Oul BMW 540i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 730 of 1002

Downloaded from www.Manualslib.com manuals search engine

(Rear Suspension

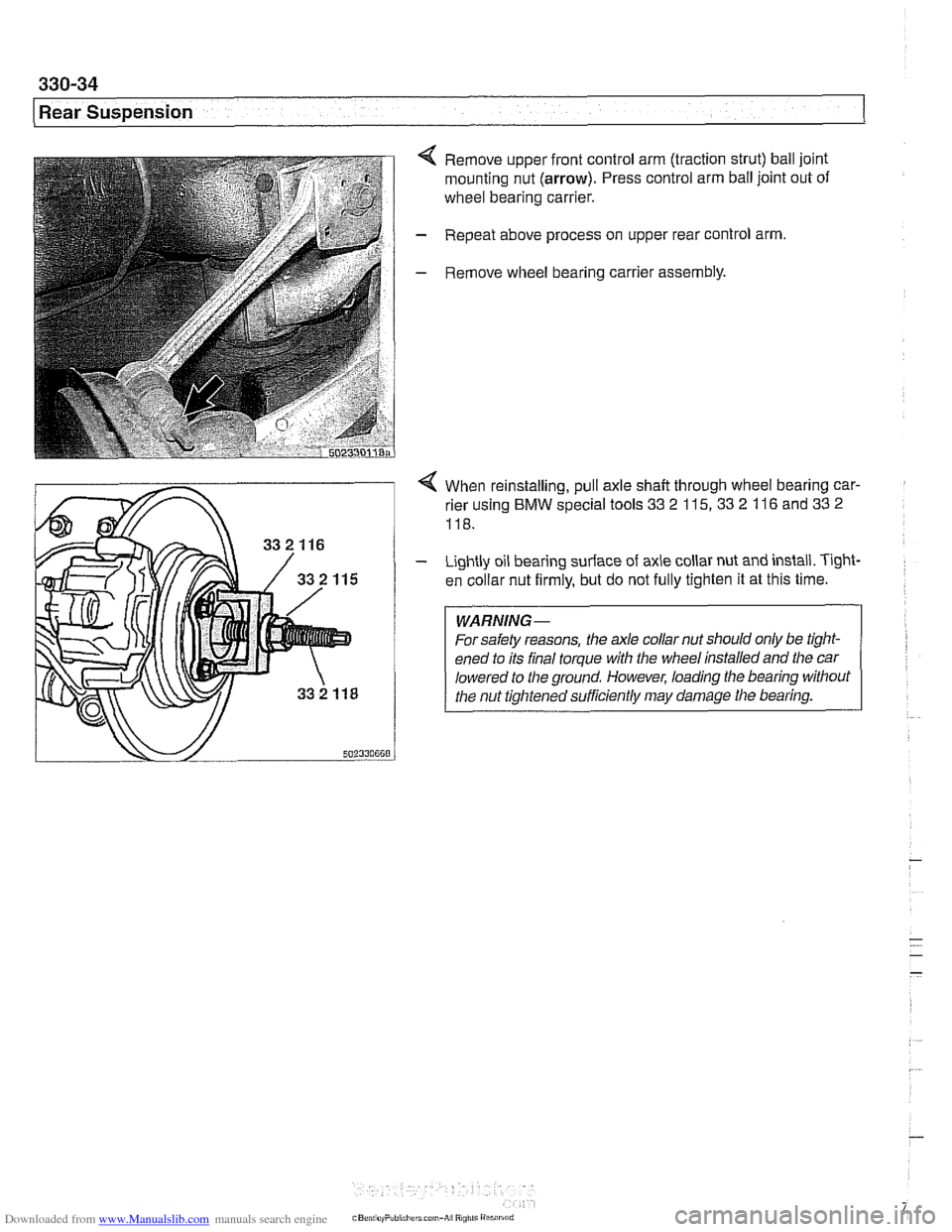

< Remove upper front control arm (traction strut) ball joint

mounting nut

(arrow). Press control arm ball joint out of

wheel bearing carrier.

- Repeat above process on upper rear control arm.

- Remove wheel bearing carrier assembly.

4 When reinstalling, pull axle shaft through wheel bearing car-

rier using

BMW special tools 33 2 115, 33 2 116 and 33 2

118.

- Lightly oil bearing surface of axle collar nut and install. T~ght-

en collar nut firmly, but do not fully tighten it at this time.

WARNING-

For safety reasons, the ale collar nut should only be tight-

ened to its final torque with the wheel installed and the car

lowered to

the ground. However, loading the bearing without

the nut tightened sufficiently may damage tlie bearing.

Page 734 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Rear Suspension

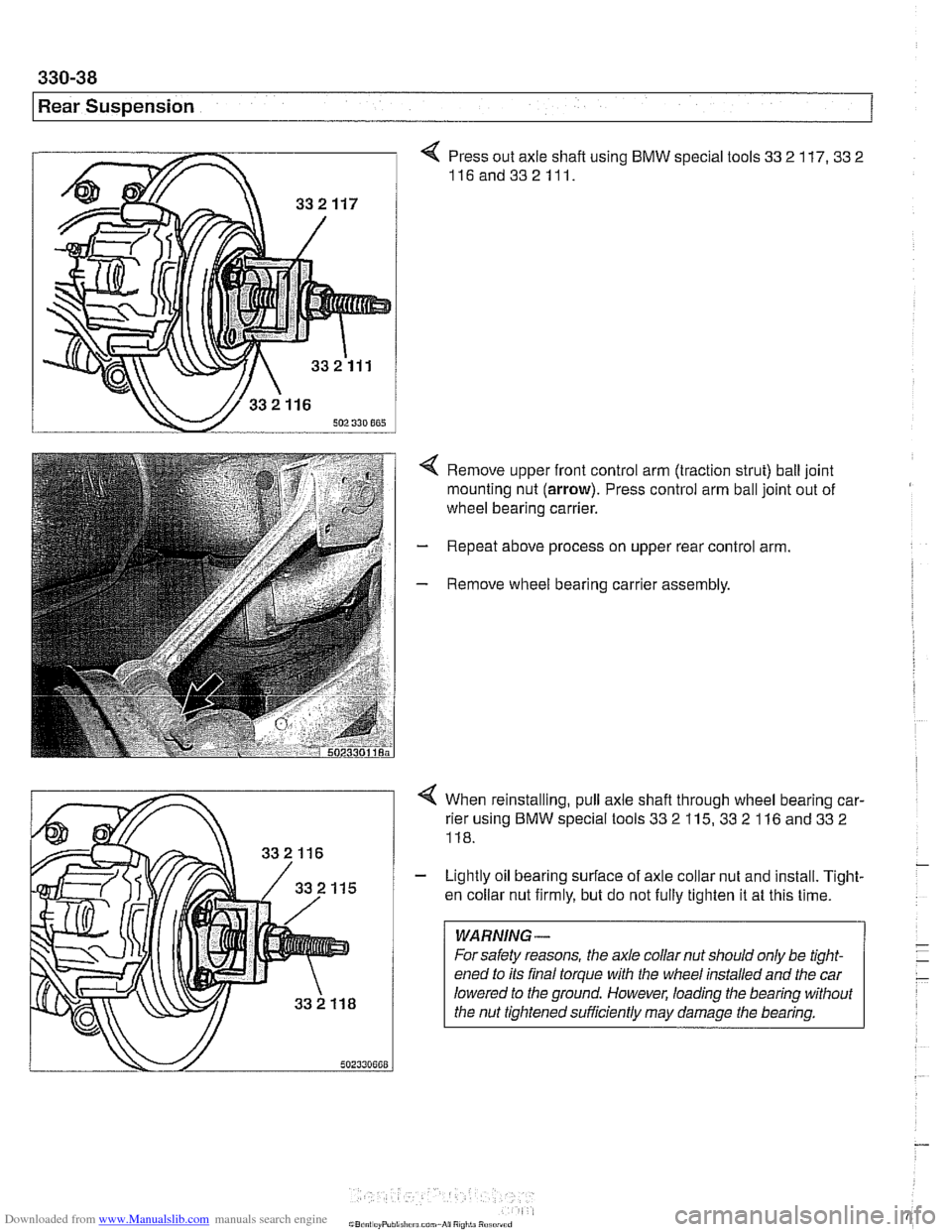

4 Press out axle shaft using BMW special tools 33 2 117. 33 2

116and332111.

4 Remove upper front control arm (traction strut) ball joint

mounting nut (arrow). Press control arm ball joint out of

wheel bearing carrier.

- Repeat above process on upper rear control arm.

- Remove wheel bearing carrier assembly.

4 When reinstalling, pull axle shafl through wheel bearing car-

rier using BMW special tools 33

2 115, 33 2 116 and 33 2

118.

- Lightly oil bearing surface of axle collar nut and install. Tight-

en collar nut firmly, but do not fully tighten it at this time.

WARNING-

For safety reasons, the axle collar nut should only be tight-

ened to its final torque with the wheel installed and the car

lowered to the ground. However, loading the bearing without

the nut tiqhtened

suificiently may darnaqe the bearina.

Page 737 of 1002

Downloaded from www.Manualslib.com manuals search engine

--. ..

Rear Suspension

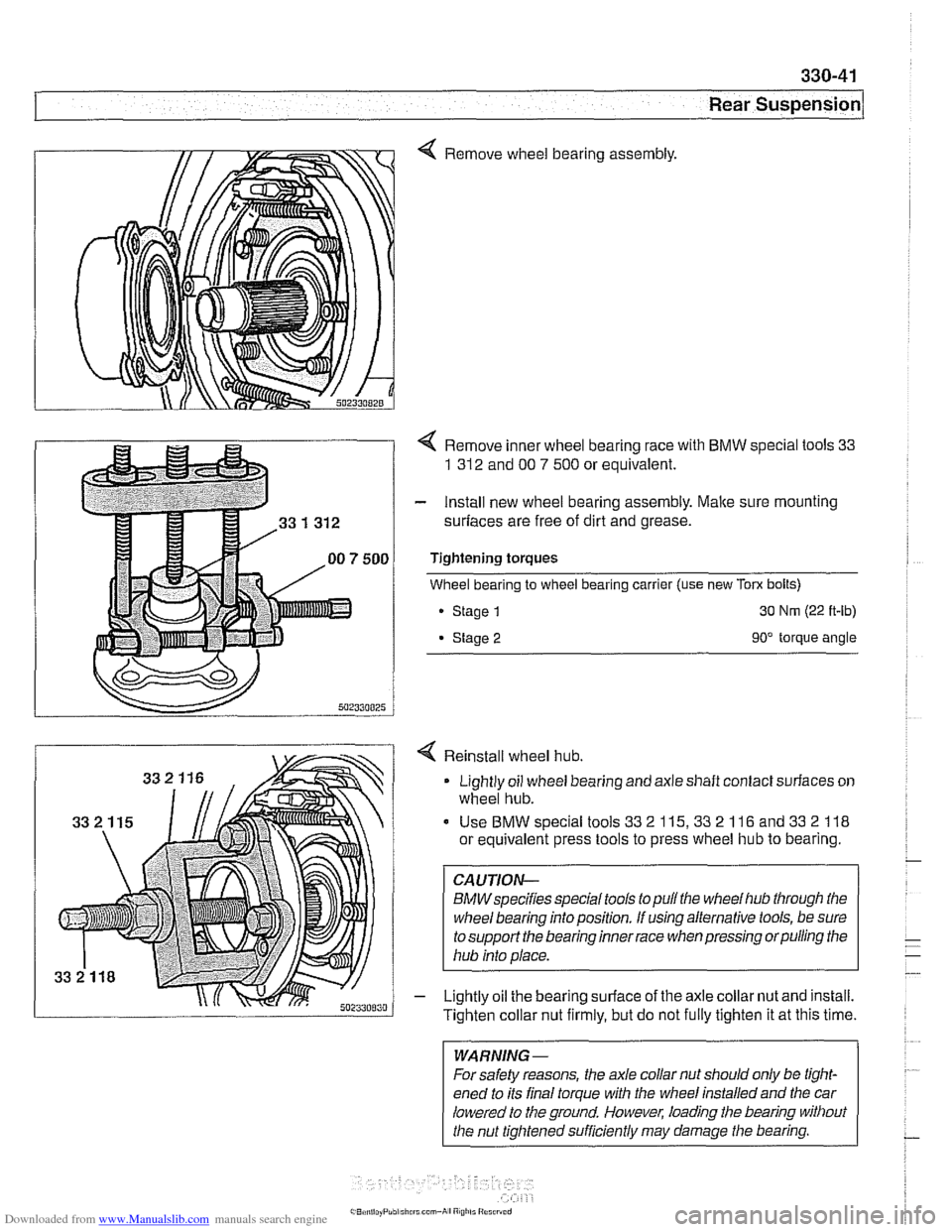

4 Remove wheel bearing assembly.

4 Remove inner wheel bearing race with BMW special tools 33

1 312

and 00 7 500 or equivalent.

- Install new wheel bearing assembly. Malte sure mounting

surfaces are free of dirt and grease.

Tightening torques

Wheel bearing to wheel bearing carrier (use new

Tom bolts)

Stage

1 30 Nm (22 ft-lb)

Stage 2 90" torque angle

4 Reinstall wheel hub.

Lightly oil wheel bearing and axle shaft contact surfaces on

wheel hub.

Use BMW special tools

33 2 115,33 2 116 and 33 2 118

or equivalent press tools to press wheel hub to bearing.

CAUTION-

BMWspecifies speclaltools to pull the wheel hub through the

wheel bearing into position. If using alternative tools, be sure

to support the bearing inner race when pressing orpulling the

hub into place.

- Lightly oil the bearing surface of the axle collar nut and install.

Tighten collar nut firmly, but do not fully tighten it at this time.

WARNING-

For safety reasons, the axle collar nut should only be tight-

ened to its final torque with the wheel installed and the car

lowered to the ground. However, loading the bearing without

the nut tightened sufficiently may damage

the bearing.

Page 750 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final Drive

Tightening torques

F~nal drive to rear axle carrier 105 Nm (77 it-lb)

Driveshaft CV joint to final drive flange

- MlO (Torx bolt) 70

Nm (51 ft-lb)

- M8 (compression nut) 32 Nm (24

ft-lb)

Drive axle to final drive

ilange

Torx bolts (M10) 83 Nm (61 ft-lb)

Torx bolt with

rlbbed teeth (M10) 64 Nm (47 ft-lb)

Torx bolt

wlth ribbed teeth (MI0 sliver) 80 Nm (59 ft-lb)

Torx

bolt with ribbed teeth (M10 black) 100 Nm (74 ft-lb)

* Torx bolt with ribbed teeth (M12) 135 Nm (100 ft-lb)

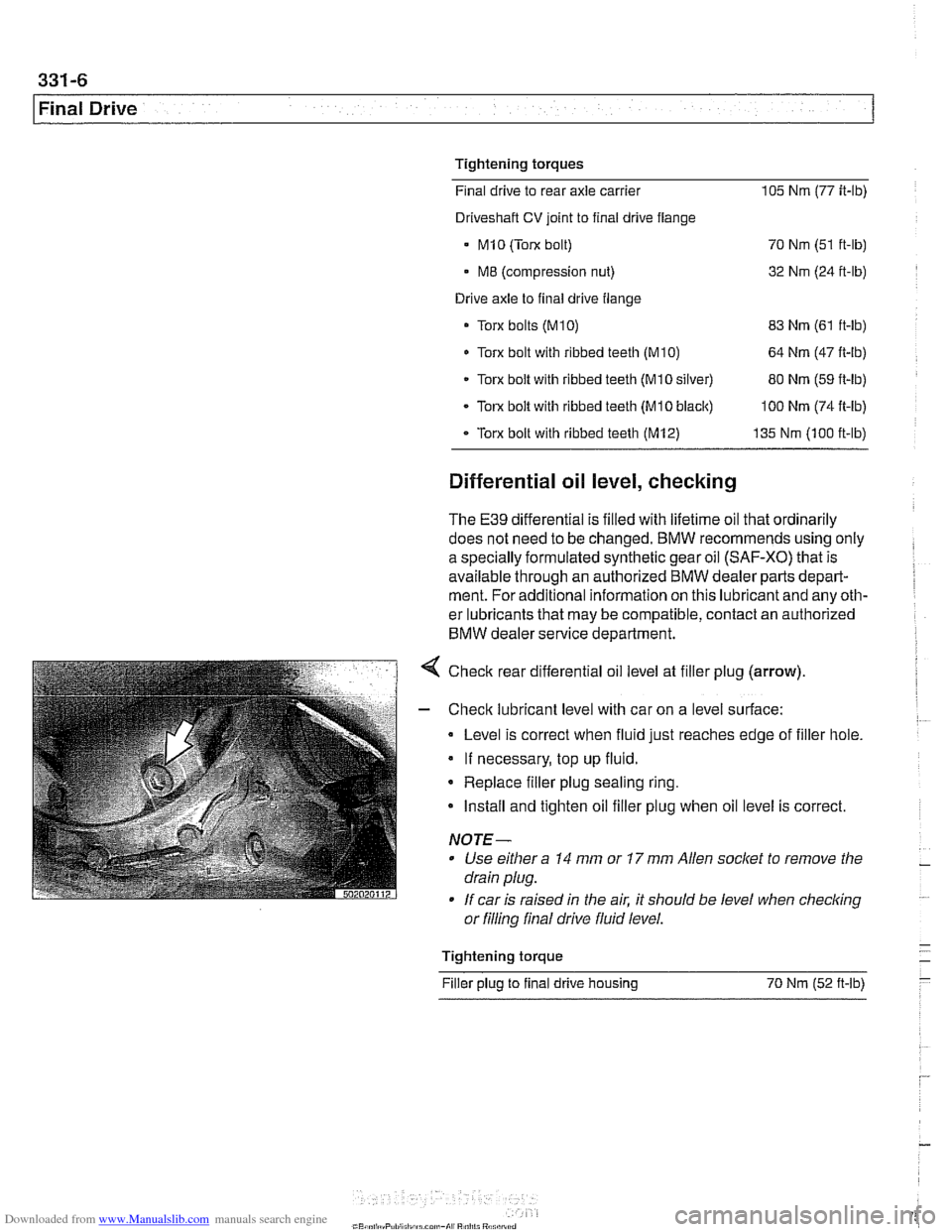

Differential oil level, checking

The E39 differential is filled with lifetime oil that ordinarily

does not need to be changed. BMW recommends using only

a specially formulated synthetic gear oil

(SAF-XO) that is

available through an authorized BMW dealer parts depart-

ment. For additional information on this lubricant and any oth-

er lubricants that may be compatible, contact an authorized

BMW dealer service department.

< Check rear differential oil level at filler plug (arrow).

- Check lubricant level with car on a level surface:

Level is correct when fluid just reaches edge of filler hole.

If necessary, top up fluid.

* Replace filler plug sealing ring.

Install and tighten oil filler plug when oil level is correct.

NOTE-

Use either a 14 mm or 17 mm Allen socket to remove the

drain plug.

If car is raised in the air. it should be level when

checkino " or filling final drive fluid level.

- Tightening torque -

Filler plug to final drive housing 70 Nm (52

ft-lb) -

Page 757 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final Drive

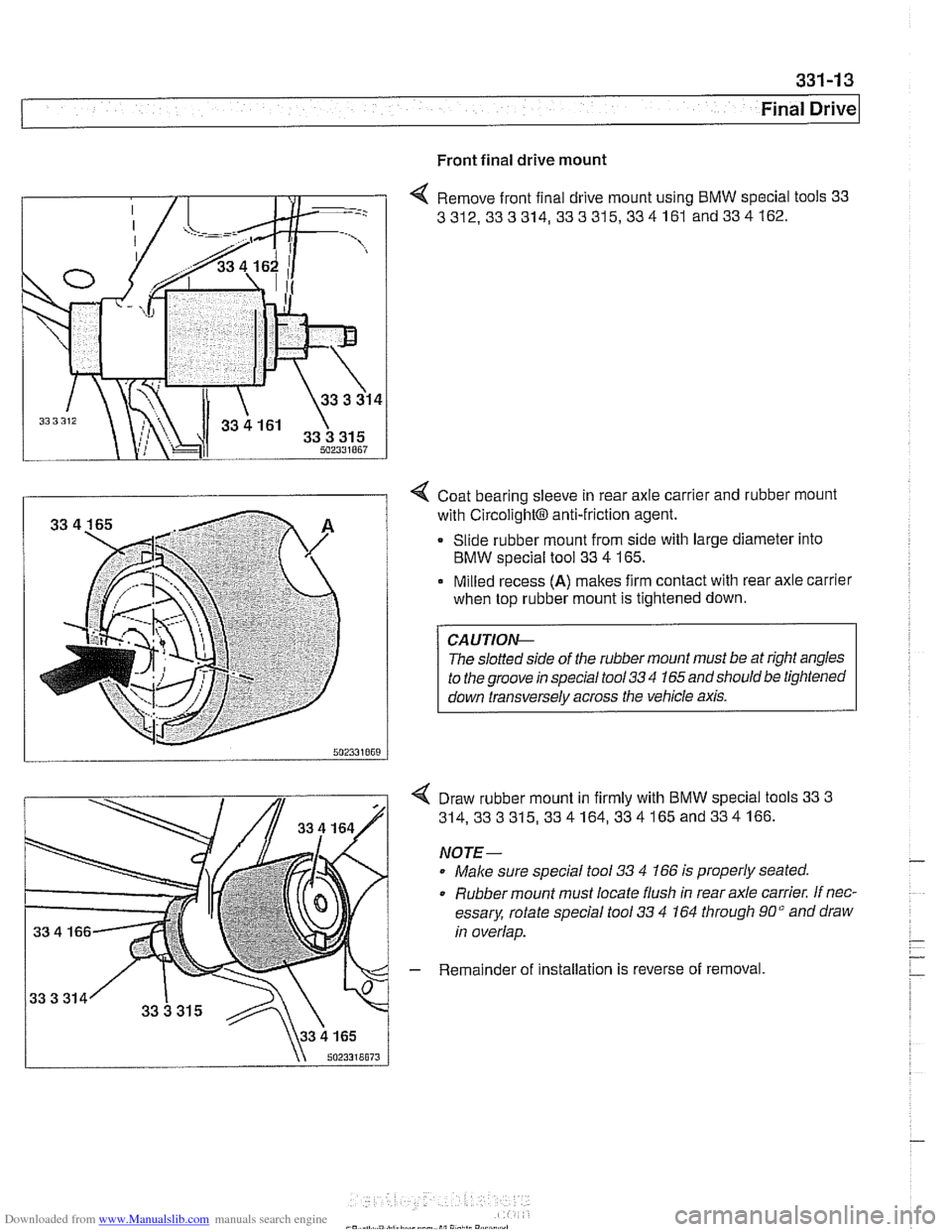

Front final drive mount

4 Remove front final drive mount using BMW special tools 33

3312,333314, 333315,334161

and334162.

I i 4 Coat bearing sleeve in rear axle carrier and rubber mount

with

~ircolight~ anti-friction agent.

Slide rubber mount from side with large diameter into

BMW special tool 33

4 165.

Milled recess

(A) makes firm contact with rear axle carrier

when top rubber mount is tightened down.

The

slolled srde ot r11e rubber mounl must be ar r#ghl angles

lo

rhe groove rn specal roo/ 33 '1 165 and shoulo be lrghrened

I down ~ransversely across the vehicle axis. I

Draw rubber mount in firmly with BMW special tools 33 3

314,333315,334164,334165and334166.

NOTE-

Male sure special tool 33 4 166 is properly seated.

0 Rubber mount must locate flush in rear axle carrier. If nec-

essary, rotate special tool

33 4 164 through 90" and draw

in overlap.

- Remainder of installation is reverse of removal

Page 770 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-8

1 Brakes

Brake bleeding is usually done for one of two reasons: either

to replace old brake fluid as part of routine maintenance or to

expel trapped air in the system that resulted

from opening the

brake hydraulic system during repairs.

Read the

Warnings listed below before beginning the bleed-

ing procedure an on any

E39 car. If air enters the ACS or DSC

hydraulic unit, the factory BMW Service Tester MUST be

used in conjunction with a bralte pressure bleeder before the

vehicle is driven.

The BMW

ServiceTester (DISpluslGT1iMoDiC) must be

used to bleed the braltes if:

Any hydraulic brake system components are replaced, in-

cluding bralte lines.

Air has enter the

ABSIASC or ABSlDSC hydraulic unit.

WARNING -

* The ASC and DSC systems use electronic controls and a

sophisticated hydraulic unit Once air enters the hydraulic

unit, it is very difficult to remove using traditional methods.

For this reason, pressure

brake bleeding should be done

in conjunction with the BMW

Sewice Tester (DIS-

plus/GTl/MoDiC). The tester electrically cycles the hy-

draulic unit solenoids in the hydraulic unit while

pressurized brake fluid is forced through the system.

When flushing the brake fluid from the system, use ex-

treme care to not let the

brale fluid reservoir run dry If

air enters the hydraulic unit, the BMW Service Tester

MUST be used to bleed the brale system before the

vehicle is driven.

Always use new brake fluid from an unopened container. It is

important to bleed the entire system when any part of the hy-

draulic system has been opened. Be sure to have the special

equipment needed before beginning the job.

When bleeding the

braltes, start atthe wheel farthest from the

master cylinder and progress in the following order:

right rear brake

left rear brake

* right front brake

left front brake

Page 780 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- -

Brakes

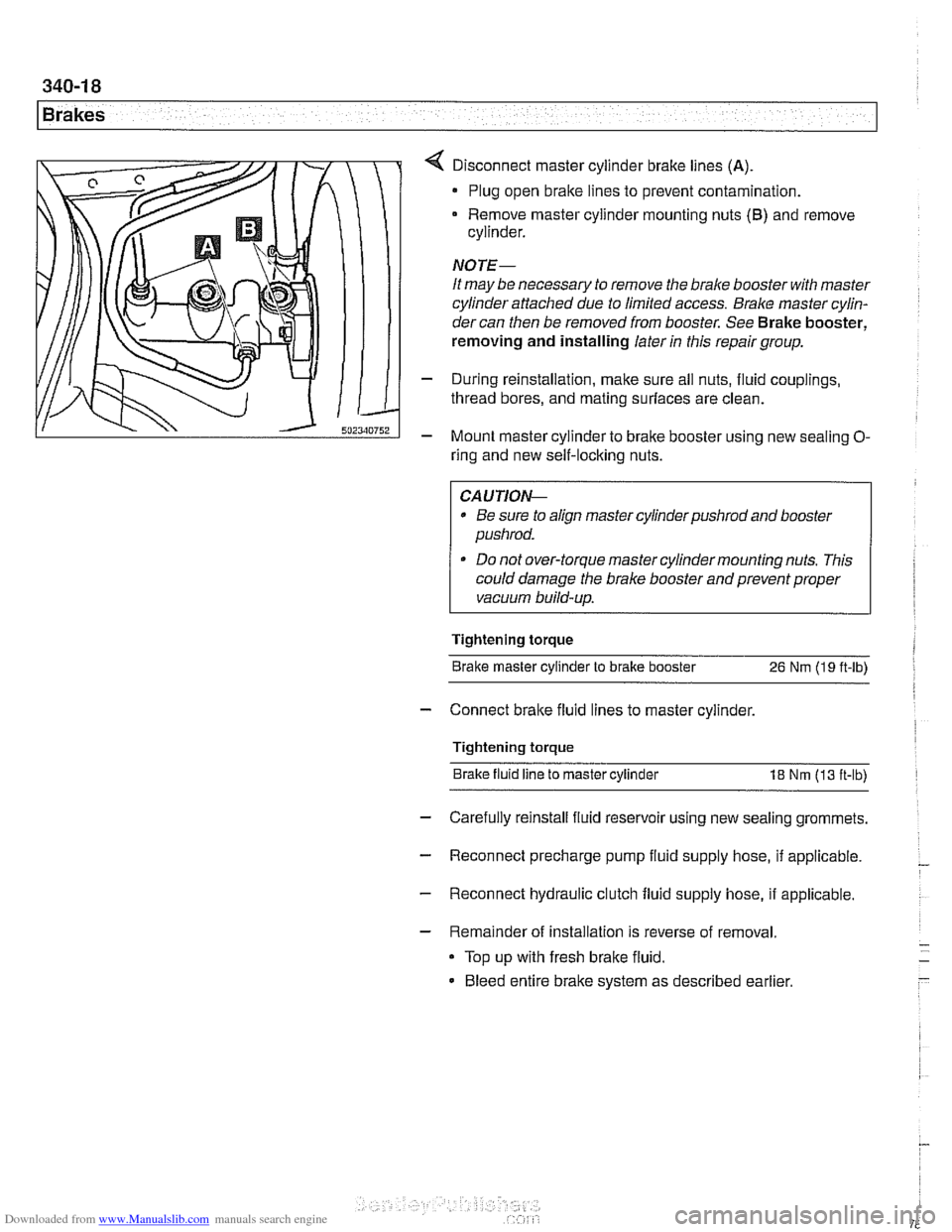

Disconnect master cylinder brake lines (A)

Plug open brake lines to prevent contamination.

Remove master cylinder mounting nuts

(6) and remove

cylinder.

NOTE-

It may be necessary to remove the brake booster with master

cylinder attached due to limited access.

Bralce master cylin-

dercan then be removed from booster. See Brake booster,

removing and installing later

in this repair group.

- During reinstallation, make sure all nuts, fluid couplings,

thread bores, and mating surfaces are clean.

- Mount master cylinder to bralte booster using new sealing O-

ring and new self-locking nuts.

CAUTIOI\C

* Be sure to align master cylinderpushrod and booster

pushrod.

* Do not over-torque master cylinder mounting nuts. This

could damage the brake booster and prevent proper

vacuum build-up.

Tightening torque Brake master cylinder to brake booster

26 Nm (19 ft-lb)

- Connect bralte fluid lines to master cylinder.

Tightening torque Brake fluid line to master cylinder

18 Nm (13 ft-lb)

- Carefully reinstall fluid reservoir using new sealing grommets.

- Reconnect precharge pump fluid supply hose, if applicable. -

- Reconnect hydraulic clutch fluid supply hose, if applicable.

- Remainder of installation is reverse of removal.

Top up with fresh brake fluid.

Bleed entire brake system as described earlier

Page 783 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

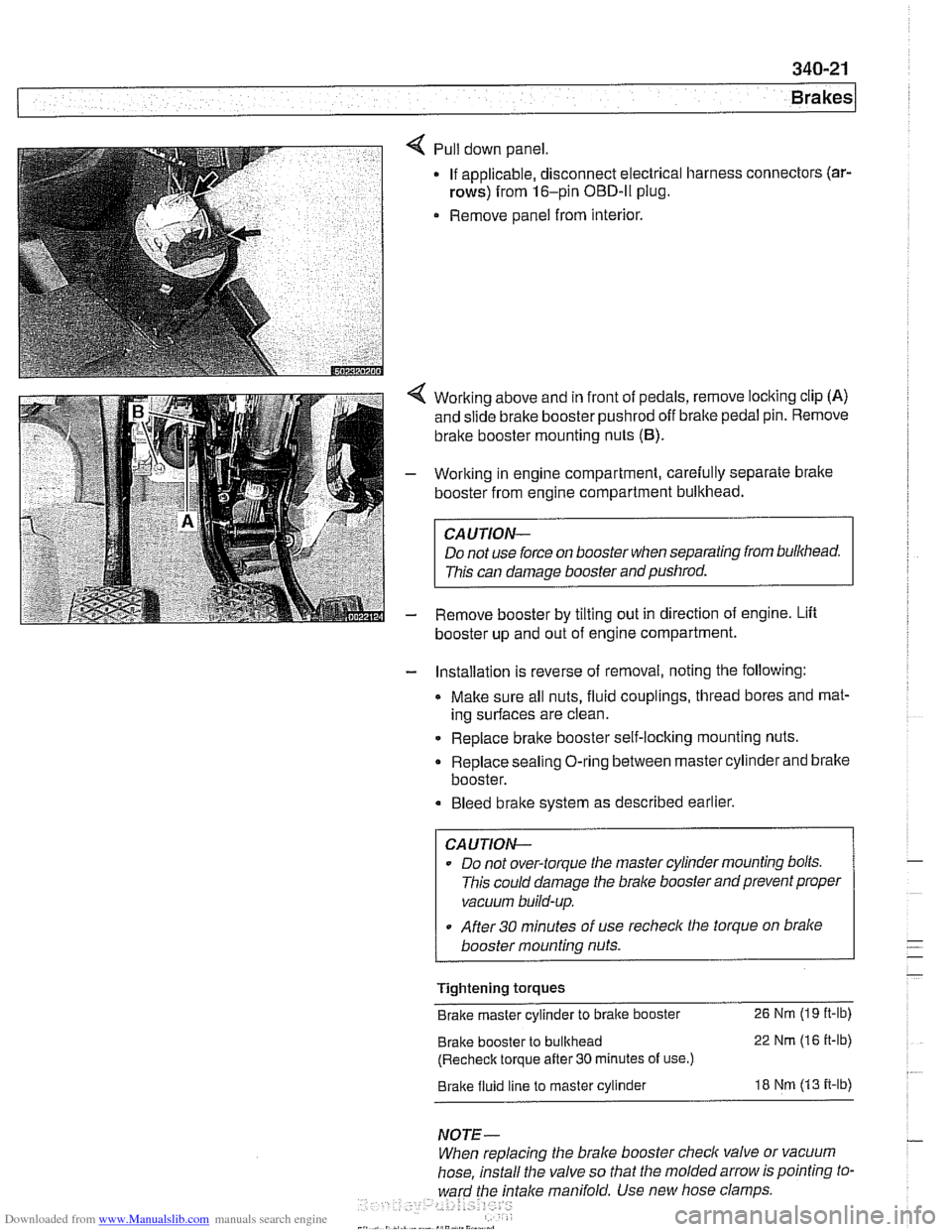

Pull down panel

If applicable, disconnect electrical harness

rows) from 16-pin OBD-ll plug.

Remove panel from interior. connectors

(ar-

Working

above and in front of pedals, remove locking clip (A)

and slide brake booster pushrod off bralte pedal pin. Remove

brake booster mounting nuts

(6).

Working in engine compartment, carefully separate bralte

booster from engine compartment bulkhead.

CAUTION-

Do not use force on booster when separating from bulkhead.

This can damage booster and pushrod.

Remove booster by tilting out in direction of engine. Lift

booster up and out of engine compartment.

- Installation is reverse of removal, noting the following:

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Replace bralte booster self-locking mounting nuts.

Replace sealing O-ring between master cylinder and bralte

booster.

Bleed bralte system as described earlier.

CAUTION--

Do not over-torque tlie master cylinder mounting bolts.

This could damage the

bralce booster and prevent proper

vacuum build-up.

After

30 minutes of use recheclc the torque on bralce

booster mounting nuts.

Tightening torques

Brake master cylinder to brake booster

26 Nm (19 it-lb)

Brake booster to bulkhead 22 Nm (16 it-lb)

(Recheck torque after

30 minutes of use.)

Brake fluid line to master cylinder 18 Nm (13 it-lb)

NOTE-

When replacing the brake booster check valve or vacuum

hose, install the valve so that the molded arrow is pointing to-

ward the

fntalce manifold. Use new hose clamps

Page 801 of 1002

Downloaded from www.Manualslib.com manuals search engine

Body-General

SAFETY AND SECURITY FEATURES

A number of new or improved safety and security features are

incorporated in

E39 cars.

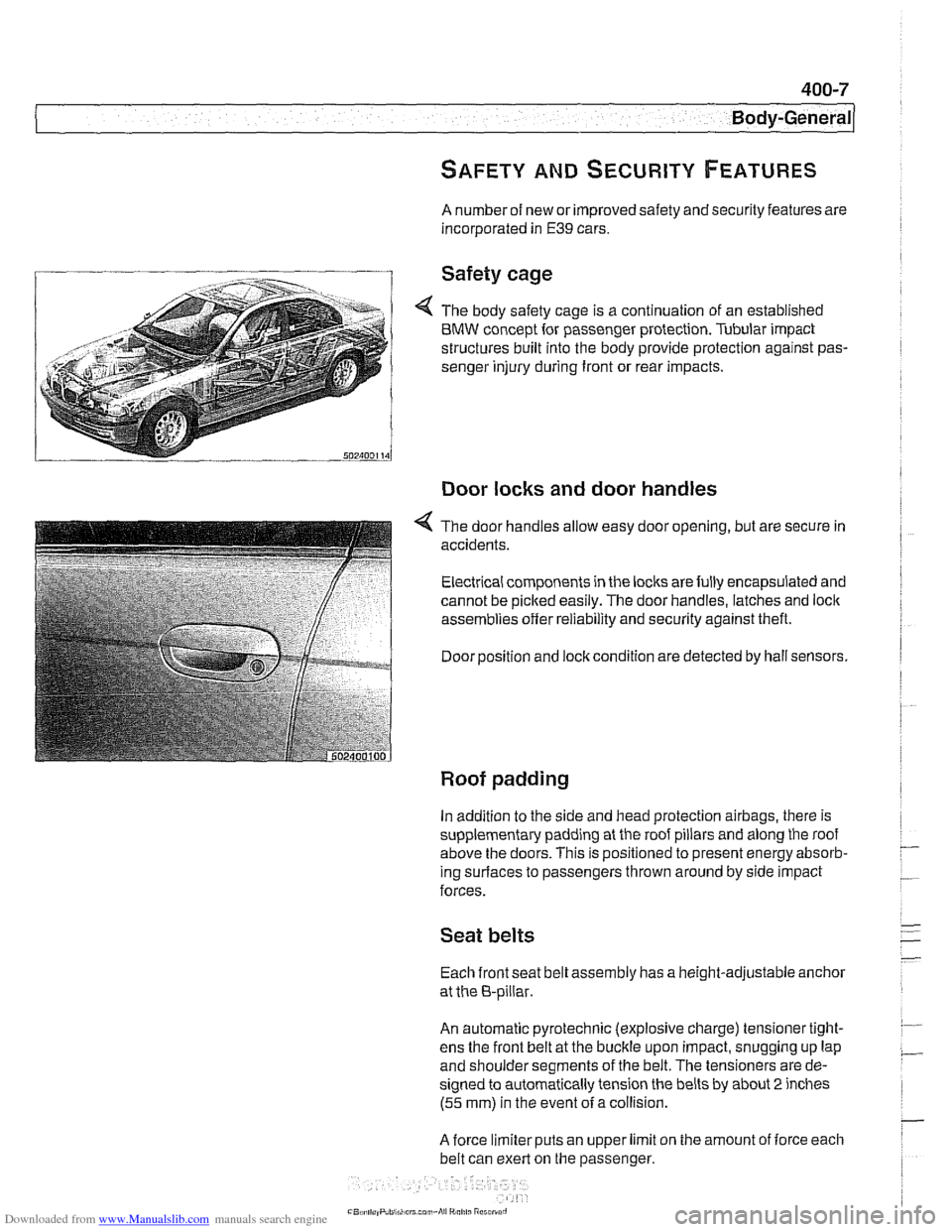

Safety cage

4 The body safety cage is a continuation of an established

BMW concept for passenger protection. Tubular impact

structures built into the body provide protection against pas-

senger injury during front or rear impacts.

Door locks and door handles

4 The door handles allow easy door opening, but are secure in

accidents.

Electrical components in the locks are fully encapsulated and

cannot be picked easily. The door handles, latches and

loclc

assemblies offer reliability and security against theft.

Door position and

loclc condition are detected by hall sensors.

Roof padding

In addition to the side and head protection airbags, there is

supplementary padding at the roof pillars and along the roof

above the doors. This is positioned to present energy absorb-

ing

surlaces to passengers thrown around by side impact

forces.

Seat belts

Each front seat belt assembly has a height-adjustable anchor

at the 8-pillar.

An automatic pyrotechnic (explosive charge) tensioner tight-

ens the front belt at the buckle upon impact, snugging up lap

and shoulder segments of the belt. The tensioners are de-

signed to automatically tension the belts by about

2 inches

(55 mm) in the event ofa collision.

A force limiter puts an upper limit on the amount of iorce each

belt can exert on the passenger.

Page 814 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 0-8

(Fenders, Engine Hood

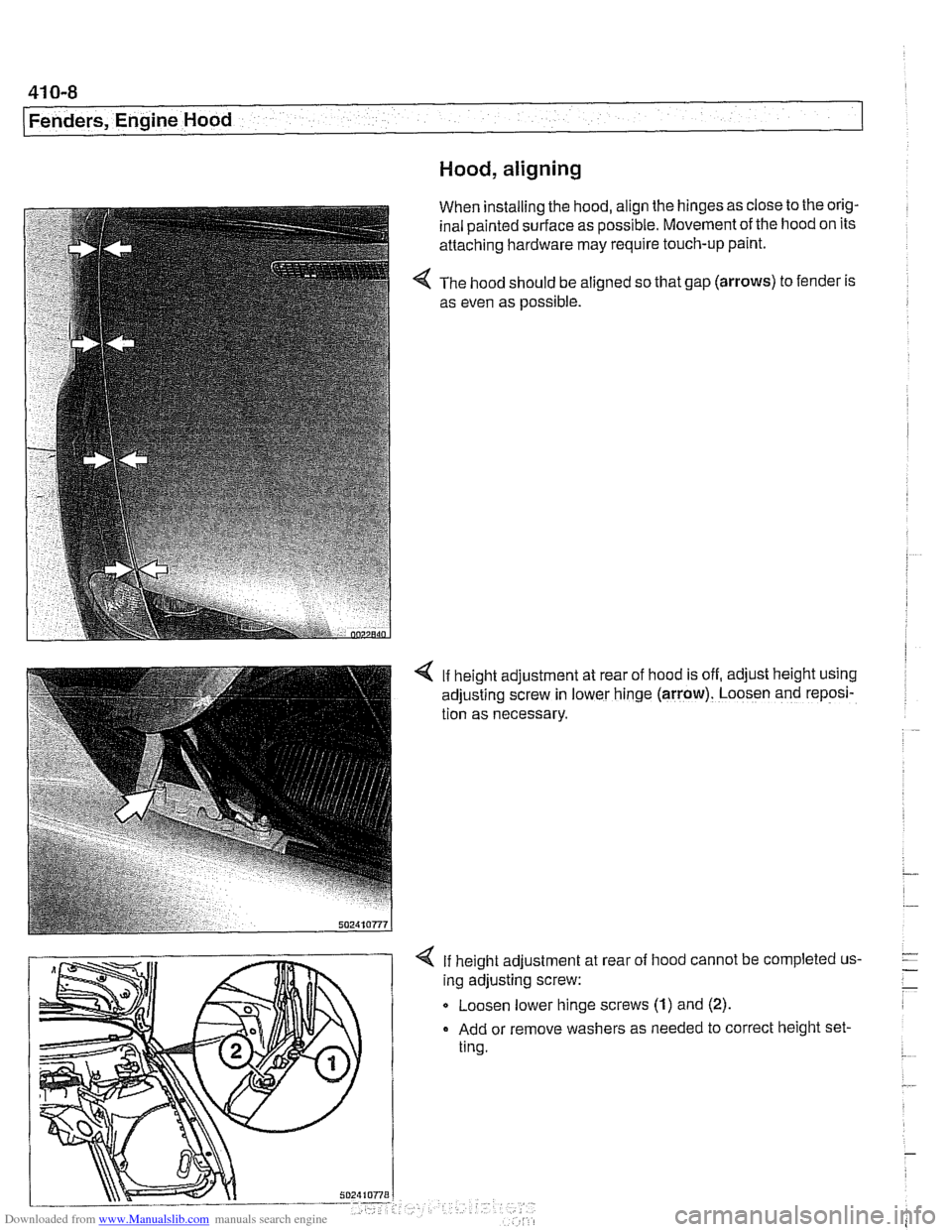

Hood, aligning

When installing the hood, align the hinges as close to the orig-

inal painted surface as possible. Movement of the hood on its

attaching hardware may require touch-up paint.

The hood should be aligned so that gap

(arrows) to fender is

as even as possible.

4 If height adjustment at rear of hood is off, adjust height using

adjusting screw in lower hinge

(arrow). Loosen and reposi-

tion as necessary.

If height adjustment at

ing adjusting screw: rear

of

hood cannot be completed us-

Q Loosen lower hinge screws (1) and (2).

Add or remove washers as needed to correct height set-

ting.