brake BUICK CENTURY 2003 Workshop Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2003, Model line: CENTURY, Model: BUICK CENTURY 2003Pages: 344, PDF Size: 2.57 MB

Page 267 of 344

Changing a Flat Tire

If a tire goes ¯at, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your

hazard warning ¯ashers.

{CAUTION:

Changing a tire can cause an injury. The

vehicle can slip off the jack and roll over you

or other people. You and they could be badly

injured. Find a level place to change your tire.

To help prevent the vehicle from moving:

1. Set the parking brake ®rmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine.

To be even more certain the vehicle won't

move, you can put blocks at the front and rear

of the tire farthest away from the one being

changed. That would be the tire on the other

side of the vehicle, at the opposite end.The following steps will tell you how to use the jack and

change a tire.

5-67

Page 275 of 344

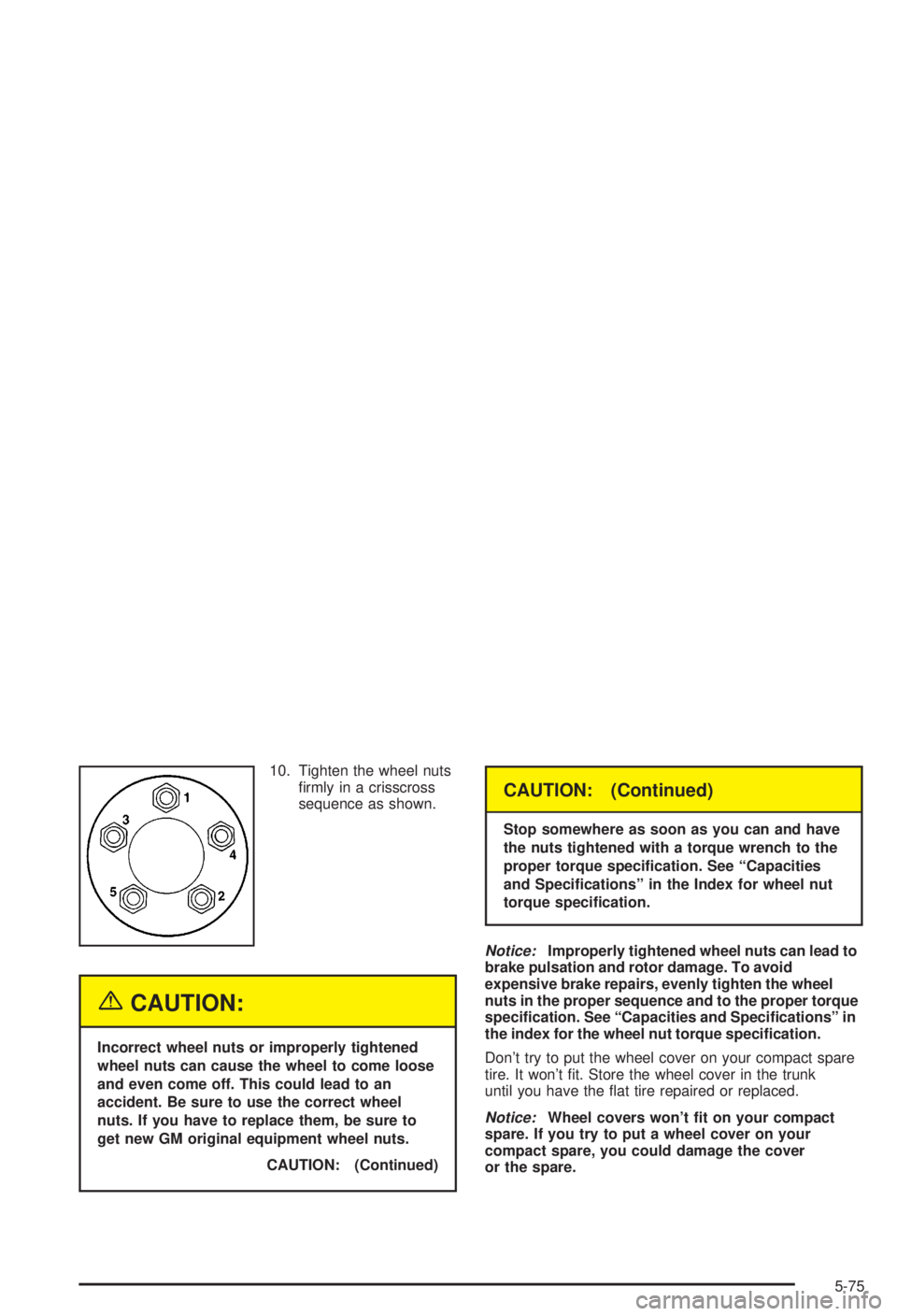

10. Tighten the wheel nuts

®rmly in a crisscross

sequence as shown.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

CAUTION: (Continued)

CAUTION: (Continued)

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci®cation. See ªCapacities

and Speci®cationsº in the Index for wheel nut

torque speci®cation.

Notice:Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

speci®cation. See ªCapacities and Speci®cationsº in

the index for the wheel nut torque speci®cation.

Don't try to put the wheel cover on your compact spare

tire. It won't ®t. Store the wheel cover in the trunk

until you have the ¯at tire repaired or replaced.

Notice:Wheel covers won't ®t on your compact

spare. If you try to put a wheel cover on your

compact spare, you could damage the cover

or the spare.

5-75

Page 291 of 344

Fuses Usage

BTSI PARK

LOCKShifter Lock Solenoid

AIR BAG Air Bag

BCM PWR Body Control Module

HAZARD Hazard Flashers

LH HEATED

SEATDriver's Heated Seat

Blank Not Used

BCM ACCIgnition Signal: Hot in ACC and Run,

Body Control Module

Blank Not Used

LOW BLOWER Low Blower

ABS Anti-Lock Brakes

TURN

SIGNALS,

CORN LPSTurn Signals, Cornering Lamps

RADIO, HVAC,

RFA,

CLUSTERRadio, Heating Ventilation Air

Conditioning Head, Remote Keyless

Entry, Cluster

HIGH BLOWER High Blower

RH HEATED

SEATPassenger's Heated Seat

STRG WHL

CONTAudio Steering Wheel Controls

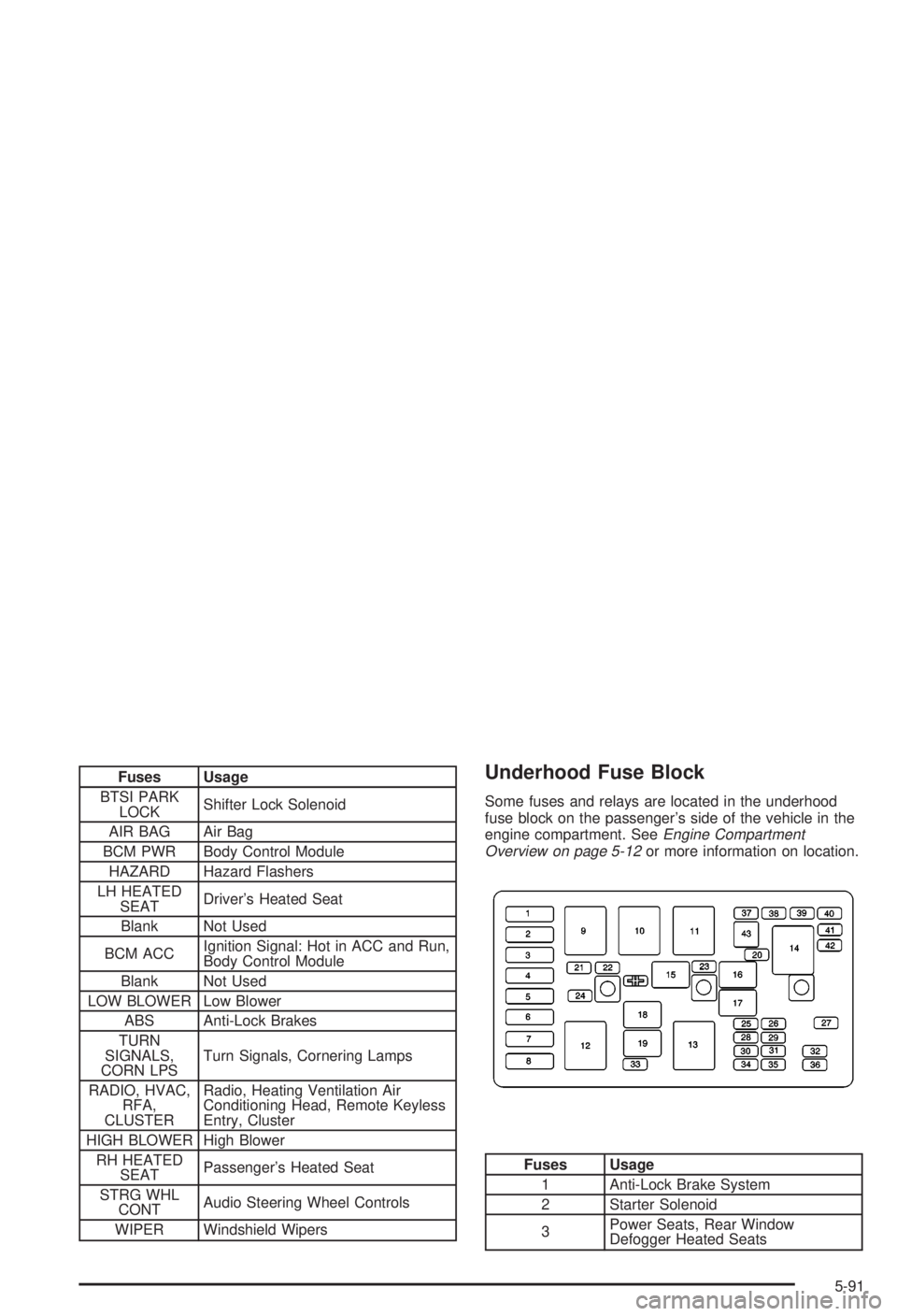

WIPER Windshield WipersUnderhood Fuse Block

Some fuses and relays are located in the underhood

fuse block on the passenger's side of the vehicle in the

engine compartment. See

Engine Compartment

Overview on page 5-12or more information on location.

Fuses Usage

1 Anti-Lock Brake System

2 Starter Solenoid

3Power Seats, Rear Window

Defogger Heated Seats

5-91

Page 292 of 344

Fuses Usage

4High Blower, Hazard Flasher,

Stoplamps, Power Mirror, Door

Locks

5Ignition Switch, BTSI, Stoplamps,

Anti-Lock Brake System, Turn

Signals, Cluster, Air Bag, Daytime

Running Lamps Module

6 Cooling Fan

7Retained Accessory Power, Keyless

Entry, Data Link, Heating Ventilation

Air Conditioning Head, Cluster,

Radio, Cigarette Lighter

8Ignition Switch, Wipers, Radio,

Steering Wheel Controls, Body

Control Module, Power Windows,

Sunroof, Heating Ventilation Air

Conditioning Controls, Daytime

Running Lamps, Rear Window

Defogger Relay

Relays Usage

9 Cooling Fan 2

10 Cooling Fan 3

11 Starter Solenoid

12 Cooling Fan 1

13 Ignition Main

14 Air Pump (Optional)

15 Not Used

16 Horn

17 Fog Lamps

18 Not Used

19 Fuel Pump

5-92

Page 297 of 344

Maintenance Schedule......................................6-2

Introduction...................................................6-2

Your Vehicle and the Environment....................6-2

Maintenance Requirements..............................6-2

How This Section is Organized.........................6-3

Part A: Scheduled Maintenance Services...........6-4

Using Your Maintenance Schedule....................6-4

Scheduled Maintenance...................................6-5

Part B: Owner Checks and Services................6-10

At Each Fuel Fill..........................................6-10

At Least Once a Month.................................6-10

At Least Twice a Year...................................6-11At Least Once a Year...................................6-11

Part C: Periodic MaintenanceInspections.........6-14

Steering, Suspension and Front Drive Axle

Boot and Seal Inspection............................6-14

Exhaust System Inspection............................6-14

Fuel System Inspection..................................6-14

Engine Cooling System Inspection...................6-14

Throttle System Inspection.............................6-15

Brake System Inspection................................6-15

Part D: Recommended Fluids and Lubricants. . . .6-16

Part E: Maintenance Record...........................6-17

Section 6 Maintenance Schedule

6-1

Page 301 of 344

Scheduled Maintenance

The services shown in this schedule up to 100,000 miles

(166 000 km) should be repeated after 100,000 miles

(166 000 km) at the same intervals for the life of

this vehicle. The services shown at 150,000 miles

(240 000 km) should be repeated at the same interval

after 150,000 miles (240 000 km) for the life of this

vehicle.

See

Part B: Owner Checks and Services on page 6-10andPart C: Periodic MaintenanceInspections on

page 6-14.

Footnotes

²The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle's useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.Whenever the tires are rotated, the Tire In¯ation Monitor

System must be reset.

+A good time to check your brakes is during tire

rotation. See Brake System Inspection on page 6-15.

Engine Oil Scheduled Maintenance

Change engine oil and ®lter as indicated by the GM

Oil Life System (or every 12 months, whichever

occurs ®rst). Reset the system.

Your vehicle has a computer system that lets you know

when to change the engine oil and ®lter. This is

based on engine revolutions and engine temperature,

and not on mileage. Based on driving conditions,

the mileage at which an oil change will be indicated can

vary considerably. For the oil life system to work

properly, you must reset the system every time the oil is

changed.

6-5

Page 308 of 344

Starter Switch Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. See

Parking Brake on page 2-26if

necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. Try to start the engine in each gear. The starter

should work only in PARK (P) or NEUTRAL (N).

If the starter works in any other position, your

vehicle needs service.

Automatic Transaxle Shift Lock Control

System Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake. See

Parking Brake

on page 2-26if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the key to the RUN

position, but don't start the engine. Without applying

the regular brake, try to move the shift lever out

of PARK (P) with normal effort. If the shift lever

moves out of PARK (P), your vehicle needs service.

6-12

Page 309 of 344

Ignition Transaxle Lock Check

While parked, and with the parking brake set, try to turn

the ignition key to LOCK in each shift lever position.

·The key should turn to LOCK only when the

shift lever is in PARK (P).

·The key should come out only in LOCK.

Parking Brake and Automatic Transaxle

Park (P) Mechanism Check

{CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could be

injured and property could be damaged. Make

sure there is room in front of your vehicle in

case it begins to roll. Be ready to apply the

regular brake at once should the vehicle begin

to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake, set the

parking brake.

·To check the parking brake's holding ability: With

the engine running and transaxle in NEUTRAL

(N), slowly remove foot pressure from the regular

brake pedal. Do this until the vehicle is held by the

parking brake only.

·To check the PARK (P) mechanism's holding

ability: With the engine running, shift to PARK (P).

Then release the parking brake followed by the

regular brake.

Underbody Flushing Service

At least every spring, use plain water to ¯ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

6-13

Page 311 of 344

Throttle System Inspection

Inspect the throttle system for interference or binding,

and for damaged or missing parts. Replace parts

as needed. Replace any components that have high

effort or excessive wear. Do not lubricate accelerator

and cruise control cables.

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook-up, binding, leaks, cracks,

cha®ng, etc. Inspect disc brake pads for wear and rotors

for surface condition. Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including

drums, wheel cylinders, calipers, parking brake, etc.

Check parking brake adjustment. You may need to have

your brakes inspected more often if your driving

habits or conditions result in frequent braking.

6-15

Page 312 of 344

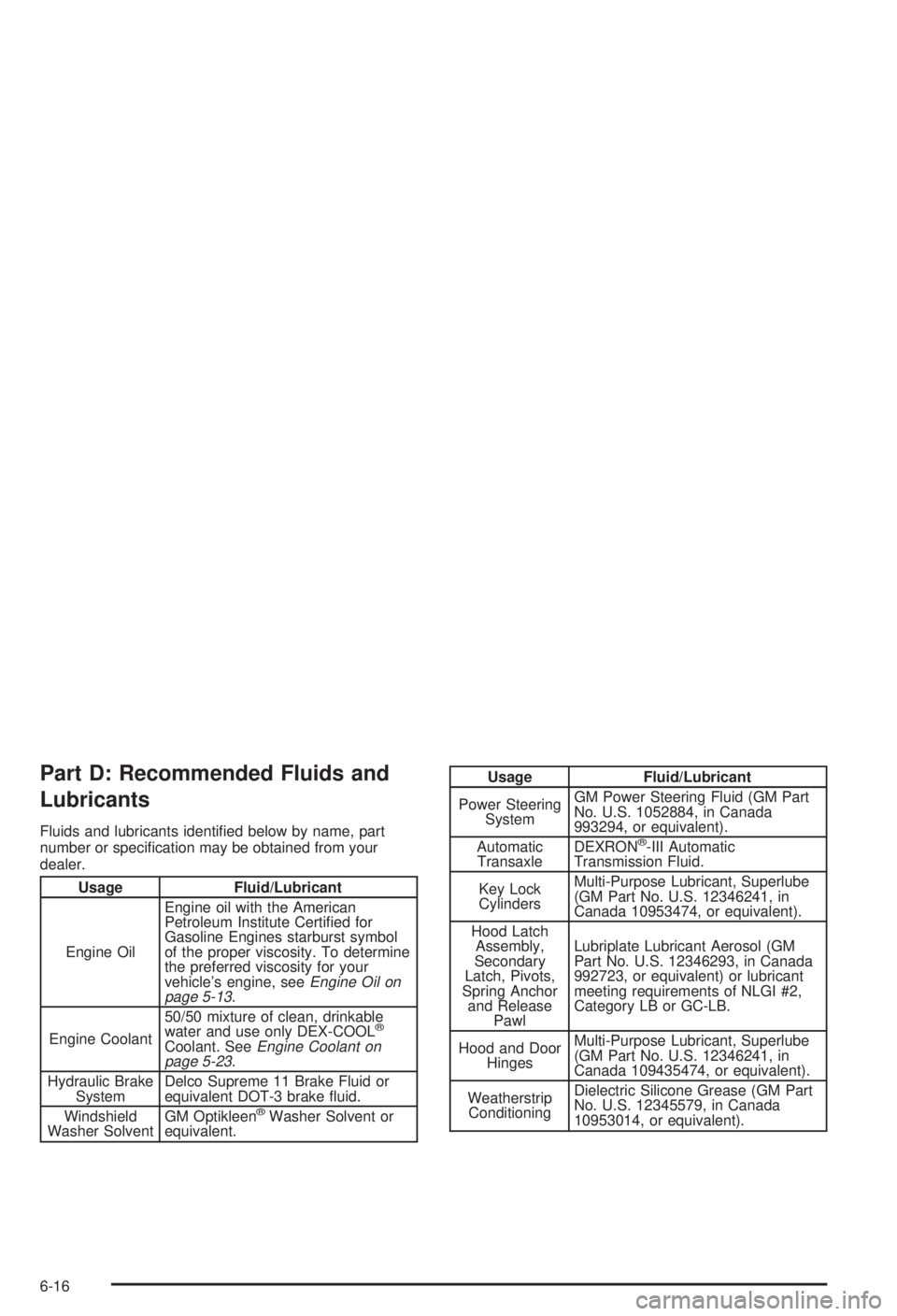

Part D: Recommended Fluids and

Lubricants

Fluids and lubricants identi®ed below by name, part

number or speci®cation may be obtained from your

dealer.

Usage Fluid/Lubricant

Engine OilEngine oil with the American

Petroleum Institute Certi®ed for

Gasoline Engines starburst symbol

of the proper viscosity. To determine

the preferred viscosity for your

vehicle's engine, see

Engine Oil on

page 5-13.

Engine Coolant50/50 mixture of clean, drinkable

water and use only DEX-COOL

ž

Coolant. SeeEngine Coolant on

page 5-23.

Hydraulic Brake

SystemDelco Supreme 11 Brake Fluid or

equivalent DOT-3 brake ¯uid.

Windshield

Washer SolventGM Optikleen

žWasher Solvent or

equivalent.

Usage Fluid/Lubricant

Power Steering

SystemGM Power Steering Fluid (GM Part

No. U.S. 1052884, in Canada

993294, or equivalent).

Automatic

TransaxleDEXRON

ž-III Automatic

Transmission Fluid.

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474, or equivalent).

Hood Latch

Assembly,

Secondary

Latch, Pivots,

Spring Anchor

and Release

PawlLubriplate Lubricant Aerosol (GM

Part No. U.S. 12346293, in Canada

992723, or equivalent) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood and Door

HingesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 109435474, or equivalent).

Weatherstrip

ConditioningDielectric Silicone Grease (GM Part

No. U.S. 12345579, in Canada

10953014, or equivalent).

6-16