ground BMW 540i 2000 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 405 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel injectors, checking and replacing

The fuel injectors are electronically controlled solenoid valves

that provide precisely metered and atomized fuel into the en-

gine intake ports.

The injectors receive voltage from the ECM relay. The ECM

controls the opening by activating the ground circuit

forthe in-

jector valve solenoids. The ECM varies the duration (in milli-

seconds) of "opening" time to regulate the

airlfuel ratio.

For a quick

check of the injectors, run the engine and touch

each injector with a screwdriver or stethoscope. You should

feel a vibration or hear a buzzing

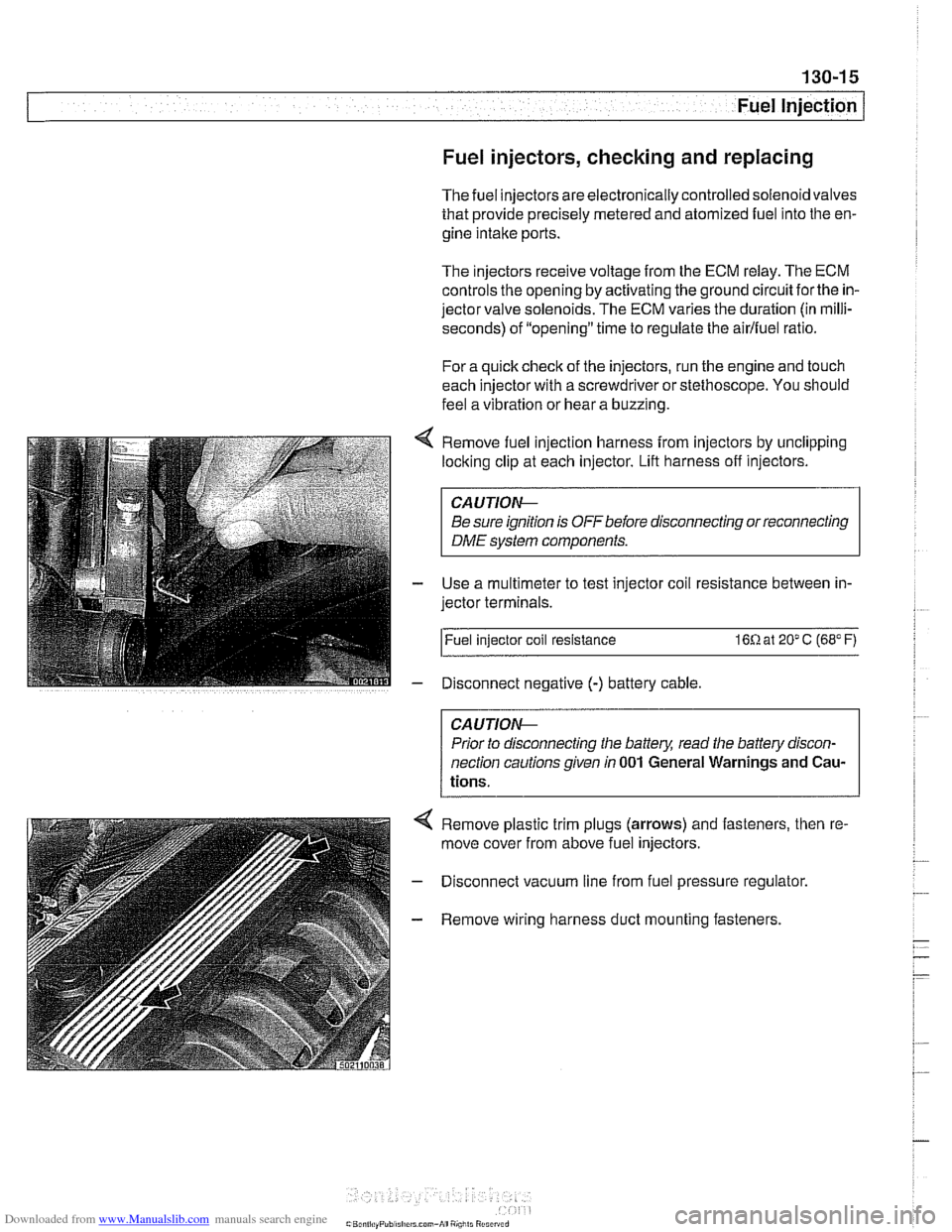

Remove fuel injection harness from injectors by unclipping

locking clip at each injector. Lift harness off injectors.

CA U JIOG

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Use a multimeter to test injector coil resistance between in-

jector terminals.

l~uel injector coil resistance 16R at 20" C (68" F)

Disconnect negative

(-) battery cable

CAUTIOG

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven

in 001 General Warnings and Cau-

tions.

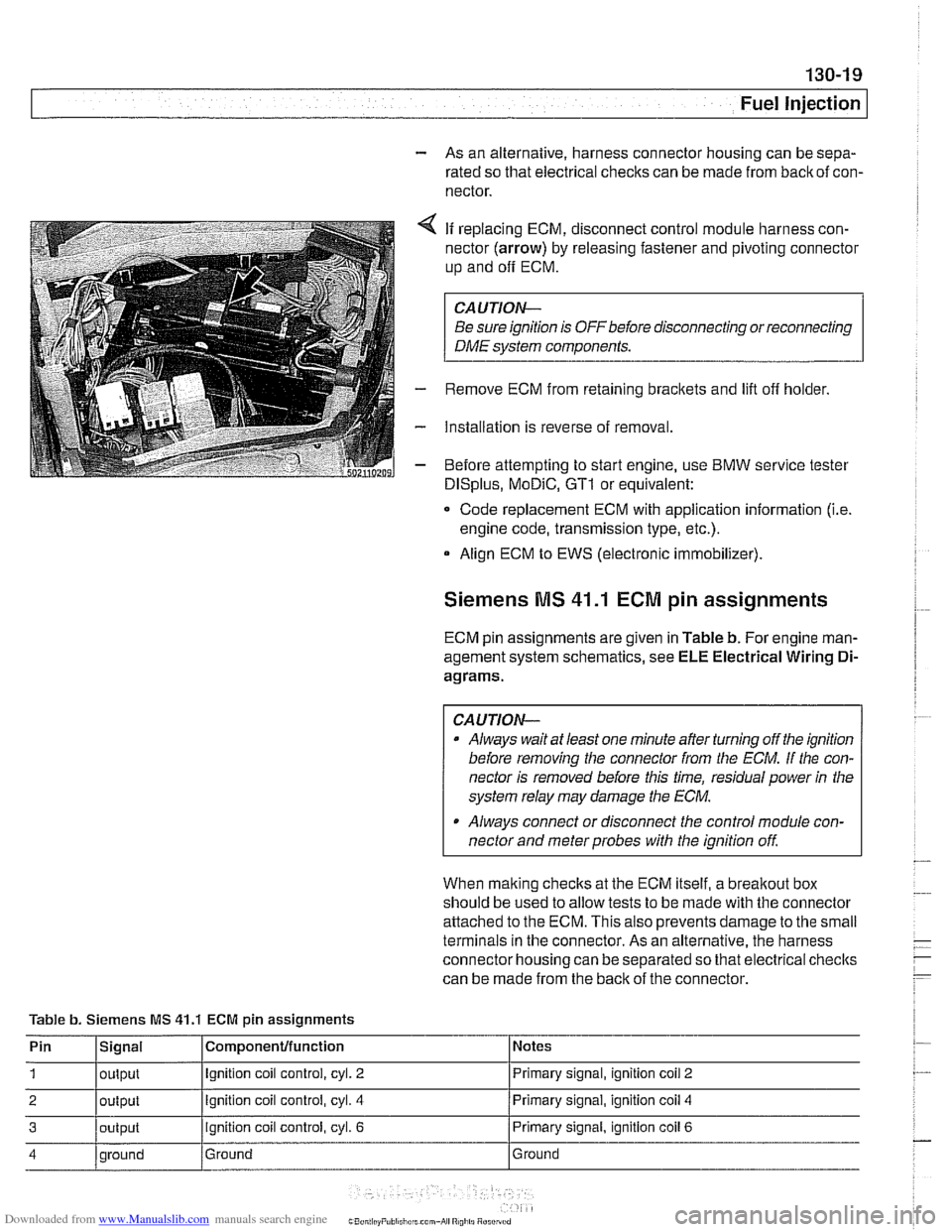

4 Remove plastic trim plugs (arrows) and fasteners, then re.

move cover from above fuel injectors.

- Disconnect vacuum line from fuel pressure regulator.

- Remove wiring harness duct mounting fasteners.

Page 409 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

- As an alternative, harness connector housing can be sepa-

rated so that electrical

checlts can be made from backof con-

nector.

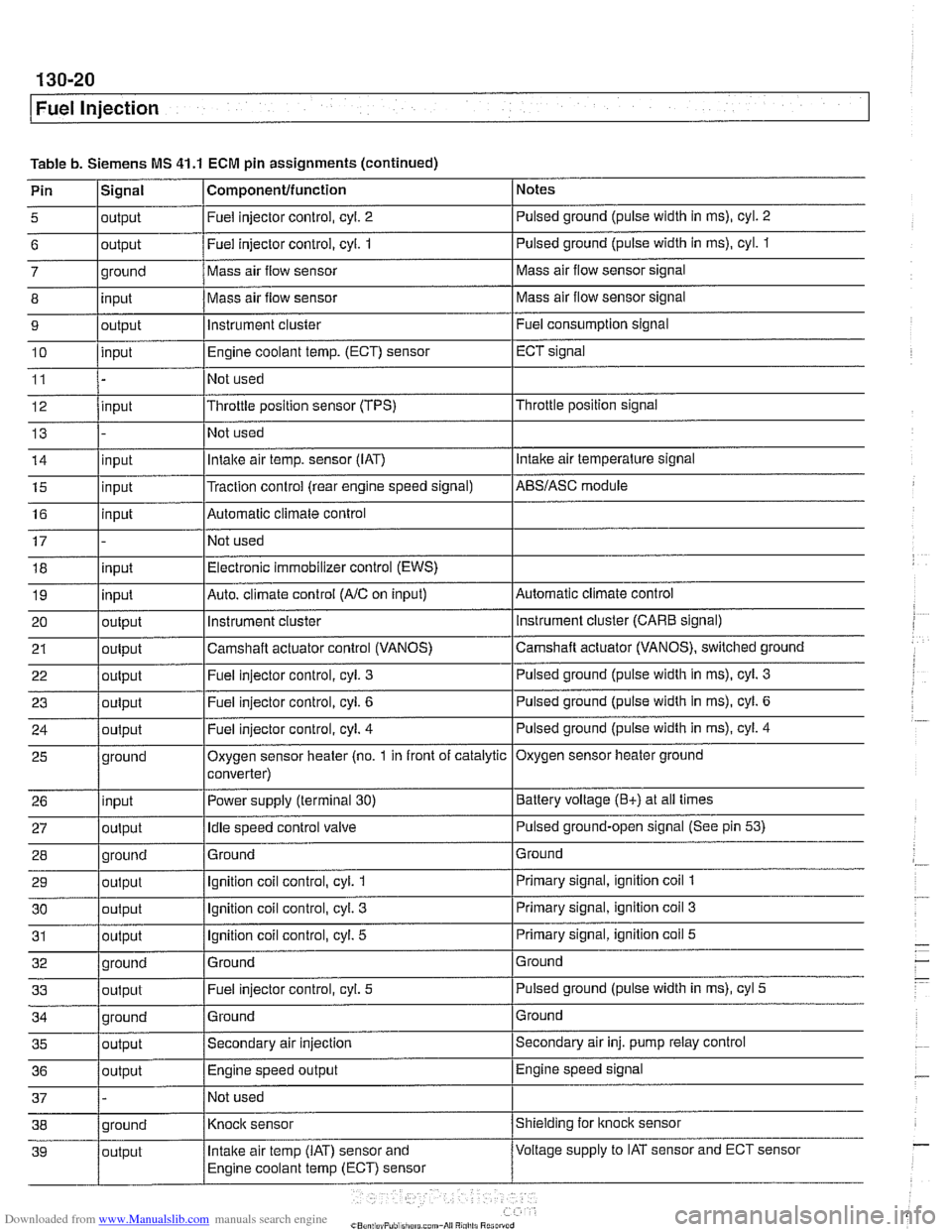

4 If replacing ECM, disconnect control module harness con-

nector (arrow) by releasing fastener and pivoting connector

up and

off ECM.

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

- Remove ECM from retaining brackets and lift off holder.

- Installation is reverse of removal.

- Before attempting to start engine, use BMW service tester

DISplus, MoDiC, GTI or equivalent:

- Code replacement ECM with application information (i.e.

engine code, transmission type, etc.).

Align ECM to EWS (electronic immobilizer).

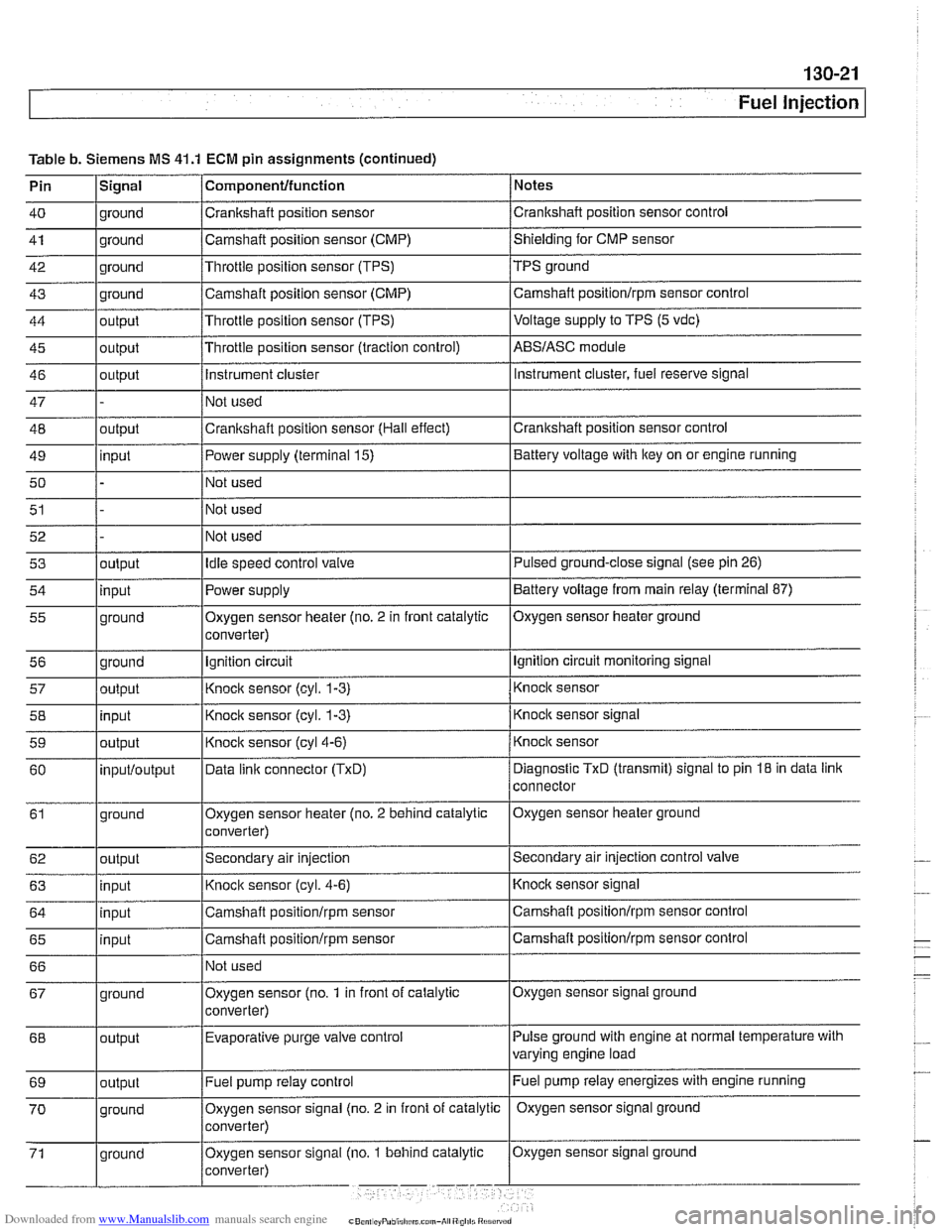

Siemens MS 41.1 ECM pin assignments

ECM pin assignments are given in Table b. For engine man-

agement system schematics, see ELE Electrical Wiring

Di-

agrams.

CAUTION-

a Always wait at least one minute after turning off the ignition

before removing the connector from the

ECM. If the con-

nector is removed before this time, residual power

in the

system relay may damage the

ECM.

Always connect or disconnect the control module con-

nector and meter probes with the ignition

off

When malting checks at the ECM itself, a breakout box

should be used to allow tests to be made with the connector

attached to the ECM. This also prevents damage to the small

terminals in the connector. As an alternative, the harness

connector housing can be separated so that electrical checlts

can be made from the back of the connector.

Table b. Siemens MS

41.1 ECM pin assignments

Pin

1

2

3

4

Signal

output

output

output

qround Componenfffunction

Ignition coil control, cyl. 2

Ignition coil control, cyl. 4

ignition coil control, cyl. 6

Ground Notes

Primary signal,

ignition

coil 2

Primary signal, ignition coil 4

Primary signal, ignition coil 6

Ground

Page 410 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

Table b. Siemens MS 41.1 ECM pin assignments (continued)

Pin

l~iqnal I Componentlfunction 1 Notes I - I I

5 loutput I Fuel injector control, cyl. 2 I Pulsed ground (pulse width in ms), cyl. 2 I I I

6 loutput /Fuel injector control, cyi. 1 I Pulsed ground (pulse width in ms), cyl. 1

I I I

14 linput I Intake air temp. sensor (IAT) I Intake air temperature signal

- 7

8

9

10

11

12

13

ground

input

output

input

input

15

16

17 18

19

20

21

22

I - I I

35 loutput /Secondary air injection ISecondary air inj. pump relay control

25

26

27

28

29

30

31

32

33

36

/output I Engine speed output IEngine speed signal

Mass air flow sensor

Mass air flow sensor

instrument cluster

Engine coolant

temp.

(ECT) sensor

Not used

Throttle position sensor (TPS)

Not used

input

input

input

input

output

output

out~ut

37 1 - /Not used I

Mass air flow sensor signal

Mass air flow sensor signal

Fuel consumption signal

ECT signal

Throttle position signal

ground

input

output

ground

output

output

output

ground

output

Traction control (rear engine speed signal) Automatic climate control

Not used Electronic immobilizer control (EWS)

Auto. climate control

(AIC on input)

instrument

cluster

Camshaft actuator control (VANOS)

Fuel iniector control, cvl.

3

AES/ASC module

Automatic climate control instrument cluster (CARE signal)

Camshaft actuator (VANOS), switched ground

Pulsed ground (pulse width in

ms), cyl. 3

Oxygen sensor heater (no. 1 in front of catalytic

converter)

Power supply (terminal

30)

Idle speed control valve

Ground

Ignition coil control, cyl.

1

Ignition coil control, cyl. 3

Ignition coil control, cyl. 5

Ground Fuel injector control, cyl.

5

Oxygen sensor heater ground

Battery voltage

(E+) at all times

Pulsed ground-open signal (See pin

53)

Ground

Primary signal, ignition coil

1

Primary signal, ignition coil 3

Primary signal, ignition coil 5

Ground

Pulsed ground (pulse width in ms), cyl

5

Page 411 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lniection 1

Table b. Siemens MS 41.1 ECM pin assignments (continued)

Pin

lSiqnal 1 Componentlfunction / Notes I - I I

40 1 ground /Crankshaft position sensor /crankshaft position sensor control I - I I

41 1 ground /Camshaft position sensor (CMP) /shielding for CMP sensor I - I I

42 1 ground I~hrottie position sensor (TPS) /TPS ground

43

44

45

46

47

48

49

50

51 ground

output

output

output

outout

I I I

input

52 53

54

55

56 57

58

59

60

61

62

63

64

65

66 Camshaft position sensor (CMP)

Throttle position sensor (TPS)

Throttle position sensor (traction control)

Instrument cluster

Not used

Crankshaft position sensor (Hall effect)

I~ot used

I I I

Fuel pump relay control Camshaft

positionlrpm sensor control

Voltage

supply to TPS (5 vdc)

ABSIASC module

Instrument cluster, fuel reserve signal

Crankshaft position sensor control

Power supply (terminal 15)

Not used

Not used

output input

ground

ground

output

input

output

inputloutput

ground

output

input

input

input

I I

Battery voltage with key on or engine running

Oxygen sensor signal ground

67

Idle speed control valve

Power supply

Oxygen sensor heater (no. 2 in front catalytic

converter)

Ignition circuit

Knock sensor

(cyl. 1-3)

Knock sensor (cyl. 1-3)

Knock sensor

(cyl4-6)

Data linic connector (TxD)

Oxygen sensor heater (no. 2 behind catalytic

converter)

Secondary air injection

Knock sensor (cyl. 4-6)

Camshaft

positionlrpm sensor

Camshaft

positionlrpm sensor

Not used

Pulse ground with engine at normal temperature with

varying engine load

68 Pulsed ground-close signal (see

pin 26)

Battery voltage from main relay (terminal 87)

Oxygen sensor heater ground

Ignition circuit monitoring signal

Knock sensor

Knock sensor signal

Knock sensor

Diagnostic

TxD (transmit) signal to pin 18 in data link

connector

Oxygen sensor heater ground

Secondary air injection control

valve

Knocic sensor signal

Camshaft positionlrpm sensor control

Camshaft

positionlrpm sensor control

ground Oxygen sensor

(no.

1 in front of catalytic

converter)

output Evaporative purge

valve control

Page 418 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-28

Fuel Injection

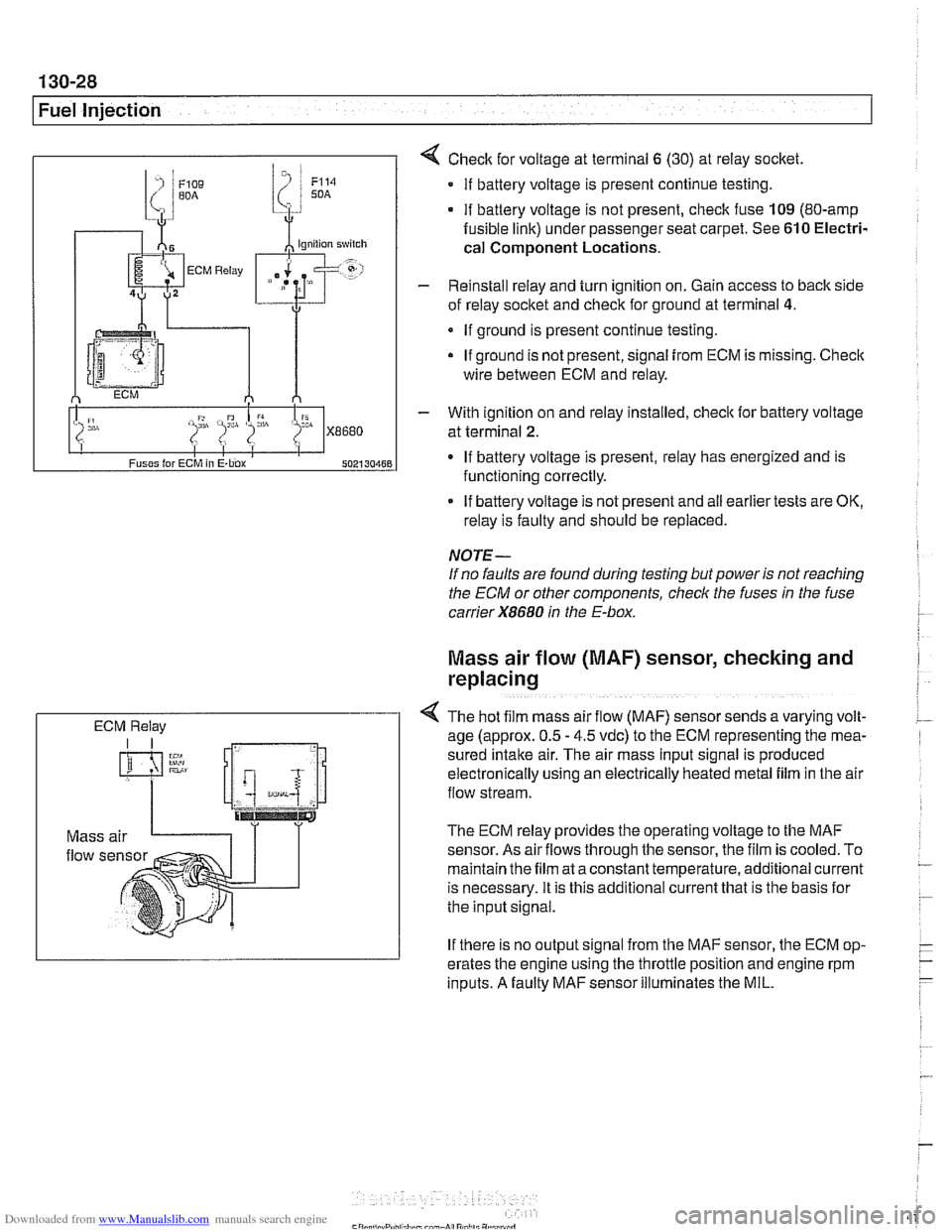

ECM Relay

4 Check for voltage at terminal 6 (30) at reiay socket

If battery voltage is present continue testing.

if battery voltage is not present, check fuse 109 (80-amp

fusible link) under passenger seat carpet. See 610 Electri-

cal

Component Locations.

- Reinstall relay and turn ignition on. Gain access to back side

of reiay socket and check for ground at terminal

4.

If ground is present continue testing.

If ground is not present, signal

from ECM is missing. Check

wire between ECM and relay.

- With ignition on and reiay installed, check lor battery voltage

at terminal

2.

If battery voltage is present, relay has energized and is

functioning correctly.

If battery voltage is not present and

ail earlier tests are OK,

relay is faulty and should be replaced.

NOTE-

If no faults are found during testing but power is not reaching

the ECM or other components, check the fuses

in the fuse

carrier

X8680 in the E-box.

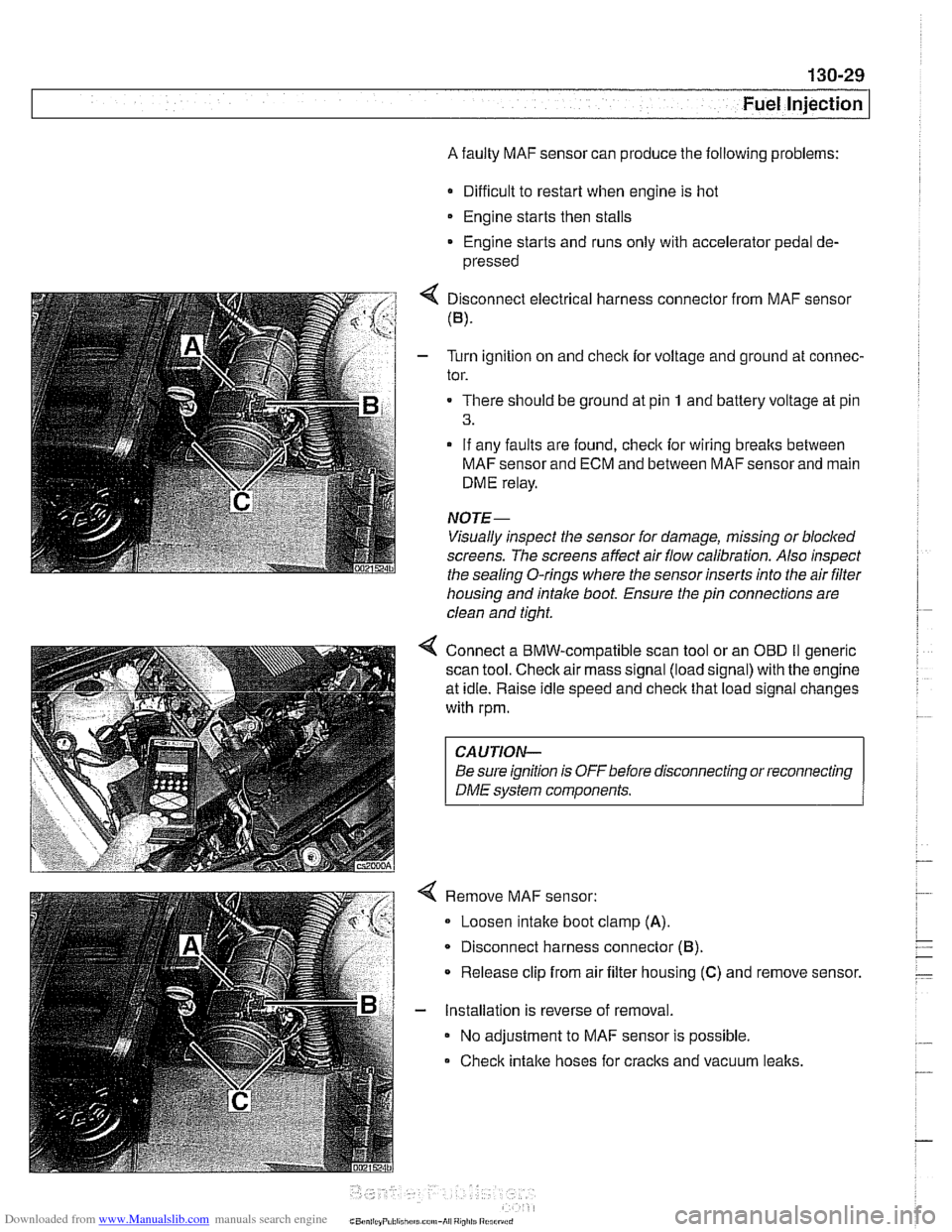

Mass air flow (MAF) sensor, checking and

replacing

4 The hot f~lm mass air flow (MAF) sensor sends a varying volt-

age (approx. 0.5 - 4.5 vdc) to the ECM representing the mea-

sured

Intake air. The alr mass input signal is produced

electron~caily uslng an electrically heated metal fllm in the air

flow stream.

The ECM relay provides the operating voltage to the MAF

sensor. As air

flows through the sensor, the film is cooled. To

maintain the film at a constant temperature, additional current

is necessary. It is this additional current that is the basis lor

the input signal.

If there is no output signal from the MAF sensor, the ECM op-

erates the engine using the throttle position and engine rpm

inputs. A faulty MAF sensor illuminates the MIL.

Page 419 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

A faulty MAF sensor can produce the following problems:

Difficult to restart when engine is hot

Engine starts then stalls

* Engine starts and runs only with accelerator pedal de-

pressed

4 Disconnect electrical harness connector from MAF sensor

(B).

- Turn ignition on and checlc for voltage and ground at connec-

tor.

There should be ground at pin

1 and battery voltage at pin

3.

- If any faults are found, checlc for wiring breaks between

MAF sensor and ECM and between MAF sensor and main

DME relay.

NOTE-

Visually inspect the sensor for damage, missing or blocked

screens. The screens affect air flow calibration. Also inspect

the sealina

0-rinas where the sensor inserts into the air filter - - housing and intake boot. Ensure the pin connections are

clean and tight.

4 Connect a BMW-compatible scan tool or an OED II generic

scan tool.

Checlc air mass signal (load signal) with the engine

at idle. Raise idle speed and

checlc that load signal changes

with rpm.

CAUTION-

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

Remove MAF sensor:

Loosen intake boot clamp

(A).

Disconnect harness connector (6).

* Release clip from air filter housing (C) and remove sensor.

- Installation is reverse of removal.

No adjustment to MAF sensor is possible.

Check intake hoses for cracks and vacuum

lealts.

Page 428 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-38

Fuel Injection

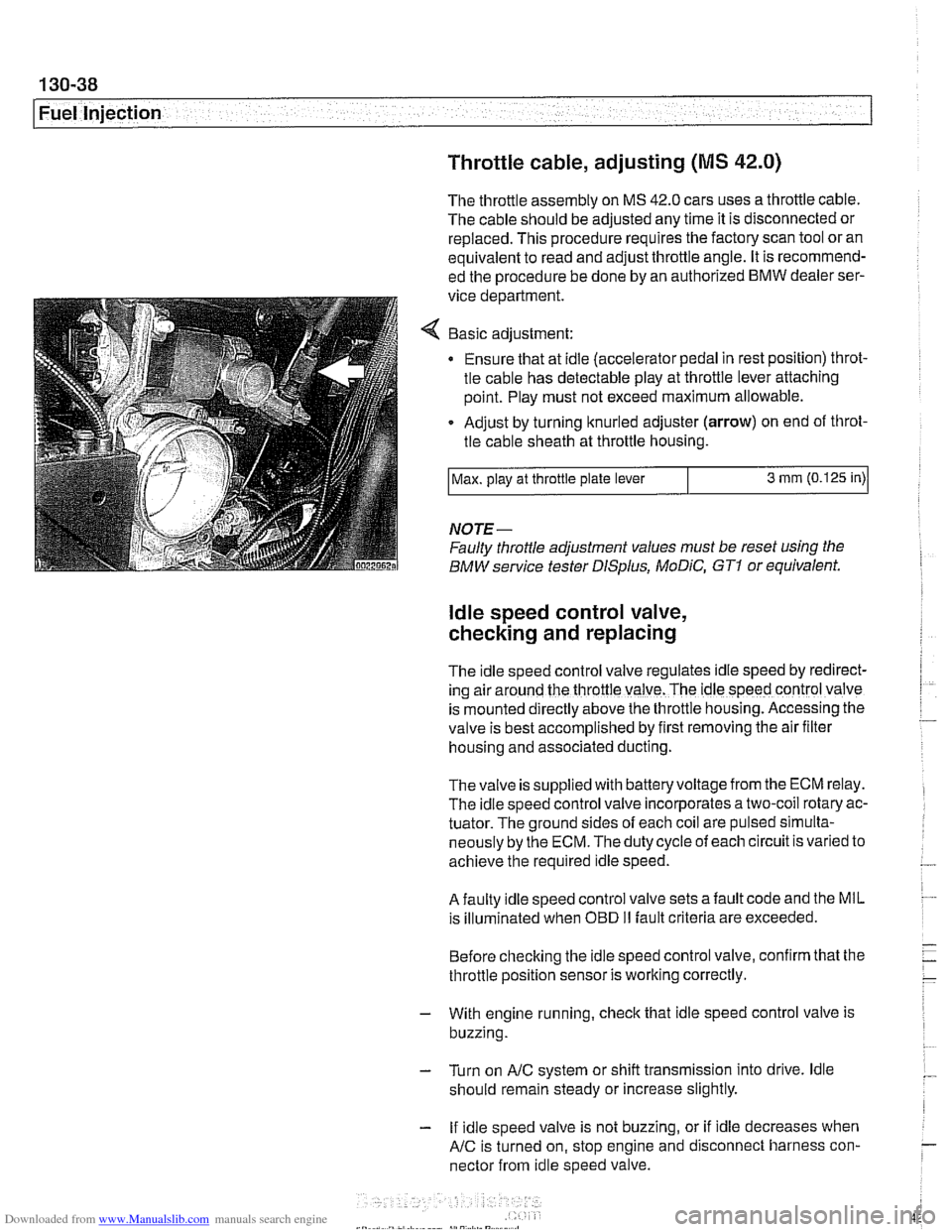

Throttle cable, adjusting

(MS 42.0)

The throttle assembly on MS 42.0 cars uses a throttle cable.

The cable should be adjusted any time it is disconnected or

replaced. This procedure requires the factory scan tool or an

equivalent to read and adjust throttle angle. It is recommend-

ed the procedure be done by an authorized

BMW dealer ser-

vice department

Basic adjustment:

Ensure that at idle (accelerator pedal in rest position) throt-

tle cable has detectable play at throttle lever attaching

point. Play must not exceed maximum allowable.

Adjust by turning knurled adjuster

(arrow) on end of throt-

tle cable sheath at throttle housing.

NOTE-

Faulty throttle adjustment values must be reset using the

BMW service tester

DISplus, MoDiC, GTI or equivalent.

Max.

play at throttle plate lever

ldle speed control valve,

checking and replacing

3 mm (0.125 in)

The Idle speed control valve regulates Idle speed by red~rect-

ing air around the throttle valve. The ldle speed control valve

is mounted

d~rectly above the throttle housing. Accessing the

valve is best accomplished by

flrst removing the air fllter

housing and associated ducting.

Thevalve is supplied with batteryvoltage from the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed simulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

A faulty idle speed control valve sets a fault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

Page 431 of 1002

Downloaded from www.Manualslib.com manuals search engine

. -

Fuel Injection I

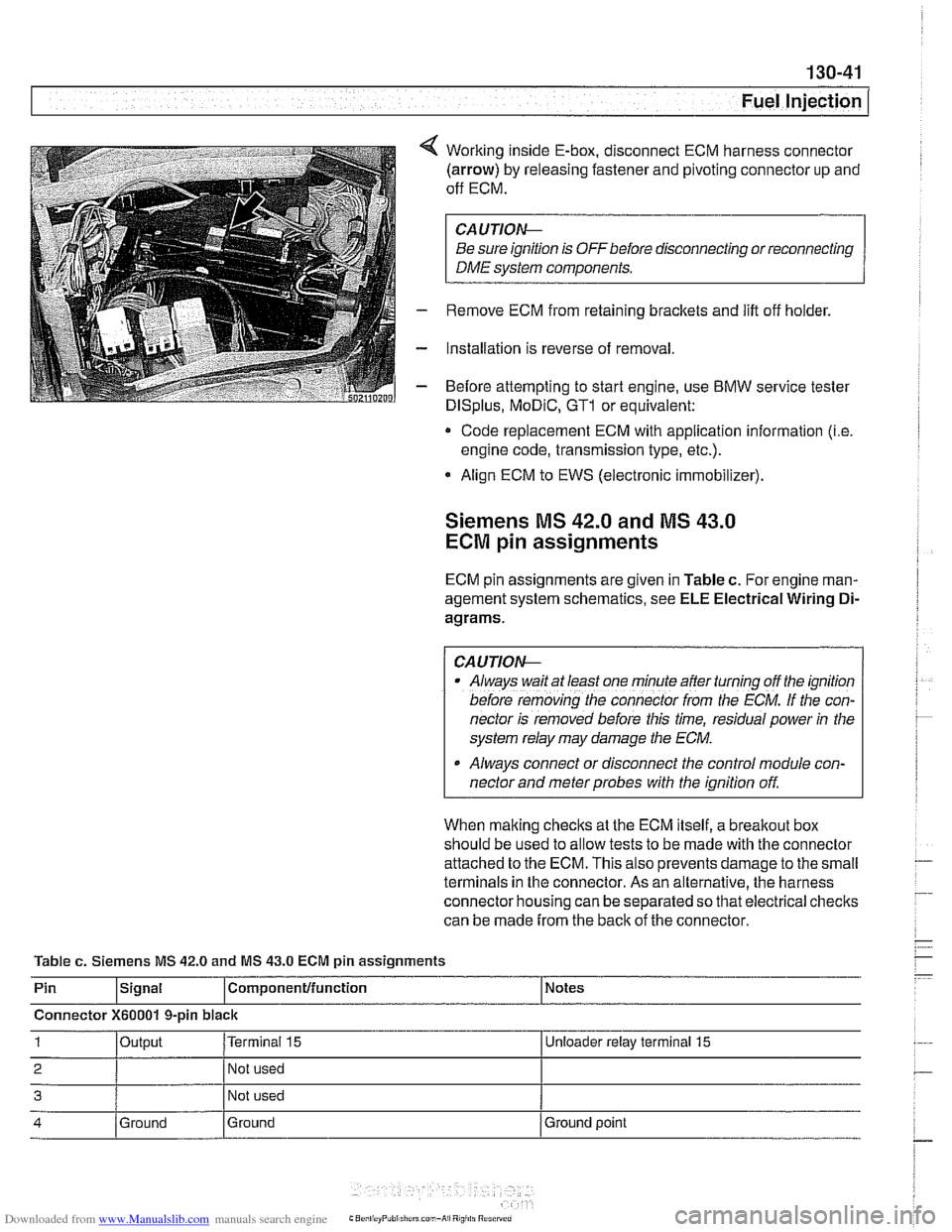

Working inside E-box, disconnect ECM harness connector

(arrow) by releasing fastener and pivoting connector up and

off ECM.

CA UTIOW

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Remove ECM from retaining brackets and lift off holder.

Installation is reverse of removal

Before attempting to start engine, use

BMW service tester

DISplus, MoDiC, GTl or equivalent:

* Code replacement ECM with application information (i.e

engine code, transmission type, etc.).

Align ECM to EWS (electronic immobilizer).

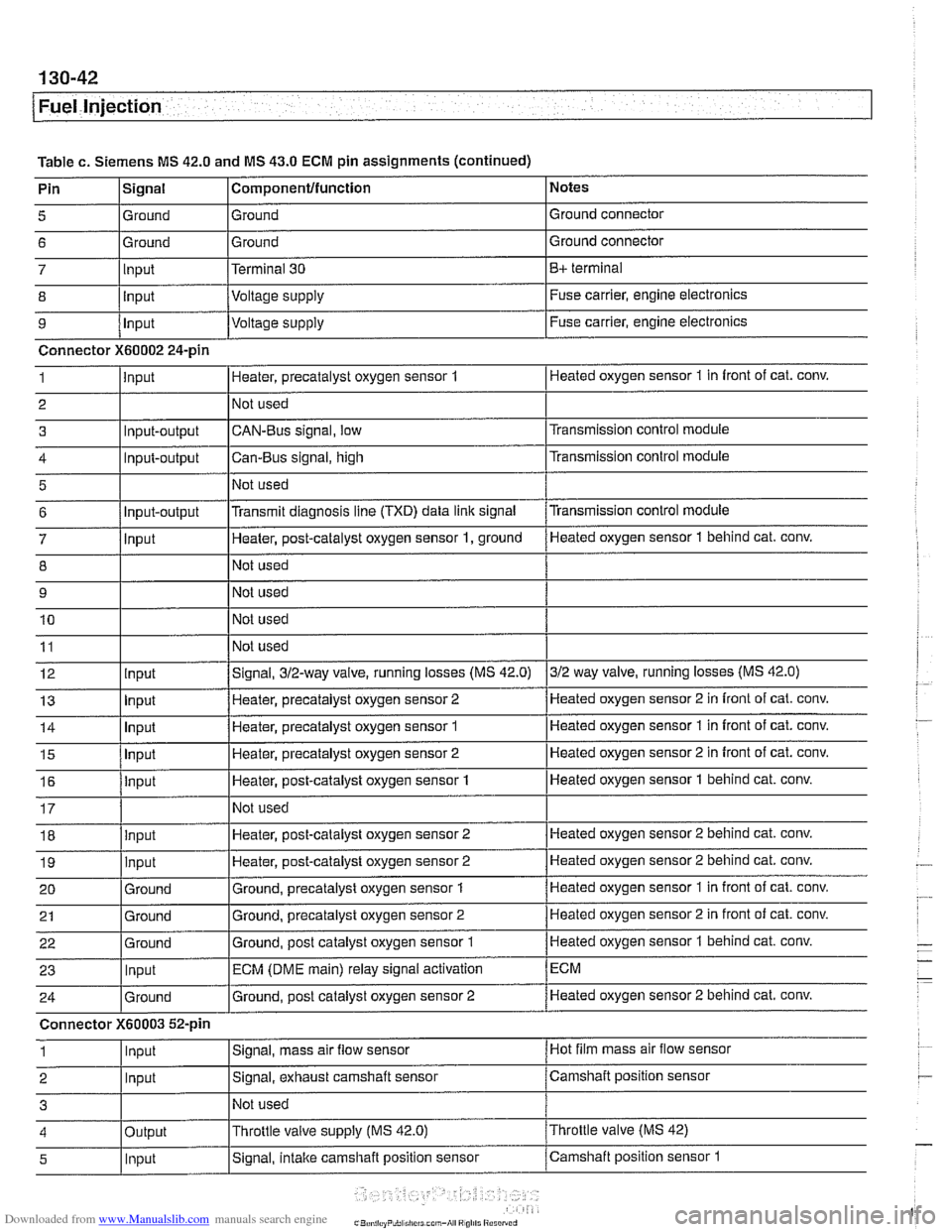

Siemens MS 42.0 and MS 43.0

ECM pin assignments

ECM pin assignments are given in Table c. For engine man-

agement system schematics, see

ELE Electrical Wiring Di-

agrams.

/ CAUTIOW I

Al~ays wait at least one mfnule after turning off the ignition

before

remov;ng [he connecror irom rhe ECM. If the con-

nector is removed before this time, residual power

in the

system relay may damage the

ECM.

Always connect or disconnect the control module con-

nector and meter probes with the ignition off.

When making checks at the ECM itself, a

breakout box

should be used to allow tests to be made with the connector

attached to the ECM. This also prevents damage to the small

terminals in the connector. As an alternative, the harness

connector housing can be separated so that electrical checks

can be made from the back of the connector.

Table

c. Siemens MS 42.0 and MS 43.0 ECM pin assignments

Pin

lslgnal l~om~onentlfunction 1 Notes

Connector

X60001 9-pin black

1 loutput I~erminai 15 I Unloeder relay terminal 15

2 I 1 Not used I

3 Not used

4 Ground

Ground Ground

point

Page 432 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

/Fuel Injection

I ' I - I

9 /ln~ut l~oltaqe supply I Fuse carrier, engine electronics

Table

c. Siemens MS 42.0 and MS 43.0 ECM pin assignments (continued) I ' I . I

Connector X60002 24-pin

1 linput IHeater, precatalyst oxygen sensor 1 I Heated oxygen sensor 1 in front of cat. conv.

I I I

18 llnout IHeater, post-catalyst oxygen sensor 2 ]Heated oxygen sensor 2 behind cat. conv.

Notes

Ground connector

Ground connector

B+ terminal

Fuse carrier, engine electronics

Pin

5

6

7

8

I I I

4 loutput l~hrottle valve supply (MS

42.0) I~hrottle valve (MS 42)

Signal

Ground

Ground Input

lnout

19

20 21

22

23

24

Connector

1

2

3

I I I

5 1 lnput ISignal, intake camshaft position sensor /camshaft position sensor 1

Componentlfunction

Ground

Ground

Terminal 30

Voltaae

SUDP~V

input

Ground

Ground

Ground

Input

Ground

X60003 52-pin

Input

Input

~ -

Heater, post-catalyst oxygen sensor 2

Ground, precatalyst oxygen sensor

1

Ground, precatalyst oxygen sensor 2

Ground, post catalyst oxygen sensor

1

ECM (DME main) relay signal activation

Ground, post catalyst oxygen sensor 2

Signal, mass air

flow sensor

Signal, exhaust camshaft sensor

Not used Heated

oxygen sensor 2 behind cat.

conv.

Heated oxygen sensor 1 in front of cat. conv.

Heated oxygen sensor 2 in front of cat. conv.

Heated oxygen sensor

1 behind cat. conv.

ECM

Heated oxygen sensor 2 behind cat. conv.

Hot film mass air flow sensor

Camshaft position sensor

Page 433 of 1002

![BMW 540i 2000 E39 Repair Manual Downloaded from www.Manualslib.com manuals search engine

130-43

Fuel Injection ]

I I I

12 llnput IFeedback signal, engine start /Starter

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments BMW 540i 2000 E39 Repair Manual Downloaded from www.Manualslib.com manuals search engine

130-43

Fuel Injection ]

I I I

12 llnput IFeedback signal, engine start /Starter

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments](/img/1/2822/w960_2822-432.png)

Downloaded from www.Manualslib.com manuals search engine

130-43

Fuel Injection ]

I I I

12 llnput IFeedback signal, engine start /Starter

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments (continued)

I I - I

13 Input /I Alternator (generator) Notes

Throttle

valve

Crankshaft position sensor

Throttle valve (MS

42.0)

Throttle valve

Pin

6

7

8

9

10

11

14

15

16

17

18

19

20

I 1- I

23 l~round I~round, intaite air temperature sensor /Intake air temperature sensor

Signal

Output

Input

Input

Input

I I I

Component/function

Not used

Throttle valve supply potentiometer

2

Signal, crankshaft position sensor

Signal,

pedal position sensor 2 (MS 42.0)

Signal, throttle position sensor 1

Not used

Ground

Ground

Input

Ground

Ground

Input

Ground Cranltshaft position sensor

21

24

25

26

27

28

29

30

I 1- I

33 1 input ISignal, cylinder 1 fuel injector /cylinder 1 fuel injector

Ground, throttle position sensor (MS

42.0)

Ground, exhaust camshaftsensor I

Signal, pedal position sensor 1 (MS 42.0)

Ground, mass air flow sensor

Ground, intake camshaft sensor

1

Signal, throttle potentiometer 1

Ground, throttle position sensor

22 loutput I~ignal, intake air temperature Ilntake air temperature sensor

I I - I

Throttle

valve (MS 42.0)

Camshaft position sensor I

Throttle valve (MS

42.0)

Hot film mass air flow sensor

Camshaft position sensor i

Throttle valve

Throttle valve

Ground

Output

Ground Input

Output

Ground

Output

Out~ut

Ground, crankshaft position sensor

Knoclt sensor

31

34

35

36

37

38

39

Signal, coolant temperature sensor

Ground, coolant temperature sensor

Signal,

oil pressure

Signal, engine

oil temperature sensor

Ground, engine oil temperature sensor

Signal, knock sensor

Signal, knock sensor

32 loutput ISignal, ltnock sensor l~nock sensor

40

41

Coolant temperature sensor

Coolant temperature sensor

Oil pressure switch

Oil temperature sensor

Oil temperature sensor

Knoclt sensor

I

Input

input

Input

Input

Input

Inout

Signal, knock sensor

Input

Input Signal, cylinder

2 fuel injector

Signal, cylinder

3 fuel injector

Signal, cylinder

4 fuel injector

Signal, cylinder

5 fuel injector

Signal, cylinder

6 fuel injector

Sianai, oil level sensor Cylinder

2 fuel

injector

Cylinder

3 fuel injector

Cylinder

4 fuel injector

Cylinder

5 fuel injector

Cylinder

6 fuel injector

Oil level sensor

-

Signal. VANOS inlet valve

Signal. VANOS outlet valve VANOS

inlet valve

VANOS outlet valve