Oul BMW 540i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 559 of 1002

Downloaded from www.Manualslib.com manuals search engine

Clutch

- Remove flywheel locking tool

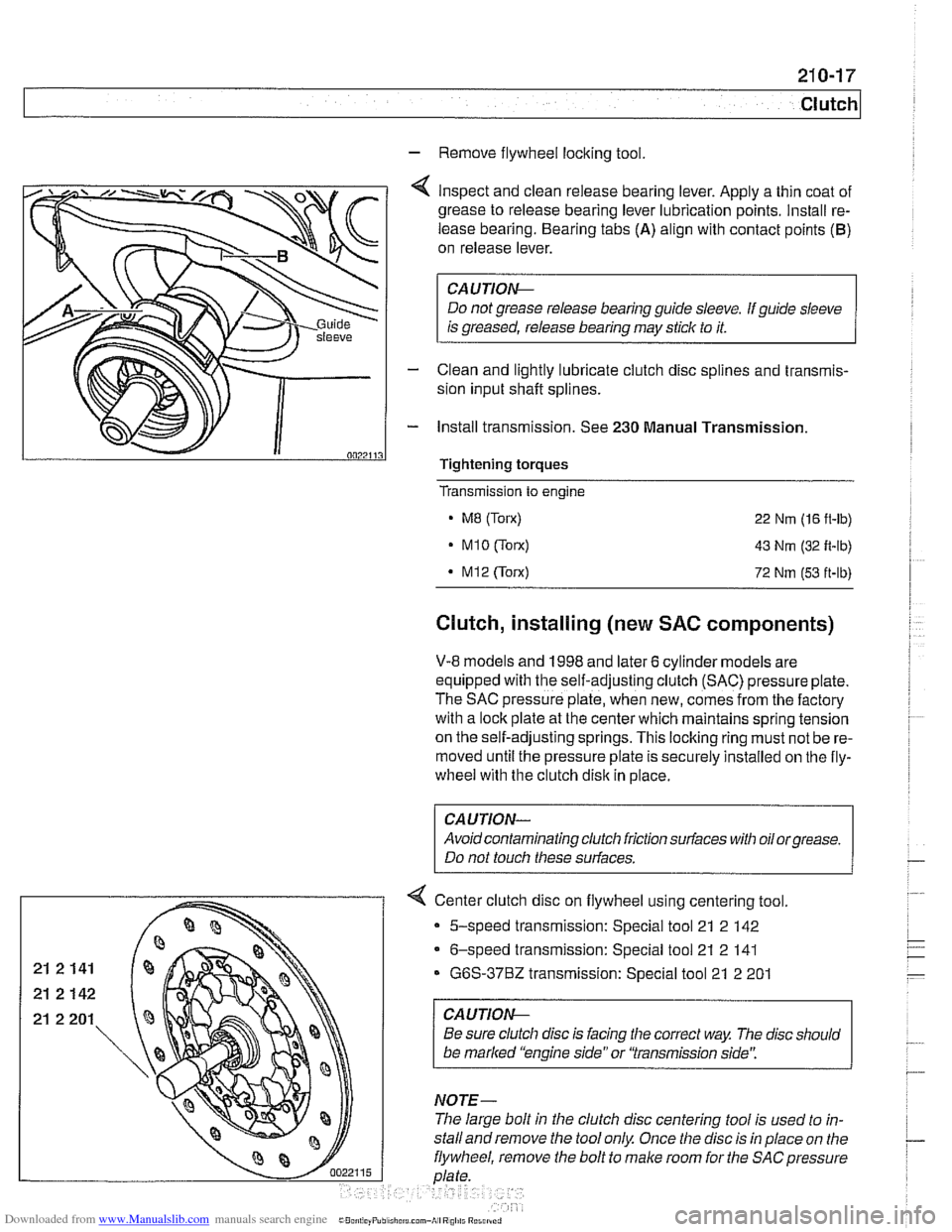

4 Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. Install re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

CAUTION-

Do not grease release bearing guide sleeve. If guide sleeve

is greased, release bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- Install transmission. See 230 Manual Transmission

.

Transmission to engine

MB (Torx) 22 Nm (16 fl-lb)

MlO(Torx) 43 Nm (32 fl-lb)

Clutch, installing (new SAC components)

V-8 models and 1998 and later 6 cylinder models are

equipped with the self-adjusting clutch (SAC) pressure plate.

The SAC pressure plate, when new, comes from the factory

with a lock plate at the center which maintains spring tension

on the self-adjusting springs. This

loclting ring must not be re-

moved until the pressure plate is securely installed on tlie fly-

wheel with the clutch disk in place.

CAUTION-

Avoidcontaminating clutch friction surfaces with oilorgrease.

Do not touch these surfaces.

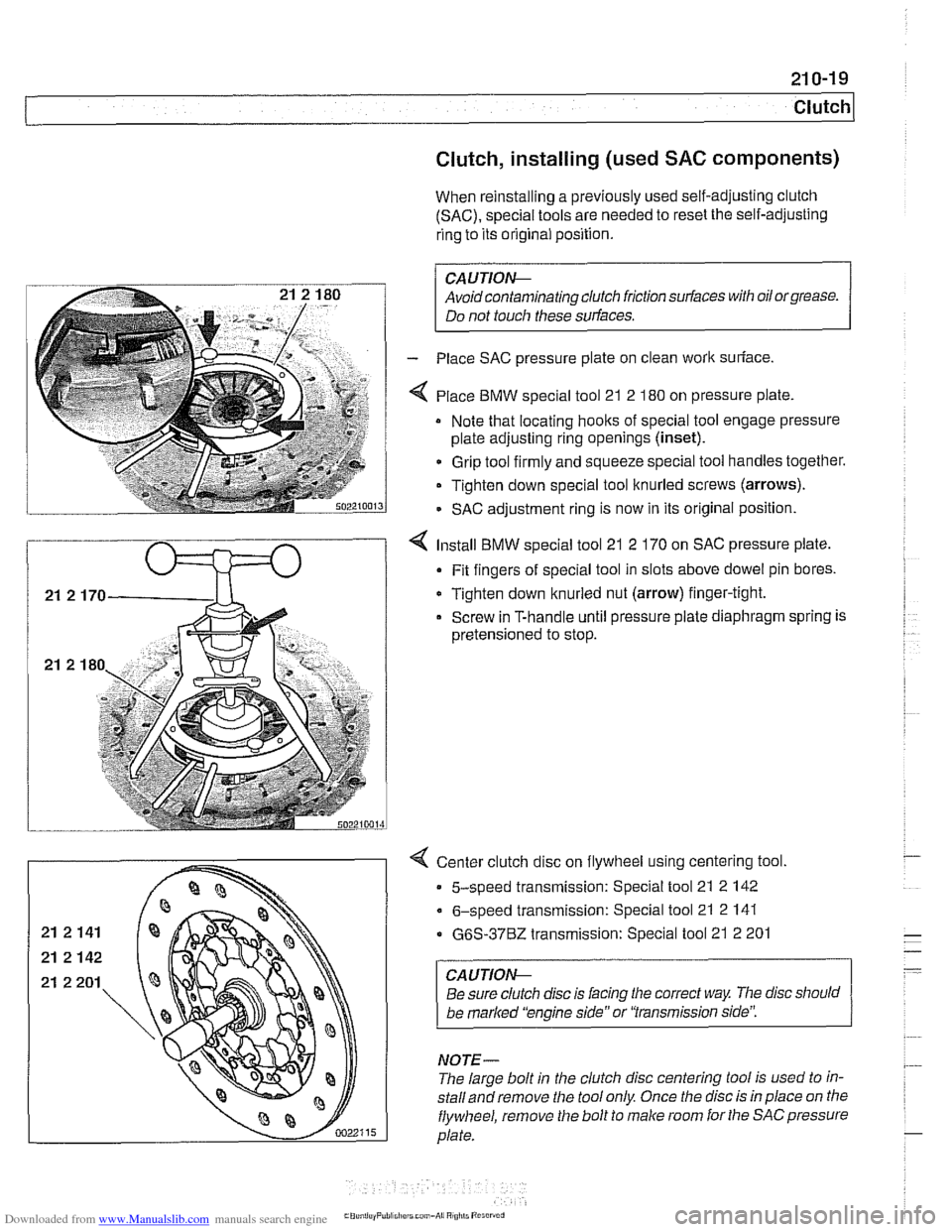

< Center clutch disc on flywheel using centering tool.

5-speed transmission: Special tool 21 2

142

- 6-speed transmission: Special tool 21 2 141

G6S-3782 transmission: Special tool 21 2 201

CAUTION-

Be sure clutch disc is facing the correct way The disc should

be marked "engine side" or "transmission side':

The large bolt in the clutch disc centering tool is used to

in-

stalland remove the tool only. Once the disc is in place on the

eel, remove the bolt to male room for tlie

SACpressure

Page 561 of 1002

Downloaded from www.Manualslib.com manuals search engine

Clutch

Clutch, installing (used SAC components)

When reinstalling a previously used self-adjusting clutch

(SAC), special tools are needed to reset the self-adjusting

ring to its original position.

CAUTIOI\C

Avoidcontaminating clutch friction suifaces with oilorgrease.

Do not touch these

suifaces.

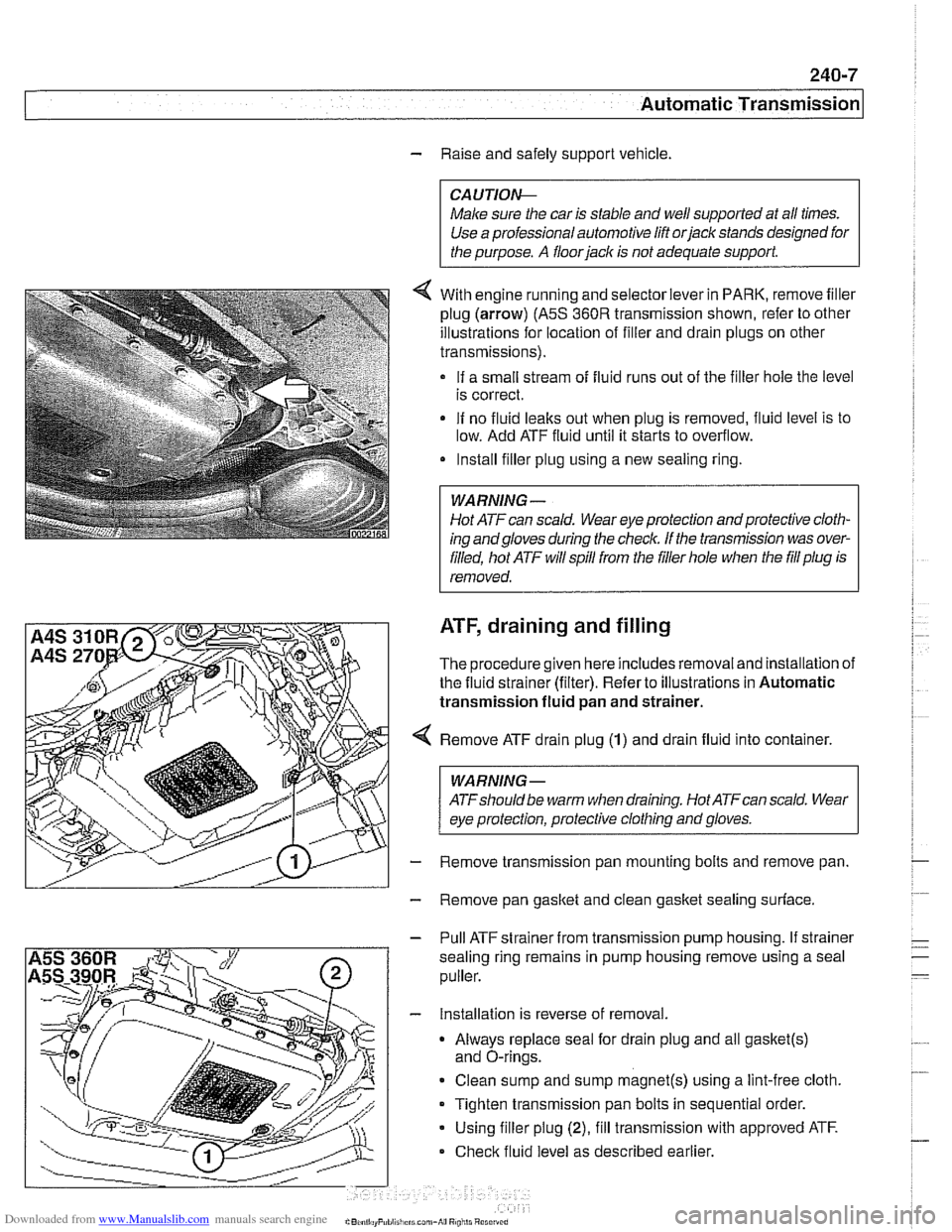

- Place SAC pressure plate on clean worlc suriace.

4 Place BMW special tool 21 2 180 on pressure plate

Note that locating hoolts of special tool engage pressure

plate adjusting ring openings

(inset).

Grip tool firmly and squeeze special tool handles together.

Tighten down special tool knurled screws (arrows).

- SAC adjustment ring is now in its original position.

4 Install BMW special tool 21 2 170 on SAC pressure plate.

Fit fingers of special tool in slots above dowel pin bores.

Tighten down knurled nut (arrow) finger-tight.

Screw in T-handle until pressure plate diaphragm spring is

pretensioned to stop.

< Center clutch disc on flywheel using centering tool.

5-speed transmission: Special tool 21 2 142

6-speed transmission: Special tool 21 2 141

G6S-3762 transmission: Special tool 21 2 201

CAUTION--

Be sure clutch disc is lacing the correct way The disc should

be

marked 'kngine side" or 'Transmission side':

NOTE-

The large bolt in the clutch disc centering tool is used to in-

stalland remove the tool only Once the disc is in place on tlie

flywheel, remove the bolt to male room for the SACpressure

plate.

Page 591 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic Transmission

- Raise and safely support vehicle.

CA U JIOG

Male sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floorjack is not adequate support

4 With engine running and selector lever in PARK, remove filler

plug (arrow)

(A5S 360R transmission shown, refer to other

illustrations for location of filler and drain plugs on other

transmissions).

If a small stream of fluid runs out of the filler hole the level

is correct.

If no fluid

leaks out when plug is removed, fluid level is to

low. Add ATF fluid until it starts to overflow.

Install filler plug using a new sealing ring.

Hot ATF can scald. Wear eye protection and protective cloth-

ing andgloves during

the check. If the tmnsmission was over-

filled, hot ATF will spill from the filler hole when the

fill plug is

removed.

ATF, draining and filling

The procedure given here includes removal and installation of

the fluid strainer (filter). Refer to illustrations in Automatic

transmission fluid

pan and strainer.

Remove ATF drain plug

(1) and drain fluid into container.

WARNING-

ATFshould be warm when draining. Hot ATFcan scald. Wear

eye protection, protective clothing and gloves.

Remove transmission pan mounting bolts and remove pan.

Remove pan gasket and clean

gasket sealing surface.

- Pull ATF strainer from transmission pump housing. If strainer

sealing ring remains in pump housing remove using a seal

puller.

- Installation is reverse of removal.

Always replace seal for drain plug and all

gasket(s)

and O-rings.

Clean sump and sump

magnet(s) using a lint-free cloth.

Tighten transmission pan bolts in sequential order.

Using filler plug

(2), fill transmission with approved ATF.

Check fluid level as described earlier.

Page 605 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-7

Gearshift ~inka~el

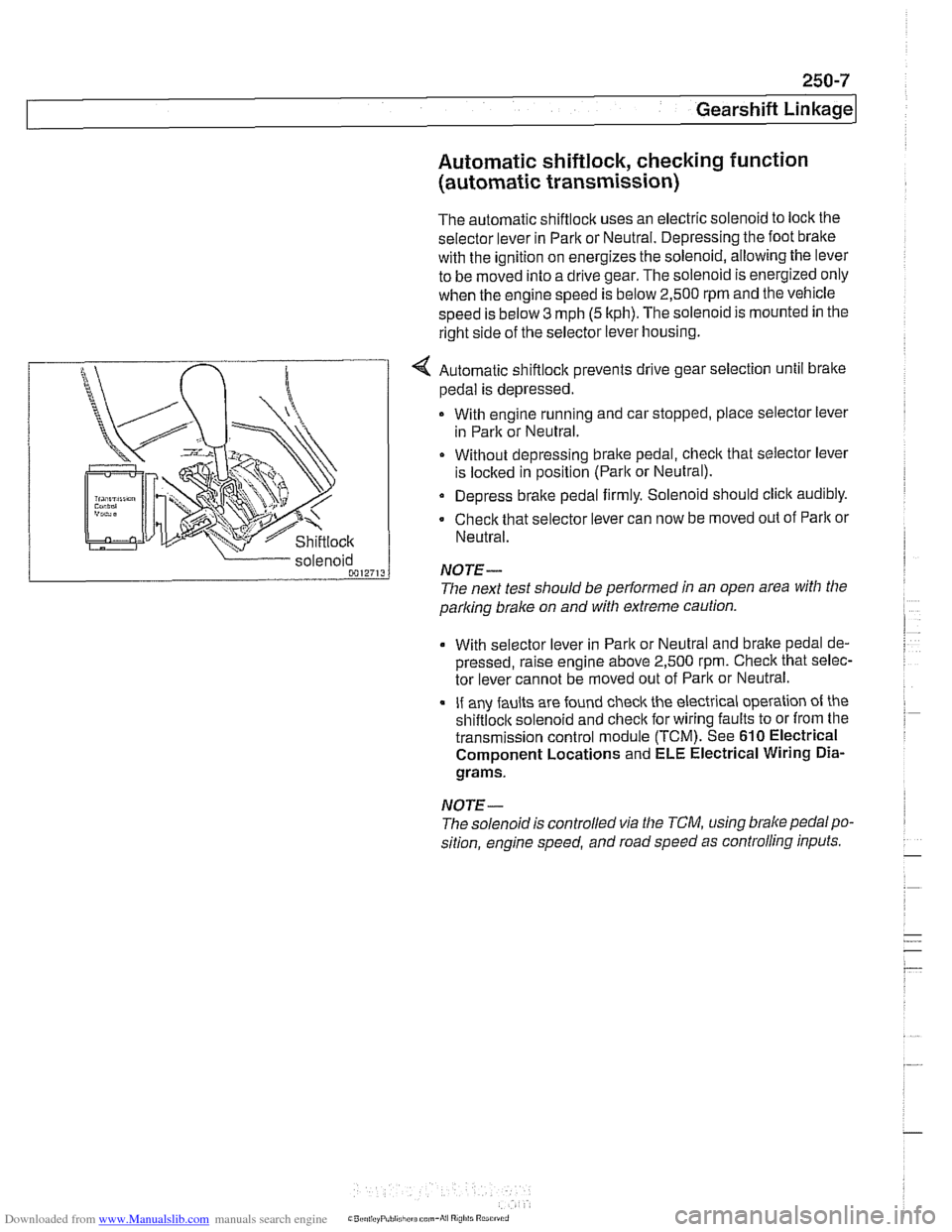

Automatic shiftlock, checking function (automatic transmission)

The automatic shiftlock uses an electric solenoid to lock the

selector lever in Park or Neutral. Depressing the foot bralte

with the ignition on energizes the solenoid, allowing the lever

to be moved into a drive gear. The solenoid is energized only

when the engine speed is below 2,500 rpm and the vehicle

speed is below

3 mph (5 kph). The solenoid is mounted in the

right side of the selector lever housing.

... nir r

Shiftlock

4 Automatic shiftlock prevents drive gear selection until brake

pedal is depressed.

With engine running and car stopped, place selector lever

in Park or Neutral.

Without depressing bralte pedal, check that selector lever

is

loclted in position (Parlt or Neutral).

Depress brake pedal firmly. Solenoid should click audibly.

Check that selector lever can now be moved out of

Parlt or

Neutral.

parking

brake on and with extreme caution.

solenoid

0012713

With selector

lever in Park or Neutral and bralte pedal de-

pressed, raise engine above 2,500

rpm. Check that selec-

tor lever cannot be moved out of Park or Neutral.

If any faults are found check the electrical operation of the

shiftloclt solenoid and checlt for wiring faults to or from the

transmission control module (TCM). See

610 Electrical

Component Locations and ELE Electrical Wiring

Dia-

grams.

NOTE-

NOTE-

The solenoidis controlled via the TCM, using brake pedalpo-

sition, engine speed, and road speed as controlling inputs.

The

next test should be performed in an open area with the

Page 606 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-8

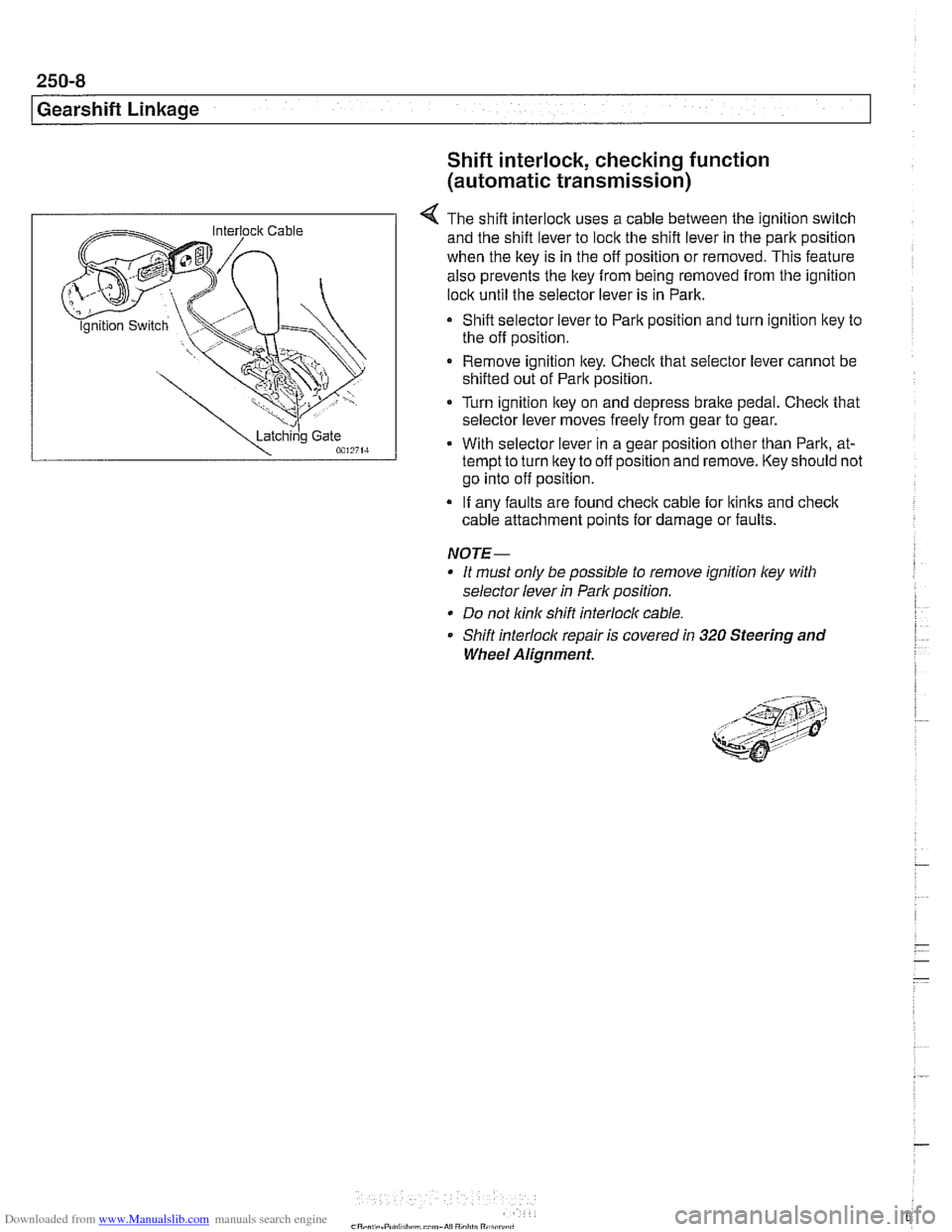

Gearshift Linkage

-;Ag Gate "",?it.,

Shift interlock, checking function

(automatic transmission)

4 The shift interlock uses a cable between the ignition switch

and the shift lever to lock the shift lever in the park position

when the key is in the off position or removed. This feature

also prevents the key

from being removed from the ignition

lock until the selector lever is in Park.

Shift selector lever to Park position and turn ignition key to

the off position.

Remove ignition key. Checlc that selector lever cannot be

shifted out of Park position.

Turn ignition lkey on and depress

brake pedal. Checlc that

selector lever moves freely from gear to gear.

With selector lever in a gear position other than Park, at-

tempt to turn lkey to off position and remove. Key should not

go into off position.

If any faults are found check cable for lkinks and

check

cable attachment points for damage or faults.

NOTE-

* It must only be possible to remove ignition ley with

selector lever

in Park position.

* Do not link shift interlocl( cable.

Shift interlock repair is covered

in 320 Steering and

Wheel Alignment.

Page 609 of 1002

Downloaded from www.Manualslib.com manuals search engine

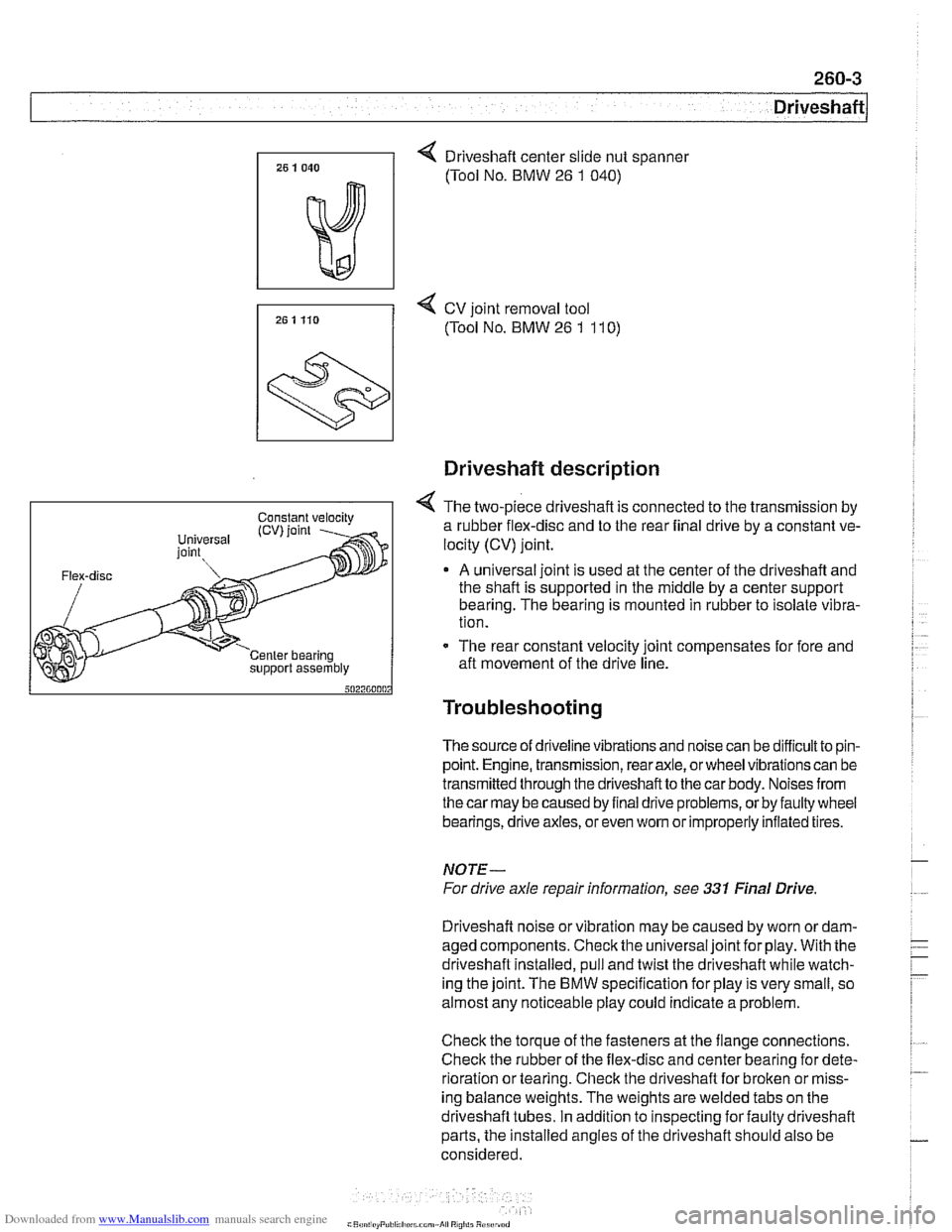

Driveshaft

4 Driveshaft center slide nut spanner

(Tool No. BMW

26 1 040)

7, 25 1 Ho 4 cv joint removal tool

(Tool No. BMW 26 1 11 0)

support assembly

Driveshaft description

4 The two-piece driveshaft is connected to the transmission by

a rubber flex-disc and to the rear final drive by a constant ve-

locity (CV) joint.

A universal joint is used at the center of the driveshaft and

the shaft is supported in the middle by a center support

bearing. The bearing is mounted in rubber to isolate vibra-

tion.

- The rear constant velocity joint compensates for fore and

aft movement of the drive line.

Troubleshooting

The source of driveline vibrations and noise can be difficultto pin-

point. Engine, transmission, rear axle, or wheel vibrations can be

transmitted through thedriveshaftto the car body. Noises from

thecar may be caused by final drive problems, or by faulty wheel

bearings, drive axles, or even

wom or improperly inflated tires.

NOTE-

For drive axle repair information, see 331 Final Drive

Driveshaft noise or vibration may be caused by worn

ordam-

aged components. Check the universal joint for play. With the

driveshaft installed, pull and twist the driveshaft while watch-

ing the joint. The

BMW specification for play is very small, so

almost any noticeable play could indicate a problem.

Check the torque of the fasteners at the flange connections.

Check the rubber of the flex-disc and center bearing for dete-

rioration or tearing. Check the driveshaft for broken or miss-

ing balance weights. The weights are welded tabs on the

driveshaft tubes. In addition to inspecting for faulty driveshaft

parts, the installed angles of the driveshaft should also be

considered.

Page 610 of 1002

Downloaded from www.Manualslib.com manuals search engine

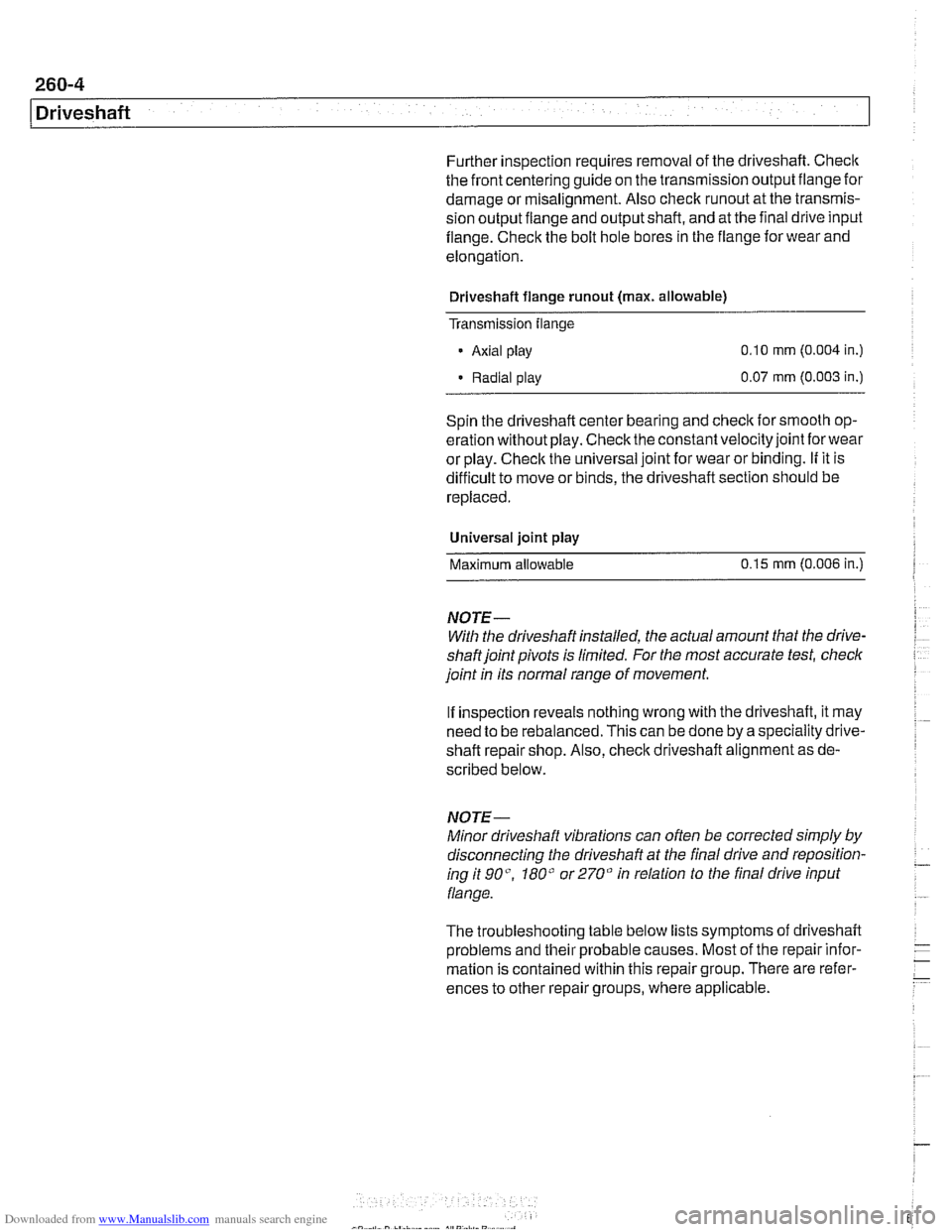

1 Driveshaft

Further inspection requires removal of the driveshaft. Checlc

the front centering guide on the transmission output flange for

damage or

misalignment. Also check runout at the transmis-

sion output fiange and output shaft, and at the final drive input

fiange. Check the bolt hole bores in the flange for wear and

elongation.

Driveshaft flange

runout (max. allowable)

Transmission

flange

- Axial play 0.10 mm (0.004 in.)

Radial play 0.07

mm (0.003 in.)

Spin the driveshaft center bearing and

check ior smooth op-

eration without play. Check the constant velocity joint

forwear

or play. Checlc the universal joint for wear or binding. If it is

difficult to move or binds, the driveshaft section should be

replaced.

Universal joint

play

Maximum allowable 0.15

mm (0.006 in.)

NOTE-

With the driveshaft installed, the actual amount that the drive-

shaftjoint pivots is limited. For the most accurate test, check

joint

in its normal range of movement.

If inspection reveals nothing wrong with the driveshaft, it may

need to be rebalanced. This can be done by a speciality drive-

shaft repair shop. Also,

checlc driveshaft alignment as de-

scribed below.

NOTE-

Minor driveshaft vibrations can often be corrected simply by

disconnecting the driveshaft at the final drive and reposition-

ing it go", 180" or 270" in relation to the final drive input

flange.

The troubleshooting table below lists symptoms

oi driveshaft

problems and their probable causes. Most of the repair infor-

mation is contained within this repair group. There are refer-

ences to other repair groups, where applicable.

Page 612 of 1002

Downloaded from www.Manualslib.com manuals search engine

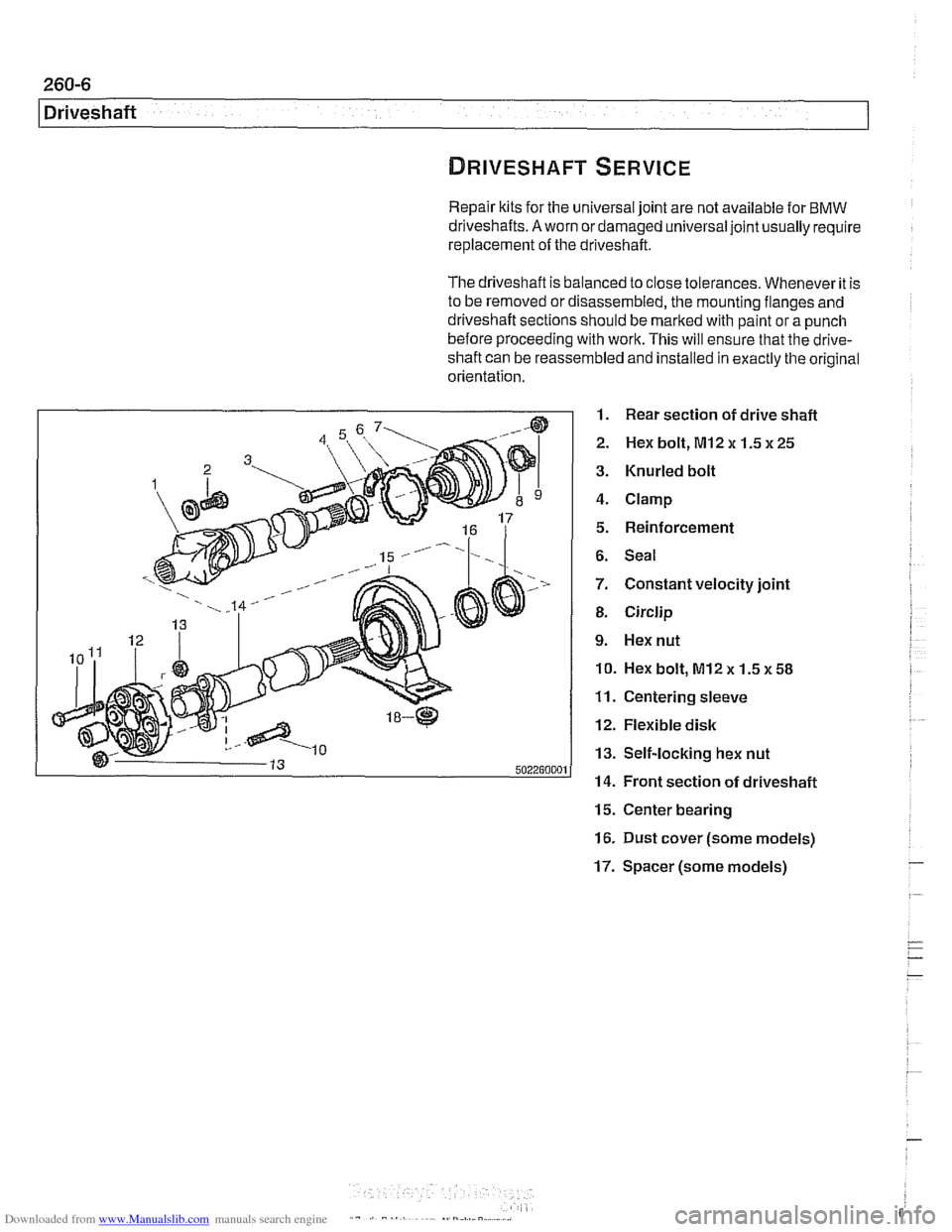

Driveshaft

Repair kits for the universal joint are not available for BMW

driveshafts.

A worn or damaged universal joint usually require

replacement of the driveshaft.

The driveshaft is balanced to close tolerances. Whenever it is

to be removed or disassembled, the mounting flanges and

driveshaft sections should be marked with paint or a punch

before proceeding with work. This will ensure that the

drive-

shaft can be reassembled and installed in exactly the original

orientation.

1. Rear section of drive shaft

2. Hex bolt, MI2 x 1.5 x 25

3. Knurled bolt

4. Clamp

5. Reinforcement

6. Seal

7. Constant velocity joint

8. Circlip

9. Hex nut

10. Hex bolt, M12x 1.5~58

11. Centering sleeve

12. Flexible disk

13. Self-locking hex nut

14. Front section of driveshaft

15. Center bearing

16. Dust cover (some models)

17. Spacer (some models) -

Page 613 of 1002

Downloaded from www.Manualslib.com manuals search engine

Driveshaft, aligning

The alignment of the driveshaft does not normally need to be

checked unless the engineltransmission or the final drive

have been removed and installed. if ail other parts of the

driveshaft have been inspected and found to be okay, but

there is still noise or vibration, driveshaft alignment should be

checked.

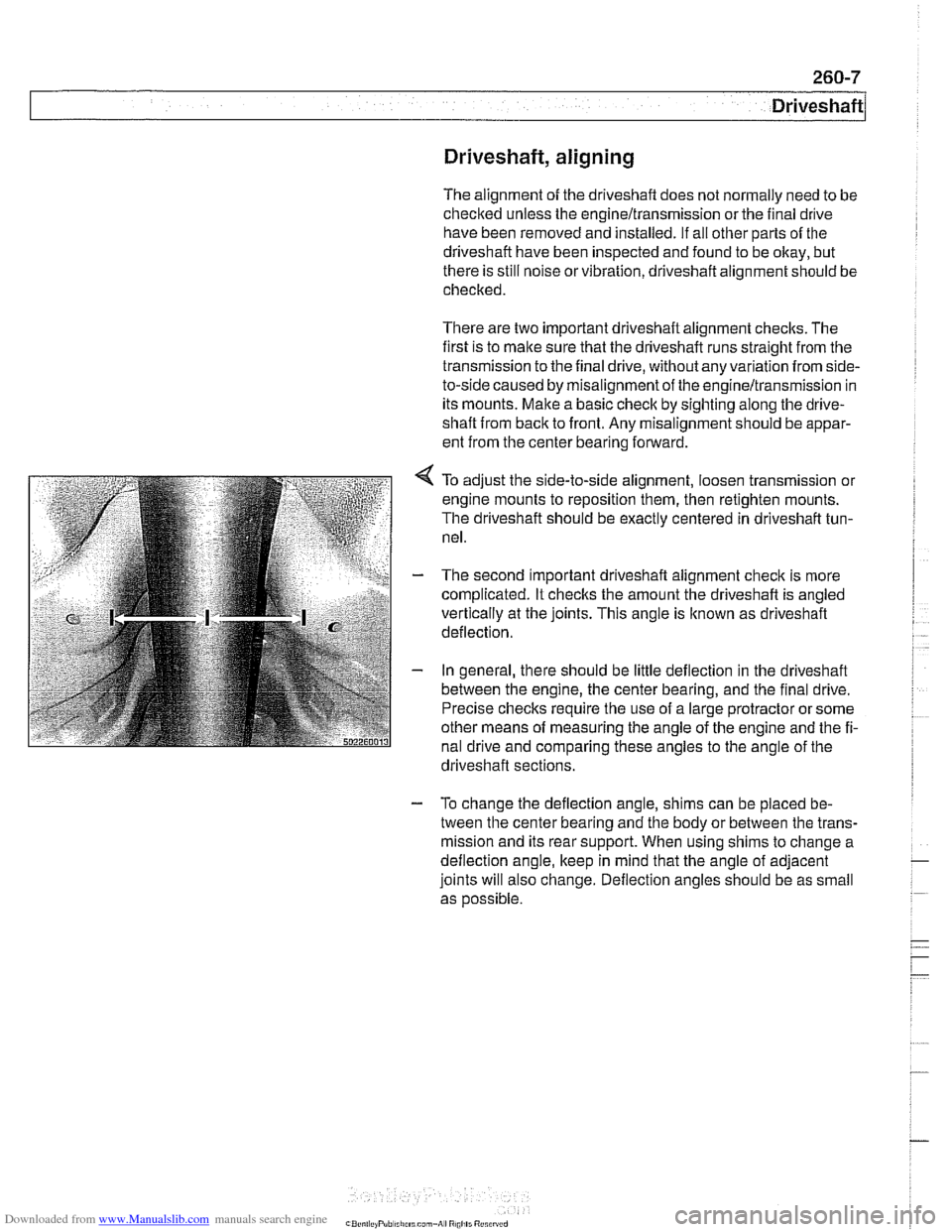

There are two important driveshaft alignment checks. The

first is to make sure that the driveshaft runs straight from the

transmission to the final drive, without any variation from

side-

to-side caused by misalignment of the engineltransmission in

its mounts. Make a basic check by sighting along the

drive-

shaft from back to front. Any misalignment should be appar-

ent from the center bearing forward.

To adjust the side-to-side alignment, loosen transmission or

engine mounts to reposition them, then retighten mounts.

The driveshaft should be exactly centered in driveshaft tun-

nel.

The second important driveshaft alignment check is more

complicated. It checlts the amount the driveshaft is angled

vertically at the joints. This angle is

lknown as driveshaft

deflection.

In general, there should be little deflection in the driveshaft

between the engine, the center bearing, and the final drive.

Precise checks require the use of a large protractor or some

other means of measuring the angle of the engine and the fi-

nal drive and comparing these angles to the angle of the

. . driveshaft sections.

- To change the deflection angle, shims can be placed be-

tween the center bearing and the body or between the trans-

mission and its rear support. When using shims to change a

deflection angle, keep in mind that the angle of adjacent

joints will also change. Deflection angles should be as small

as

oossible.

Page 614 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.- .

/ Driveshaft Driveshaft, removing

CAUTION-

. Be sure the wheels are off the ground before removing the

driveshak Set the parl(ing brake before removing the

driveshaft.

Once the driveshaft has been removed, the vehicle can

roll regardless of whether the transmission is in gear or

not.

The driveshaft is mounted to the transmission and final

drive

with self-locliing nuts. These nuts are designed to

be used only once and should be replaced during reas-

sembly.

Remove complete exhaust system. See

180 Exhaust

System.

- Remove exhaust heat shields.

- Support transmission with transmission jack.

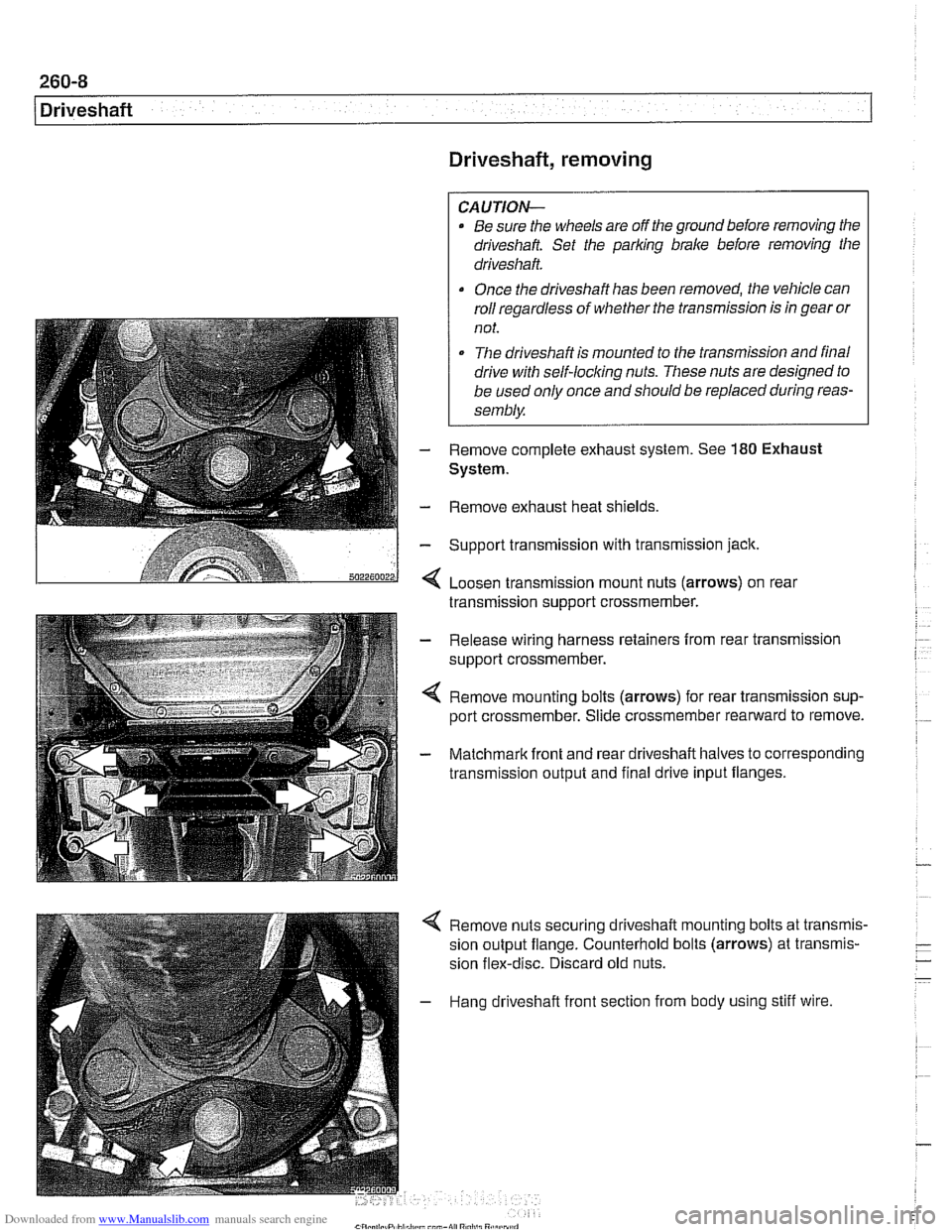

< Loosen transmission mount nuts (arrows) on real

transmission support crossmember.

- Release wiring harness retainers from rear transmission

support crossmember.

< Remove mounting bolts (arrows) for rear transmission sup-

port crossmember. Slide crossmember rearward to remove.

- Matchmark front and rear driveshaft halves to corresponding

transmission output and final drive input flanges.

4 Remove nuts securing driveshaft mounting bolts at transmis-

sion output flange. Counterhold bolts (arrows) at transmis-

sion flex-disc. Discard old nuts.

- Hang driveshaft front section from body using stiff wire.