warning BMW M3 1992 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: M3, Model: BMW M3 1992 E36Pages: 759

Page 253 of 759

NOTE-

The

traction

control

system

referred

to

as

AST

(all

sea-

son

traction)

may

also

be

referred

to

as

ASC

(Automat-

ic

Stability

Control)

and

ASC+T

(Automatic

Stability

Control+Traction)

.

The

AST

system

improves

traction

by

electronically

apply-

ing

the

rear

brakes

when

therear

drive

wheels

are

spinning

at

a

faster

rate

than

the

front

wheels

.

The

combined

ABS/AST

control

module,

operating

through

the

ABS

hydraulic

control

unit,

modulates

braking

force

at

therear

wheels

.

In

addition,

AST

uses

retarded

ignition

timing

and

an

auxil-iary

engine

throttle

plate

to

reduceengine

torque

and

maintain

vehicle

stability

.

The

auxiliary

throttle

plate

is

held

open

by

spring

pressure

.

The

AST

system

actívates

the

auxiliary

throttie

position

motor

(ADS)

to

cose

the

AST

throttle

as

needed

.

This

reduces

the

volume

of

engine

intake

air

.

Due

to

the

throttle

closing

very

rapidly

during

AST

operationthe

driver

cannot

increase

theengine

power

output

regardless

of

how

far

theaccelerator

pedal

is

pushed

to

the

floor

.

The

auxiliary

throttle

plate

is

placed

ahead

of

the

conven-

tional

throttle

plate

in

the

throttle

body

.

Traction

control

also

comes

into

operationduringdecelera-

tion

.

Decelerating

on

snowy

or

icy

road

surfaces

can

lead

to

rear

wheel

slip

.

If

a

rear

wheel

startsto

drag

or

lock

up

when

the

throttle

is

closed

rapidly

orduringdownshifting,the

AST

system

can

limit

the

problem

by

advancing

the

ignition

timing

.

A

switch

on

the

center

console

is

used

to

togglethe

AST

on

or

off

.

The

AST

system

is

designed

to

be

maintenance

free

.

There

are

no

adjustments

that

can

be

made

.

Repair

and

trouble-

shooting

of

the

AST

system

requires

special

test

equipment

andknowledgeand

should

be

performed

only

by

an

autho-

rized

BMW

dealer

.

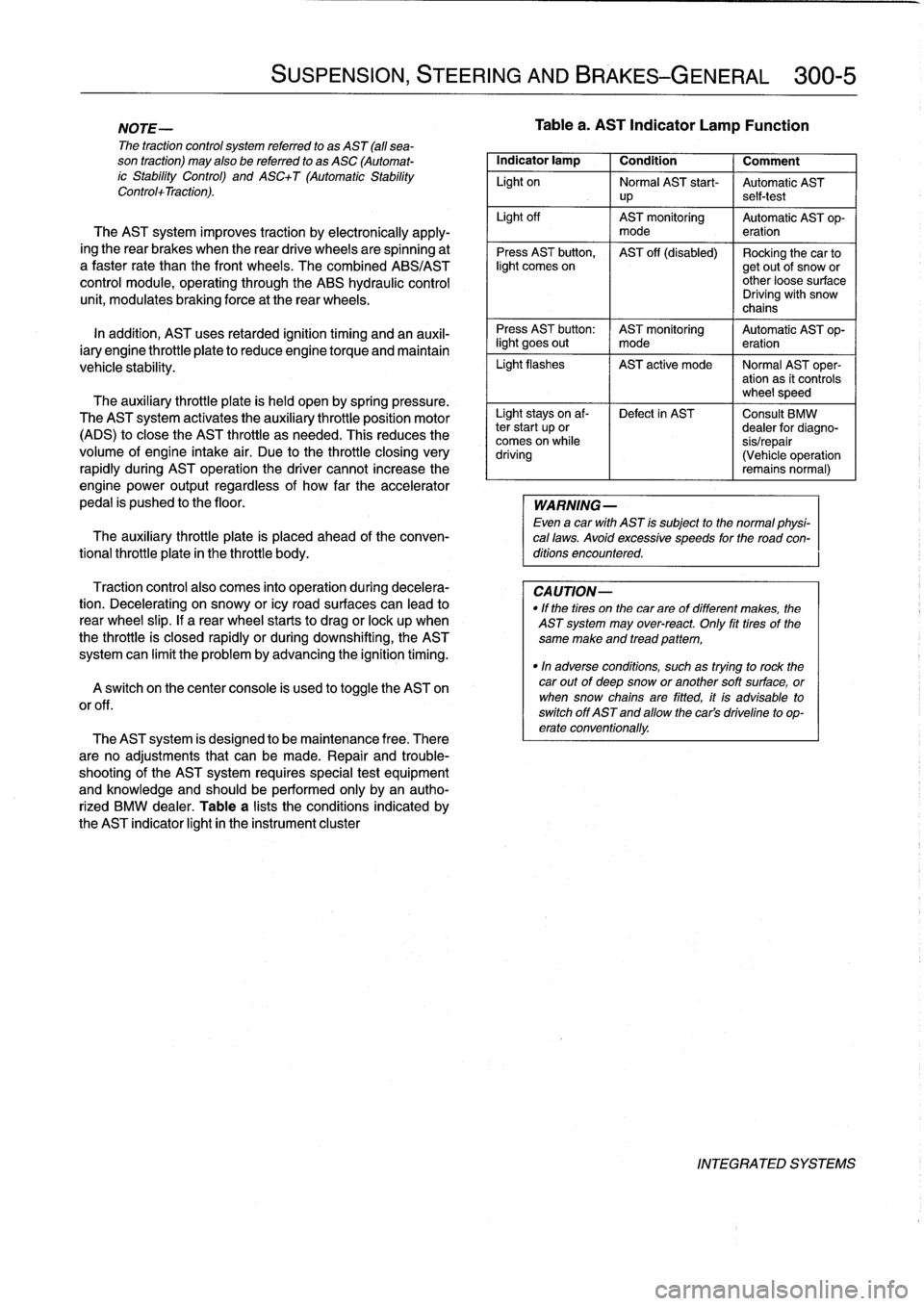

Table

a

lists

theconditions

indicated

by

the

AST

indicator

light

in

the

instrument

cluster

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

300-5

Tablea

.

AST

Indicator

Lamp

Function

Indicator

lamp

1

Condition

1

Comment

Light

on

Normal

AST

start-

Automatic

AST

up

self-test

Light

off

AST

monitoring

Automatic

AST

op-

mode

eration

Press

AST

button,

AST

off

(disabled)

Rocking

the

car

tolight

comes

on

getout

of

snow

or

other

loose

surface

Driving

with

snow

chains

Press

AST

button

:

AST

monitoring

Automatic

AST

op-

light

goes

out

I

mode

eration

Light

flashes

AST

active

mode

I

Normal

AST

oper-

ation

as

it

controls

wheel

speed

Light

stays

on

af-

Defect

in

AST

Consult

BMW

ter

start

up

or

dealer

for

diagno-

comes

on

while

sis/repair

driving

(Vehicle

operation

remains

normal)

WARNING

-

Even

a

car

with

AST

is

subject

to

the

normal

physi-

cal

laws

.

Avoid

excessive

speeds

for

the

road

con-

ditions

encountered

.

CAUTION-

"

If

the

tires

on

the

carare

of

different

makes,

the

AST

system

may

over-react

.

Only

fit

tires

of

the

same

make

and

tread

pattem,

"In

adverse

conditions,

such

as

trying

to

rock

the

car

outof

deep

snow

or

another

soft

surface,

or

when

snow

chainsare

fitted,

it

is

advisable

to

switch

off

AST

and

allow

the

cars

driveline

to

op-

erate

conventionally

.

INTEGRATED

SYSTEMS

Page 258 of 759

310-2

FRONT

SUSPENSION

WARNING-

"

Physical

safety

could

be

impaired

if

procedures

described

here

areundertaken

without

the

proper

service

tools

and

equipment

.

Be

sure

to

have

the

right

tools

onhand

before

beginning

any

job

.

"

Do

notreuse

self-locking

nuts

or

bolts

.

They

are

designed

to

beused

only

once

and

may

fail

if

re-

used

.

Always

replace

self-locking

fasteners

any

timethey

are

loosenedor

removed

.

"

Do

not

install

bolts

and

nuts

coated

with

under-

coating

wax,

as

the

correct

tightening

torque

can-

not

beassured

.

Always

clean

the

threads

with

solventbefore

installation,

or

install

new

parts

.

"

Do

not

attempt

to

weld

or

straighten

any

suspen-

sion

components

.

Replace

damaged

parts

.

SHOCK

ABSORBERS

AND

SPRINGS

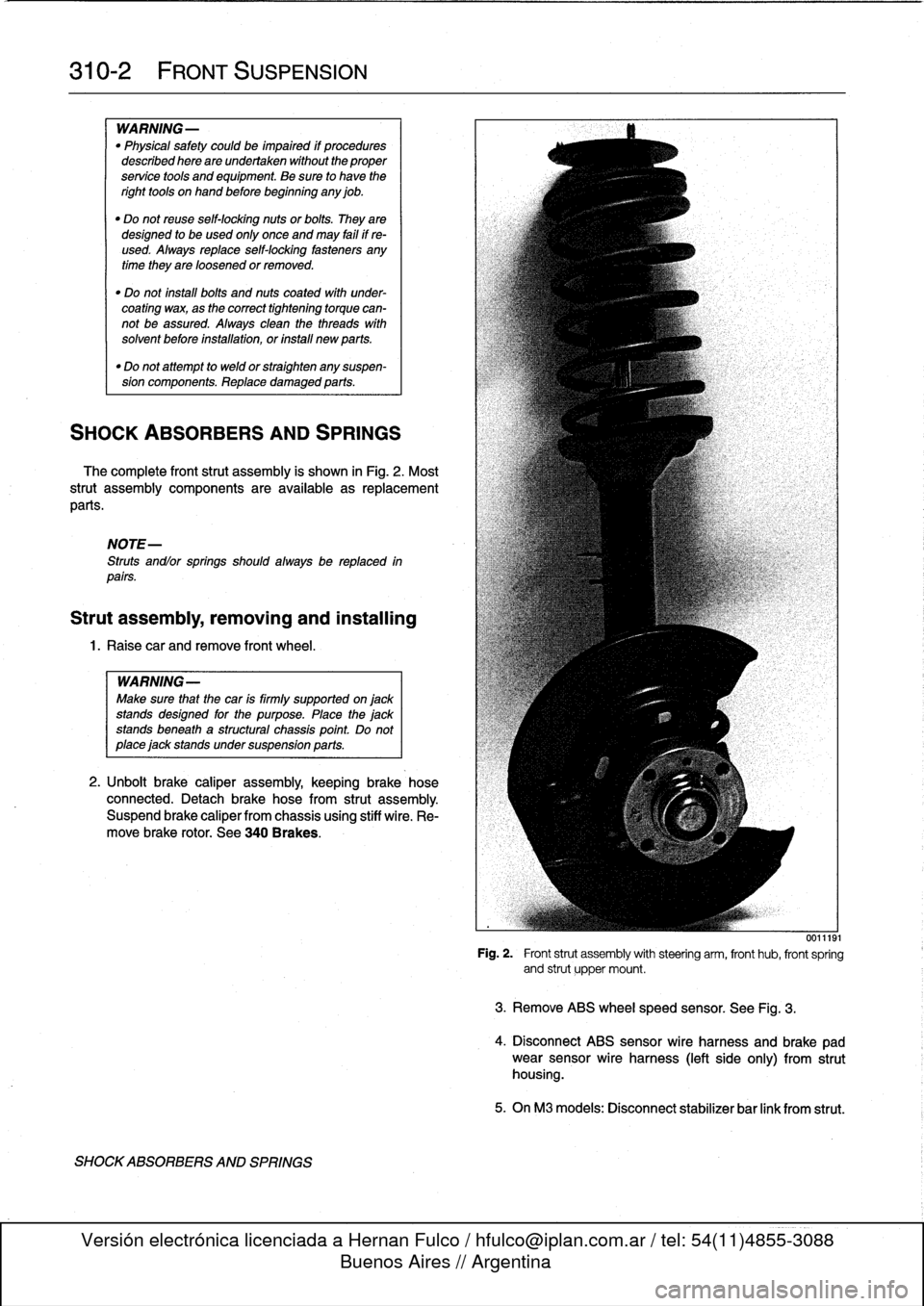

The

complete

front

strut

assembly

is

shown

in

Fig

.

2

.

Most

strut

assembly

components

are

available

asreplacement

parts

.

NOTE-

Struts

andlor

springs

shouldalways

be

replaced

in

parts

.

Strut

assembly,

removing

and

installing

1

.

Raisecar

and

remove

front

wheel

.

WARNING-

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneath

a

structural

chassis

point

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Unbolt

brake

caliper

assembly,

keepingbrake

hose

connected

.

Detach

brake

hose

from

strut

assembly

.

Suspend

brake

caliper

from

chassis

using

stiff

wire

.

Re-

move

brake

rotor

.

See

340

Brakes

.

SHOCKABSORBERS

AND

SPRINGS

0011191

Fig

.

2

.

Front

strut

assembly

with

steering

arm,

front

hub,

front

spring

and

strut

upper

mount

.

3

.

Remove

ABS

wheelspeed

sensor

.

See

Fig

.

3

.

4

.

Disconnect

ABS

sensor

wire

harness

and

brake

pad

wear

sensor

wire

harness

(left

side

only)

from

strut

housing

.

5

.

OnM3

modeis

:

Disconnect

stabilizer

bar

link

from

strut

.

Page 260 of 759

310-

4

FRONT

SUSPENSION

Strut

assembly,

disassembling

and

assembling

-

Be

sure

upper

spring

pad

is

correctly

installed

to

upper

NOTE-

spring

plate

and

spring

end

is

correctly

seated

in

up-

Springs

andlor

struts

should

always

be

replaced

in

per

and

lower

spring

plates

.

pairs

.

"

Use

a

new

self-locking

top

(center)

nut

.

Tighten

nut

fui-

¡y

before

releasing

spring

compressor

.

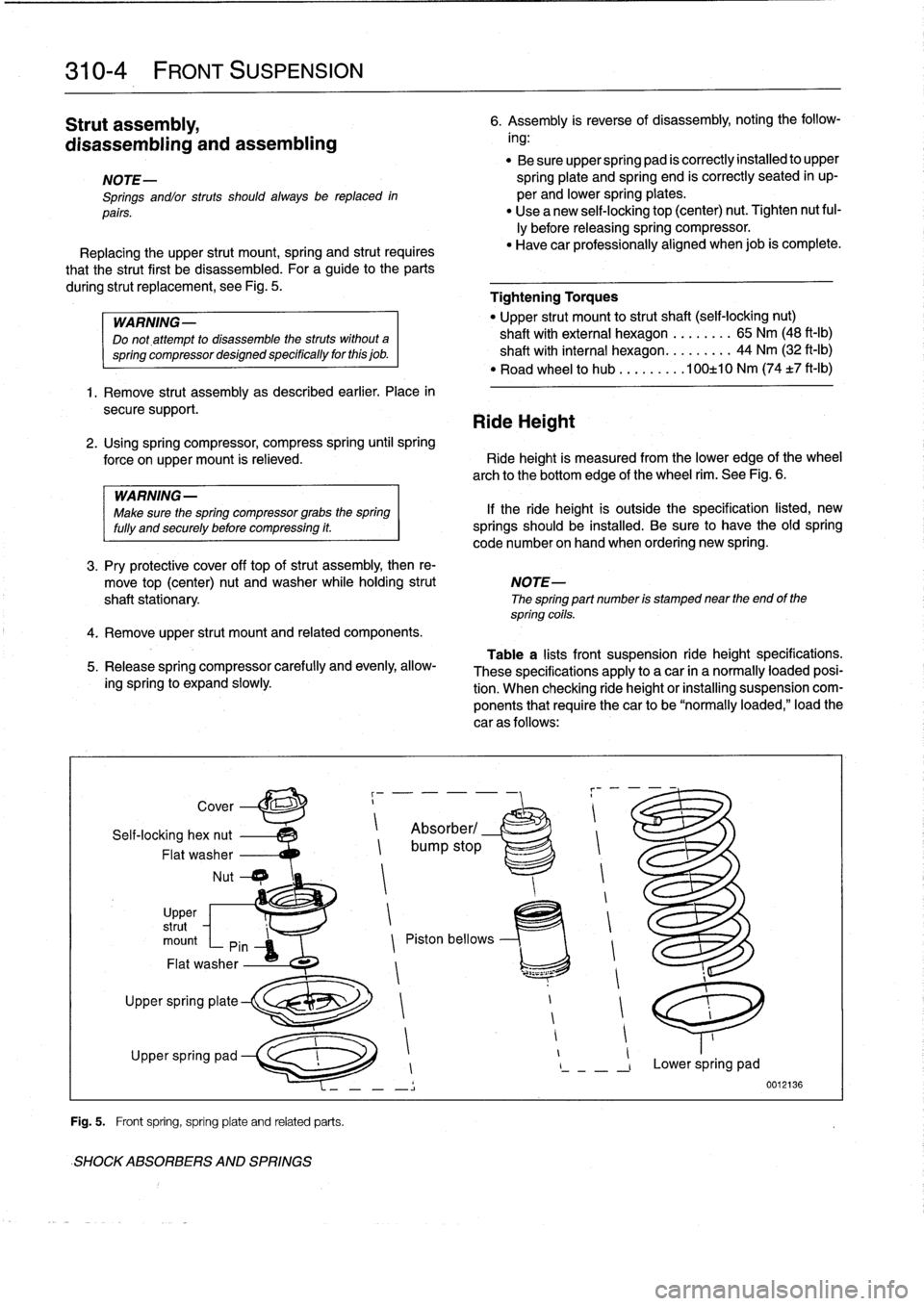

Replacing

the

upper

strut

mount,

spring

and

strut

requires

"

Have

car

professionally

aligned

when

job

is

complete

.

that

the

strut

first

bedisassembled

.

For

a

guide

to

the

parts

during

strut

replacement,

see

Fig

.

5

.

Tightening

Torques

WARNING-

"

Upper

strut

mount

to

strut

shaft

(seif-locking

nut)

Do

not,attempt

to

disassemble

thestruts

without

a

shaft

with

external

hexagon

......

..

65

Nm

(48

ft-1b)

springcompressordesignedspecificallyforthisjob

.

shaft

with

interna¡

hexagon

.......

..

44

Nm

(32

ft-Ib)

"

Road

wheel

to

hub

........

.100±10

Nm

(74

±7

ft-lb)

1

.

Remove

strut

assembly

as

described

earlier

.

Place

in

secure

support

.

Ride

Height

2

.

Using

spring

compressor,

compress

spring

until

spring

force

onupper

mount

is

relieved

.

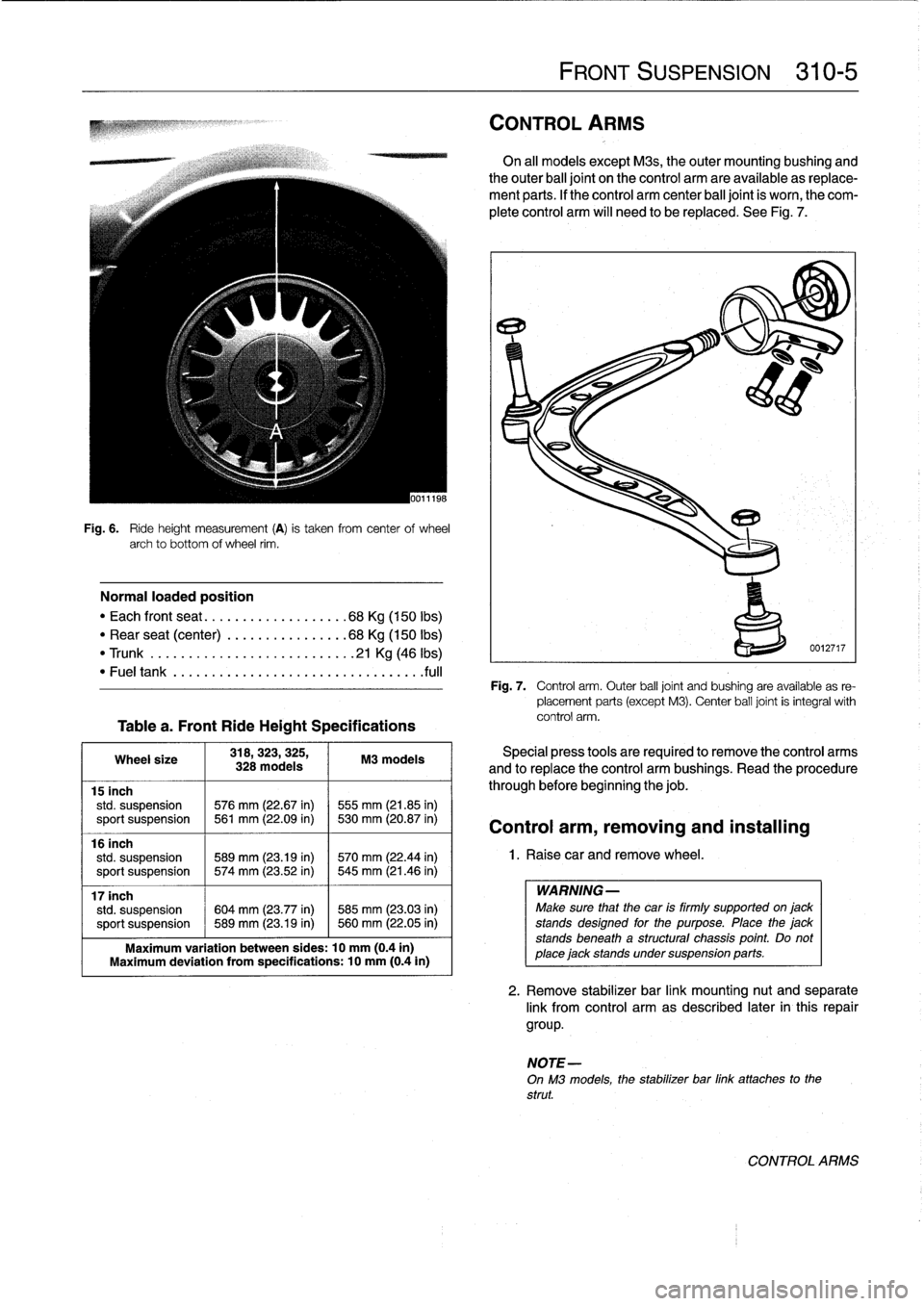

Ride

height

is

measured

from

the

lower

edge

of

the

wheel

arch

to

the

bottom

edge

of

the

wheel

rim

.

See

Fig

.

6

.

WARNING

-

Make

sure

the

spring

compressor

grabs

the

spring

lf

the

ride

height

is

outside

the

specification

listed,

new

fully

and

securely

before

compressing

it

.

springs

should

be

installed

.

Be

sure

to

have

theold

spring

code

number

on

hand

when

ordering

new

spring

.

3

.

Pry

protective

cover

off

top

ofstrut

assembly,

then

re-

move

top

(center)

nut

andwasher

whileholding

strut

NOTE-

shaftstationary

The

spring

part

number

is

stamped

near

the

end

of

the

spring

cofls

.

4

.

Remove

upper

strut

mount

and

related

components

.

5

.

Release

spring

compressor

carefully

and

evenly,

allow-

ing

spring

lo

expand

slowly

1

Self-locking

hex

nut

Absorber/

Flat

washer

bump

stop

Nut

Cover

Upper

~

strut

mount

Pin

Z

Piston

bellows

Flat

washer

r

i

t1

~

1

Upper

spring

plate

1

1

1

Upper

spring

pad

I

1

-

,

Lower

spring

pad

-

Í

0012136

Fig

.

5

.

Front

spring,

spring

plate

and

related

parts

.

SHOCKABSORBERS

AND

SPRINGS

6

.

Assembly

is

reverse

of

disassembly,

noting

the

follow-

ing

:

Table

a

lists

front

suspension

ride

height

specifications

.

These

specifications

apply

to

a

car

in

a

normally

loaded

posi-

tion

.

When

checking

ride

height

or

installing

suspension

com-

ponents

that

require

thecar

to

be

"normally

loaded,"load

the

car

as

follows

:

Page 261 of 759

Fig

.

6

.

Ride

height

measurement

(A)

is

taken

from

centerof

wheel

archto

bottom

of

wheel

rim

.

Normal

loaded

position

"

Each

front

seat

...

...

.

..

..........

68Kg

(150

Ibs)

"

Rear

seat

(center)

...

.

.

...........

68Kg

(150

Ibs)

"

Trunk

..........

...

.

.

...........

.21

Kg

(46

lbs)

"

Fuel

tank

...

.

..

....

.

.

....................

.fuf

Tablea

.

Front

RideHeight

Specifications

318,323,325,

Wheel

size

M3

models

328

models

15

inch

std

.

suspension

576

mm

(22.67

in)

1555

mm

(21.85

in)

sport

suspension

~

561

mm

(22.09

in)

530

mm

(20

.87

in)

16

inch

std

.

suspension

589

mm

(23.19

in)

1570

mm

(22

.44

in)

sport

suspensíon

~

574

mm

(23.52

in)

545

mm

(21.46

in)

17

inch

std

.

suspension

604

mm

(23.77

in)

585

mm

(23

.03

in)

sport

suspension

~

589

mm

(23.19

in)

~

560

mm

(22

.05

in)

Maximum

variation

between

sides

:

10

mm

(0.4in)

Maximum

deviation

from

specifications

:

10

mm

(0

.4in)

FRONT

SUSPENSION

310-

5

CONTROL

ARMS

On

al¡

models

except

Mas,

theouter

mounting

bushing

and

theouter

ball

joint

on

the

control

arm

are

available

as

replace-

ment

parts

.

If

the

control

arm

center

ball

joint

is

worn,

the

com-

plete

control

arm

will

need

to

be

replaced

.

See

Fig

.

7

.

Fig

.

7

.

Control

arm

.

Outer

ball

joint

and

bushing

are

available

as

re-

placement

parts

(except

M3)

.

Center

ball

joint

is

integral

with

control

arm

.

Special

press

tools

are

requiredto

remove

the

control

arms

and

to

replace

the

control

arm

bushings

.

Read

the

procedure

through

before

beginning

the

job

.

Control

arm,

removing

and

installing

1

.

Raise

car

and

remove

wheel

.

WARNING-

Make

sure

that

thecar

is

firmly

supportedon

jack

standsdesigned

for

the

purpose

.

Place

the

jack

stands

beneath

a

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Remove

stabilizer

bar

link

mounting

nut

and

separate

link

from

control

arm

as

described

later

in

this

repair

group

.

NOTE-

On

M3

models,

the

stabilizer

bar

link

attaches

to

the

strut

.

CONTROL

ARMS

Page 262 of 759

310-

6

FRONT

SUSPENSION

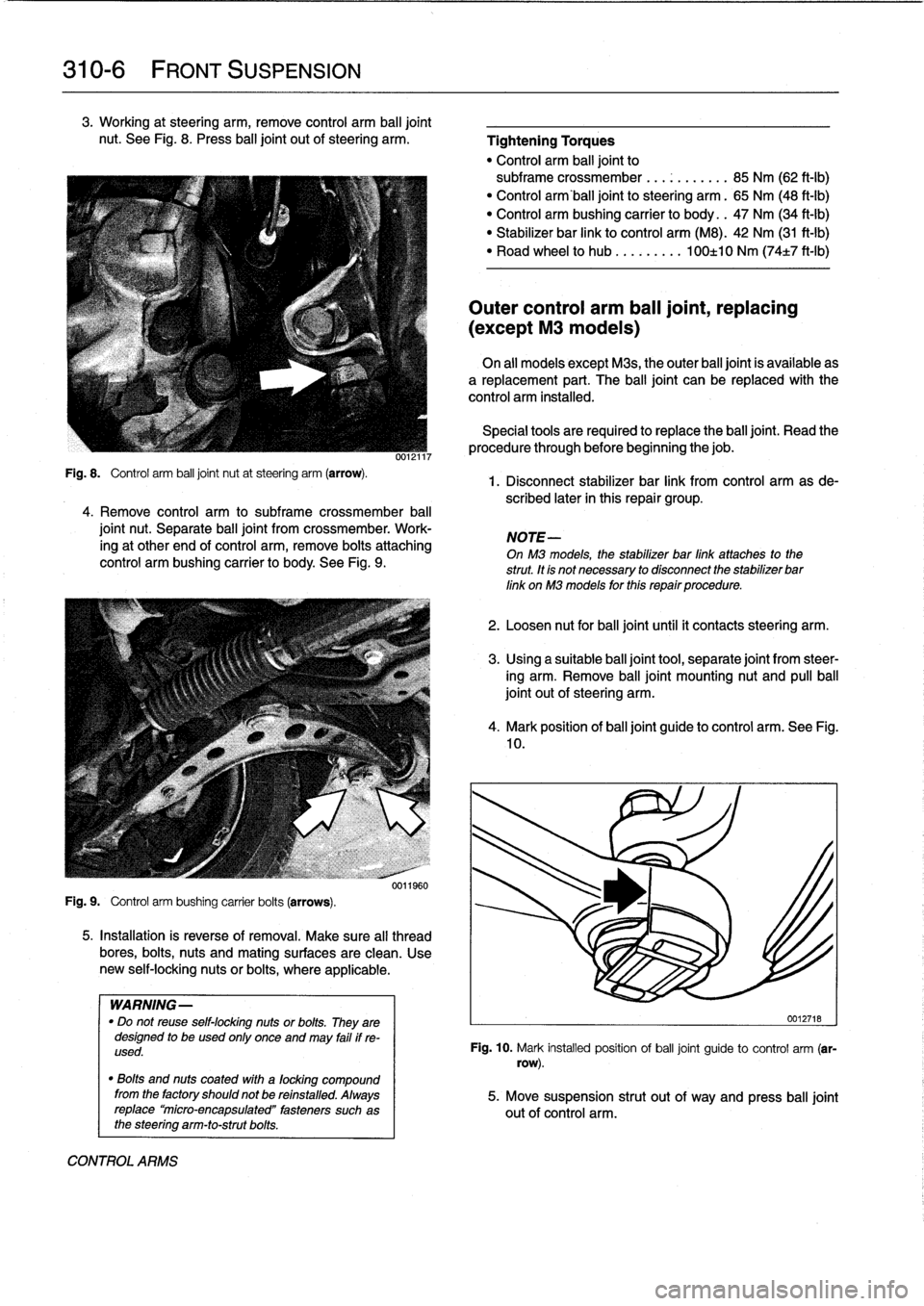

3

.

Working

at

steering

arm,

remove

control

arm

balljoint

nut

.

See

Fig

.

8

.

Press

ball

joint

out

ofsteering

arm

.

Fig

.

8

.

Control

arm

ball

joint

nut

at

steering

arm

(arrow)

.

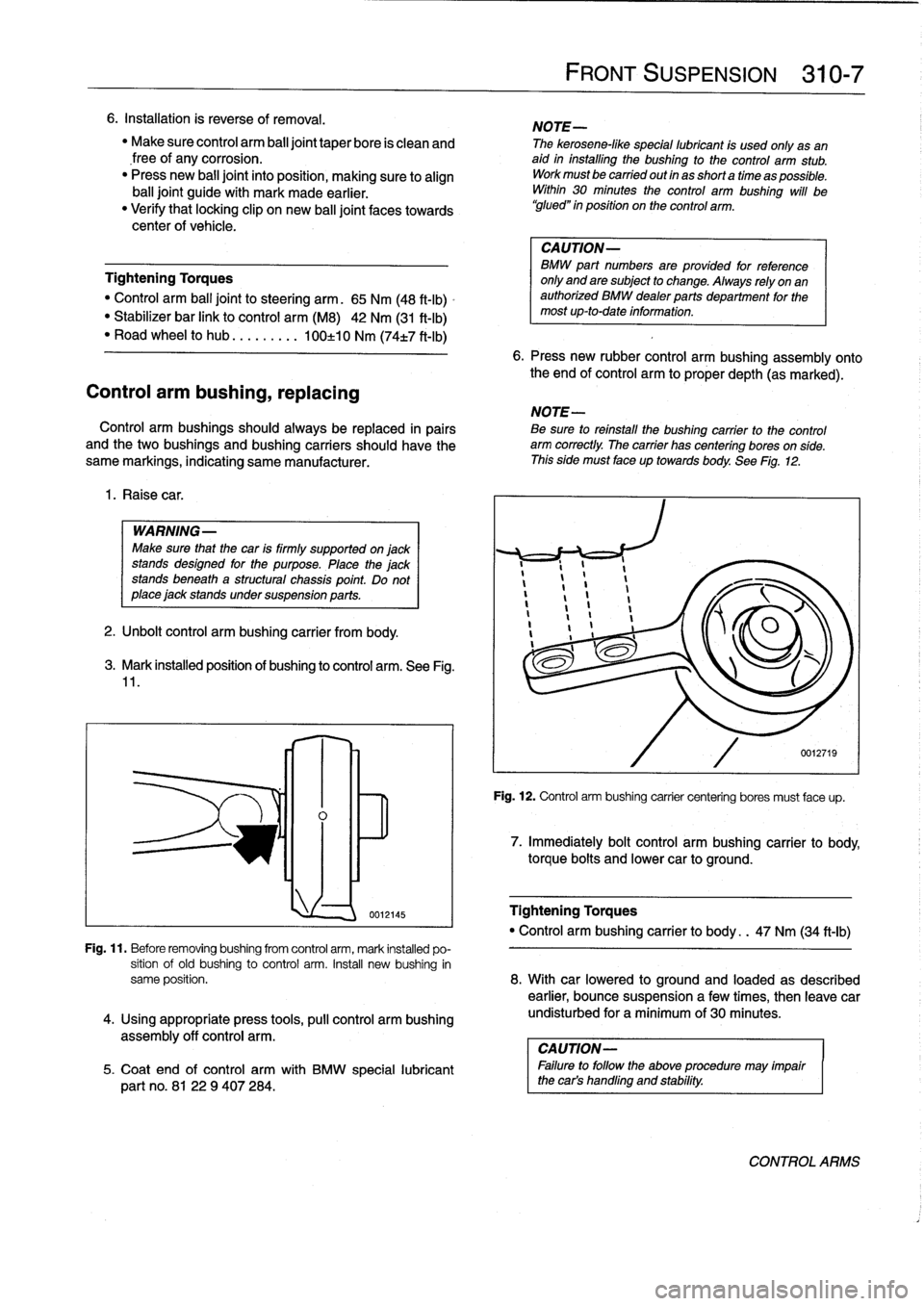

4

.

Remove

control

arm

to

subframe

crossmember

ball

joint

nut

.

Separate

ball

joint

from

crossmember

.

Work-

ing

at

other

end

of

control

arm,

remove

bolts

attaching

control

arm

bushing

carrier

to

body

.

See

Fig

.

9

.

Fig

.

9

.

Control

arm

bushing

carrier

bolts

(arrows)

.

0012117

0011960

5

.

Installation

is

reverse

of

removal

.

Make

sure

al¡

thread

bores,

bolts,

nuts

and

mating

surfaces

are

clean

.

Use

new

self-locking

nutsor

bolts,

where

applicable

.

WARNING-

"

Do

not

reuse

self-locking

nuts

or

bolts

.

They

are

designed

to

be

used

only

once

and

may

failif

re-

used

.

"

Bolts

and

nuts

coated

with

a

focking

compound

from

the

factory

shouldnot

be

refnstalled

.

Always

replace`micro-encapsulated"

fasteners

such

as

the

steering

arm-to-strutbolts

.

CONTROL

ARMS

Tightening

Torques

"

Control

arm

balljoint

to

subframe

crossmember

.

..

...

...

.

.

85

Nm

(62

ft-Ib)

"

Control

arm'ball

joint

to

steering

arm

.

65

Nm

(48

ft-Ib)

"

Control

arm

bushing

carrier

to

body

.

.

47

Nm

(34

ft-Ib)

"

Stabilizer

bar

link

to

control

arm

(M8)

.

42

Nm

(31

ft-Ib)

"

Road

wheel

to

hub

.

...

...

.

.

100±10

Nm

(74±7

ft-Ib)

Outer

control

arm

ball

joint,

replacing

(except

M3

models)

On

all

models

except

Mas,

the

outer

balljoint

is

available

as

a

replacement

part

.

The

ball

joint

can

be

replaced

with

the

control

arm

installed

.

Special

tools

are

requiredto

replace

the

balljoínt

.

Read

the

procedure

through

before

beginning

thejob

.

1

.

Disconnect

stabilizer

bar

link

from

control

arm

asde-

scribed

later

in

this

repair

group

.

NOTE-

On

M3

models,

the

stabilizer

bar

link

attaches

to

the

strut

.

tt

fs

not

necessary

to

disconnect

the

stabilizer

bar

link

on

M3

models

for

thfs

repair

procedure

.

2

.

Loosen

nut

for

balljointuntil

it

contacts

steering

arm

.

3

.

Using

a

suitable

ball

joint

tool,

separate

joint

from

steer-

íng

arm

.

Remove

ball

joint

mounting

nut

and

pullball

joint

out

of

steering

arm

.

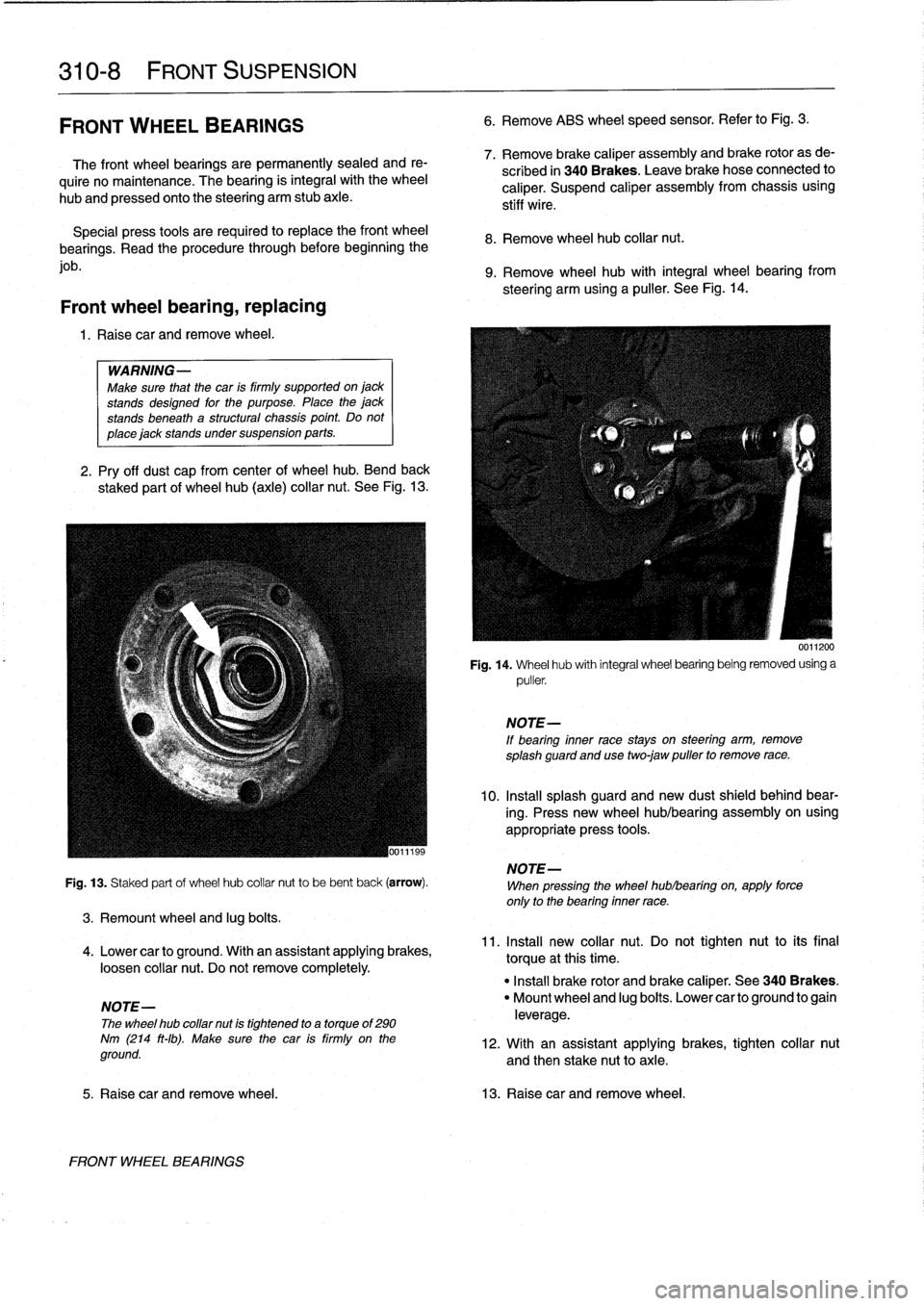

4

.

Mark

position

of

balljoint

guide

to

control

arm

.

See

Fig

.

10

.

0012718

Fig

.

10

.

Mark

installed

position

of

ball

joint

guide

to

control

arm

(sr-

row)

.

5

.

Move

suspension

strut

out

of

way

and

press

ball

joint

out

of

control

arm

.

Page 263 of 759

6

.

Installation

is

reverse

of

removal

.

"

Make

sure

control

arm

ball

joint

taper

bore

is

clean

and

free

of

any

corrosion

.

"

Press

new

balljoint

into

position,

making

sure

to

align

balljoint

guide

with

mark

made

earlier

.

"

Verify

that

locking

clip

on

new

ball

joint

faces

towards

center

of

vehicle

.

Tightening

Torques

"

Control

arm

ball

jointto

steering

arm

.

65

Nm

(48

ft-Ib)

"

Stabilizer

bar

link

to

control

arm

(M8)

42

Nm

(31

ft-Ib)

"

Road

wheel

to

hub

.

...

...

.

.

100±10

Nm

(74t7

ft-lb)

Control

arm

bushing,

replacing

Control

arm

bushings

should

aiways

be

replaced

in

pairs

and

the

two

bushings

and

bushing

carriers

should

have

the

same

markings,

indicating

same

manufacturer

.

1

.

Raisecar

.

WARNING-

Make

sure

that

the

car

is

firmly

supportedonjackstandsdesigned

for

the

purpose

.

Place

the

jackstands

beneath

a

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Unbolt

control

arm

bushing

carrier

from

body

.

3

.

Mark

installed

position

of

bushing

to

control

arm

.

See

Fig

.

11

.

assembly

off

control

arm

.

lnl~

0012145

FRONT

SUSPENSION

310-

7

NOTE-

The

kerosene-like

special

lubricant

is

used

only

asan

aid

in

installing

the

bushing

to

the

control

arm

stub

.

Workmustbe

carried

out

in

as

short

a

time

as

possible

.

Within

30

minutes

the

control

arm

bushing

will

be

`glued"

in

position

on

the

control

arm

.

CAUTION-

BMW

part

numbers

areprovided

for

reference

only

and

are

subject

to

change

.

Always

rely

on

an

authorized

BMW

dealerparts

department

for

the

most

up-to-date

information

.

6

.

Press

new

rubber

control

arm

bushing

assembly

onto

the

end

of

control

arm

to

proper

depth

(as

marked)

.

NOTE-

Be

sure

toreinstall

the

bushing

carrier

to

the

control

arm

correctly

.

The

carrier

has

centering

bores

on

side

.

This

side

must

face

up

towards

body

.

See

Fig

.

12

.

Fig

.

12

.

Control

arm

bushing

carrier

centering

bores

must

face

up

.

7

.

Immediately

bolt

control

arm

bushing

carrier

to

body,

torque

boits

and

lower

car

to

ground

.

Tightening

Torques

"

Control

arm

bushing

carrier

to

body

.

.

47

Nm

(34

ft-ib)

Fig

.

11

.

Before

removingbushing

from

control

arm,

mark

installed

po-

sition

of

old

bushing

to

control

arm

.

Insta¡¡

new

bushing

in

same

position

.

8

.

With

car

lowered

to

ground

and

loaded

as

described

earlier,

bounce

suspensiona

few

times,

then

leave

car

4

.

Using

appropriate

press

tools,

pull

control

arm

bushing

undisturbed

for

a

minimum

of

30

minutes

.

CAUTION-

5

.

Coat

end

of

control

arm

with

BMW

special

lubricant

I

Failure

to

follow

the

above

procedure

may

impair

part

no

.

8122

9

407284

.

the

car's

handling

and

stability

.

CONTROLARMS

Page 264 of 759

310-

8

FRONT

SUSPENSION

FRONT

WHEEL

BEARINGS

The

front

wheel

bearings

are

permanently

sealed

and

re-

quire

no

maintenance

.

The

bearing

is

integral

with

the

wheel

hub

and

pressed

onto

the

steering

arm

stub

axle

.

Special

press

tools

are

requiredto

replace

the

front

wheel

bearings

.

Read

the

procedure

through

before

beginning

the

job

.

Front

wheel

bearing,

replacing

1

.

Raise

car

and

remove

wheel

.

WARNING-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

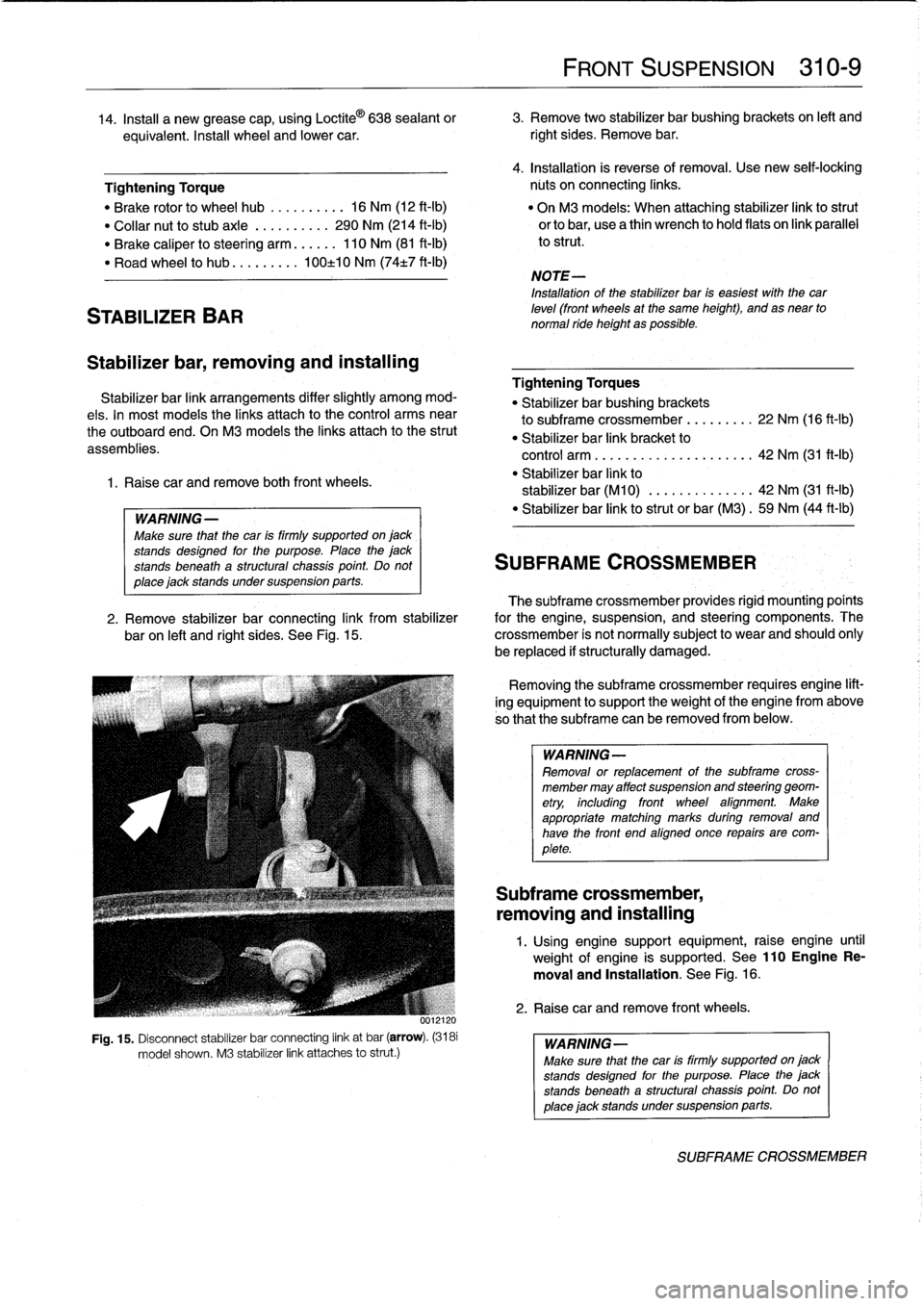

2

.

Pry

off

dust

cap

from

centerof

wheel

hub

.

Bend

back

staked

part

of

wheel

hub

(axle)

collar

nut

.

See

Fig

.

13

.

Fig

.

13

.

Staked

part

of

wheel

hub

collar

nut

to

be

bent

back

(arrow)

.

3

.

Remount

wheel

and

lug

bolts

.

4

.

Lower

canto

ground

.

With

an

assistant

applying

brakes,

loosen

collar

nut

.

Do

not

remove

completely

.

NOTE-

The

wheel

hub

collar

nut

is

tightened

to

a

torque

of

290

Nm

(214

ft-Ib)

.

Make

sure

the

car

is

firmly

on

the

ground

.

FRONT

WHEEL

BEARINGS

6

.

Remove

ABS

wheel

speed

sensor

.

Refer

to

Fig

.

3

.

7

.

Remove

brake

caliper

assembly

and

brake

rotor

as

de-

scribed

in

340

Brakes

.

Leave

brakehose

connected

to

caliper

.

Suspend

caliper

assembly

from

chassis

using

stiff

wire

.

8

.

Remove

wheel

hub

collar

nut

.

9

.

Remove

wheel

hub

with

integral

wheel

bearing

from

steering

arm

using

a

puller

.

See

Fig

.

14

.

0011200

Fig

.

14

.

Wheel

hub

with

integral

wheel

bearing

being

removed

using

a

puller

.

NOTE-

If

bearing

inner

race

stays

on

steering

arm,

remove

splash

guard

and

usetwo

jaw

puller

to

remove

race

.

10

.

Insta¡¡

splash

guard

and

new

dust

shield

behind

bear-

ing

.

Press

new

wheel

hub/bearing

assembly

on

using

appropriate

press

tools

.

NOTE-

When

pressing

the

wheel

hublbearing

on,

apply

force

only

to

the

bearing

inner

race

.

11

.

Install

new

collar

nut

.

Do

not

tighten

nut

to

its

final

torque

atthis

time

.

"

Install

brake

rotor

and

brake

caliper

.

See

340

Brakes

.

"

Mount

wheel

and

lug

boits

.

Lower

canto

ground

to

gain

leverage

.

12

.

With

an

assistant

applying

brakes,

tighten

collar

nut

and

then

stake

nut

toaxle

.

5

.

Raise

car

and

remove

wheel

.

13

.

Raisecar

and

remove

wheel

.

Page 265 of 759

STABILIZER

BAR

Stabilizer

bar,

removing

and

installing

Stabilizer

bar

link

arrangements

differ

slightly

among

mod-

els

.

In

most

models

the

links

attach

lo

the

control

arms

near

the

outboard

end

.

OnM3

models

the

links

attach

lo

the

strut

assemblies

.

1

.

Raise

car

and

remove

both

front

wheels

.

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

stands

desígned

for

the

purpose

.

Place

the

jack

stands

beneath

a

structural

chassís

point

.

Do

not

place

jack

stands

under

suspension

parts

.

uul

Fig

.

15

.

Disconnect

stabilizer

bar

connecting

link

at

bar

(arrow)

.

(3181

model

shown

.

M3

stabilizer

link

attaches

lo

strut

.)

FRONT

SUSPENSION

310-

9

14

.

Insta¡¡

a

new

grease

cap,

using

Loctite

©

638

sealant

or

3

.

Remove

two

stabilizer

bar

bushing

brackets

on

left

and

equivalent

.

Insta¡¡

wheel

and

lower

car

.

right

sides

.

Remove

bar

.

4

.

Installation

is

reverse

of

removal

.

Use

new

seif-lockíng

Tightening

Torque

núts

on

connecting

links

.

"

Brake

rotor

lo

wheel

hub

..........

16

Nm

(12

ft-Ib)

"

On

M3

models

:

When

attaching

stabilizer

link

lostrut

"

Collar

nut

lo

stubaxle

.

.........

290

Nm

(214

ft-Ib)

orlobar,

usea

thin

wrench

lo

hold

flats

on

link

parallel

"

Brake

caliper

losteering

arm

......

110

Nm

(81

ft-Ib)

lo

strut

.

"

Road

wheel

lo

hub

...

...

.

.

.

100±10

Nm

(74t7

ft-Ib)

NOTE-

Installation

of

the

stabilizer

bar

is

easiest

with

thecar

leve¡

(front

wheels

at

the

same

height),

and

as

near

to

normal

ride

height

as

possible

.

Tightening

Torques

"

Stabilizer

bar

bushing

brackets

lo

subframe

crossmember

...

..

.

..

.

22

Nm

(16

ft-Ib)

"

Stabilizer

bar

link

bracket

lo

control

arm

................

.

.

.

.

.

42

Nm

(31

ft-1b)

"

Stabilizer

bar

link

lo

stabilizer

bar

(M10)

.............

.

42

Nm

(31

ft-Ib)

"

Stabilizer

bar

link

lostrut

or

bar

(M3)

.

59

Nm

(44

ft-Ib)

SUBFRAME

CROSSMEMBER

The

subframe

crossmember

provides

rigid

mounting'poínts

2

.

Remove

stabilizer

bar

connecting

link

from

stabilizer

for

the

engine,

suspension,

and

steering

components

.

The

baron

left

and

right

sides

.

See

Fig

.

15

.

crossmember

is

not

normally

subject

lo

wear

and

should

ohly

be

replaced

if

structurally

damaged

.

Removing

the

subframe

crossmember

requires

engine

lift-

ing

equipment

lo

support

theweight

of

tfhe

engine

from

above

so

that

the

subframe

can

be

removed

from

below

.

WARNING-

Removal

or

replacement

of

the

subframe

cross-

member

may

affect

suspension

and

steering

geom-

etry,

including

front

wheel

afignment

.

Make

appropriate

matching

marks

during

removal

and

have

the

front

end

aligned

once

repairs

are

com-

plete

.

Subframe

crossmember,

removing

and

installing

1

.

Using

enginesupport

equipment,

raise

engine

until

weight

of

engine

is

supported

.

See

110EngineRe-

moval

and

Installation

.

See

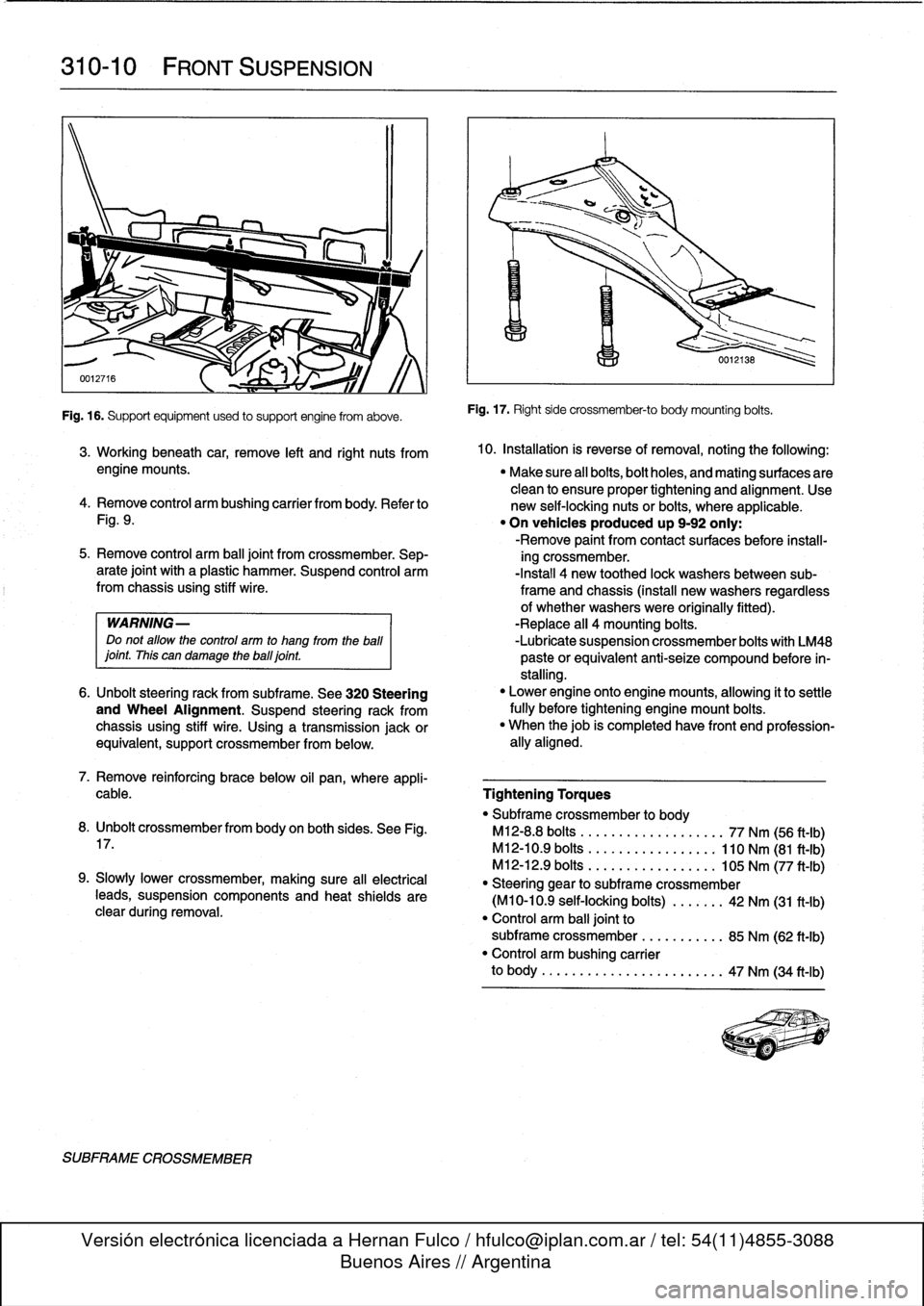

Fig

.

16

.

2

.

Raise

car

andremove

front

wheels

.

WARNING-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

desígned

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassís

point

Do

not

place

jack

standsundersuspension

parts

.

SUBFRAME

CROSSMEMBER

Page 266 of 759

310-

1

0

FRONT

SUSPENSION

Fig

.

16

.

Supportequipment

used

to

support

engine

from

aboye

.

SUBFRAME

CROSSMEMBER

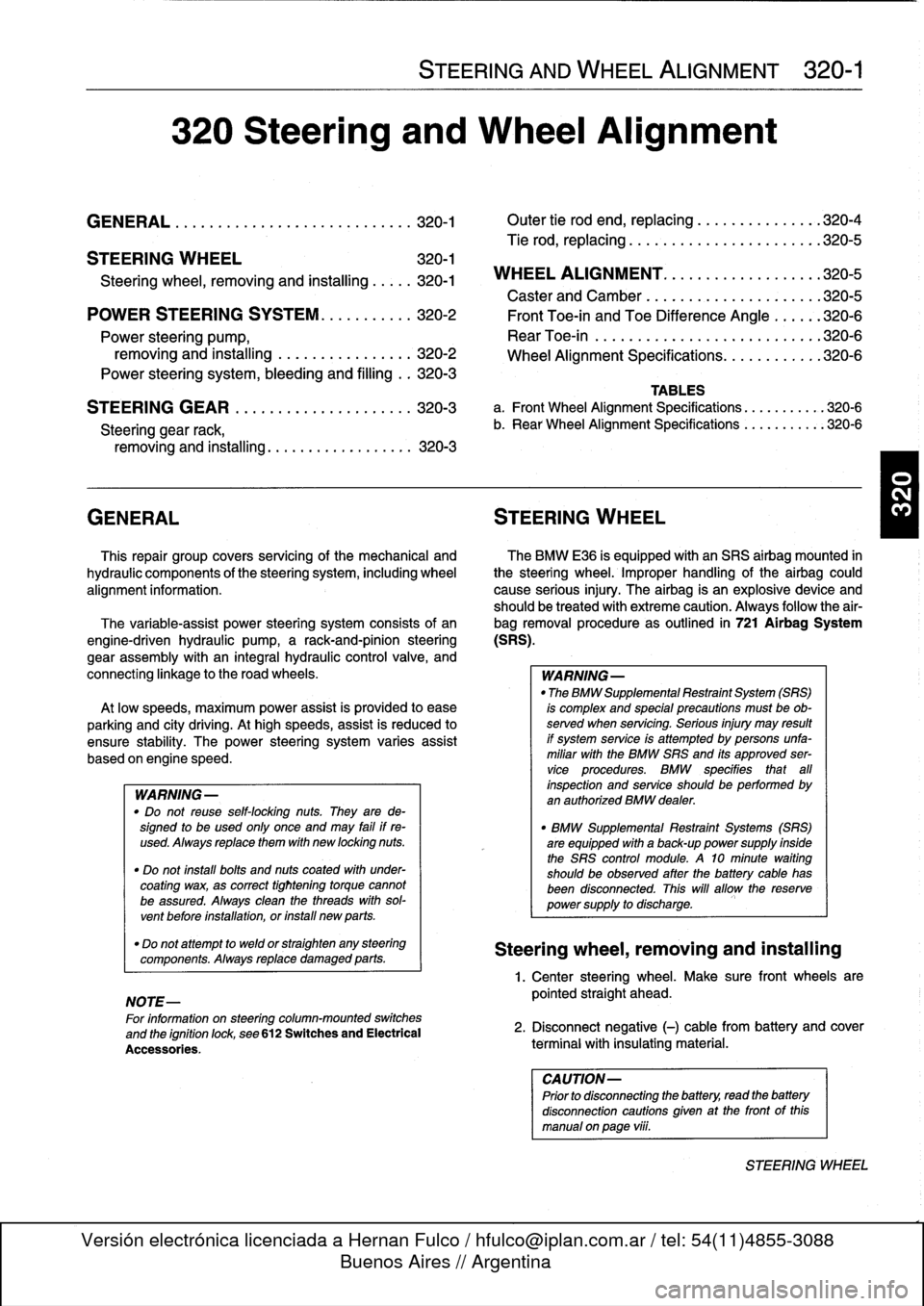

Fig

.

17

.

Right

side

crossmember-to

body

mounting

bolts

.

3

.

Working

beneath

car,

remove

left

and

right

nuts

from

10

.

Installation

is

reverse

ofremoval,

noting

the

followíng

:

engine

mounts

.

"

Make

sure

all

bolts,bolt

holes,

and

mating

surfaces

are

clean

to

ensure

proper

tightening

and

alignment

.

Use

4

.

Remove

control

arm

bushing

carrier

from

body

.

Refer

to

new

self-locking

nuts

or

bolts,

where

applicable

.

Fig

.

9

.

"

On

vehicles

produced

up

9-92

only

:

-Remove

paint

from

contact

surfaces

before

ínstall-

5

.

Remove

control

arm

ball

joint

from

crossmember

.

Sep-

ing

crossmember

.

arate

joint

with

a

plastic

hammer

.

Suspend

control

arm

-Install

4

new

toothed

lock

washersbetween

sub-from

chassis

using

stiff

wire

.

frame

and

chassis

(install

new

washers

regardless

of

whether

washers

were

originally

fitted)

.

WARNING-

-Replace

all

4

mounting

bolts

.

Do

not

allow

the

control

arm

to

hang

from

the

ball

-Lubrícate

suspension

crossmember

bolts

with

LM48

¡oint

.

This

can

damage

theball¡oint

.

paste

orequivalent

anti-seize

compound

before

ín-

stalling

.

6

.

Unbolt

steering

rack

from

subframe

.

See

320

Steering

"

Lower

engine

onto

enginemounts,

allowing

it

to

settle

and

Wheel

Alignment

.

Suspend

steering

rack

from

fully

before

tightening

engine

mount

bolts

.

chassis

using

stiff

wire

.

Using

a

transmission

jackor

"

When

thejob

is

completed

have

front

end

profession-

equivalent,

support

crossmember

from

below

.

ally

aligned

.

7

.

Remove

reinforcing

brace

below

oil

pan,

where

appli-

cable

.

Tightening

Torques

"

Subframe

crossmember

to

body

8

.

Unbolt

crossmemberfrom

body

on

both

sides

.

See

Fig

.

M12-8

.8

bolts

..................

.

77

Nm

(56

ft-Ib)

17

.

M12-10

.9

bolts

.................

110

Nm

(81

ft-Ib)

M12-12

.9

bolts

............

.

...

.

105

Nm

(77

ft-Ib)

9

.

Slowly

Lower

crossmember,

making

sure

all

electrical

"

Steering

gear

to

subframe

crossmember

teads,

suspension

components

and

heat

shields

are

(M10-10

.9

self-locking

bolts)

..

.

.

.

.

.

42

Nm

(31

ft-Ib)

clear

during

removal

.

"

Control

arm

balljoint

to

subframe

crossmember

...

.......

.

85

Nm

(62

ft-Ib)

"

Control

arm

bushing

carrier

to

body

..........

...

.

.....

.

..

..

47

Nm

(34

ft-Ib)

Page 267 of 759

320

Steering

and

Wheel

Alignment

GENERAL

...

.

.

.

...

.

....

.

.

.

.

.

.

.

.

.

...

.

.

320-1

Outer

tie

rod

end,

replacing

.

...

.

.

.

.

.

.

.

...

.

320-4

Tie

rod,

replacing

.

.

.

.

.

.

.

.......

.

.

.

.

.

...

.

320-5

STEERING

WHEEL

320-1

Steering

wheel,

removing

and

installing

.....

320-1

WHEEL

ALIGNMENT

.

.

.

.........

.

.....

.320-5

POWER

STEERING

SYSTEM

.

.

.

.

.

.

.....

320-2

Front

Toe-in

and

Toe

Difference

Angle

.

.

...

.

320-6

Power

steering

pump,

Rear

Toe-in

.

.

.

.

.

.

.

...

.

................

320-6

removing

and

installing

..

.

.

.

.

.

.

.

.

.

.....

320-2

Wheel

Alignment

Specifications

.....

.

......

320-6

Power

steering

system,

bleeding

and

filling

.

.

320-3

STEERING

GEAR

.

.

.

.

...

.

.

.

.

.

.

.

.

.

.....

320-3

Steering

gear

rack,

removing

and

installing

.

...

.

..

.

..

..

..

.

..

.

320-3

GENERAL

STEERING

WHEEL

This

repair

group

covers

servicing

of

the

mechanical

and

The

BMW

E36

is

equipped

with

an

SRS

airbag

mounted

in

hydraulic

components

of

the

steering

system,

including

wheel

the

steering

wheel

.

Improper

handling

of

the

airbag

could

alignment

information

.

cause

serious

injury

.

The

airbag

is

an

explosivedevice

and

should

be

treated

with

extreme

caution

.

Always

follow

the

air-

The

variable-assist

power

steering

system

consistsof

an

bag

removal

procedure

as

outlined

in

721

Airbag

System

engine-driven

hydraulic

pump,

a

rack-and-pinion

steering

(SRS)

.

gear

assembly

with

an

integral

hydraulic

control

valve,

and

connecting

linkage

to

the

road

wheels

.

WARNING-

"

The

BMW

Supplemental

Restraint

System

(SRS)

At

lowspeeds,

maximum

power

assist

is

provided

to

ease

is

complex

and

special

precautions

must

be

ob-

parking

and

city

driving

.

At

high

speeds,

assist

is

reduced

to

served

when

servicing

.

Serious

injury

may

result

ensure

stability

.

The

power

steering

system

varies

assist

if

system

service

is

attempted

by

persons

unfa-

based

on

engine

speed

.

miliar

with

the

BMW

SRS

and

its

approved

ser-

vice

procedures

.

BMW

specifies

that

all

ING-

inspection

and

service

shouldbe

performed

by

WARN

an

authorized

BMW

dealer

.

"

Do

not

reuse

self-locking

nuts

.

They

are

de-signed

to

beused

only

once

and

may

failif

re-

"

BMW

Supplemental

Restraint

Systems

(SRS)

used

.

Always

replace

them

with

new

locking

nuts

.

are

equipped

with

a

back-up

power

supply

inside

the

SRS

control

module

.

A

10minute

waiting

"

Do

not

ínstall

bolts

and

nuts

coated

with

under-

shouldbe

observed

after

the

battery

cable

has

coating

wax,

as

correct

tightening

torque

cannot

been

disconnected

.

This

will

allow

the

reserve

be

assured

.

Always

clean

the

threads

with

sol-

power

supply

to

discharge

.

vent

before

installation,

or

install

new

parts

.

"

Do

not

attempt

to

weldor

straighten

any

steering

components

.

Always

replace

damaged

parts

.

NOTE-

For

information

on

steering

column-mounted

switches

and

the

ignition

lock,

see

612

Switches

and

Electrical

Accessories

.

STEERING

AND

WHEEL

ALIGNMENT

320-1

Caster

and

Camber

.

.

.

.

.

...........

.

....

320-5

TABLES

a

.

Front

Wheel

Alignment

Specifications

.

...

.......

320-6

b

.

Rear

Wheel

Alignment

Specifications

.

...

.......

320-6

Steering

wheel,

removing

and

installing

1

.

Center

steering

wheel

.

Make

sure

front

wheelsare

pointed

straight

ahead

.

2

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

STEERING

WHEEL