BMW M3 1998 E36 Workshop Manual

Manufacturer: BMW, Model Year: 1998, Model line: M3, Model: BMW M3 1998 E36Pages: 759

Page 281 of 759

9

.

Packeach

CV

joint

and

rubber

boot

with

specified

REAR

SUSPENSION

ARMS

amount

of

lubricant

supplied

.

Apply

adhesive

to

large

end

of

boot

and

mount

it

on

joint

.

Secure

boot

with

clamps

.

The

trailing

arms,

control

arms

and

their

mountingbushings

Apply

sealer

to

inner

CV

joint

dust

cover

and

instan

.

control

the

position

of

the

rear

wheels

.

A

damaged

suspen-

sion

arm

or

worn

bushings

will

change

the

rear

wheel

align

NOTE-

ment

and

may

adversely

affect

handling

and

stability

.

"

Before

installing

each

small

boot

clamp

be

sure

to

"burp"

the

boot

by

flexing

the

CV

joint

as

far

overas

it

WARNING

will

go

.

A

small

screw-driver

inserted

between

the

Do

notattempt

to

straighten

a

damaged

suspension

boot

and

the

axle-shaft

will

help

the

process

.

arm

.

Bending

or

heating

may

weaken

the

original

"

BMW

recommends

Bostil101513

or

EppleC4851

ad-

part

.

If

the

suspension

arm

shows

any

signs

of

hesive,

and

Epple®39

or

Curil©T

sealer

damage

or

excessive

corrosion,

it

must

be

re-

placed

.

CV

Joint

Lubricant

Capacity

"

Wheel

hub

end

ex

.

M3

..

..

.

....

.

.............

80

gram

(2.8

oz

.)

M3

..

...

.

..

.................

100

gram

(3

.5

oz

.)

"

Finaldrive

end

.................

85

gram

(3

.0

oz

.)

10

.

Install

drive

axle

as

described

earlier

.

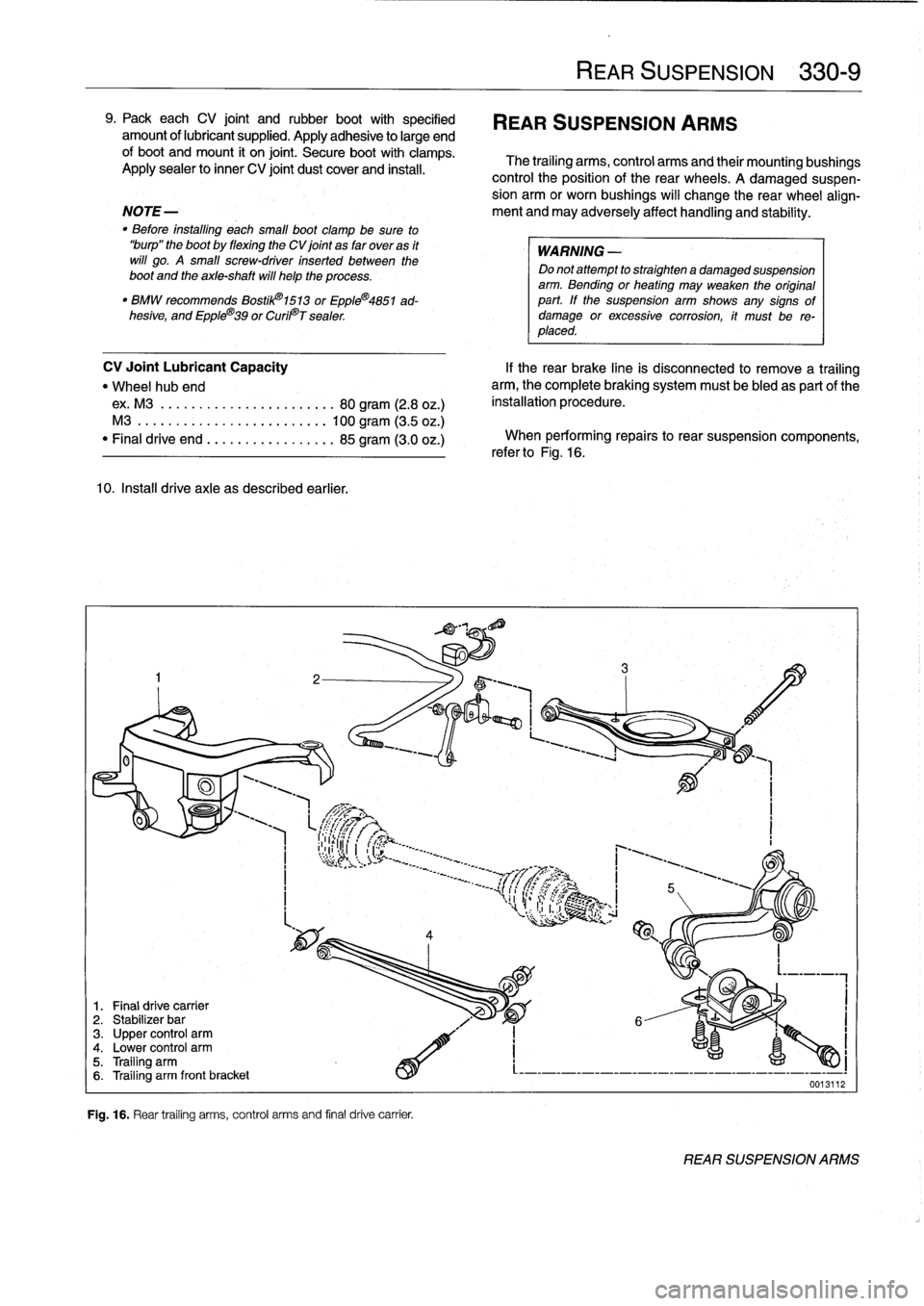

1

.

Final

drive

carrier

2

.

Stabilizer

bar

3

.

Upper

control

arm4

.

Lower

control

arm5

.

Trailing

arm6

.

Trailing

arm

front

bracket

Fig

.

16

.

Rear

trailing

arms,

control

arms

and

final

drive

carrier

.

If

the

rear

brake

cine

is

disconnected

to

remove

a

trailing

arm,

the

complete

braking

system

must

be

bled

as

partof

the

installation

procedure

.

When

performing

repairs

to

rear

suspension

components,

refer

to

Fig

.

16

.

REAR

SUSPENSION

330-

9

0013112

REAR

SUSPENSION

ARMS

Page 282 of 759

330-

1

0

REAR

SUSPENSION

Trailing

arm,

removing

and

installing

1

.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

brake

rotor

and

caliper

as

described

in

340

Brakes

.

Do

not

remove

brake

line

from

caliper

.

Hang

caliper

from

body

with

wire

.

4

.

Remove

parking

brakecable

frombrake

shoe

expand-

er

.

See

340

Brakes

.

5

.

Remove

rear

brake

line

bracket

from

trailing

arm

.

See

Fig

.

17

.

Fig

.

17

.

Brake

line

bracket

bolts

on

trailing

arm

(arrow)

.

WARNING

-

It

is

recommended

that

a

restraining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retainthe

spring

in

case

of

accidentalrelease

.

Personal

injury

can

re-sult

if

the

compressed

coil

spring

is

not

released

slow1y

and

carefully

.

REAR

SUSPENSION

ARMS

6

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

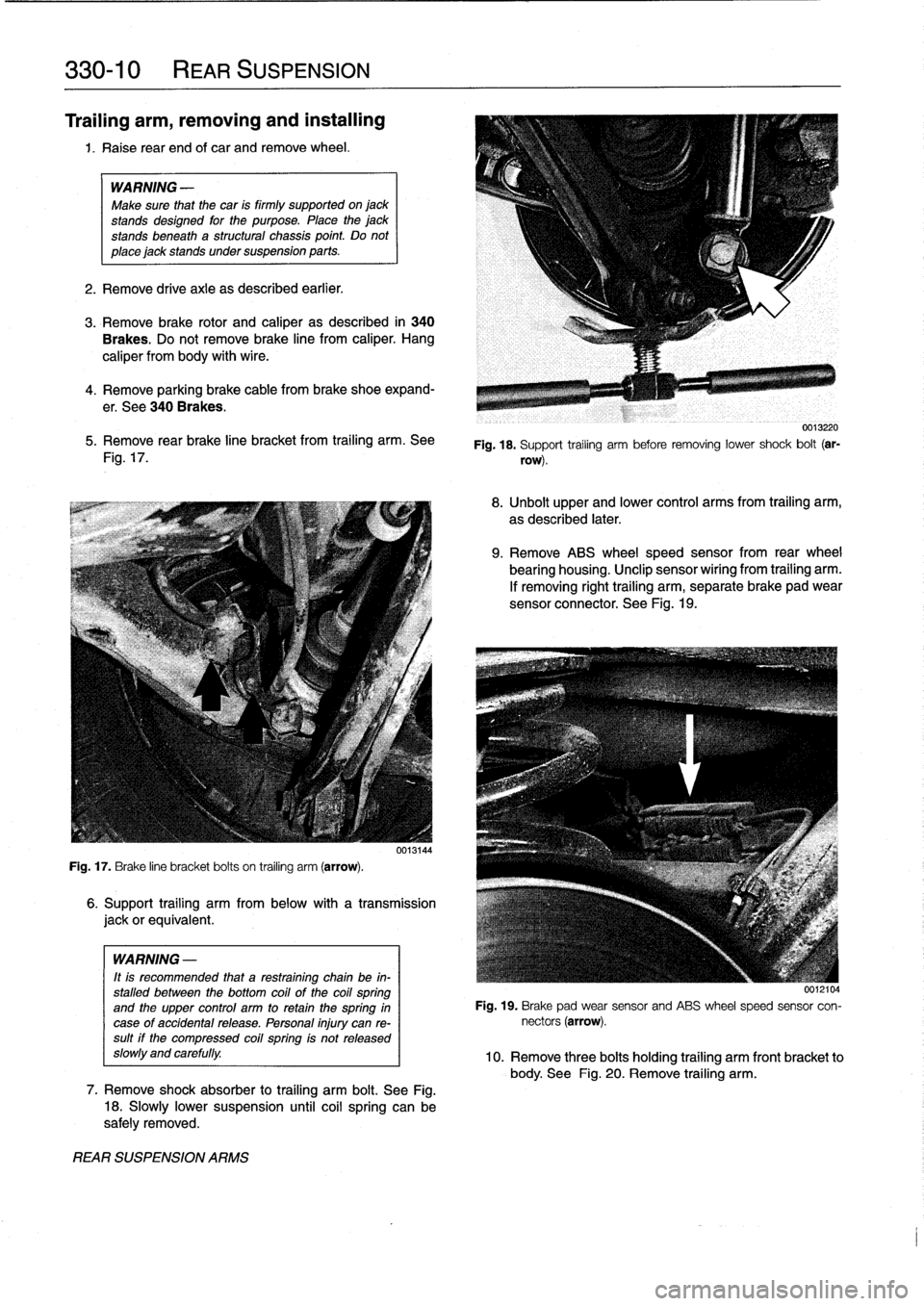

7

.

Remove

shock

absorber

to

trailing

arm

bolt

.

See

Fig

.

18

.

Slowly

lower

suspension

until

coil

spring

can

be

safely

removed

.

0013220

Fig

.

18

.

Support

trailing

arm

before

removing

lower

shock

bolt

(ar-

row)

.

8

.

Unbolt

upper

and

lower

control

arms

from

trailing

arm,

as

described

later

.

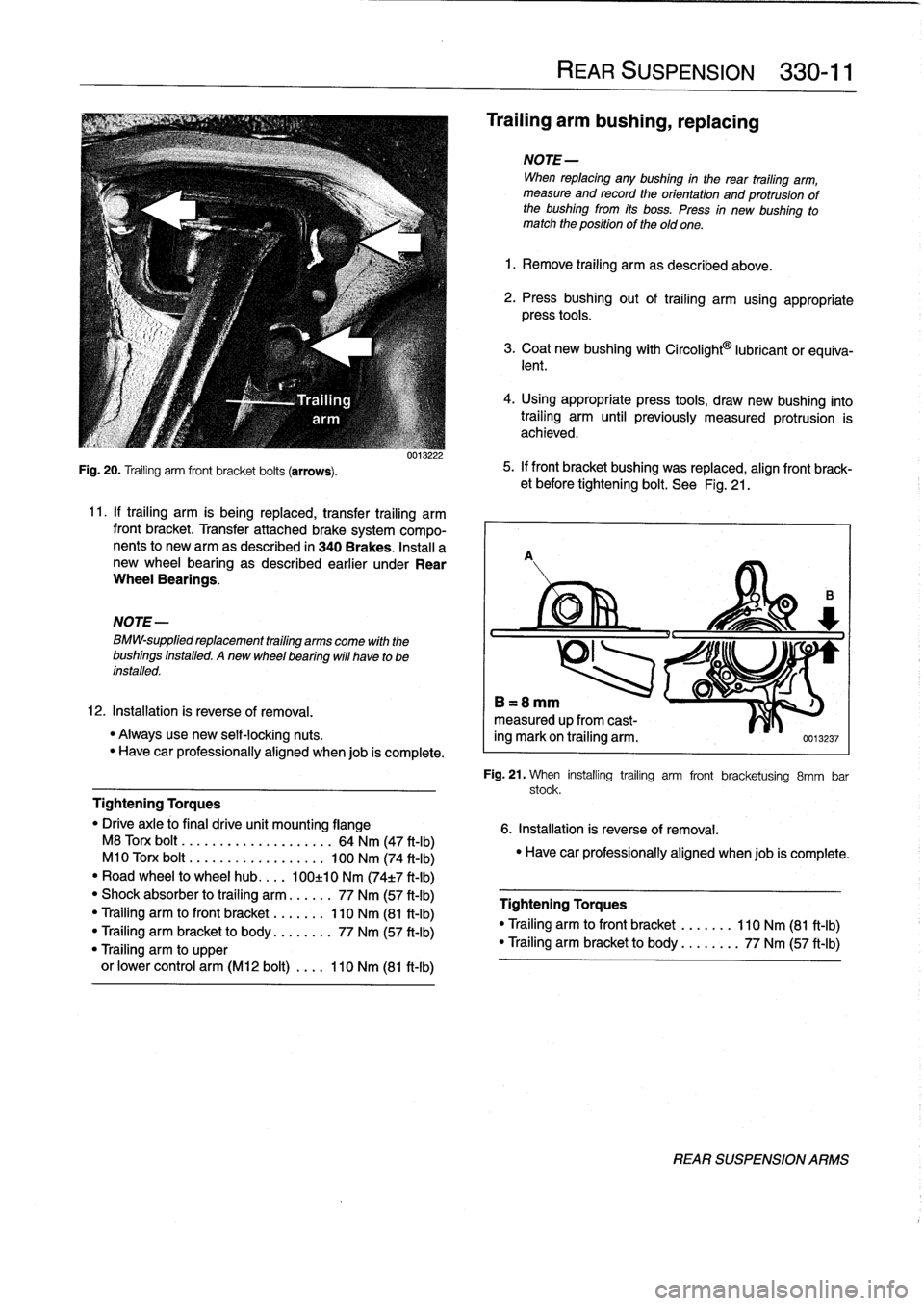

9

.

Remove

ABS

wheel

speed

sensor

from

rear

wheel

bearing

housing

.

Unclip

sensor

wiríng

from

trailing

arm

.

If

removing

right

trailing

arm,

separate

brake

pad

wear

sensor

connector

.

See

Fig

.

19

.

0012104

Fig

.

19

.

Brake

pad

wear

sensor

and

ABS

wheel

speed

sensor

con-

nectors

(arrow)

.

10

.

Remove

three

bolts

holding

trailing

arm

front

bracket

to

body

.

See

Fig

.

20

.

Remove

trailing

arm

.

Page 283 of 759

Fig

.

20

.

Trailing

arm

front

bracket

bolts

(arrows)

.

NOTE-

BMW-supplied

replacement

trailing

arms

come

with

the

bushings

installed

.

Anew

wheel

bearing

will

have

to

be

installed

.

0013222

11

.

If

trailing

arm

is

being

replaced,

transfer

trailing

arm

front

bracket

.

Transfer

attached

brake

system

compo-

nents

to

newarm

as

described

in

340Brakes

.

Insta¡¡

a

new

wheel

bearing

as

described

earlier

under

Rear

Wheel

Bearings

.

12

.

Installation

is

reverse

of

removal

.

"

Alwaysuse

new

self-locking

nuts

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Drive

axle

#o

final

drive

unit

mounting

flange

M8

Torx

bolt

......

.

...

.....

.

..

..

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.....

...

.

....

.....

100

Nm

(74

ft-Ib)

"

Road

wheel

to

wheel

hub

.

...

100±10

Nm

(74t7

ft-Ib)

"

Shock

absorber

to

trailing

arm

......

77

Nm

(57

ft-Ib)

"

Trailing

arm

tofront

bracket

.......

110

Nm

(81

ft-Ib)

"

Trailing

arm

bracket

to

body

........

77

Nm

(57

ft-Ib)

"Trailing

arm

to

upper

or

lower

control

arm

(M12

bolt)

....

110

Nm

(81

ft-Ib)

REAR

SUSPENSION

330-

1

1

Trailing

arm

bushing,

replacing

NOTE-

When

replacing

any

bushing

in

the

rear

trailing

arm,

measure

and

recordthe

orientation

and

protrusion

of

the

bushing

from

its

boss

.

Press

in

new

bushing

to

match

the

positionof

theold

one

.

1

.

Remove

trailing

arm

as

described

above

.

2

.

Pressbushing

out

of

trailing

arm

using

appropriate

press

tools

.

3

.

Coat

new

bushing

with

Circolight

9

lubricant

or

equiva-

lent

.

4

.

Using

appropriate

press

tools,

draw

new

bushing

into

trailing

arm

until

previously

measured

protrusion

is

achieved

.

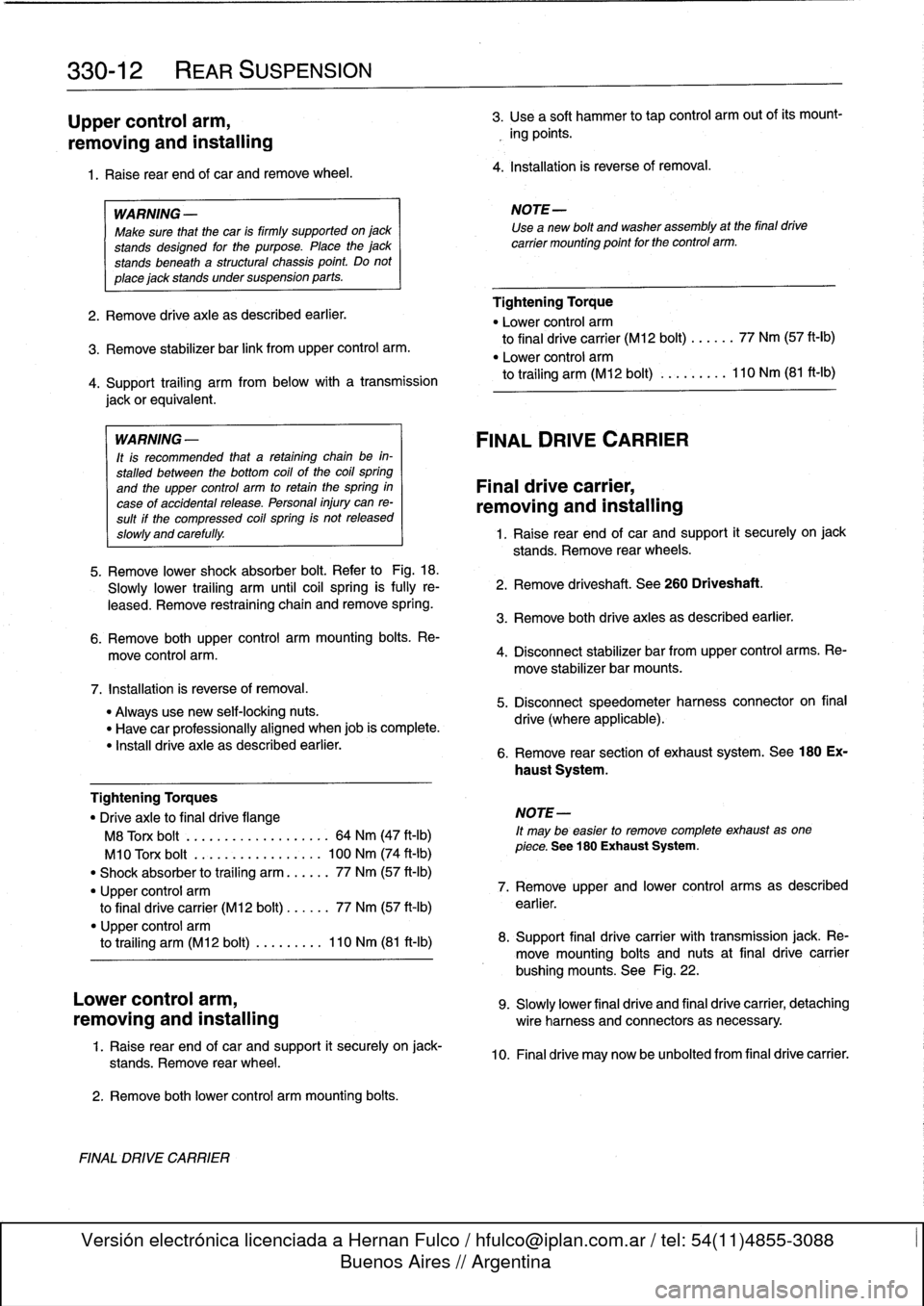

5

.

If

front

bracket

bushing

was

replaced,

alignfront

brack-

et

before

tightening

bolt

.

See

Fig

.

21

.

A

B=8mm

measured

upfrom

cast-

ing

mark

on

trailing

arm

.

0013237

Fig

.

21

.

When

installing

trailing

arm

front

bracketuising

8mm

bar

stock

.

6

.

Installation

is

reverse

of

removal

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Trailing

arm

tofront

bracket

.......

110

Nm

(81

ft-Ib)

"Trailing

arm

bracket

to

body

......

.

.

77

Nm

(57

ft-Ib)

REAR

SUSPENSION

ARMS

Page 284 of 759

330-

1

2

REAR

SUSPENSION

Upper

control

arm,

removing

and

installing

1.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

stabilizer

bar

link

fromupper

control

arm

.

4

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

WARNING

-

It

is

recommended

that

a

retaining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retain

thespring

in

case

of

accidental

release

.

Personal

injury

can

re-

sult

if

the

compressed

coil

spring

ís

not

released

slowly

and

carefully

.

5

.

Remove

lower

shock

absorber

bolt

.

Refer

to

Fig

.

18

.

Slowly

lower

trailing

arm

until

coil

spring

is

fully

re-

leased

.

Remove

restraining

chain

and

remove

spring

.

7

.

Installation

is

reverse

of

removal

.

"

Always

use

new

self-locking

nuts

.

"

Have

car

professionally

aligned

when

job

is

complete

.

"

Insta¡¡

drive

axle

as

described

earlier

.

Tightening

Torques

"

Drive

axleto

final

drive

flange

M8

Torx

bolt

..........

..

.

..

....

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.........

..

..

.

...

100

Nm

(74

ft-Ib)

"

Shock

absorber

to

trailing

arm

..

..

..

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

final

drive

carrier

(M12

bolt)

...

..

.

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

trailing

arm

(M12

bolt)

.........

110

Nm

(81

ft-Ib)

Lower

control

arm,

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack-

stands

.

Remove

rear

wheel

.

2

.

Remove

both

lower

control

arm

mounting

bolts

.

FINAL

DRIVE

CARRIER

3

.

Use

a

soft

hammer

to

tap

control

arm

out

of

its

mount-

ing

points

.

4

.

Installation

is

reverse

of

removal

.

NOTE-

Use

a

new

bolt

and

washer

assembly

at

the

final

drive

carrier

mountíng

point

forthe

control

arm

.

Tightening

Torque

"

Lower

control

arm

to

final

drive

carrier

(M12

bolt)

......

77

Nm

(57

ft-Ib)

"

Lower

control

arm

to

trailing

arm

(M12

bolt)

....

..

.

..

110

Nm

(81

ft-Ib)

FINAL

DRIVE

CARRIER

Final

drive

carrier,

removing

and

installing

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

.

See

260

Driveshaft

.

3

.

Remove

both

drive

axles

as

described

earlier

.

6

.

Remove

both

upper

control

arm

mounting

bolts

.

Re-

move

control

arm

.

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

move

stabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Remove

rear

section

of

exhaust

system

.

See

180

Ex-

haust

System

.

NOTE-

It

may

be

easier

to

remove

complete

exhaust

asonepiece

.

See

180

Exhaust

System

.

7

.

Remove

upper

and

lower

control

arms

as

described

earlier

.

8

.

Support

final

drive

carrierwith

transmissíon

jack

.

Re-

move

mounting

bolts

and

nuts

at

final

drive

carrier

bushing

mounts

.

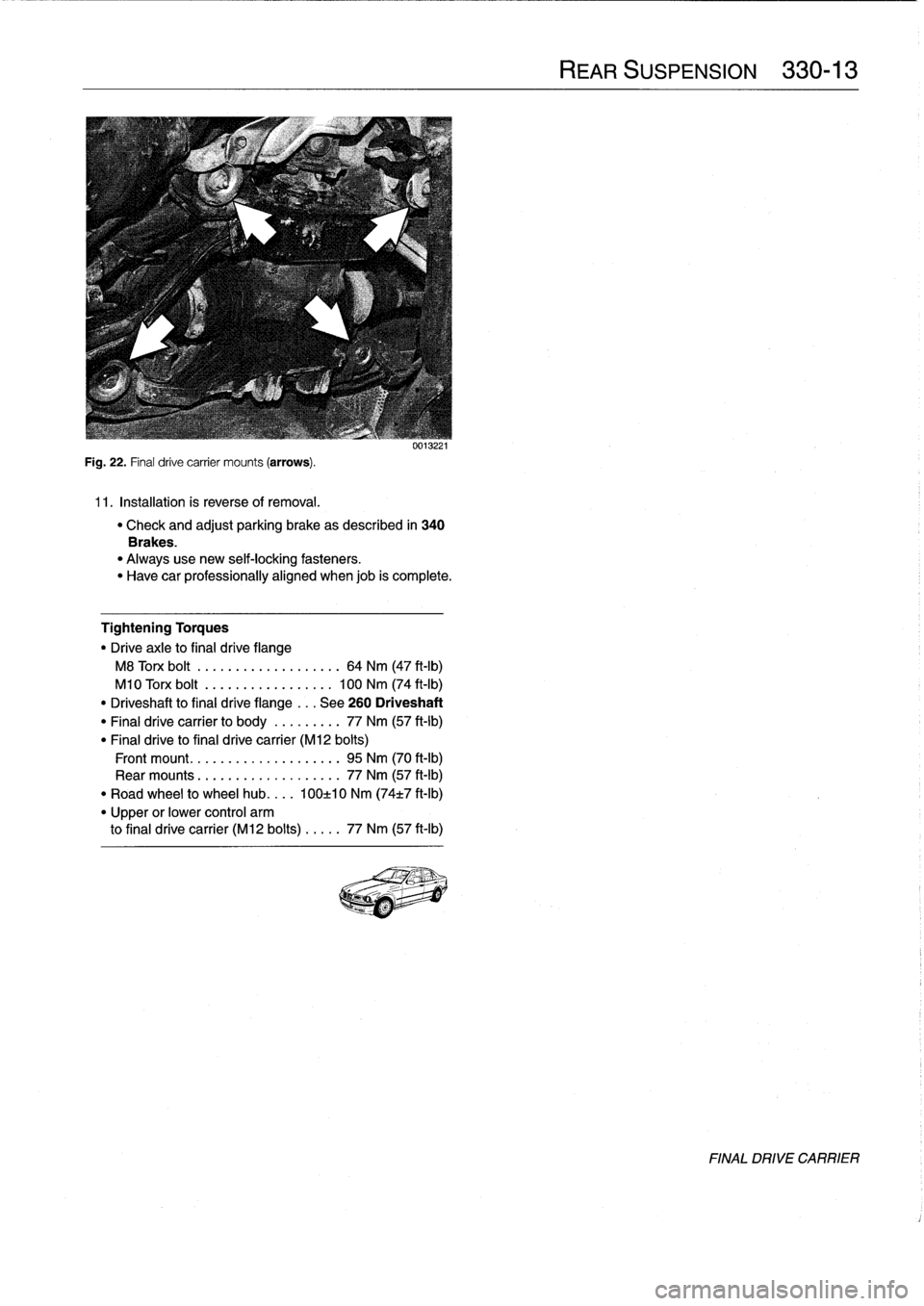

See

Fig

.

22

.

9

.

Slowly

lower

final

drive

and

final

drive

carrier,

detaching

removing

and

installing

wire

harness

and

connectors

as

necessary

.

10

.

Finaldrive

may

now

be

unbolted

from

final

drive

carrier

.

Page 285 of 759

Fig

.

22

.

Final

drive

carrier

mounts

(arrows)

.

11

.

Installation

is

reverse

of

removal

.

uu1J221

"

Check

and

adjust

parking

brake

as

described

in

340

Brakes

.

"

Alwaysuse

new

self-locking

fasteners

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

................

...

64

Nm

(47

ft-Ib)

M10

Torx

bolt

..........

..

...

.

.

100

Nm

(74

ft-Ib)

"

Driveshaft

to

final

drive

flange

...

See

260

Driveshaft

"

Final

drive

carrier

to

body

......

...

77

Nm

(57

ft-Ib)

"

Final

drive

to

final

drive

carrier

(M12

bolts)

Front

mount

.................

...

95

Nm

(70

ft-lb)

Rear

mounts

................

...

77

Nm

(57

ft-Ib)

"

Road

wheel

to

wheel

hub

....

100±10

Nm

(74t7

ft-Ib)

"

Upper

or

lower

control

arm

to

final

drive

carrier

(M12

bolts)

....

.

77

Nm

(57

ft-Ib)

Page 286 of 759

Page 287 of 759

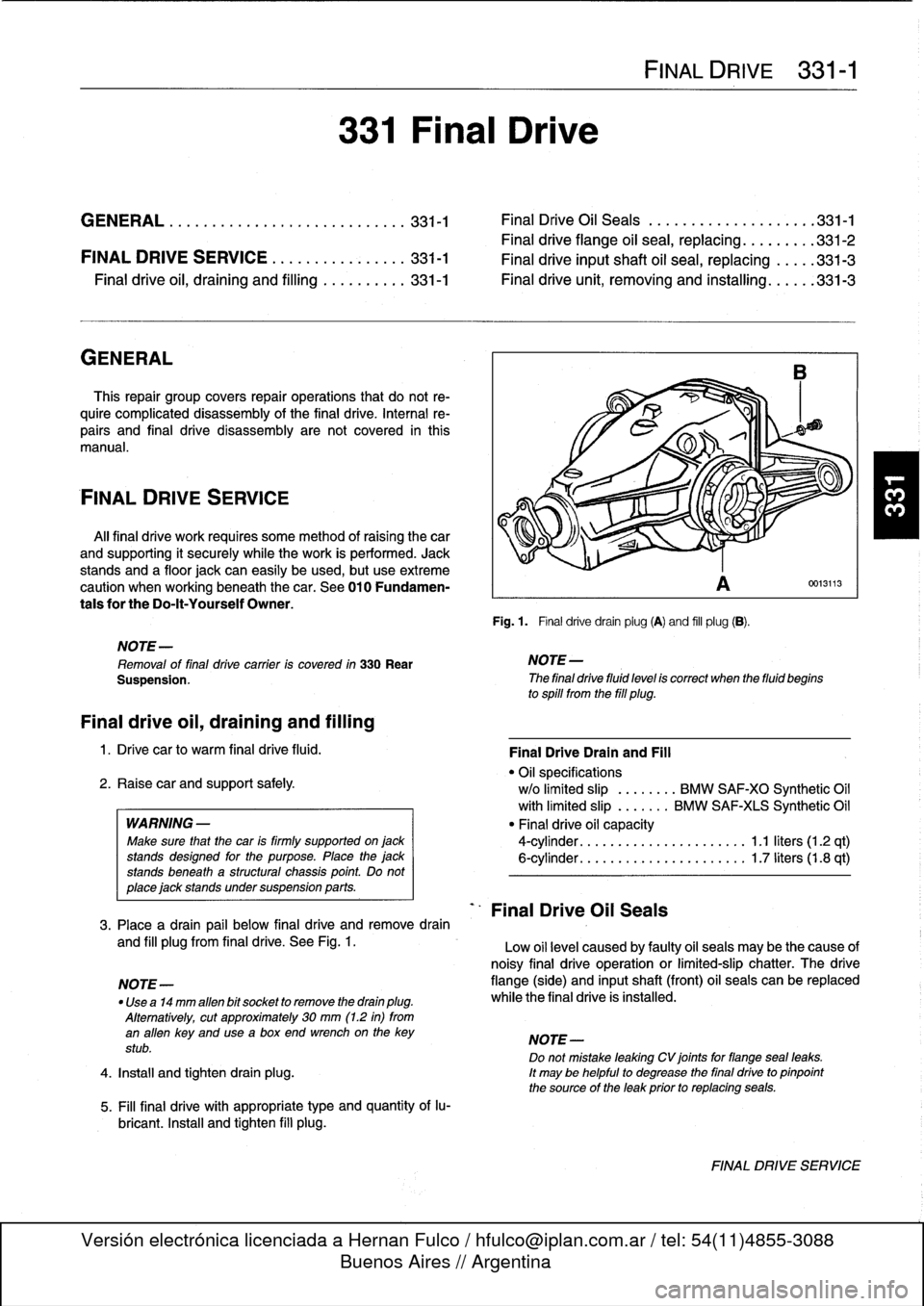

GENERAL

......

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Final

Drive

Oil

Seals

.

.

...

.

.

.

.......

.

.

.

.

.

331-1

Finaldrive

flange

oil

sea¡,

replacing

....

.

.

.

..

331-2

FINAL

DRIVE

SERVICE

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

inputshaft

oil

seal,

replacing

.

.

.

.

.

331-3

Final

drive

oí¡,

draining

and

filling

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

unit,

removíng

and

installing

.

.

.

.

.

.

331-3

GENERAL

This

repa¡r

group

covers

repair

operations

that

do

not

re-

quire

complicated

disassembly

of

the

final

drive

.

Internal

re-

pairs

and

final

drive

disassembly

are

not

covered

in

this

manual

.

FINAL

DRIVE

SERVICE

Al¡

final

drive

work

requires

some

method

of

raising

thecar

and

supporting

it

securely

while

the

work

is

performed

.

Jack

stands

and

a

floor

jack

can

easily

be

used,

but

use

extreme

caution

when

working

beneath

the

car

.

See010

Fundamen-

tais

for

the

Do-It-Yourself

Owner

.

NOTE-

Removal

of

final

drive

carrier

is

covered

in

330

Rear

Suspension

.

Final

drive

oil,

draining

and

filling

1

.

Drive

car

to

warm

final

drive

fluid

.

2

.

Raise

car

and

support

safely

.

WARNING

-

Make

sure

that

thecar

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

5

.

Fill

final

drive

with

appropriate

type

and

quantity

of

lu-

bricant

.

Insta¡¡

and

tighten

fill

plug

.

331

Final

Drive

0

Fig

.

1

.

Final

drivedrain

plug

(A)

and

fill

plug

(B)

.

D

NOTE-

The

final

drive

fluid

level

is

correct

when

the

fluid

begins

to

spill

from

the

fill

plug

.

Final

Drive

Oil

Seals

FINAL

DRIVE

331-1

0013113

Final

DriveDrain

and

Fill

"

Oil

specifications

w/o

limited

slip

.

.......

BMW

SAF-XO

Synthetic

Oil

with

limited

slip

.

......

BMW

SAF-XIS

Synthetic

Oil

"

Final

drive

oil

capacity

4-cylinder

.

.

.

...

................

1

.1

liters

(1

.2

qt)

6-cylinder

.

.

.

...

................

1

.7liters(1.8

qt)

3

.

Place

a

drain

pail

below

final

drive

andremove

drain

and

fill

plugfrom

final

drive

.

See

Fig

.

1

.

Low

oil

level

caused

by

faulty

oil

seals

may

be

the

cause

of

noisy

final

drive

operation

or

limited-slip

chatter

.

The

drive

NOTE-

flange

(side)

and

inputshaft

(front)

oil

seals

can

be

replaced

"

Use

a14

mm

alíen

bit

socket

to

remove

the

drain

plug

.

while

the

final

drive

is

installed

.

Alternatively,

cut

approximately

30

mm

(1

.2

in)

from

an

alíen

key

and

usea

box

end

wrenchon

the

key

NOTE-

stub

.

Do

not

mistake

leaking

CV

joints

for

flangeseal

leaks

.

4

.

Install

and

tighten

drain

plug

.

It

may

be

helpful

to

degrease

the

final

drive

to

pinpoint

the

source

of

the

leak

prior

to

replacing

seals

.

FINAL

DRIVE

SERVICE

Page 288 of 759

331-2

FINAL

DRIVE

Make

sure

that

the

car

is

firm1y

supportedon

Tjack

.

.-

"

:

.-

:

.

n

-

2

.

Detach

drive

axle(s)

from

final

drive

.

See330

Rear

Suspension

.

CA

UTION-

Suspend

the

detached

drive

axlefrom

the

car

body

with

a

stiff

wire

hook

to

prevent

damage

to

the

outer

CV

joint

.

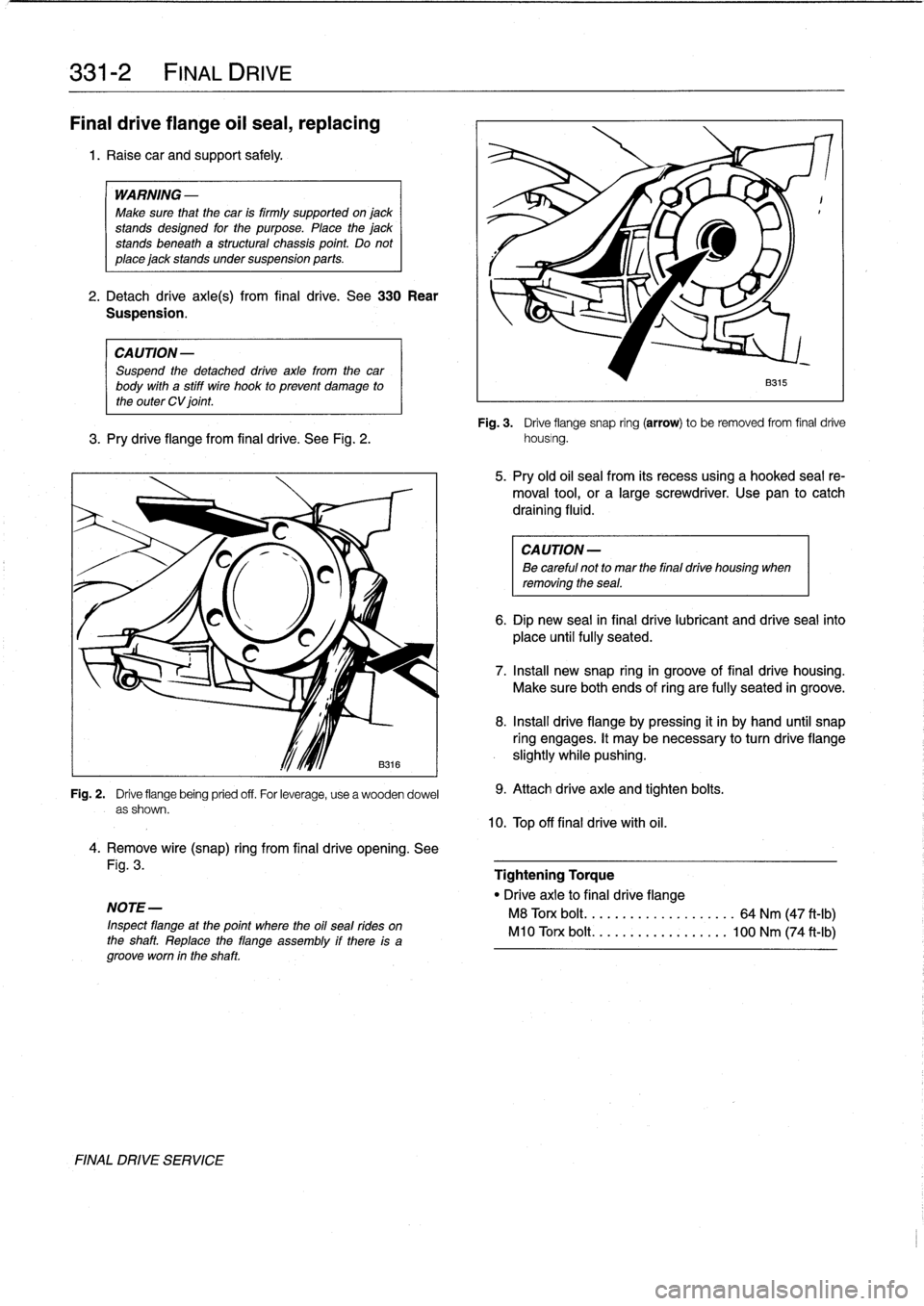

Fig

.

3

.

Drive

flange

snap

ring

(arrow)

to

be

removed

from

final

drive

3

.

Pry

drive

flange

from

final

drive

.

See

Fig

.

2

.

housing

.

Fig

.

2

.

Drive

flange

being

pried

off

.

For

leverage,

use

a

wooden

dowel

as

shown

.

4

.

Remove

wire(snap)

ring

from

final

drive

opening

.

See

Fig

.

3

.

NOTE-

Inspect

flangeat

the

point

where

the

oil

seal

rides

on

the

shaft

.

Replace

the

flange

assembly

if

there

is

agrooveworn

in

the

shaft

FINAL

DRIVE

SERVICE

9

.

Attach

drive

axle

and

tighten

bolts

.

10

.

Top

off

final

drive

with

ofl

.

B315

5

.

Pry

old

oil

sea¡

from

its

recess

using

a

hooked

seal

re-

moval

tool,

or

a

large

screwdriver

.

Use

pan

to

catch

draining

fluid

.

CA

UTION-

Be

careful

not

to

mar

the

final

drive

housing

when

removing

the

sea¡

.

6

.

Dip

new

seal

in

final

drive

lubricant

and

drive

seal

into

place

untilfully

seated

.

7

.

Insta¡¡

new

snap

ringin

groove

of

final

drive

housing

.

Make

sureboth

ends

ofring

are

fully

seated

in

groove

.

8

.

Insta¡¡

drive

flangeby

pressing

it

in

by

hand

until

snap

ring

engages

.

It

may

benecessary

to

turn

drive

flange

slightly

while

pushing

.

Tightening

Torque

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

..

..................

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.

.................

100

Nm

(74

ft-Ib)

Page 289 of 759

Final

driveinputshaft

oil

sea¡,

replacing

1

.

Raise

car

and

support

safely

.

2

.

Drain

final

drive

oil

as

described

earlier

.

3

.

Remove

driveshaft

from

final

drive

inputshaft

flange

.

See

260

Driveshaft

.

4

.

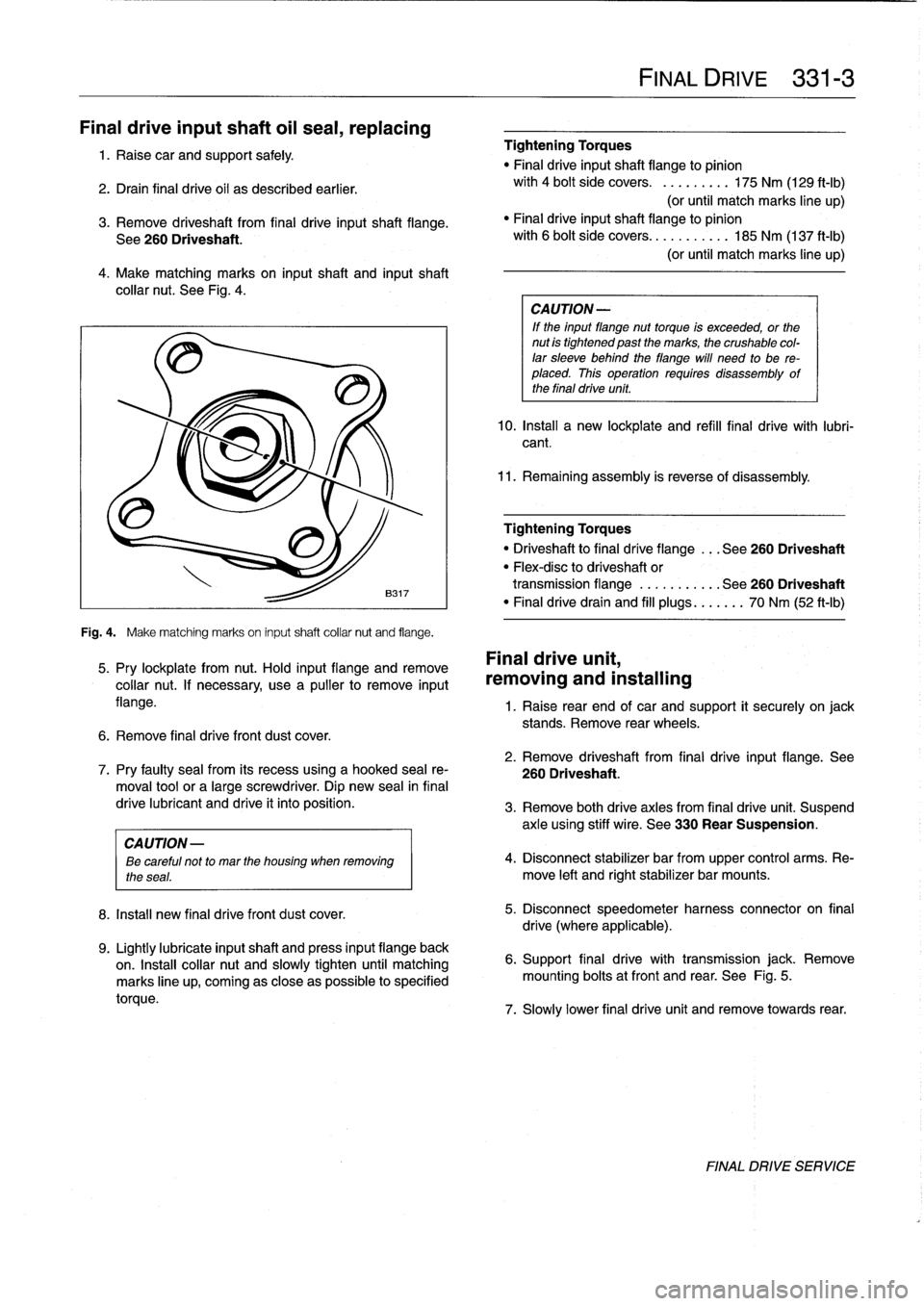

Make

matching

marks

on

input

shaft

and

inputshaft

collar

nut

.

See

Fig

.

4

.

Fig

.

4

.

Make

matching

marks

on

input

shaft

collar

nut

and

flange

.

5

.

Pry

lockplate

from

nut

.

Hold

input

flange

andremove

collar

nut

.

If

necessary,

usea

pullerto

remove

input

flange

.

6

.

Remove

final

drive

front

dust

cover

.

8

.

Install

new

final

drivefront

dust

cover

.

9

.

Lightly

lubricate

inputshaft

and

press

input

flange

back

on

.

Insta¡¡

collar

nut

and

slowly

tighten

until

matching

marks

line

up,

coming

as

close

aspossible

to

specified

torque

.

Tightening

Torques

"

Final

driveinputshaft

flange

to

pinion

with

4

bolt

side

covers

.

.........

175

Nm

(129

ft-Ib)

(or

until

match

marks

line

up)

"

Finaldriveinputshaft

flange

to

pinion

with

6

bolt

side

covers

...........

185

Nm

(137

ft-Ib)

(or

until

match

marks

line

up)

CA

UTION-

If

the

input

flange

nuttorque

is

exceeded,

or

the

nut

is

tightened

past

the

marks,

the

crushable

col-

lar

sleeve

behind

theflange

will

need

to

be

re-

placed

.

This

operation

requires

disassembly

of

the

final

drive

unit

.

10

.

Install

a

new

lockplate

and

refill

final

drive

with

lubri-

cant

.

11

.

Remaining

assembly

is

reverse

of

disassembly

.

Tightening

Torques

"

Driveshaftto

final

dríve

flange

...

See260

Driveshaft

"

Flex-disc

to

driveshaft

or

transmission

flange

...........

See260

Driveshaft

"

Finaldrivedrain

and

fill

plugs

...

.

..

.

70

Nm

(52

ft-Ib)

Final

drive

unit,

removing

and

installing

FINAL

DRIVE

331-

3

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

from

final

drive

input

flange

.

See

7

.

Pry

faulty

sea¡

from

its

recess

using

a

hooked

sea¡

re-

260

Driveshaft

.

moval

toolor

a

large

screwdriver

.

Dip

new

sea¡

in

final

drive

lubricant

and

drive

it

into

position

.

3

.

Remove

both

drive

axles

from

final

drive

unit

.

Suspend

axle

using

stiff

wire

.

See

330

Rear

Suspension

.

CAUTION

-

ee

careful

not

to

mar

the

housing

when

removing

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

the

seas

.

move

left

and

rightstabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

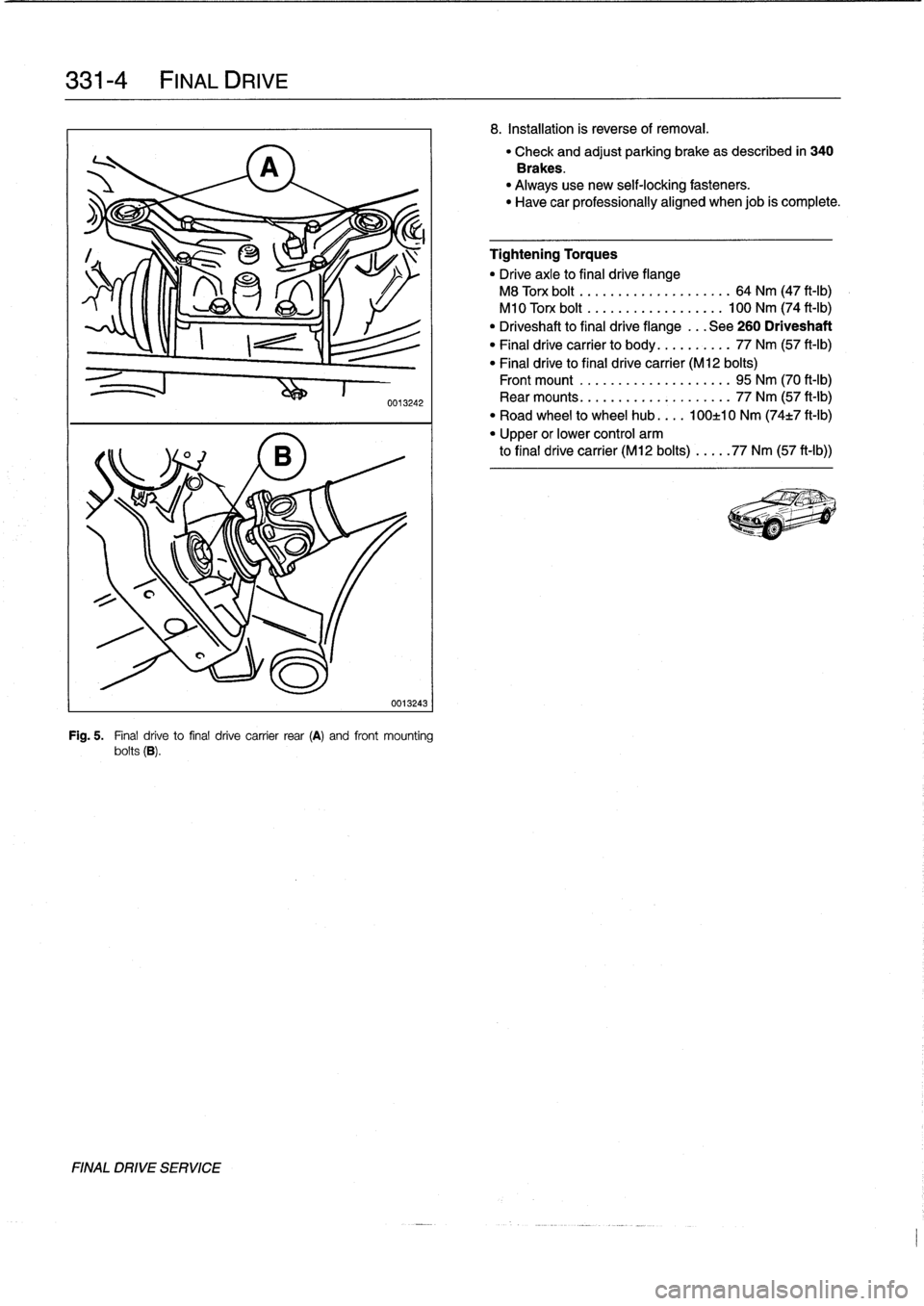

6

.

Support

final

drive

with

transmission

jack

.

Remove

mounting

bolts

atfront

and

rear

.

See

Fig

.

5

.

7

.

Slowly

lower

final

drive

unit

and

remove

towards

rear

.

FINAL

DRIVE

SERVICE

Page 290 of 759

331-

4

FINAL

DRIVE

FINAL

DRIVE

SERVICE

0013242

0013243

Fig

.

5

.

Final

drive

to

final

drive

carrier

rear

(A)

and

front

mounting

bolts

(B)

.

8

.

Installation

is

reverse

of

removal

.

"

Check

and

adjust

parking

brake

as

described

in

340

Brakes

.

"

Always

use

new

self-locking

fasteners

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

..

.

...

...

..

.........

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.

.

...

...

..

........

100

Nm

(74

ft-Ib)

"

Driveshaft

to

final

drive

flange

...

See

260

Driveshaft

"

Final

drive

carrier

to

body

..

........

77

Nm

(57

ft-Ib)

"

Final

drive

to

final

drive

carrier

(M12

bolts)

Front

mount

.....

...

.

...

........

95

Nm

(70

ft-Ib)

Rear

mounts

.....

.......

.

.

.

..

...

77

Nm

(57

ft-Ib)

"

Road

wheel

to

wheel

hub

....

100±10

Nm

(74±7

ft-Ib)

"

Upper

or

lower

control

arm

to

final

drive

carrier

(M12

bolts)

...

..

77

Nm

(57

ft-Ib))