warning BMW M3 1992 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: M3, Model: BMW M3 1992 E36Pages: 759

Page 268 of 759

320-2

STEERING

AND

WHEEL

ALIGNMENT

3

.

Carefully

remove

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Store

airbag

unit

in

a

safe

place

.

WARNING-

Improper

handling

of

theaírbag

could

cause

seri-

ous

ínjury

.

Store

theaírbag

with

the

horn

pad

facing

up

.

If

stored

facing

down,

accidental

deployment

could

propel

it

vlolently

into

the

air,

causíng

ínjury

.

4

.

Remove

steering

wheel

center

bolt

.

Lightly

punch

mark

or

scribe

position

of

steering

wheel

to

steering

column

shaft

.

See

Fig

.

1

.

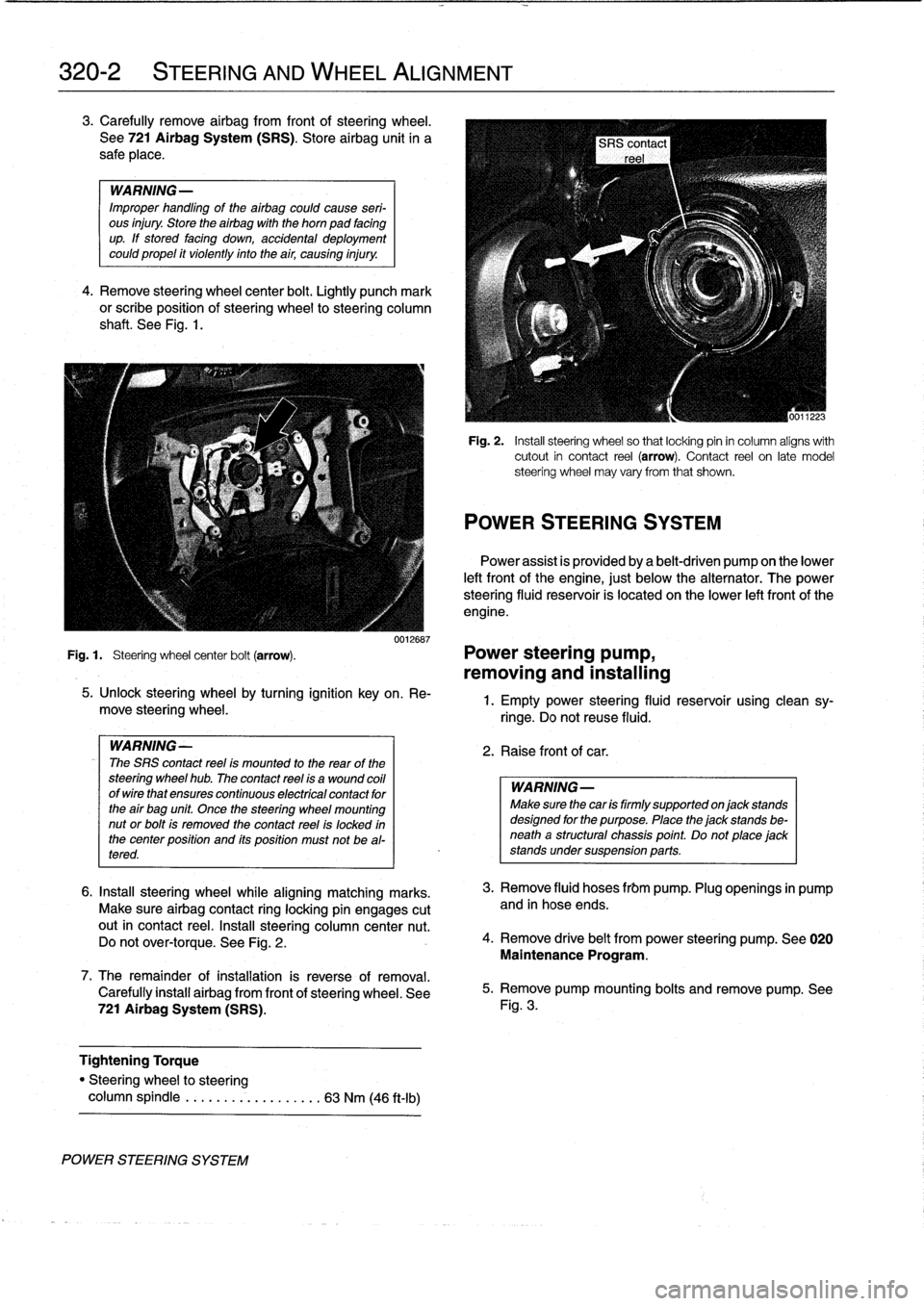

0012687

Fig

.

1

.

Steering

wheel

center

bolt

(arrow)

.

Power

steering

pump,

removing

and

installing

POWER

STEERING

SYSTEM

5

.

Unlock

steering

wheel

by

turning

ignition

key

on

.

Re-

move

steering

wheel

.

WARNING-

The

SRS

contact

reel

ís

mounted

to

the

rear

of

the

steering

wheel

hub

.

The

contact

reel

ís

a

wound

coil

ofwirethat

ensures

continuous

electrícal

contact

for

the

air

bag

unit

Once

the

steering

wheel

mounting

nut

or

bolt

is

removed

the

contact

reel

is

locked

in

the

center

position

and

its

position

must

not

be

al-

tered

.

6

.

Insta¡¡

steering

wheel

while

aligning

matching

marks

.

Make

sure

airbag

contact

ring

locking

pin

engages

cutout

in

contact

reel

.

Insta¡¡

steering

column

center

nut

.

Do

not

over-torque

.

See

Fig

.

2

.

7

.

The

remainder

ofinstallation

is

reverse

of

removal

.

Carefully

install

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Tightening

Torque

"

Steering

wheel

to

steering

column

spindle

...

..

..

.

..........

63

Nm

(46

ft-Ib)

Fig

.

2

.

Insta¡¡

steering

wheel

so

that

locking

pin

in

column

aligns

with

cutout

in

contact

reel

(arrow)

.

Contact

reel

on

late

model

steering

wheel

may

vary

from

that

shown

.

POWER

STEERING

SYSTEM

Power

assist

is

províded

by

a

belt-driven

pump

on

the

lower

left

front

of

the

engine,

just

below

the

alternator

.

The

power

steering

fluid

resenroir

is

located

on

the

lower

left

front

of

the

engine

.

1

.

Empty

power

steering

fluid

reservoir

usingclean

sy-

ringe

.

Do

not

reuse

fluid

.

2

.

Raise

front

of

car

.

WARNING

Make

sure

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

3

.

Remove

fluid

hoses

frbm

pump

.

Plug

openings

in

pump

and

in

hose

ends

.

4

.

Remove

drive

belt

from

power

steering

pump

.

See

020

Maintenance

Program

.

5

.

Remove

pump

mounting

bolts

and

remove

pump

.

See

Fig

.

3

.

Page 274 of 759

330-2

REAR

SUSPENSION

Table

a

.

Rear

RideHeight

Specifications

Wheel

size

318,323,

325,

M3

modeis

328

modeis

17inch

std

.

suspension

546

mm

(21.69

in)

sport

suspension

~

535

mm

(21.06

in)

1

540

mm

(21

.26

in)

Maximum

variation

between

sides

:

10

mm

(0

.4in)

Maximum

deviation

from

specifications

:

10

mm

(0

.4in)

SHOCK

ABSORBERS

AND

SPRINGS

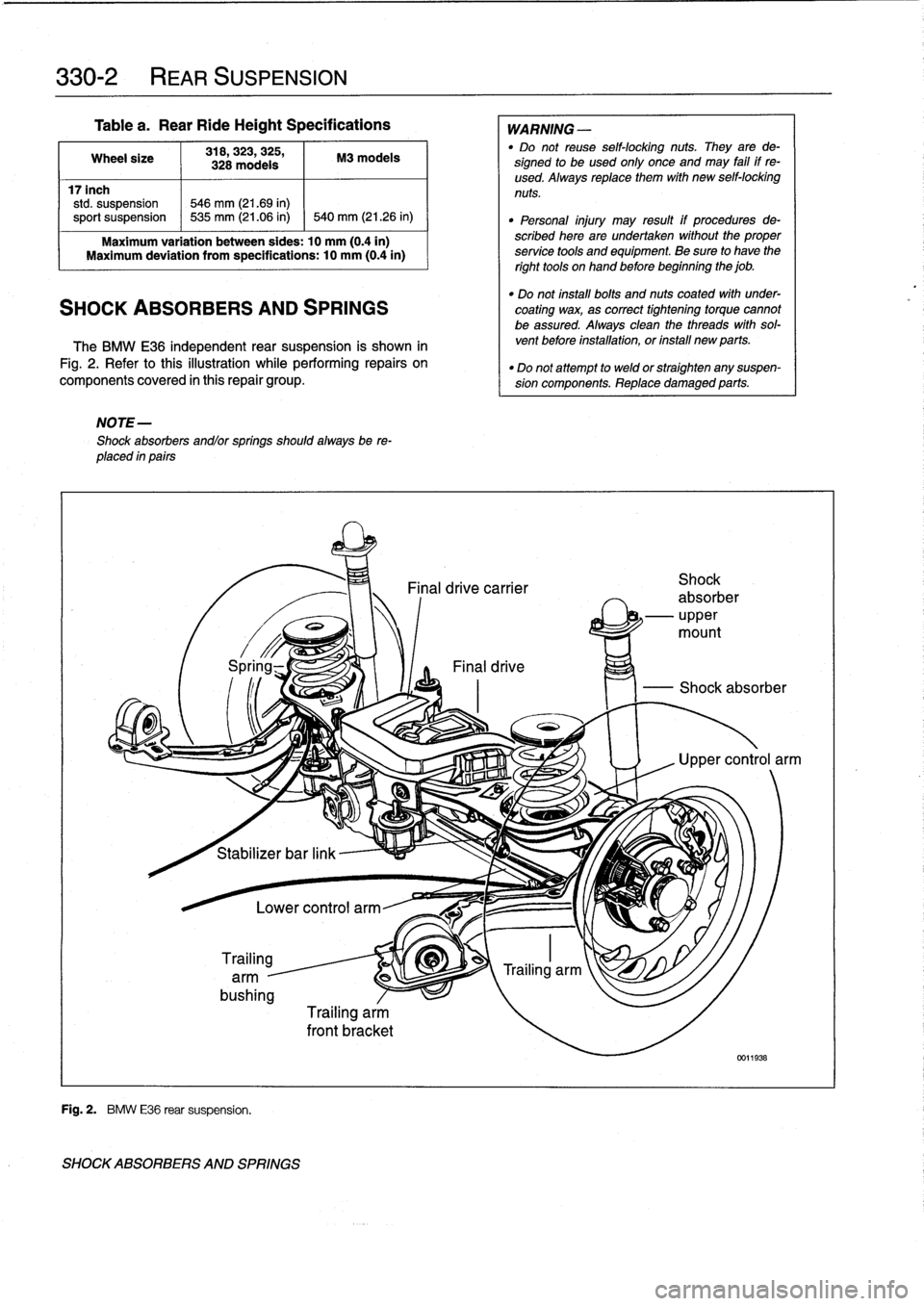

The

BMW

E36

independent

rear

suspension

is

shown

in

Fig

.

2

.

Refer

tothis

illustration

while

performing

repairs

on

components

covered

in

this

repair

group

.

NOTE-

Shock

absorbers

andlor

springs

shouldalways

be

re-

placed

in

pairs

i

Stabilizer

bar

link

Trailing

arm

-

bushing

Fig

.

2

.

BMW

E36

rear

suspension

.

SHOCK

ABSORBERS

AND

SPRINGS

Lower

control

arm

Trailing

arm

front

bracket

WARNING

-

"

Do

not

reuse

self-locking

nuts

.

They

arede-

signed

to

beused

only

once

and

may

fail

if

re-

used

.

Always

replace

them

with

new

self-locking

nuts

.

"

Personal

injury

may

result

if

procedures

de-

scribed

here

are

undertaken

without

the

proper

service

tools

and

equipment

.

Be

sure

to

have

the

right

tools

onhand

before

beginning

the

job

.

"

Do

not

install

bolts

and

nuts

coated

with

under-

coating

wax,

as

correct

tightening

torque

cannot

be

assured

.

Always

clean

the

threads

with

sol-

vent

before

installation,

or

ínstall

new

parts

.

"

Do

not

attempt

to

weld

or

straighten

any

suspen-

sion

components

.

Replace

damaged

parts

.

Page 275 of 759

Rear

shock

absorber,

removing

and

installing

1.

Raisecar

and

remove

rear

wheels

.

WARNING

-

Make

sure

that

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Remove

rear

speakers

.

See

650

Radio

.

3

.

Pryoutluggage

compartment

liner

retaining

clips

and

peel

back

liner

to

gain

access

to

upper

shock

absorber

mounting

nuts

.

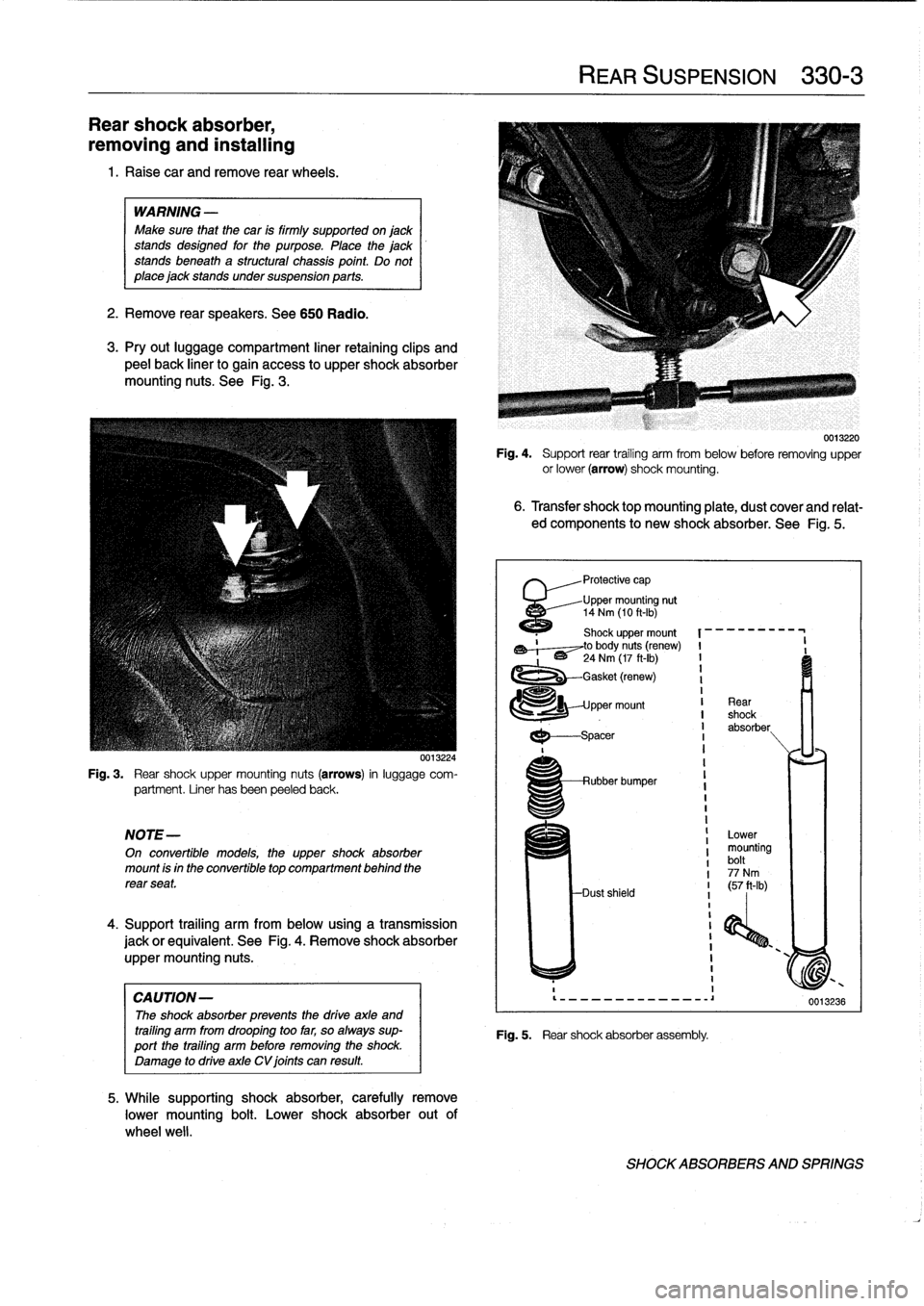

See

Fig

.

3

.

Fig

.

3

.

Rear

shock

upper

mounting

nuts

(arrows)

in

luggage

com-

partment

.

Liner

hasbeen

peeled

back

.

NOTE-

On

convertible

models,

the

uppershock

absorber

mount

is

in

the

convertible

top

compartment

behind

the

rear

seat

.

4

.

Support

trailing

arm

from

below

using

a

transmission

jack

orequivalent

.

See

Fig

.

4

.

Remove

shock

absorber

uppermounting

nuts

.

CAUTION-

The

shock

absorber

prevenís

the

drive

axle

and

trailing

arm

from

drooping

too

far,

so

always

sup-port

the

trailing

arm

before

removing

the

shock

.

Damage

to

drive

axle

CV

joints

can

result

.

0013224

5

.

While

supporting

shock

absorber,

carefully

remove

lower

mounting

bolt

.

Lower

shock

absorber

out

of

wheel

well

.

Fig

.

4

.

Support

rear

trailing

arm

from

below

before

removing

upper

or

lower

(arrow)

shock

mounting

.

6

.

Transfer

shocktopmounting

plate,

dust

coverand

relat-

ed

components

to

new

shock

absorber

.

See

Fig

.

5

.

'

Protective

cap

Upper

mounting

nut

14

Nm

(10

ft-Ib)

1120

Shock

upper

mount

,~,--~to

body

nuts

(renew)

I

-

'

~

24

Nm

(17

ft-Ib)

I

1

-Gasket

(renew)

I

1

pper

mount

I

Rear

I

shock

I

absorber

I

I

---spacer

REAR

SUSPENSION

330-

3

Rubber

bumper

Dust

shield

Fig

.

5

.

Rear

shock

absorber

assembly

.

Lower

mounting

bolt

77

Nm

I

(57

ft-Ib)

i

I

I

1

I

0013220

0013236

SHOCKABSORBERS

AND

SPRINGS

Page 276 of 759

330-

4

REAR

SUSPENSION

7

.

Installation

is

reverse

ofremoval,

noting

the

following

:

"

Make

sure

all

threaded

bolts,

nuts

and

makng

surfaces

are

clean

.

"

Instan

shock

absorber

finto

shock

tower

using

a

new

uppermounting

gasket

and

new

self-locking

nuts

.

"

Tighten

lower

boltto

its

final

torque

oncecar

is

on

ground

.

Tightening

Torques

"

Road

wheel

to

hub

.........

100±10

Nm

(74±7

ft-Ib)

"

Shock

absorber

to

trailing

arm

(car

in

normalloaded

position)

......

77

Nm

(57

ft-Ib)

"

Shock

absorber

to

upper

mount

.....

14

Nm

(10

ft-Ib)

"

Shock

absorber

upper

mount

to

body

(M8

self-locking

nuts)

.............

24

Nm

(17

ft-Ib)

Coil

spring,

removing

and

installing

WARNING

-

"

The

coil

spring

is

undercompressive

force

and

ís

extremely

dangerous

until

compression

isre-

moved

.

"

lt

is

recommended

that

a

restraining

chain

be

in-

stalled

between

the

bottomof

the

coil

spring

and

the

upper

control

arm

to

retain

the

spring

in

case

of

accidental

release

.

Personal

injury

can

result

if

the

compressed

coil

spring

is

not

released

slowly

and

carefully

.

"

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

1

.

Raise

car

and

remove

rear

wheel

.

2

.

Support

suspension

arm

from

below

using

a

transmis-

sion

jack

orequívalent

.

Tightening

Torques

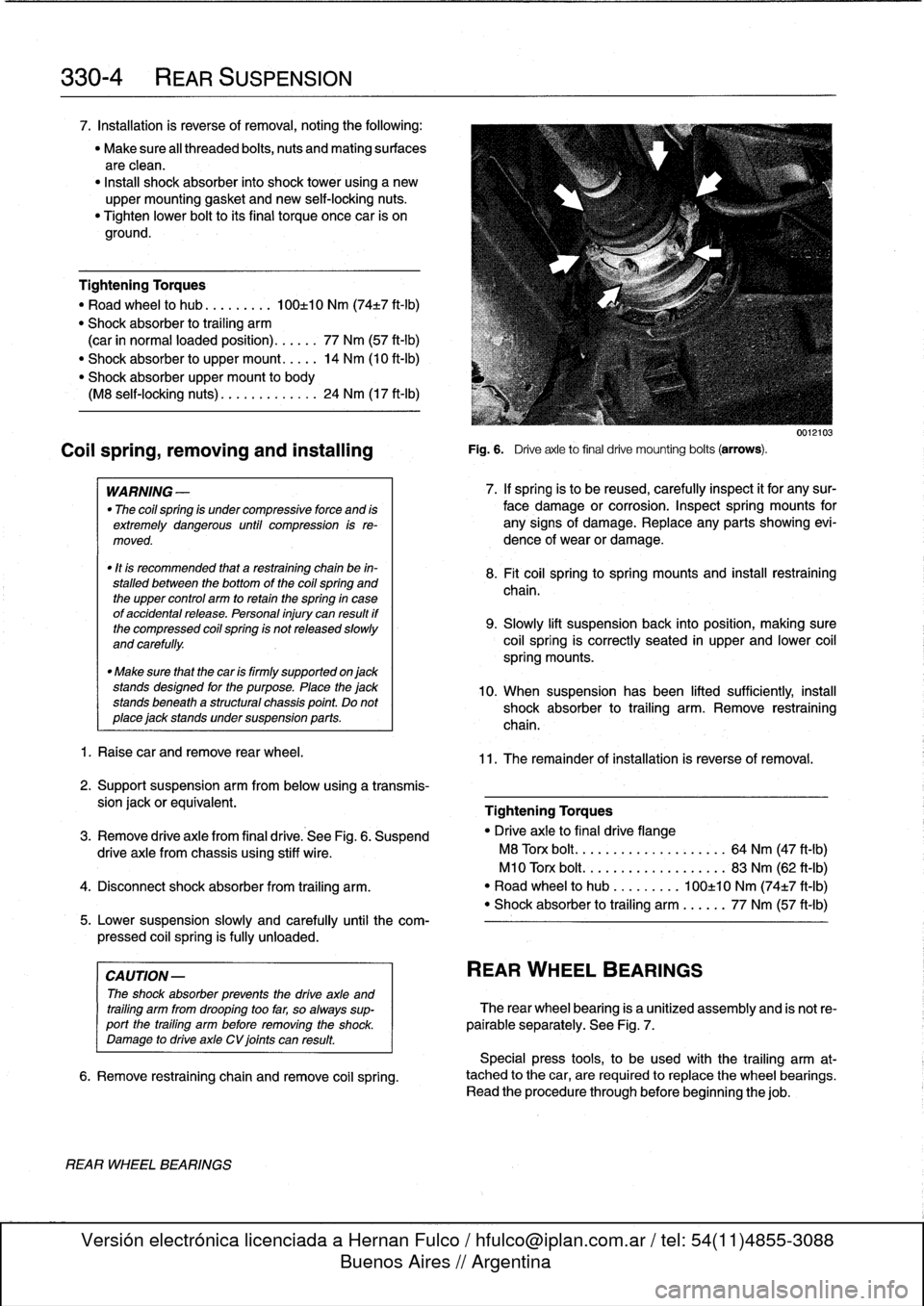

3

.

Remove

drive

axle

from

final

drive

.

See

Fig

.

6

.

Suspend

"

Drive

axle

to

final

drive

flange

drive

axle

from

chassis

using

stiff

wire

.

M8

Torx

bolt

.

..

...

.

.............

64

Nm

(47

ft-Ib)

M10

Torx

bolt

...................

83

Nm

(62

ft-Ib)

4

.

Disconnect

shock

absorber

from

traíling

arm

.

"

Road

wheel

to

hub

.........

100±10

Nm

(74±7

ft-Ib)

"

Shock

absorber

to

trailing

arm

......

77

Nm

(57

ft-Ib)

5

.

Lower

suspension

slowly

and

carefully

until

the

com-

pressed

coil

spring

is

fully

unloaded

.

CAUTION

-

The

shock

absorber

prevents

the

drive

axle

and

trailíng

arm

from

drooping

too

far,

so

always

sup-port

the

trailing

arm

before

removing

the

shock

.

Damage

to

drive

axle

CV

joints

can

result

.

6

.

Remove

restraining

chain

and

remove

coi¡

spring

.

REAR

WHEEL

BEARINGS

Fig

.

6

.

Driveaxle

to

final

drive

mounting

bolts

(arrows)

.

0012103

7

.

If

spring

is

to

be

reused,

carefully

inspect

it

for

any

sur-

face

damage

or

corrosion

.

Inspect

spring

mounts

for

any

signs

of

damage

.

Replace

any

parts

showing

evi-

dence

of

wear

or

damage

.

8

.

Fit

coil

springtospring

mountsand

insta¡¡

restraíning

chaina

9

.

Slowly

lift

suspensionback

into

position,

making

sure

coil

spring

is

correctly

seated

in

upper

and

lower

coil

spring

mounts

.

10

.

When

suspension

has

been

lifted

sufficiently,

instan

shock

absorber

to

trailing

arm

.

Remove

restraining

chain

.

11

.

The

remainder

of

installation

is

reverse

of

removal

.

REAR

WHEEL

BEARINGS

The

rear

wheel

bearing

is

a

unitized

assembly

and

is

not

re-

pairable

separately

.

See

Fig

.

7

.

Special

press

tools,

to

be

used

with

the

trailing

arm

at-

tached

to

the

car,

are

requiredto

replace

the

wheel

bearings

.

Read

the

procedure

through

before

beginning

thejob

.

Page 277 of 759

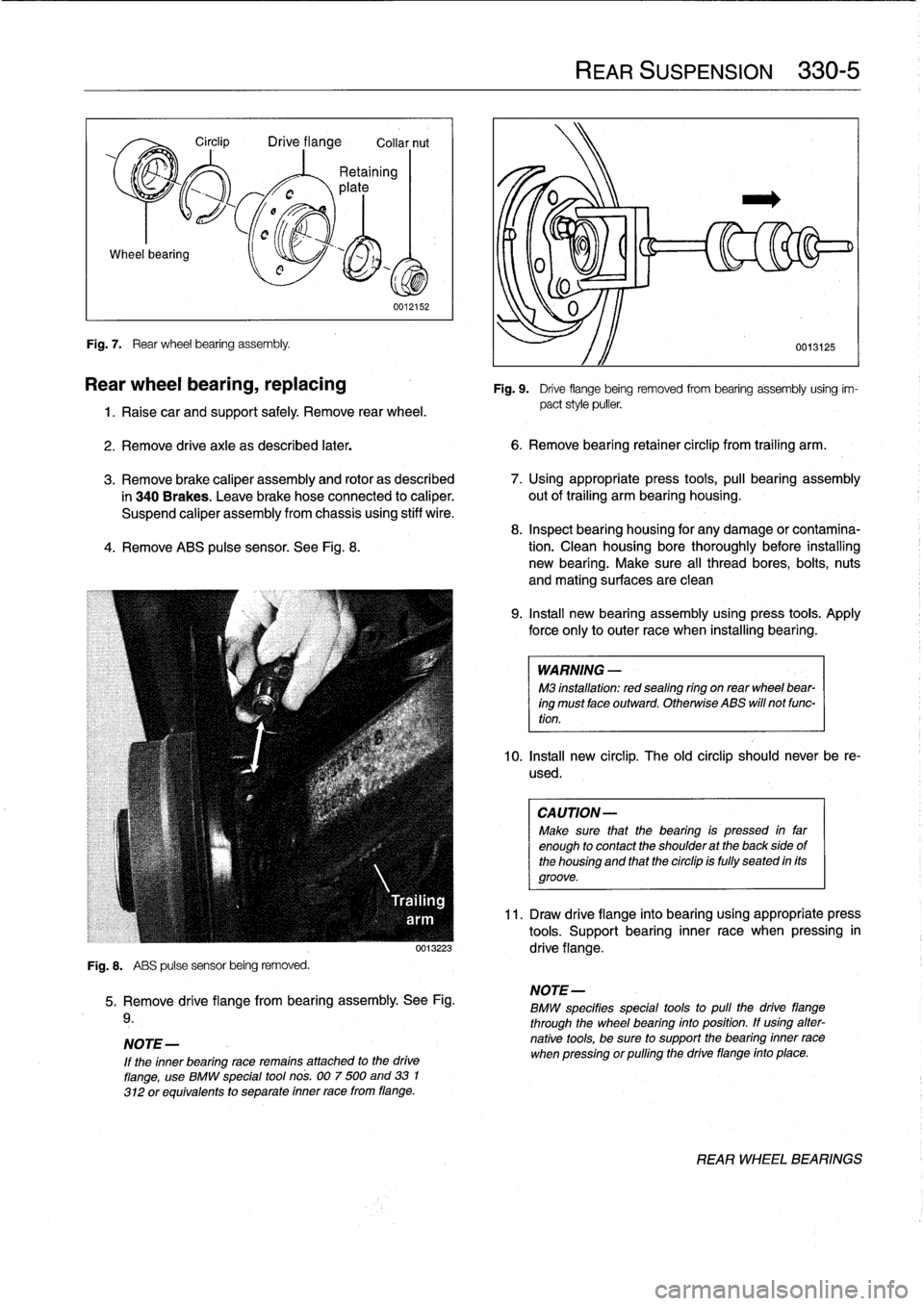

Wheel

bearing

Fig

.

7

.

Rear

wheel

bearing

assembly

.

Circlip

Drive

flange

Collar

nut

0012152

Rear

wheel

bearing,

replacing

1

.

Raise

car

and

support

safely

.

Remove

rear

wheel

.

2

.

Remove

drive

axle

as

described

later

.

6

.

Remove

bearíng

retainer

circlip

from

trailing

arm

.

3

.

Remove

brake

caliper

assembly

and

rotor

as

described

7

.

Using

appropriate

press

tools,

pull

bearing

assembly

in

340

Brakes

.

Leave

brake

hose

connected

to

caliper

.

out

of

trailing

arm

bearing

housing

.

Suspend

caliper

assembly

from

chassís

using

stiff

wire

.

8

.

Inspect

bearing

housing

for

any

damage

or

contamina

4

.

Remove

ABS

pulse

sensor

.

See

Fig

.

8

.

tion

.

Clean

housing

bore

thoroughly

before

installing

new

bearing

.

Make

sure

al¡

thread

bores,

bolts,

nuts

and

mating

surfaces

are

clean

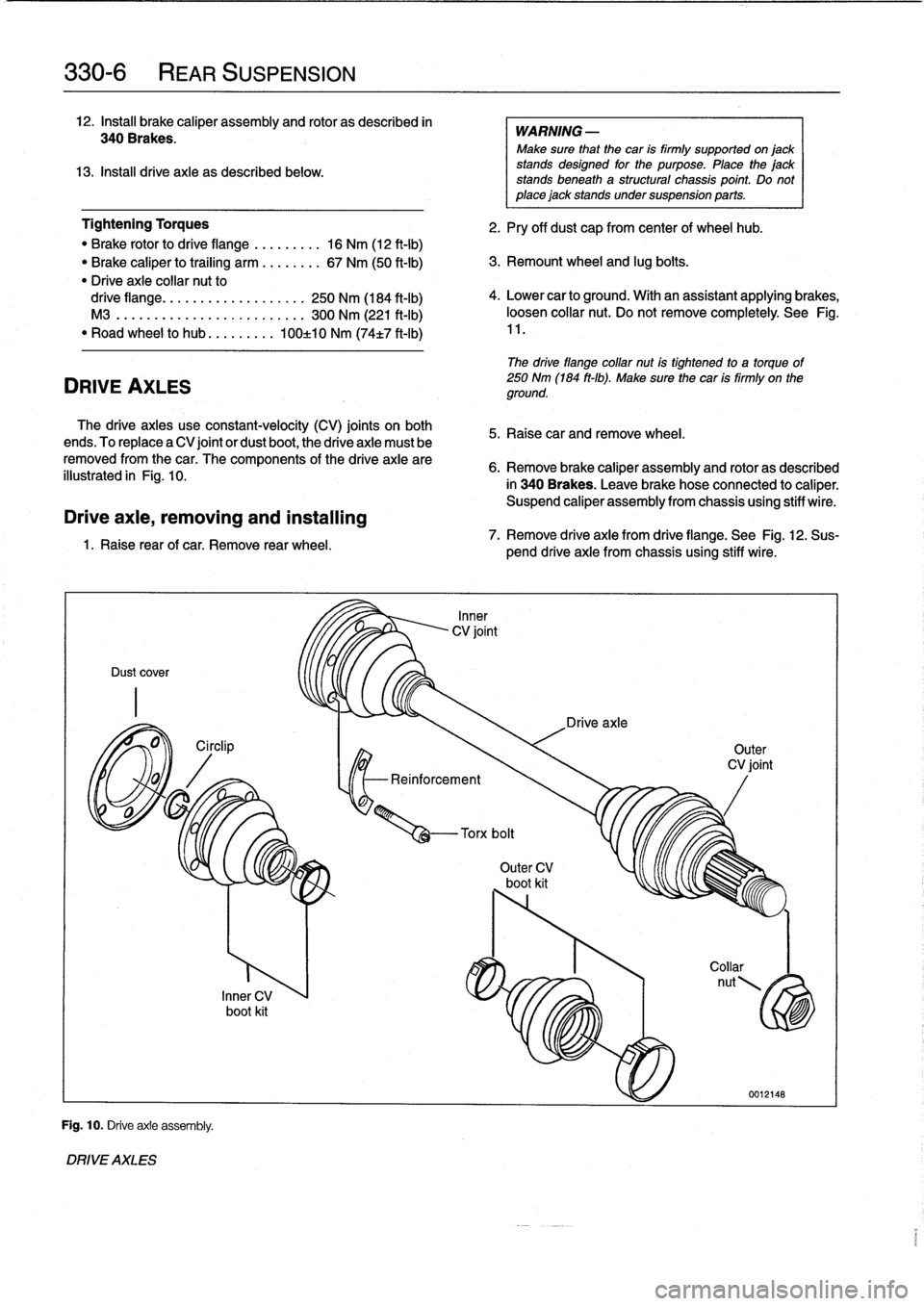

Fig

.

8

.

ABS

pulse

sensor

being

removed

.

5

.

Remove

drive

flange

from

bearing

assembly

.

See

Fig

.

9

.

NOTE-

If

the

inner

bearing

race

remains

attached

to

the

drive

flange,

use

BMW

special

tool

nos

.

007

500

and

33

1

312

or

equivalents

to

separate

inner

race

from

flange

.

REAR

SUSPENSION

330-

5

0013125

Fig

.

9

.

Drive

flange

being

removed

from

bearing

assembly

using

im-

pact

style

puller

.

9

.

Install

new

bearing

assembly

using

press

tools

.

Apply

force

only

to

outer

race

when

installing

bearing

.

WARNING

-

M3

installation

:

redsealing

ríng

on

rear

wheel

bear-

ing

must

face

outward

.

Otherwíse

ABS

will

not

func-

tion

.

10

.

Insta¡¡

new

circlip

.

The

old

circlip

should

never

be

re-

used

.

CAUTION-

Make

sure

that

the

bearing

is

pressed

in

far

enough

to

contact

the

shoulder

at

the

back

sideof

the

housing

and

that

the

circlip

is

fully

seated

in

its

groove

.

11

.

Draw

drive

flange

into

bearing

using

appropriate

press

tools

.

Support

bearing

inner

race

when

pressing

in

0013223

drive

flange

.

NOTE-

BMW

specifies

special

tools

to

pull

the

drive

fiange

through

the

wheel

bearing

into

position

.

If

using

alter-

native

tools,

be

sure

to

support

the

bearing

inner

race

when

pressing

orpulling

the

drive

flange

finto

place

.

REARWHEEL

BEARINGS

Page 278 of 759

330-

6

REAR

SUSPENSION

12

.

Install

brake

caliper

assembly

and

rotor

as

described

in

340Brakes

.

13

.

Install

drive

axie

as

described

below

.

Tightening

Torques

"

Brake

rotor

to

drive

flange

.........

16

Nm

(12

ft-ib)

"

Brake

caliper

to

trailing

arm

........

67

Nm

(50

ft-Ib)

"

Drive

axie

collar

nut

to

drive

flange

..

.

..

..............

250

Nm

(184

ft-Ib)

M3

.....

...

..

.

.............

.

300

Nm

(221

ft-Ib)

"

Road

wheel

to

hub

.........

100±10

Nm

(74±7

ft-Ib)

DRIVE

AXLES

The

drive

axles

use

constant-velocity

(CV)

joints

on

both

ends

.

To

replace

a

CV

joint

or

dust

boot,

the

drive

axie

must

be

removed

fromthe

car

.

The

components

of

the

drive

axie

are

illustrated

in

Fig

.

10

.

Drive

axie,

removing

and

installing

1

.

Raise

rear

of

car

.

Remove

rear

wheel

.

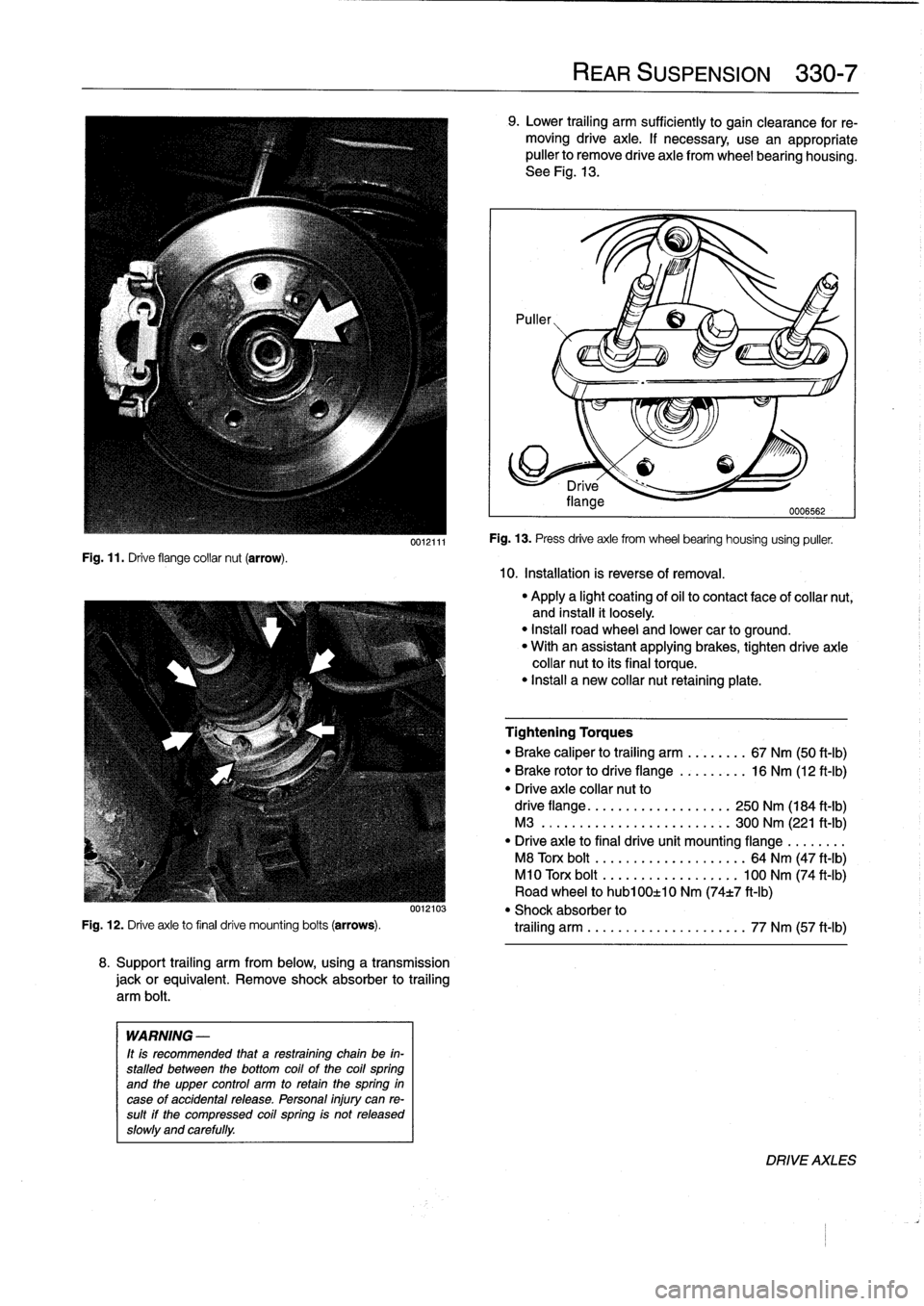

Dust

cover

Fig

.

10

.

Driveaxie

assembly

.

DRIVE

AXLES

Inner

CV

boot

kit

-Reinforcement

WARNING

-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Pry

off

dust

cap

from

center

of

wheel

hub

.

3

.

Remount

wheel

and

lug

boits

.

4

.

Lower

car

to

ground

.

With

an

assistant

applying

brakes,

loosen

collar

nut

.

Do

not

remove

completely

.

See

Fig

.

11

.

The

drive

flange

collar

nut

is

tightened

to

a

torque

of

250

Nm

(184

ft-Ib)

.

Make

sure

the

car

is

firmly

on

the

ground

.

5

.

Raisecar

andremove

wheel

.

6

.

Remove

brake

caliper

assembly

and

rotor

as

described

in

340

Brakes

.

Leave

brake

hose

connected

to

caliper

.

Suspend

caliper

assembly

from

chassis

using

stiff

wire

.

7

.

Remove

drive

axie

from

drive

flange

.

See

Fig

.

12

.

Sus-

pend

drive

axie

from

chassis

using

stiff

wire

.

Outer

CV

boot

kit

Drive

axle

Outer

CV

joint

Page 279 of 759

Fig

.

11

.

Drive

flange

collar

nut

(arrow)

.

0012111

8

.

Support

trailing

arm

from

below,

using

a

transmission

jackorequivalent

.

Remove

shock

absorber

to

trailing

arm

bolt

.

WARNING

-

It

is

recommended

that

a

restraining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retain

thespring

in

case

of

accidental

release

.

Personal

injury

can

re-

sult

if

the

compressed

coil

spring

is

not

released

slowly

and

carefully

.

REAR

SUSPENSION

330-

7

9

.

Lower

trailing

arm

sufficiently

to

gain

clearance

for

re-

moving

drive

axle

.

If

necessary

use

an

appropriate

puller

to

Rmove

drive

axle

from

wheel

bearing

housing

.

See

Fig

.

13

.

10

.

Installation

is

reverse

of

removal

.

Fig

.

13

.

Press

drive

axle

from

wheel

bearing

housing

using

puller

.

"

Apply

a

light

coating

of

oil

to

contact

face

of

collar

nut,

and

install

it

loosely

.

"

Install

road

wheel

and

lower

car

to

ground

.

"

With

an

assistant

applying

brakes,

tighten

drive

axle

collar

nut

to

its

final

torque

.

"

Install

a

new

collar

nut

retaining

plate

.

Tightening

Torques

"

Brake

caliper

to

trailing

arm

........

67

Nm

(50

ft-Ib)

"

Brake

rotor

to

drive

flange

.........

16

Nm

(12

ft-Ib)

"

Drive

axle

collar

nut

to

drive

flange

.

.

....

..

.

..........

250

Nm

(184

ft-Ib)

M3

......

.

.

.....

.

.

..........

300

Nm

(221

ft-Ib)

"

Drive

axie

to

final

drive

unit

mounting

flange

.

.

.

.....

M8

Torx

bolt

.

...

...

.

............

64

Nm

(47

ft-Ib)

M10

Torx

bolt

...

...............

100

Nm

(74

ft-Ib)

Road

wheel

to

hub100±10

Nm

(74t7

ft-Ib)

0012103

"

Shock

absorber

to

Fig

.

12

.

Drive

axle

to

final

drive

mounting

bolts

(arrows)

.

trailing

arm

.

.

...

...

.

............

77

Nm

(57

ft-Ib)

DRIVE

AXLES

Page 280 of 759

330-

8

REAR

SUSPENSION

CV

boot,

replacing

NOTE-

"

The

outer

CV

joint

cannot

be

removed

from

the

axle

shaft

.

In

order

to

replace

the

outer

CV

boot,

it

is

nec-

essary

to

remove

the

inner

joint

and

boot

first

.

"

If

the

CV

joints

are

worn

or

defective,

acomplete

re-

built

axle

shaft

is

available

from

an

authorized

BMW

dealerparts

department

.

1

.

Remove

drive

axle

from

car

as

described

above

.

2

.

Remove

inner

and

outer

CV

boot

clamping

bands

and

cut

old

boots

off

joints

and

shaft

.

Clean

grease

from

joints

.

3

.

Lift

off

dust

cover

from

inner

CV

joint

and

remove

circlip

5

.

Clean

all

old

lubricantoff

shaftsplines

and

inner

joint's

retaining

joint

inner

hub

to

axle

shaft

.

See

Fig

.

14

.

splines

.

DRIVE

AXLES

-0

1

,

1

1,1

1

L

"I

C

OYA

Drive

axle-"

e

:>,

)

0006560

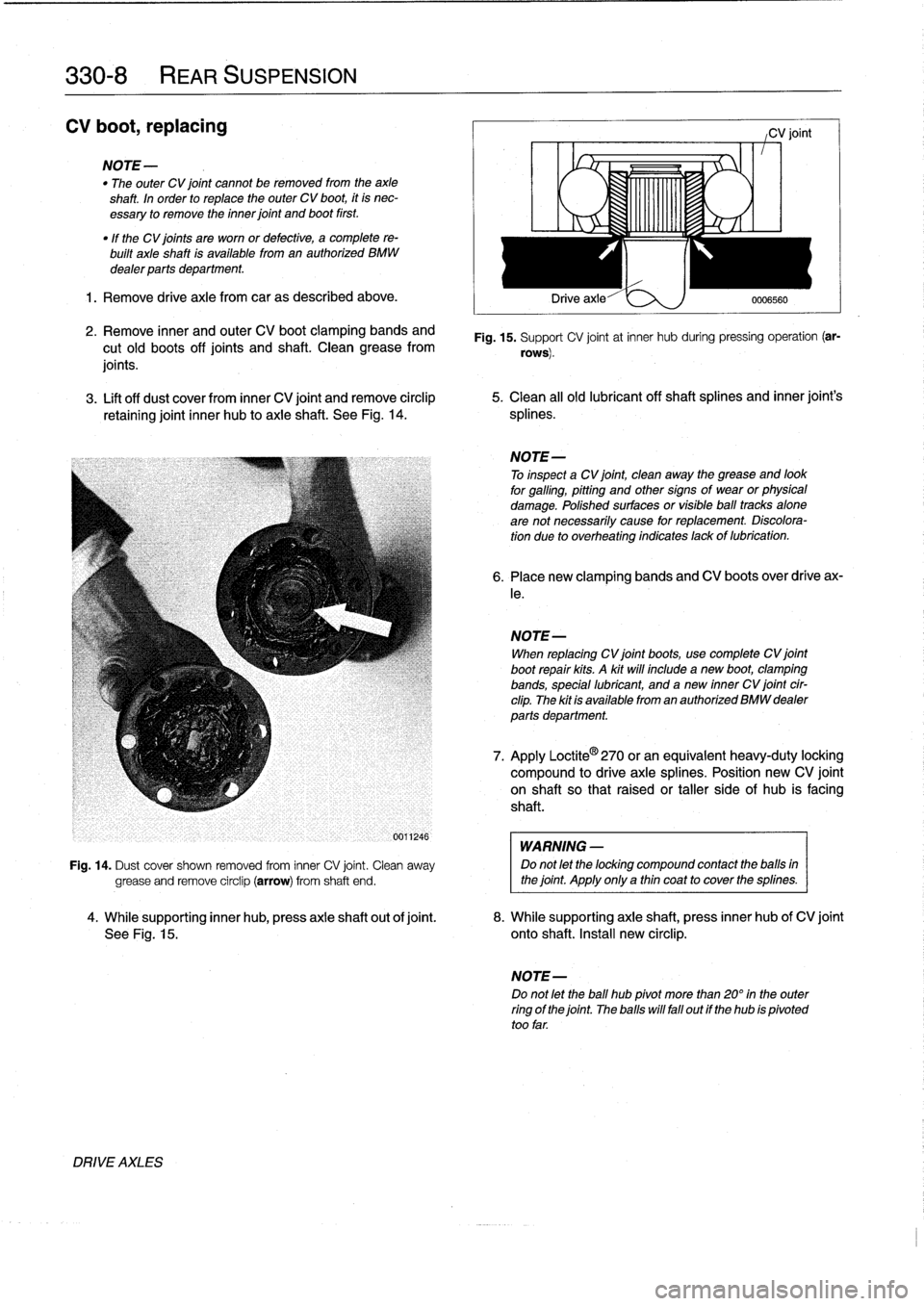

CV

joint

Fig

.

15

.

Support

CV

joint

at

inner

hub

duringpressing

operation

(ar-

rows)

.

NOTE-

To

inspect

a

CV

joint,

clean

away

the

grease

and

look

for

galling,pittihg

and

othersigns

of

wear

or

physical

damage

.

Polished

surfaces

or

visible

ball

tracks

alone

are

not

necessarily

cause

for

replacement

.

Discolora-

tion

due

to

overheating

indicates

lackof

lubrication

.

6

.

Place

new

clamping

bands

and

CV

boots

over

drive

ax-

le

.

NOTE-

When

replacing

CV

joint

boots,

usecomplete

CV

joint

boot

repair

kits

.

A

kit

will

include

a

new

boot,

clamping

bands,

special

lubricant,

and

anew

inner

CV

joint

cir-

clip

.

The

kit

is

available

from

an

authorized

BMW

dealer

parts

department

.

7

.

Apply

Loctite

®

270

or

an

equívalent

heavy-duty

lockíng

compound

to

drive

axlesplines

.

Position

new

CV

joint

on

shaft

so

that

raisedor

taller

side

of

hub

is

facing

shaft

.

WARNING

-

Fig

.

14

.

Dust

cover

shown

removed

from

inner

CV

joint

.

Clean

away

Do

not

let

the

locking

compound

contact

the

balls

in

grease

and

remove

circlip

(arrow)

from

shaft

end

.

the

joint

.

Apply

only

a

thin

coat

to

cover

the

splines

.

4

.

While

supporting

inner

hub,

press

axle

shaft

out

of

joint

.

8

.

While

supporting

axle

shaft,

press

inner

hub

of

CV

joint

See

Fig

.

15

.

onto

shaft

.

Install

new

circlip

.

NOTE-

Do

not

let

the

ball

hub

pivot

more

than

20°

in

the

outer

ring

of

the

joint

.

The

halls

will

fall

out

if

the

hub

ís

pivoted

too

far

.

Page 281 of 759

9

.

Packeach

CV

joint

and

rubber

boot

with

specified

REAR

SUSPENSION

ARMS

amount

of

lubricant

supplied

.

Apply

adhesive

to

large

end

of

boot

and

mount

it

on

joint

.

Secure

boot

with

clamps

.

The

trailing

arms,

control

arms

and

their

mountingbushings

Apply

sealer

to

inner

CV

joint

dust

cover

and

instan

.

control

the

position

of

the

rear

wheels

.

A

damaged

suspen-

sion

arm

or

worn

bushings

will

change

the

rear

wheel

align

NOTE-

ment

and

may

adversely

affect

handling

and

stability

.

"

Before

installing

each

small

boot

clamp

be

sure

to

"burp"

the

boot

by

flexing

the

CV

joint

as

far

overas

it

WARNING

will

go

.

A

small

screw-driver

inserted

between

the

Do

notattempt

to

straighten

a

damaged

suspension

boot

and

the

axle-shaft

will

help

the

process

.

arm

.

Bending

or

heating

may

weaken

the

original

"

BMW

recommends

Bostil101513

or

EppleC4851

ad-

part

.

If

the

suspension

arm

shows

any

signs

of

hesive,

and

Epple®39

or

Curil©T

sealer

damage

or

excessive

corrosion,

it

must

be

re-

placed

.

CV

Joint

Lubricant

Capacity

"

Wheel

hub

end

ex

.

M3

..

..

.

....

.

.............

80

gram

(2.8

oz

.)

M3

..

...

.

..

.................

100

gram

(3

.5

oz

.)

"

Finaldrive

end

.................

85

gram

(3

.0

oz

.)

10

.

Install

drive

axle

as

described

earlier

.

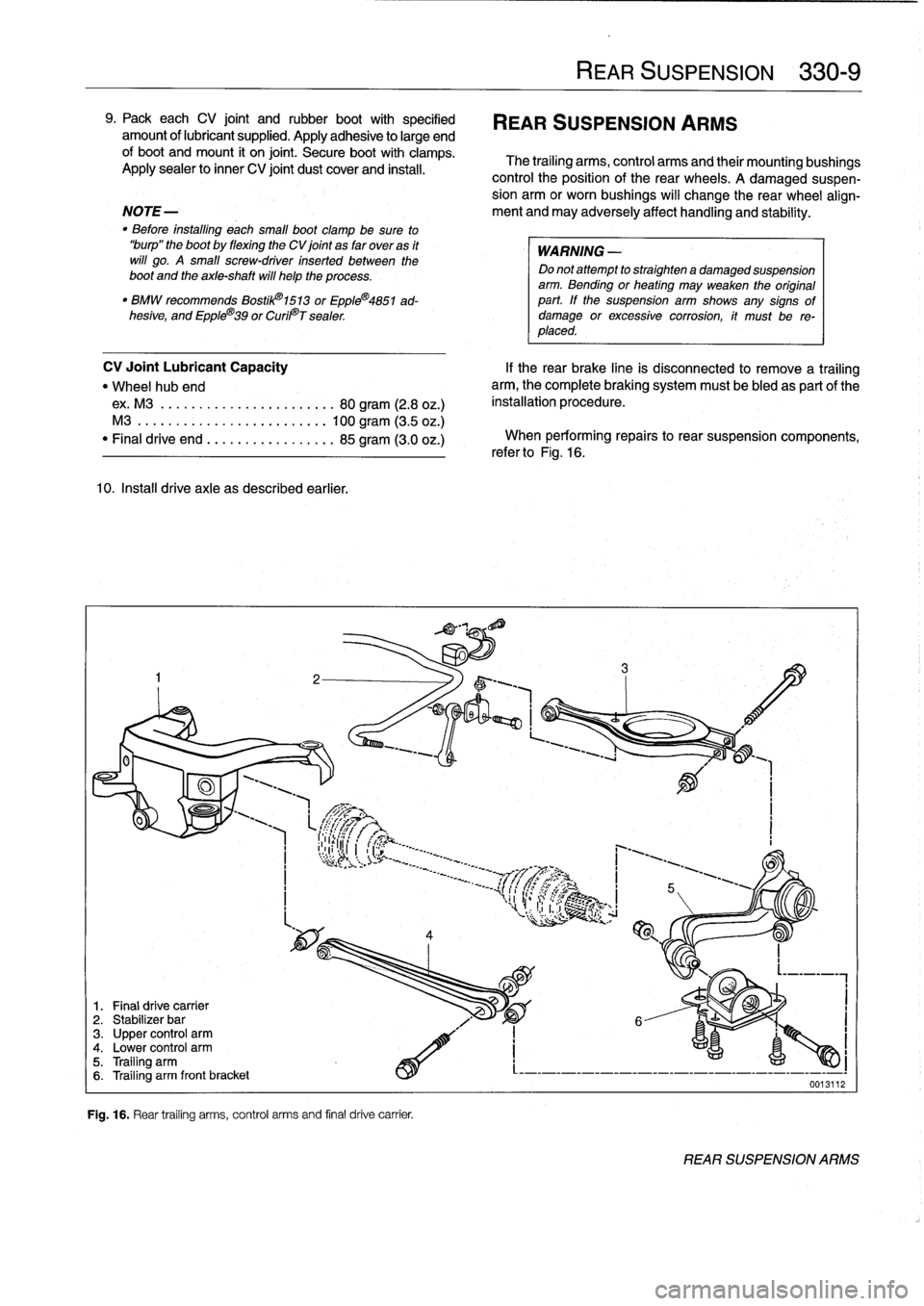

1

.

Final

drive

carrier

2

.

Stabilizer

bar

3

.

Upper

control

arm4

.

Lower

control

arm5

.

Trailing

arm6

.

Trailing

arm

front

bracket

Fig

.

16

.

Rear

trailing

arms,

control

arms

and

final

drive

carrier

.

If

the

rear

brake

cine

is

disconnected

to

remove

a

trailing

arm,

the

complete

braking

system

must

be

bled

as

partof

the

installation

procedure

.

When

performing

repairs

to

rear

suspension

components,

refer

to

Fig

.

16

.

REAR

SUSPENSION

330-

9

0013112

REAR

SUSPENSION

ARMS

Page 282 of 759

330-

1

0

REAR

SUSPENSION

Trailing

arm,

removing

and

installing

1

.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

brake

rotor

and

caliper

as

described

in

340

Brakes

.

Do

not

remove

brake

line

from

caliper

.

Hang

caliper

from

body

with

wire

.

4

.

Remove

parking

brakecable

frombrake

shoe

expand-

er

.

See

340

Brakes

.

5

.

Remove

rear

brake

line

bracket

from

trailing

arm

.

See

Fig

.

17

.

Fig

.

17

.

Brake

line

bracket

bolts

on

trailing

arm

(arrow)

.

WARNING

-

It

is

recommended

that

a

restraining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retainthe

spring

in

case

of

accidentalrelease

.

Personal

injury

can

re-sult

if

the

compressed

coil

spring

is

not

released

slow1y

and

carefully

.

REAR

SUSPENSION

ARMS

6

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

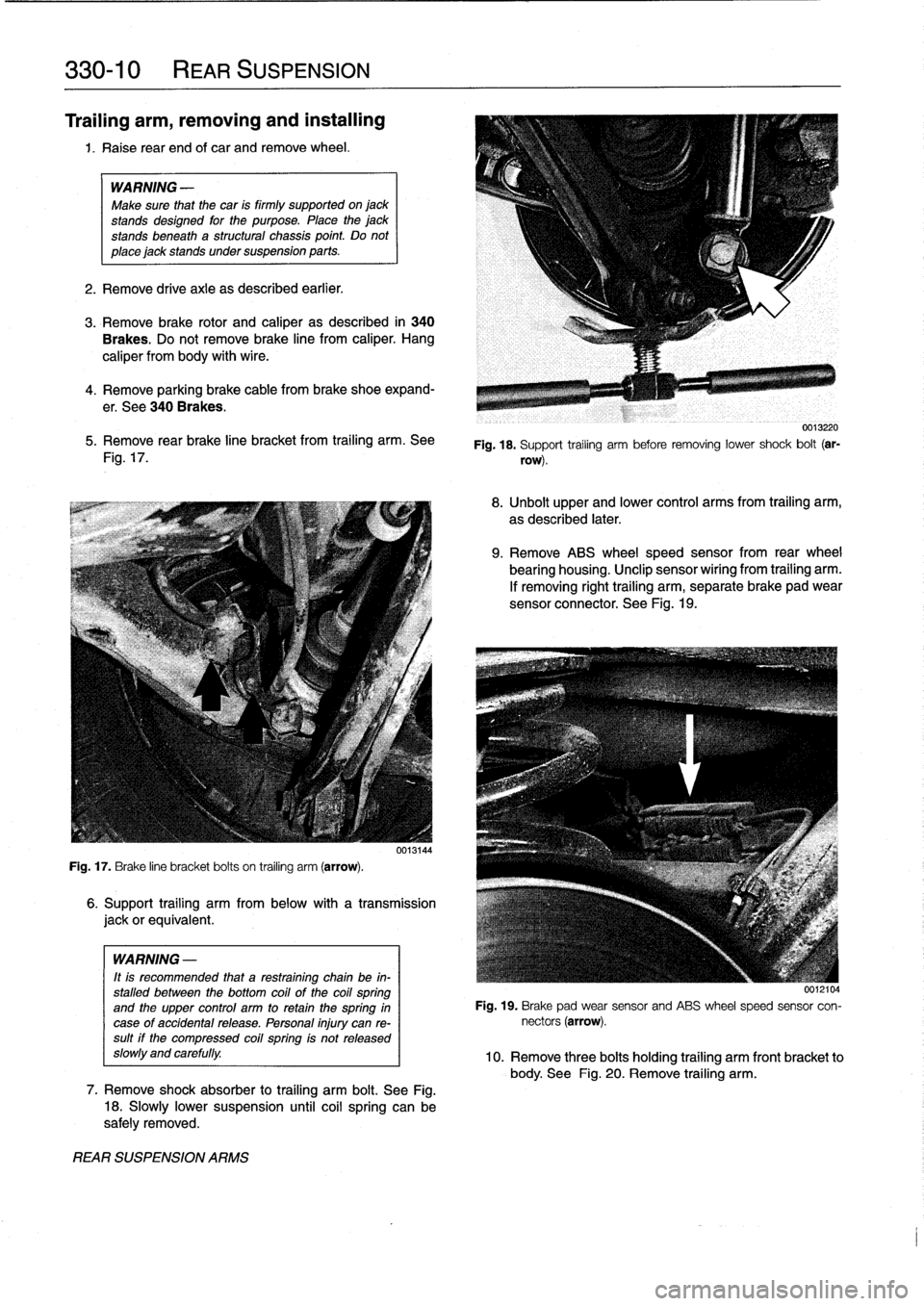

7

.

Remove

shock

absorber

to

trailing

arm

bolt

.

See

Fig

.

18

.

Slowly

lower

suspension

until

coil

spring

can

be

safely

removed

.

0013220

Fig

.

18

.

Support

trailing

arm

before

removing

lower

shock

bolt

(ar-

row)

.

8

.

Unbolt

upper

and

lower

control

arms

from

trailing

arm,

as

described

later

.

9

.

Remove

ABS

wheel

speed

sensor

from

rear

wheel

bearing

housing

.

Unclip

sensor

wiríng

from

trailing

arm

.

If

removing

right

trailing

arm,

separate

brake

pad

wear

sensor

connector

.

See

Fig

.

19

.

0012104

Fig

.

19

.

Brake

pad

wear

sensor

and

ABS

wheel

speed

sensor

con-

nectors

(arrow)

.

10

.

Remove

three

bolts

holding

trailing

arm

front

bracket

to

body

.

See

Fig

.

20

.

Remove

trailing

arm

.