engine removal BMW 540i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 583 of 1002

Downloaded from www.Manualslib.com manuals search engine

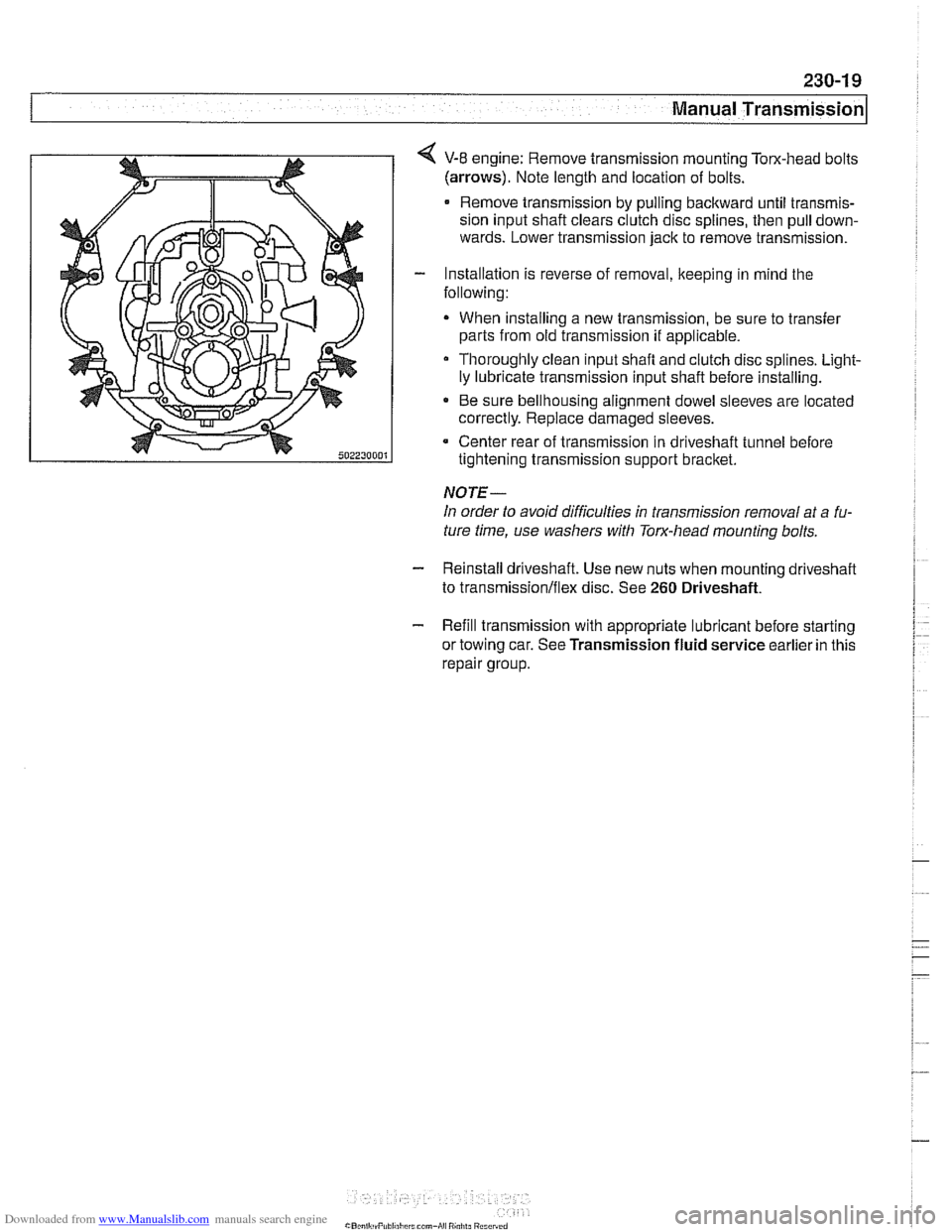

Manual Transmission

4 V-8 engine: Remove transmission mounting Tom-head bolts

(arrows). Note length and location of bolts.

Remove transmission by pulling backward until transmis-

sion input shaft clears clutch disc splines, then pull down-

wards. Lower transmission jack to remove transmission.

- Installation is reverse of removal, keeping in mind the

following:

When installing a new transmission, be sure to transfer

parts from old transmission

if applicable.

Thoroughly clean input shafl and clutch disc splines. Light-

ly lubricate transmission input shaft before installing.

* Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Center rear of transmission in driveshaft tunnel before

tightening transmission support bracket.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

- Reinstall driveshaft. Use new nuts when mounting driveshaff

to transmission/flex disc. See 260 Driveshaft.

- Refill transmission with appropriate lubricant before starting

or towing car. See Transmission fluid service earlier in this

repair group.

Page 585 of 1002

Downloaded from www.Manualslib.com manuals search engine

240 Automatic Transmission

General . . . . . . . . . . . . . . . . . . . . . .

Special tools . . . . . . . . . . . . . . . . . . .

Automatic transmission applications

. . . . . ,240-2 ATF, draining and filling . . . . . . . . . . . . . . . . 240-7

. . . . . ,240-2 Automatic transmission fluid

. . . . . ,240-4 pan and strainer. . . . . . . . . . . . . . . . . . . . . . 240-9

Troubleshooting . . . . . . . . . . . . . . . . . . .240-4 Transmission Removal

and Installation

. . . . . . . . . . . . . . . . . . . 240-10 Automatic Transmission Fluid Transmission, removing and installing . . . 240-10 (ATF) Service . . . . . . . . . . . . . . . . . . . . . ,240-6

Automatic transmission fluid (ATF) . . . . . . . ,240-6

ATF level, checking . . . . . . . . . . . . . . . . . . ,240-6

Page 586 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-2

/ ~utomatic Transmission

This section covers maintenance and replacement of the

automatic transmission for

E39 models.

Automatic transmission internal repairs are not covered.

Such repairs require special service equipment and knowl-

edge. If it is determined that transmission internal

sewice is

required, consult an authorized BMW dealer about a factory

reconditioned unit or a transmission rebuild.

CAUTION-

ATF does not circulate unless the engine is running. When

towing an automatic transmission vehicle, use a flat bed truck

or raise the rear wheels off the ground.

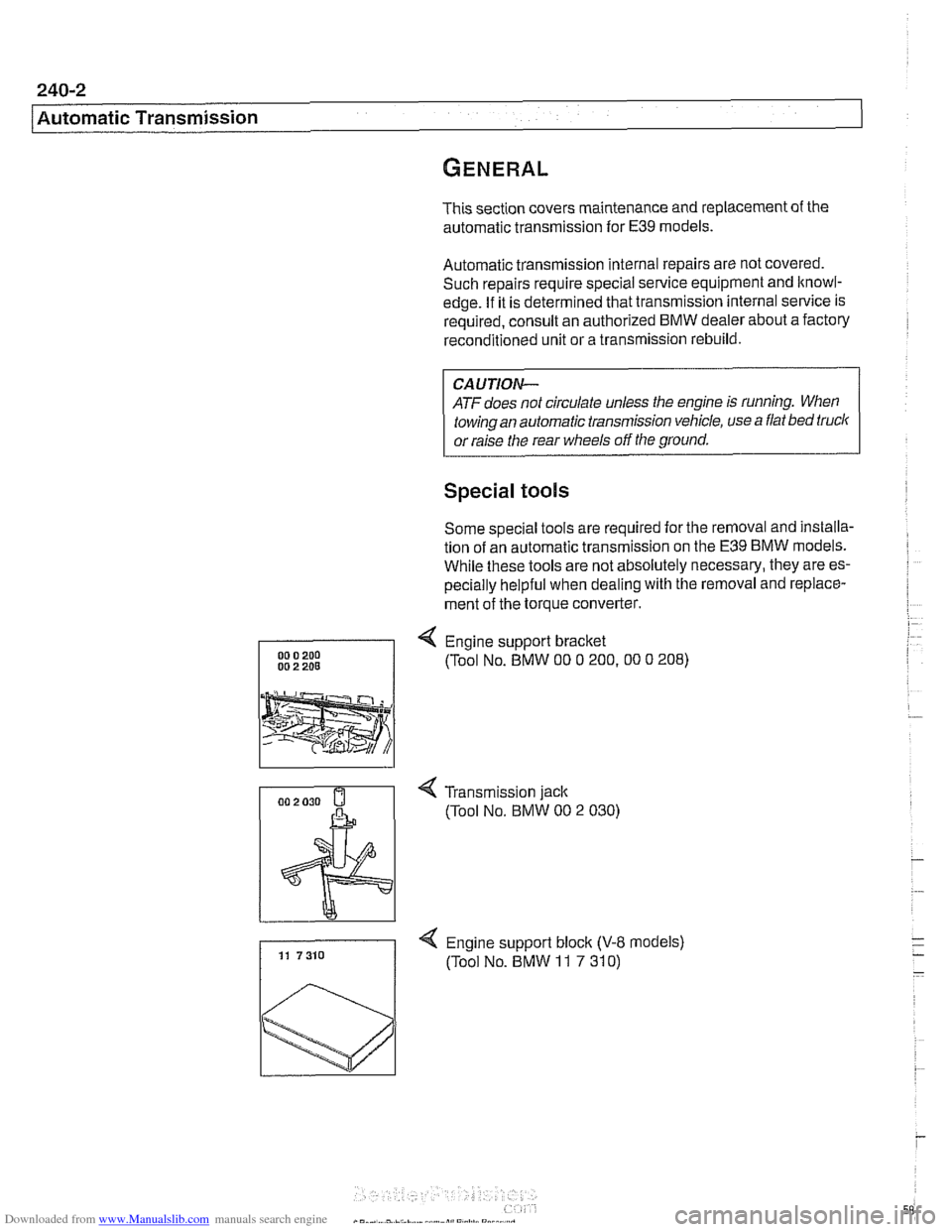

Special tools

Some special tools are required for the removal and installa-

tion of an automatic transmission on the

E39 BMW models.

While these tools are not absolutely necessary, they are es-

pecially helpful when dealing with the removal and replace-

ment of the torque converter.

4 Engine support bracket

(Tool No. BMW

00 0 200.00 0 208)

4 Transmission jack

(Tool No.

BMW 00 2 030)

4 Engine support block (V-8 models) 11 7310 (Tool No. BMW 11 7 310)

Page 591 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic Transmission

- Raise and safely support vehicle.

CA U JIOG

Male sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floorjack is not adequate support

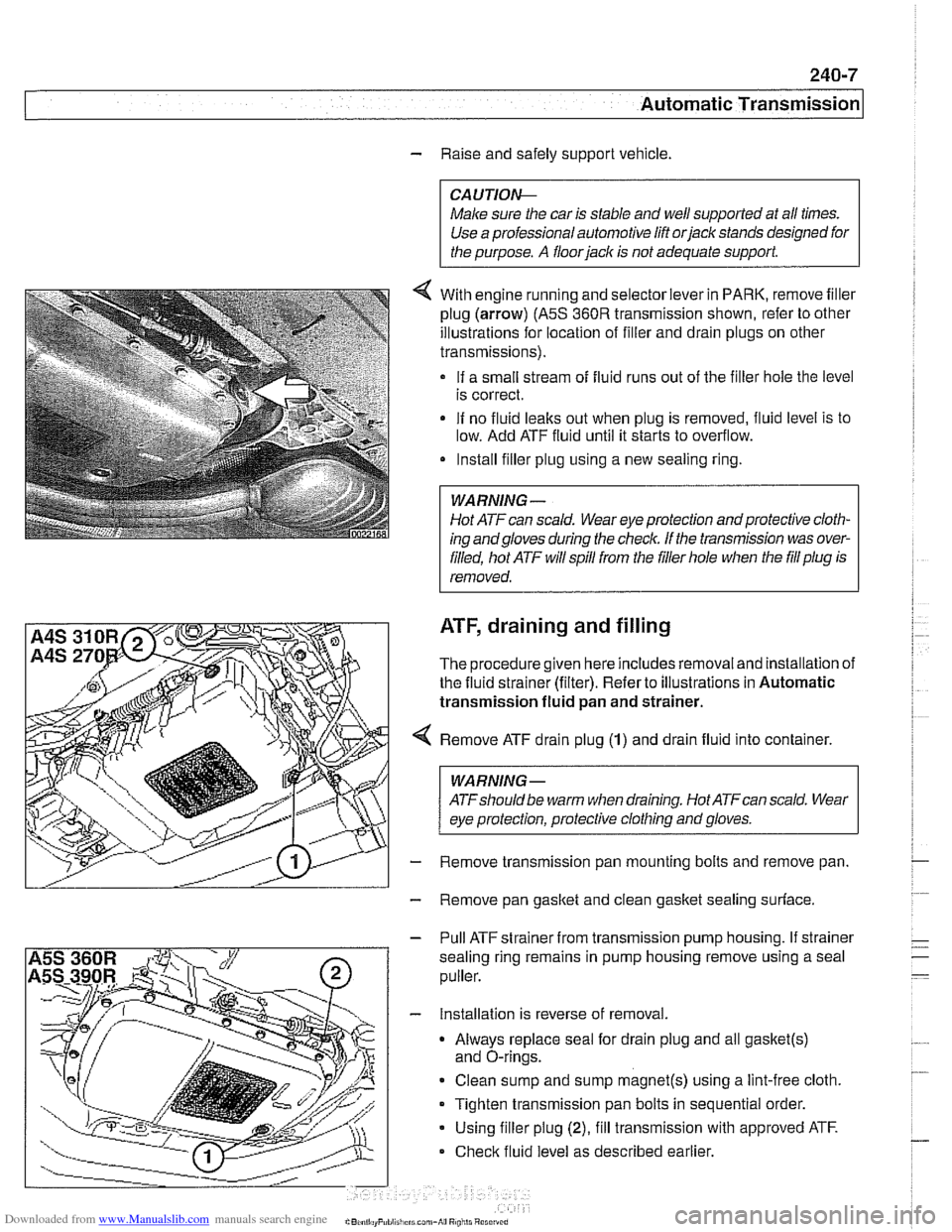

4 With engine running and selector lever in PARK, remove filler

plug (arrow)

(A5S 360R transmission shown, refer to other

illustrations for location of filler and drain plugs on other

transmissions).

If a small stream of fluid runs out of the filler hole the level

is correct.

If no fluid

leaks out when plug is removed, fluid level is to

low. Add ATF fluid until it starts to overflow.

Install filler plug using a new sealing ring.

Hot ATF can scald. Wear eye protection and protective cloth-

ing andgloves during

the check. If the tmnsmission was over-

filled, hot ATF will spill from the filler hole when the

fill plug is

removed.

ATF, draining and filling

The procedure given here includes removal and installation of

the fluid strainer (filter). Refer to illustrations in Automatic

transmission fluid

pan and strainer.

Remove ATF drain plug

(1) and drain fluid into container.

WARNING-

ATFshould be warm when draining. Hot ATFcan scald. Wear

eye protection, protective clothing and gloves.

Remove transmission pan mounting bolts and remove pan.

Remove pan gasket and clean

gasket sealing surface.

- Pull ATF strainer from transmission pump housing. If strainer

sealing ring remains in pump housing remove using a seal

puller.

- Installation is reverse of removal.

Always replace seal for drain plug and all

gasket(s)

and O-rings.

Clean sump and sump

magnet(s) using a lint-free cloth.

Tighten transmission pan bolts in sequential order.

Using filler plug

(2), fill transmission with approved ATF.

Check fluid level as described earlier.

Page 594 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 0

Automatic Transmission

TRANSMISSION REMOVAL AND

INSTALLATION

Removal and installation of the transmission is best accorn-

plished on an automotive lift using a transmission jack. Use

caution and safe workshop practices when working beneath

car and lowering transmission.

Torx-head bolts are used to mount the transmission to the

bellhousing.

Besure to have appropriate tools on hand before

starting the job.

WARNING-

Be sure the vehicle is properly supported. The removal of the

transmission may upset the balance of the vehicle on a lift

CAUJION-

Tilting the engine to remove the transmission can lead to

damaae to various components due to

laclc of clearance. 1

Transmission, removing and installing

WARNING -

Allow engine and transmission to cool down before starting

work on the transmission.

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warninas.

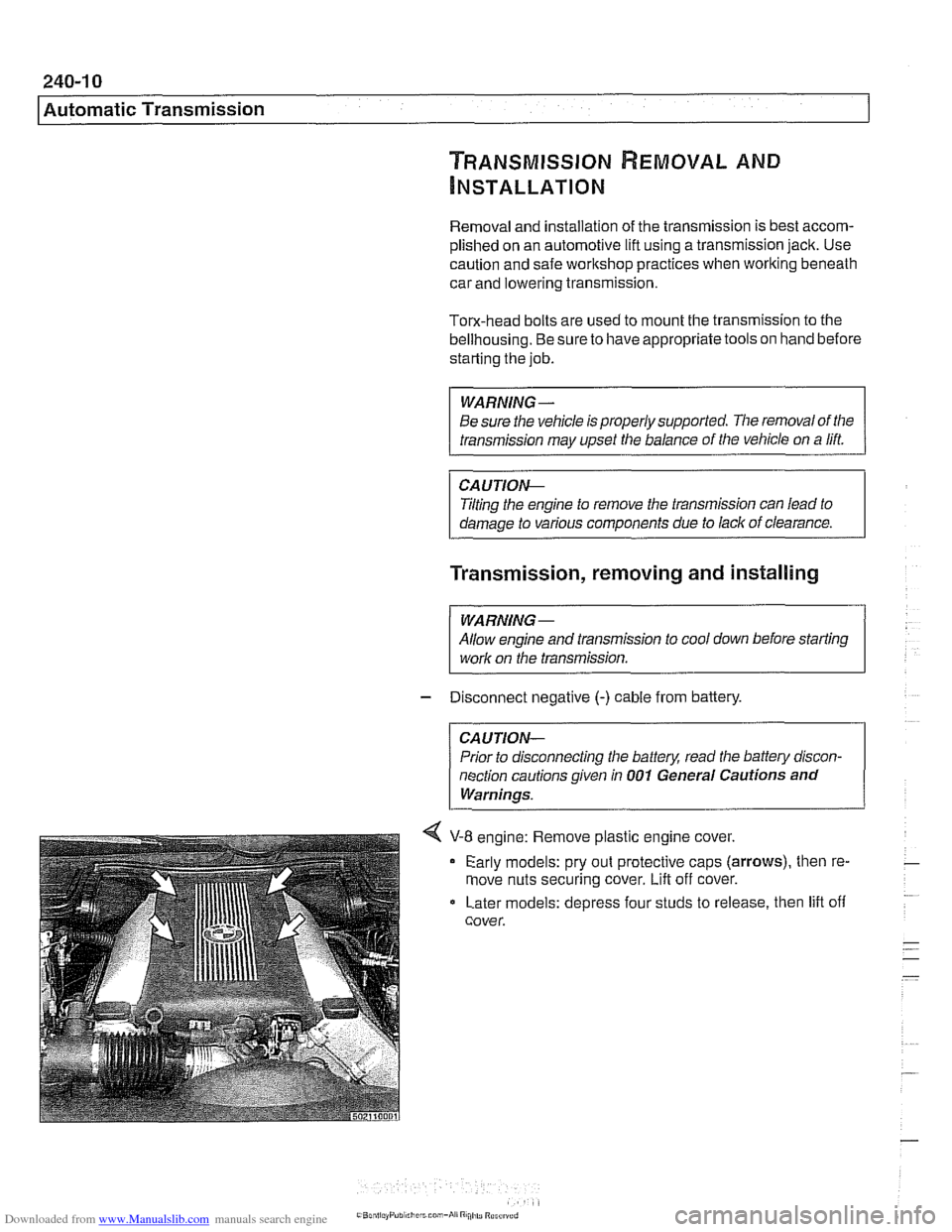

4 V-8 engine: Remove plastic engine cover.

Early models: pry out protective caps

(arrows), then re-

move nuts securing cover.

Lift off cover.

Later models: depress four studs to release, then lift off

cover.

Page 595 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic ~ransmissionl

II I

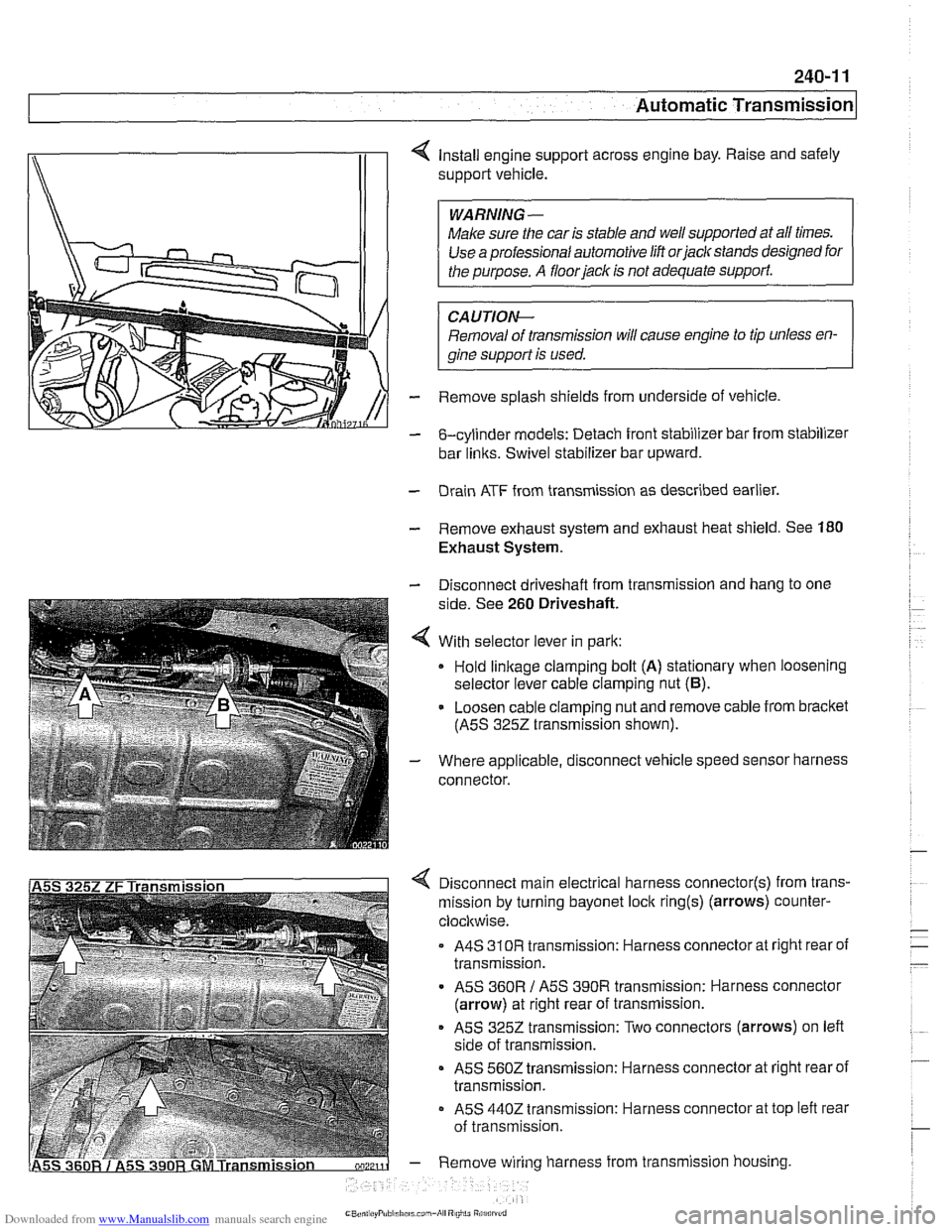

4 Install engine support across engine bay. Raise and safely

support vehicle.

Make sure the car is stable and

we1 supported at all times.

Use a professional automotive lift

orjaclc stands designed for

CAUTIOI\C

Removal of transmission will cause engine to tip unless en-

gine support is used.

- Remove splash shields from underside of vehicle.

- &cylinder models: Detach front stabilizer bar from stabilizer

bar

links. Swivel stabilizer bar upward.

- Drain ATF from transmission as described earlier.

- Remove exhaust system and exhaust heat shield. See 180

Exhaust System.

- Disconnect driveshaft from transmission and hang to one

side. See

260 Driveshaft.

4 With selector lever in park:

Hold

linkage clamping bolt (A) stationary when loosening

selector lever cable clamping nut

(6).

- Loosen cable clamping nut and remove cable from bracket

(ASS

3252 transmission shown).

- Where applicable, disconnect vehicle speed sensor harness

connector.

4 Disconnect main electrical harness connector(s) from trans-

mission by turning bayonet lock

ring(s) (arrows) counter-

clocltwise.

A4S

310R transmission: Harness connector at right rear of

transmission.

ASS

360R / ASS 390R transmission: Harness connector

(arrow) at right rear of transmission.

ASS 3252 transmission: Two connectors (arrows) on left

side of transmission.

ASS 5602 transmission: Harness connector at right rear of

transmission.

- ASS 4402 transmission: Harness connector at top left rear

of transmission.

- Remove wiring harness from transmission housing

Page 596 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic Transmission

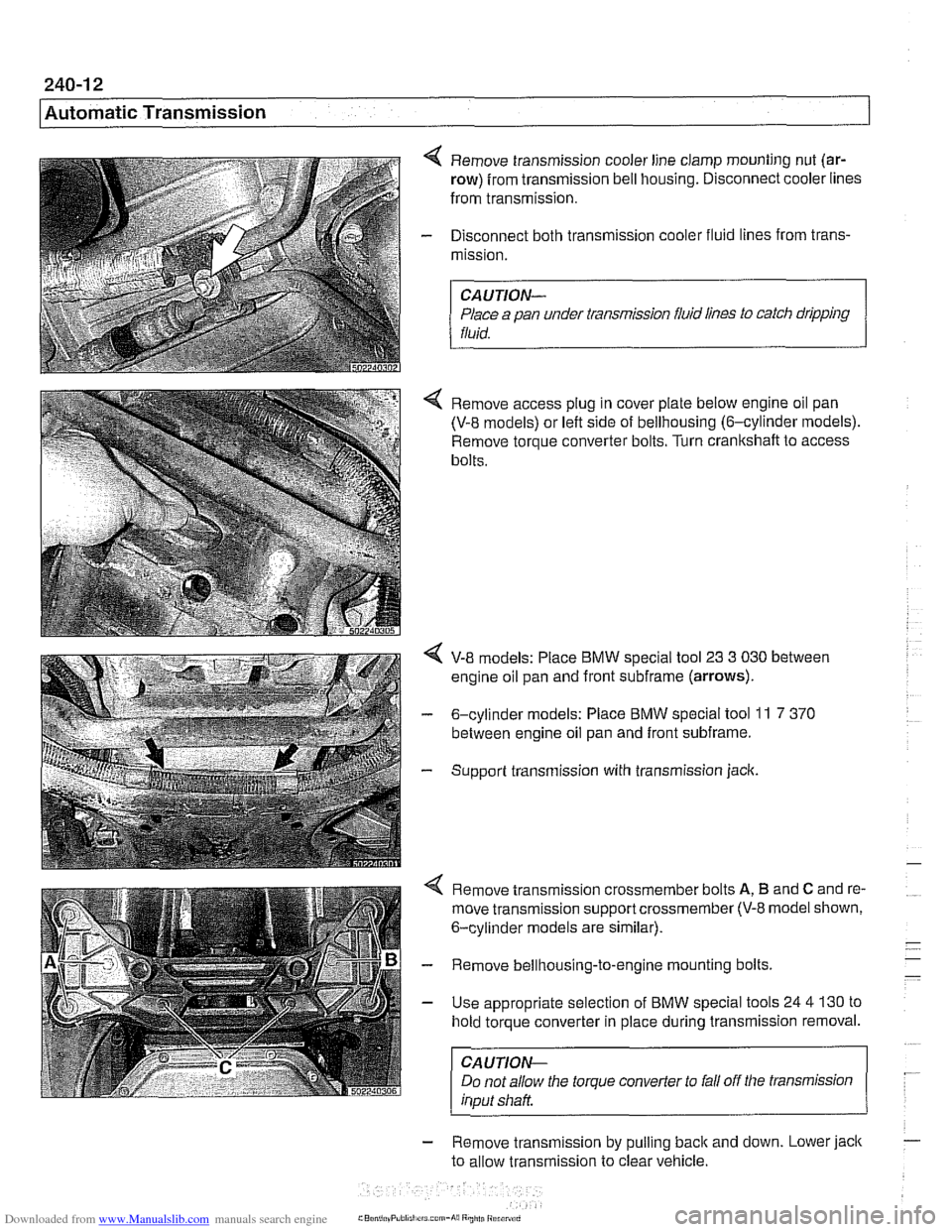

4 Remove transmission cooler line clamp mounting nut (ar-

row) from transmission bell housing. Disconnect cooler lines

from transmission.

- Disconnect both transmission cooler fluid lines from trans-

mission.

CAUTION-

Place a pan under transmission fluid lines to catch dripping

fluid.

4 Remove access plug in cover plate below engine oil pan

(V-8 models) or left side of bellhousing (6-cylinder models).

Remove torque converter bolts. Turn

cranltshaft to access

bolts.

V-8 models: Place BMW special tool 23 3 030 between

engine oil pan and front

subframe (arrows).

- 6-cylinder models: Place BMW special tool 11 7 370

between engine oil pan and front subframe.

- Support transmission with transmission jack.

4 Remove transmission crossmember bolts A, B and C and re-

move transmission support crossmember

(V-8 model shown,

6-cylinder models are similar).

- Remove bellhousing-to-engine mounting bolts.

- Use appropriate selection of BMW special tools 24 4 130 to

hold torque converter in place during transmission removal.

CAUTION-

Do not allow the torque converter to fall off the transmission

input shaft

- Remove transmlsslon by pull~ng back and down. Lower jack

to allow transmiss~on to clear vehicle.

rrs corn-hi8 Rniiti Riranrd

Page 597 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 3

Automatic ~ransmissionl

- Blow out oil cooler lines with low-pressure compressed air

and flush cooler with clean ATF twice before reattaching lines

to transmission.

CA UTIOG

Wear safety glasses when worling with compressed air:

@ Do not reuse ATF used for flushing.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Reinstall driveshafl using new nuts.

Install new sealing washers on transmission cooling line

banjo bolts.

Install new O-rings on transmission cooler lines, where

applicable.

Inspect engine drive plate (flywheel) for cracks or elongat-

ed holes. Replace

if necessary.

Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Checlc to be sure torque converter is seated correctly in

transmission during final installation.

Use

BMW special tool 24 2 300 to align three mounting

tabs on torque converter with indentations on drive plate

(flywheel).

Fill transmission with clean ATF until oil level is even with

fill hole. Then check fluid level as described earlier.

Adjust gearshift mechanism. See

250 Gearshift Linkage.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

Page 600 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-2

I Gearshift Linkage

This repair group covers transmission gearshift and linkage service for both manual and automatic transmission

equipped vehicles.

To gain access to the complete gearshift mechanism it is

necessary to remove the exhaust system and the driveshaft

as described in

180 Exhaust System and 260 Driveshaft.

NOTE-

In models with automatic transmission, the electronic immo-

bilizer

(EWS) prevents starter operation unless the gear po-

sition is Park or Neutral.

Special tools

BMW suggests the use of one special tool in the removal

of the gear shift lever for manual transmission equipped

I I vehicles.

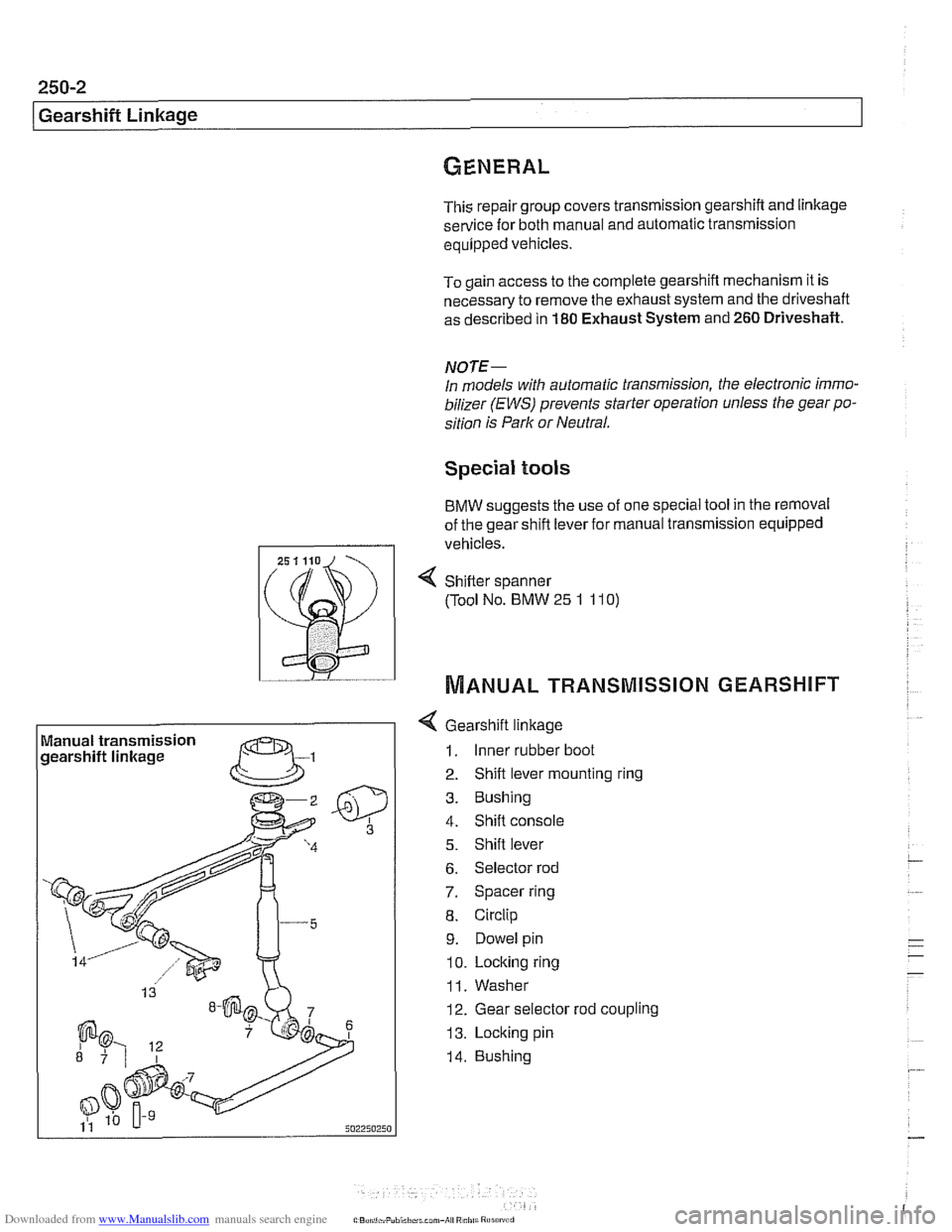

Manual transmission

gearshift linkage

--

4 Gearshift linkage

1. Inner rubber boot

2. Shift lever mounting ring

3. Bushing

4. Shift console

5. Shift lever

6. Selector rod

7. Spacer ring

8. Circlip

9. Dowel pin

10. Locking ring

11. Washer

12. Gear selector rod coupling

13. Locking pin

14. Bushing

4 Sh~fter spanner

(Tool No. BMW

25 1 11 0)

MANUAL TRANSMISSION GEARSHIFT

Page 609 of 1002

Downloaded from www.Manualslib.com manuals search engine

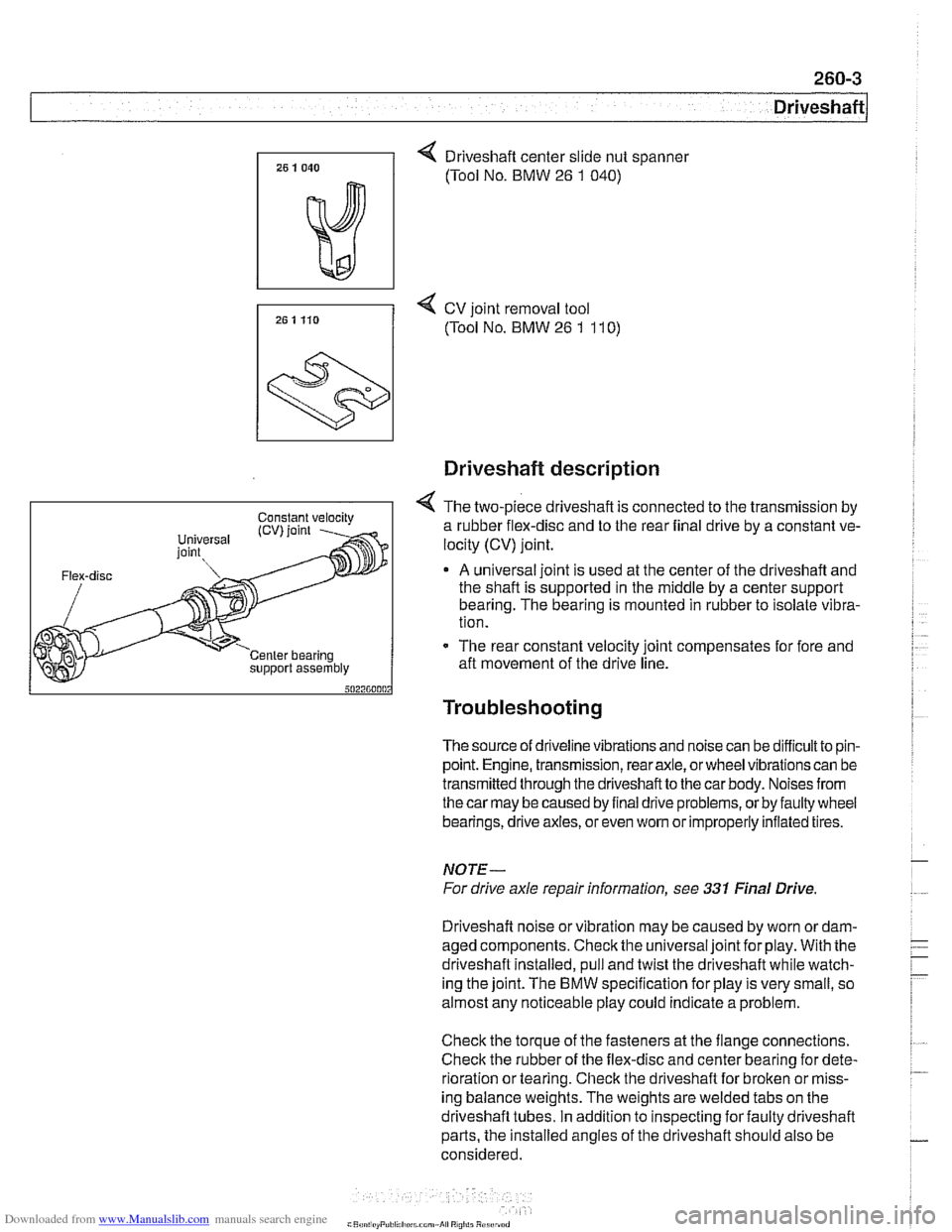

Driveshaft

4 Driveshaft center slide nut spanner

(Tool No. BMW

26 1 040)

7, 25 1 Ho 4 cv joint removal tool

(Tool No. BMW 26 1 11 0)

support assembly

Driveshaft description

4 The two-piece driveshaft is connected to the transmission by

a rubber flex-disc and to the rear final drive by a constant ve-

locity (CV) joint.

A universal joint is used at the center of the driveshaft and

the shaft is supported in the middle by a center support

bearing. The bearing is mounted in rubber to isolate vibra-

tion.

- The rear constant velocity joint compensates for fore and

aft movement of the drive line.

Troubleshooting

The source of driveline vibrations and noise can be difficultto pin-

point. Engine, transmission, rear axle, or wheel vibrations can be

transmitted through thedriveshaftto the car body. Noises from

thecar may be caused by final drive problems, or by faulty wheel

bearings, drive axles, or even

wom or improperly inflated tires.

NOTE-

For drive axle repair information, see 331 Final Drive

Driveshaft noise or vibration may be caused by worn

ordam-

aged components. Check the universal joint for play. With the

driveshaft installed, pull and twist the driveshaft while watch-

ing the joint. The

BMW specification for play is very small, so

almost any noticeable play could indicate a problem.

Check the torque of the fasteners at the flange connections.

Check the rubber of the flex-disc and center bearing for dete-

rioration or tearing. Check the driveshaft for broken or miss-

ing balance weights. The weights are welded tabs on the

driveshaft tubes. In addition to inspecting for faulty driveshaft

parts, the installed angles of the driveshaft should also be

considered.