locking BMW 540i 1998 E39 Owners Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 653 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-1 7

Front ~uspensionl

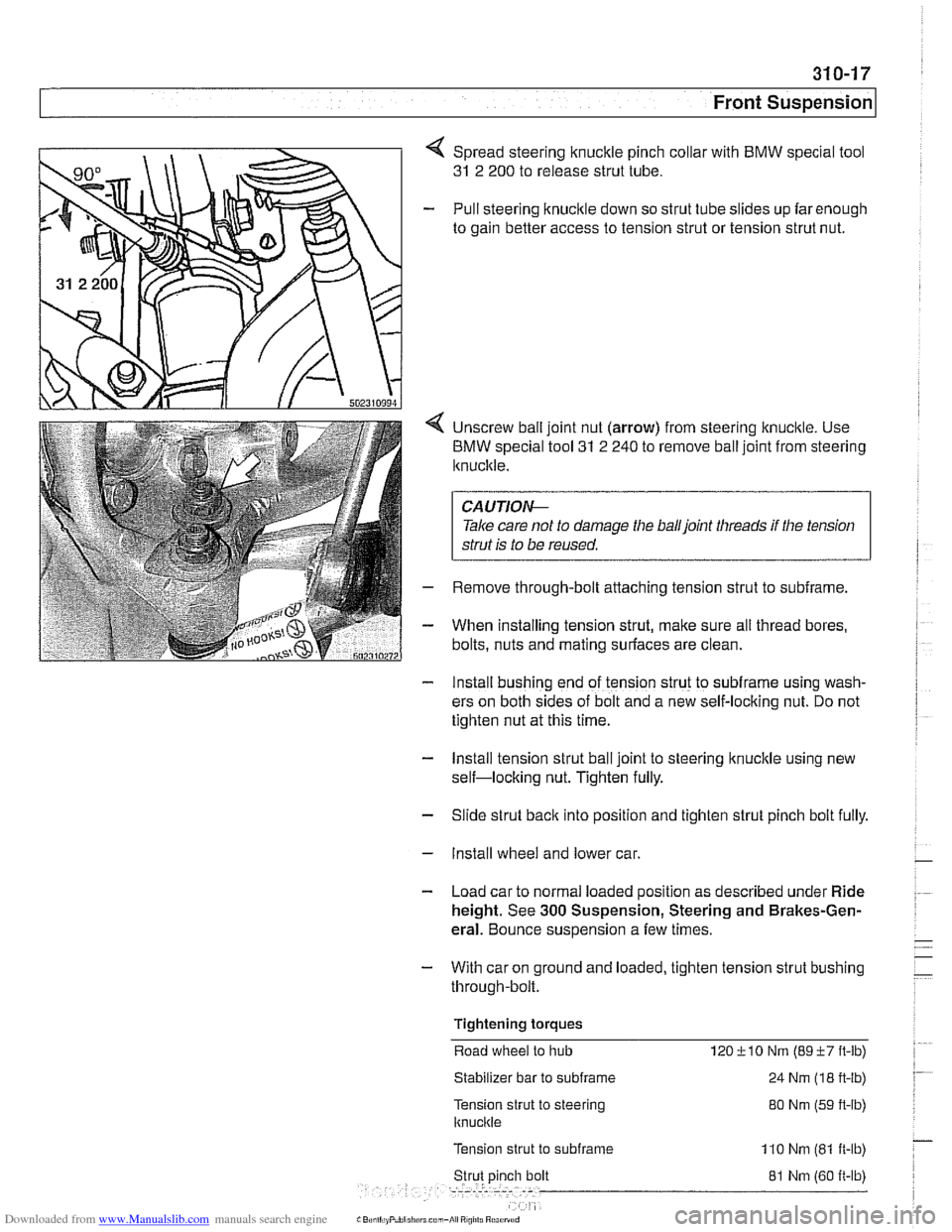

< Spread steering knuckle pinch collar with BMW special tool

31 2 200 to release strut tube.

- Pull steering knuckle down so strut tube slides up farenough

to gain better access to tension strut or tension strut nut.

4 Unscrew ball joint nut (arrow) from steering knuckle. Use

BMW special tool

31 2 240 to remove ball joint from steering

Iknucltle.

CAUTION--

Tale care not to damage the balljoint threads if the tension

strut

is to be reused.

- Remove through-bolt attaching tension strut to subframe.

- When installing tension strut, make sure all thread bores,

bolts, nuts and mating

suriaces are clean.

- Install bushing end of tension strut to subframe using wash-

ers on both sides of bolt and a new self-locking nut. Do not

tighten nut at this time.

- Install tension strut ball joint to steering knuckle using new

self-locking nut. Tighten fully.

- Slide strut back into position and tighten strut pinch bolt fully.

- Install wheel and lower car.

- Load car to normal loaded position as described under Ride

height. See

300 Suspension, Steering and Brakes-Gen-

eral. Bounce suspension a few times.

- With car on ground and loaded, tighten tension strut bushing

through-bolt.

Tightening torques Road

wheel to hub 120-i-10 Nm (89+7ft-lb)

Stabilizer bar to subframe 24 Nm (1 8 ft-lb)

Tension strut to steering

knucltle

80 Nm (59 ft-lb)

Tension strut

to subframe 110 Nm (81 ft-lb)

81 Nm (60 it-lb)

L BcniliiyFlrblrillirn con,-*I R!,illJ Rci,:n>d

Page 657 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-21

Front Suspension

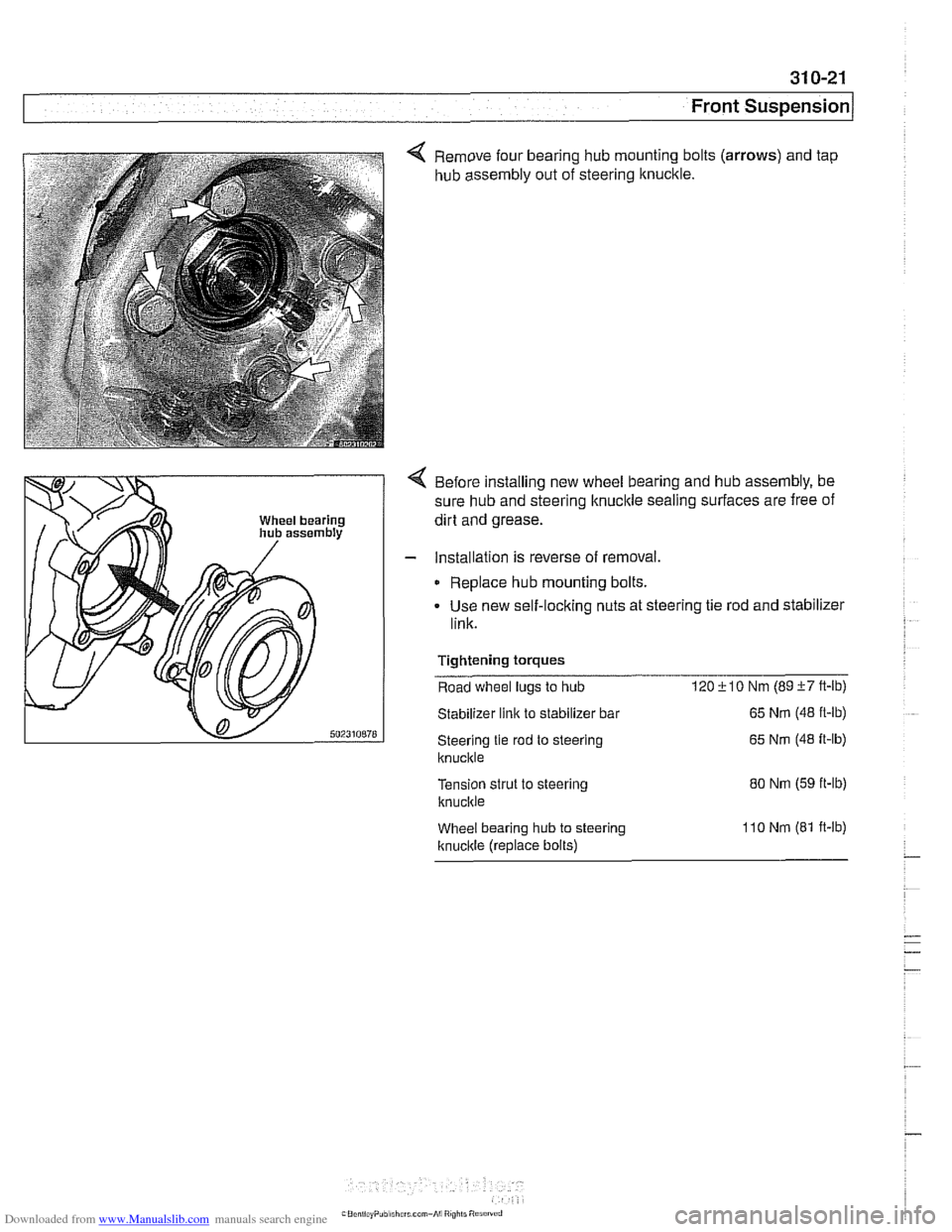

4 Remove four bearing hub mounting bolts (arrows) and tap

hub assembly out of steering knuckle.

4 Before installing new wheel bearing and hub assembly, be

sure hub and steering knuckle sealing surfaces are free of

dirt and grease.

- Installation is reverse of removal.

Replace hub mounting bolts.

Use new self-locking nuts at steering tie rod and stabilizer

link.

Tightening

torques

Road wheel lugs to hub 120i-10 Nm (89i-7ft-lb)

Stabilizer link to stabilizer bar

Steering tie rod to steering

ltnuckle

Tension strut to steering

knucltie

Wheel bearing hub to steering

Itnucltle (replace bolts)

65 Nm (48 ft-lb)

65

Nm (48 it-lb)

80 Nm (59 ft-lb)

1

lo Nm (81 ft-lb)

Page 658 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-22

I Front Suspension

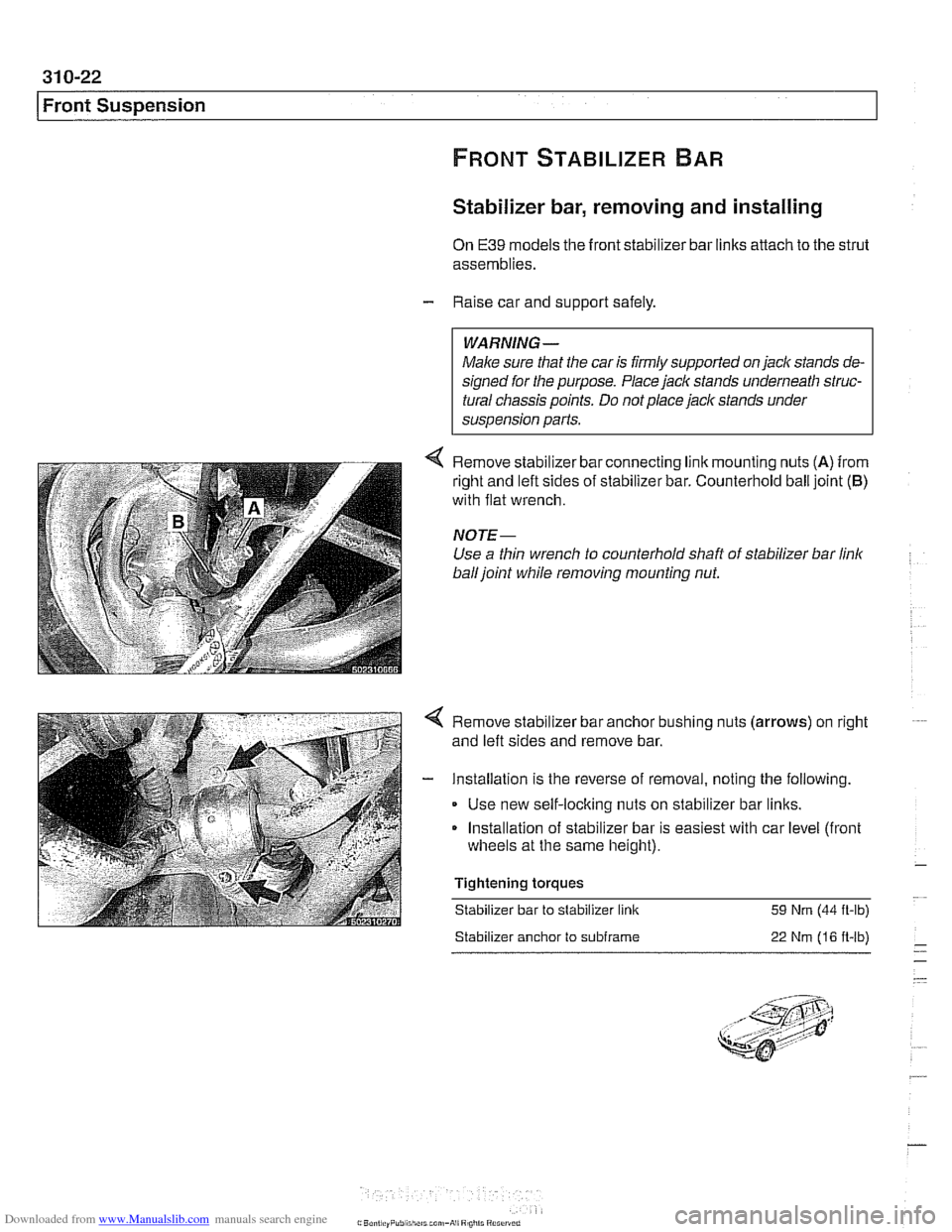

Stabilizer bar, removing and installing

On E39 models the front stabilizer bar links attach to the strut

assemblies.

- Raise car and support safely.

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jaclc stands under

suspension parts.

< Remove slaol zer bar connecring I nk rnounl ng nLts (A) from

r~glit and eft s~des of slaol lzer bar C~~nIerhol~ ball ]olnl (6)

with flat wrench

NOTE-

Use a thin wrench to counterhold shaft of stabilizer bar link

ball joint while removing mounting nut.

< Remove stabilizer bar anchor bushing nuts (arrows) on right

and left sides and remove bar.

- Installation is the reverse of removal, noting the following.

Use new self-locking nuts on stabilizer bar links.

Installation of stabilizer bar is easiest with car level (front

wheels at the same height).

Tightening torques Stabilizer bar to stabilizer link

59 Nm (44 ft-lb)

Stabilizer anchor to subframe 22 Nm (16 ft-lb)

Page 664 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

Steering system warnings and cautions

WARNING -

The BMW airbag system is complex. Special precautions

must be observed when servicing the system. Serious in-

jury may result if system service is attempted by persons

unfamiliar with the BMW

airbag system and its approved

service procedures. BMW specifies that all inspection and

service should be

peiformed by an authorized BMW deal-

e,:

The BMW E39 is equipped with an airbag mounted in

the steering wheel. The

airbag is an explosive device

and should be treated with extreme caution. Always fol-

low the

airbag removal procedure as outlined in 721

Airbag System (SRS).

BMW airbags are equipped with a bacli-up power sup-

ply inside the

airbag control module. A 5 second wait-

ing period should be observed after the battery cable

has been disconnected. This will allow the reserve

power supply to discharge.

Do not reuse self-locking nuts. They are designed to

be used only once and may fail if reused. Always re-

place them with new locliing nuts.

* Do not install bolts and nuts coated with undercoating

wax, as correct tightening torque cannot be assured.

Always clean the threads with solvent before installa-

tion, or install new parts.

Do not attempt to weld or straighten any steering com-

ponents. Always replace damagedparts.

CAUTION--

- Some E39 models are equipped with aluminum suspen.

sion components. The following cautions apply:

Due to the chemical and corrosion characteristics of

aluminum, do not bring into contact with battery acid.

Do not clean with wire brushes with brass or iron bris-

tles. Only use brushes with stainless steel bristles.

Do

not expose to flying sparks from grindinghutting op-

erations.

Do not subject to steel welding splashes.

* Do not expose to temperatures over 80% (176°F).

even for short periods. Temperatures in painting iacili-

ties are not a problem.

Page 677 of 1002

Downloaded from www.Manualslib.com manuals search engine

i Steering and Wheel Alignment

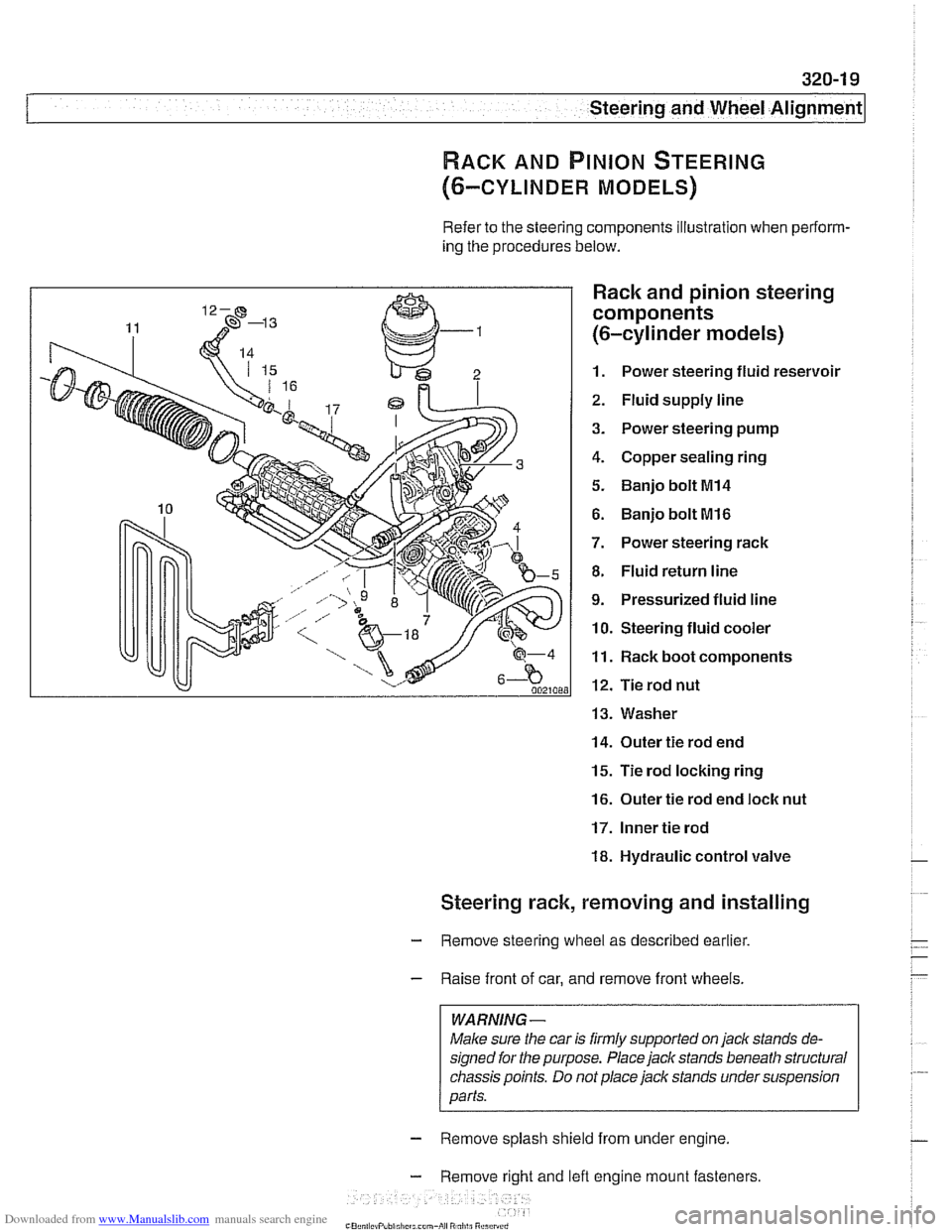

RACK AND PINION STEERING

(6-CYLINDER MODELS)

Refer to the steering components illustration when perform-

ing the procedures below.

Rack and pinion steering

components

(6-cylinder models)

1. Power steering fluid reservoir

2. Fluid supply line

3. Power steering pump

4. Copper sealing ring

5. Banjo bolt MI4

6. Banjo bolt MI6

7. Power steering rack

8. Fluid return line

9. Pressurized fluid line

10. Steering fluid cooler

11. Rack boot components

12. Tie rod nut

13. Washer

14. Outer tie rod end

15. Tie rod locking ring

16. Outer tie rod end loclc nut

17. Inner tie rod

18. Hydraulic control valve

Steering rack, removing and installing

- Remove steering wheel as described earlier.

- Raise front of car, and remove front wheels.

WARNING -

Male sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do

not place jack stands under suspension

parts.

- Remove splash shield from under engine.

- Remove right and lefl engine mount fasteners

-" ., - , . ,

Page 679 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel ~lignmentl

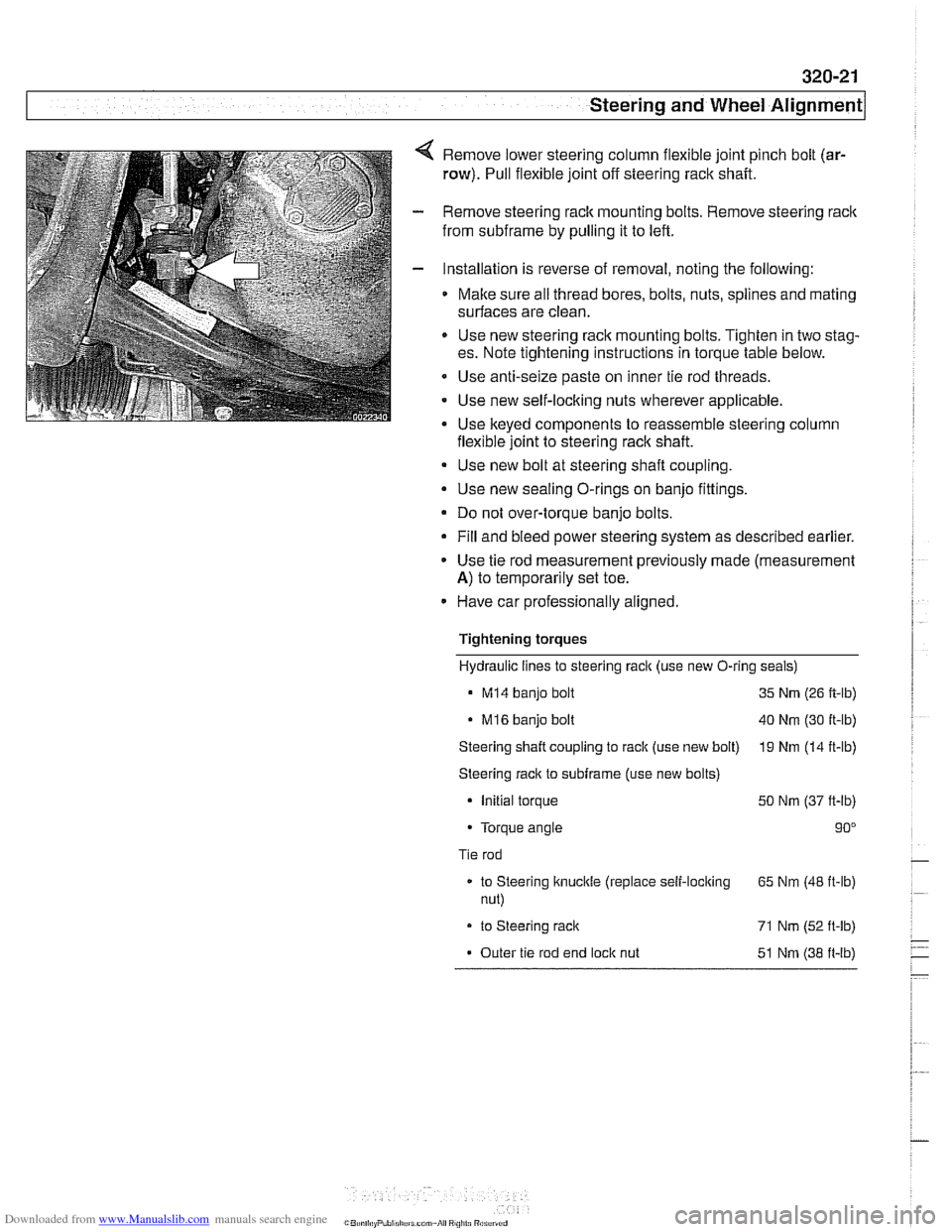

Remove lower steering column flexible joint pinch bolt (ar-

row). Pull flexible joint off steering rack shaft.

Remove steering rack mounting bolts. Remove steering

raclc

from subframe by pulling it to left.

Installation is reverse of removal, noting the following:

Make sure all thread bores, bolts, nuts, splines and mating

surfaces are clean.

Use new steering rack mounting bolts. Tighten in two stag-

es. Note tightening instructions in torque table below.

Use anti-seize paste on inner tie rod threads.

Use new self-loclting nuts wherever applicable.

Use keved

comDonents to reassemble steerino column

flexible\oint to ;teering raclt shaft. u

Use new bolt at steering shaft coupling.

Use new sealing O-rings on banjo fittings.

Do not over-torque banjo bolts.

Fill and bleed power steering system as described earlier.

Use tie rod measurement previously made (measurement

A) to temporarily set toe.

Have car professionally aligned.

Tightening torques Hydraulic lines to steering rack (use new O-ring

seals)

M14 banjo bolt 35 Nrn (26 ft-lb)

. M16 banjo bolt 40 Nm (30 ft-lb)

Steering shaft coupling

to rack (use new bolt) 19 Nm (14 it-lb)

Steering rack to subframe (use new bolts)

- initial torque 50 Nm (37 ft-lb)

Torque angle 90"

Tie rod

to Steering knuckle (replace self-locking

65 Nm (48 ft-lb)

nut)

- to Steering rack 71 Nm (52 ft-ib)

Outer tie rod end lock nut

51 Nm (38 ft-lb)

Page 680 of 1002

Downloaded from www.Manualslib.com manuals search engine

--. --

Steering and Wheel Alignment

Steering rack boot, replacing

- Remove outer tie rod end. See Tie rod (outer), replacing

- Cut rack boot band clamps and remove boot.

- Cut rack boot band clamp and slide bellows back. Inspect

boot for any sign of damage. Replace

if necessary.

NOTE-

New rack boot lit comes with new band clamp.

- Grease tie rod taper so that small end of rack boot slides on

tie rod when tie rod is tightened, preventing raclc boot from

twisting.

- Slide new boot into position and replace band clamps

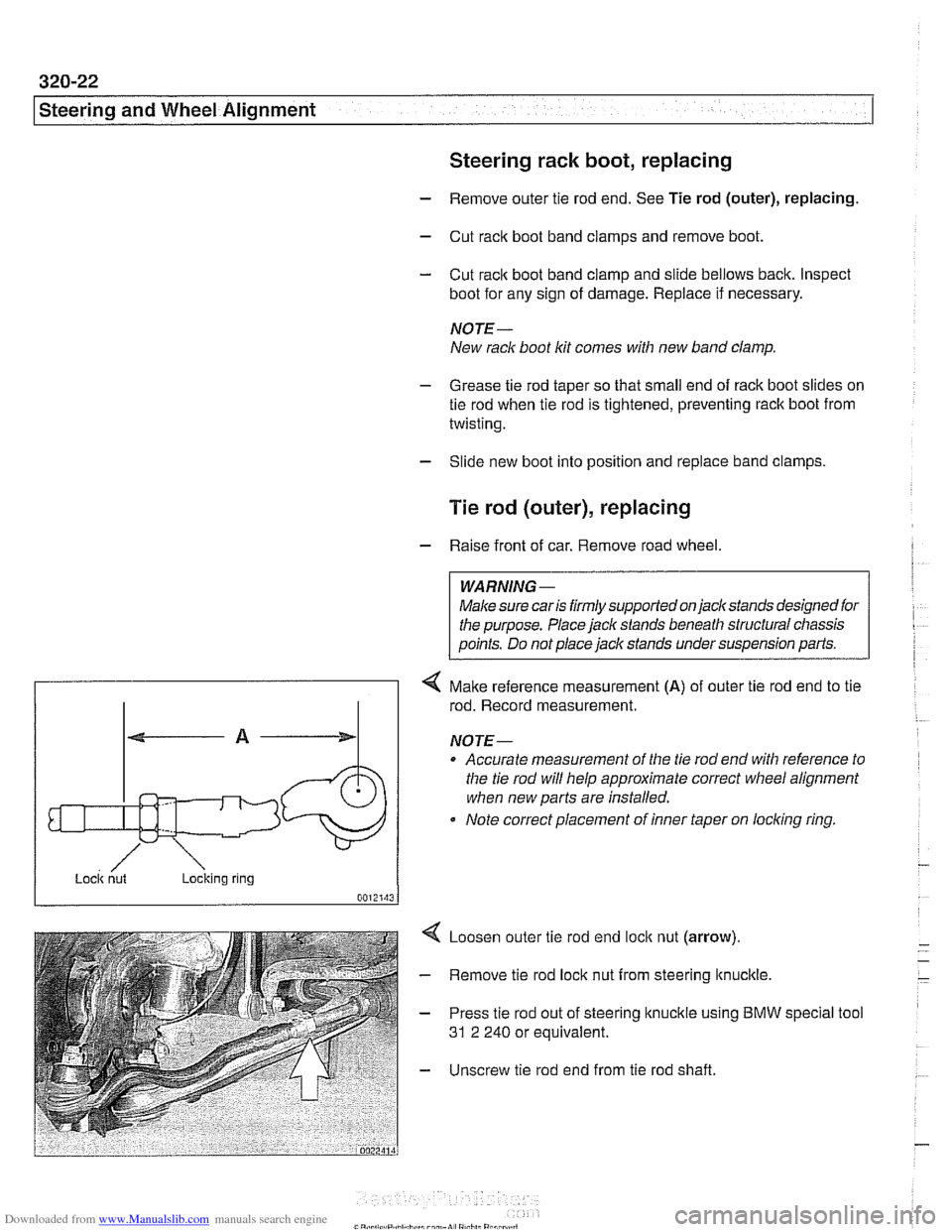

Tie rod (outer), replacing

LOCI( nut Locking ring

- Raise front of car. Remove road wheel

WARNING-

Male sure caris firmly suppoiiedon jackstands designed for

the purpose. Place jack stands beneath structural chassis

ooints. Do not olace iack stands under

susoension oaiis.

4 Make reference measurement (A) of outer tie rod end to tie

rod. Record measurement.

NOTE-

Accurate measurement of the tie rod end with reference to

the tie rod will help approximate correct

wheel alignment

when new parts are installed.

Note correct placement of inner taper on

loclcing ring.

Loosen outer tie rod end

loclc nut (arrow).

Remove tie rod lock nut from steering

ltnuclcle.

Press tie rod out of steering knuckle using BMW

31 2 240 or equivalent. special tool

Unscrew tie rod end from tie rod shaft.

Page 681 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

- lnstallation is reverse of removal.

Make sure all threaded parts are clean.

Use anti-seize paste on inner tie rod threads.

Use new self-locking nuts, where applicable.

Use tie rod measurement

(A) to set toe temporarily.

Have car professionally aligned.

Tightening torque

Tie rod

to steering itnuckle (replace seii-loclting nut) 65 Nm ( 46 ft-lb)

Outer tie rod end ioclt nut 51 Nm (38 ft-ib)

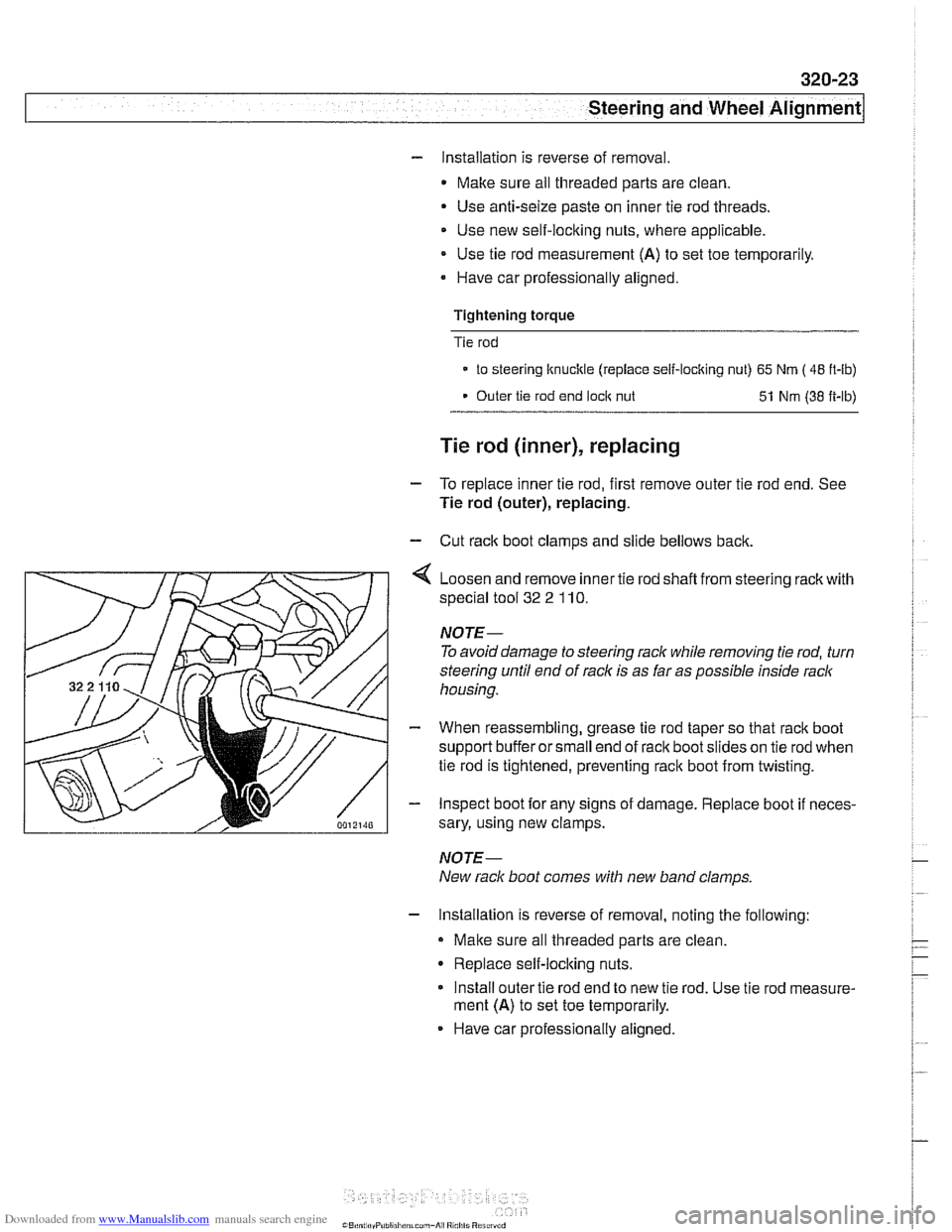

Tie rod (inner), replacing

- To replace inner tie rod, first remove outer tie rod end. See

Tie rod (outer), replacing.

- Cut rack boot clamps and slide bellows back

4 Loosen and remove inner tie rod shafl from steering rack with

special tool

32 2 110.

NOTE-

To avoid damage to steering rack while removing tie rod, turn

steering until end of rack is as far as possible inside rack

housing.

- When reassembling, grease tie rod taper so that rack boot

support buffer or small end of rack boot slides on tie rod when

tie rod is tightened, preventing rack boot from twisting.

- Inspect boot for any signs of damage. Replace boot if neces-

sary, using new clamps.

NOTE-

New rack boot comes with new band clamps

- Installation is reverse of removal, noting the following:

Make sure all threaded parts are clean

Replace self-locking nuts.

Install outer tie rod end to new tie rod. Use tie rod measure-

ment

(A) to set toe temporarily.

Have car professionally aligned.

Page 682 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

Tightening torques

Tie rod

to Steering knuckle (replace self-locking nut) 65 Nm (48 it-lb)

to Steering rack 71 Nrn (52 ft-lb)

Outer tie rod end lock nut 51 Nrn (38 ft-lb)

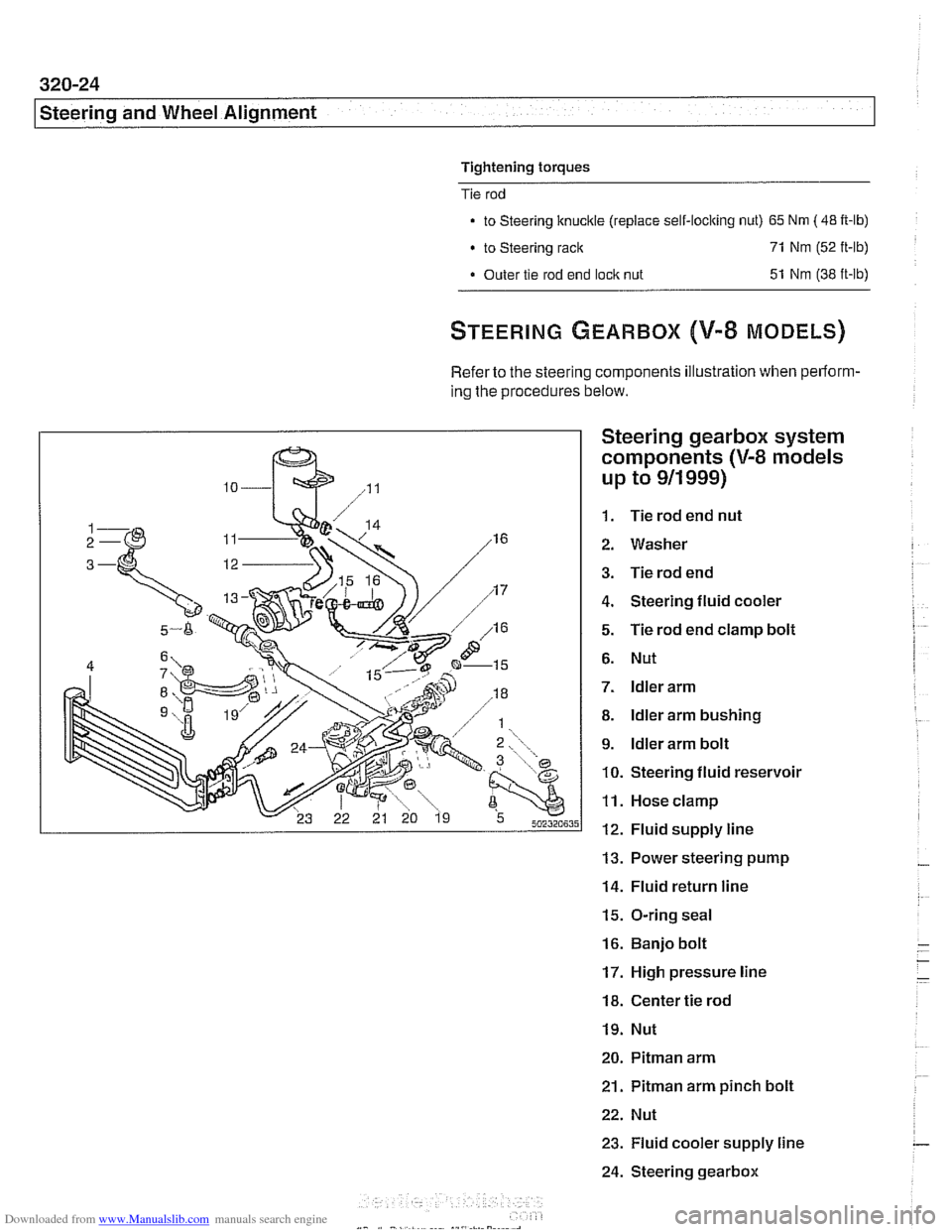

Refer to the steering components illustration when perform-

ing the procedures below.

Steering gearbox system

components

(V-8 models

up to

911 999)

1. Tie rod end nut

2. Washer

3. Tie rod end

4. Steering fluid cooler

5. Tie rod end clamp bolt

6. Nut

7. ldler arm

8. ldler arm bushing

9. ldler arm bolt

10. Steering fluid reservoir

11. Hose clamp

12. Fluid supply line

13. Power steering pump

14. Fluid return line

15. O-ring seal

16. Banjo bolt

17. High pressure line

18. Center tie rod

19. Nut

20. Pitman arm

21.

Pitman arm pinch bolt

22. Nut

23. Fluid cooler supply line

24. Steering gearbox

Page 684 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

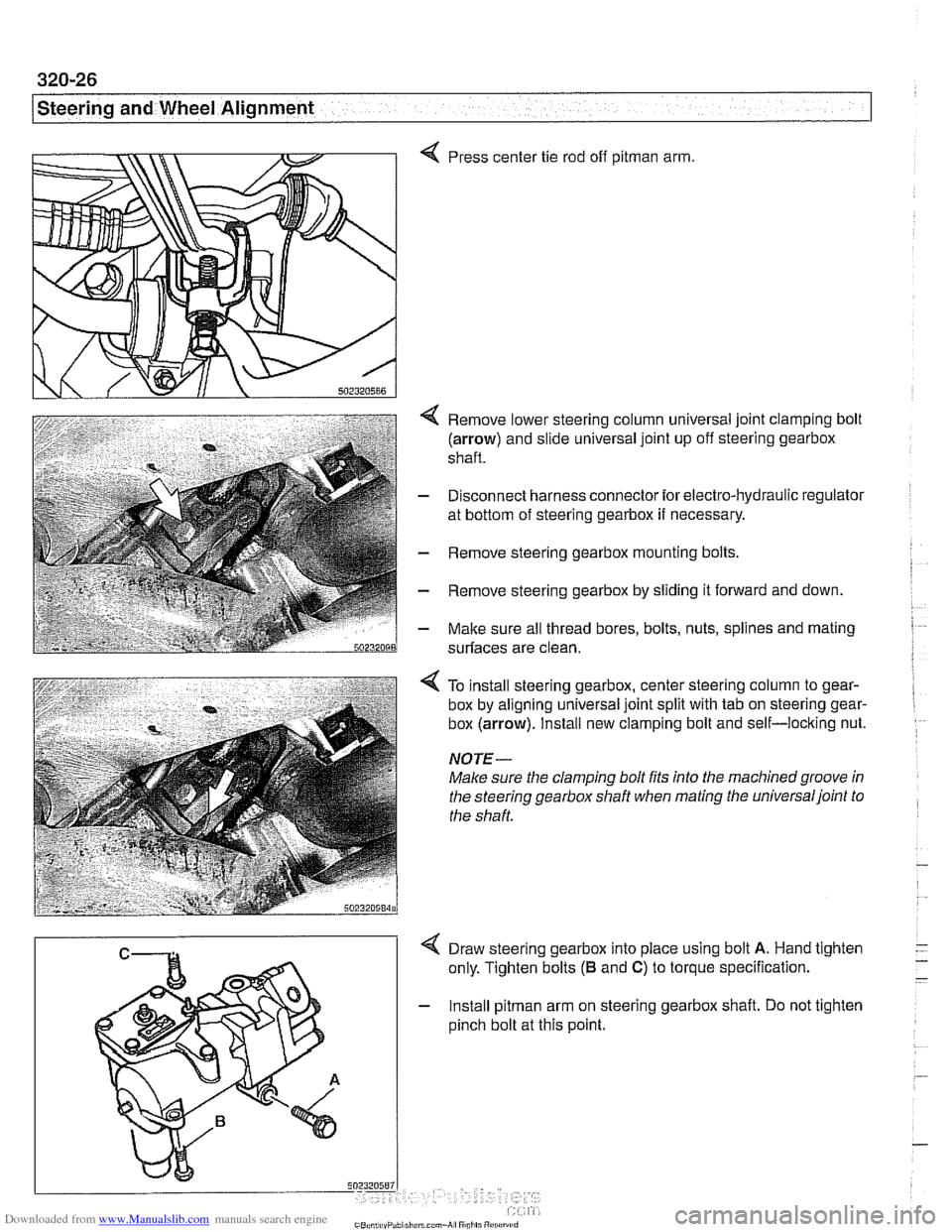

Press center tie rod off pitman arm.

Remove lower steering column universal joint clamping bolt

(arrow) and slide universal joint up off steering gearbox

shaft.

Disconnect harness connector for electro-hydraulic regulator

at bottom of steering gearbox

if necessary.

Remove steering gearbox mounting bolts

Remove steering gearbox by sliding it forward and down.

Malte sure all thread bores, bolts, nuts, splines and mating

surfaces are clean.

4 To install steering gearbox, center steering column to gear-

box by aligning universal joint split with tab on steering gear-

box

(arrow). Install new clamping bolt and self-locking nut.

NOTE-

Make sure the clamping bolt fits into the machinedgroove in

the steering gearbox shaft when mating the universaljoint to

the shaft.

4 Draw steering gearbox into place using bolt A. Hand tighten

only. Tighten bolts

(B and C) to torque specification.

- Install pitman arm on steering gearbox shaft. Do not tighten

pinch bolt at this point.