compound on the sensor tip.

Tightening torque

Oxygen sensor to exhaust system

50 Nm (37 ft-lb)

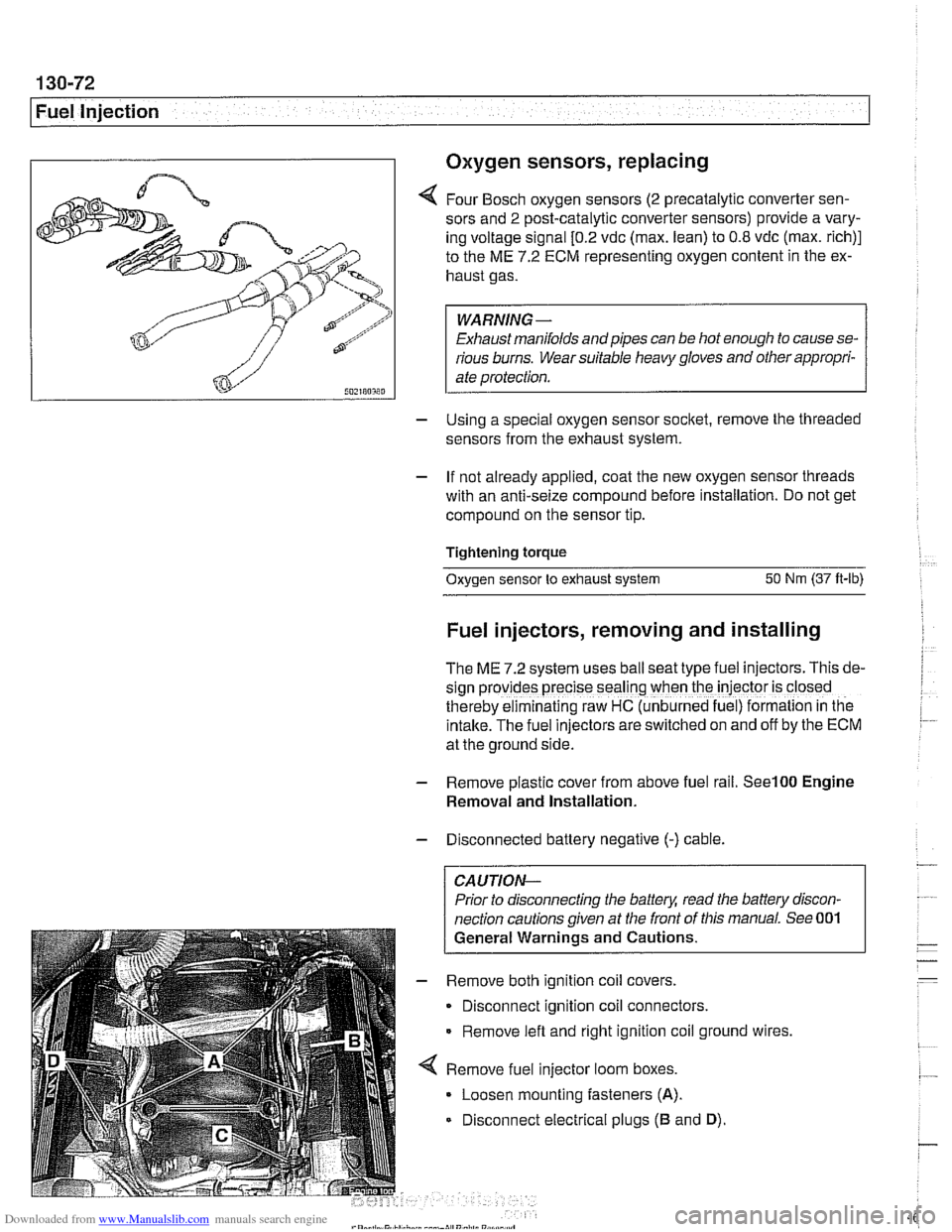

Fuel injectors, removing and installing

The ME 7.2 system uses ball seat type fuel injectors. This de-

sign

prov:des precise seal'ng when the iniector is closed

therebv eiminalinq raw HC (unb~rned fue ) formalion in tne

intake.-~he fuel inkctors areswitched on and off by the ECM

at the ground side.

- Remove plastic cover from above fuel rail. See100 Engine

Removal and Installation.

- Disconnected battery negative (-) cable.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given at the front of this manual. See 001

General Warnings and Cautions.

- Remove both ignition coil covers.

Disconnect ignition coil connectors.

Remove left and right ignition coil ground wires,

4 Remove fuel injector loom boxes.

Loosen mounting fasteners

(A).

Disconnect electrical plugs (B and D).

Page 463 of 1002

Downloaded from www.Manualslib.com manuals search engine

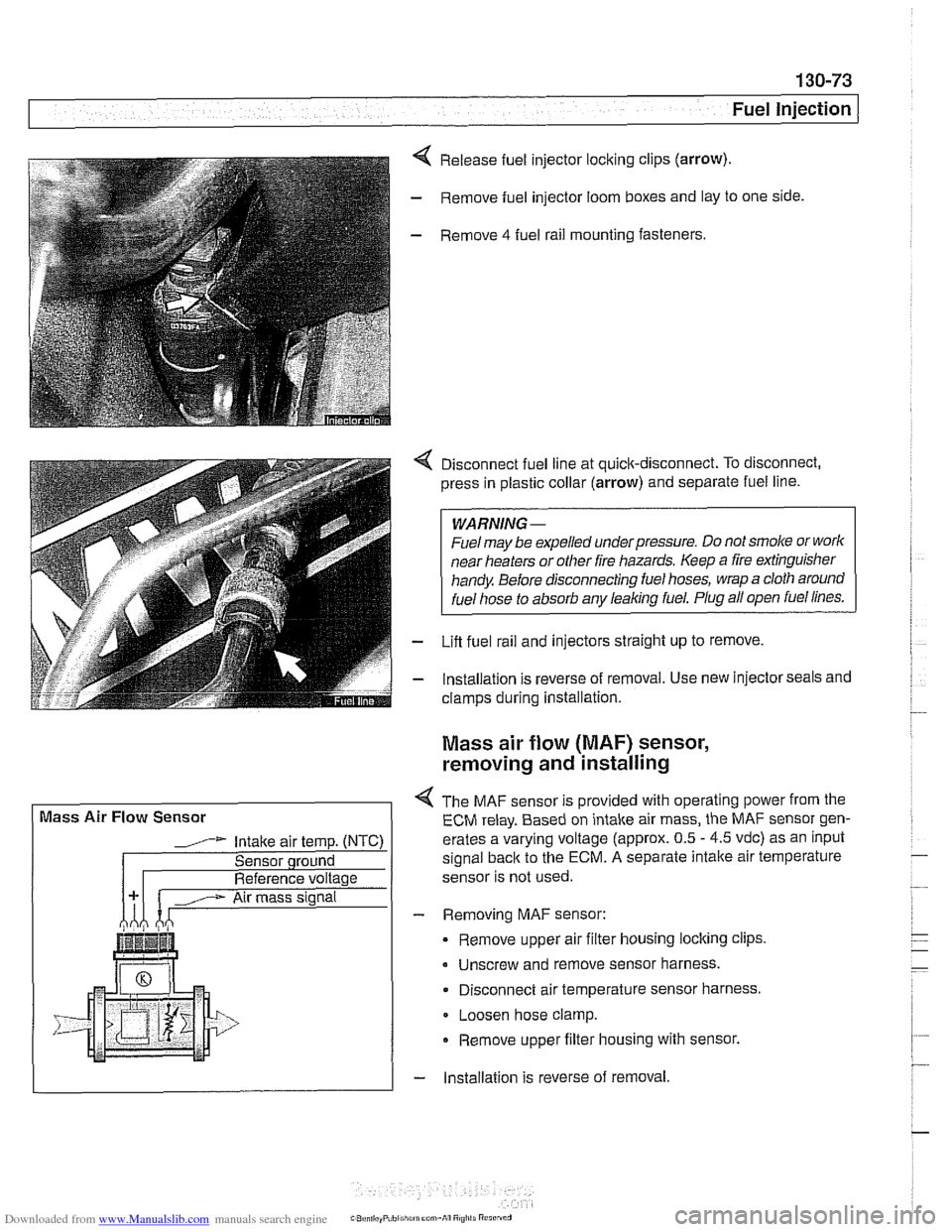

( Mass Air Flow Sensor

1" Intake air temp. (NTC)

Sensor qround

Reference voltage . . . -., f fitr mass signal I

Fuel Injection I

Release fuel injector locking clips (arrow).

- Remove fuel injector loom boxes and lay to one side.

- Remove 4 fuel rail mounting fasteners.

4 Disconnect fuel line at quick-disconnect. To disconnect,

press in plastic collar (arrow) and separate fuel line.

WARNING -

Fuel may be expelled underpressure. Do not srnol(e or work

near heaters or

other fire hazards. Keep a fire extinguisher

handy. Before disconnecting fuel hoses, wrap a cloth around

fuel hose

to absorb anv leakinq fuel. Plug all open fuel lines.

- Lifl fuel rail and injectors straight up to remove.

- lnstallation is reverse of removal. Use new injector seals and

clamps during installation.

Mass air flow (MAF) sensor,

removing and installing

4 The MAF sensor is provided with operating power from the

ECM relay. Based on intake air mass, the MAF sensor gen-

erates a varying voltage (approx. 0.5

- 4.5 vdc) as an input

signal

back to the ECM. A separate intalte air temperature

sensor is not used.

- Removing MAF sensor:

Remove upper air filter housing locking clips

Unscrew and remove sensor harness.

Disconnect air temperature sensor harness.

Loosen hose clamp.

Remove upper filter housing with sensor.

- lnstallation is reverse of removal

Page 473 of 1002

Downloaded from www.Manualslib.com manuals search engine

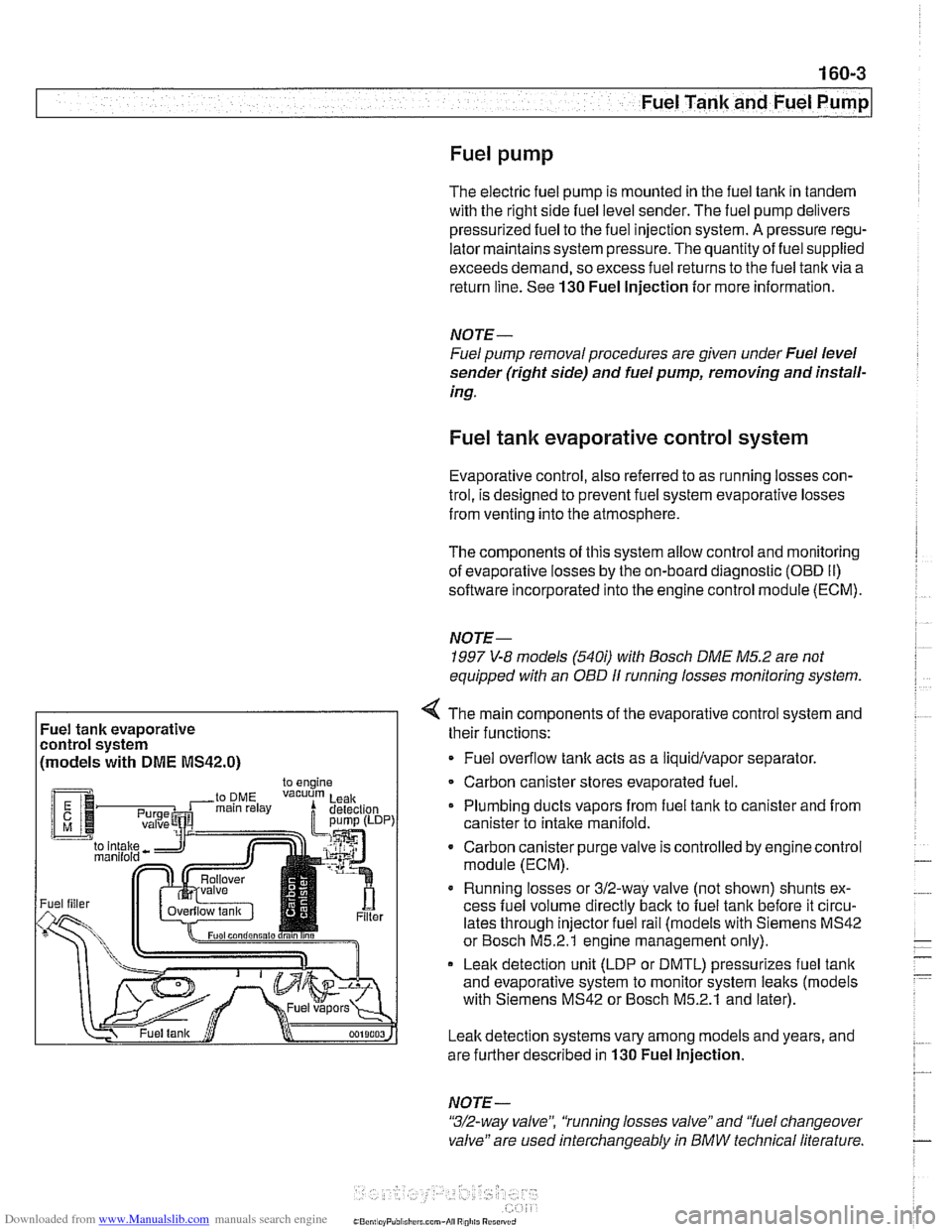

Fuel Tank and Fuel Pump

Fuel pump

The electric fuel pump is mounted in the fuel tank in tandem

with the right side fuel level sender. The fuel pump delivers

pressurized fuel to the fuel injection system.

A pressure regu-

lator maintains system pressure. The quantity of fuel supplied

exceeds demand, so excess fuel returns to the fuel tank via a

return line. See

130 Fuel Injection for more information.

NOTE-

Fuel pump removal procedures are given under Fuel level

sender (right side) and fuel pump, removing and install-

ing.

Fuel tank evaporative control system

Evaporative control, also referred to as running losses con-

trol, is designed to prevent fuel system evaporative losses

from venting into the atmosphere.

The components of this system allow control and monitoring

of evaporative losses by the on-board diagnostic

(OED II)

software incorporated into the engine control module (ECM).

NOTE-

1997 V-8 models (540i) with Bosch DME M5.2 are not

equipped with an

OBD I1 running losses monitoring system.

Fuel tank evaporative

control system

(models with

DME MS42.0)

4 The main components of the evaporative control system and

their functions:

Fuel overflow

tank acts as a liquidlvapor separator

Carbon canister stores evaporated fuel.

Plumbing ducts vapors from fuel tank to canister and from

canister to intake

manifold.

- Carbon canister purge valve is controlled by enginecontrol

module (ECM).

Running losses or 312-way valve (not shown) shunts ex-

cess fuel volume directly

back to fuel tank before it circu-

lates through injector fuel rail (models with Siemens MS42

or Bosch M5.2.1 engine management only).

Leak detection unit (LDP or DMTL) pressurizes fuel

tank

and evaporative system to monitor system leaks (models

with Siemens MS42 or Bosch M5.2.1 and later).

Leak detection systems vary among models and years, and

are further described in

130 Fuel Injection.

NOTE -

"3/2-way valve", 'tunning losses valve" and "fuel changeover

valve" are used interchangeably

in BMW technical literature.

Page 480 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Tank and Fuel Pump --

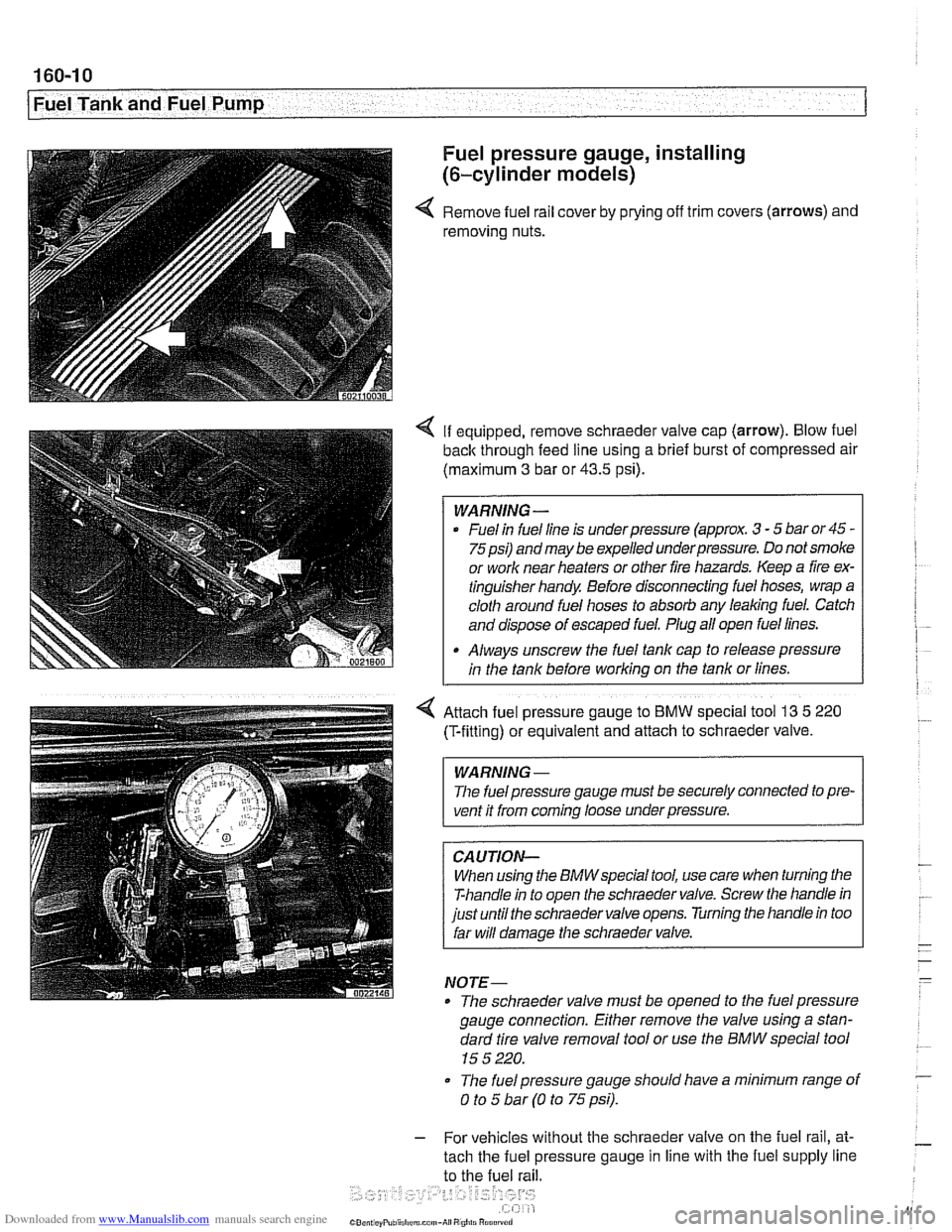

Fuel pressure gauge, installing

(6-cylinder models)

4 Remove fuel rail cover by prying off trim covers (arrows) and

removing nuts.

4 If equipped, remove schraeder valve cap (arrow). Blow fuel

back through feed line using a brief burst of compressed air

(maximum

3 bar or 43.5 psi).

WARNING -

Fuel in fuel line is underpressure (approx. 3 - 5 bar or 45 -

75psi) andmay be expelled underpressure. Do not smoke

or work near heaters or other fire hazards. Keep a fire ex-

tinguisher handy Before disconnecting fuel hoses, wrap a

cloth around fuel hoses to absorb any leaking fuel. Catch

and dispose of escaped fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

in the tank before working on the tank or lines.

4 Attach fuel pressure gauge to BMW special tool 13 5 220

(T-fittlng) or equivalent and attach to schraeder valve.

WARNING -

The fuel pressure gauge must be securely connected to pre-

vent it from

coming loose underpressure.

CAUTION-

When using the BMWspecial tool, use care when turning the

T-handle in to open the schraeder valve. Screw the handle in

just until the schraeder valve opens. Turning the handle in too

far will damage the schraeder valve.

NOTE-

* The schraeder valve must be opened to the fuel pressure

gauge connection. Either remove the valve using a stan-

dard tire valve removal tool or use the BMW special tool

15 5 220.

* The fuel pressure gauge should have a minimum range of

0 to 5 bar (0 to 75 psi).

- For vehicles without the schraeder valve on the fuel rail, at-

tach the fuel pressure gauge in line with the fuel supply line

to the fuel rail.

Page 486 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

I Fuel Tank and Fuel Pump

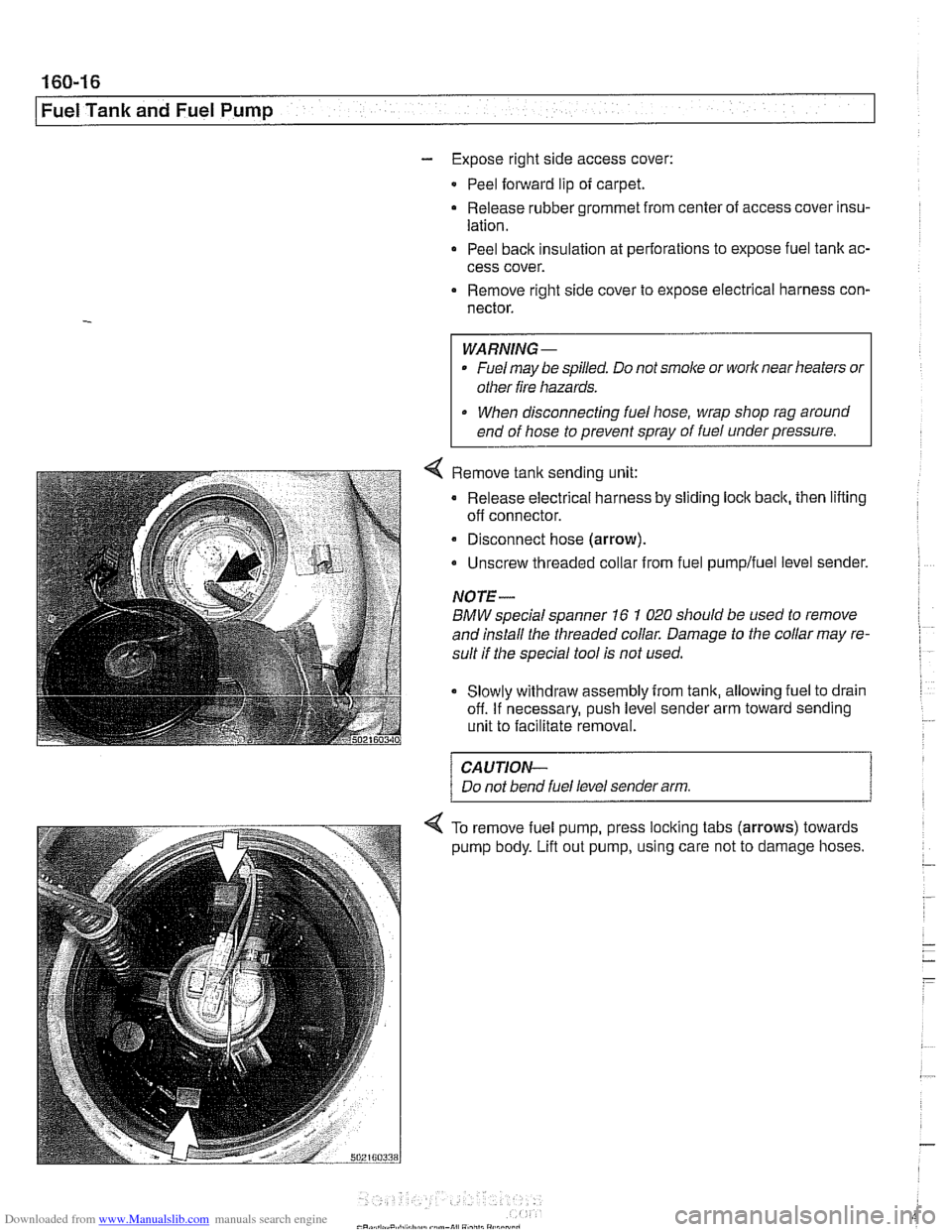

- Expose right side access cover:

Peel forward lip of carpet.

Release rubber grommet from center of access cover insu-

lation.

Peel back insulation at

perforations to expose fuel tank ac-

cess cover.

Remove right side cover to expose electrical harness con-

nector.

WARNING -

Fuel may be spilled. Do not smolce or work near heaters or

other fire hazards.

When disconnecting fuel hose, wrap shop rag around

end of hose to prevent spray of fuel under pressure.

Remove

tank sending unit:

Release electrical harness by sliding lock back, then lifting

off connector.

a Disconnect hose (arrow).

Unscrew threaded collar from fuel

pumpifuel level sender.

NOTE-

BMW special spanner 16 1 020 should be used to remove

and install the threaded collar. Damage to the collar may re-

sult if the special tool is not used.

Slowly withdraw assembly from tank, allowing fuel to drain

off. If necessary, push level sender arm toward sending

unit to facilitate removal.

CAUTION-

Do not bend fuel level sender arm.

To remove fuel pump, press locking tabs (arrows) towards

pump body.

Lifl out pump, using care not to damage hoses.

Page 488 of 1002

Downloaded from www.Manualslib.com manuals search engine

/ ~uel Tank and Fuel Pump

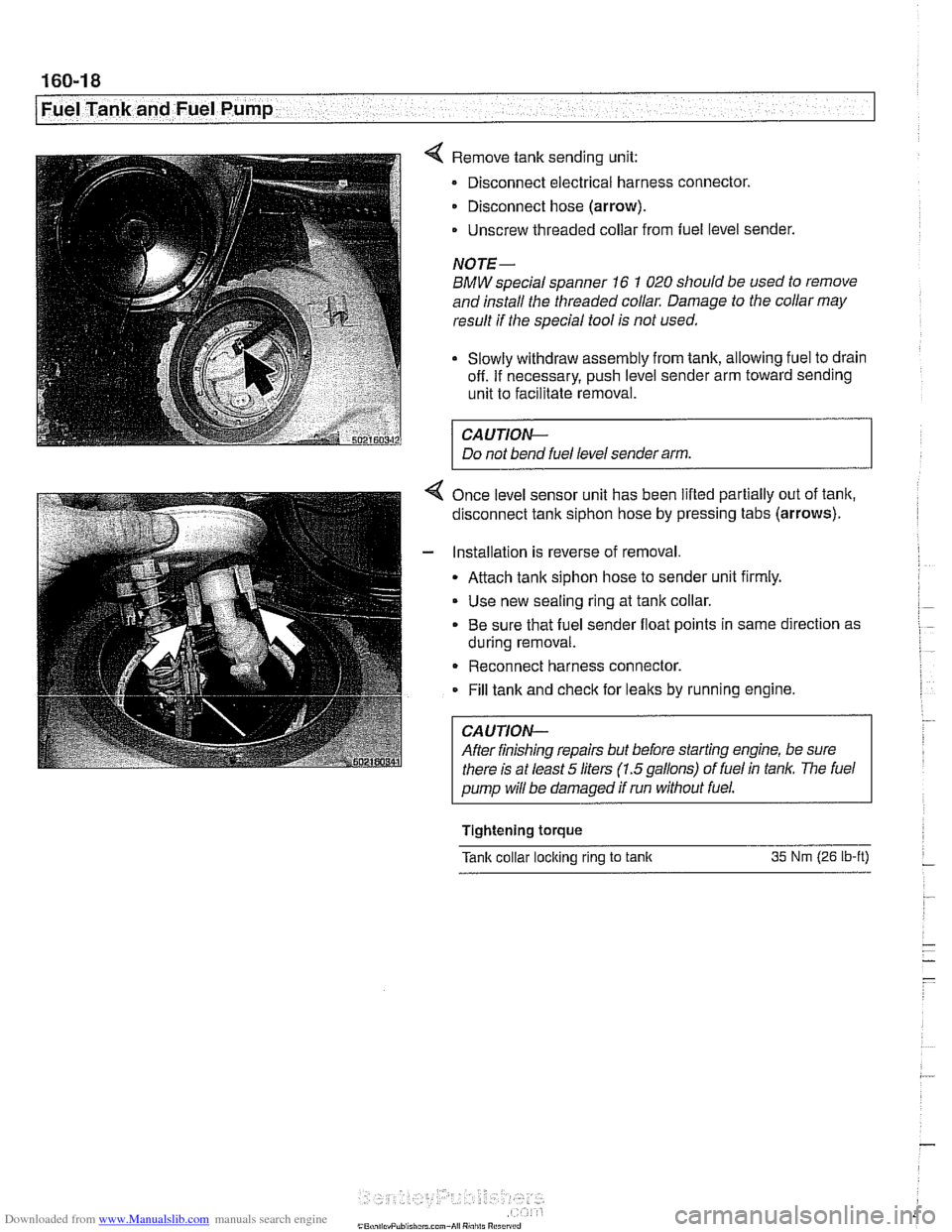

4 Remove tank sending unit:

Disconnect electrical harness connector.

Disconnect hose (arrow).

- Unscrew threaded collar from fuel level sender.

NOTE-

BMW special spanner 16 1 020 should be used to remove

and install the threaded collar. Damage to the collar may

result if the special tool is not used.

Slowly withdraw assembly from tank, allowing fuel to drain

off. If necessary, push level sender arm toward sending

unit to facilitate removal.

CA UTIOW-

Do not bend fuel level sender arm.

4 Once level sensor unit has been lifted partially out of tank,

disconnect tank siphon hose by pressing tabs (arrows).

- Installation is reverse of removal

Attach tank siphon hose to sender unit firmly.

Use new sealing ring at tank collar.

. Be sure that fuel sender float points in same direction as

during removal.

- Reconnect harness connector.

Fill tank and

check for leaks by running engine.

CAUTION-

After finishing repairs but before starting engine, be sure

there is at least

5 liters (1.5gallons) of fuel in tan/(. The fuel

pump will be damaged if run without fuel.

Tightening

torque

Tank collar loclting rlng to tanlt 35 Nm (26 lb-ft) -

Page 489 of 1002

Downloaded from www.Manualslib.com manuals search engine

7 .- A Fuel Tank and Fuel Pump

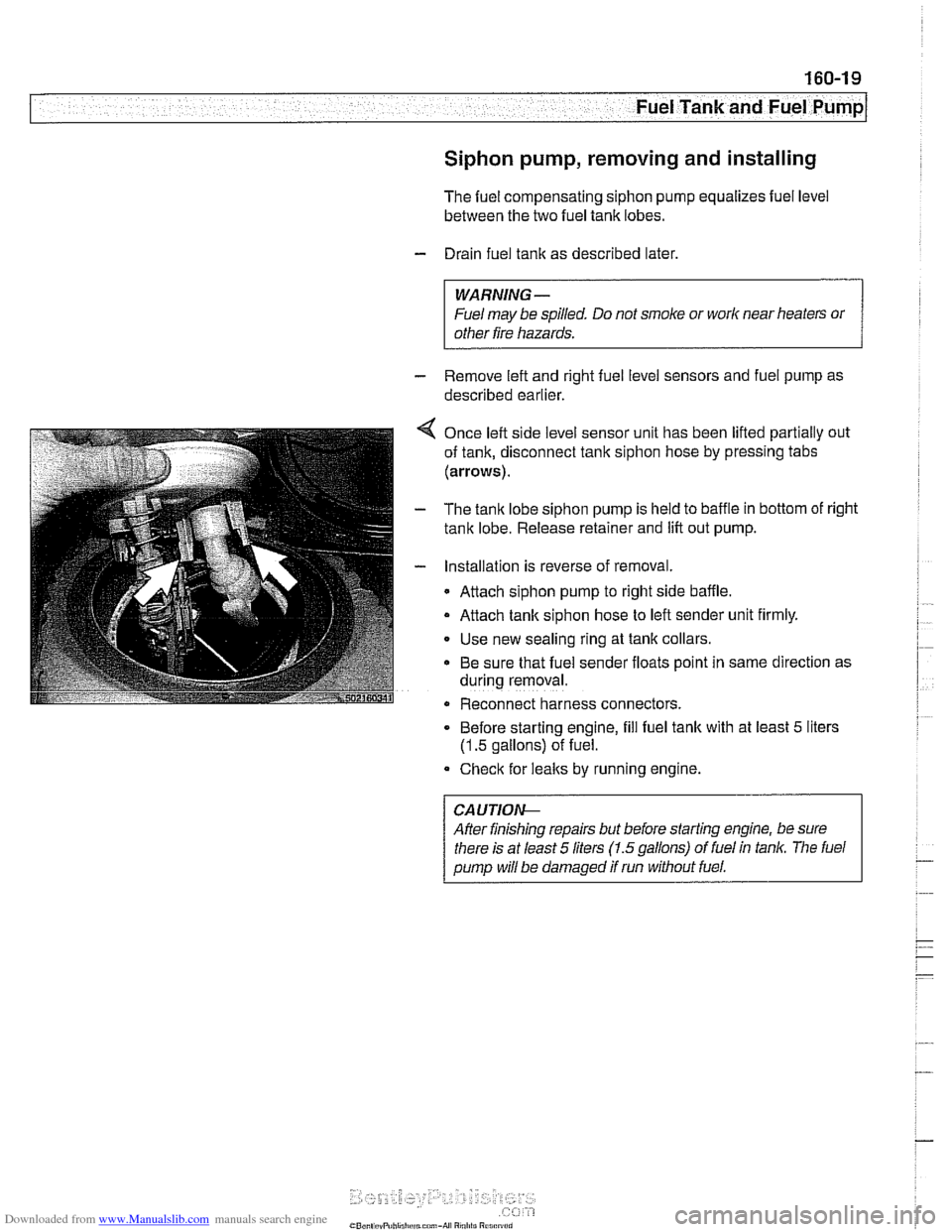

Siphon pump, removing and installing

The fuel compensating siphon pump equalizes fuel level

between the two fuel tank lobes.

- Drain fuel tank as described later,

WARNING -

Fuel may be spilled. Do not smoke or work near heaters or

other fire hazards.

- Remove left and right fuel level sensors and fuel pump as

described earlier.

4 Once left side level sensor unit has been lifted partially out

of tank, disconnect tank siphon hose by pressing tabs

(arrows).

- The tank lobe siphon pump is held to baffle in bottom of right

tank lobe. Release retainer and lift out pump.

- Installation is reverse of removal.

Attach siphon pump to right side baffle.

Attach tank siphon hose to left sender unit firmly.

Use new sealing ring at tank collars

Be sure that fuel sender floats point in same direction as

during removal.

Reconnect harness connectors.

. Before starting engine, fill fuel tank with at least 5 liters

(1.5 gallons) of fuel.

Check for

leaks by running engine.

Afler finishing repairs but before starting engine, be sure

Page 493 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- Fuel Tank and Fuel pump( -

Fuel expansion tank, removing

and installing

- Raise rear end of car and support safely.

CA U TIOG

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the

ouroose. A floor iack is not adequate support

- Remove left rear wheel and wheel housing inner shield.

4 Remove plastic nut (A) and disconnect hose (B).

4 Tilt vent tank down and loosen or cut off hose clamps

(arrows). Pull hoses off fittings.

- Release vacuum line loclting clips and remove tank

- Installation is reverse of removal. Use new hose clamps.

Tightening torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp 13 - 16 mm dia. 3 Nm (27 in-lb)

Hose clamp

42 - 48 mm dia. 4 Nm (36 in-lb)

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

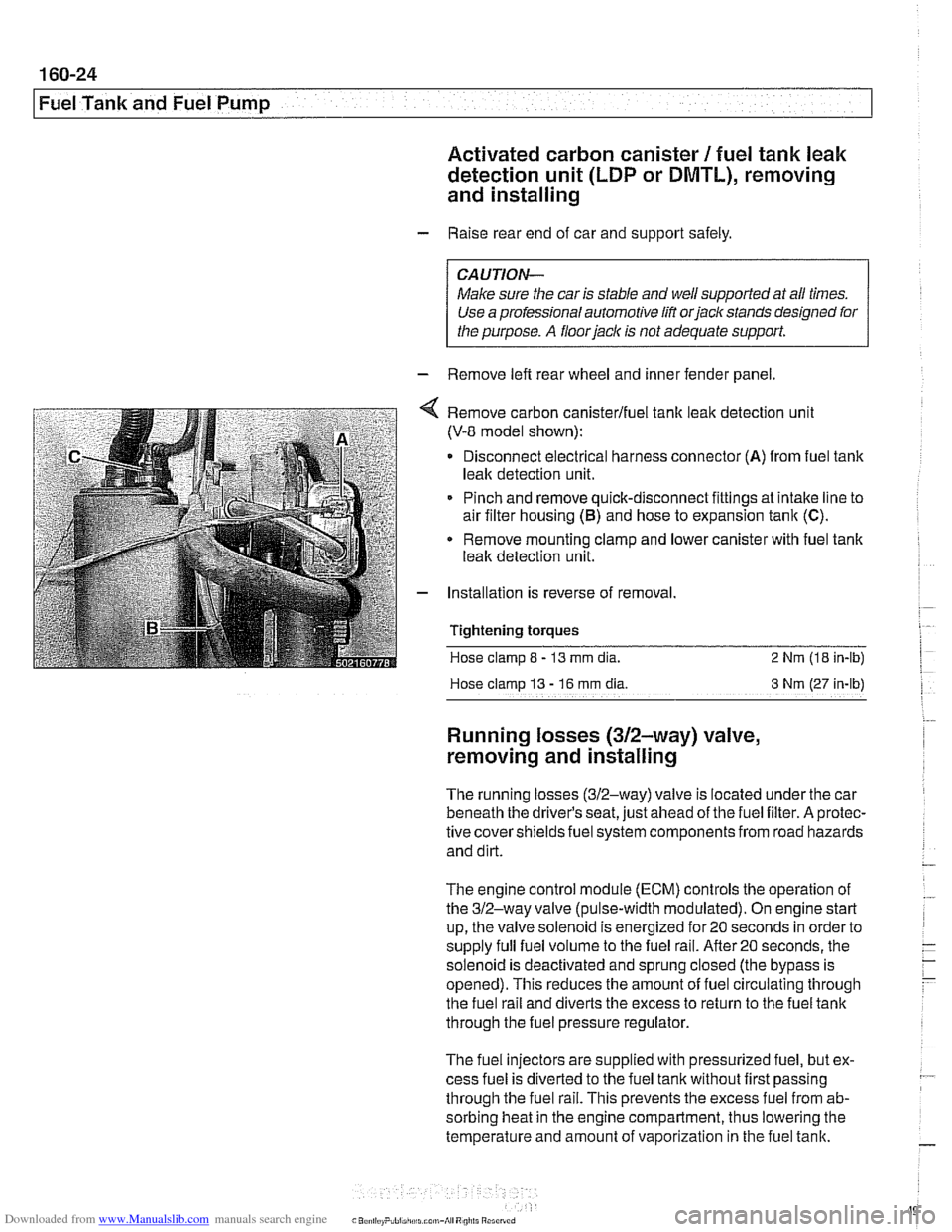

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 495 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-25

Fuel Tank and Fuel pump1

The 312-way valve is also activated briefly if an engine misfire

is detected. This provides full fuel flow through the fuel rail to

determine if the misfire was caused by a lean fuel condition.

The valve is monitored by the ECM forfaults.

- Using BMW or compatible scan tool, read out fault memory.

See

OBD On-Board Diagnostics.

- Turn off ignition.

- Raise car and support safely.

CA UTIOW

Male sure the car is stable and well suppodedat all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Worlting under car beneath driver's seat, remove protective

panel from fuel filter and 312-way valve.

- Clamp off fuel lines at 312-way valve.

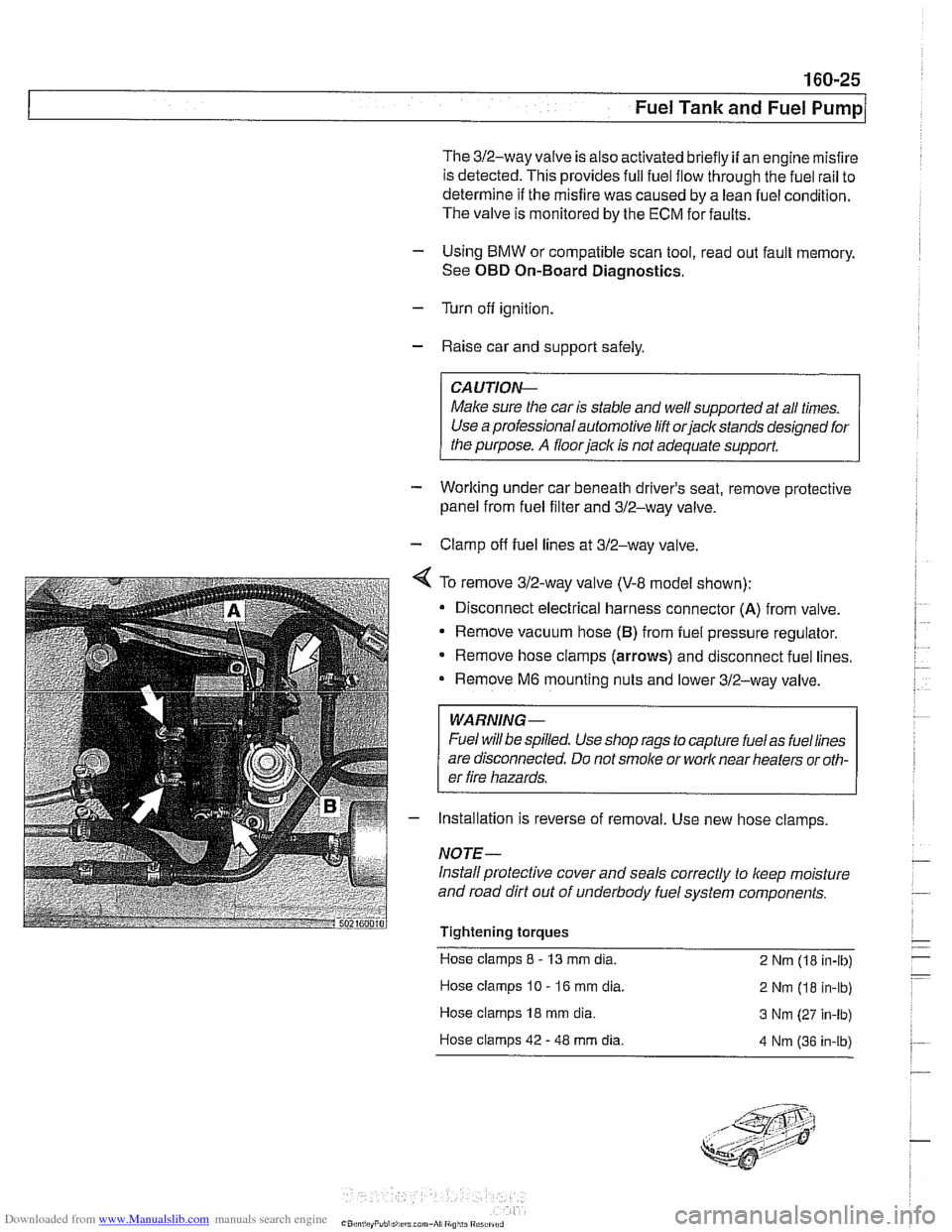

4 To remove 312-way valve (V-8 model shown):

Disconnect electrical harness connector

(A) from valve.

Remove vacuum hose

(B) from fuel pressure regulator.

* Remove hose clamps (arrows) and disconnect fuel lines.

Remove

M6 mounting nuts and lower 312-way valve.

WARNING-

Fuel will be spilled. Use shop rags to capture fuelas fuellines

are disconnected. Do not

smoke or work near heaters or oth-

er fire hazards.

- Installation is reverse of removal. Use new hose clamps

NOTE-

Install protective cover and seals correctly to keep moisture

and road dirt out of underbody fuel system components.

Tightening torques Hose clamps

8 - 13 mm dia.

2 Nm (18 in-lb)

Hose clamps

10 - 16 mm dia.

2 Nm (18 in-lb)

Hose clamps

18 mm dia. 3 Nm (27 in-lb)

Hose clamps 42

- 48 mm dia. 4 Nm 136 in-ib)