BMW M3 1998 E36 Workshop Manual

Manufacturer: BMW, Model Year: 1998, Model line: M3, Model: BMW M3 1998 E36Pages: 759

Page 251 of 759

Wheel

brake

caliper

Electronic

control

module

Fig

.

4

.

Schematic

representation

of

ABS

.

SUSPENSION,

STEERING

ANDBRAKES-GENERAL

300-3

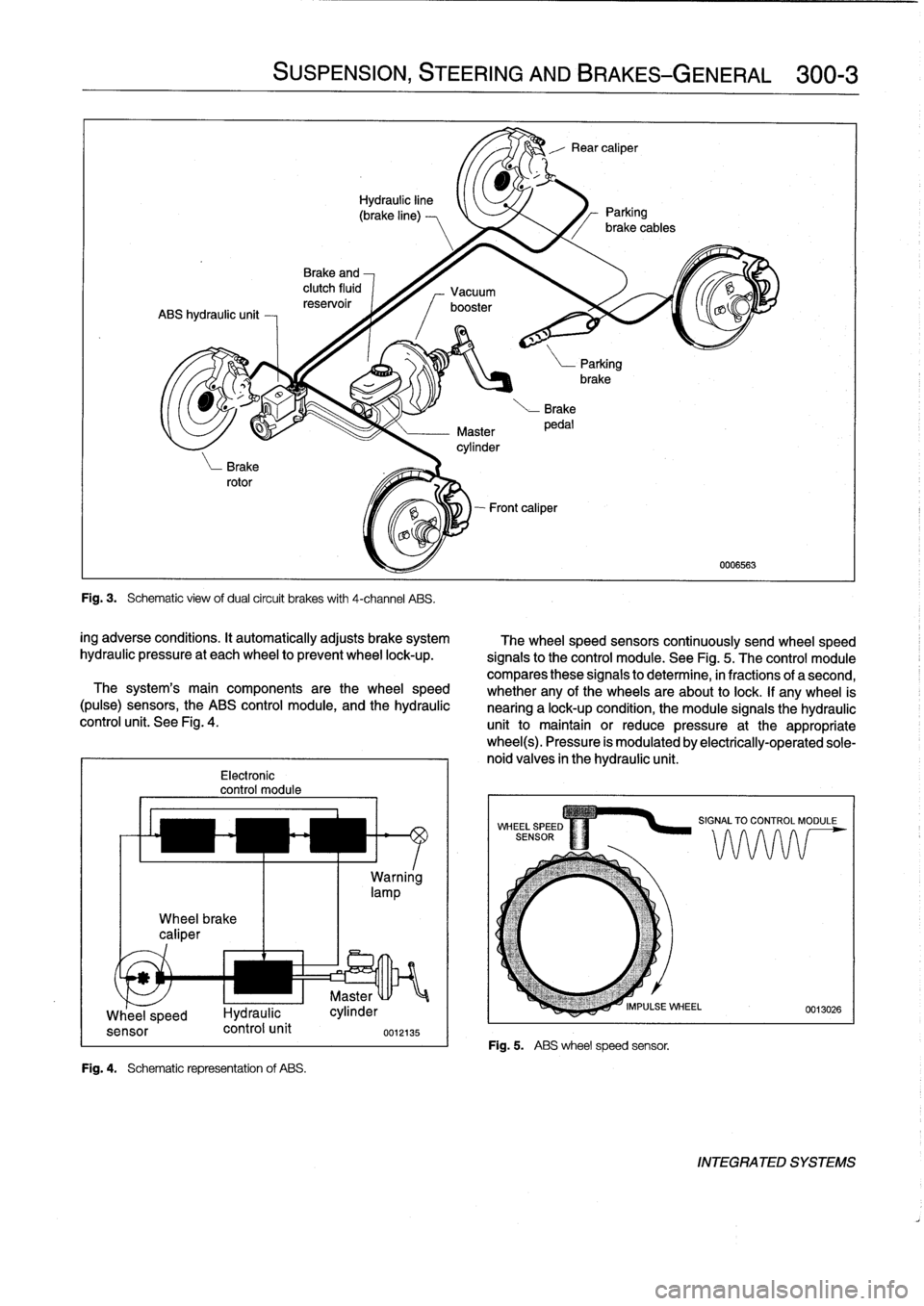

Fig

.

3

.

Schematic

view

ofdual

circuit

brakes

with

4-channel

ABS

.

ing

adverse

conditions

.

It

automatically

adjusts

brake

system

hydraulic

pressure

at

each

wheel

to

prevent

wheel

lock-up

.

The

system's

main

components

arethe

wheel

speed

(pulse)

sensors,

the

ABS

control

module,

and

the

hydraulic

control

unit

.

See

Fig

.

4

.

Warning

lamp

u

Master

Whee

_

l

speed

I-lydraulic

cylinder

sensor

control

unit

0012135

UNI

The

wheel

speed

sensors

continuously

send

wheel

speed

signals

to

the

control

module

.

See

Fig

.

5

.

The

control

module

compares

these

signals

to

determine,

in

fractions

of

a

second,

whether

any

of

the

wheels

areabout

to

lock

.

If

any

wheel

is

nearing

a

lock-up

condition,

the

module

signals

the

hydraulic

unit

to

maintain

or

reduce

pressure

at

the

appropriatewheel(s)

.

Pressure

is

modulated

by

electrically-operated

sole-

noid

valves

in

the

hydraulic

unit

.

Fig

.

5

.

ABS

wheelspeed

sensor

.

0006563

INTEGRATED

SYSTEMS

Page 252 of 759

300-4

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

Three-channel

ABS

ís

used

on

al[

E36

cars

equipped

with

Al¡

Season

Traction

(AST)

standard

ABS

.

Each

front

wheelhas

a

separate

solenoid

valve

to

modulate

hydraulic

pressure

to

that

brake

caliper

.

The

traction

control

system

works

in

conjunction

with

ABS

The

rear

wheels

are

modulated

asa

pair,

controlled

by

a

sin-

and

the

engine

management

system

to

enhance

vehicle

con

gle

solenoid

valve

.

trol

.

The

main

function

of

the

AST

system

is

to

maintain

the

rolling

contact

between

the

tires

and

the

road

surface

under

al¡

driving

E36

cars

equipped

with

ABS/AST

utilize

a

four

channel

sys-

conditions

.

This

is

achieved

through

exact

application

and

tem,

which

functionsexactly

as

the

three

channelsystem

management

of

braking

and

drivetrain

forces

.

above,except

that

the

rear

wheels

are

modulated

individually

.

IDLE

SPEED

CONTROL

VALVE

HROTTLE

PLATE

6

.

Í

III

i

ADS

ACTU

AT

OR

THROTTLE

PLATE

POSITION

SENSOR

DME

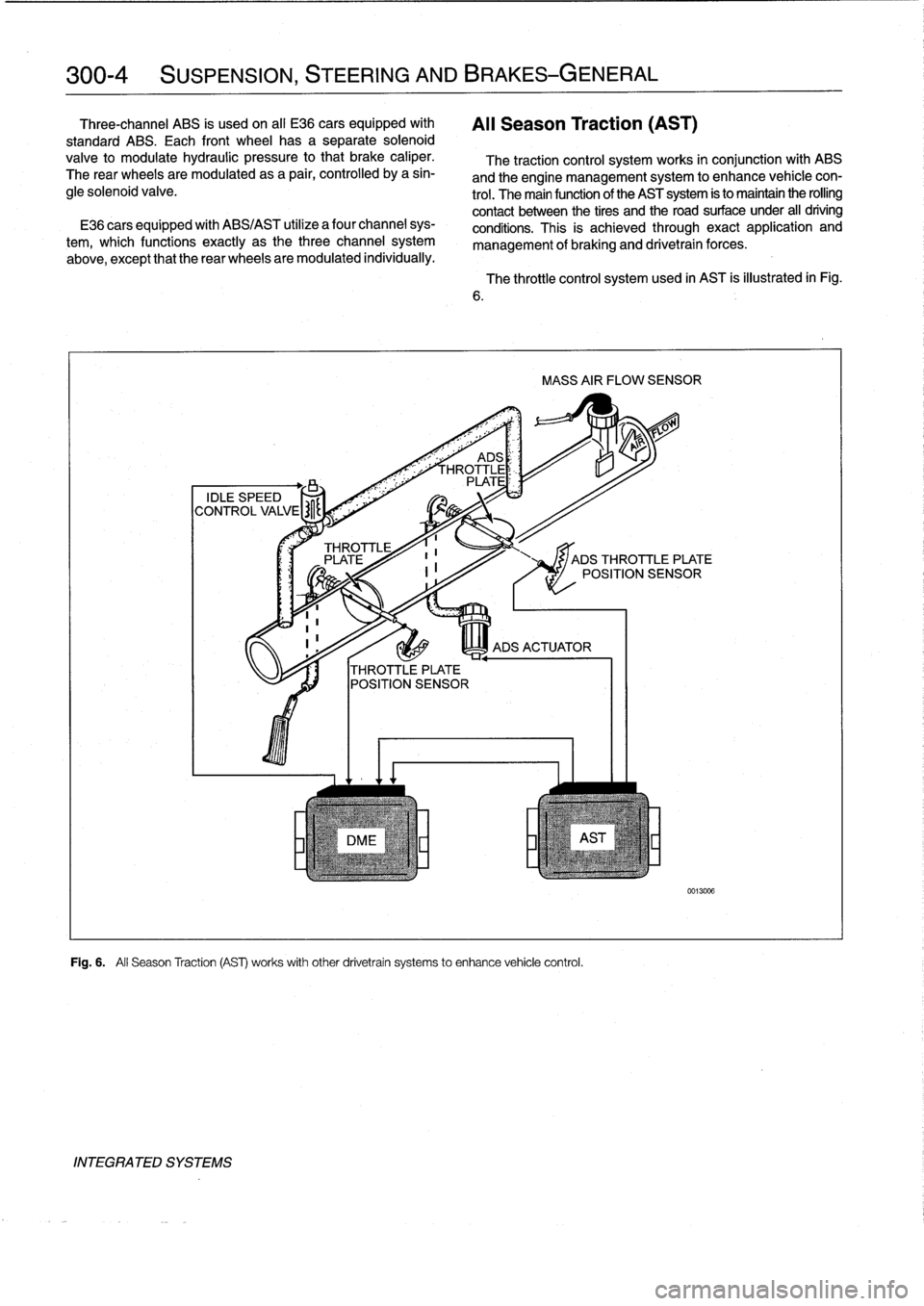

Fig

.

6

.

All

Season

Traction

(AS)

works

withother

drivetrain

systems

to

enhance

vehicle

control

.

INTEGRATED

SYSTEMS

The

throttle

control

system

used

in

AST

is

illustrated

in

Fig

.

MASS

AIR

FLOW

SENSOR

JADS

THROTTLE

PLATE

POSITION

SENSOR

0013006

Page 253 of 759

NOTE-

The

traction

control

system

referred

to

as

AST

(all

sea-

son

traction)

may

also

be

referred

to

as

ASC

(Automat-

ic

Stability

Control)

and

ASC+T

(Automatic

Stability

Control+Traction)

.

The

AST

system

improves

traction

by

electronically

apply-

ing

the

rear

brakes

when

therear

drive

wheels

are

spinning

at

a

faster

rate

than

the

front

wheels

.

The

combined

ABS/AST

control

module,

operating

through

the

ABS

hydraulic

control

unit,

modulates

braking

force

at

therear

wheels

.

In

addition,

AST

uses

retarded

ignition

timing

and

an

auxil-iary

engine

throttle

plate

to

reduceengine

torque

and

maintain

vehicle

stability

.

The

auxiliary

throttle

plate

is

held

open

by

spring

pressure

.

The

AST

system

actívates

the

auxiliary

throttie

position

motor

(ADS)

to

cose

the

AST

throttle

as

needed

.

This

reduces

the

volume

of

engine

intake

air

.

Due

to

the

throttle

closing

very

rapidly

during

AST

operationthe

driver

cannot

increase

theengine

power

output

regardless

of

how

far

theaccelerator

pedal

is

pushed

to

the

floor

.

The

auxiliary

throttle

plate

is

placed

ahead

of

the

conven-

tional

throttle

plate

in

the

throttle

body

.

Traction

control

also

comes

into

operationduringdecelera-

tion

.

Decelerating

on

snowy

or

icy

road

surfaces

can

lead

to

rear

wheel

slip

.

If

a

rear

wheel

startsto

drag

or

lock

up

when

the

throttle

is

closed

rapidly

orduringdownshifting,the

AST

system

can

limit

the

problem

by

advancing

the

ignition

timing

.

A

switch

on

the

center

console

is

used

to

togglethe

AST

on

or

off

.

The

AST

system

is

designed

to

be

maintenance

free

.

There

are

no

adjustments

that

can

be

made

.

Repair

and

trouble-

shooting

of

the

AST

system

requires

special

test

equipment

andknowledgeand

should

be

performed

only

by

an

autho-

rized

BMW

dealer

.

Table

a

lists

theconditions

indicated

by

the

AST

indicator

light

in

the

instrument

cluster

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

300-5

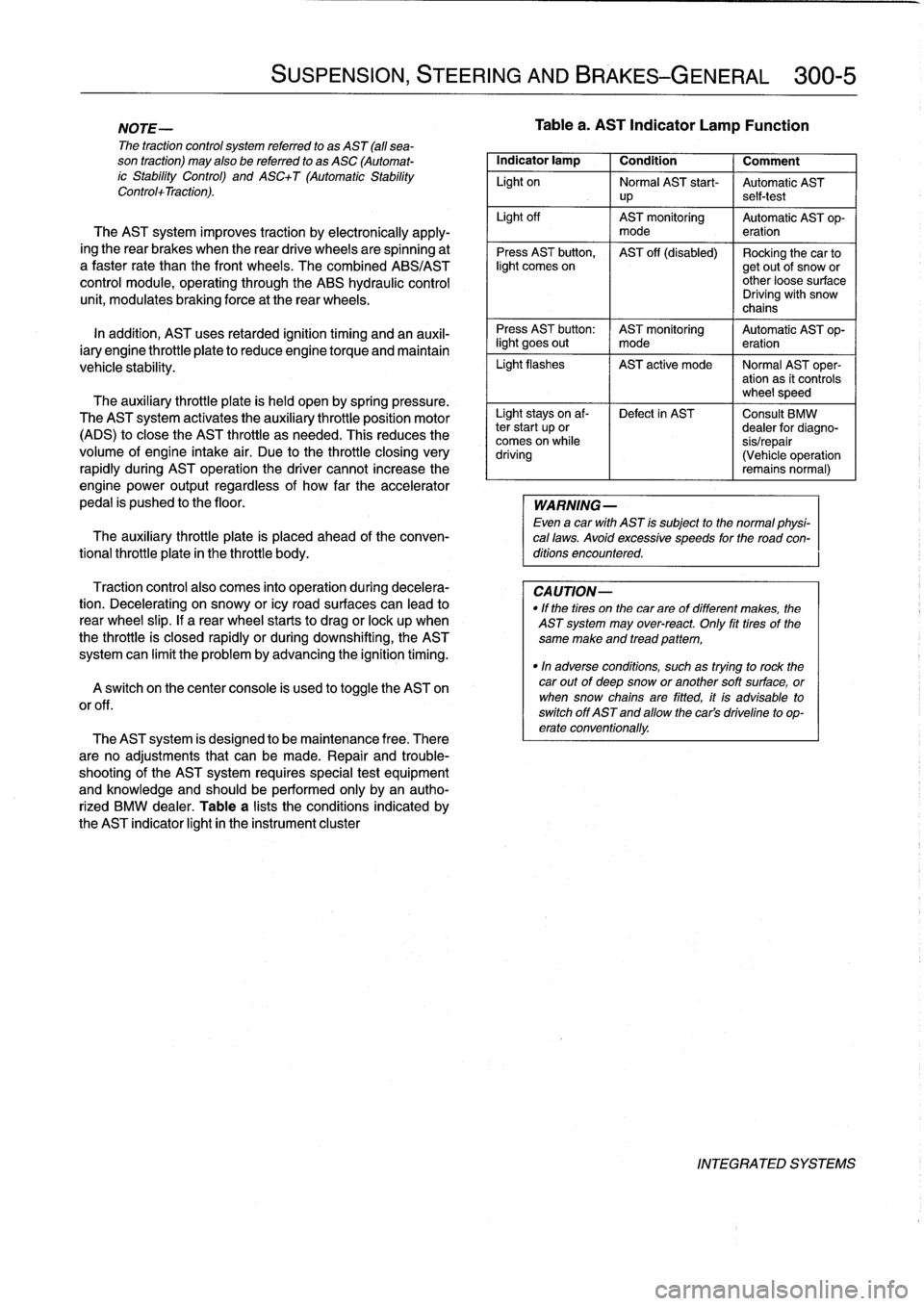

Tablea

.

AST

Indicator

Lamp

Function

Indicator

lamp

1

Condition

1

Comment

Light

on

Normal

AST

start-

Automatic

AST

up

self-test

Light

off

AST

monitoring

Automatic

AST

op-

mode

eration

Press

AST

button,

AST

off

(disabled)

Rocking

the

car

tolight

comes

on

getout

of

snow

or

other

loose

surface

Driving

with

snow

chains

Press

AST

button

:

AST

monitoring

Automatic

AST

op-

light

goes

out

I

mode

eration

Light

flashes

AST

active

mode

I

Normal

AST

oper-

ation

as

it

controls

wheel

speed

Light

stays

on

af-

Defect

in

AST

Consult

BMW

ter

start

up

or

dealer

for

diagno-

comes

on

while

sis/repair

driving

(Vehicle

operation

remains

normal)

WARNING

-

Even

a

car

with

AST

is

subject

to

the

normal

physi-

cal

laws

.

Avoid

excessive

speeds

for

the

road

con-

ditions

encountered

.

CAUTION-

"

If

the

tires

on

the

carare

of

different

makes,

the

AST

system

may

over-react

.

Only

fit

tires

of

the

same

make

and

tread

pattem,

"In

adverse

conditions,

such

as

trying

to

rock

the

car

outof

deep

snow

or

another

soft

surface,

or

when

snow

chainsare

fitted,

it

is

advisable

to

switch

off

AST

and

allow

the

cars

driveline

to

op-

erate

conventionally

.

INTEGRATED

SYSTEMS

Page 254 of 759

300-6

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

BATTE

RY

KL

30

ECM

MAIN

C~

RELAY

KL

15

DSC

SWITCH

LF1

;1~lZZ~

nSLn

l'

z

sJ

WHEEL

RF

c_

.

LR

r_

.

>

RR

ELECTRONIC

BRAKE

LIGHT

SWITCH

SPEED

SENSORS

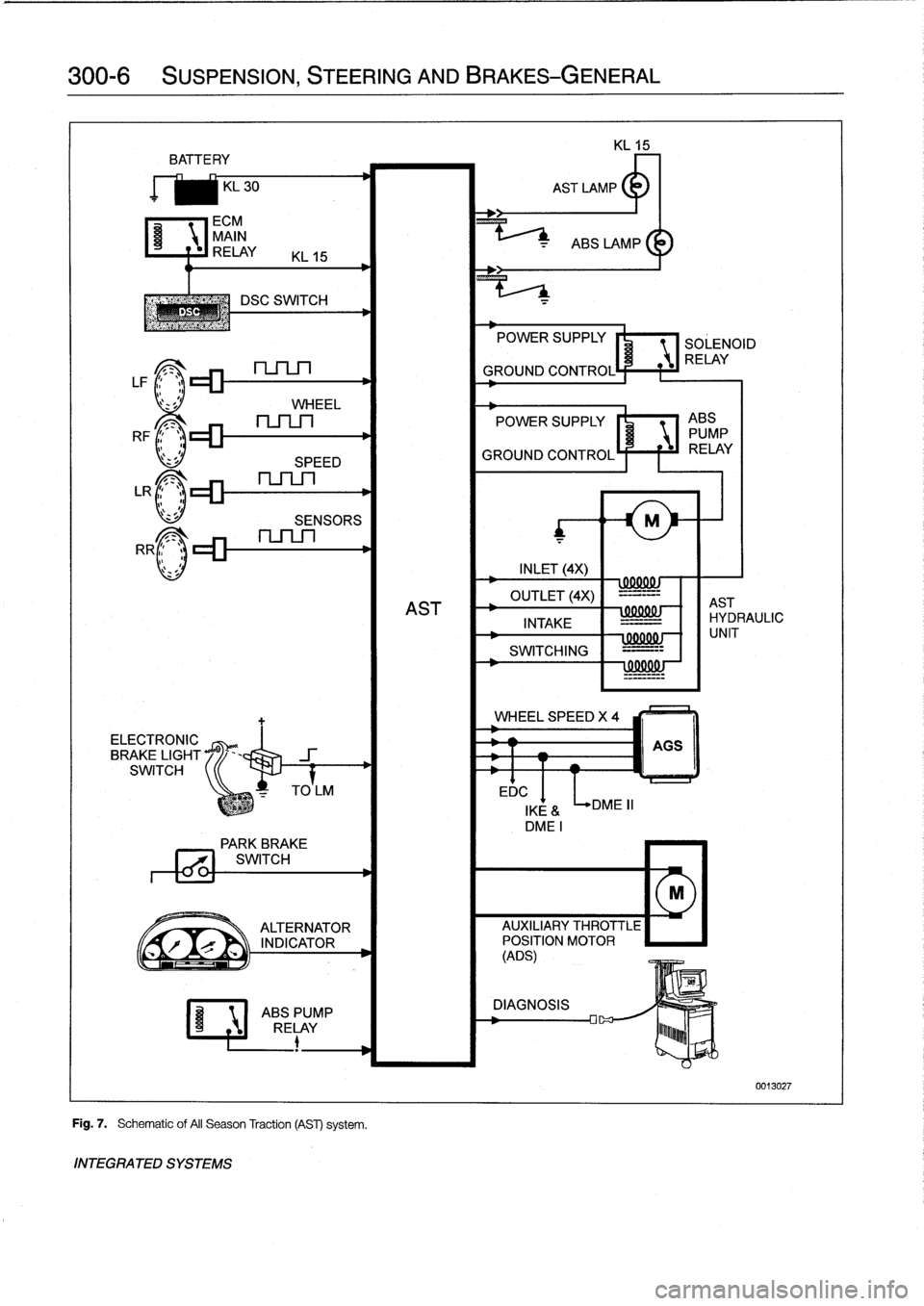

Fig

.

7

.

Schematic

of

AII

Season

Traction

(AST)

system

.

INTEGRATED

SYSTEMS

EDC

POWER

SUPPLY

SOLENOID

RELAY

GROUND

CONTROL

POWER

SUPPLY

I'

1

ABS

PUMP

GROUND

CONTROLÍ

F

f

iJ

RELAY

INLET

(4X)

wxxuw

OUTLET

(4X)

-=-=--

AST

AST

INTAKE

IHYDRAULIC

-

=-

SWITCHING

=---

!

99001

!J

WHEEL

SPEED

X

4

DME

II

000001

-

f

1

UNIT

AGS

IKE

&

DMEI

PARK

BREVE

771

SWITCH

M

ALTERNATOR

AUXILIARY

THROTTLE

r

`

INDICATOR

POSITION

MOTOR

(ADS)

ABSPUMP

DIAGNOSIS

RELAY

lu~~~b

0013027

Page 255 of 759

increased

power

output

and

road-handling

demands

.

The

steering

geometry

is

modified

by

changing

the

cast-

er/camber

angles

slightly

.

This

is

accomplishedby

reposition-

ing

the

upper

strut

mounting

holes

in

the

frontstrut

towers

and

through

different

front

and

rear

control

arms

.

M3

Brake

System

Improvements

"

Vented

directionalfront

rotors

:

315

mm

dia

.

x

28

mm

thick

.

"

Vented

directional

rear

rotors

:

312

mm

dia

.

x20

mm

thick

.

"

Larger

brake

pads

and

calipers

.

"

Modified

Teves

ABS

system

.

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

300-

7

M3

SUSPENSION

AND

BRAKES

NOTE-

M3

brake

rotors

are

directional,

having

a

different

part

TheE36

M3

was

introduced

in

late

1994

as

a

1995

model

.

number

for

each

side

.

Rotors

with

an

odd

part

number

The

design

of

the

M3

suspension,

steering

and

brakes

is

a

go

on

the

left

while

rotors

with

en

even

part

numbergo

modification

of

existing

E36

systems

which

accommodates

on

the

right

.

M3

Front

SuspensionImprovements

"

Reinforced

spring

plates,control

arms,

control

arm

bush-

ings,

steering

arms

.

"

Recalibrated

struts,

firmer

springs

.

"

Stiffer

stabilizerbar,

larger

stabilizer

bar

bushings

.

"

Front

stabilizer

linked

to

struts

.

M3

Wheels/Tires

"

Front

wheels

1992-1998

:.....

7

.5J

x

17

in

.

light

alloy

"

Rear

wheel

1992-1997

.......

7

.5J

x17

in

.

light

alloy

"

Rear

wheel

(option)

........

.8

.5

Jx17

in

.

light

alloy

"

Front

and

rear

tire

1992-1997

.............

.

.

.

...

...

235/40

x

17

in

.

"

Front

tire

1998

only

......

...

.

.

.

...

225/45

x

17

in

.

"

Rear

tire

1998

only

.......

.

.

.

...

...

245/40

x

17

in

.

CAUTION-

In

en

emergency,

an

M3

front

wheel/tire

assembly

may

be

mounted

on

the

rearaxle

.

However

a

rear

wheel/tire

assemblymust

not

be

mounted

on

the

front

axle

.

M3

RearSuspensionImprovements

"

Reinforced

trailing

arms

.

"

Recalibrated

shock

absorbers,

firmer

springs

.

SUSPENSION

AND

STEERING

TROUBLESHOOTING

Stable

handling

and

ride

comfort

both

depend

on

the

integ-

rity

of

the

suspension

and

steering

components

.

Any

symp-

tom

of

instability

or

imprecise

road

feel

may

be

caused

by

worn

or

damaged

suspension

components

.

When

troubleshooting

suspension

and

steering

problems,

also

consider

the

condition

of

tires,

wheels,

and

their

align-

ment

.

Tire

wear

and

incorrect

inflation

pressures

can

dramati-

cally

affect

handling

.

Subtie

irregularities

in

wheel

alignment

angles

also

affect

stabílity

.

Mixing

different

types

or

sizes

of

tires,

particularly

on

the

same

axle,

can

affect

alignment

and

may

unbalancea

car's

handling

.

Table

b

lists

the

symptoms

of

common

suspension

and

steering

problems

and

their

probable

causes,

and

suggests

corrective

actions

.

Bold

type

indicates

the

repair

groups

where

applicable

test

and

repair

procedures

can

befound

.

SUSPENSION

AND

STEERING

TROUBLESHOOTING

Page 256 of 759

300-8

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

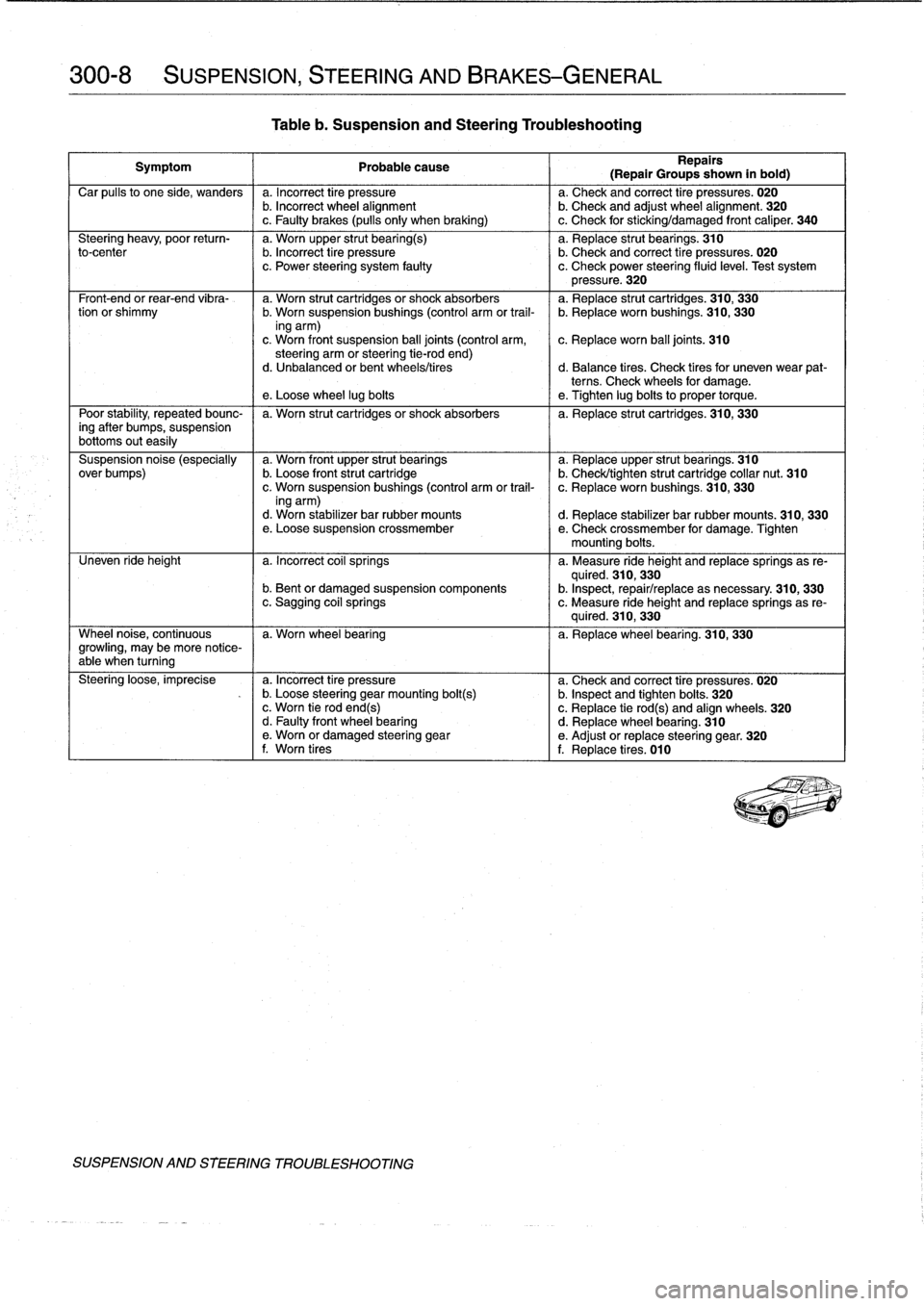

Tableb

.

Suspension

and

Steering

Troubleshooting

Symptom

1

Probable

cause

Repairs

(Repair

Groups

shown

in

bold)

Car

pulís

to

one

side,

wanders

a

.

Incorrect

tire

pressure

a

.

Check

and

correct

tire

pressures

.

020

b

.

Incorrect

wheel

alignment

b

.

Check

and

adjust

wheel

alignment

.

320

c

.

Faulty

brakes

(pulls

only

when

braking)

I

c

.

Check

for

sticking/damaged

front

caliper

.

340

Steering

heavy,

poor

return-

a

.

Worn

upper

strut

bearing(s)

a

.

Replace

strut

bearings

.

310

to-center

b

.

Incorrect

tire

pressure

b

.

Check

and

correct

tire

pressures

.

020

c

.

Power

steering

system

faulty

c

.

Check

power

steering

fluid

level

.

Test

system

pressure

.

320

Front-end

or

rear-end

vibra-

a

.

Worn

strut

cartridgesor

shock

absorbers

a

.

Replace

strut

cartridges

.

310,

330

tion

or

shimmy

b

.

Worn

suspension

bushings

(control

arm

or

trail-

b

.

Replace

worn

bushings

.

310,

330

ing

arm)

c

.

Worn

front

suspension

ball

joints

(control

arm,

c

.

Replace

worn

ball

joints

.

310

steering

arm

orsteering

tie-rod

end)d

.

Unbalanced

or

bent

wheels/tires

d

.

Balance

tires

.

Check

tiresfor

uneven

wear

pat-

terns

.

Check

wheels

for

damage

.

e

.

Loose

wheel

lug

boits

e

.

Tighten

lug

boits

to

proper

torque

.

Poor

stability,

repeated

bounc-

I

a

.

Worn

strut

cartridgesor

shock

absorbers

I

a

.

Replace

strut

cartridges

.

310,

330

ing

after

bumps,

suspension

bottoms

outeasily

Suspension

noise

(especially

a

.

Worn

front

upper

strut

bearings

a

.

Replaceupper

strut

bearings

.

310

over

bumps)

b

.

Loose

front

strut

cartridge

b

.

Check/tighten

strut

cartridge

collar

nut

.

310

c

.

Worn

suspensionbushings

(control

arm

or

trail-

c

.

Replace

worn

bushings

.

310,

330

ing

arm)d

.

Worn

stabilizer

bar

rubber

mounts

d

.

Replace

stabilizer

bar

rubber

mounts

.

310,

330

e

.

Loose

suspension

crossmember

e

.

Check

crossmember

for

damage

.

Tighten

mounting

boits

.

Uneven

ride

height

a

.

Incorrect

coil

springs

a

.

Measure

ride

height

and

replacesprings

as

re-

quired

.

310,

330

b

.

Bent

or

damaged

suspension

components

b

.

Inspect,

repair/replace

asnecessary

.

310,

330

c

.

Sagging

coil

springs

c

.

Measure

ride

height

and

replace

springs

as

re-

quired

.

310,

330

Wheel

noise,

continuous

I

a

.

Worn

wheel

bearing

I

a

.

Replacewheel

bearing

.

310,

330

growling,

may

be

more

notíce-

able

when

turning

Steering

loose,

imprecise

a

.

Incorrect

tire

pressure

a

.

Check

and

correct

tire

pressures

.

020

-

b

.

Loose

steering

gearmounting

bolt(s)

b

.

Inspect

and

tighten

boits

.

320

c

.

Worn

tie

rodend(s)

c

.

Replace

tie

rod(s)

and

align

wheels

.

320

d

.

Faulty

front

wheel

bearing

d

.

Replace

wheel

bearing

.

310

e

.

Worn

or

damaged

steering

gear

e

.

Adjust

or

replace

steering

gear

.

320

f

.

Worn

tires

f

.

Replace

tires

.

010

SUSPENSION

AND

STEERING

TROUBLESHOOTING

Page 257 of 759

GENERAL

310

Front

Suspension

GENERAL

..

.

.

.

.

.

.

.

.

.

.......

.

........

.

310-1

FRONT

WHEEL

BEARINGS

..

.

.

.

.......

310-8

SHOCK

ABSORBERS

AND

SPRINGS

..

.

310-2

Front

wheel

bearing,

replacing

...

.

.

.

.

.

.

.

...

310-8

Strut

assembly,

removing

and

installing

.....

310-2

STABILIZER

BAR

..........

.

.

.

.

.

.

.

.

.

.

.

.

310-9

Strut

assembly,

disassembling

Stabilizerbar,

removing

and

installing

.

.

.

.

...

310-9

and

assembling

.

.

.

...

.

.....

.

.........

310-4

Ride

Height

.

.

.

.

.

.

.

.

.

.

.

.

.....

.

........

.

310-4

SUBFRAME

CROSSMEMBER

.

.

.

.

.

.

.

.

.

.

.

310-9

Subframe

crossmember,

CONTROL

ARMS

.

.

...

.

.

.

.

.

.

.

...

.

.....

310-5

removing

and

installing

.....

.

.

.

.

.

.

.

.

.

...

310-9

Control

arm,

removing

and

installing

....

..

310-5

Outer

control

arm

ball

joint,

replacing

Table

exce

t

M3

models

310-6

a

.

Front

Ride

Height

Specifications

..

.

.....

..

.

..

..

310-5

Control

arm

bushing,

replacing

.

.

.

...

.

.....

310-7

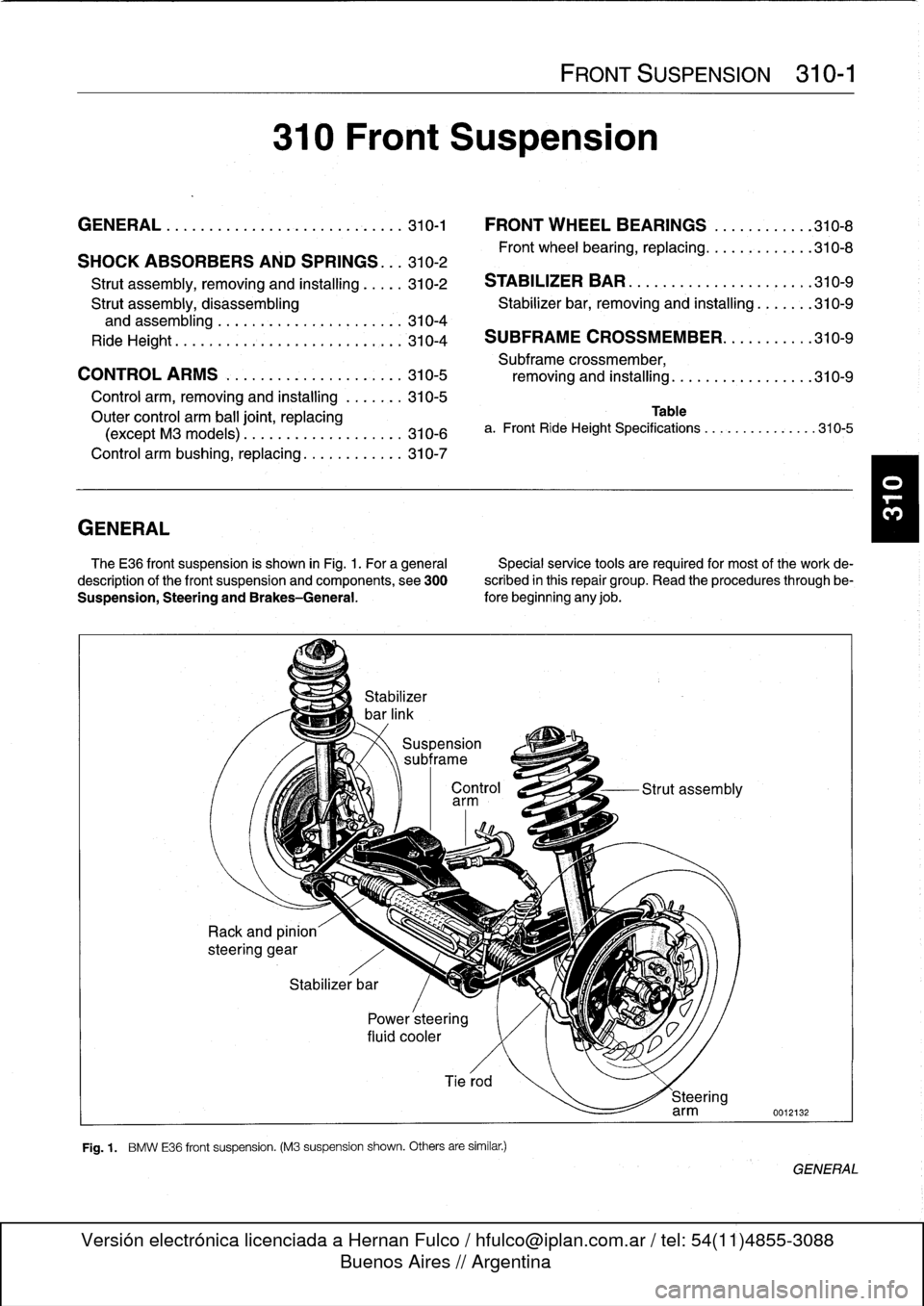

The

E36

front

suspension

is

shown

in

Fig

.

1

.

For

a

general

Specialservice

tools

arerequired

for

most

of

the

work

de-

description

of

the

front

suspension

and

components,

see

300

scribed

in

this

repair

group

.

Read

the

procedures

through

be-

Suspension,

Steering

and

Brakes-General

.

fore

beginning

any

job

.

Stabilizer

bar

Power

steering

fluid

cooler

Control

Strut

assembly

arm

Tierod

Fig

.

1

.

BMW

E36

front

suspension

.

(M3

suspension

shown

.

Others

are

similar

.)

FRONT

SUSPENSION

310-1

Steering

arm

0012132

GENERAL

Page 258 of 759

310-2

FRONT

SUSPENSION

WARNING-

"

Physical

safety

could

be

impaired

if

procedures

described

here

areundertaken

without

the

proper

service

tools

and

equipment

.

Be

sure

to

have

the

right

tools

onhand

before

beginning

any

job

.

"

Do

notreuse

self-locking

nuts

or

bolts

.

They

are

designed

to

beused

only

once

and

may

fail

if

re-

used

.

Always

replace

self-locking

fasteners

any

timethey

are

loosenedor

removed

.

"

Do

not

install

bolts

and

nuts

coated

with

under-

coating

wax,

as

the

correct

tightening

torque

can-

not

beassured

.

Always

clean

the

threads

with

solventbefore

installation,

or

install

new

parts

.

"

Do

not

attempt

to

weld

or

straighten

any

suspen-

sion

components

.

Replace

damaged

parts

.

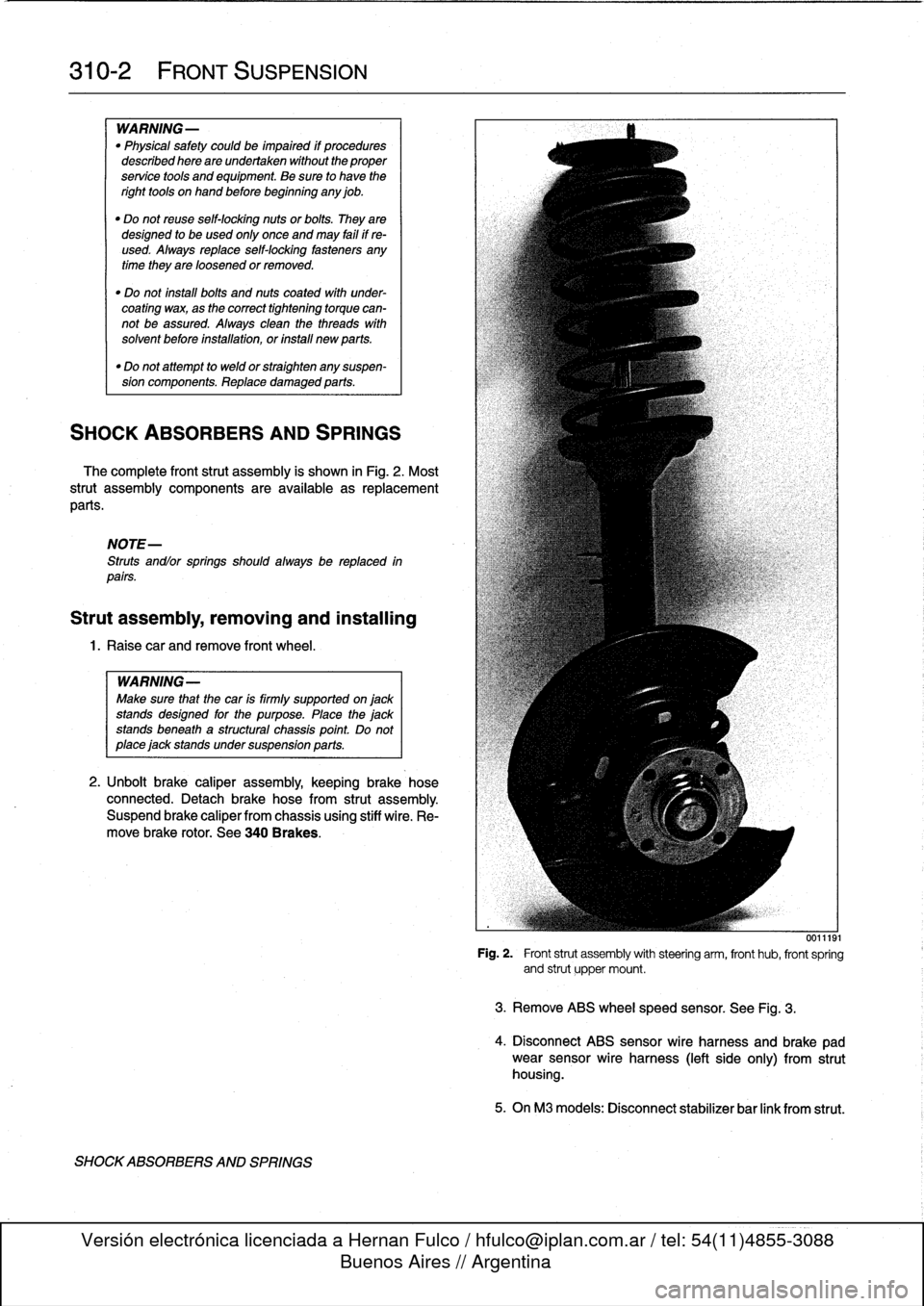

SHOCK

ABSORBERS

AND

SPRINGS

The

complete

front

strut

assembly

is

shown

in

Fig

.

2

.

Most

strut

assembly

components

are

available

asreplacement

parts

.

NOTE-

Struts

andlor

springs

shouldalways

be

replaced

in

parts

.

Strut

assembly,

removing

and

installing

1

.

Raisecar

and

remove

front

wheel

.

WARNING-

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneath

a

structural

chassis

point

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Unbolt

brake

caliper

assembly,

keepingbrake

hose

connected

.

Detach

brake

hose

from

strut

assembly

.

Suspend

brake

caliper

from

chassis

using

stiff

wire

.

Re-

move

brake

rotor

.

See

340

Brakes

.

SHOCKABSORBERS

AND

SPRINGS

0011191

Fig

.

2

.

Front

strut

assembly

with

steering

arm,

front

hub,

front

spring

and

strut

upper

mount

.

3

.

Remove

ABS

wheelspeed

sensor

.

See

Fig

.

3

.

4

.

Disconnect

ABS

sensor

wire

harness

and

brake

pad

wear

sensor

wire

harness

(left

side

only)

from

strut

housing

.

5

.

OnM3

modeis

:

Disconnect

stabilizer

bar

link

from

strut

.

Page 259 of 759

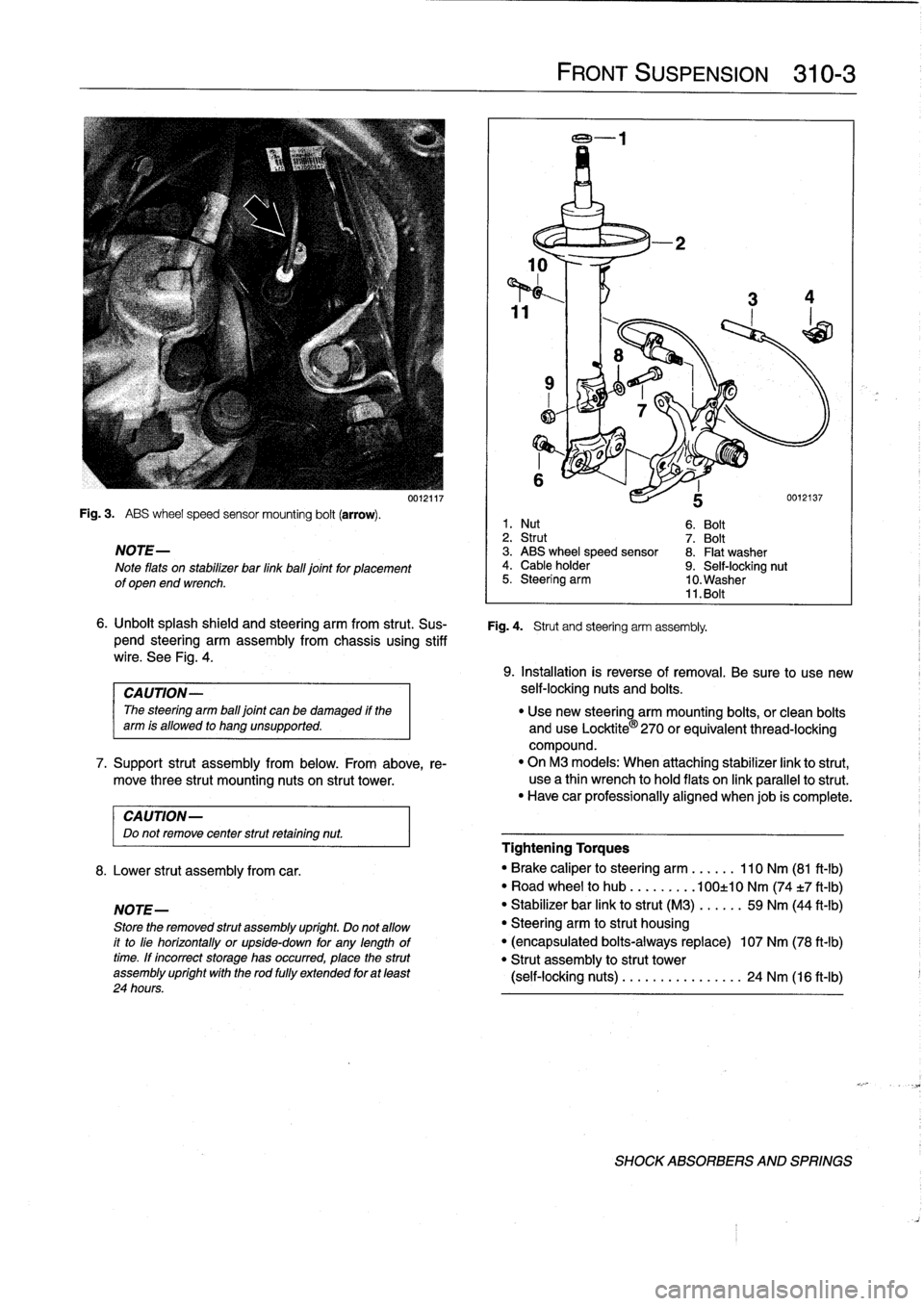

Fig

.

3

.

ABS

wheel

speed

sensor

mounting

bolt

(arrow)

.

NOTE-

Note

flats

on

stabilizer

bar

linkball

joint

for

placement

of

open

end

wrench

.

CAUTION-

Do

not

remove

center

strut

retaining

nut

.

8

.

Lower

strut

assembly

from

car

.

NOTE-

Store

the

removed

strut

assembly

upríght

.

Do

not

allow

it

to

líe

horizontally

or

upside-down

for

any

lengthoftime

.

If

íncorrect

storage

has

occurred,

place

the

strut

assembly

upríght

wíth

the

rod

fully

extended

for

at

least

24

hours

.

0012117

FRONT

SUSPENSION

310-3

6

.

Unbolt

splash

shield

and

steering

arm

from

strut

.

Sus-

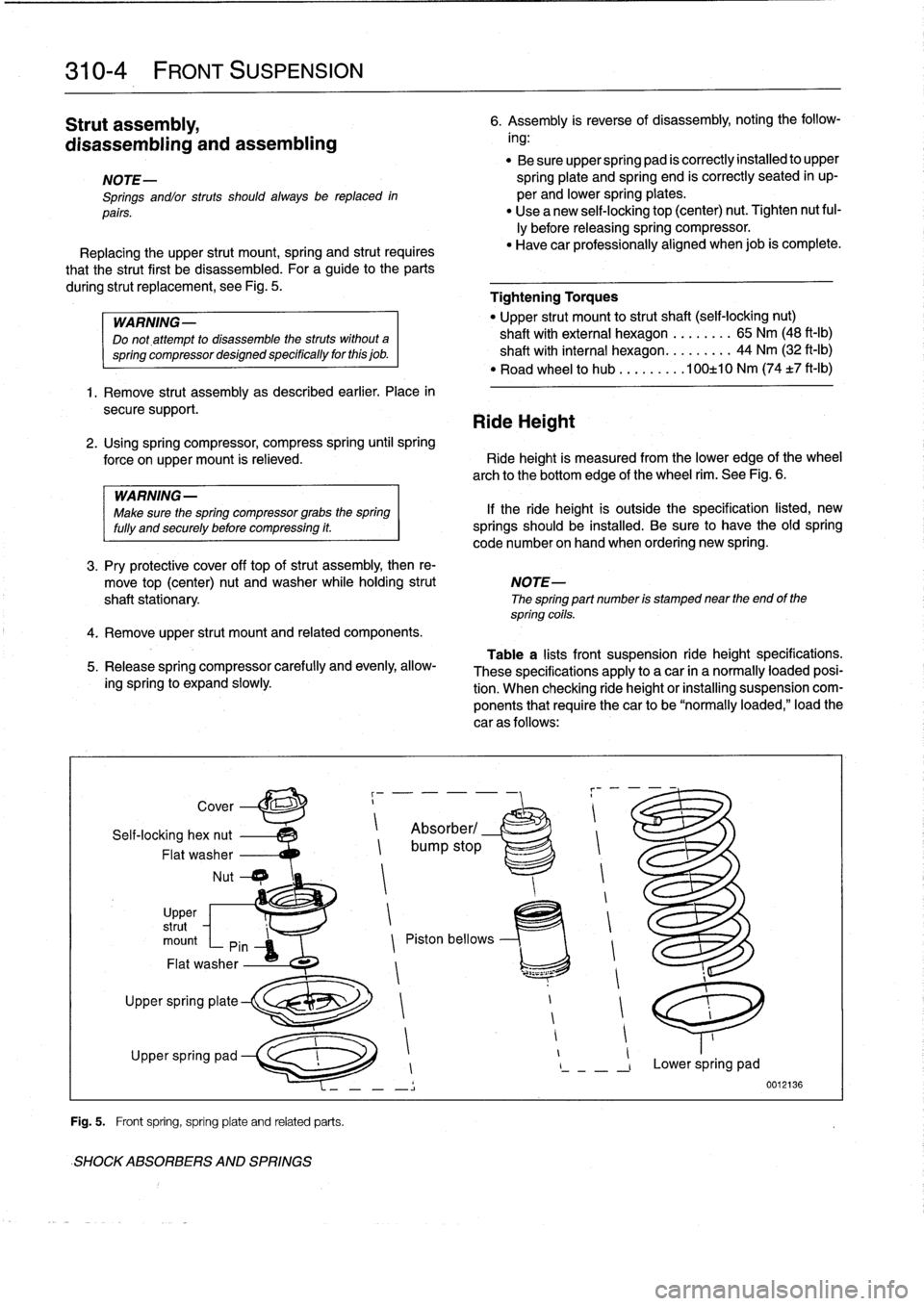

Fig

.

4

.

Strut

and

steering

arm

assembly

.

pend

steering

arm

assembly

from

chassis

using

stiff

wire

.

See

Fig

.

4

.

1

.

Nut

6

.

Bolt

2

.

Strut

7

.

Bolt

3

.

ABS

wheel

speed

sensor

8

.

Flat

washer

4

.

Cable

holder

9

.

Self-locking

nut

5

.

Steering

arm

10

.

Washer

11

.

Bolt

9

.

Installation

is

reverse

of

removal

.

Be

sure

to

use

new

CAUTION-

self-locking

nuts

and

bolts

.

The

steering

arm

ball

joint

can

be

damaged

if

the

"

Use

new

steering

arm

mounting

bolts,

or

clean

bolts

arm

is

allowed

to

hang

unsupported

.

and

use

Locktite

®

270

orequivalent

thread-locking

compound

.

7

.

Support

strut

assembly

from

below

.

From

above,

re-

"

On

M3

models

:

When

attaching

stabilizer

link

to

strut,

move

three

strut

mounting

nuts

on

strut

tower

.

use

a

thin

wrench

to

hold

flats

on

link

parallelto

strut

.

"

Have

car

professionally

aligned

When

job

is

complete

.

Tightening

Torques

"

Brake

caliper

to

steering

arm

......

110

Nm

(81

ft-lb)

"

Road

wheel

to

hub

.........

100±10

Nm

(74

t7

ft-Ib)

"

Stabilizer

bar

link

to

strut

(M3)

.....

.

59

Nm

(44

ft-lb)

"

Steering

arm

to

strut

housing

"

(encapsulated

bolts-always

replace)

107

Nm

(78

ft-lb)

"

Strut

assembly

to

strut

tower

(self-locking

nuts)

........

...

..

..

.

24

Nm

(16

ft-Ib)

SHOCK

ABSORBERS

AND

SPRINGS

Page 260 of 759

310-

4

FRONT

SUSPENSION

Strut

assembly,

disassembling

and

assembling

-

Be

sure

upper

spring

pad

is

correctly

installed

to

upper

NOTE-

spring

plate

and

spring

end

is

correctly

seated

in

up-

Springs

andlor

struts

should

always

be

replaced

in

per

and

lower

spring

plates

.

pairs

.

"

Use

a

new

self-locking

top

(center)

nut

.

Tighten

nut

fui-

¡y

before

releasing

spring

compressor

.

Replacing

the

upper

strut

mount,

spring

and

strut

requires

"

Have

car

professionally

aligned

when

job

is

complete

.

that

the

strut

first

bedisassembled

.

For

a

guide

to

the

parts

during

strut

replacement,

see

Fig

.

5

.

Tightening

Torques

WARNING-

"

Upper

strut

mount

to

strut

shaft

(seif-locking

nut)

Do

not,attempt

to

disassemble

thestruts

without

a

shaft

with

external

hexagon

......

..

65

Nm

(48

ft-1b)

springcompressordesignedspecificallyforthisjob

.

shaft

with

interna¡

hexagon

.......

..

44

Nm

(32

ft-Ib)

"

Road

wheel

to

hub

........

.100±10

Nm

(74

±7

ft-lb)

1

.

Remove

strut

assembly

as

described

earlier

.

Place

in

secure

support

.

Ride

Height

2

.

Using

spring

compressor,

compress

spring

until

spring

force

onupper

mount

is

relieved

.

Ride

height

is

measured

from

the

lower

edge

of

the

wheel

arch

to

the

bottom

edge

of

the

wheel

rim

.

See

Fig

.

6

.

WARNING

-

Make

sure

the

spring

compressor

grabs

the

spring

lf

the

ride

height

is

outside

the

specification

listed,

new

fully

and

securely

before

compressing

it

.

springs

should

be

installed

.

Be

sure

to

have

theold

spring

code

number

on

hand

when

ordering

new

spring

.

3

.

Pry

protective

cover

off

top

ofstrut

assembly,

then

re-

move

top

(center)

nut

andwasher

whileholding

strut

NOTE-

shaftstationary

The

spring

part

number

is

stamped

near

the

end

of

the

spring

cofls

.

4

.

Remove

upper

strut

mount

and

related

components

.

5

.

Release

spring

compressor

carefully

and

evenly,

allow-

ing

spring

lo

expand

slowly

1

Self-locking

hex

nut

Absorber/

Flat

washer

bump

stop

Nut

Cover

Upper

~

strut

mount

Pin

Z

Piston

bellows

Flat

washer

r

i

t1

~

1

Upper

spring

plate

1

1

1

Upper

spring

pad

I

1

-

,

Lower

spring

pad

-

Í

0012136

Fig

.

5

.

Front

spring,

spring

plate

and

related

parts

.

SHOCKABSORBERS

AND

SPRINGS

6

.

Assembly

is

reverse

of

disassembly,

noting

the

follow-

ing

:

Table

a

lists

front

suspension

ride

height

specifications

.

These

specifications

apply

to

a

car

in

a

normally

loaded

posi-

tion

.

When

checking

ride

height

or

installing

suspension

com-

ponents

that

require

thecar

to

be

"normally

loaded,"load

the

car

as

follows

: