Oul BMW 540i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 880 of 1002

Downloaded from www.Manualslib.com manuals search engine

I lnterior Trim

This repair group covers interior trim removal and installation

procedures.

- Refer to the following repair groups for additional information:

250 Gearshift Linkage

41 1 Doors (interior door panels)

@ 612 Switches

620 Instruments

640 Heating and Air Conditioning [IHKA control panel!

650 Radio

721 Airbag System (SRS)

lnterior trim repairs

lnterior trim and finish panels are clipped or screwed into

place. Many of the trim retaining clips are designed

to be used

only once. When removing trim that is held in place with clips,

it is a good idea to have spare clips on hand before beginning

the job.

WARNING-

Special precautions must be observed when servicing the

BMWSupplementai Restraint System (SRS). Serious inju-

ry may result if system service is attempted by persons un-

familiar with the BMW

SRS and its approved service

procedures. BMW

speciiies that all inspection and service

should be performed by an authorized BMW

dealer.

Before performing any work involving airbags, discon-

nect the negative

() battery cable. See 721 Airbag

System (SRS).

Airbags contain a back-uppowersupply within the SRS

control module. A

5 second discharge period should be

allowed after the battery cable has been disconnected.

CAUTION-

* When working on electrical switclies or lights, always dis-

connect the negative

(-) cable from the battery and insu-

late the cable end to prevent accidental reconnection.

a Prior to disconnecting the battery, read the battery dis-

connection cautions given in

W1 General Warnings

and Cautions.

To prevent marring the trim when working on interior

components, work with plastic prying

tools or wrap the

tips of screwdrivers and pliers with tape before prying

Page 901 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

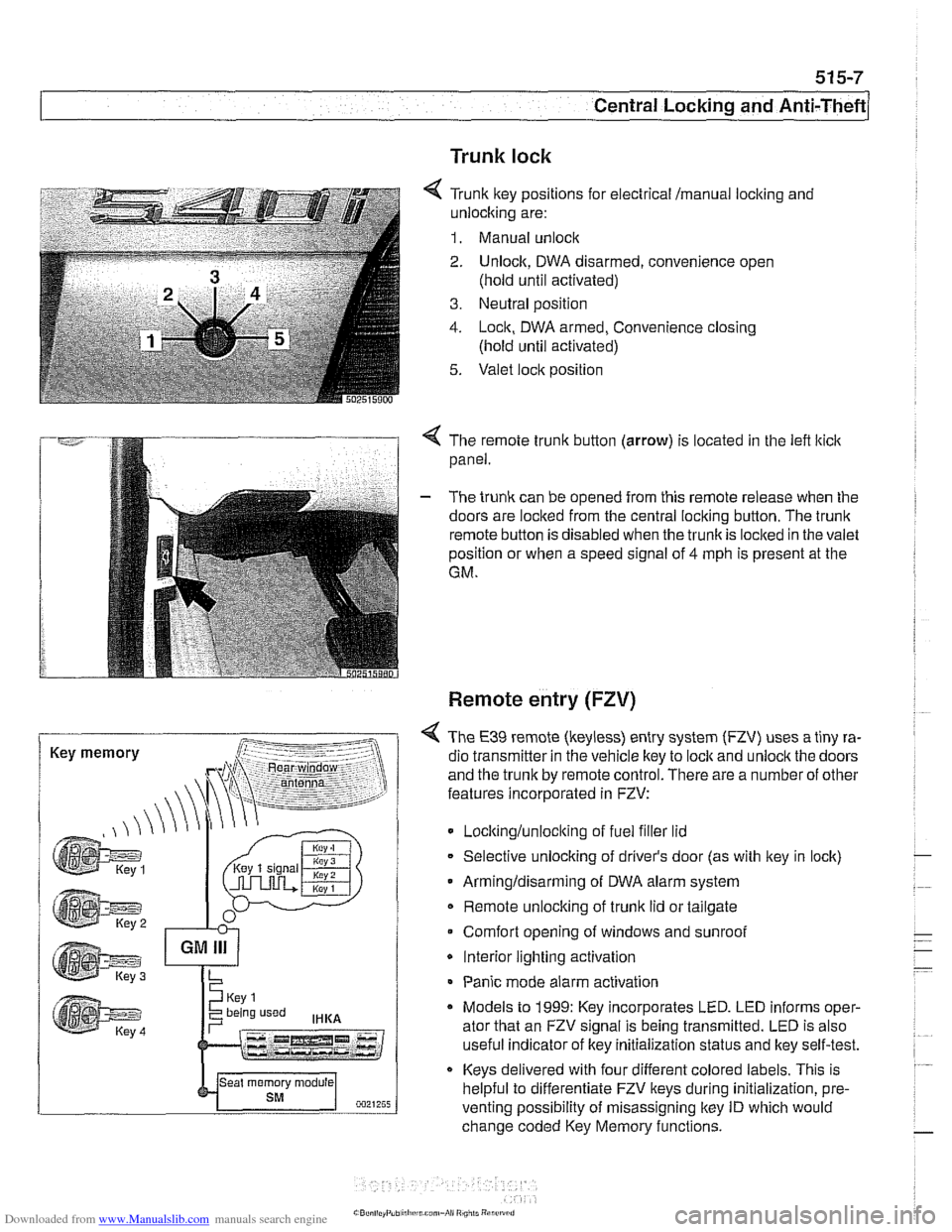

Trunk lock

6 Tr~nk ftey pos~rions for eecir'cal mama, locking and

-nlock~ng are:

1. Manual unock .. - - - ........ - ..- .- ................. s.=.=-- 2. Unlock. DWA oisarmed, conven:ence open

(nold

un1:l aclivaledj

3. Ne~tral posit'on

1. -ocn. DWA armeo, Convenience closng

(hold ~nti activated)

5. Valet .oc,t position

. -- .............-... .- . - -.....

Key memory

< The remote trunk button (arrow) is located in the lefl lticlc

panel.

- The trunk can be opened from this remote release when the

doors are locked from the central locking button. The

trunk

remote button is disabled when the trunkis loclted in the valet

position or when a speed signal of

4 mph is present at the

GM.

Remote entry (FZV)

< The €39 remote (keyless) entry system (FZV) uses a tiny ra-

dio transmitter in the vehicle key to

lock and unlock the doors

and the trunk by remote control. There are a number of other

features incorporated in FZV:

Locltinglunloclting of fuel filler lid

Selective unlocking of driver's door (as with key in lock)

Armingldisarming of DWA alarm system

Remote unlocking of

trunk lid or tailgate

Comfort opening of windows and sunroof

* Interior lighting activation

Panic mode alarm activation

* Models to 1999: Key incorporates LED. LED informs oper-

ator that an FZV signal is being transmitted. LED is also

useful indicator of key initialization status and lkey self-test.

Keys delivered with four different colored labels. This is

helpful to differentiate FZV keys during initialization,

pre.

venting possibility of misassigning key ID which would

change coded Key Memory functions.

Page 903 of 1002

Downloaded from www.Manualslib.com manuals search engine

515-9

Central Locking and ~nti-~heftl

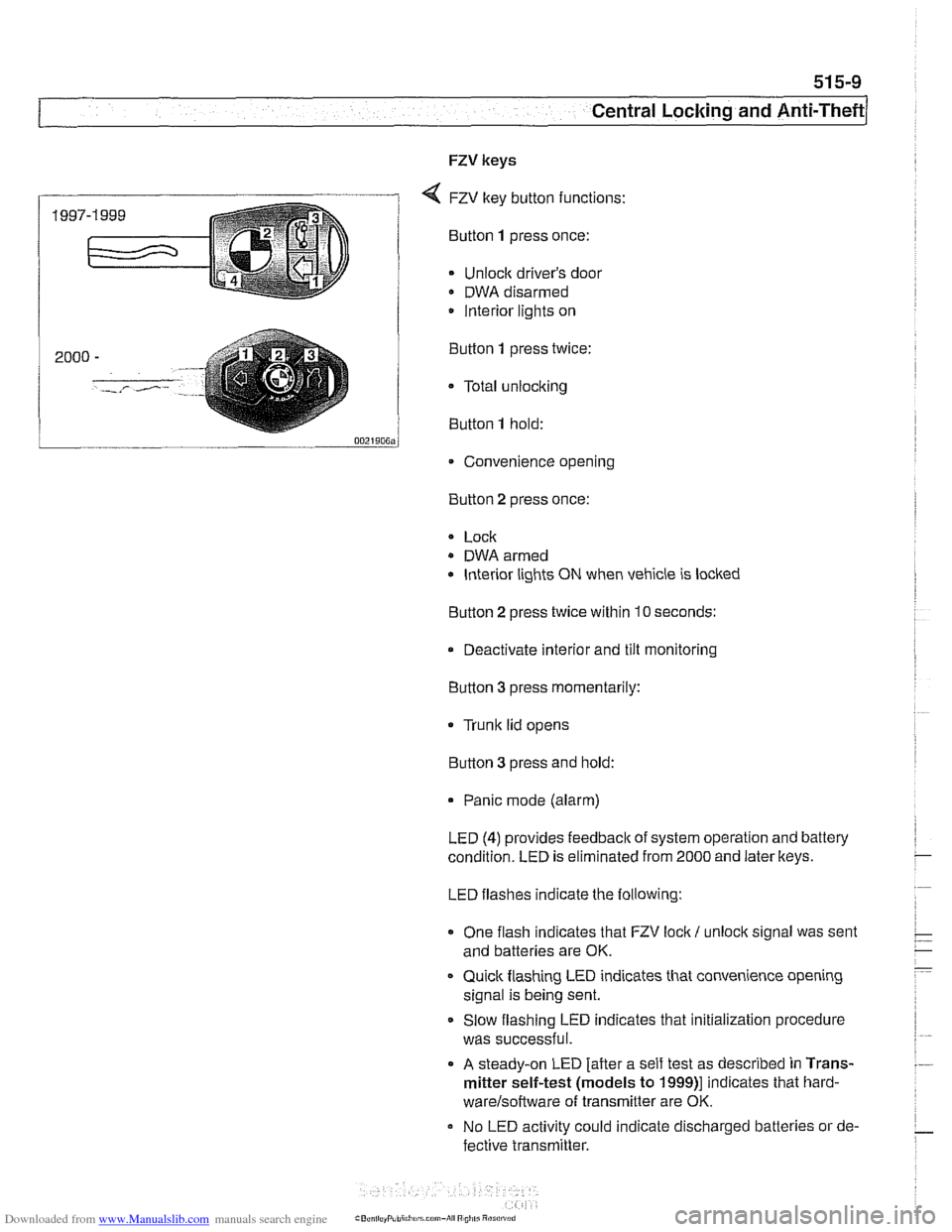

FZV keys

4 FZV key button functions:

Bunon 1 press once:

Unlock driver's door

DWA disarmed

/ lnterior lights on

... - 0021~0~~j

Convenience opening

2000

-

'.-,- /- ..,.

Button 2 press

once:

Button

1 press twice:

a Total

unlocking

Button

1 hold:

* Lock

- DWA armed

lnterior lights ON when vehicle is locked

Button

2 press twice within 10 seconds:

Deactivate interior and tilt monitoring

Button 3 press momentarily:

Trunk lid opens

Button

3 press and hold:

Panic mode (alarm)

LED

(4) provides feedback of system operation and battery

condition. LED is eliminated from 2000 and later

lkeys.

LED flashes indicate the following:

One flash indicates that FZV

lock I unlock signal was sent

and batteries are OK.

Quick flashing LED indicates that convenience opening

signal is being sent.

Slow flashing LED indicates that initialization procedure

was successful.

A steady-on LED [after a self test as described in Trans-

mitter self-test (models to

1999)l indicates that hard-

warelsoftware of transminer are OK.

No LED activity could indicate discharged batteries or de-

fective

transmitter.

Page 905 of 1002

Downloaded from www.Manualslib.com manuals search engine

515-11

Central Lockinq and ~nti-l heft/

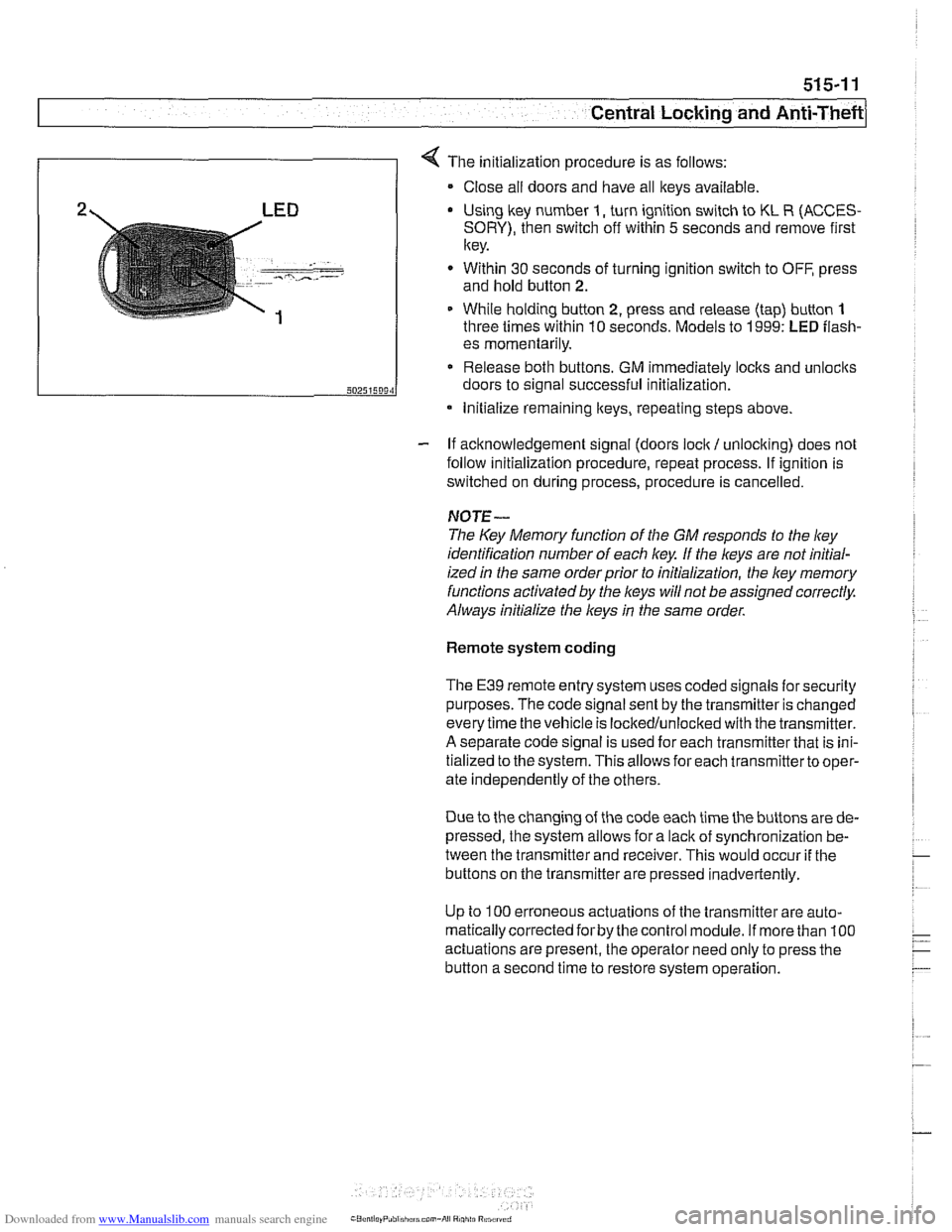

4 The initialization procedure is as follows:

Close ail doors and have all keys available

2 LED Using lkey number I, turn ignition switch to KL R (ACCES-

SORY), then switch off within 5 seconds and remove first

key.

. - -- , ..-.---- - Within 30 seconds of turning ignition switch to OFF, press

and hold button

2.

1 While holding button 2, press and release (tap) button 1

three times within 10 seconds. Models to 1999: LED flash-

- If acknowledgement signal (doors lock / unlocking) does not

follow initialization procedure, repeat process. If ignition is

switched on during process, procedure is cancelled.

50251509‘1

NOTE-

The Key Memory function of the GM responds to the ley

identification number of each key If the keys are not initial-

ized

in the same orderprior to initialization, the ley memory

functions activated by the

l(eys will not be assigned correctly.

Always initialize the keys

in the same order.

es momentarily.

Release both buttons. GM immediately locks and unlocits

doors to signal successful initialization.

Remote system coding

* Initialize remaining lteys, repeating steps above.

The E39 remote entry system uses coded signals for security

purposes. The code signal sent by the transmitter is changed

every time the vehicle is lockedlunlocked with the transmitter.

A separate code signal is used for each transmitter that is ini-

tialized to the system. This allows for each transmitterto oper-

ate independently of the others.

Due to the changing of the code each time the buttons are de-

pressed, the system allows for a

lacit of synchronization be-

tween the transmitter and receiver. This would occur

if the

buttons on the transmitter are pressed inadvertently.

Up to

100 erroneous actuations of the transmitter are auto-

matically corrected

forby the control module. If more than 100

actuations are present, the operator need only to press the

button a second time to restore system operation.

Page 916 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anii-Theft

- If the starter engages, the following EWS inputs are function-

ing normally:

Ignition key

Code function

Transmission range switch or clutch position switch

Engine speed sensor

NO JE -

If a vehicle key is lost or stolen, the electronic authorization

for that key

can be cancelled using the BMW scan and di-

agnostic tools

DISplus, GTl or MoDiC.

Force applied to a ley can damage the electronic circuitry

in the key A damaged ley will not start the engine. In that

case, a new key should be purchased and initialized

by an

authorized BMW dealer.

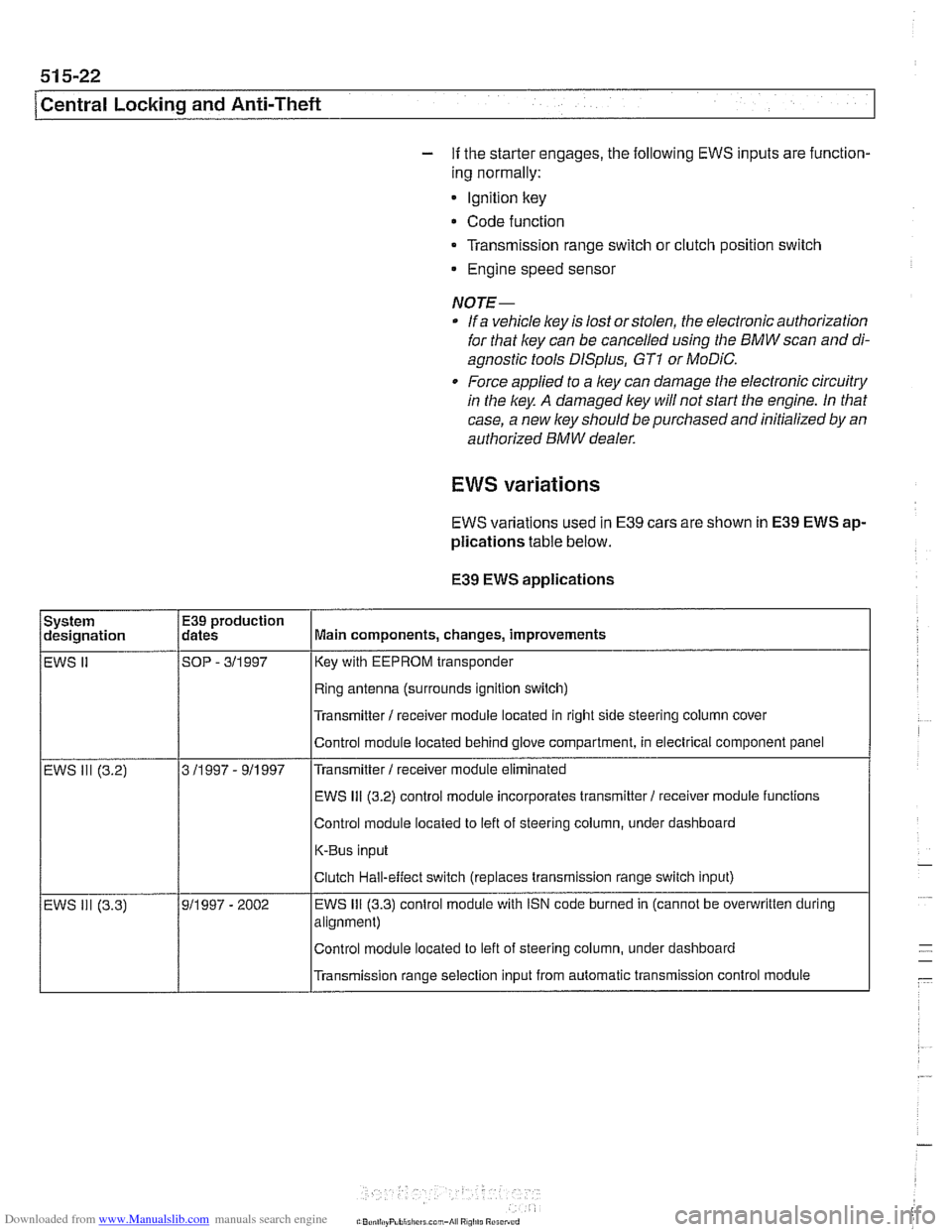

EWS variations

EWS variations used in E39 cars are shown in E39 EWS ap-

plications

table below.

E39

EWS applications

I I Ifling antenna (surrounds ignition switch) I

System

designation

EWS

II

I I l~ransmitter I receiver module located in right side steering column cover I

E39 production

dates

SOP

- 311 997

I I IEWS 111 (3.2) control module incorporates transmitter1 receiver moduie functions /

Main components, changes, improvements

Key with EEPROM transponder

Control moduie located behind glove compartment, in electrical component panel

Control module located to left of steering column, under dashboard

K-Bus input

Transmitter

I receiver module eliminated

EWS 111 (3.2)

Transmission range selection input from automatic transmission control module

3

11997 - 911997

- EWS ill (3.3) Clutch

Hall-effect switch (replaces transmission range switch input)

911997 - 2002 EWS 111 (3.3) control

module with iSN code burned in (cannot be overwritten during

alignment)

Control module located to left of steering column, under dashboard

Page 924 of 1002

Downloaded from www.Manualslib.com manuals search engine

l Seats

Seat repair and component replacement is possible once the

seat has been removed from the vehicle.

Before servicing front seats read safety regulations on han-

dling

airbag modules and pyrotechnic seatbelt tensioners.

See

720 Seat belts and 721 Airbag system (SRS).

WARNING-

. The front seats are equipped with pyrotechnic seat belt

tensioners. These tensioners are powerful devices and

should be handled with exfreme care. Incorrect handling

can trigger off the tensioner and cause injury.

BMW recommends that all repair or replacement

worlc

on pyrotechnic devices must be carried out by a quali-

fied

BMW technician.

Be sure to disconnect the battery and wait

5 seconds

before attempting to work on pyrotechnic devices.

During body straightening and welding with an electric

arc welder, always disconnect the battery and the con-

nection to the pyrotechnic gas generators.

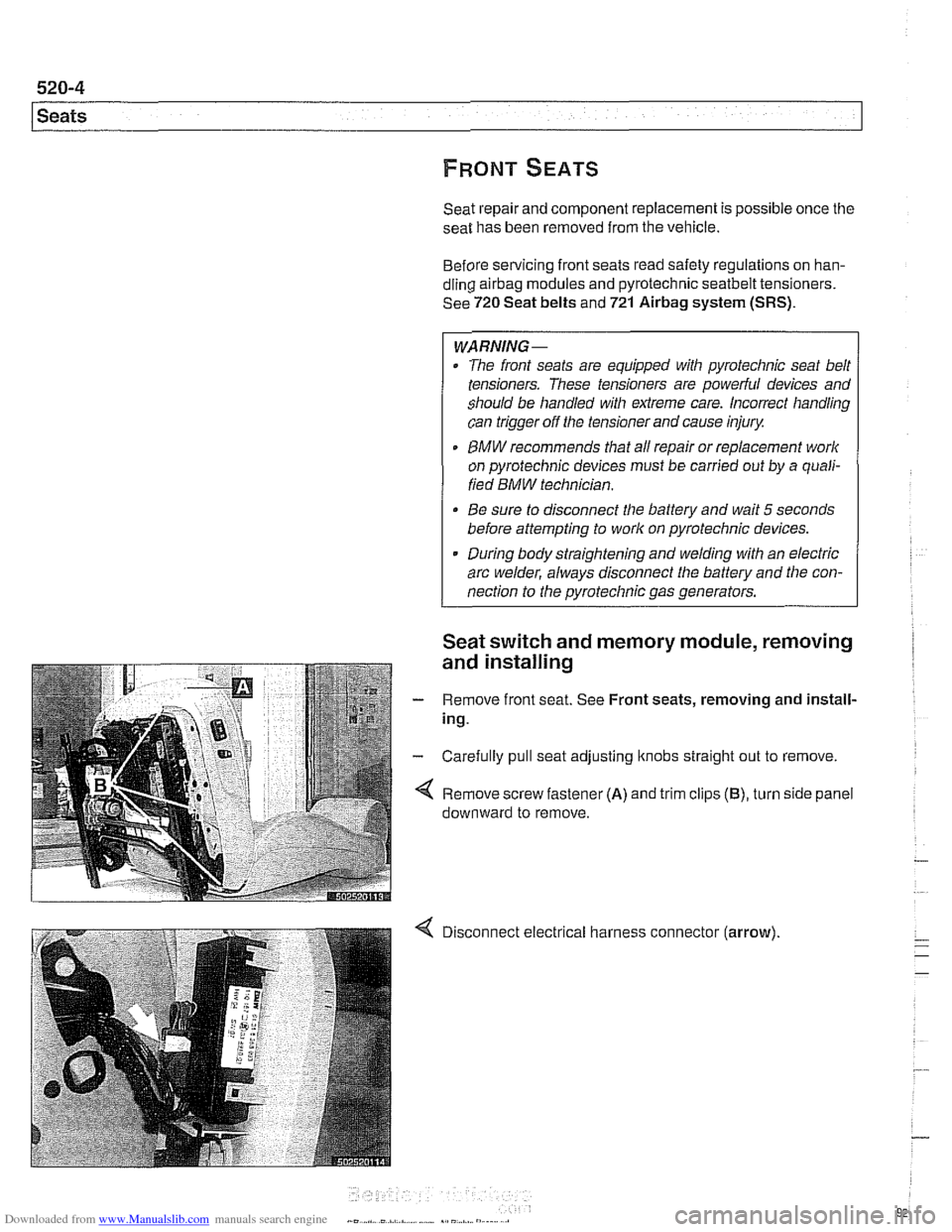

Seat switch and memory module, removing

and installing

- Remove front seat. See Front seats, removing and install-

ing.

- Carefully pull seat adjusting ltnobs straight out to remove.

Remove screw fastener

(A) and trim clips (B), turn side panel

downward to remove.

Disconnect electrical harness connector

(arrow).

Page 933 of 1002

Downloaded from www.Manualslib.com manuals search engine

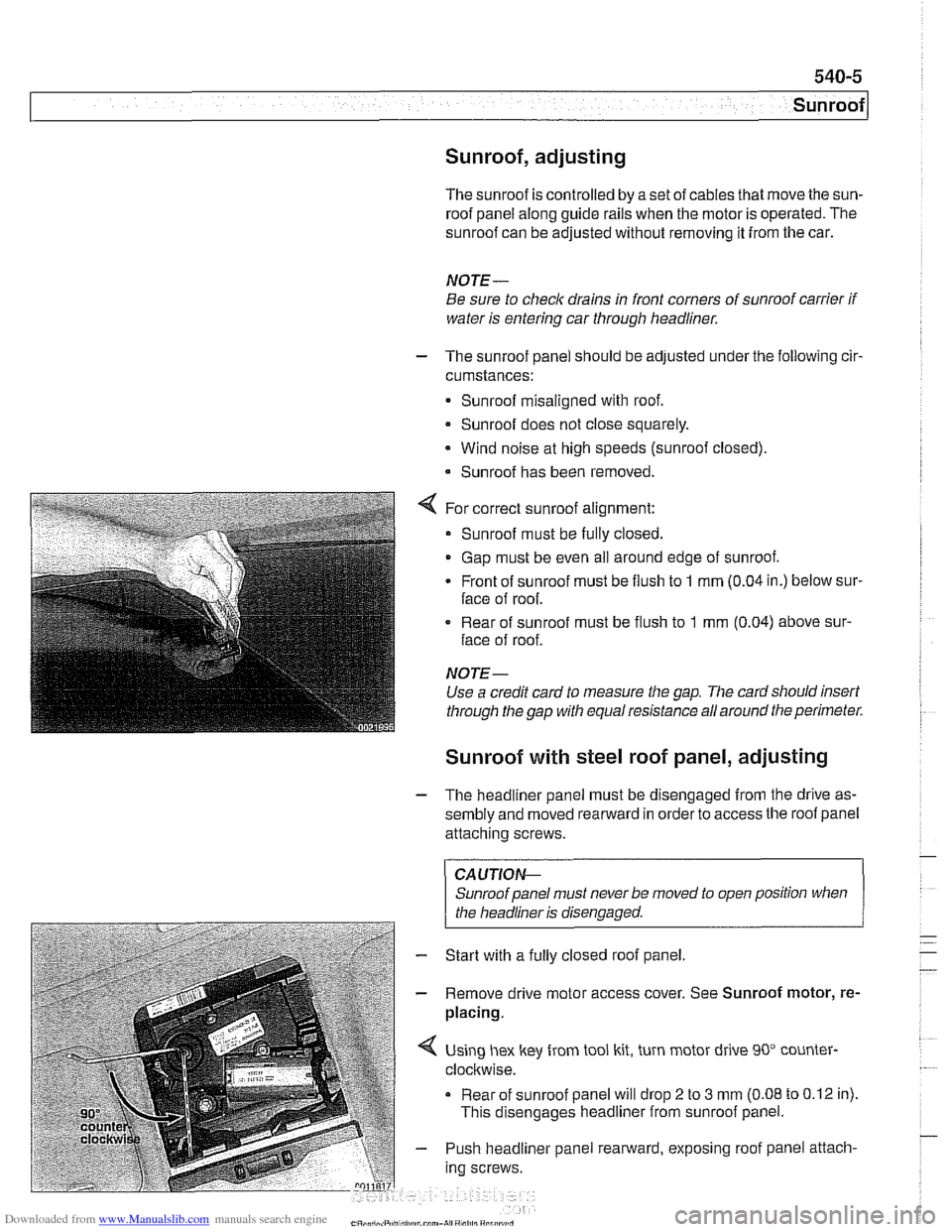

Sunroof, adjusting

The sunroof is controlled by a set of cables that move the sun-

roof panel along guide rails when the motor is operated. The

sunroof can be adjusted without removing it from the car.

NOTE-

Be sure to check drains in front corners of sunroof carrier if

water is entering car through headliner.

- The sunroof panel should be adjusted under the following cir-

cumstances:

Sunroof misaligned with roof.

Sunroof does not close squarely.

* Wind noise at high speeds (sunroof closed).

Sunroof has been removed.

For correct sunroof alignment:

Sunroof must be fully closed.

Gap must be even all around edge of sunroof.

Front of sunroof must be flush to

1 mm (0.04 in.) below sur-

face of roof.

. Rear of sunroof must be flush to 1 mm (0.04) above sur-

face of roof.

NOTE-

Use a credit card to measure the gap. The card sllould insert

through the gap with equal resistance all around the perimeter.

Sunroof with steel roof panel, adjusting

- The headliner panel must be disengaged from the drive as-

sembly and moved rearward in order to access the roof panel

attaching screws.

CAUTIOI\C

Sunroof panel must never be moved to open position when . .

I the headliner is disenaaaed. 1

- Start with a fully closed roof panel.

- Remove drive motor access cover. See Sunroof motor, re-

placing.

Using hex key from tool kit, turn motor drive 90" counter-

clockwise.

Rear of sunroof panel will drop

2 to 3 mm (0.08 to 0.12 in).

This disengages headliner from sunroof panel.

- Push headliner panel rearward, exposing roof panel attach-

ing screws.

Page 940 of 1002

Downloaded from www.Manualslib.com manuals search engine

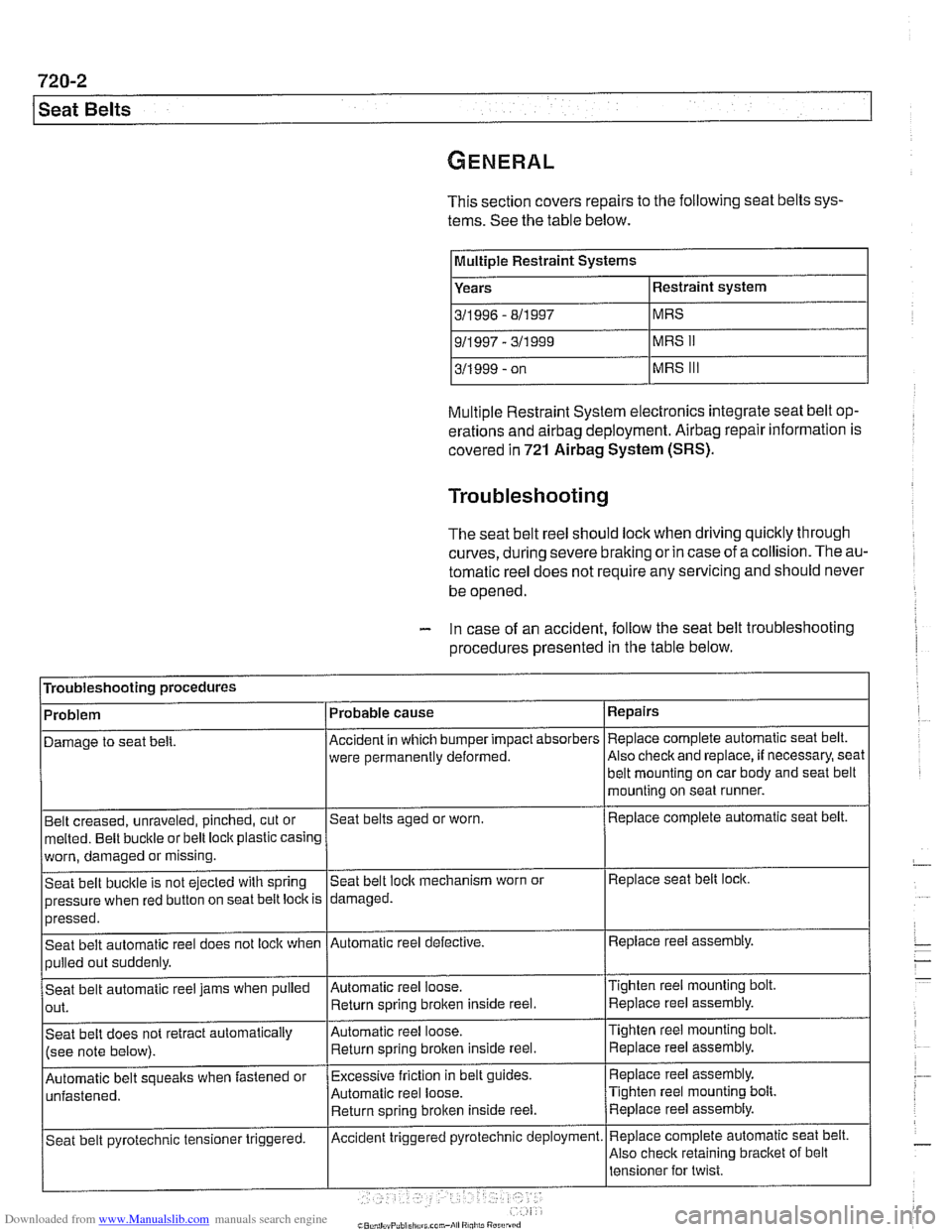

I Seat Belts

This section covers repairs to the following seat belts sys-

tems. See the table below.

IMultIple Restraint Systems I

Years

311 996 - 811 997

Multiple Restraint System electronics integrate seat belt op-

erations and

airbag deployment. Airbag repair information is

covered

in 721 Airbag System (SRS).

Troubleshooting

The seat belt reel should lock when driving quicltly through

curves,

during severe braking or in case of a collision. The au-

tomatic reel does not require any servicing and should never

be opened.

- In case of an accident, follow the seat belt troubleshooting

procedures presented

in the table below.

Troubleshooting procedures

Belt creased, unraveled, pinched, cut or

melted. Belt buckle or belt loclt plastic casing Repairs

Replace complete automatic

seat belt.

Also

checlt and replace, if necessary, seat

Problem

Damage to seat

belt.

worn, damaged or missing.

Seat belt bucltle is not ejected with spring

pressure when red button on seat belt loclt is

>--- I I

Automatic belt soueaks when fastened or I~xcessive friction in belt guides. I Replace reel assembly.

Probable

cause

Accident in which bumper impact absorbers

were permanently deformed.

Seat belts aged or worn.

pressed.

Seat belt automatic reel does not lock when

pulled out suddenly.

Seat belt automatic reel jams when pulled

out.

Seat belt does not retract automatically

(see note below).

Automatic reel loose. Return sorino broken inside reel. belt mounting on car body and

seat belt

mounting on seat runner.

Replace complete automatic seat belt.

Seat belt

loclt mechanism worn or

damaged.

Tighten reel mounting bolt Replace reel assembly.

Replace seat belt lock.

Automatic reel defective.

Automatic reel loose. Return spring

broken inside reel.

Automatic reel loose.

Return spring brolten inside reel. Replace reel

assembly.

Tighten reel mounting

bolt.

Replace reel assembly.

Tighten reel mounting bolt. Replace reel assembly.

~ ~-~~ , - I'

Replace complete automatic seat belt.

Also check retaining bracket of belt

Seat belt

pyrotechnic tensioner triggered. Accident triggered pyrotechnic deployment.

Page 941 of 1002

Downloaded from www.Manualslib.com manuals search engine

Seat Belts

NOTE-

The rear bench seat belt strap may not retract fully due to in-

creased friction between strap and seat cover.

A small re-

maining loop in belt strap when fully retracted is acceptable.

WARNING-

* For maximum protection from injury, seat bells should be

replaced as a set (including all hardware), if they are sub-

ject to occupant loading in a collision.

Seat belts should not be modified or repaired. The seat

belt mounting points should not be changed or modi-

fied.

Do not bleach or dye seat belt webbing. Webbing that

is severely faded or

redyed will not meet the strength

requirements of a collision and must be replaced.

Clean belts with a luke-warm soap solution only:

Seat belts should be periodically inspected for webbing

defects such as cuts or pulled threads.

* Immediately after replacing a damaged or worn seat

belt, destroy the old belt to prevent it from being used

again.

Page 942 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

Seat Belts

Front seat belt tensioner, removing and

installing

- Disconnect battery negative (-) cable in trunk.

The

front seat belt loclts are equipped with pyrotechnic (ex-

plosive charge) automatic tensioners. These tensioners are

designed to automatically retract and tension the seat belt by

55 mm (approximately 2 inches) in the event of an accident.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

WARNING-

Pyrotechnic seat belt tensioners are powerful devices and

should be handled with extreme care. Incorrect handling

can trigger the tensioner and cause injury

BMW recommends that all repair or replacement work

on pyrotechnic devices must be carried out by a quali-

fied BMW technician.

Be sure to disconnect the battery and wait

5 seconds

before attempting to work on pyrotechnic devices.

Pyrotechnic devices cannot be repaired. Always re-

place them.

Never treat pyrotechnic components with cleaning

agents or grease.

- Do not expose pyrotechnic components to tempera-

tures above

75% (167°F).

Pyrotechnic components can only be tested electrically

when installedusing the

BMWService Tester (DISplus,

GTI, or MoDiC).

Do not fire a pyrotechnic gas generatorprior to dispos-

al. It must be fired by a special disposal company or

shipped

back to BMW in the packaging of the new com-

ponent.

During body straightening and welding with an electric

arc welder, always disconnect the battery and the con-

nection to the pyrotechnic gas generators.

- Remove front seat as described in 520 Seats.

-