locking BMW 540i 1998 E39 Manual Online

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 602 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-4

I Gearshift Linkage

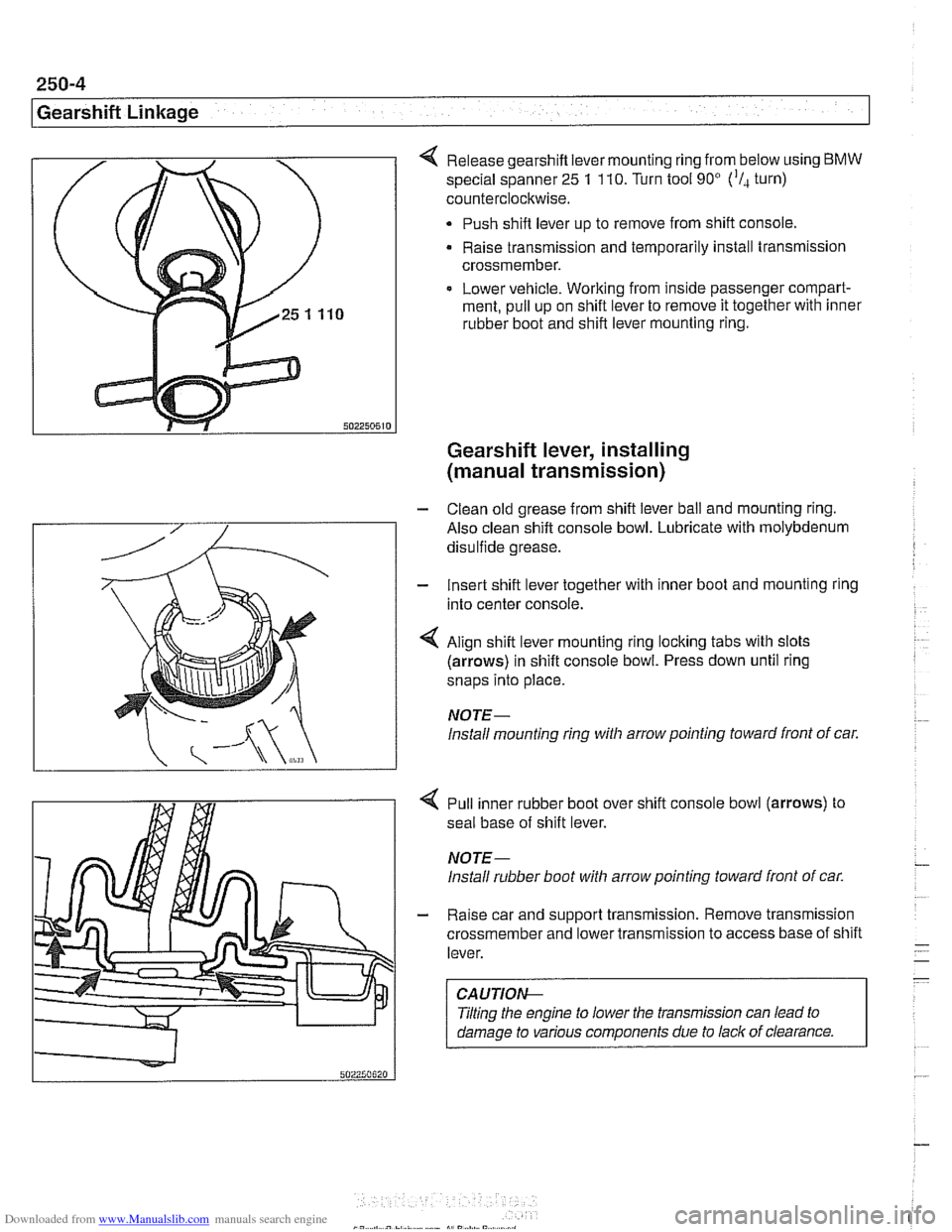

Release gearshift lever mounting ring from below using BMW

special spanner 25 1 110. Turn tool 90' ('I, turn)

counterclockwise.

Push shift lever up to remove from shift console,

Raise transmission and temporarily install transmission

crossmember.

Lower vehicle. Working from inside passenger compart-

ment, pull up on shift lever to remove it together with inner

rubber boot and shift lever mounting ring.

Gearshift lever, installing

(manual transmission)

- Clean old grease from shift lever ball and mounting ring.

Also clean shift console bowl. Lubricate with molybdenum

disulfide grease.

- Insert shift lever together with inner boot and mounting ring

into center console.

4 Align shift lever mounting ring locking tabs with slots

(arrows) in shift console bowl. Press down until ring

snaps into place.

NOTE-

lnstall mounting ring witli arrow pointing toward front of car.

4 Pull inner rubber boot over shift console bowl (arrows) to

seal base of shift lever.

NOTE-

lnstall rubber boot witli arrow pointing toward front of car.

- Raise car and support transmission. Remove transmission

crossmember and lower transmission to access base of shift

lever.

CAUTIOI\C

Tilting the engine to lower the transmission can lead to

damage to various components due to lack of clearance.

Page 612 of 1002

Downloaded from www.Manualslib.com manuals search engine

Driveshaft

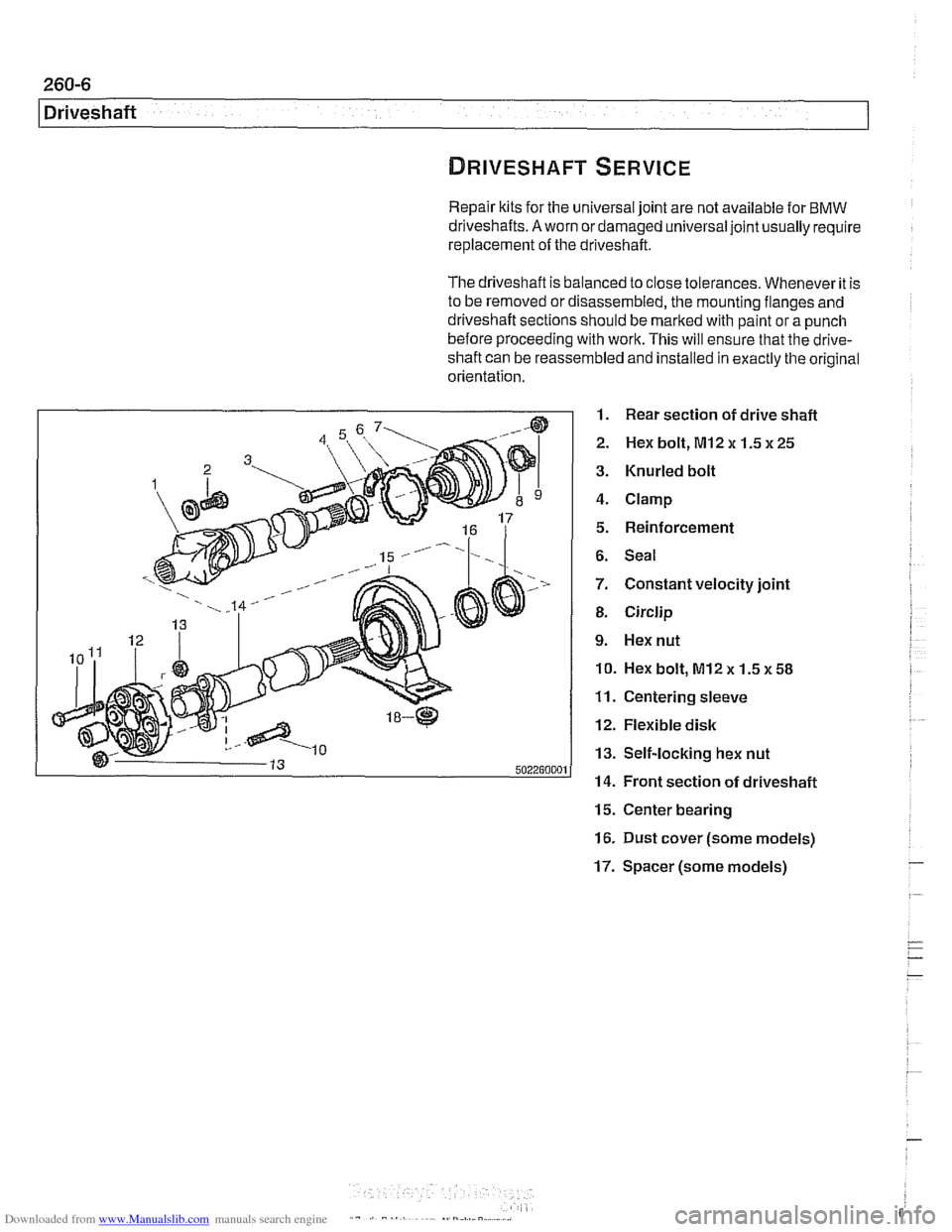

Repair kits for the universal joint are not available for BMW

driveshafts.

A worn or damaged universal joint usually require

replacement of the driveshaft.

The driveshaft is balanced to close tolerances. Whenever it is

to be removed or disassembled, the mounting flanges and

driveshaft sections should be marked with paint or a punch

before proceeding with work. This will ensure that the

drive-

shaft can be reassembled and installed in exactly the original

orientation.

1. Rear section of drive shaft

2. Hex bolt, MI2 x 1.5 x 25

3. Knurled bolt

4. Clamp

5. Reinforcement

6. Seal

7. Constant velocity joint

8. Circlip

9. Hex nut

10. Hex bolt, M12x 1.5~58

11. Centering sleeve

12. Flexible disk

13. Self-locking hex nut

14. Front section of driveshaft

15. Center bearing

16. Dust cover (some models)

17. Spacer (some models) -

Page 616 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 0

/ Driveshaft

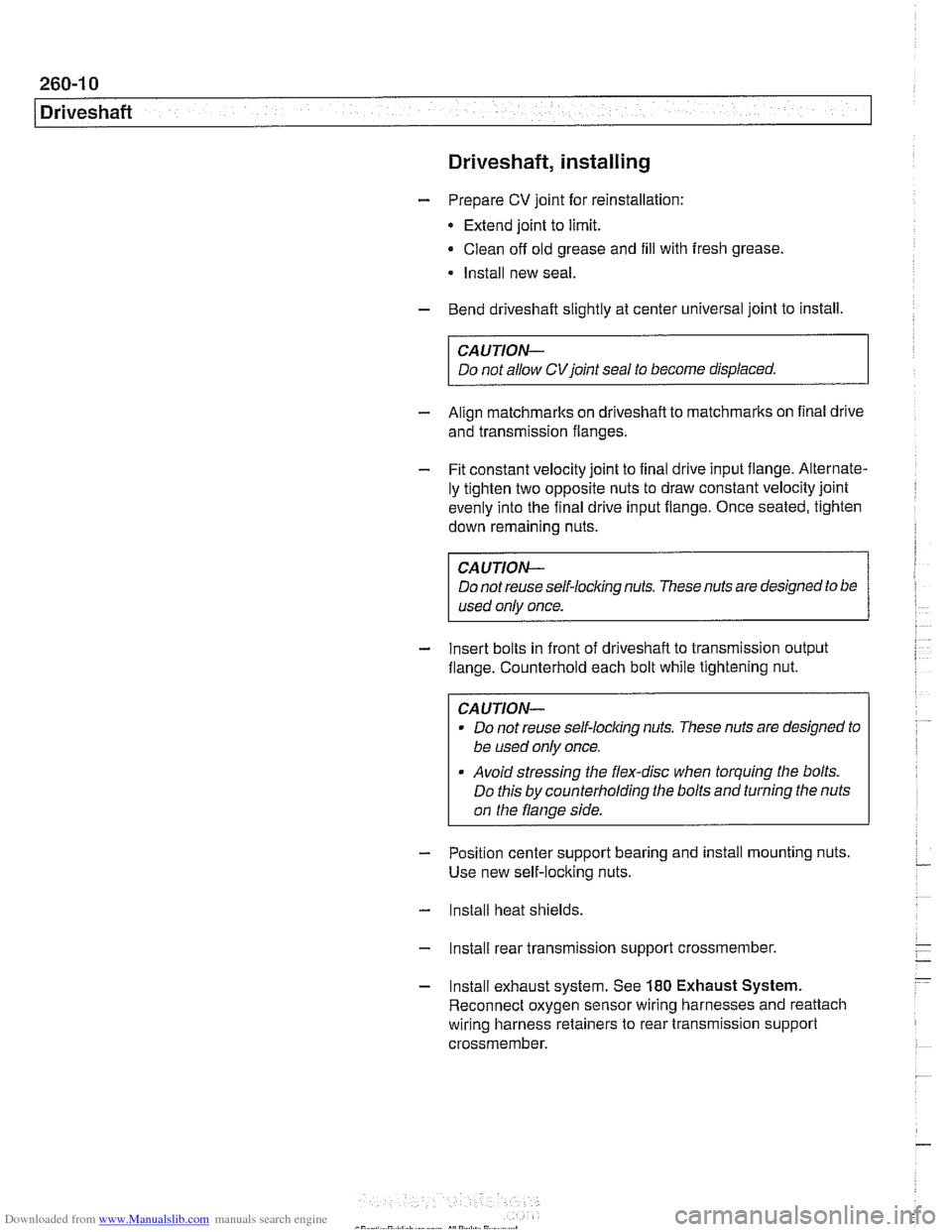

Driveshaft, installing

- Prepare CV joint for reinstallation:

Extend joint to limit.

Clean off old grease and fill with fresh grease

Install new seal.

- Bend driveshaft slightly at center universal joint to install

CAUTION-

Do not allow CVjoint seal to become displaced.

- Align matchmarlts on driveshaft to matchmarks on final drive

and transmission flanges.

- Fit constant velocity joint to final drive input flange. Alternate-

ly tighten two opposite nuts to draw constant velocity joint

evenly into the final drive input flange. Once seated, tighten

down remaining nuts.

I CAUTION-

I Do not reuse self-locking nuts. These nuts are designed to be /

I used onlv once. 1

- Insert bolts in front of driveshafl to transmission output

flange. Counterhold each bolt while tightening nut.

CAUTION-

. Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

- Position center support bearing and install mounting nuts.

Use new self-locking nuts.

- Install heat shields.

- Install rear transmission support crossmember.

- Install exhaust system. See 180 Exhaust System.

Reconnect oxygen sensor wiring harnesses and reattach

wiring harness retainers to rear transmission support

crossrnernber.

Page 617 of 1002

Downloaded from www.Manualslib.com manuals search engine

Driveshaft

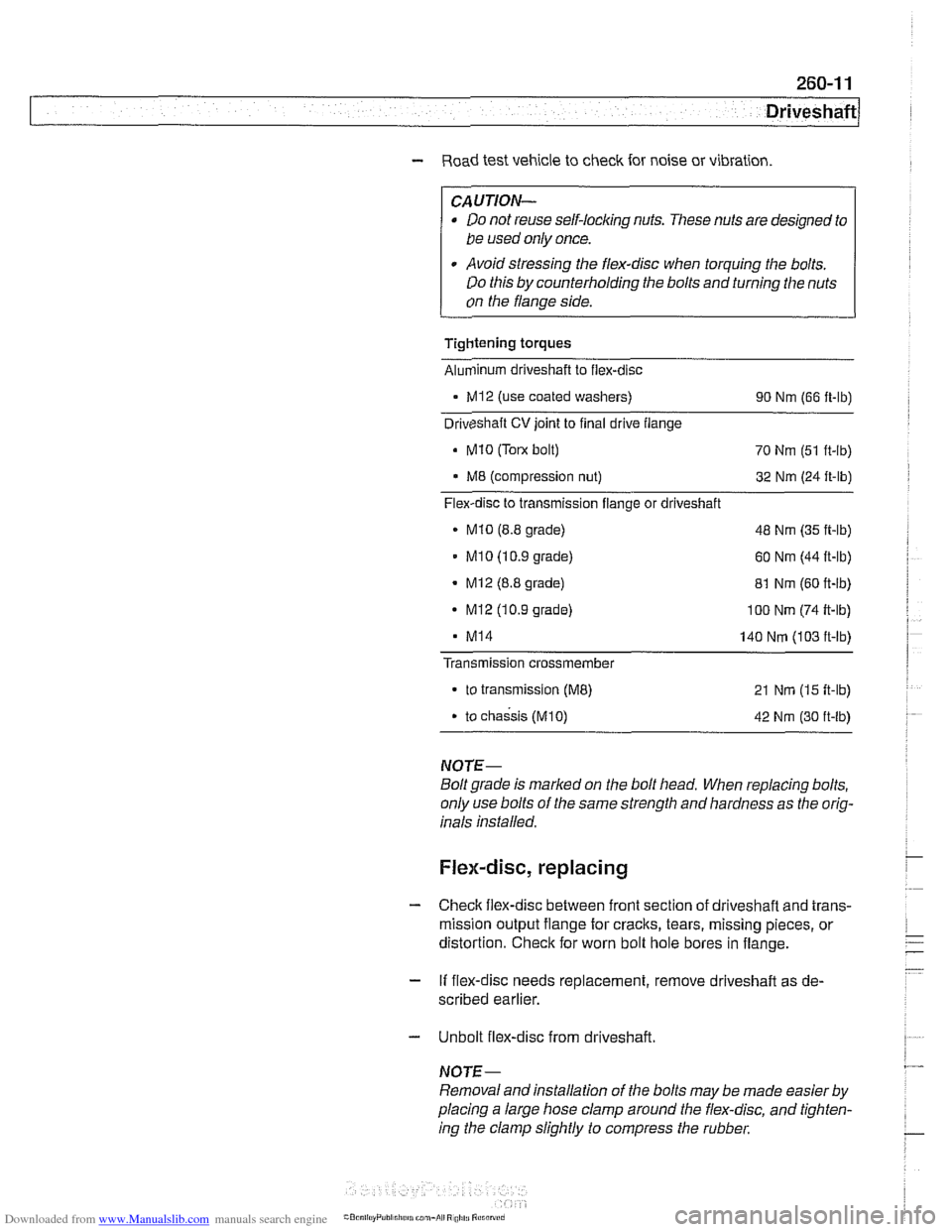

- Road test vehicle to check for noise or vibration

CAUTION-

Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

Tightening torques

Alunlinum driveshaft to flex-disc

- MI2 (use coated washers)

90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

Mi0 (Tom bolt)

70 Nm (51 ft-lb)

M8 (compression nut) 32 Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

MI0 (8.8 grade) 48 Nm (35 ft-lb)

MI 0 (1 0.9 grade) 60 Nm (44 ft-lb)

- Mi2 (8.8 grade)

81 Nm (60 ft-lb)

- MI2 (10.9 grade) I00 Nm (74 ft-lb)

MI4 140 Nm (103 ft-lb)

Transmission

crossmember

to transmission (ME) 21 Nm (15 ft-lb)

. to chassis (M10) 42 Nm (30 ft-lb)

NOTE-

Boltgrade is marked on the bolt head. When replacing bolts,

only use bolts of the same strength and hardness as the orig-

inals installed.

Flex-disc, replacing

- Checlc flex-disc between front section of driveshafl and trans-

mission output flange for craclts, tears, missing pieces, or

distortion. Check for worn bolt hole bores in flange.

- If flex-disc needs replacement, remove driveshafl as de-

scribed earlier.

- Unbolt flex-disc from driveshaft.

NOTE-

Removal andinstallation of the bolts may be made easier by

placing a large hose clamp around the flex-disc, and tighten-

ing the clamp slightly to compress the rubber.

Page 618 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 2

1 Driveshaft

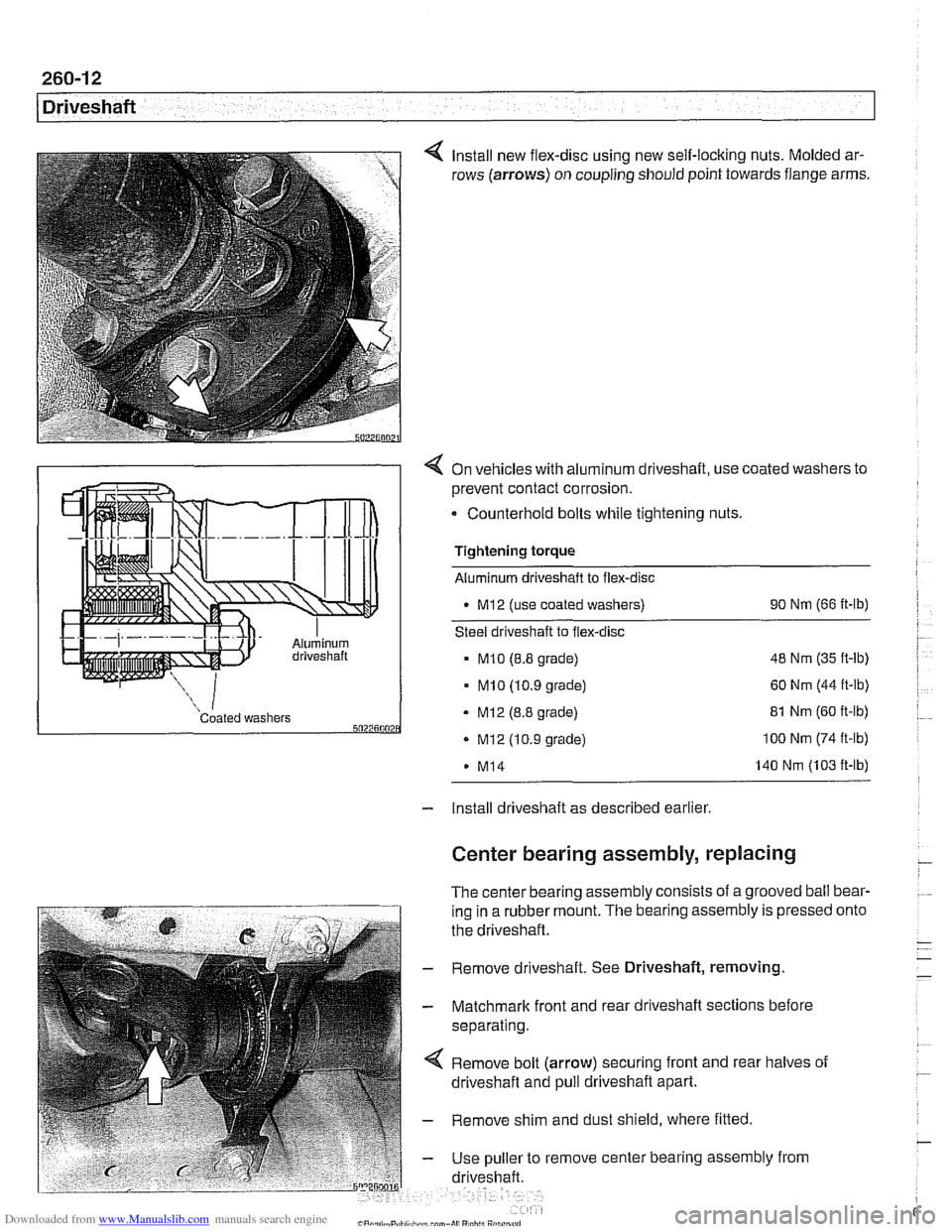

Install new flex-disc using new self-locking nuts. Molded ar-

rows (arrows) on coupling should point towards flange arms.

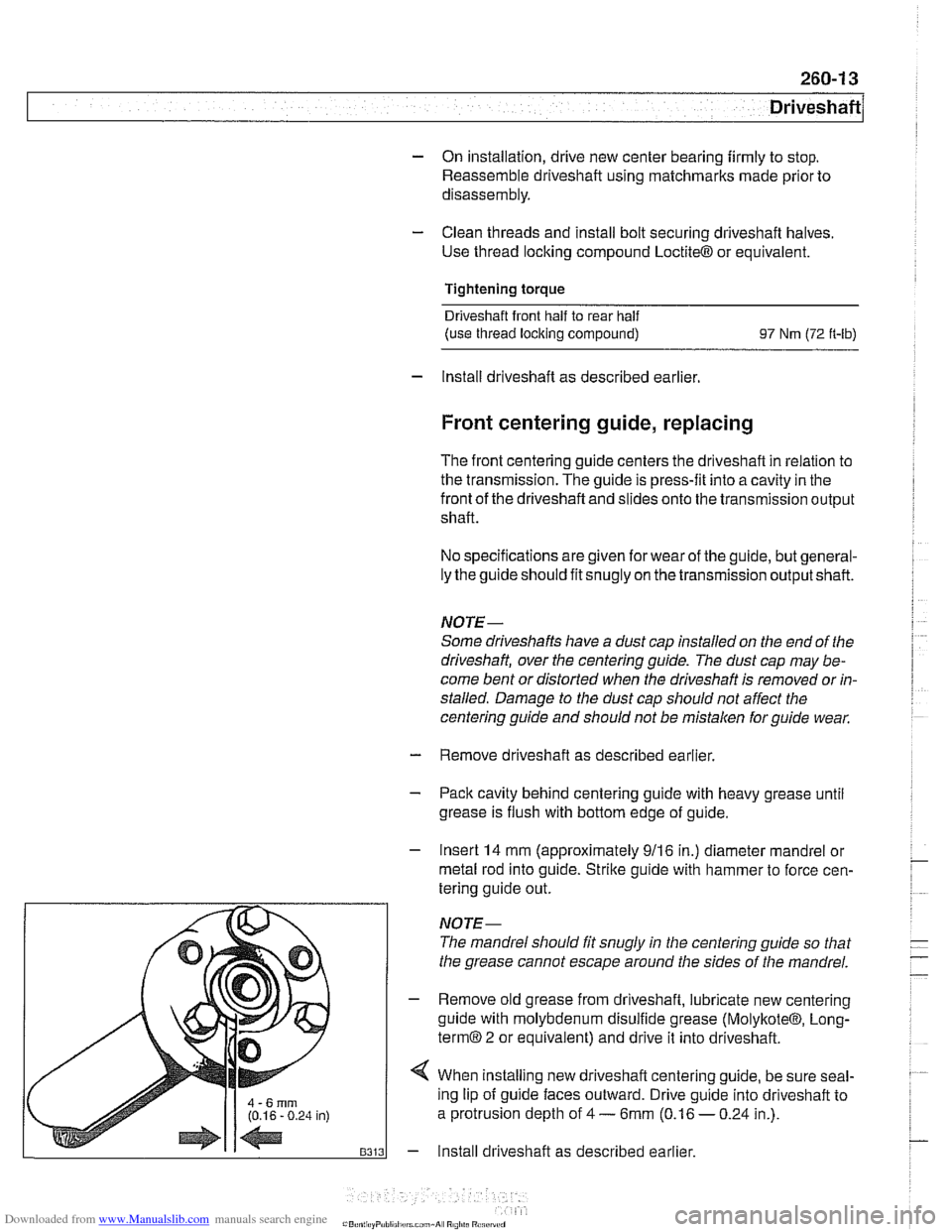

4 On vehicles with aluminum driveshaft, use coated washers to

prevent contact corrosion.

- Counterhold bolts while tightening nuts.

Tightening torque

Aluminum driveshaft to flex-disc

M12 (use coated washers) 90

Nm (66 ft-lb)

Steel driveshaft to flex-disc

MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60 Nm (44 ft-lb)

Coated washers - MI2 (8.8 grade) 5027500 . Mi2 (10.9 grade)

M14 81

Nm (60 ft-lb) 100 Nm (74 ft-lb)

140 Nm (103 ft-lb)

- Install driveshaft as described earlier

Center bearing assembly, replacing

The center bearing assembly consists of a grooved ball bear-

ing in a rubber mount. The bearing assembly is pressed

the driveshaft.

- Remove driveshaft. See Driveshaft, removing

- Matchmark front and rear driveshaft sections before

separating.

Remove bolt (arrow) securing front and rear halves of

driveshaft and pull driveshaft apart.

- Remove shim and dust shield, where fitted

- Use puller to remove center bearing assembly from

driveshaft. onto

Page 619 of 1002

Downloaded from www.Manualslib.com manuals search engine

- On installation, drive new center bearing firmly to stop.

Reassemble driveshaft using matchmarks made prior to

disassembly.

- Clean threads and install bolt securing driveshaft halves.

Use thread locking compound

LoctiteO or equivalent.

Tightening torque Driveshaft front half to rear half

(use thread locking compound) 97

Nm (72 fl-lb)

- Install driveshaft as described earlier.

Front centering guide, replacing

The front centering guide centers the driveshafl in relation to

the transmission. The guide is press-fit into a cavity in the

front of the driveshafl and slides onto the transmission output

shaft.

No specifications are given

forwear of the guide, but general-

ly the guide should fit snugly on the transmission output shafl.

NOTE-

Some driveshafts have a dust cap installed on the end of the

driveshaft, over the centering guide. The dust cap may be-

come bent or distorted when the driveshaft is removed or

in-

stalled. Damage to the dust cap should not affect the

centering guide and should not be mistaken for guide wear.

- Remove driveshafl as described earlier

- Pack cavity behind centering guide with heavy grease until

grease is flush with bottom edge of guide.

- Insert 14 mm (approximately 9/16 in.) diameter mandrel or

metal rod into guide. Strike guide with hammer to force cen-

tering guide out.

NOTE-

Tlie mandrel should fit snugly in the centering guide so that

the grease cannot escape around the sides of the mandrel.

- Remove old grease from driveshaft, lubricate new centering

guide with molybdenum disulfide grease

(MolykoteO, Long-

term8 2 or equivalent) and drive it into driveshaft.

4 When installing new driveshafl centering guide, be sure seal-

ing lip of guide faces outward. Drive guide into driveshaft to

a protrusion depth of

4 - 6mm (0.16 - 0.24 in.).

- Install driveshaft as described earlier.

Page 644 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-8

Front Suspension

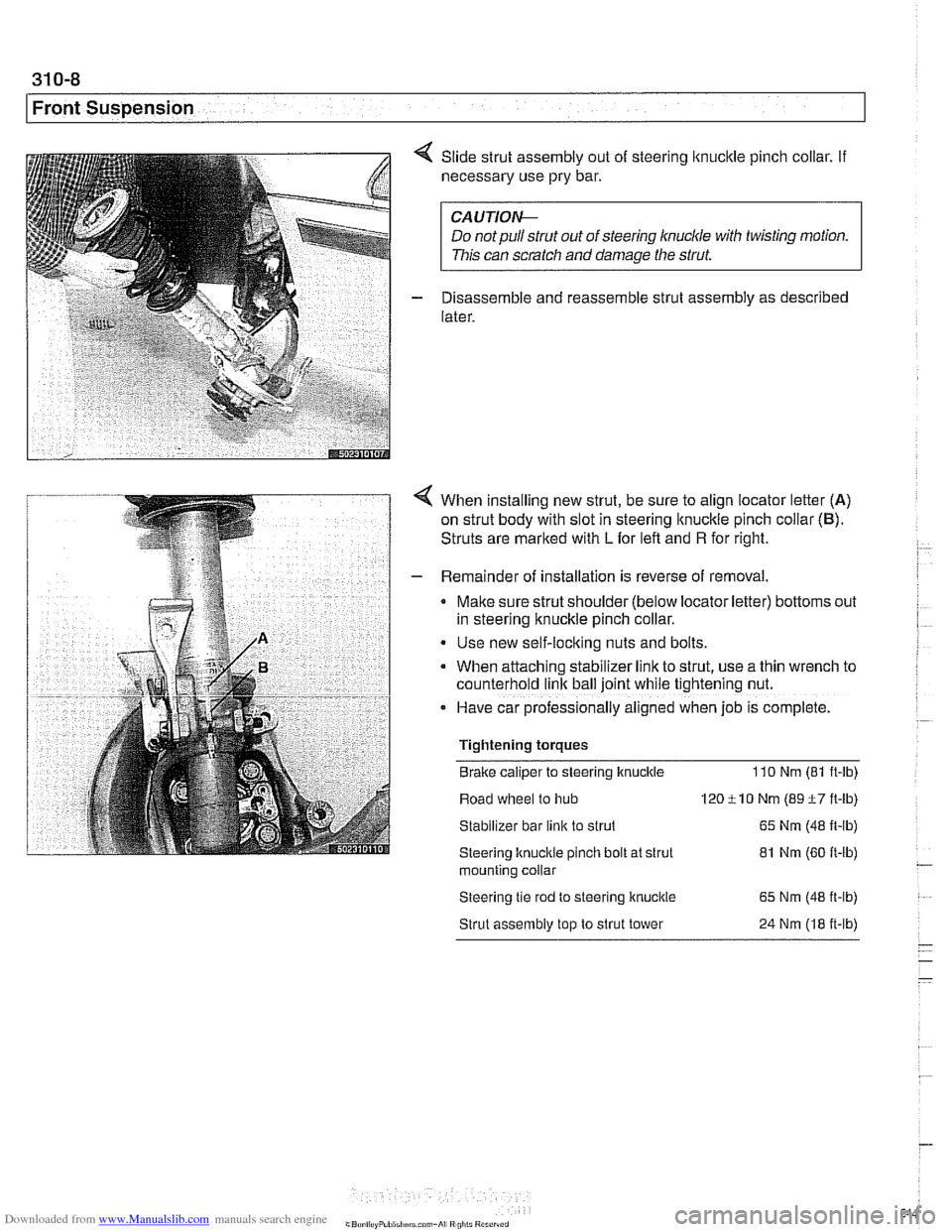

Slide strut assembly out of steering lknucltle pinch collar. If

necessary use pry bar.

CA UTIOI\C

Do notpullstrut out of steering knuckle with twisting motion.

This can scratch and damage the strut.

Disassemble and reassemble strut assembly as described

later.

When installing new strut, be sure to align locator letter (A)

on strut body with slot in steering

lknuckle pinch collar (6).

Struts are marked with L for left and R for right.

Remainder of installation is reverse of removal.

Make sure strut shoulder (below locator letter) bottoms out

in steering knuckle pinch collar.

Use new self-locking nuts and bolts.

When attaching stabilizer

lrnk to strut, use a thin wrench to

counterhold

link ball joint while t~ghtening nut.

- Have car professionally al~gned when job IS complete.

Tightening torques

Brake caliper to steering knuckle

110 Nm (81 ft-ib)

Road wheel to hub 120 ti0 Nm (89 t7 ft-lb)

Stabilizer bar

link to strut 65 Nm (48 It-lb)

Steering knucltle pinch bolt at strut 81 Nm (60 It-lb) - mountlng collar

Steering tle rod to steerlng knuckle 65 Nm (48 it-lb)

Strut assembly top to strut tower 24 Nm (18 it-lb)

- - -

Page 645 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-9

Front Suspension

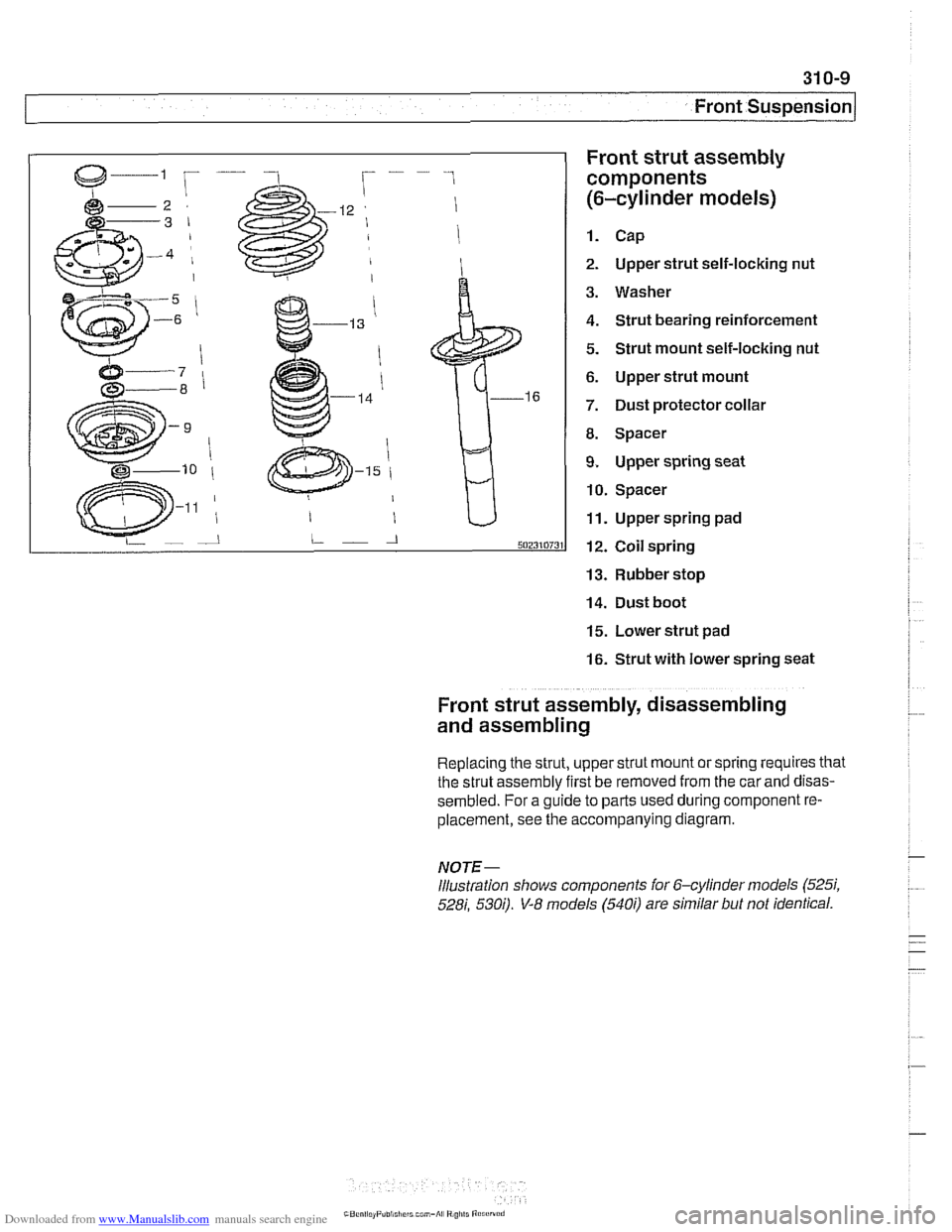

Front strut assembly

components

(6-cylinder models)

1. Cap

2. Upper strut self-locking nut

3. Washer

4. Strut bearing reinforcement

5. Strut mount self-locking nut

6. Upper strut mount

7. Dust protector collar

8. Spacer

9. Upper spring seat

10. Spacer

11. Upper spring pad

12. Coil spring

13. Rubber stop

14. Dust boot

15. Lower strut pad

16. Strut with lower spring seat

Front strut assembly, disassembling

and assembling

Replacing the strut, upper strut mount or spring requires that

the strut assembly first be removed from the car

and disas-

sembled. For a guide to parts used during component re-

placement, see the accompanying diagram.

NOTE-

Illustration shows components ior 6-cylinder models (525i,

528i, 530;). V-8 models (540i) are similar but not identical.

Page 649 of 1002

Downloaded from www.Manualslib.com manuals search engine

Front Suspension

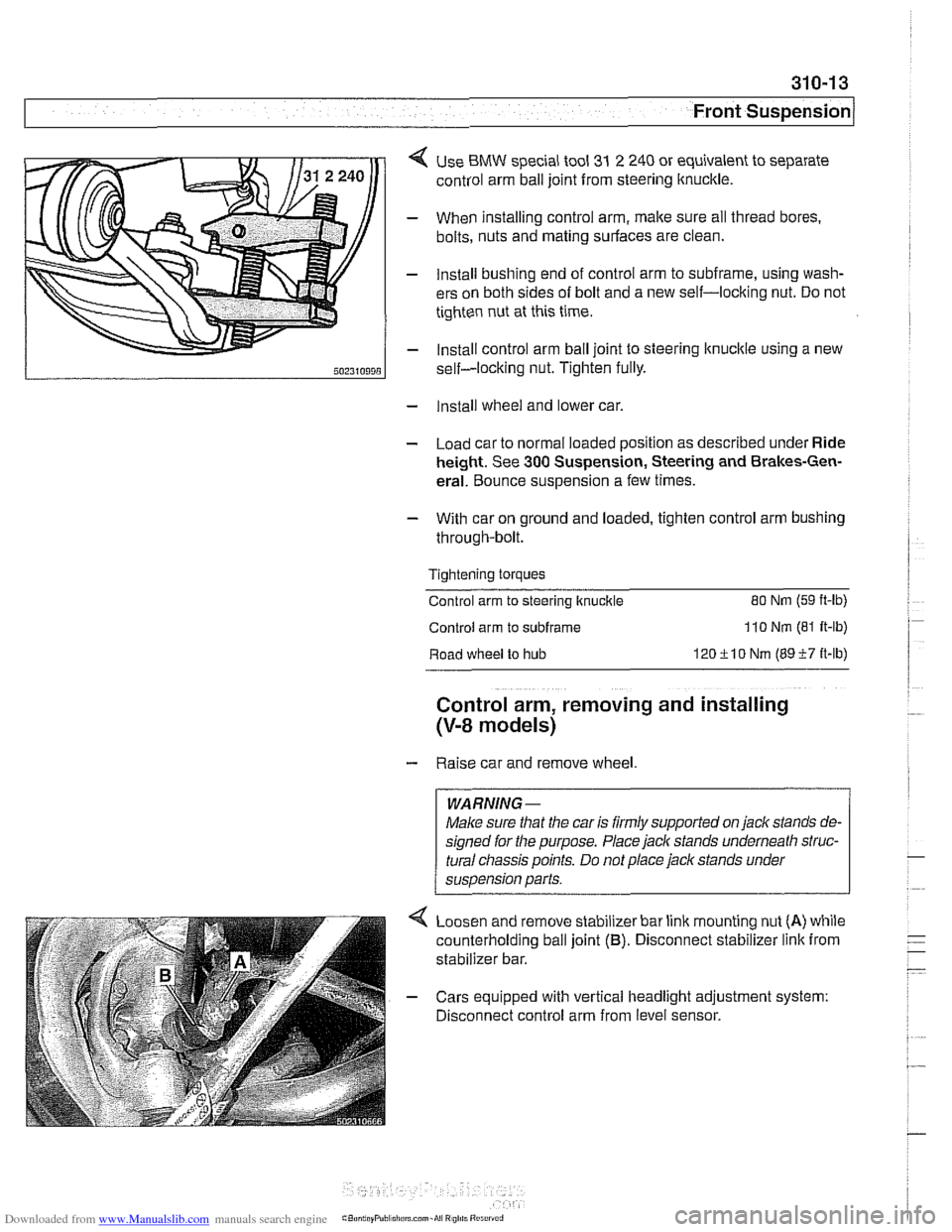

< Use BMW special tool 31 2 240 or equivalent to separate

control arm ball joint from steering ltnuckle.

- When installing control arm, make sure all thread bores.

bolts, nuts and mating surfaces are clean.

- Install bushing end of control arm to subframe, using wash-

ers on both sides of bolt and a new self-locking nut. Do not

tighten nut at this time.

- Install control arm ball joint to steering lknucltle using a new

self-locking nut. Tighten fully.

- Install wheel and lower car.

- Load car to normal loaded position as described under Ride

height. See

300 Suspension, Steering and Brakes-Gen-

eral. Bounce suspension a few times.

- With car on ground and loaded, tighten control arm bushing

through-bolt.

Tightening torques

Control arm to steering ltnuckle

80 Nm (59 ft-lb)

Control arm to subframe 110 Nm (81 It-lb)

Road wheel to hub 120ilO Nm (8957 it-lb)

Control arm, removing and installing

(V-8 models)

- Raise car and remove wheel

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural

cliassis points. Do not place jack stands under

suspension parts.

Loosen and remove stabilizer bar link mounting nut

(A) while

counterholding ball joint

(B). Disconnect stabilizer link from

stabilizer bar.

- Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

Page 651 of 1002

Downloaded from www.Manualslib.com manuals search engine

310-1 5

Front ~us~ension/

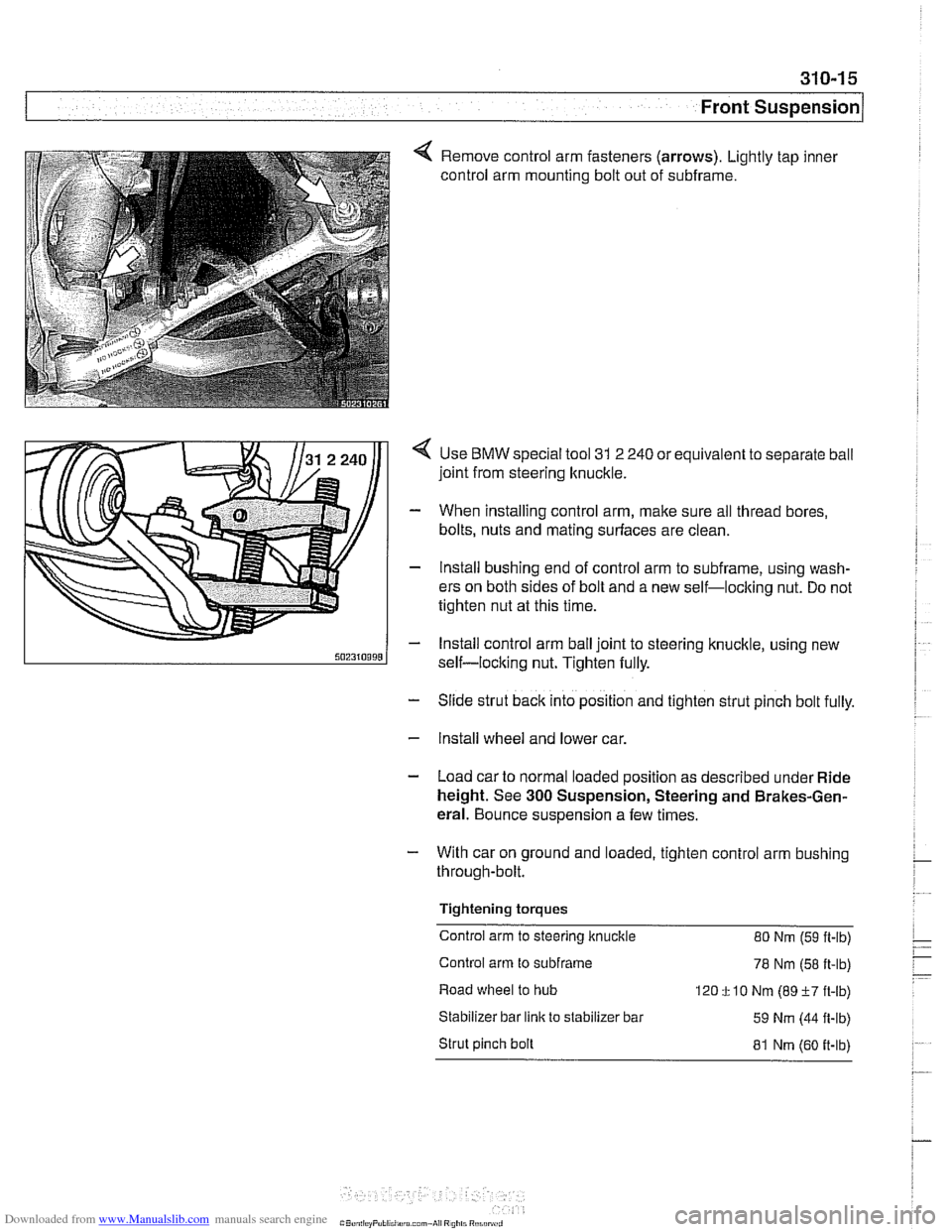

4 Remove control arm fasteners (arrows). Lightly tap inner

control arm mounting bolt out of subframe.

Use

BMW special tool 31 2 240 or equivalent to separate ball

joint from steering knuckle.

When installing control arm, make sure all thread bores,

bolts, nuts and mating surfaces are clean.

lnstall bushing end of control arm to subframe, using wash-

ers on both sides of bolt and a new self-loclting nut. Do not

tighten nut at this time.

lnstall control arm ball joint to steering knuckle, using new

self-locking nut. Tighten fully.

- Slide strut back into position and tighten strut pinch bolt fully.

- Install wheel and lower car.

- Load car to normal loaded position as described under Ride

height. See

300 Suspension, Steering and Brakes-Gen-

eral. Bounce suspension a few times.

- With car on ground and loaded, tighten control arm bushing

through-bolt.

Tightening torques

Control arm to steering knuckle 80 Nm

(59 ft-lb)

Control arm to

subframe 78 Nm (58 ft-lb)

Road wheel to hub

120

f 10 Nm (89 +7 ft-lb)

Stabilizer bar

link to stabilizer bar

59 Nm (44 fl-lb)

Strut pinch bolt

81 Nm (60 it-lb)